Page 1

OPERATION MANUAL

Model: DI-600

Edition Month Year

1st August 2002

2nd

3rd

4th

5th

SHANGHAI TERAOKA ELECTRONIC Co., Ltd. --- Technical Support Dept.

A/18F East Tower, New Hua Lian Building,755# Huai Hai Zhong Road, Shanghai China 200020

Tel: +86-21-64739918 Fax: +86-21-54901934 E-mail: steservice@digi-scale.com

Page 2

DI-600 Operation Manual

1

CONTENTS

1. General Specification

1.1. Specifications -------------------------------------------------------------------------------------------------- 1

1.2. Features ------------------------------------------------ ----------------------------------------------- --------- 1

1.2.1. Indicators -------------------------------------------------------------------------------------------------- 1

1.2.2. Battery Indicator ----------------------------------------------------------------------------------------- 1

1.2.3. Interface --------------------------------------------------------------------------------------------------- 1

1.2.4. Printer ------------------------------------------------------------------------------------------------------ 1

1.2.5. Load Cell -------------------------------------------------------------------------------------------------- 2

1.2.6. Housing ---------------------------------------------------------------------------------------------------- 2

1.2.7. Calibration ------------------------------------------------------------------------------------------------ 2

1.2.8. Power Source -------------------------------------------------------------------------------------------- 2

1.2.9. Rechargeable Battery Specification ---------------------------------------------------------------- 2

1.2.10. Operation Condition --------------------------------------- --------------------------------------------- 2

1.3. Main Functions ------------------------------------------------------------------------------------------------ 2

1.4. Overall View ------------------------------------------------------------ --------------------------------------- 2

1.4.1. Layout & Dimension ------------------------------------------------ ------------------------------------ 2

1.4.2. Display Panel -------------------------------------------------------------------------------------------- 3

1.5. Keyboard & Display Layout and Function ----------------------------------------- --------------------- 3

1.5.1. Indicators -------------------------------------------------------------------------------------------------- 3

1.5.2. Keyboard --------------------------------------------- ----------------------------------------------- ------ 4

1.6. Hardware --------------------------------------------------------------------------- ---------------------------- 4

2. Main Operation

2.1. Power On ------------------------------------------------------------------------------------------------------- 5

2.2. Power Off ------------------------------------------------------------------------------------------------------- 5

2.3. One Touch Tare ----------------------------------------------------------------------------------------------- 5

2.4. Digital Tare ------------ -------------------------------------------------- --------------------------------------- 5

2.5. Tare Clear ------------------------------------------------------------------------------------------------------ 6

2.6. Date and Time Setting -------------------------------------------------------------------------------------- 6

2.7. Date and Time Recall ----------------------------------------------------------------------------------- ---- 6

2.8. Grand Total Data Clear -------------------------------------------------------------------------------------- 7

2.8.1. Weight Grand Total Clear ---------------------------------------------------------------- ------------- 7

2.8.2. Quantity Grand Total Clear --------------------------------------------------------------------------- 7

2.9. Serial Number Setup ---------------------------------------------------------------------------------------- 7

2.10. Weight Unit Conversion ----------------------------------------------------------------------------------- 8

2.11. Set Point Value Setting & S. Memory Recall --------------------------------------------------------- 8

2.11.1. Set Point Value Setting ------------------------------------------------------------------------------- 8

2.11.2. Set Point Value Recall -------------------------------------------------------------------------------- 9

2.11.3. Set-Point Check and Alarm Mode Select -------------------------------------------------------- 9

2.11.4. Weight Check Bar of Set-Point ------------------------------------------------------------ --------- 10

Page 3

2.12. Counting Mode ---------------------------------- ------------------------------------------------------------- 11

2.12.1. Key Entry Quantity ------------------------------------------------------------------------------------ 11

2.12.2. Sample Quantity Setting ----------------------------------------------------------------------------- 11

2.12.3. Sample Quantity Modification and Print Receipt ---------------------------------------------- 11

2.13. Accumulation Operation ----------------------------------------------------------------------------------- 12

2.13.1. Weight Accumulation --------------------------------------------------------------------------------- 12

2.13.2. Quantity Accumulation ------------------------------------------------------------------------------- 13

2.14. Grand Total Check and Print ----------------------------------------------------------------------------- 14

2.15. Printed Ticket Sample ------------------------------------------------------------------------------------- 14

3. Error Message

3.1. Error Message List & Solution ------------------------------------------------------- --------------------- 15

4. Interface & Protocol

4.1. Load Cell Connector ----------------------------------------------------------------------------------------- 16

4.2. RS-232C Port ------------------------------------------------------------------------------------------------- 16

4.2.1. RS-232C Cable Connection ------------------------------------------------------------------------- 16

4.2.2. RS-232 Protocol ---------------------------------------------------------------------------------------- 17

4.3. Set-Point Connector ----------------------------------------------------------------------------------------- 20

4.3.1. Set-Point Control Cable Specification ------------------------------------------------------------- 20

4.3.2. Set-Point Port Specification -------------------------------------------------------------------------- 20

4.3.3. Set-Point Signal ON Timing -------------------------------------------------------------------------- 20

4.3.4. Set-Point Output Control ---------------------------------------------------- -------------------------- 21

Page 4

DI-600 Operation Manual

1. General Specification

1.1. Specifications

z Model Name : DI-600

z Display Resolution : 1/1,000, 1/1,500, 1/2,000, 1/2,500, 1/3,000, 1/4,000, 1/5,000,

1/6,000, 1/7,500, 1/10,000, 1/15,000, 1/20,000, 1/25,000, 1/30,000

z Internal Resolution : 1/1,000,000 (Max)

z Non-linearity : <0.008% FS ( Just only include the indicator)

z Capacity Weight : Input when calibrating

z Display : 8 Segment 6 digits High density LCD GD-586. (With back-light)

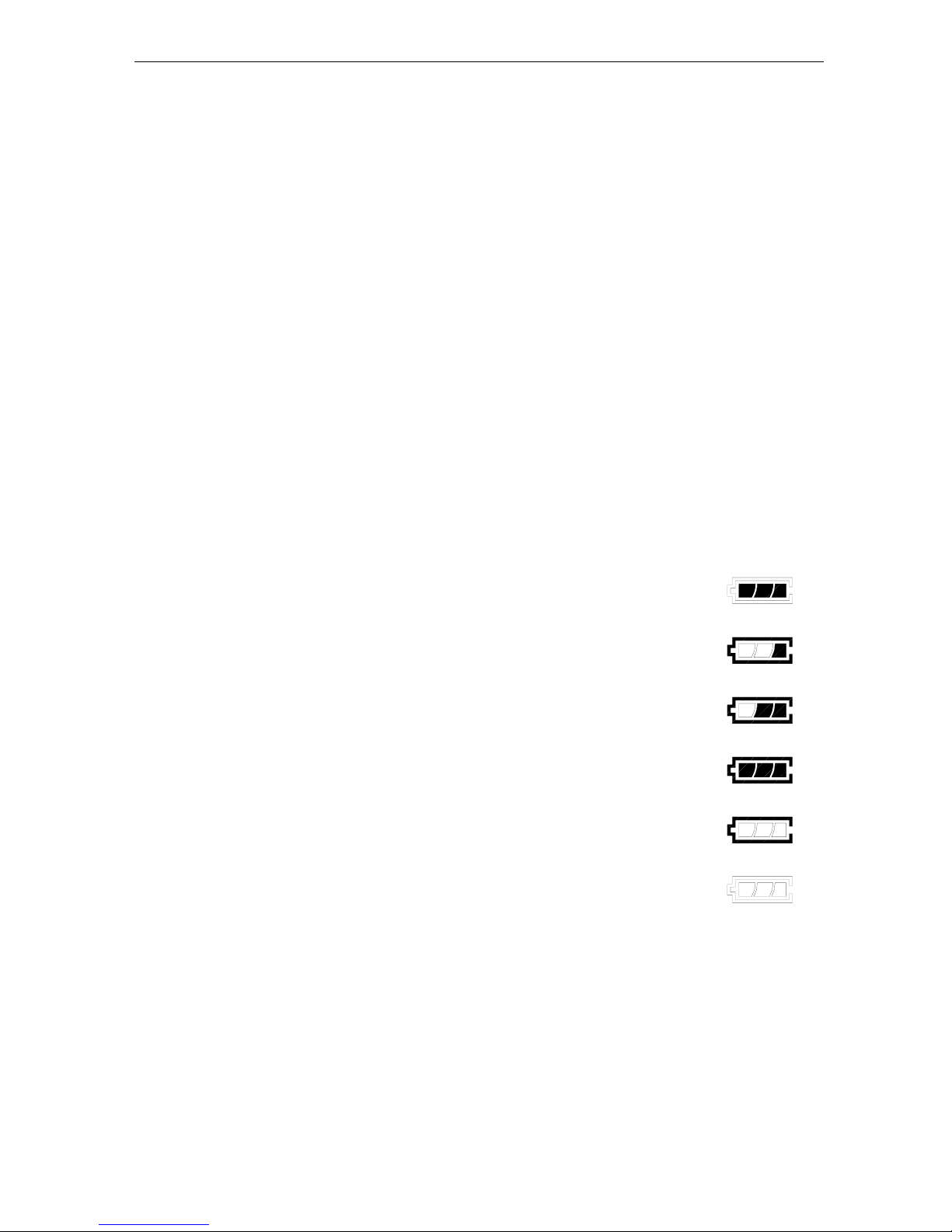

z Overall Dimensions : 280mm (L) x 200mm(W) x 118mm(H)

1.2. Features

1.2.1. Indicators

z 4 types selectable unit symbol: g, kg, lb and PCS

z 4 piece set Point Indicator symbol (OV1,OV2,OV3,OV4)

z 11 class drawing display for point checking indicator.

z And 21 indicators for other symbols.

z 1 battery indicator.

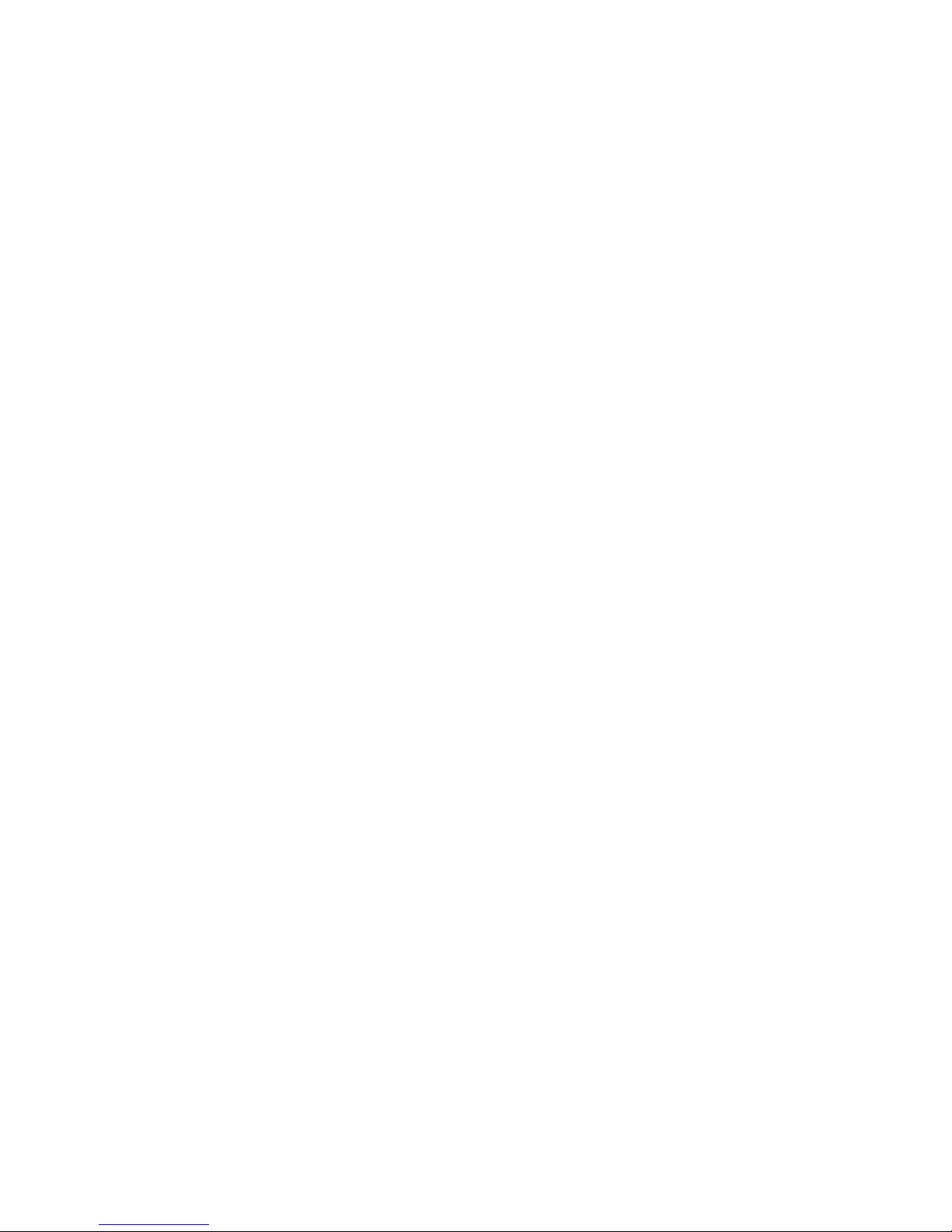

1.2.2. Battery Indicator

There are 3 levels in battery indicator to display the volume of battery

power.

Fig.6

Fig.5

Fig.4

Fig.3

Fig.2

Fig.1

z Fig. 1 means battery not installed, and AC power linked only.

z Fig. 2 ~ Fig. 4 shows the volume of rechargeable battery in charging or

discharging mode.

z Fig. 5 means battery lower, Fig. 6 is a flash indicator will keep about 2

minutes if still using battery for power supply only, then display will auto

off.

z When the AC power is connected, the battery indicator will keep light

on display although the On/Off key is pressed for display off. The

battery will be kept in charging mode till the AC plugged off.

1.2.3. Interface

z 1 RS-232C port

z Set point output port

z 14 Pin DDK Load Cell connecter

1.2.4. Printer (Optional):

Built-in dot matrix printer with English or Chinese printing

Page No. 1

Page 5

DI-600 Operation Manual

1.2.5. Load Cell:

Exiting Voltage : 12V (DC)

Sensitivity (Selectable) : 0.4mV/V ~3.5mV/V

Input impedance : 350 Ohm

Maximum number of L/C : Max. 8 pcs L/C connected in parallel (350 Ohm only)

1.2.6. Housing: New design

1.2.7. Calibration: Software Calibration

1.2.8. Power Source: AC 220V (+10%, -15%) 50/60Hz

Or recharge battery 12V 2.7AH

1.2.9. Rechargeable Specification: 12V 2.7AH

a) Continuous Usage:

z 8 Hours for 1 L/C connected & printer installed but not printing when fully charged.

z Or 5 hours for 8 L/C connected & printer installed but not printing when fully

charged.

z 10 hours for 1 L/C connected & no printer when fully charged.

z Or 6 hours for 8 L/C connected & no printer when fully charged.

z Or 1 hour for continuously printing.

b) Charging specification

z Normally the charging current will be about 1.2A, but it depends on how much

power remained when charging.

z Please ensure more than 8 hours for charging.

1.2.10. Operation Condition:

Temperature: 0 - 40 ℃

Humidity: < 85 % RH

1.3. Main Functions

z Base Unit selection : kg or g

z Unit conversion : between kg and lb

z Counting mode

z Weight & Quantity data can be output via RS-232 port to PC

1.4. Overall View

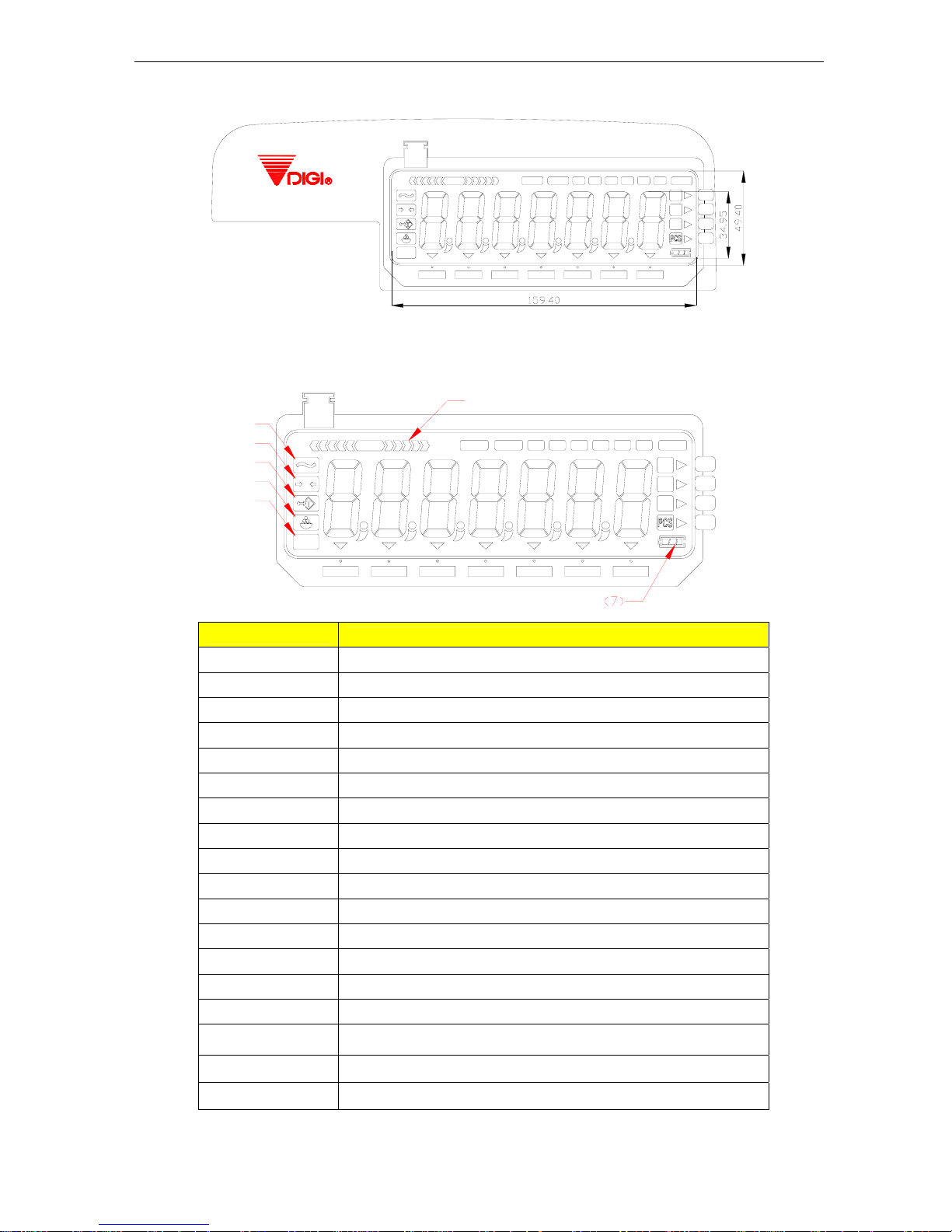

1.4.1. Layout & Dimension

Page No. 2

Page 6

DI-600 Operation Manual

COUNT

SET CAL SP1 SP2 SP3 SP4

TOTALCHECK

OK

LOW HIGH

O

kg

lb

g

MEM

0

0

CH

T

C

1 2

3

4

5

7

8

6

9

SlbM

DI- 6 00

Page No. 3

Page 7

DI-600 Operation Manual

1.4.2. Display Panel

DI-600

OK

MEM

O

LOW

g

kg

lb

SP2

HIGH

CHECK COUNT

SET SP1CAL SP3 S P4

TOTAL

SM1

SM2

SM3 SM 4

SM5 ALMHOLD

OS4

OS3

OS2

OS1

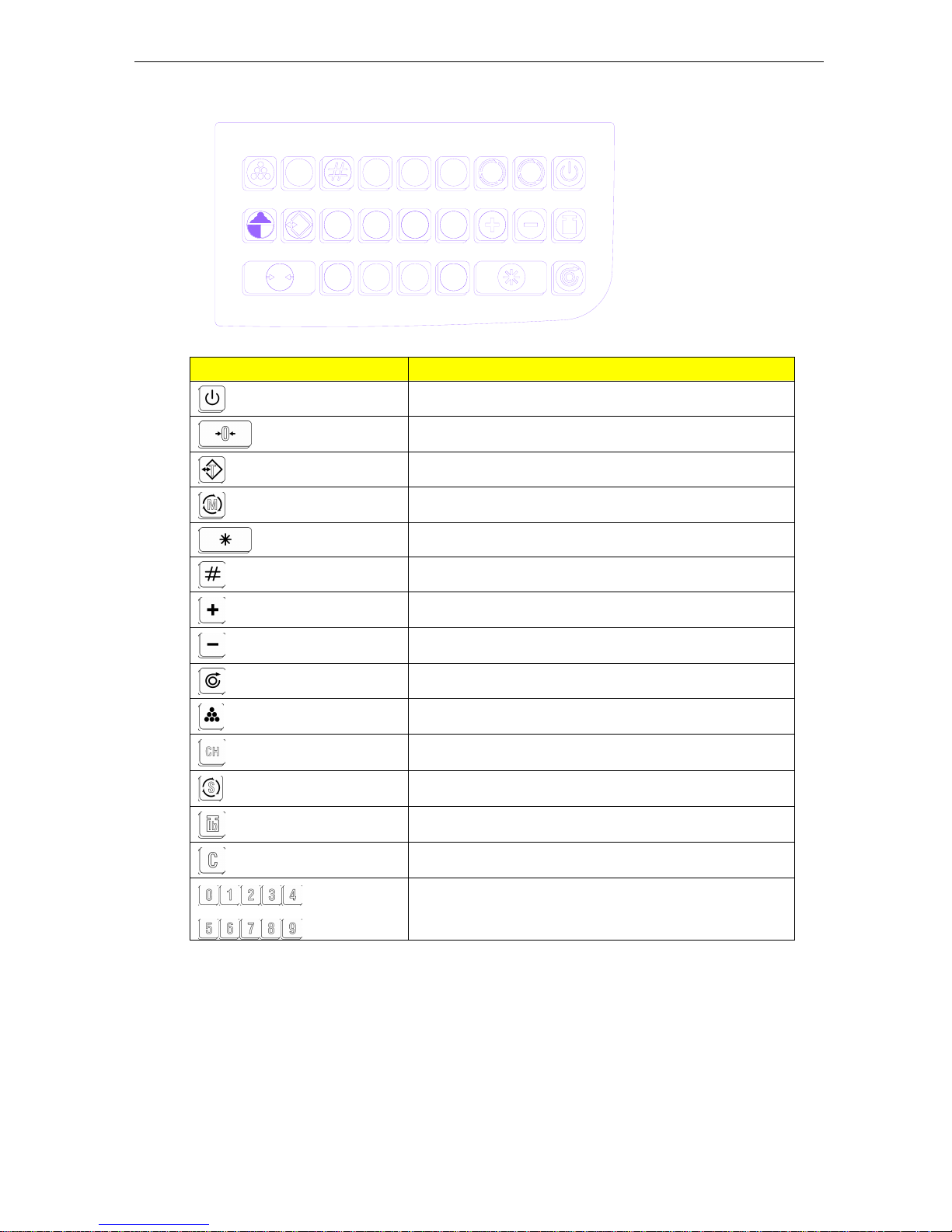

1.5. Keyboard & Display Layout and Function

1.5.1. Indicators

OK

MEM

O

LOW

SP2

HI GH

CHECK COUNT

SET SP1CAL

g

kg

lb

SP3 SP4

TOTAL

⑴

⑵

⑷

⑶

⑸

⑹

SM1

SM2

SM3 SM 4

SM5 HOLD AL M

OS4

OS3

OS2

OS1

Indicator

Definition & Function

(1) Stable

Light on when weight is stable

(2) Zero

Light on when weight display is zero and stable

(3) Tare

Light on when tare weight is set

(4) Net

Display value is net weight indicator.

(5) MEM

Memory indicator. Light on when accumulated

(6) Weight range

Weight range checking indicator

(7) Battery

Battery indicator

CHECK

Light on when in weight checking mode

COUNT

Counter Mode

SET

Data set mode

CAL

Light on when perform the system calibration or spec setting

SP1,SP2,SP3,SP4

Set point indicator

TOTAL

Total Weight accumulation display mode indicator.

SM1,SM2,SM3,SM4

Set point memory group by used indicator.

HOLD

Display hold mode

ALM

Set point alarm is “on”, when it is flash the alarm is at filling mode.

When it is light on, means at the check mode.

g ,kg ,lb

Weight unit

PCS

Counter unit

Page No. 4

Page 8

DI-600 Operation Manual

1.5.2. Keyboard

65

4

0

C

1

0

2

3

CH

7

9

8

T

lb

S M

Key Function

[ On/Off]

Switch the display On/Off

[ Re-Zero ]

Set the weight to zero

[ Tare ]

Set tare value or escape form program mode

[ Mode]

Set point setting Mode → Weighing Mode change

[ Enter ]

(1) Sent the data to PC.

(2) Calculate unit weight in sample quantity setting mode

[ Number ]

Set code number.

[Plus]

Weight addition.

[Minus]

Modification total weight.

[Feed]

The print paper feed

[Count]

Entry counting Mode

[Check]

Entry check mode and hold switch

[MEM SEL]

Set point memory select (1~4)

[Unit]

Switch the weight unit.

[Clear]

Clear data

[Numeric]

Number key

1.6. Hardware

Microcomputer : MCS 51 single microprocessor (Winbond w78e58 8 bit)

Display Drive : HT 1620

LCD Display : MODEL GD-587

A/D Board : New design A/D

Page No. 5

Page 9

DI-600 Operation Manual

Page No.

5

2. Main Operation

2.1. Power On

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Press [On/Off] Key

di-600

First display the

Indicator model,

Ur 1.00 Display version No.

0000000

1111111

:

9999999

▼ ▼

Segment checking

0.000

kg ▼ ▼

Weighting mode

Note: The segment checking mode can be skipped If [Re-Zero] key pressed after power on.

2.2. Power OFF

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode 0.000

kg ▼ ▼

Press [On/Off] Key

2.3. One Touch Tare

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Load Tare weight

2.500 kg ▼ Ex: tare 2.5kg

Press [Tare] Key [ tare]

0.000 kg

▼ ▼

Back to Weighing

mode

2.4. Digital tare

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Enter tare weight

value (Ex: 2.5kg)

[2][5][0][0]

2.500 kg ▼

Using number key.

Example:2.5kg

Press [Tare] Key [ Tare]

0.000 kg

▼ ▼

Back to weighing

mode

Page 10

DI-600 Operation Manual

Page No.

6

2.5. Tare Clear

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode -2.500

kg ▼ ▼ ▼

Press [Tare] key [ Tare ]

0.000

kg ▼ ▼

Clear tare data and

back to weighing

mode

2.6. Date and Time Setting

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode 0.000

kg ▼ ▼

Press [Mode] [Mode]

P. totAL

Press [Mode] [Mode]

C. totAL

Input Date

(Ex: 2002.6.9)

[0][2][0]

[6][0][9]

d.Y. N. d

d.020401

d.020609

Press [Enter] Key [Enter]

t. HH-NN

t. 00-00

Input TIME

(Ex: 18:26)

[1][8][2][6]

t. 18-26

Press [Enter] key [Enter]

S.PoInt1

Press [Tare] return

t

o weighing mode

[ Tare ]

0.000

kg ▼ ▼ ▼

Escape to weighing

mode

Note: If SPEC 07 bit3=1, the clock function will be disabled.

The date format is yy-mm-dd, the time format is HH-MM, date format can be set on

SPEC18 Bit0~1.

2.7. Date & Time Recall

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Press [Time] key [ Time ]

t. 18-26

▼ ▼

At this time must be

the weigh is 0 and

total weight as

same.

Press [Date] key [ Date ]

d.020618

▼ ▼

Press [Tare] key [ Tare ]

0.000

kg ▼ ▼

Return to weight

mode.

Page 11

DI-600 Operation Manual

Page No.

7

2.8. Grand Total Data Clear

3.8.1. Weight Grand Total Clear

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Press [Mode] key [Mode ]

P. totAL

12.0235

Press [Clear] key [Clear]

0.000

Press [Enter] key [Enter]

C. totAL

Press [Tare] key [Tare]

0.000

kg ▼ ▼

Escape to

weighting mode

Note: SPEC 20 Bit1 should be set as 0 to enable the grand total operation.

3.8.2. Quantity Grand Total Clear

INDICATION FLAG : (▼ EXPRESS BRIGHT, SPARKLING)

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM 8293225 13964731996

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Press [Mode] key [Mode ]

P. totAL

Press [Mode] [Mode]

C. totAL

12899

Press [Clear] key [Clear]

0

Press [Enter] key [Enter]

d. Y.N.d

Press [Tare] key [ Tare ]

0.000

kg ▼ ▼

Escape to

weighting mode

Note: SPEC 20 Bit 0 should be set as 0 to enable the quantity grand total operation.

2.9. Serial number setup

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode

0.000

kg ▼ ▼

Press [ # ] [ # ]

C.000000

▼ ▼

Input CODE

number value

[1][8][5]

[6][2][6]

C.185626

▼ ▼

Example: the serial

code is 185626

Press [Enter] key [ENTER]

0.000

kg ▼ ▼

Back to weighting

mode

Note: This serial number can be used for print.

Page 12

DI-600 Operation Manual

Page No.

8

2.10. Weight Unit Conversion

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode

0.000

kg ▼ ▼

1.000

kg

▼

Put 1.0kg

Press [lb] key

[ lb]

2.204

Lb

▼

Display in lb

Press [lb] key

[ lb]

1.000

kg

▼ Display in kg

Note: Set the SPEC 19 Bit 0 as 0 to enable this function.

2.11. Set Point Value Setting & S. Memory Recall

System can be set 5 groups of set-point value, each group can be registered 4 points data.

Before be use this function, we should program the group data of set point into memory first.

When the weight exceeds the first point value, the indicator OS1 will be light.

When the weight exceeds the second point values, the indicator OS1 and OS2 will be light.

When the weight exceeds the third point values, the indicator OS1, OS2 and OS3 will be light.

When the weight exceeds the fourth point values, OS1, OS2, OS3 and OS4 will be light.

2.11.1. Set Point Value Setting

INDICATION FLAG : (▼ EXPRESS BRIGHT, SPARKLING)

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Press [M][M][M][M]

[M][M]

[M][M]

S.PoInt1

6.000

kg ▼ ▼

▼

SM1, SP1 data Set.

SM1 bright

Input value

(Ex: 1.000kg)

[1][0][0][0]

1.000

kg ▼ ▼

▼ ▼

SP1 Value is 1 kg

Press [Enter] key [Enter]

S.PoInt2

6.000

kg ▼ ▼

▼

SM1, SP2 data Set.

SM1 bright

Input number value

(Example: 2.000kg)

[2][0][0][0]

2.000

kg ▼ ▼

▼

▼

SP2 value is 2 kg

Press [Enter] key [Enter]

S.PoInt3

6.000

kg ▼ ▼

▼

SM1, SP3 data Set.

SM1 bright

Input number value

(Example: 3.000kg)

[3][0][0][0]

3.000

kg ▼ ▼

▼ ▼

SP3 value is 3 kg

Press [Enter] key [Enter]

S.PoInt4

6.000

kg ▼ ▼

▼

SM1, SP4 data Set.

SM1 bright

Input number value

(Example: 4.000kg)

[4][0][0][0]

4.000

kg ▼ ▼

▼ ▼

SP4 value is 4 kg

Press [Enter] key [Enter]

S.PoInt1

6.000

kg ▼ ▼

▼

SM2, SP1 data Set.

SM2 bright

Repeat above

operation

:

:

SM2~SM5 data

Press [Tare] key [Tare]

0.000

kg ▼ ▼

Weighing mode

Note: The value of each set point should be assure SP1 less then SP2, SP2 less then SP3,

SP3 less then SP4 and SP4 less then full capacity.

Page 13

DI-600 Operation Manual

Page No.

9

2.11.2. Set Point Memory Recall

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

▼

Press [ S ] [ S ]

SEL. S. 1

▼ ▼

Input number of

SM (1~5) (Ex: 2)

[ 2 ]

SEL. S. 2

▼ ▼

Select activity SM2

Press [Enter] key [Enter]

0.000

kg ▼ ▼

▼

Weighting mode,

Weight is stabled

Note: The numeric keys 1~5 are available only for this operation.

2.11.3. Set-Point Check and Alarm Mode Select

There is Filling or Check Weighing methods for application of Set-Point Alarm Function.

z Filling Application

Operator can set the certain weight point to judge the filled weight reached or over target

range. The target range can be determined between 2 set-point (set-point 2 and set-point

3), the continuous and fast alarm will alert when weight is reached target weighing range.

And the range of Set-point 1 to 2 and Set-point 3 to 4 can be programmed as fine

adjustment range.

(Min.) (Max.)

Near Min. Target Over Max.

Zero Set-point 1 Set-point 2 Set-point 3 Set-point 4 Capacity

Note: means slow alarm and means fast alarm.

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0 .000

kg ▼ ▼ ▼

Press [ CH ] [ CH ]

ALA. FIL

▼ ▼

Press [Enter] [Enter]

0.000

kg ▼ ▼ ▼

Entry weighting

mode, filling check

alarm on.

Note: Please enable the set-point alarm via setting of SPEC 06 bit 1.

z Weight Check Application

Operator can set the allowable error weight range between 2 set-points (set-point 2 and

set-point 3), and the range of Set-point 1 to 2 and Set-point 3 to 4 can be programmed as

out of range.

(Min.) (Max.)

Out Allowable Out

Zero Set-point 1 Set-point 2 Set-point 3 Set-point 4 Capacity

Note: means slow alarm and means fast alarm.

Page 14

DI-600 Operation Manual

Page No.

10

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode 0.000

kg ▼ ▼ ▼

Press [ CH ] [ CH ]

ALA. FIL

▼ ▼

Press [ CH ] [ CH ]

ALA. CH

▼ ▼

Press [enter] key [Enter]

0.000

kg ▼ ▼ ▼

▼

Entry weighting

mode, weight

check alarm on

Note: Please enable the set-point alarm via setting of SPEC 06 bit 1.

z Alarm Sound Off

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode

0.000

kg ▼ ▼ ▼

Press [ CH ] [ CH ]

ALA. FIL

▼ ▼

Press [ CH ] [ CH ]

ALA. CH

▼ ▼

Press [ CH ] [ CH ]

ALA.OFF

▼ ▼

A

larm off

Press [Enter] key [Enter]

0.000

kg ▼ ▼ ▼

Back weighing mode

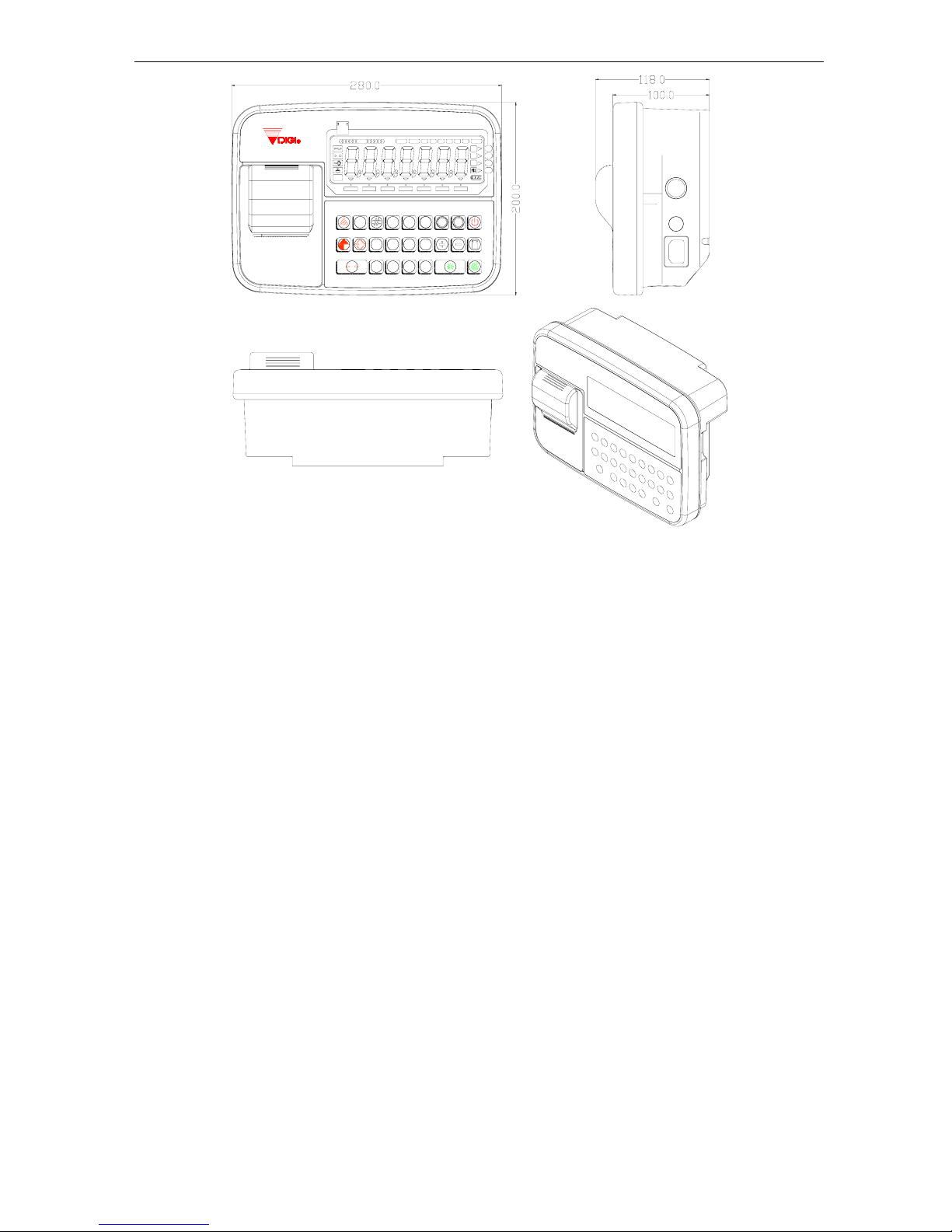

2.11.4. Weight Check Bar of Set-Point

The check bar can be separated as three phases of display range.

First phase corresponds to the range between set-point 1 and 2.

Second phase corresponds to the range between set-point 2 and 3.

Third phase equals to the range between set-point 3 and 4.

The first and third range has 5 grades of

indicators for each, and one grade of indicator

equals to 20% of weight range between

set-point 1 & 2 or 3 & 4.

Ex: The system once increment is 5 g.

Set-point data:

Set-point 1 = 1.000kg, Set-point 2 = 2.000kg

Set-point 3 = 4.000kg, Set-point 4 = 5.000kg

Display Sample Weight

Fig 1

1.000 ~ 1.195 kg

Fig 2

1.800 ~ 1.995 kg

Fig 3

2,000 ~ 3,995 kg

Fig 4.

4.800 ~ 4.395 kg

Fig 5

Over 5.000kg

LOW

OK

CHECK

HI GH

LOW

OK

CHECK

HI GH

LOW

OK

CHECK

HI GH

LOW

OK

CHECK

HI GH

LOW

OK

CHECK

HI GH

LOW

OK

CHECK

HI GH

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

SP1 SP2 SP3 SP4

Page 15

DI-600 Operation Manual

Page No.

11

2.12. Counting Mode

DI-600 has counting function. It can set the sample quantity.

The default sample quantity is 10, or you can set the certain quantity as you need.

2.12.1. Key Entry Quantity

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode

0.000

kg ▼ ▼ ▼

Load10 pcs sample

0.025

kg

▼

▼

Counting mode

Press [ Count ] [ Count ]

10

PCS

▼ ▼ ▼

Remove all

0

PCS ▼ ▼ ▼ ▼

Put one package

100

PCS

▼ ▼ ▼

Remove all

0

PCS ▼ ▼ ▼ ▼

Press [ C ] key [ C ]

0.000

kg ▼ ▼ ▼

Weighing mode.

2.12.2. Sample Quantity Setting

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode

0.000

kg ▼ ▼ ▼

Press [ Count ] [Count]

10

PCS ▼ ▼ ▼

▼

Key in quantity [8][5][0]

850

PCS ▼ ▼ ▼

▼

Press [Enter] key [Enter]

0.000

kg ▼ ▼ ▼

Weighing mode

2.12.3. Sample Quantity Modification and Print Receipt

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode

0.000

kg ▼ ▼ ▼

Load10 pieces

0.025

kg

▼

▼

Into counting mode

Press [Count] [ Count ]

10

PCS

▼ ▼ ▼

Remove

0

PCS ▼ ▼ ▼ ▼

Press [ Count ] [ Count ]

10

PCS ▼ ▼ ▼ ▼ ▼

Weight is “0”

Key in quantity [1][0][0][0]

1000

PCS ▼ ▼ ▼

▼

EX: 1000

Press [Enter] key [Enter]

0.000

kg ▼ ▼ ▼

Load 1000 pieces

1.525

kg

▼

▼

Counting mode

Press [ Count ] [ Count ]

1000

PCS

▼ ▼ ▼

Put one package

2000

PCS

▼ ▼ ▼

Press [Enter] key [Enter]

2000

PCS

▼

▼

Print receipt

Remove all

0

PCS ▼ ▼ ▼ ▼

Press [ C] key [ C ]

0.000

kg ▼ ▼ ▼

Weighing mode.

Page 16

DI-600 Operation Manual

Page No.

12

Same of Printed Receipt:

2.13. Accumulation Operation

2.13.1. Weight Accumulation

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

W

eighing mode 0.000

kg ▼ ▼ ▼

Load weight on

25.500

kg

▼

▼

EX: 25.50kg

Press [ + ] key [ + ]

Add. 1

25.500

kg

▼

▼ ▼

Or auto print weight

receipt

W

ait for printing end

25.500

kg ▼ ▼ ▼

Auto return to

weighing mode.

Remove weight

0.000

kg ▼ ▼ ▼ ▼

Load weight on

15.500

kg

▼

▼ ▼

Ex: 15.50kg

Press [ + ] key [ + ]

Add. 2

41.000

kg

▼

▼ ▼

Or auto print weight

receipt

W

ait for printing end

15.500

kg ▼ ▼ ▼

Auto return to

weighing mode.

Remove weight

0.000

kg ▼ ▼ ▼ ▼

Press [ + ] key [ + ]

tot. 2

41.000

kg▼ ▼ ▼ ▼

Display the total

weights stored

Press [ C ] key

O

r

Press [ Enter ]

[ C ]

[ Enter ]

0.000

kg ▼ ▼

Here you can clear

or print the total

value and grand

total operation.

W

ait for printing end

0.000

kg ▼ ▼ ▼

Return to weighting

mode.

Note: After printed the total value, accumulator will be clear to “0”, in meantime this total will be

added into grand total.

02 06-18 15:21

CODE: 123456

PIECES: 2000

------------------------------

Page 17

DI-600 Operation Manual

Page No.

13

2.13.2. Quantity Accumulation

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼ ▼

Load 10 pieces

0.025

kg

▼

▼

Ex: 10 pcs

Press [ Count ] [ Count ]

10

PCS

▼

▼

Remove all

0

PCS ▼ ▼ ▼

Load one bag

200

PCS

▼

▼

Ex: 200 pieces

Press [ + ] [ + ]

Add. 1

200

PCS

▼

▼ ▼

With printing the

accumulated data

Remove all

0

PCS ▼ ▼ ▼ ▼

Put one bag

300

PCS

▼

▼

Ex: 300 pieces

Press [ + ] [ + ]

Add. 2

500

PCS

▼

▼ ▼

With printing the

accumulate data

Remove all

0

PCS ▼ ▼ ▼ ▼

Press [ + ] key

again

[ + ]

tot. 2

500

PCS ▼ ▼ ▼ ▼

Display the total

PCS.

Press [ C ] key

or

Press [ Enter ]

[ C ]

[ Enter ]

0

PCS

▼ ▼

Hear you can clear

or print the total

Wait for printing

end

0

PCS ▼ ▼ ▼

Return to weighing

mode.

Note: After printed the total value, accumulator will be clear to “0”, in meantime this total will be

added into grand total.

Sample of Printed Receipt:

02 06-18 15:21

# 123456

+ 200 PCS

# 123456

+ 300 PCS

A 0002

T 500 PCS

02 06-18 15:28

# 123456

+ 25.500kg

# 123456

+ 15.500kg

A 0002

T 41.000kg

Page 18

DI-600 Operation Manual

Page No.

14

2.14. Grand Total Check and Print

INDICATION FLAG : ( ▼ EXPRESS BRIGHT, SPARKLING )

(1) Zero (2) Net (3) STA (4) Count (5) Check (6) MEM (7) OS1 (8) OS2 (9) OS3 (10) OS4

(11) Hold (12) ALM

Indicators

Operation Key Weight

1 2 3 4 5 6 7 8 9 10 11 12

Remarks

Weighing mode 0.000

kg ▼ ▼

Press [ Mode ] [ Mode ]

P.tOtAL

41.000

kg ▼ ▼

Ex: 41.000kg,

Auto print grand

total weight.

Press [ Enter ] [ Enter ]

C.tOtAL

500

PCS ▼ ▼

Ex: 500PCS,

Auto print grand

total quantity.

Press [ Enter ] [ Enter ]

D

02.06.1

8

▼ ▼

Press [ Tare ] key [ Tare ]

0

kg ▼ ▼ ▼

Wighting mode.

Note: After printed the grand total value, memory will be clear to “0”.

Sample Receipt of Grand total Printed. (English)

2.15. Printed Ticket Sample

02 06-18 15:28

GRAND TOTAL

GT 41.000kg

---------------------------------

-

02 06-18 15:28

GRAND TOTAL

GT 500PCS

---------------------------------

-

02 06-18 10:16

CODE: 123456

GROSS: 1.000kg

NET: 0.520kg

TARE: 0.480kg

--------------------------

DI-600 PRINT

Page 19

DI-600 Operation Manual

3. Error Message

3.1. Error Message List & Solution

DI-600 will display error message if improper operation is performed or system defect.

No. Display Contents Solution

01 OF

Over Flow, weight is over full

capacity.

Remove some weight form platform.

02 LO

Lower weight, weight value is

lower then limit of display

mask weight.

Add some weight or restart the

indicator

03 nOt Ad

A/D error

Check the A/D board and load cell are

defective or not.

04 zErO Er

Zero Point error, not at zero

point or over start range

Remove weight on platter or restart

the scale, otherwise calibrate it again.

05 Add. OF

Accumulated data over flow Clear the total data and operate again.

06 GrA. OF

Grand Total data over flow Clear the grand total.

If the problems still can not be resolved according to above information, please contact to our

local dealer or Technical Service Dept. of Shanghai Teraoka via the information which described

on manual cover.

Page No.

15

Page 20

DI-600 Service Manual

4. Interface & Protocol

4.1. Load Cell Connecter

z DDK-14PIN connector.

z Allows to parallel connected 8 load cells with 350 Ohm impedance for each.

z Regulated 6 wire connection with power feedback signal.

z Exciting voltage: DC 12V, 280 mA.

z Pin connection:

Pin No. Signal Wire Color Pin No. Signal Wire Color

1 RS+ Orange 8 F.GND

Wire Layer

2 RS- Blue 9 NC

3 V+ Red 10 NC

4 V - White 11 NC

5 GND Black 12 NC

6 IN+ Green 13 NC

7 IN - Yellow 14 NC

4.2. RS-232C Port

The Baud Rate of RS-232C setting is selectable in SPEC 04, and the other parameters are fixed

as following:

(1) Data Length : 8 bit

(2) Stop Bit: : 1 bit

(3) Parity Bit : No

4.2.1. RS-232 Cable Connection

DI-600 (D-Din 8Pin) PC (D-SUB 9 Pins)

Pin No. Signal Name Pin No Signal Name

1

NC 1 NC

2

GND 2 RXD

3

NC 3 TXD

4

RXD 4 DTR

5

TXD 5 GND

6

DTR 6 DSR

7

NC 7 RTS

8

NC 8 CTS

9

SHIELD

9NC

Page No. 23

Page 21

DI-600 Service Manual

4.2.2. RS-232 Protocol

4.2.2.1. Text Command

Data Type Code Contents Hex Data

CR End of data 0DH

Terminal Code

LF End of Text 0AH

0 ~ 9 Numeric data (30H~39H)

- (Minus) Minus sign 2DH

. (Period) Period 2EH

Data

, (Comma) Comma 2CH

0 Net Weight 30H

4 Tare Weight 34H

Header Code

C Quantity data 43H

NUL Stable 00H

Stable Sign

SOH Un-stable 01H

4.2.2.2. Data Format

SPEC03 Bit 0 for Header Code, SPEC03 Bit 1 for Weight Stable sign definition.

a) Without header code & Without weight stable sign (Total 19 Bytes)

Net Weight CR Tare Weight CR LF

8 Byte 1byte 8 Byte 1 Byte 1 Byte

b) Without header code & With weight stability sign (Total 21 Bytes)

Stable

status

CR Net Weight CR Tare Weight CR LF

1 Byte 1 Byte 8 Byte 1byte 8 Byte 1 Byte 1 Byte

c) With header code & Without weight stability code (Total 21 Bytes)

Header

status

Net Weight CR

Header

status

Tare Weight CR LF

1 Byte 8 Byte 1byte 1 Byte 8 Byte 1 Byte 1 Byte

d) With header code and weight stability code (Total 23 Bytes)

Stable

status

CR

Header

Code

Net

Weight

CR

Header

Code

Tare

Weight

CR LF

1 Byte 1 Byte 1 Byte 8 Byte 1byte 1 Byte 8 Byte 1 Byte 1 Byte

e.g.) With Header code and weight stability code

Net weight =-1,2340 Tare weight = 0,450 weight status = stable

NUL CR 0 - 0 1 , 2 3 0 CR

4 0 0 0 , 4 5 0 CR LF

Note 1: The data format consists of (header code), minus/plus sigh, numeric data and

decimal data. If weight data is minus, -(2DH) is added after header data. If weight is

plus data, 0(30H) is output.

Note 2: The data is aligned form right except plus/minus sign if weight data are less then 5

digits.

Note 3: When weight is over the capacity, the following data is output:

0OV00000CR4???????CRLF (With Header Code)

Page No. 24

Page 22

DI-600 Service Manual

4.2.2.3. Communication Method

Communication method can be selected as Stream (continuous), Manual and Command by

specification settings.

a) Stream (continuous output)

Data will transmit to PC side continuously, and the function of SPEC 03 bit 0 is disabled.

b) Manual Command

Data will output after ↑ key pressed, customer may select to transmit the data right away

or hold the command until weight becomes stable through the SPEC setting. If weight not

stable within certain interval, error message “ERR C” will appear on display.

Data Flow (Stream Output after Weight Stable):

PC Side DI-600 Side

Weight Stable

?

X. Seconds

Time Out

Yes

Manual Command

Yes

No

No

Text

Page No. 25

Page 23

DI-600 Service Manual

c) Command Mode

Data will be sent out after received command (ACK 06H) form external device (Ex. PC).

If PC required data from DI-600 side, PC should transmit an ACK signal to DI-600 , after

DI-600 received the ACK signal, DI-600 would transmit the weight data to PC

SPEC setting can define the data It is alter to send the weight data right away or to hold

the command unit weight. Become stable. If weight is not back to stable condition within

the certain interval, DI-600 transmits NAK (15H) to PC.

Note) If ACK signal is sent to DI-600 during digital tare entry or re-zero operation NAK

signal is sent to PC right away.

PC Side DS-600 Side

Weight Mode?

X. Seconds Stable?

NAK

NAK

DATA

ACK

EOT

No

Yes

Yes Yes

No No

Page No. 26

Page 24

DI-600 Service Manual

4.3. Set-Point Connector

Max. 4 points can be programmed for one item code.

4.3.1. Set-Point Control Cable Specification

DI-600 Set-Point Output

Pin No Signal

1 Set-Point 1 Control out

2 Set-Point 2 Control out

3 Set-Point 3 Control out

4 Set-Point 4 Control out

5 GND

6 Shield

4.3.2. Set-Point Port Specification

(1) Interface: Open collector type (Passive type)

(2) Max. Rated Input Voltage: 24VDC

(3) Max. Rated Across Current: 50 mA

(4) External Power (VEXT): 12VDC (6~15VDC) Recommended

Max. 24VDC 100mA.

4.3.3. Set-Point Signal ON Timing

When the weight display reaches each programmed value, the set point signal will be ON.

The following figure shows an example of the set point signal ON timing.

Note1: When programmed set point value is 0, the set point signal will not be ON.

Page No. 27

Page 25

DI-600 Service Manual

4.3.4. Set-Point Output Control

Combine with the external devices, the set-point port can realize the control function

according to the weight changing.

Following is a sample circuitry diagram for out devices control:

Note: This Circuit Diagram is for Referenced only.

Page No. 28

Loading...

Loading...