Page 1

OPERATION MANUAL

Model: DI-162

Edition Month Year

1st November 2005

2nd March 2006

3rd May 2006

4th June 2006

5th Dec. 2007

SHANGHAI TERAOKA ELECTRONIC Co., Ltd. --- Technical Support Dept.

3rd Floor of 2nd Building, Jia Yuan Business Center,

51# Long Wu Road, Shanghai China 200232.

Tel: +86-21-64085151 Fax: +86-21-64083468 E-mail: steservice@digi-scale.com

Page 2

DI-600 Operation Manual

1

CONTENTS

1. General Specification

1.1. General Layout ------------------------------------------------------------------------------------------- 1

1.2. Features ----------------------------------------------------------------------------------------------------- 4

1.3. Operating Conditions ------------------------------------------------------------------------------------- 5

1.4. Charging Conditions ------------------------------------------- ------------------------------------------- 5

1.5. Analog Specification -------------------------------- ------------------------------------------------------ 5

1.6. Display and Indicators -------------------------------------------- -------------------------------------- 6

1.7. Dimensions ------------------------------------------------------------------------------------------------ 10

1.8. External Connectors ------------------------------------------------------------------------------------ 10

2. Main Operation

2.1. Zero Resetting ------------------------------------------------------------------------------------------- - 11

2.2. One-touch Tare Weight Reduction ---------------------------------------------------------------- 12

2.3. Digital Tare Weight Reduction ---------------------------------------------------------------------- 12

2.4. Change Weight Unit --------------------------------------------------------------------------------- 13

2.5. Span SW ON / OFF Check ---------------------------------------------------------------------------- 13

2.6. Internal Count Display --------------------------------------------------------------------------------- 14

2.7. Spec Data Setting For Weigh & Measure -------------------------------------------------------- 14

2.8. Setpoint Set -------------------------------------------------------------------------------------- 16

3. Initial Setup

3.1. Prepare ---------------------------------------------------------------------------------------------- ----- 17

3.2. Setup ---------------------------------------------------------------------------------------- -------------- 17

3.2.1. Weight Caliberation ----------------------------------------------------------------------------- 18

3.2.2. G Caliberation ------------------------------------------------------------------------------------ 20

4. Specification List ----------------------------------------------------------------------------------- 21

5. Error Message --------------------------------------------------------------------------------------- 25

Page 3

1

1. General Specification

1.1 General Layout

¾ DI-162

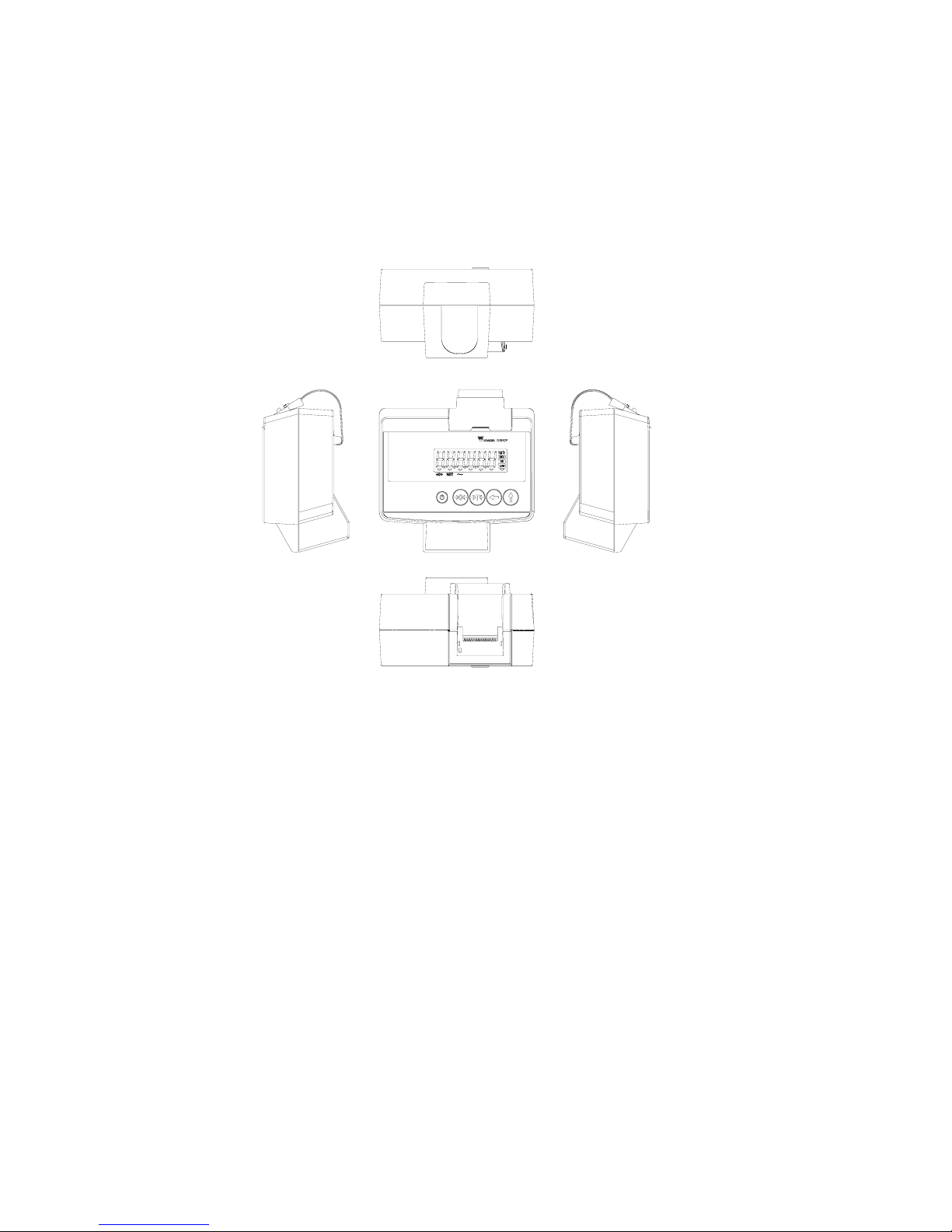

Page 4

2

DI-162SS

Page 5

3

DI-162C

Page 6

4

DS-162 HD

Page 7

5

DI-162 P

Page 8

6

1.2 Features

* Low cost digital indicator.

* Quick response to weight changes.

* Resolution : Display Resolution: variable

: Internal Resolution: 1/300,000.

*Low power consumption.

* Auto Power Off

* Calibration by software.

* 6 digits with 8 segments LCD Operator displays.

* 5 operational keys:

UP; LEFT; TARE; ZERO; ON/OFF;

* One scale channels for remote weighing platforms

connection.(14 pin Am phenol)

* Support 4x load cells 350 Ohm.

* RS-232C interface for data communication

*Two set point(Hi/OK/Low).

* External Remote Display.

* IP67 waterproof, moisture-proof, mist-proof and dustproof

(DI-162SS)

* Waterproof keyboard and splash proof housing

(DI-162SS)

Page 9

7

DI-162 P:

* Low cost digital indicator.

* Quick response to weight changes.

* Resolution : Display Resolution: variable

: Internal Resolution : 1/300,000.

* Calibration by software.

* 6 digits with 8 segments large size LCD Operator displays

with backlight. (figure size: 23×10.9 mm).

* Waterproof keyboard and splash proof housing.

* 5 operational keys:

UP; LEFT; TARE; ZERO; ON/OFF;

* Plastic housing or Stainless housing.

* One scale channels for remote weighing platforms

connection .(14 pin Am phenol)

* Support 4x load cells 350 Ohm.

*Two set point(Hi/OK/Low).

* External Remote Display.

Page 10

8

DS-162 HD

* Quick response to weight changes.

* Low power consumption: Rechargeable Battery backup for

30 hours (Backlight Off) 5 hours (Backlight On)of continuous

usage .

* Intelligent power control

A. When AC power is available, scale will use AC power only

whatever rechargeable battery is installed or not. When AC

power is shut off, scale will use battery automatically.

B. When scale works on rechargeable battery, if the battery is

weak, the battery indictor will light up. When the power

from battery becomes low such that the scale cannot

compute accurately, all Displays will shut off except the

Battery indicator. The power is then shut off completely after

1 minute.

C. Scale detects rechargeable battery voltage and control battery

charge process automatically. The battery charge indicator

lights up when rechargeable battery is being charged.

* Calibration by software.

* 6 digits with 8 segments large size LCD Operator displays

with backlight. (figure size: 19×9 mm).

* Waterproof keyboard and splash proof housing.

Page 11

9

* 5 operational keys:

UP; LEFT; TARE; ZERO; ON/OFF;

* RS-232C interface for data communication .

* Capacity: 60kg/(10~20)g, 150kg/(20~50)g

* Platter size: 429mmx429mm

* Waterproof rating: IPX5

*,Net weight: 6.4 kg

Page 12

10

1.3 Operating Conditions

* Power Source : AC 240/230/220V,

117/100V(+10%,-15%).

: Rechargeable battery (6V 1.2Ah).

* Operating Temperature : -10 /14 ~ +40 /+104 ℃℉ ℃ ℉

(OIML).

* Operating Humidity : 15 ~ 85% RH.

* Power Consumption : 18W when using AC power.

: 0.5W when using rechargeable battery.

1.4 Charging Conditions (for Rechargeable battery only)

* Power Source : AC 240/230/220V,

117/100V(+10%,-15%).

* Charge Current : 300 mA.

* Charge Time : 5 - 6 hours.

1.5 Analog Specification

* Input sensitivity : 0.4mV/V~ 4mV/V.

* Zero adjust range : 0 ± 5mV.

* Zero balance range : 0 ± 0.5mV.

* L/C applied voltage : DC 5V.

* Speed of A/D conversion : 20times/sec ~ 30 times/sec.

* Internal Resolution : 300,000.

Page 13

11

1.6 Display and Indicators

¾ DI-162

* Weight Display : 6 digits

Page 14

12

DI-162SS

* Weight Display : 6 digits

DI-162 SS Max kg gMin e=d=

g

Page 15

13

DI-162C

* Unit Price : 5 digits (Display when use

Checkout-Dialog 02/04/06 protocol)

*Total Price : 6 digits (Display when use

Checkout-Dialog 02/04/06 protocol)

* Tare : 4 digits (Display when use

Checkout-Dialog 02/04/06 protocol)

* Weight Display: 6 digits

Page 16

14

¾ Indicators

-------▼sign will light up when current zero

point is within 1/4d of true zero and true zero.

------- ▼sign will light up when tare weight is

set.

-------▼sign will light up when weight/scale is

in stable condition.

-------▼sign on when Battery is weak and

needs to charge (only for rechargeable battery type).

-------▼sign on when Battery is charging

(only for rechargeable battery type).

-------sign on when the display unit of weight

is kg.

-------sign on when the display unit of weight

is lb.

-------sign on when weight is high than

setpoint2.

-------sign on when weight is between

setpoint1 and setpoint2

------- sign on when weight is below setpoint1

Page 17

15

and high than 1d.

1.7 Dimensions

DI-162: 200mm/7.9in (W) × 164mm/6.5in (H)

×150mm/5.9in (D)

DI-162SS: 200mm/7.9in (W) × 164mm/6.5in (H)

×150mm/5.9in (D)

DI-162C: 130mm (W) × 110mm (H) ×35mm (D)

1.8 External Connectors

* AC plug.

* Load cell connect.

* RS-232C interface.

* Remote Display interface

Page 18

16

DS-162HD

* Weight Display : 6 digits

DS-162HD

Max 60/150 kg e=d= 20/50 gMin 400 g

Indicators

-------▼sign will light up when current zero point

is within 1/4d of true zero and true

zero.

------- ▼sign will light up when tare weight is set.

-------▼sign will light up when weight/scale is in

stable condition.

-------▼sign on when Battery is weak and needs to

charge (only for rechargeable

battery type).

-------▼sign on when Battery is charging (only for

rechargeable battery type).

Page 19

17

External Dimensions

External Connectors

* AC plug.

* RS-232C interface.

Page 20

18

DS-162 P

Display and Indicators

Display Specifications

* Weight Display : 6 digits

Indicators

-------▼sign will light up when current zero point

is within 1/4d of true zero and true zero.

------- ▼sign will light up when tare weight is set.

-------▼sign will light up when weight/scale is in

stable condition.

Page 21

19

-------sign on when the display unit of weight is kg.

-------sign on when the display unit of weight is lb.

-------sign on when weight is high than

setpoint2.

-------sign on when weight is between setpoint1

and setpoint2

------- sign on when weight is below setpoint1 and

high than 1d.

Dimensions

200mm/7.9in (W) × 16

External Connectors

* AC plug.

* Load cell connect.

* Remote Display interface

Page 22

11

2. Main Operation

[ON/OFF] ------To turn on or off the display.

[REZERO] ------To re-zero the scale.

[TARE] -------To set tare weight.

[Í] -------To set digital tare weight value, /To shift the digital

which to be edit.

[Ï] -------To change weight unit, /To change numeric data for

set-up mode.

2.1 Zero Resetting

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

Put tare (e.g. 3 g) on platter 0.0 0 3

Zero resetting. [REZERO] 888888

0.0 0 0

Remove the weight - 0.0 03

Zero resetting.

[REZERO] 888888

0.0 0 0

Note: 1) If the weight is within the available range of zero

resetting, the display will return to 0.

If it is out of the range, the weight will remain in the display, the

buzzer will beep alarm.

Page 23

12

2.2 One-touch Tare Weight Reduction

OPERATION Key-in WEIGHT

ZERO NET

STABLE

Weighing mode.

0.0 0 0

Put tare (e.g. 30 g) on platter 0.0 3 0

Subtract the tare weight. [TARE] 0.0 0 0

Remove the weight - 0.0 3 0

Clear the tare weight.

[TARE] 0.0 0 0

Note: 1) If the tare weight is within the available rang of

tare reduction, the display will return to 0 and NET lamp

will light up .

If it is out of the range, the weight will remain in the

display, the buzzer will beep alarm.

2.3 Digital Tare Weight Reduction

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

Press [Í] to shift a digit to where tare weight to be

set.

Digit to set the tare will blink

[Í] 0.0 0 0

Press [Ï] to input the weight.

Each time [Ï] is pressed, the figure will advance 1

only.

[Ï] 0.0 0 1

Repeat step # 1 and # 2 until desired tare weight is

set at each digit.

0.0 3 5

Set the tare weight. [TARE] -0.0 3 5

Clear the tare weight.

[TARE] 0.0 0 0

Note: 1) If the tare weight is within the available rang of

tare reduction, the display will return to 0 and NET lamp

will light up .

Page 24

13

If it is out of the range, the weight will remain in the

display, the buzzer will beep alarm.

2.4 Change Weight Unit

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

kg

Put tare (e.g. 400 g) on platter 0.4 0 0

kg

Press [Ï] to shift weight unit alternately

between kg and lb.

[Ï] 0.8 8 0

lb

Return to kg mode [Ï] 0.4 0 0

kg

Remove the weight

0.0 0 0

kg

2.5 SPAN SW ON/OFF Check

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [T][Í][Í] by holding [REZERO]

Displays software code for 2 seconds.

[REZERO]+

[T][Í][Í]

STE20

If the SPAN SW is at off status, it will display

“S-OFF”.

S-OFF

If the SPAN SW is at on status, it will display

“S-ON”.

S-ON

Returns to weight mode after 3 seconds. 0.0 0 0

kg

Page 25

14

2.6 Internal Count Display

OPERATION

Key-in

WEIGHT

ZERO NET STABLE

Weighing mode.

0.0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [Í][Í][T] by holding [REZERO]

To display A / D row data

[REZERO]+

[Í][Í][T]

1,2,0,2,3,4

Press[Ï] key. To display internal Count,

1.0.0.0.0.0

Press[Ï] key. To display A / D row data.

1,2,0,2,3,4

Press[ T ]key returns to weight mode. [ T ] 0.0 0 0

kg

2.7 SPEC Data Setting for Weigh & Measure

Turn on the SPAN SW. (JP1 on Main Board.)

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [Í] 3 times by holding [REZERO]

SP No. and SP data alternately display

[REZERO]+

[Í][Í][Í]

SP00/ 1 1 0 0

Press [Í] to shift a digit to where SPEC data

to be set.

Digit to set the SPEC will blink.

[Í] 1 1 0 0

Press [Ï] to select SPEC set.

Each time [Ï] is pressed, the figure will shift

between 1 and 0.

[Ï] 1 1 1 0

Press [REZERO] to save SPEC change. [REZERO] SP01/ 0 0 0 0

Press [TARE] to store the SPEC setting and

exit to weight mode

0.0 0 0

kg

Note:

1): Press [TARE] key to go back to weighing mode without save

change.

Page 26

15

2):As introduced at the previous section, there are 2 kinds of

key-operation when entering SPEC setting mode.

a . [REZERO] + [T] [T] [T] ------- for SPEC No.0-No.19

b . [REZERO] + [Í] [Í] [Í] -------for SPEC No.20-No.39

When SPEC setting operation , the following display will

appear.

Bit3 Bit2 Bit1 Bit0

1 1 0 0

SPEC data

*The SPEC No. such as “SP01” and SPEC data such as “1100”

alternately display at start.

*After any key is pressed , it stop alternately display.

*The blinking digit indicates the current programmable

position.

When setting or changing SPEC data, key switches function are

as follows.

[REZERO] -----------SPEC No. skips each time this key is

pressed.

[ T ] ------------ To renew the data and exit this mode.

[Í] ------------ To move digit position. The blinking position

Page 27

16

will move to next digit.

[Ï] ------------ To change SPEC data to either “0” or “1”.

2.8 Set point Set

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [Ï][Ï][Ï] by holding [REZERO] [REZERO]+

[Ï][Ï][Ï]

SPT1/ 0 0.0 0 0

0

Move the position to edit according to

capacity by[Í].

[Í][Í][Í] 0 0.0 0 0 0

Enter the setpoint1 weight at the blink digit

by press [Ï].

[Ï][Ï] 0 0.2 0 0 0

Press [REZERO] to next step.

[REZERO] SPT2/0 0 0. 0 0

0

Move the position to edit according to

capacity by[Í].

[Í][Í][Í][Í]0 0.0 0 0 0

Enter the capacity weight at the blink digit

by press [Ï].

[Ï] 0 1.0 0 0 0

Press [REZERO] to save setting and return

to weight.

[REZERO] 0.0 0 0 0

kg

Put weight (e.g. 0.1kg) on platter. 0.1 0 0 0

kg LOW

Add weight (e.g. 0.2kg) on platter. 0.3 0 0 0

kg OK

Add weight (e.g. 0.8kg) on platter. 1.1 0 0 0

kg HIGH

Remove the weight on platter. 0.0 0 0 0

kg

Note: This function depends on SPEC3 bit0.

Page 28

17

3. Initial Setup

3.1 Prepare

¾ Connect DI-162 with the weighing platform

¾ Plug in the power supply

3.2 Setup

¾ Set the relative specification

¾ Calibration

z Turn on the SPAN SW first (JP1 on Main Board.)

SPAN SWITCH

Page 29

18

3.2.1. Weight Calibration (SPAN Adjustment)

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

0.0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [Í] [T] [T] by holding [REZERO] [REZERO]+

[Í][T][T]

CAL

“G0” and “0.0000” alternately display G0 / 9.7 9 4 6

Move the position to edit G by press [Í].

[Í][Í][Í][Í] 0. 0 0 0 0

Select the G value at the blink digit by press

[Ï].

[Ï][Ï][Ï][Ï][Ï][Ï]

[Ï][Ï][Ï]

9. 0 0 0 0

Press [REZERO] to save setting and exit to

next step.

“DP” and “00000.0” alternately display

DP / 0 0 0 0 0.0

Change the position of Decimal Point by press

[Í].

[Í][Í] 0 0 0.0 0 0

OPERATION Key-in WEIGHT ZERO NET STABLE

Press [REZERO] to save setting and exit to

next step.

[REZERO] CAP1 /0 0 0. 0 0 0

Move the position to edit capacity by press

[Í].

[Í][Í][Í][Í] 0 0 0. 0 0 0

Select the capacity weight at the blink digit by

press [Ï].

[Ï][Ï] 0 2 0. 0 0 0

Press [REZERO] to save setting and exit to

next step.

[REZERO] d1 / 1

Press [Ï]to select set minimum display figure.

[Ï][Ï] 5

Press [REZERO] to save setting and exit to

next step.

[REZERO] CAP2 /0 0 0. 0 0 0

Move the position to edit according to capacity

by[Í].

[Í][Í][Í][Í] 0 0 0. 0 0 0

Enter the capacity weight at the blink digit by

press [Ï].

[Ï] 0 1 0. 0 0 0

Press [REZERO] to save setting and exit to

next step.

[REZERO] d2 / 1

Press [Ï] to select set minimum display figure. 2

Press [REZERO] to save setting and exit to

next step.

Select weight unit by press [Ï].

[REZERO] UNIT / kg kg

Press [REZERO] to save setting and exit to

next step.

[REZERO] CAL00 kg

Page 30

19

Press [REZERO] to insure the zero point. [REZERO] - - - - - - kg

CALSP /2 0.0 0 0 kg

Put weight (e.g. 10kg) on platter.

Enter the weight which is used to calibrate by

taking the same steps as above.

1 0.0 0 0 kg

Press [REZERO] to take SPAN calibration. [REZERO] - - - - - - kg

Return to weight mode. 1 0.0 0 0

kg

Note:

1): G value entry may be skipped if G calibration inhibit (depends on

SPEC23 bit1).

9.976 is the default G value of Shanghai.

2): If calibrate with FS weight, skip enter weight by press [REZERO], the

default calibration weight is FS.

3): You had better use more than 1/3 capacity weight to calibrate the full

SPAN. If using less 30 % of capacity weight, weight error may be created

incidentally.

4): Check to see if the displayed weight is correct when placing 1 / 3, 2 / 3,

and full capacity weight.

Page 31

20

z 3.2.2. G Calibration (Gravity Adjustment)

Turn on the SPAN SW. (JP1 on Main Board.)

OPERATION Key-in WEIGHT ZERO NET STABLE

Weighing mode.

9.0 0 0

kg

Press [REZERO]

[REZERO] 8 8 8 8 8 8

Press [Í][T][Ï] by holding [REZERO] [REZERO]+ [Í][T][Ï] G1/ 0.0 0 0 0

“G1” and “0.0000” alternately display G1/ 0.0 0 0 0

Move the position to edit G by press

[Í].

[Í][Í][Í][Í] 0. 0 0 0 0

Select the G value at the blink digit by

press [Ï].

[Ï][Ï][Ï][Ï][Ï][Ï][Ï][Ï] 8. 0 0 0 0

Press [REZERO] to calibration and exit

to weight mode.

8.0 0 0

kg

Note: This function depends on SPEC23 bit1.

Page 32

Specification List DI-162 V1.09 07-2-1

Operational Specification List

For The Customer - (1 4 1)

SPEC NO. BIT 3 BIT 2 BIT 1 BIT 0

0

Auto Power-off function

(for no key operation & weigh operation)

0000 - Auto power-off disable when scale is not in use

0001 - 3 minute

0010 - 10 minutes

0011 - 30 minutes

0100 - 1 hour

0101 - 3 hours

0110 ~ 1111 - Not used

1

Buzzer

0 - On

1 - Off

Error alarm

0 - On

1 - Off

Set point alarm

0 - On

1 - Off

2

Control of LCD Backlight

00 - Always ON

01 – Always OFF

10 - Auto

11 - Not used

Stable and weight

change > =[10e, RS232C Standard stream

type only output one

data

0 – Yes (V1.13)

1 - No

Set point type

0 - % Weight

1 – Weight

3

RTS/CTS handshaking

of RS-232C

0 - On

1 - Off

Baud rate of RS-232C

000 - 1200 bps 100 - 19200 bps

001 - 2400 bps 101 - Not used

010 - 4800 bps 110 - Not used

011 - 9600 bps 111 - Not used

4

Stop bit of RS-232C

0 - 1 bit

1 - 2 bit

Data length of RS232C

0 - 7 bit

1 - 8 bit

Parity of RS-232C

00 - None

01 - Odd

10 - Even

11 - Not used

5

RS-232C PC protocol

0000 - Inhibit data transfer 0110 - type S

(ICL CS500)

0001 - Standard stream type (Continuous output) 0111~1011not used

0010 - Standard manual type 1100 – Printer GP460Pro (V1.12)

0011 - Standard command type 1101 – Printer LP2844 (V1.12)

0100 - type M

(Checkout-Dialog 02/04)

1110 - Printer GP460R or LableDoctor

0101 - type P(Checkout-Dialog 06) 1111 - Printer EPSON TM-U220

6

Interval of time out error of RS-232C

00 - 1 second

01 - 3 second

10 - 5 second

11 - 10 second

Transmission

condition of RS-232C

0 - Weight stable

1 – Unconditional

Additional parity code

in text of RS-232C

0 - No

1 – Yes

7

Tare weight in text of

RS-232C

0 - No

1 – Yes

Scale No. in text of

RS-232C

0 - No

1 – Yes

Header Code in text of

RS-232C

0 - No

1 – Yes

Weight range of data

output

0 – Always

1 – Over 20e

8

Key operation for tare

in POS-weight-mode.

(for checkout

Dialog02/04 and Dialog

06 only.)

0 - Allow

1 - Inhibit

Calculate and check

CS, KW validly.

(for checkout Dialog 06

only.)

0 - No

1 – Yes

STATUS data in text

of RS-232C

0 - No

1 – Yes

RS-232C Manual t

y

pe

output when weight is

0.

(V1.13)

0 - No

1 - Yes

Page 33

2

9

PC send “w” in

Standard command

mode

0 - Allow

1 - Inhibit(V1.09)

PC send “t” in

Standard command

mode

0 - Allow

1 - Inhibit(V1.09)

RS232C High speed

output when baud

rates >=9600

(V1.13)

0 – high speed

1 – low speed

Wei

g

ht unit after net

wei

g

ht and tare weight

in the text of RS-232C

0 - Allow

1 - Inhibit(V1.11)

10

Scale No.

Low 4 digit

(0000~1111)

(

V1.03)

11

Scale No.

High 4 digit

(0000~1111)

(

V1.03)

12

Output RS232 data

condition

(V1.13)

0 – Set Point ok

1 - Always

External printer print format for LP2844 or GP460Pro

000 - Default Format

001 - Customer Format 1 101 - Customer Format 5

010 - Customer Format 2 110 - Customer Format 6

011 - Customer Format 3 111 - Customer Format 7

100 - Customer Format 4 (V1.12)

13

Set Point buzzer type

(V1.13)

0 – beep between SP

1 – beep outside SP

Total weight printing

when weight is zero

(V1.13)

0 - Inhibit

1 - Allow

Sending default format

to the LP2844 or

GP460Pro (V1.13)

0 - Inhibit

1 - Allow

Output data when

SPEC 2 bit 1 is enable

or using printer

(V1.13)

0 - Net weight > 0

1 - Always

For Weight & Measure - (1 4 2)

NOTE: It can only work when the SPAN Switch is on (Enable)

SPEC NO. BIT 3 BIT 2 BIT 1 BIT 0

20

Version display when

power on

0 - Allow

1 – Inhibit

Type of Decimal

point

0 - .(Standard)

1 - ,(Europe)

Start range

00 - ±10% F.S.

01 - ±20% F.S.

10 - ±50% F.S.

11 - ±100% F.S.(V1.02)

21

Negative weight display

mask

0 - Minus gross > 9e

1 - Minus gross

Weight

Re-call Last zero data

0 - Allow

1 – Inhibit

GAIN

00 – 16 /* 3mV/V */

01 – 32 /* 2mV/V */

10 – 64 /* 1mV/V */

11 – 128 /* 0.4mV/V */

22

Weight stability condition

00 - Loose

01 - Normal

10 - Tight

11 – Stringent

G Calibration

0 - Allow

1 – Inhibit

IR mode protected by

SPAN SW

0 - NO

1 – YES

23

Manual tare

cancellation

0 - Allow

1 – Inhibit

Tare subtraction

0 - Allow

1 – Inhibit

Tare accumulation

0 - Allow

1 – Inhibit

Auto tare clear when

rezero

0 - Allow

1 – Inhibit

Page 34

3

24

Digital tare

0 - Allow

1 – Inhibit

Priority of Tare

Operation

0 – One Touch Tare

Priority

1 –Digit Tare Priority

Zero tracking when

tare

0 - Allow

1 – Inhibit

Weight reset when tare

0 - Allow

1 – Inhibit

25

Tare auto clear

0 - Allow

1 – Inhibit

Auto clear condition

0 - >= Gross 21e

& >= Net 5e

1 - >=Net 1e &

Price not 0

(Remote display

version set to 1 only)

Unit price auto clear

0 - Allow

1 – Inhibit

Animal Mode

0 - Allow

1 – Inhibit

26

Decimal point position on unit price and total

price display

00 - No decimal point for Unit & Total Price

01 - 2nd digit (0000.0) for Unit,

2nd digit (00000.0) for Total Price

10 - 3rd digit (000.00) for Unit,

3rd digit (0000.00) for Total Price

11 - 4th digit (00.000) for Unit,

4th digit (000.000) for Total Price

Rounding for total price

00 - Rounding

01 - Truncation

10 - Cut up

11 - Not used

27

Weight change or

remove check of data

output

0 - Change

1 - Remove

Additional rounding for total price

000 - No additional rounding

001 - 1/4 rounding (25 step)

010 - Special rounding (5 step)

011 - 5 floor rounding (0-4 -> 0, 5-9 -> 5)

100 - Rounding for 1

st

digit

101 - Truncate 1

st

digit

110 - Cut up 1

st

digit

111 - Not used

28

UP key function

0 – Weight unit convert

1 – Data send

(

V1.04

)

Re-zero function

0 - Allow

1 – Inhibit

(

V1.02

)

Re-Zero range

00 - ±2% F.S.

01 - ±4% F.S.

10 - ±10% F.S.

11 - ±100% F.S.

(V1.02)

29

Motion Detection

000 Set inhibit

001 Weak

010 Little bit weak

011 Standard

100 Little bit strong

101 Strong

110

111 (SP_29_321)(V1.05

)

Internal Count Display

0 - 15000

1 - 30000

(SP_29_0)

(V1.04)

30

Auto Hold

0 – Off

1 – On

(

V1.08)

Remote display indicate

type

0 - Icon

1 – Triangle

(V1.08)

Page 35

25

5. Error Message

¾ Error Message Display

Please following the solution when you see the error message

ERROR Probable Cause Solution

8 8 8 8 8 8 (Lock-up) Zero-point is out of range. Need to re-calibrate the scale.

O F

When displayed weight exceeded

capacity +9d, or something is on the

platter when power on.

Remove the item on the

platter.

U F When displayed minus weight >= 9d. REZERO or ON/OFF again.

Loading...

Loading...