Page 1

MM

MMiiiinnnniiii----BBBBeeeennnncccchhhh SSSSccccaaaalllleeee

DI-28

OO

OO

pp

pp

ee

ee

rr

rr

aa

aa

ttiiii

tt

oo

oo

nn

nn

MM

MM

aa

aa

nn

nn

uu

uu

aallll

aa

73356

Page 2

ii

Page 3

DI-28 SERIES OPERATING MANUAL

SECTION INDEX PAGE NUMBER

1.0. GENERAL 2

1.1. Description 2

2.0. SPECIFICATIONS 3

2.1. Platforms & Capacities 3

2.2. Technical 4

3.0. INSTALLATION 5

3.1. Unpacking 5

3.2. Inspection 5

3.3. Repackaging 5

3.4. Mini Grand Unlocking Procedure 5-7

3.5. Mini Grand Assembly 8-9

4.0. ELECTRICAL TEST 10

4.1. Set-Up Procedure 10

4.2. Keyboard & Display Test 10

4.3. Control Panel 11

4.3.1. Lamps 11

4.3.2. Keys 11

5.0. OPERATION PROCEDURE 12

5.1. Power On 12

5.2. Tare Subtraction 12

5.2.1. One Touch Tare 12

5.2.2. Digital Tare 12

5.3. Battery Life Check 12

5.4. Set Point Value Entry 13

5.5. Changing Weight Units 13

6.0. PROGRAMMING 14

6.1. DI-28 Key Function Summery 14

6.2. Internal Count 14

6.3. Set Up And Calibration 15

6.4. Specification List 15-17

6.5. Span Adjustment 17-18

6.6. Span Enable Switch 18

7.0. DI-20 OPTIONS 19

7.1. Battery Option 19

7.2. Set Point Output, & Setpoint Wiring 21

7.3. RS-232, RS-232 Wiring 21-27

8.0. MAINTENANCE, CALIBRATION, TEST PROCEDURE, SERVICE 28

8.1. Maintenance Procedures 28

8.2. Service & Repair

8.3. Load Cell Wiring 29

8.4

Limited Warranty 30

29

1

Page 4

DI-28 OPERATING MANUAL

1.0. GENERAL

1.1. Features

The DI-28 Indicator offers a practical solution to a wide range of weighing applications.

There are a variety of weight capacities and increments available. The display resolution

is selectable from 1/2000 to 1/7500. It features RS-232 & 4 Setpoint outputs (factory

options) and keyboard calibration with auto-span. It operates on 6 “C” cell batteries or

with its AC/DC adapter. The DI-28 is able to support single load cells that have an output

range of 0.4mV/V to 4.0mV/V and is able to support up to 4 load cells when used with

the AC/DC adapter. This indicator features ON/OFF, REZERO, TARE, for both one

touch and digital key operation. A recharging circuit is incorporated for use with

rechargeable NiCAD batteries. For a list of platforms sizes and available capacities see

page 3.

This instruction manual will provide the user with all the information necessary to

understand, set-up and operate the DI-28 scale. Included in this manual are descriptions,

specifications, drawings, and operating instructions.

2

Page 5

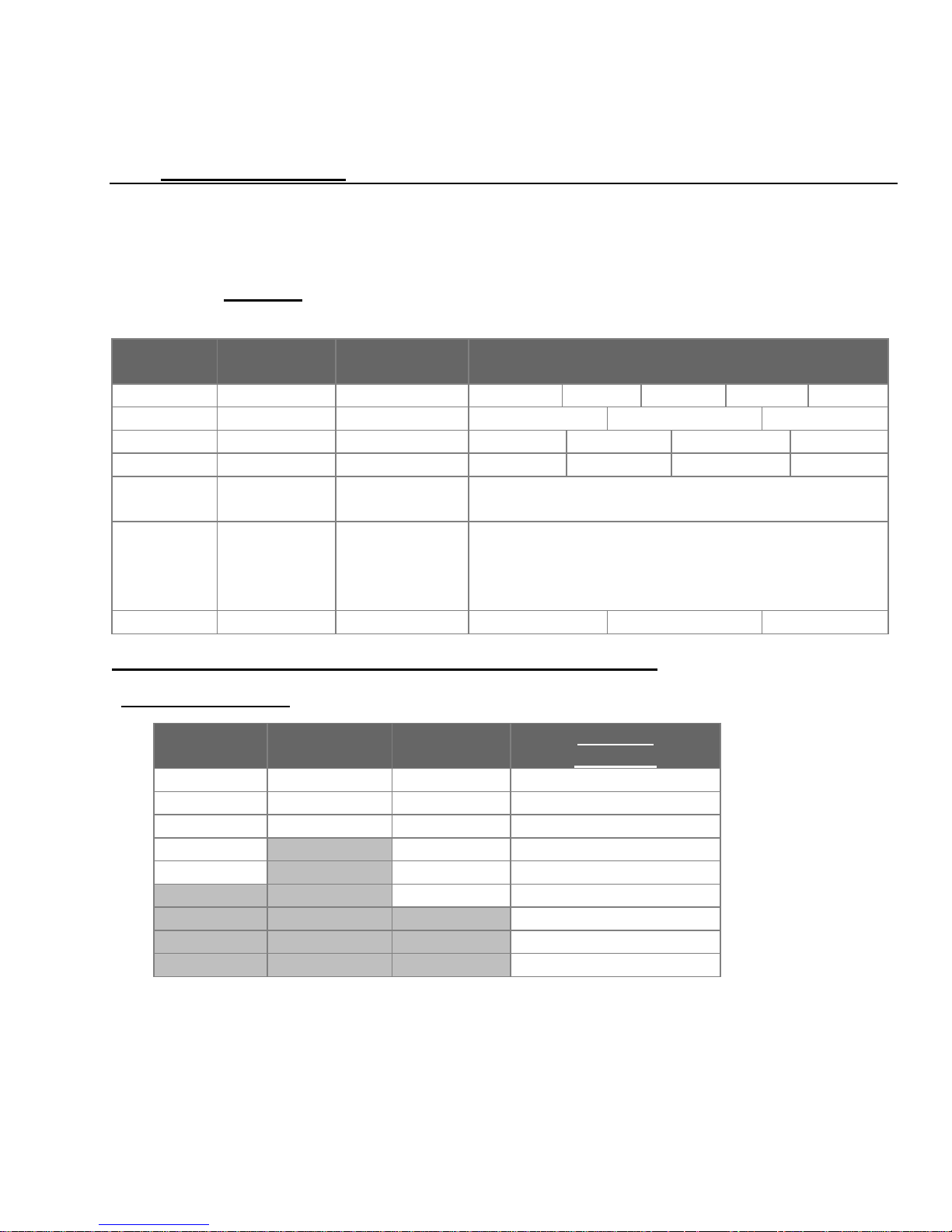

2.0. SPECIFICATIONS

This section includes a detailed listing of all pertinent specifications and parameters for each of

the DI-28 weighing scales. The system weighing accuracy is 0.02 % for all models and they

meet or exceed the requirements of OIML Class III and NIST Handbook, Number 44.

2.1 Platforms

The following is a list of platforms :

Model Platform

Size/Platter

S-AL bench 12” x 14” x3” 1 LB. 5 LB. 10 LB. 25 LB. 50 LB.

S-SL bench / floor 13” x 17” 60 LB. 150 LB. 300 LB.

S-TL floor 17” x 21” 150 LB. 300 LB. 500 LB. 1000 LB.

S-UL floor 24” x 28” 150 LB. 300 LB. 500 LB. 1000 LB.

S-PL floor 30” x 30”

36” x 36”

S-PL floor 48” x 48”

48” x 72”

60” x 60”

60” x 84”

Ramps , Other Capacities And Stainless Steel Platforms Also Available

Choosing A Capacity :Decimal Location (*) Minimum Weight (*) Display Resolution (=) Capacity

Decimal

Location

Minimum

Weight

Display

Resolution

Available

Capacities

0.0000 1 1 / 2000 1lb,2.5lb,3lb.,5lb.,6lb,.

0.000 2 1 / 2500 10lb.,25lb.,30lb.,50lb.,

0.00 5 1 / 3000 60lb.,75lb.,100lb.,125lb

0.0 1 / 5000 150lb.,200lb.,250lb.,

0 1 / 6000 300lb.,375lb.,500lb.,

1 / 7500 600lb.,750lb.,1000lb.,

1500lb.,2000lb.,2500lb.

3000lb.,3750lb.,5000lb.

6000lb.,7500lb.,10000lb

Example: dec. loc. (*) min. wt. (*) disp. res. = avail cap.

0.00 (*) 5 (*) 1 / 7500 = 375. 00 lb.

* Units can be programmed to primarily weigh in lb., oz., kg., g., or dwt.

Capacities

1000 lb. to 3000 lb.

2500 lb.

to

25000 lb.

3

Page 6

2.2. SPECIFICATIONS Technical

2.2.1. Id Plate :

Model # DI-28

Serial #

Power Dissipation .3w

Voltage Battery size C 6x1.5v or 12v AC Adapter

2.2.2. Operating Conditions :

Power source : AC/DC adapter (12V, Digi Model PS-100 only, See 2.2.4.

below) or 6x 1.5V size C battery, alkaline or rechargeable.

Temperature Range : -10° to +40° C.

Humidity : 15% to 85% R.H.

Power Consumption : 0.3 to 1.5 Watts.

2.2.3. Display Specifications

Display Device: LCD (Liquid Crystal Display)

Character Height, 25mm.

No. of Digits: 6 Digits (including minus sign digit)

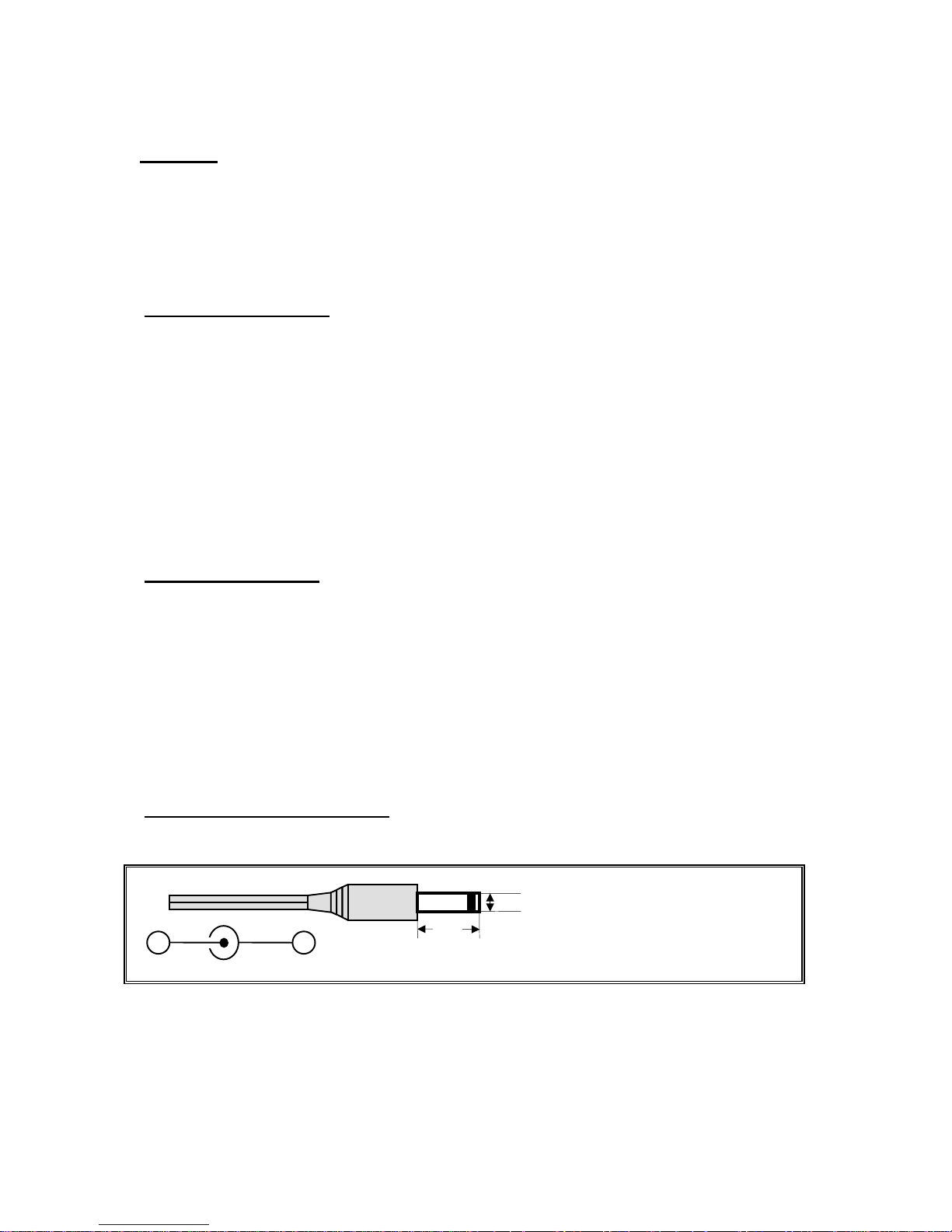

2.2.4. AC/DC Adapter Specifications

a) 9.5±0.5mm

b) Inside 2.1±0.5mm

Outside 5.5±0.5mm

−−−−

++++

a

b

4

Page 7

3.0. INSTALLATION

This section provides the information required for installation of the DI-28 weight indicator.

The following steps accomplish installation.

1. Unpacking

2. Set-up Procedure

3.1. Unpacking

Each component of the DI-28 is packed in a specially designed carton. Remove each

component from the carton, separate the component from its polystyrene shell assembly

and set aside. Inspect the carton interior to be sure that all accessories have been

removed from the carton. Inspect the carton inner panels for accessories.

NOTE: Be sure to repack all materials within the carton set. Store the cartons in a

secure area so they can be available whenever shipment of the scale is required.

3.2. Inspection

Immediately after unpacking, a visual inspection of the instrument should be performed.

If any damage has been incurred during transportation the shipper and DIGI MATEX

INC. should be notified immediately. Instructions for assessment of damage and further

procedures will then be determined.

3.3. Repackaging

If, at anytime, the DI-28 weight indicator must be returned for modification, calibration,

or repair, be sure that it is properly packed with sufficient cushioning materials.

Whenever possible, the original carton assembly should be retained for this purpose.

Any damage caused by improper packaging will not be covered by warranty.

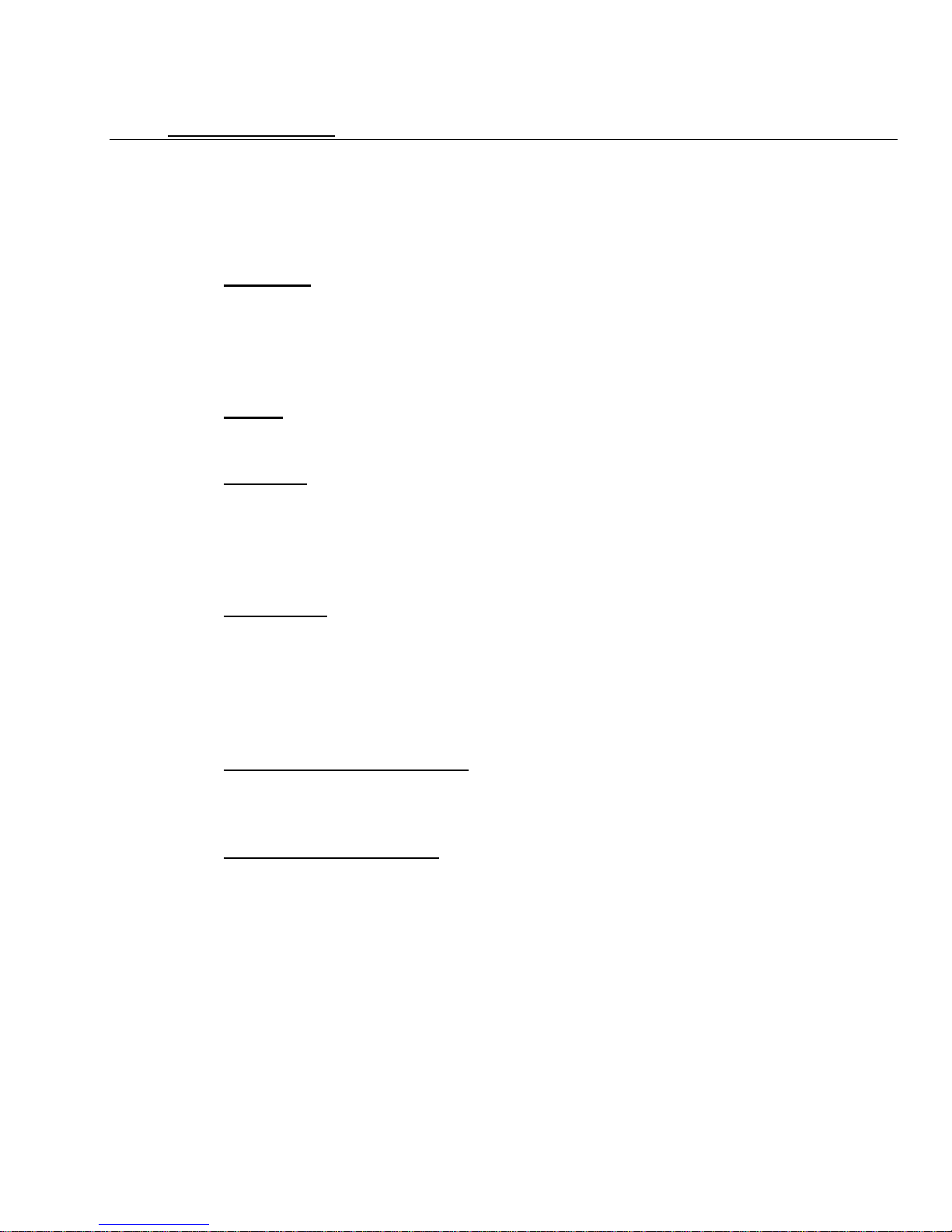

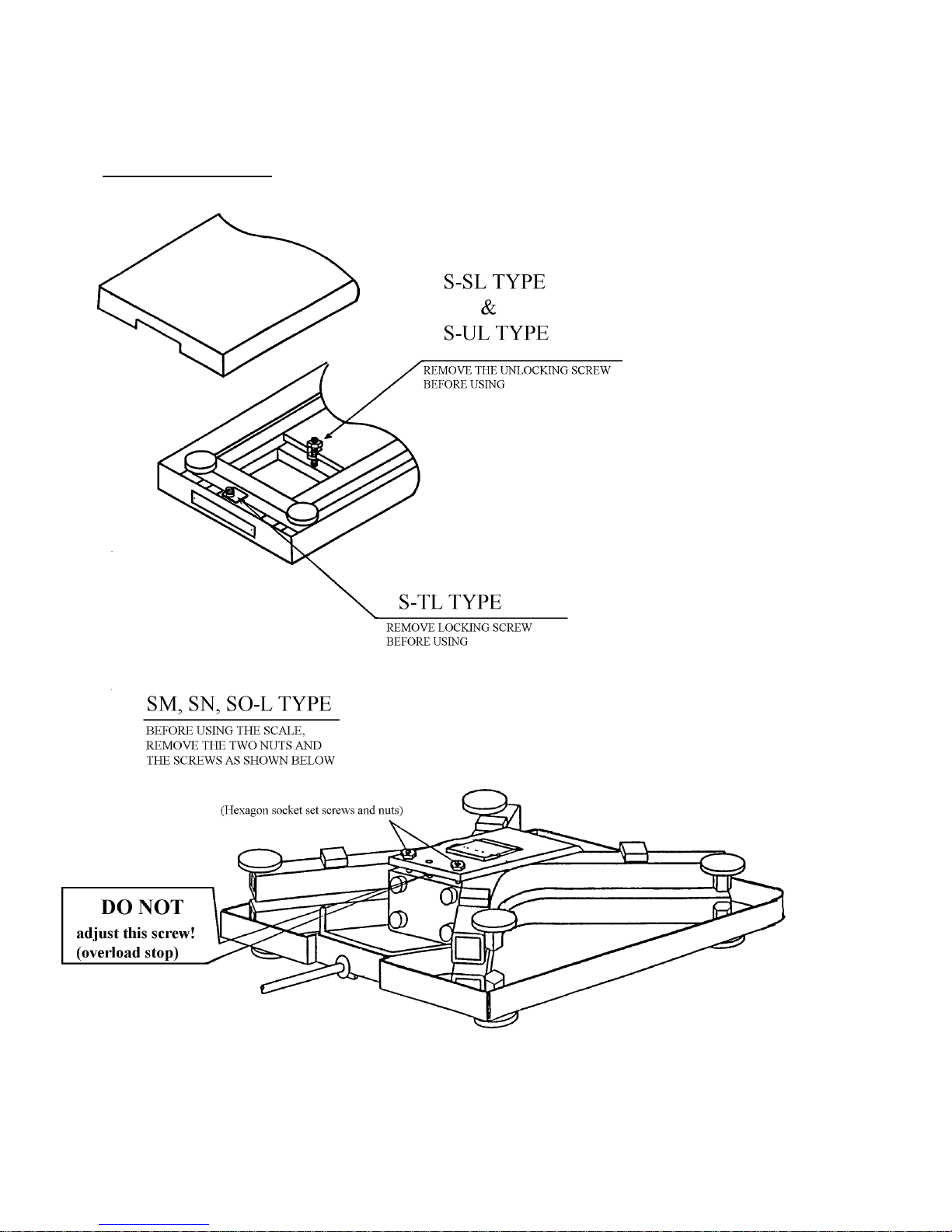

3.4. Platform Unlocking Procedure

The unlocking procedure is different for each style of platform and is included on

the following pages.

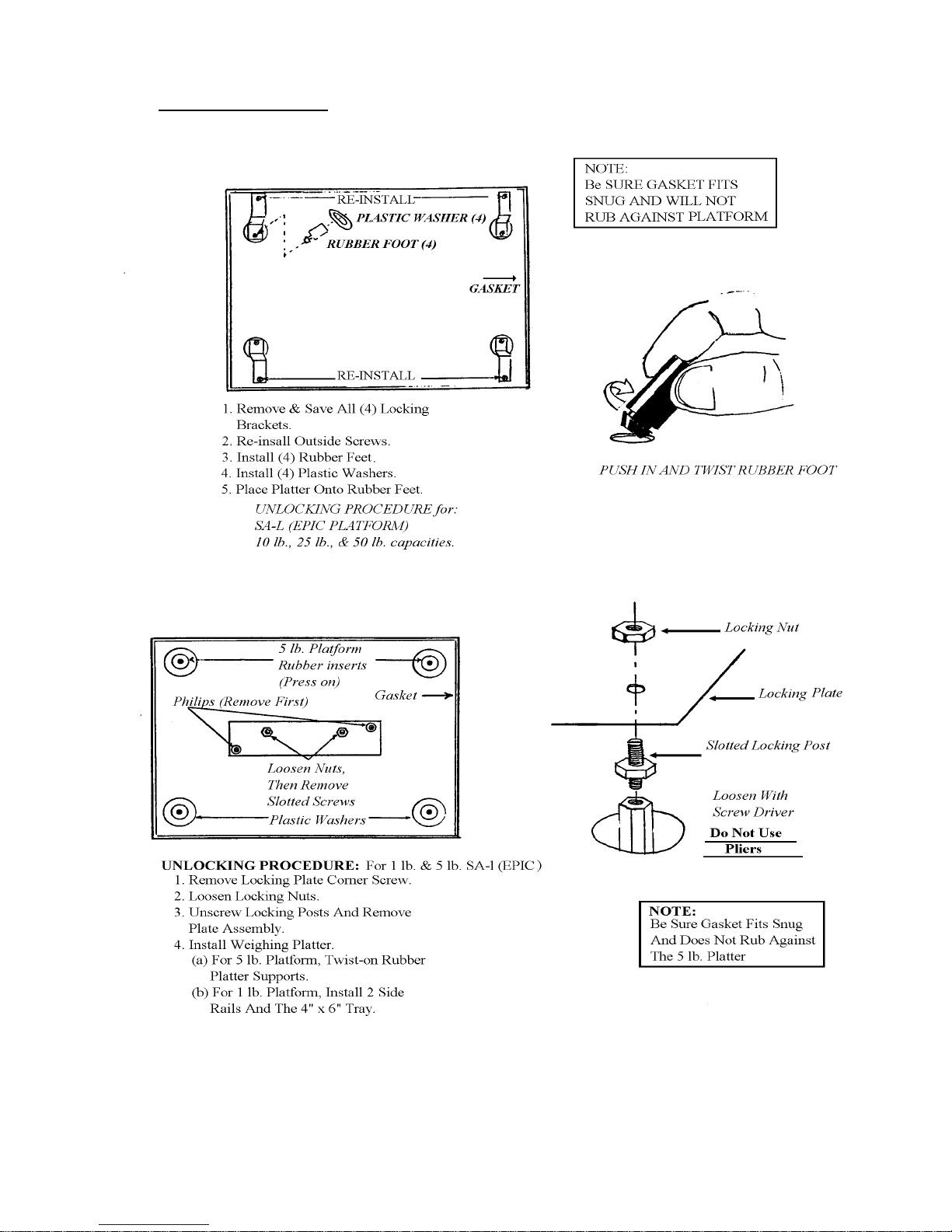

3.5. Mini Grand Pole Assembly

The optional pole mounting kit comes with all the necessary hardware and assembly

is easy. See pages 8 & 9 for details.

5

Page 8

3.4.1. Unlocking Procedure

6

Page 9

3.4.2. Unlocking Procedure

7

Page 10

3.5.1. Mini Grand Assembly

8

Page 11

3.5.2. DI-28 Adapter Plate

9

Page 12

4.0. ELECTRICAL TEST

4.1. Set-up Procedure

This part of the procedure is used to verify proper operation of the scale.

Connect the AC power source, and press the [ON/OFF] key. At turn-on, the display will

momentarily show the version number then, all digits from 0 to 9 in a “count-up” mode.

Then the display will blank, show all “8’s”, and enter the regular operating display.

If at any time the scale displays erratic data, it may be caused by a power transient. Turn

the scale “off” and momentarily unplug it from the wall outlet. Then restart, by plugging

the scale back in and pressing the [ON/OFF] key.

4.2. Keyboard and Display

This part of the procedure is used to verify proper operation of various switches and

displays. The following functions will be tested in this procedure:

A. Tare Entry

B. Digital Tare Entry

4.2.1. One Touch Tare

a. Press [REZERO] key, to rezero the scale.

b. Place the empty container on the scale and press the [TARE] key once.

The Weight Display should now read zero with the empty container on the

scale.

4.2.2. Digital Tare Entry

a. Press the [REZERO] key. After resetting, the display will resd zero.

b. Enter the number 0.2 by using the keyboard, select the digit to change

using [ ←←←← DIGIT ] key, then press [ ↑↑↑↑ INCR ]key for the desired Tare

value. Then press the [TARE] key.

The Weight Display will show the weight entered with a negative sign

indicating that the weight displayed is a Tare Weight.

10

Page 13

4.3. Control Panels

4.3.1. Keys

Key Name Functions

ON/OFF

Turn power on or off.

REZERO

O

TARE

T

DIGIT SELECT

INCREASE

Reset the weight to zero.

Enter or clear tare value.

Select the digits to set tare or setpoint value.

Increase the value of tare or setpoint weight on

selected digit when setting data. Manual transmit

key for RS-232 output.

4.3.2. Lamps

Indicators Name Functions

BATTERY LAMP

On when battery becomes too weak and needs to

be replaced/ recharged.

O

ZERO LAMP

NET NET LAMP

g GRAM LAMP

lb/kg LB/KG LAMP

11

On when weight is stable at zero point.

On when tare is subtracted.

On when grams are used as weighing unit.

On when pounds are used as weighing unit.

Page 14

5. Operation Procedure

5.1 Power On

PROCEDURE

Connect DI-28 to power supply.

Make sure nothing is on the platform,

1.

and press [ON/OFF] key.

000000

888888

0.000

5.2 Tare Subtraction

5.2a One touch tare

PROCEDURE

Stand-by status 0.000

Place tare weight on the platform.

1.

Press [TARE] key.

2.

3. Remove the tare weight. -0.010

Note 1) To clear the tare weight, remove tare from the load receptor then, press [TARE] key.

5.2b Digital tare entry (When the tare weight is known)

PROCEDURE

Stand-by status 0.000

Move cursor to the left two digits.

1.

Set tare value by increasing the

2.

value.

3. Enter the tare value.

Note 1) To clear the tare weight, press [TARE] key.

Note 2) “0” and “2” means that the cursor is blinking.

5.3. Battery Life Check

The battery life can be checked

PROCEDURE

Stand-by status 0.000

Press [TARE], [], [TARE] key

1.

while pressing [RE-ZERO] key.

2. Press [TARE] key to be back to

weighing mode.

The number of boxes in the display indicates the battery power. When batteries are fully charged, 6 boxes appear.

As the battery is running out of power, the number of boxes will decrease gradually.

KEY OPERATION DISPLAY REMARKS

Ver0.01

KEY OPERATION DISPLAY INDICATOR

Show Software Version

Segment check starts.

Ready for weighing

0 NET

♦

e.g. 0.010 kg 0.010

0.000

T

♦

♦ ♦

KEY OPERATION DISPLAY INDICATOR

0 NET

♦

,

,

T

KEY OPERATION DISPLAY INDICATOR

t00.0”0”0

t00.0”2”0

-0.020

♦ ♦

0

♦

0

T

+ , ,

T

0.000 ♦

T

NET

12

Page 15

5.4 Setpoint Value Entry

PROCEDURE

Stand-by status 0.000

Enter the setpoint entry mode by

1.

pressing [] three times while

pressing [RE-ZERO] key.

Enter Setpoint 1 value by using []

2.

and [] keys.

3. Store the data.

4. Enter Setpoint 2 value by using [] and

[] keys.

5. Store the data.

6. Enter Setpoint 3 value by using [] and

[] keys.

7. Store the data.

Enter Setpoint 4 value by using []

8.

and [] keys.

9. Store the data.

Note: To exit from setpoint entry mode without storing the data, press [TARE] key instead of [RE-ZERO] key.

KEY OPERATION DISPLAY INDICATOR

0 NET g lb

♦

0

+ , ,

,

, ,

, , ,

0

0

0

0

00.000

01.000

00.000

02.000

00.000

03.000

00.000

04.000

0.000

♦

5.5. Changing Weight Units (kg , g , lb)

PROCEDURE

Stand-by status

1. Allow user to switch between

KG, g and lb. (Assuming scale is

calibrated in KG.)

2. To switch to g

Press [REZERO] key and hold followed

by [] then release [REZERO]

3. To switch to lb

Press [REZERO] key and hold followed

by [] then release [REZERO]

4. To switch to kg

Press [REZERO] key and hold followed

by [] then release [REZERO]

KEY OPERATION DISPLAY INDICATOR

0

0.000

5.000

ET g lb

♦

(Ex. 5kg)

0

+

5000

(Ex. 5000g)

0

+

11.023

(Ex. 11.023lb)

0

+

5.000

(Ex. 5kg)

♦

♦

13

Page 16

6.0. PROGRAM MODE

6.1. DI-28 Key Function Summary

KEY REZERO TARE

INTERNAL COUNT

REZERO (D D T)

OPERATIONAL SPECS

REZRO (D D D)

REZERO EXIT - - - - CHANGE

STORE &

EXIT INPUT 0 INPUT 1

INCREMENT

←←←← DIGIT ↑↑↑↑ INCREASE

MODE

SPEC

W & M SPECS

REZERO (D T D)

STORE &

INCREMENT

EXIT INPUT 0 INPUT 1

SPEC

SPAN ADJUSTMENT

REZERO (D T T)

SET POINT

PROGRAMMING

REZERO ( I I I )

SPAN SWITCH STATUS

STORE / RDY

FOR CAL

STORE &

INCREMENT

EXIT SELECT

DIGIT

EXIT SELECT

DIGIT

SET POINT

- - - - - - - - - - - - - - - -

INCREASE

NUMBER

INCREASE

NUMBER

REZERO (T D D)

BATTERY LIFE CHECK

- - - - EXIT - - - - - - - -

REZERO ( T D T)

D = ←←←←DIGIT I = ↑↑↑↑INCR

T = TARE

6.2. Internal Count

This function is provided to check the internal count value from the A/D (pre-amp)

To Enter Internal AD Count Mode

1. Press and hold down the [REZERO] key.

2. While holding , press the [←←←← DIGIT] key two times, the [TARE] key once.

3. Then release the [REZERO] key.

In This Mode, Each Key Functions As Follows

[↑↑↑↑ INCREASE] key

Used to switch between internal count and A/D

Raw Data

[REZERO] key

[TARE] key

14

Used to rezero the internal counts

Used to exit from internal count mode

Page 17

6.3. Set Up And Calibration

6.3.1. Specification Change

Function key for spec. change.

Accessing Operational Specs. (50 - 59)

1. Press and hold down the [REZERO] key.

2. While holding , press the [←←←← DIGIT] key three times .

3. Then release the [REZERO] key.

In This Mode, Each Key Functions As Follows

[←←←← DIGIT] key

[↑↑↑↑ INCREASE] key

[REZERO] key

Used to input 0

Used to input 1

Used to save the specification and increment to

the next specification

[TARE] key

Used to exit from specification mode

THE SLEEP TIMER IS LOCATED IN OPERATIONAL SPECS.

Spec.50 = sleep timer ( 0000 = none to 1111 = 15 min. )

6.3.2. Specification Change (Continued)

Function key for spec. change.

Accessing Weights & Measures Specs. (00 - 09 / 20 - 29)

1. Press and hold down the [REZERO] key.

2. While holding , press the [←←←← DIGIT] key, the [TARE] key, the[←←←← DIGIT] key.

3. Then release the [REZERO] key.

In This Mode, Each Key Functions As Follows

[←←←← DIGIT] key

[↑↑↑↑ INCREASE] key

[REZERO] key

Used to input 0

Used to input 1

Used to save the specification and increment to

the next specification

[TARE] key

Used to exit from specification mode

15

Page 18

6.4. Di - 28 Specification List

6.4.1. DI - 28

Spc. No. BIT 3 BIT 2 BIT 1 BIT 0

Spec. 00 Not Used

Spec. 01 Comma or Dec. Pt. Not Used Decimal Point Position

0 =comma, 1= dec.pt. 00 = no dec.pos.

Spec. 2 Not Used

Spec. 3 Change Weight Units

Spec. 04-09 Not Used

Spec. 20 Tare Accumulate

Spec. 21 One Touch Tare Clear

Spec. 22-23 Not Used

Spec. 24 load cell sensitivity (mv/V)

0000 = 4.00mV/V

Spec. 25 Not Used Not Used Ignore Span Switch

Spec. 26-27 Not Used

Spec. 28 Not Used Minus Weight

Spec. 29 Not Used

W & M Specs.

W & M SPECS. PRESS AND HOLD REZERO THEN PRESS (D - T - D)

0 = no, 1 = yes

0 = no, 1 = yes

0 = no, 1 = yes

0001 = 3.75mV/V

0010 = 3.50mV/V

0011 = 3.25mV/V

10 = two dec.pos.

Scale Type

0 = kg , 1 = lb

Not Used Digital Tare

Rezero In Tare

0 = no, 1 = yes

0100 = 3.00mV/V

0101 = 2.75mV/V

0110 = 2.50mV/V

0111 = 2.25mV/V

0 = 9 ext. increments,

1 = No Limit

01 = one dec.pos.

Internal Count When

Span SW off

0 = no, 1 = yes

0 = no, 1 = yes

Not Used Not Used

1000 = 2.00mV/V

1001 = 1.75mV/V

1010 = 1.50mV/V

1011 = 1.25mV/V

0 = no, 1 = yes

Zero Reset Range

0 =± 10% , 1 =± 100%

11 = three dec.pos.

Tare Limit

0= 50%, 1 = 100%

1100 = 1.00mV/V

1101 = 0.80mV/V

1110 = 0.70mV/V

1111 = 0.60mV/V

Re-Zero Range

0 = ± 2 % , 1 = ± 100%

Not Used

Recall Zero

0 = no, 1 = yes

16

Page 19

6.4. DI - 28 Specification List (Continued)

6.4.2. DI - 28

OPERATIONAL SPECS. PRESS AND HOLD REZERO THEN PRESS (D - D - D)

Spc. No. BIT 3 BIT 2 BIT 1 BIT 0

Operational Specs.

Spec. 50 Sleep Timer

0000 = None

0001 = 1 Min.

0010 = 2 Min.

0011 = 3 Min.

Spec. 51 Not Used Power Save

0100 = 4 Min.

0101 = 5 Min.

0110 = 6 Min.

0111 = 7 Min.

0 = no, 1 = yes

1000 = 8 Min.

1001 = 9 Min.

1010 = 10 Min.

1011 = 11 Min.

Motion Detection

0 = strong ,

1100 = 12 Min.

1101 = 13 Min.

1110 = 14 Min.

1111 = 15 Min.

Animal Mode

0 = no, 1 = yes

1 = weak

Spec. 52 Handshaking for

RS-232

0 = no, 1 = yes

Spec. 53 RS-232 Stable Flag

0 = without flag

1 = with stable flag

Spec. 54 RS - 232 Output

0 = Disable

1 = Enable

Spec. 55 Parity

0 0 = no parity

Spec. 56-58 Not Used

Spec. 59 Remote Trigger

0 = Disable

1 = Enable

Send STX Before

Text

0 = no, 1 = yes

RS-232 Data Format

0 = without header

1 = with header

0 0 0 = 1200 bps

0 1 1 = 9600 bps

0 1 = odd

1 0 = even

Communication

Mode

0 = stream

Set Point Output

0 = active low,

1= active high

Non-Stable Output

0 = no, 1 = yes

Baud Rate

0 0 1 = 2400 bps

1 0 0 = 19200 bps

Stop Bit

0 = 1 bit

1 = 2 bits

RS-232 Time Out

0 0 = 1 sec.

0 1 = 3 sec.

Set Point

0 = disable,

1 = enable

Send Header As

0 = no, 1 = yes

0 1 0 = 4800 bps

Data Length

0 = 7 bits

1 = 8 bits

1 0 = 5 sec.

1 1 = 10 sec.

1 = manual

6.5.1. Span Adjustment

This Mode Is Provided To Calibrate Scale

Accessing Calibration Mode

1. Press and hold down the [REZERO] key.

2. While holding , press the [←←←← DIGIT] key, the [TARE] key, the [TARE] key.

3. Then release the [REZERO] key.

In This Mode, Each Key Functions As Follows

[↑↑↑↑ INCREASE] key

[←←←← DIGIT] key

[REZERO] key

[TARE] key

Used to increase value of digit

Used to change digits as needed

Used to save changes and advance through calibration

Used to exit calibration mode without saving changes

Text

17

Page 20

6.5.2. Calibration Procedure

PROCEDURE KEY OPERATION DISPLAY Remarks

1. Enter calibration mode.

[REZERO] [←←←← DIGIT]

[TARE] [TARE]

2. Enter the minimum display.

3. Enter the capacity weight.

4. Enter weight to be used for

calibration. (If other than

[↑↑↑↑ INCR]

[REZERO]

[←←←←] [ ↑↑↑↑ ] [ ↑↑↑↑ ] [ ↑↑↑↑ ] [ ↑↑↑↑ ]

[ ↑↑↑↑ ] [ ↑↑↑↑ ]

[REZERO]

[←←←←] [ ↑↑↑↑ ] [ ↑↑↑↑ ] [ ↑↑↑↑ ] [ ↑↑↑↑ ]

[ ↑↑↑↑ ] [ ↑↑↑↑ ]

capacity.)

5. Set zero point.

6. Place weight on platter

[REZERO]

[REZERO]

[REZERO]

from step 4.

7. Exit internal count mode.

8. Rezero scale place weight

[TARE]

[REZERO]

on scale to test calibration.

888888

Press and hold [REZERO] key

while pressing [DIGIT], [TARE],

| 1

| 2

[ 00.000

∇

[ 06.000

∇

〈 06.000

∇

〈 02.000

∇

CAL 0

CAL SP

[TARE] then release [REZERO] key.

Press [↑↑↑↑ INCR] key. (Ex. 0.002)

Press [REZERO] to

advance through

calibration

Press

[DIGIT] once and [↑↑↑↑ INCR] key

six times. (Ex. 6KG)

Press [REZERO] to

advance through

calibration

Press

[DIGIT] once and [↑↑↑↑ INCR] key

six times. (Ex. 2KG)

Press [REZERO] to

calibration

advance through

xxxxxx When calibration is complete scale

shows internal count.

xx.xxx

[TARE] key to return to

Press

weighing mode.

6.6. Span Enable Switch Check

This Mode Is Provided To Check The Status of The Span Switch. The SPAN SWITCH is

on the main board near the pre-amp housing and is labeled JP 1. See Figure on Page 19.

Accessing Mode

1. Press and hold down the [REZERO] key.

2. While holding , press the[TARE] key, the[←←←← DIGIT] key, the [←←←← DIGIT] key.

3. Then release the [REZERO] key.

When Calibration is enabled Display Shows : S- ON

18

Page 21

7.0. OPTIONS

7.1. Battery Options

The DI-28 may be used with an A/C adapter or with batteries for portable operation.

The indicator requires 6 x 1.5V size C battery. Alkaline or rechargeable batteries may

be used. There is a built in charging circuit controlled by a jumper JP-2, which is located

on the main board near the power connector. The jumper must be set for the type of

battery being used and is normally set for alkaline. See figure below for switch position

FIGURE 1:

19

Page 22

Options (continued)

Interface

7.2. SETPOINT Interface

4 setpoint signal can be output though Setpoint connector

Method: 24V Open Drain CMOS

4 Setpoint Signal Output

7.3. Hardware Options

7.3.1.

1. Pole set for DI-10/28 series

Standard pole used with DIGI Platform

Scales. The height of stainless steel

pole is 33 in.

7.3.2. Mount Bracket Set for DI-28

The kit is for any one of the following

mounting options, desk-top, wall mount, DI- pole kit.

7.4. RS-232C Interface

RS-232C serial data output. (Mini DIN 8 PIN )

The data transaction method can be set for

continuous output, manual (by key entry), or

command(Inquiry from an external device).

Protocol

Baud Rate: 1200/ 2400/ 4800/ 9600/ 19200

Start Bit: 1 bit

Stop Bit: 1/ 2 bit

Data Bit: 7/ 8 bit

Parity Bit: Even/ Odd/ None

Text Command

CR (0DH) The end of data

LF (0AH) The end of text

0 - 9 (30H-39H) Numeric data

- (2DH) Minus

. (2EH) Decimal Point

STX (02H) Start of Text

SOH (01H) Weight stable flag

NUL (00H) Weight un-stable flag

20

Page 23

Options (continued)

7.2.1 Set Point Connection

7.2.1.1. Connector Configuration

Set point Pin

1 3

2 4

3 5

4 6

*Vcc 8

GND 1 & 2

* When Pin 8 of CN 2

on the main board is

shorted to Vcc.

8 Pin DIN Plug ( Front view )

An external voltage is needed to drive the devices like relays or LEDs. The external voltage can go up to a max.

30V DC depending on the device requirements, or a Vcc voltage, 5V DC, can be used on PIN 8 as an external

voltage.

7.2.2. Spec Setting

SPEC 52 Bit 0 Set point control

0 Disable 1 Enable

SPEC 52 Bit 1 Set point output

0 Active high 1 Active low

7.2.3. How Set Points Work

Set Point 1

_

External voltage

+

The state where no set point is reached.

Set Point 2

Set Point 3

Set Point 4

Set Point 1

Set Point 2

Set Point 3

Set Point 4

External voltage

_

+

External voltage

When set point 1 is reached, the relay at set

point 1 will be on (eg. 1 kg.)

When set point 2 is reached, the relays at set

Set Point 1

Set Point 2

21

Set Point 3

Set Point 4

_

+

point 1 and set point 2 will be on (eg. 1 kg

and 2 kg.)

Page 24

Options (continued)

7.4.1 RS232C Connection

7.4.1.1. Wire Configuration

9 PIN D-SUB (FEMALE) 8 PIN MINI DIN (MALE)

PC DI 28

Signal Pin Pin Signal

RXD 2 2 TXD

TXD 3 4 RXD

GND 5 8 GND

DTR 4

DSR 6

RTS 7

CTS 8

25 PIN D-SUB (FEMALE) 8 PIN MINI DIN (MALE)

PC DI 28

Signal Pin Pin Signal

RXD 3 2 TXD

TXD 2 4 RXD

GND 7 8 GND

RTS 4

CTS 5

DSR 6

DTR 20

7.4.2. RS232C Configuration

Baud rate : 1200 / 2400 / 4800 / 9600 /19200 bps

Data bit : 7 bits or 8 bits

Parity bit : None / Odd / Even

Stop bit : 1 bit or 2 bits

22

Page 25

Options (continued)

7.4.3. Spec Setting

SPEC 52 Bit 2 Send STX before text

0 No 1 Yes

SPEC 52 Bit 3 Handshaking for RS232 output

0 No 1 Yes

SPEC 53 Bit 0 Send Header as text

0 No 1 Yes

SPEC 53 Bit 1 RS232C data sending method

0 Send immediately 1 After data is stable

SPEC 53 Bit 2 RS232 data format

0 Without header 1 With header

SPEC 53 Bit 3 Stable flag in RS232C

0 Without stable flag 1 With stable flag

SPEC 54 Bit 0, 1 and 2 RS232C baud rate

0 0 0 1200 0 1 0 4800 1 0 0 19200

0 0 1 2400 0 1 1 9600

SPEC 54 Bit 3 RS232C output

0 Disable 1 Enable

SPEC 55 Bit 0 RS232C data length

0 7 bit 1 8 bit

SPEC 55 Bit 1 RS232C stop bit

0 1 bit 1 2 bits

SPEC 55 Bit 2 and 3 RS232C parity bit

0 0 No parity 0 1 Odd 1 0 Even

SPEC 59 Bit 0 and 1 RS232C time out error

0 0 1 sec 1 0 5 sec

0 1 3 sec 1 1 10 sec

SPEC 59 Bit 2 Stream / Manual method

0 Stream 1 Manual

SPEC 59 Bit 3 Remote trigger for RS232C

0 Disable 1 Enable

23

Page 26

Options (continued)

7.4.4. RS-232 Communication Protocols

7.4.4.1. Text Format

STX* Stable flag CR *Header Net weight CR *Header Tare weight CR LF

1 1 1 1 7 1 1 7 1 1

* Options set in Spec.

Stable Flag * Header

(Send as code or text depend on SPEC 53 bit 0)

Stable flag Data

Header As Code As Text

Stable SOH (01H) Net weight 0 (30H) NET WEIGHT :

Unstable NUL (00H) Tare 4 (34H) TARE WEIGHT :

Text

Text Data

0 ~ 9 30H ~ 39H

.

,

-

2EH

2CH

2DH

Example: Net Weight = - 1.20 lb. Tare Weight = 0.45lb.

(a) Header Send As Code

STX SOH CR 0 - 0 1 . 2 3 0 CR 4 0 0 0 . 4 5 0 CR LF

(a) Header Send As Text

STX SOH CR N

- 0 1 . 2 3 0 CR T

E

T

W

E

I

G

H

T

:

0 0 0 . 4 5 0 CR LF

A

R

E

W

E

I

G

H

T

:

NOTE:

✍ Net Weight and Tare Weight excluding a sign are transmitted shifting to the right.

✍ When it is minus data (0x2D) or plus data (0x30), net and tare weight data are transmitted

setting 2DH or 30H into the left most byte of each 7 byte data block.

✍ In case of over weight, the data will transmitted as follows:

0 OV 00000 CR 4??????? CR LF

✍ Decimal points are transmitted as[ , ] comma 0x2C or [ . ] Period 0x2E (See Spec 01 bit 3)

24

Page 27

Options (continued)

7.4.5. Communication Method

There are three methods of sending the data :

i) Stream

- Send the data immediately

ii) Manual

- Send the data when [↑] is pressed using handshaking or no handshaking protocol.

iii) Command

- Send data when ACK code is received from remote system using handshaking or no

handshaking protocol.

i) Stream method (SPEC 59 Bit 2 is 0)

This method will sending the data immediately.

PC DI - 28

TEXT

ii) Manual method (SPEC 59 Bit 2 is 1)

No handshaking (SEPC 52 bit 3 is 0)

Press [ ↑ ] key to send data.

PC DI - 28

TEXT

25

Page 28

Options (continued)

With handshaking (SPEC 52 bit 3 is 1)

Press [↑] key to send data

PC / DP - 122 DI - 28

ACK NO RESP.

ACK NO RESP.

Weight stable time out

DC3

DC3

Normal end

Response time out

Error

Error

Weight unstable after time out

iii) Command Method (SPEC 59 Bit 3 is 1)

No handshaking (SPEC 52 bit 3 is 0)

PC DI - 28

ACK

DC1

TEXT

EOT

CAN

When error

NAK

26

DC1

Page 29

Options (continued)

With handshaking (SPEC 52 bit 3 is 1)

PC / DP 122 DI - 28

ACK NO RESP.

ACK NO RESP.

DC3

DC3

Response time out

Weight stable time out

ENQ

Normal end

DC1

Error

TEXT

Error

EOT

CAN

When error

NAK

Weight unstable after time out

27

Page 30

8.0. MAINTENANCE, CALIBRATION, TEST PROCEDURE & SERVICE

This section contains information and instructions concerning maintenance of the DI-28

weighing indicator.

Preventive maintenance consists of periodically cleaning the external surfaces of the instrument

and should be performed as often as operating conditions warrant.

The calibration procedure is designed to be an aid in maintaining the scale accuracy within

specifications. The calibration procedure may also serve as a performance test procedure.

CAUTION: DO NOT ATTEMPT ANY SERVICE WHILE THE INSTRUMENT IS

CONNECTED TO THE POWER LINES.

8.1. Maintenance Procedures

8.1.1. Exterior Maintenance

The exterior surfaces of the weighing scale can be easily cleaned using soap and

water. However, extreme caution should be used so that there is no possibility of

water penetration into the scale electrical or mechanical sections. A damp cloth or

sponge is suggested. NEVER USE ACETONE, MEK, OR SIMILAR SOLVENTS

ON THE PLASTIC HOUSING AS THEY WILL ETCH THESE SURFACES.

For grease or other difficult spots, a chlorothane or naphtha based cleaner may be

used. Never use any solvents on the front or rear panels.

Accumulations of dust or direct particles between the pins of the connectors may be

removed by using dry forced air or a small dry brush.

8.1.2. Internal Maintenance

Internal maintenance is not normally required and if it is, should not be attempted

except by a qualified, authorized service technician.

8.1.3. Calibration

The following procedure should be followed periodically (every six to twelve months

is suggested) to determine that the scale is functioning in all modes.

a. Electrical

Follow section 4.0 through all its steps

28

Page 31

8.1.3 Continued

b. Accuracy

Weighing: The scale weighing accuracy can be determined by applying

various known weights to the platform. Because of the scale's very high

accuracy, only weights that are certifiably more accurate than the scale's

specifications should be used in testing for accuracy. (NBS class "F" or

higher)

Since the scale owner does not normally have such certifiable weights

available to him, it is suggested that the customer call their authorized

DIGI dealer.

8.2. Service & Repair

No service or repair should be attempted except by qualified personnel, and not until

it has been positively determined that the weighing scale requires such service. All

service should be done in a clean, dry, dust-proof area.

8.3. Load Cell Wiring

Connector : Amphenol 14 Pin 57 Series Cable Connector (male)

Part # 57-30140

Pin Assignments

14 PIN AMPHENOL FEMALE

PIN # FUNCTION

1 + Sense

2 - Sense

3 + Excitation

4 - Excitation

5 Shield

6 + Signal

7 - Signal

29

Page 32

DI-28 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed

by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects

in materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications

authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If

any equipment fails to conform to these warranties, RLWS will, at its option, repair or replace such goods

returned within the warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a detailed explanation

of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent electrostatic

discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, “Protecting Your Components

From Static Damage in Shipment,” available from RLWS Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair or improper testing; RLWS shall be the sole

judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping charges

both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT,

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER

IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS

WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any legal effect unless

made in writing and signed by a corporate officer of RLWS and the Buyer.

© 2002 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

• 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

1

Loading...

Loading...