Page 1

CCCChhhheeeecccckkkk WW

WWeeeeiiiigggghhhhiiiinnnngggg SSSSccccaaaalllleeee

DI-10

When Accuracy Counts

OO

OO

pp

pp

ee

ee

rr

rr

aa

aa

ttiiii

tt

oo

oo

nn

nn

MM

MM

aa

aa

nn

nn

uu

uu

aallll

aa

73354

Page 2

DI-10 OPERATION MANUAL

SECTION CONTENTS PAGE NUMBER

1.0. GENERAL 2-5

1.1. DESCRIPTION 2

1.2. APPEARANCE 3

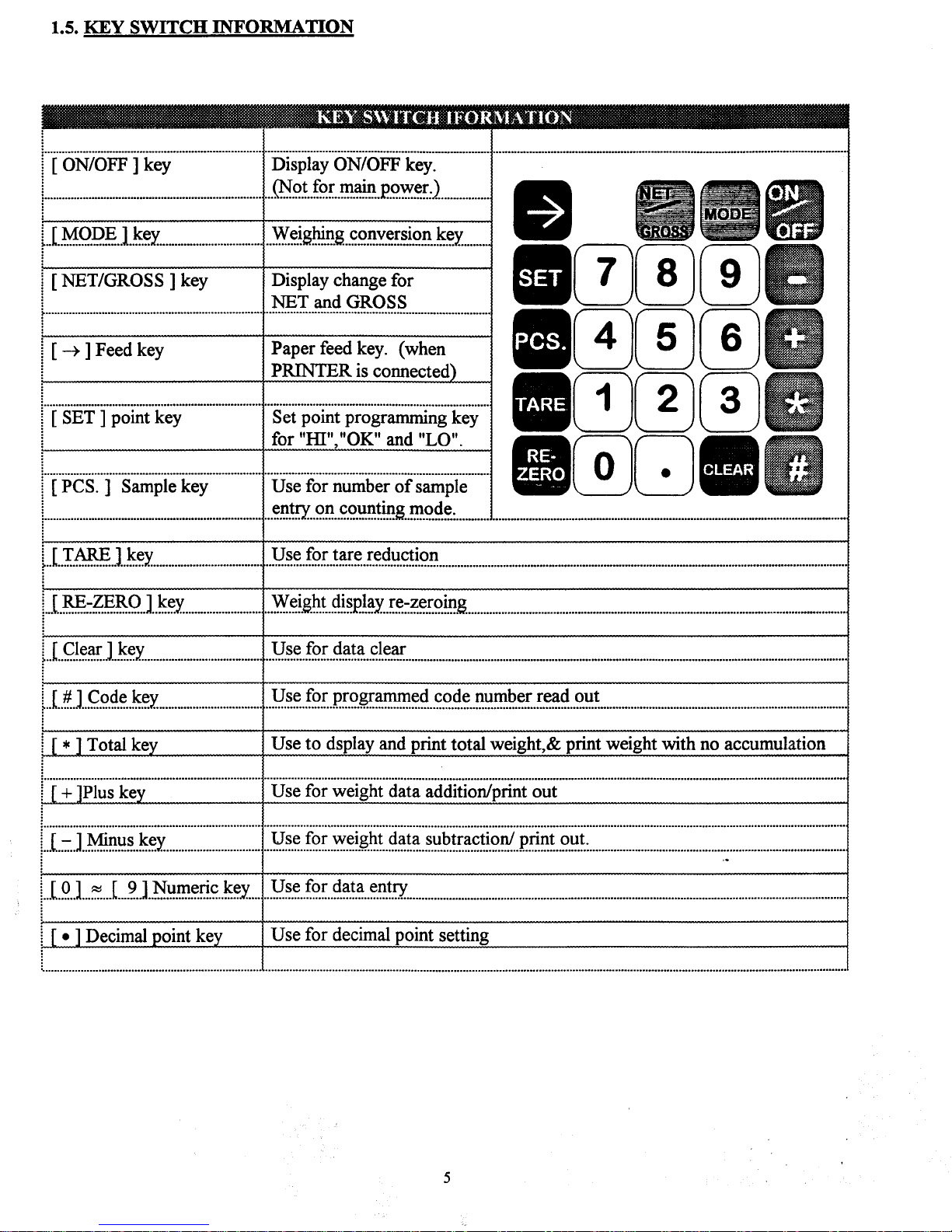

1.3. DISPLAY & KEYS 4

1.4. INDICATOR LAMPS 5

2.0. INSTALLATION 6-9

2.1. UNPACKING 6

2.2. INSPECTING 6

2.3. REPACKAGING 6

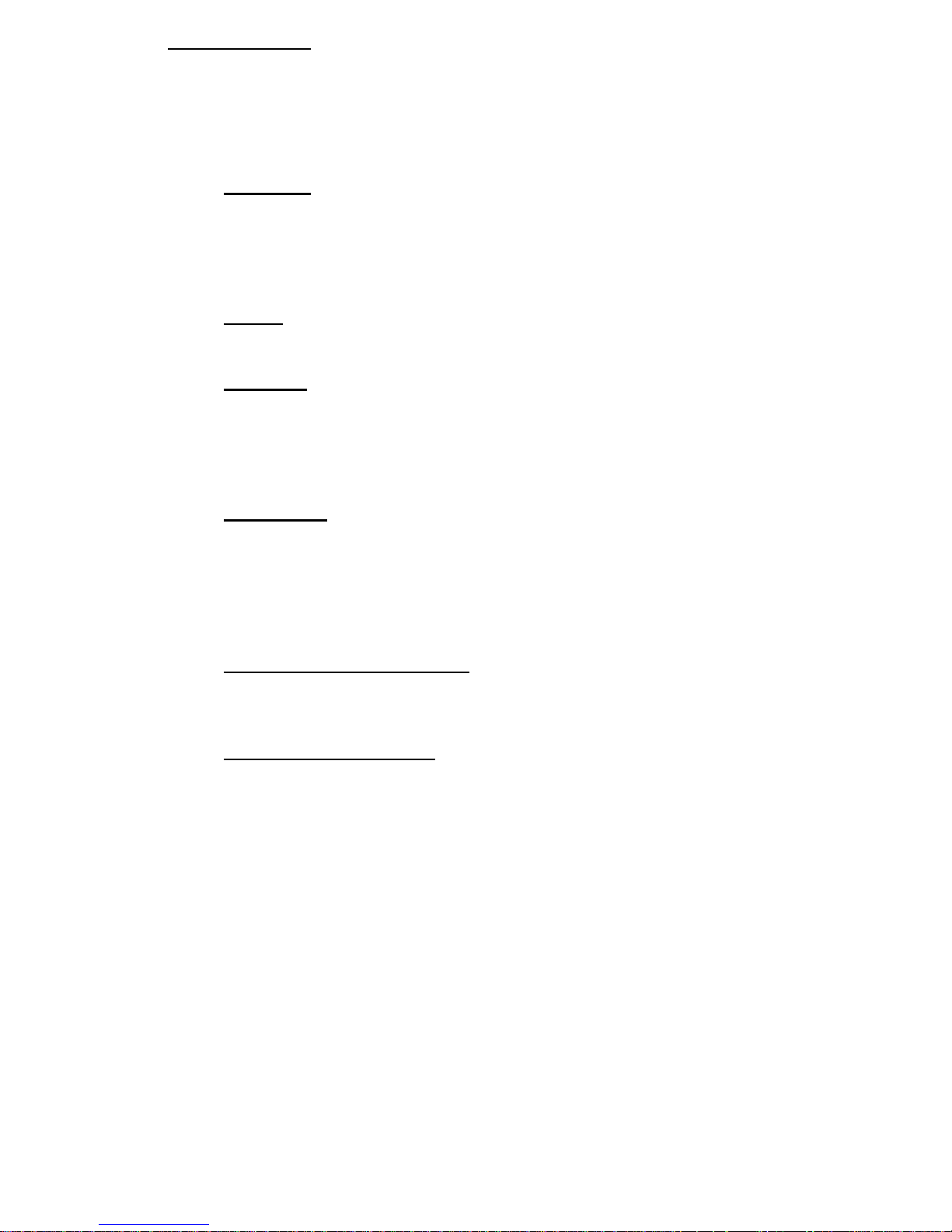

2.4. UNLOCKING (DIGI GRAND) 6-8

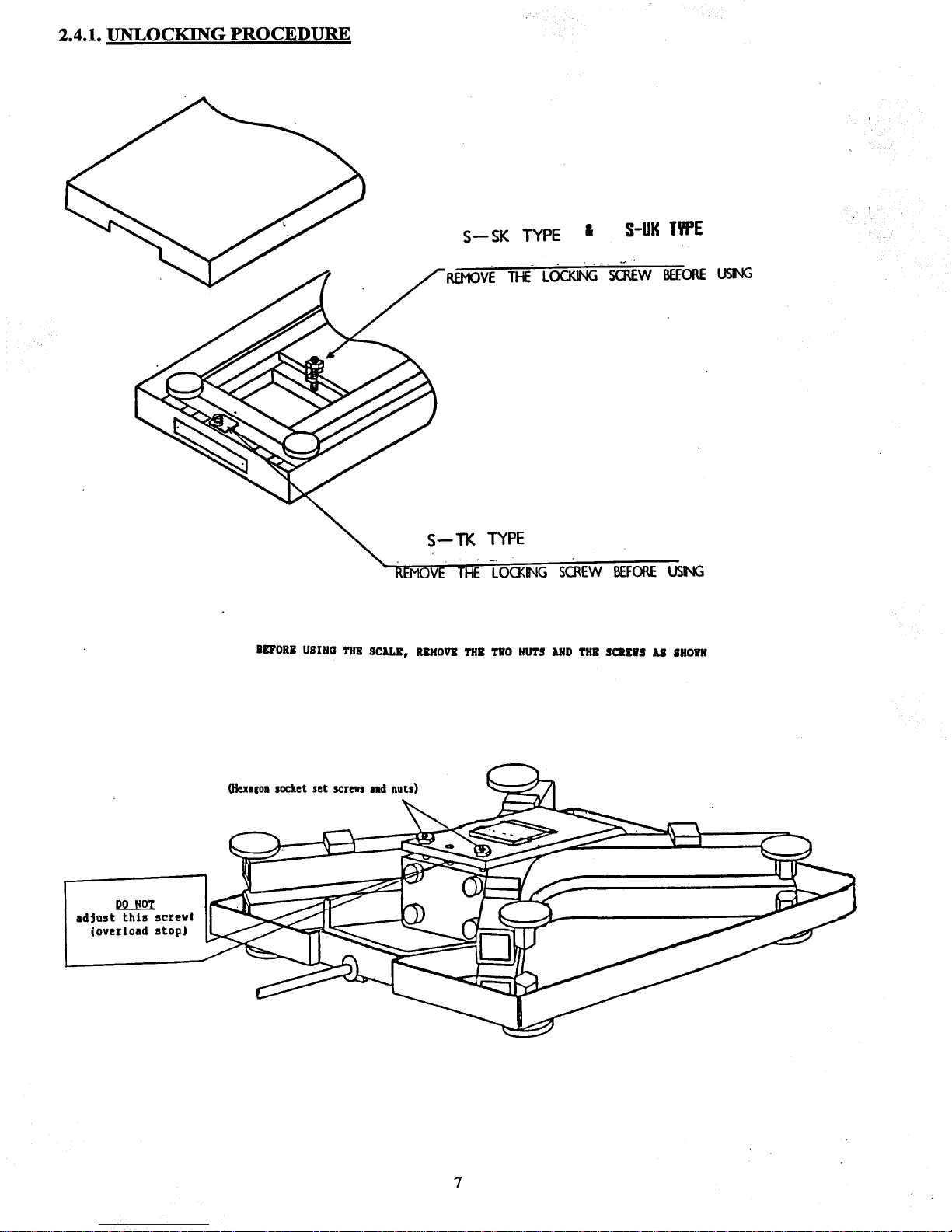

2.5. DI-10 POLE ASSEMBLY 9

3.0. SPECIFICATIONS 10-15

3.1. CAPACITIES 10

3.2. TECHNICAL 11

3.3. SET-UP PROCEDURE 12-13

3.4. FEATURES 14-15

4.0. OPERATION INSTRUCTION. 16-24

4.1. POWER ON 16

4.2. ONE TOUCH TARE 17

4.3. DIGITAL TARE 18

4.4. DIGITAL TARE WHILE WEIGHING 19

4.5. SET POINTS 20-21

4.6. ADDITION AND SUBTRACTION 22

4.7. COUNTING. 23

4.8. NET/GROSS DISPLAY 23

4.9. DATE & TIME SETTING 24

4.10. LB/KG CONVERSION 24

5.0. DI-10 OPTIONAL EQUIPMENT 25-30

5.1. PRINTER 25

5.2. SETPOINT OUTPUT. 26-27

5.3. RS-232C DATA OUT 28-30

5.4. AC/DC ADAPTOR. 30

6.0. MAINTENANCE, CALIBRATION, TEST PROCEDURE & SERVICE 31-39

6.1. MAINTENANCE PROCEDURES 31-32

6.2. SERVICE & REPAIR 32

6.3. PLATFORM WIRING 32

6.4. ERROR MESSAGE LIST 33

6.5. SPEC. LIST 34-36

6.6. CALIBRATION 37-38

NOTES: 39

1

Page 3

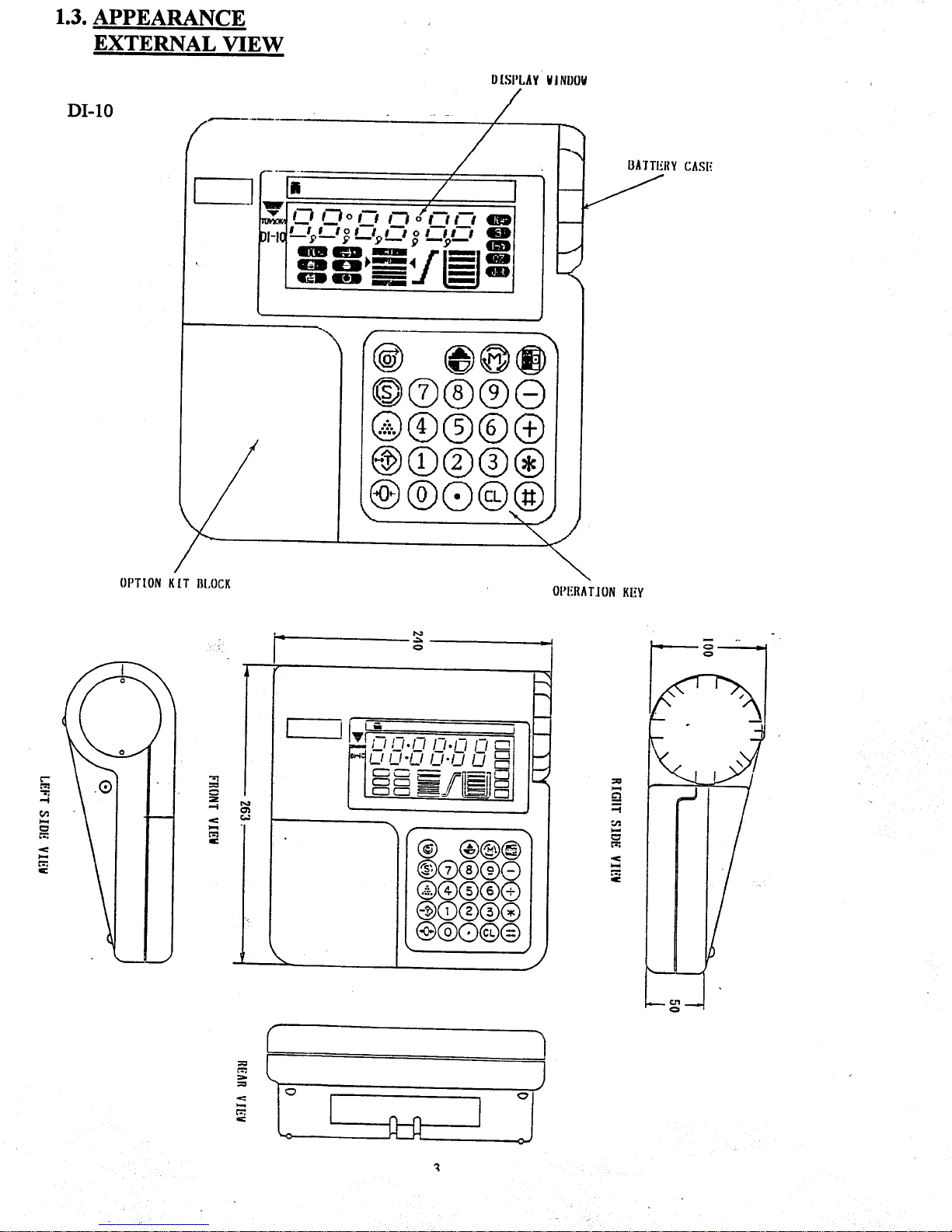

DI-10 OPERATING MANUAL

1.0. GENERAL

1.1. DESCRIPTION

The DI-10 Indicator offers a practical solution to a wide range of weighing applications.

There are a variety of weight capacities and increments available. The display resolution

is selectable from 1/3000 to 1/10000. It features keyboard calibration with auto-span.

Operates on 6 “C” cell batteries or with its AC/DC adapter. The DI-10 is able to support

single load cells that have an output range of 0.4mV/V to 4.0mV/V. The DI-10 is able to

support up to 4 load cells when used with the AC/DC adapter. This indicator features

LCD graphic display, 5 weighing modes, optional devices such as RS-232, Set Point

Output, and a built in Printer. For a list of platforms sizes and available above mentioned

capacities see page 2.

This instruction manual will provide the user with all the information necessary to

understand, set-up and operate the DI-10 scale. Included in this manual are descriptions,

specifications, drawings, and operating instructions.

2

Page 4

Page 5

Page 6

Page 7

2.0. INSTALLATION

This section provides the information required for installation of the DI-10 weight indicator.

The following steps accomplish installation.

1. Unpacking

2. Set-up Procedure

2.1. Unpacking

Each component of the DI-10 is packed in a specially designed carton. Remove each

component from its carton, separate the component from its polystyrene shell assembly

and set aside. Inspect the carton interior to be sure that all accessories have been

removed from the carton. Inspect the carton inner panels for accessories.

NOTE:

Be sure to repack all materials within the carton set. Store the cartons in a

secure area so they can be available whenever shipment of the scale is required.

2.2. Inspection

Immediately after unpacking, a visual inspection of the instrument should be performed.

If any damage has been incurred during transportation the shipper and DIGI MATEX

INC. should be notified immediately. Instructions for assessment of damage and further

procedures will then be determined.

2.3. Repackaging

If, at anytime, the DI-10 weight indicator must be returned for modification, calibration,

or repair, be sure that it is properly packed with sufficient cushioning materials.

Whenever possible, the original carton assembly should be retained for this purpose.

Any damage caused by improper packaging will not be covered by warranty.

2.4. Platform Unlocking Procedure

The unlocking procedure is different for each style of platform and are included on

the following pages.

2.5. Digi Grand Pole Assembly

The optional pole mounting kit comes with all the necessary hardware and assembly

is easy. See page 9 for details.

6

Page 8

Page 9

Page 10

Page 11

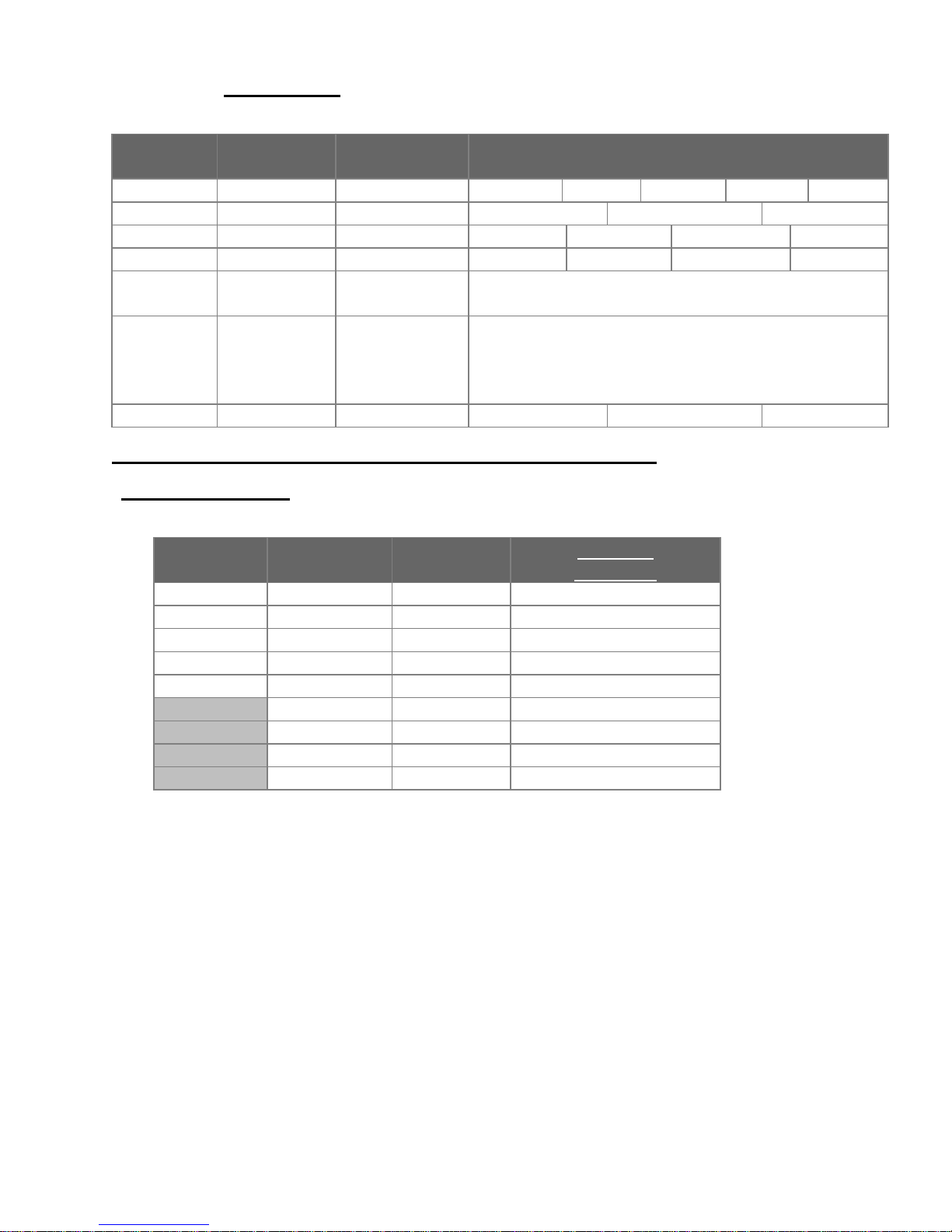

3.0. SPECIFICATION

3.1. PLATFORMS

The following is a list of platforms :

Model Platform

Size/Platter

Capacities

S-AL bench 12” x 14” x3” 1 LB. 5 LB. 10 LB. 25 LB. 50 LB.

S-SL bench / floor 13” x 17” 60 LB. 150 LB. 300 LB.

S-TL floor 17” x 21” 150 LB. 300 LB. 500 LB. 1000 LB.

S-UL floor 24” x 28” 150 LB. 300 LB. 500 LB. 1000 LB.

S-PL floor 30” x 30”

1000 lb. to 3000 lb.

36” x 36”

S-PL floor 48” x 48”

48” x 72”

60” x 60”

2500 lb.

to

25000 lb.

60” x 84”

Ramps , Other Capacities And Stainless Steel Platforms Also Available

Choosing A Capacity : Multiply the Decimal Location by the Minimum Weight by the Display

Resolution (=) Capacity

Decimal

Location

Minimum

Weight

Display

Resolution

Available

Capacities

0.0000 1 1 / 2000 1lb,2.5lb,3lb.,5lb.,6lb,.

0.000 2 1 / 2500 10lb.,25lb.,30lb.,50lb.,

0.00 5 1 / 3000 60lb.,75lb.,100lb.,125lb

0.0 10 1 / 5000 150lb.,200lb.,250lb.,

0 20 1 / 6000 300lb.,375lb.,500lb.,

50 1 / 7500 600lb.,750lb.,1000lb.,

100 1/10000 1500lb.,2000lb.,2500lb.

200 1/12500 3000lb.,3750lb.,5000lb.

500 1/15000 6000lb.,7500lb.,10000lb

Example: dec. loc. ‘TIMES’ min. wt. ‘TIMES’ disp. res. = avail cap.

0.00 ‘TIMES’ 5 ‘TIMES’ 1 / 7500 = 375. 00 lb.

* Units can be programmed to primarily weigh in lb., oz., kg., g., or dwt.

10

Page 12

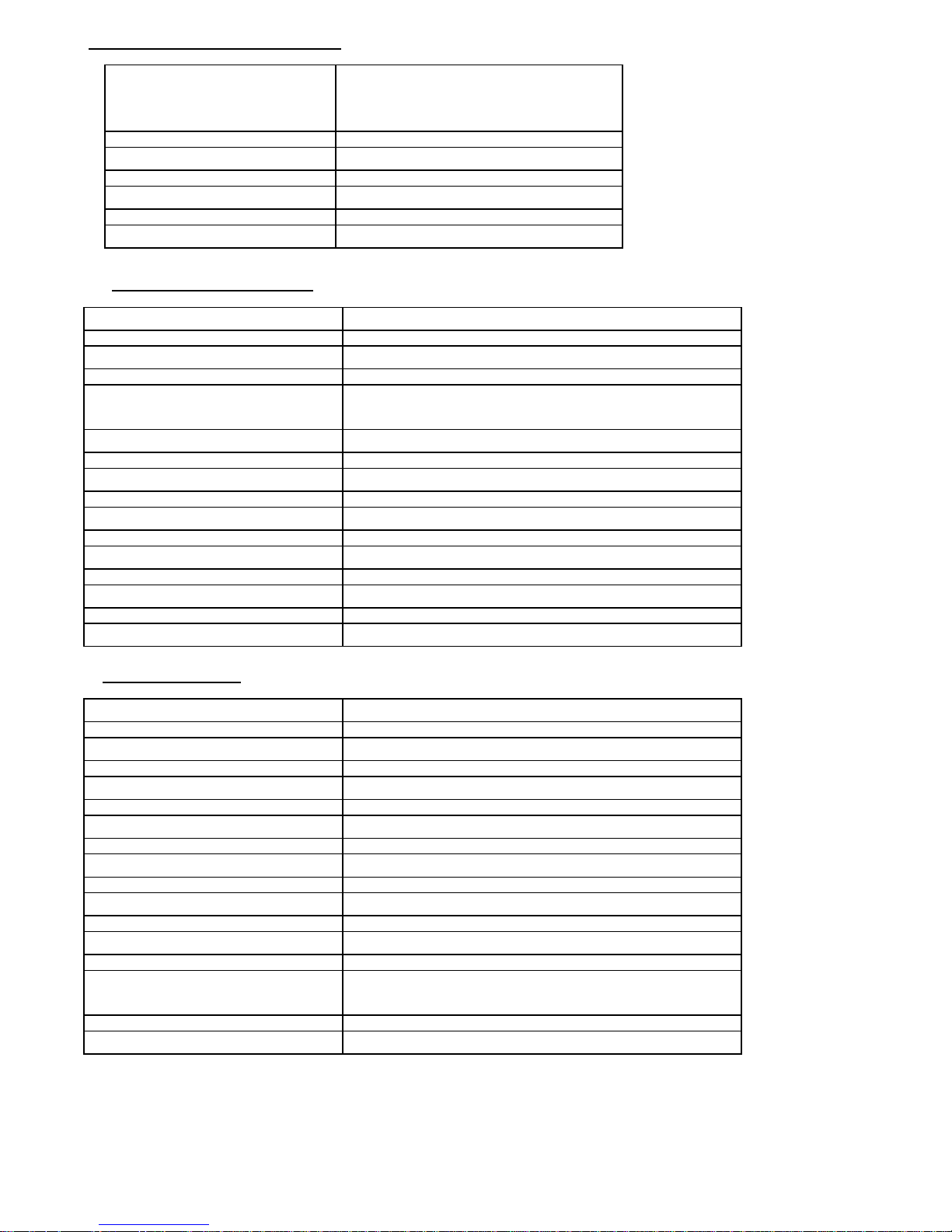

3.2. TECHNICAL (MODEL SPEC)

* Power source * D.C 12V 0.5A (AC/DC adaptor)

* D.C 1.5V x 6 pcs. (“C” cell)

(“C” cell can't operate printer)

* Operating temperature * -10 ... +40EC

* Operating humidity * 15 ... 85% RH.(Non-condensing)

* Power consumption * 1 w/h.

ANALOG SPEC. (DI-10)

* Input sensitivity * 0.25 :V/div. to 20 :V/div.

* Zero adj. range * 1 mV

* Temp. characteristic * ZERO"(0.2:V " 6ppm of ZERO)/EC

SPAN ..." 6 ppm/EC

* Speed of A/D conversion: * 10 times/sec.

* Non linearity * 0.016 % of F.S or less

* L/C to be used * 0.4 mV/V to 4 mV/V

* L/C excitation voltage * DC 5V.

* Number of the scale * 1 (one) scale

* Display resolution * up to 1/10000

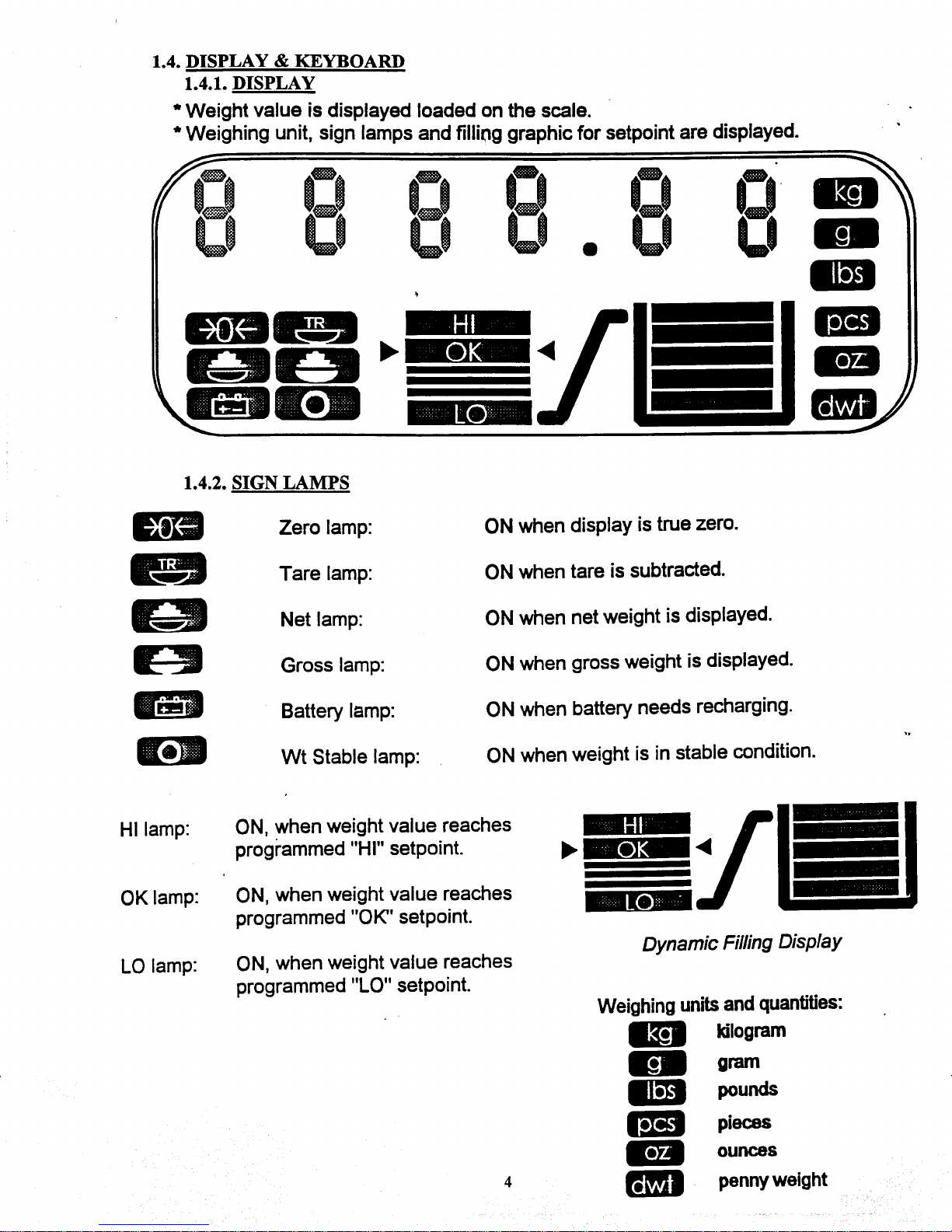

DISPLAY SPEC.

* Display * 6 digits.

* Tare * 6 digits

* Setpoint 1 (LO) * 6 digits.

* Setpoint 2 (OK) * 6 digits.

* Setpoint 3 (HI) * 6 digits

* Weighing unit * 5 kinds "g","kg","lbs","oz","dwt".

* Counting unit * 1 kind "pcs"

* Sign lamps * 9 kinds "ZERO","TARE","NET","GROSS

"BATT","W.S","HI","OK","LO".

* Filling graphic * 2 kinds rough and fine

11

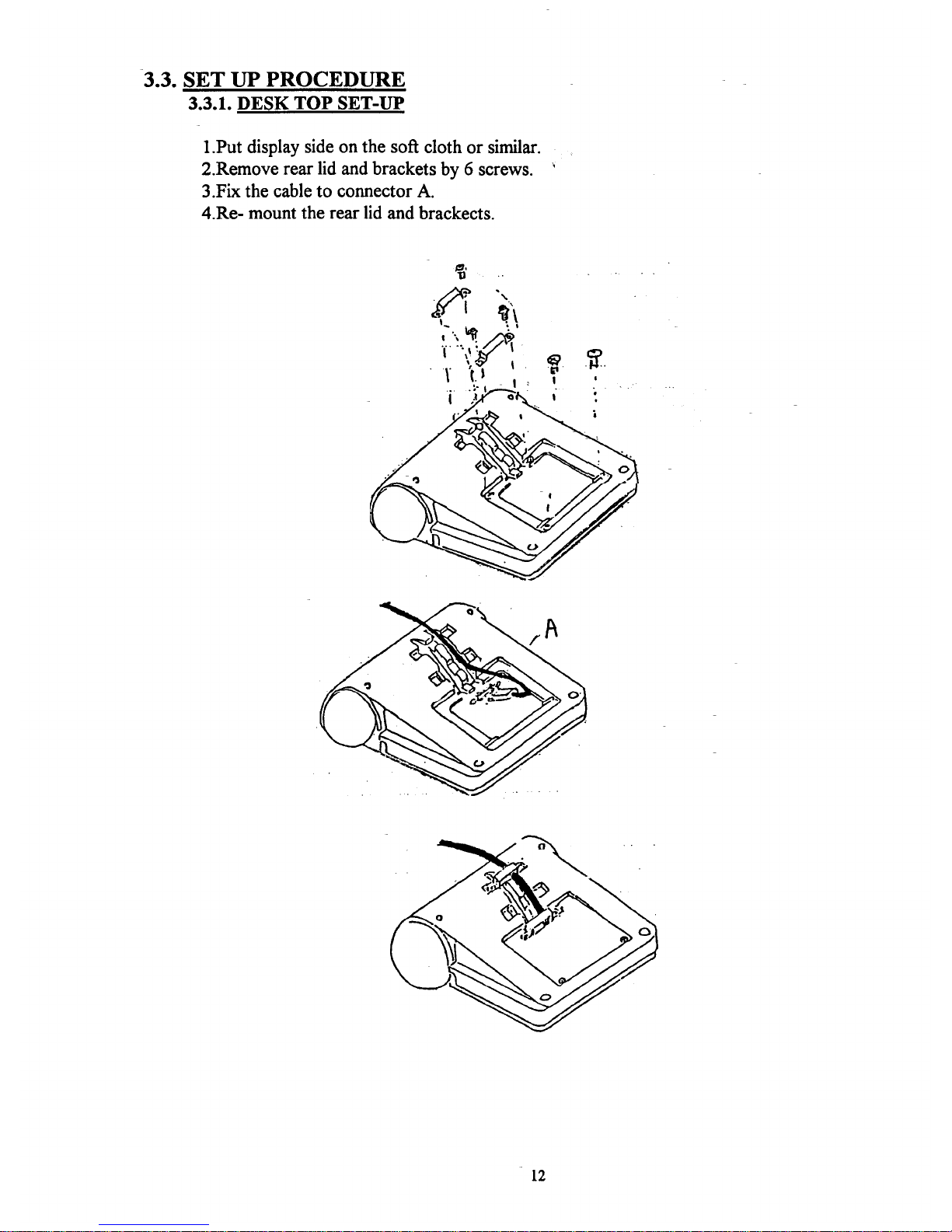

Page 13

Page 14

Page 15

3.4. FEATURES

1. Super Large LCD And

Dynamic Filling In Graphic

Display.

* 25.4 mm figure height.

* 2 kinds of filling in graphic, rough and fine.(selectable)

* 9 kinds of weighing sign and 5 kinds of weighing unit.

2. Battery Drive Available. * D.C 1.5 V x 6 pcs.(AM-2)

* In The Case Of Battery Drive, Printer Option And 4 Load

Cell Construction Scale Is Not Available

* Alkaline cell is better than another material.

3. Automatic Power

Off.(Selectable Time Off)

* To save power specially in the case of battery drive,

automatic power off function is provided

4. Up To 4 - 350Ω Load Cells

Can Be Driven with a (DI-10)

* This is available only in the case AC/DC adaptor is used as

power supply. (Only One Load Cell Can Be Driven In The

Case Of Battery Operation.)

* DIGI's S-S,S-T,S-U are recommendable as external scale.

5. Five Kinds Of Weighing

* In "kg","g","lbs","oz" or "dwt" mode.

Mode.(Selectable)

6. Weighing

Conversion.(Selectable)

* "kg" to "lb." and vise-versa. (1 lb = 0.45359 kg,

1 kg = 2.2046 lb. )

* "g" to "oz" or "dwt" and vise-versa. (1 g = 0.03527 oz,

1 oz = 20 dwt.)

7. Three Kinds Of Taring

* One touch tare, Digital tare, Digital tare during weighing.

Method.(Selectable)

8. Addition & Subtraction. * Max. 6 digits and an alarm sign "Add OFF" and "SUb OFF"

are provided when they exceed the limit.

9. NET/GROSS Conversion. * Individual indicator for NET and GROSS.

10. Automatic Zero Tracking. * To eliminate small weight display drifting.

11. Automatic Print.(Selectable) * To print out weighing result automatically

12. Automatic Calibration.

13. Data Output By RS-232C For

* For data transfer to external device

External Device. (Option)

14

Page 16

FEATURES (continued)

14. Setpoint Data Output.

* To drive external device.

(Option)

15. Built In Printer. (Option) * To print out weighing result.

In The Case Of Battery Drive, Printer Option Is Not Available

16. Code No. Printing. * To specify the printed out weighing result.

17. Date & Time Printing. * To specify the printed out weighing result.

* Built in clock.(no back up after power disconnect)

18. Counting Function. * For parts counting operation.

* Print out, addition and subtraction are not possible.

19. Programmable Scale Capacity

And Scale Interval.

* Minimum graduation (increment),1,2,5,10,20 and 50 are

available.

* Display resolution up to 1/10.000 is available.

20. Meets Or Exceeds The

1/3000 display resolution.

Requirements Of OIML Class 3

21. Articulated Head Mount for

*At an angle of 80 °.

Pole Mount

15

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

5.3. RS-232 (continued)

2. Communication Control Command.

DC1 (11H) : Data request from DI-10.

DC3 (13H) : Communication break request.

(DI-10 receives “DC3”, the time out will be extended to 5 sec.

ACK (06H) : Positive response.

NAK (15H) : Negative response.

EOT (04H) : Communication end.

3. Text Code

* Data Code

0 (30H) Represents NET WEIGHT.

3 (33H) Represents CODE NO.

4 (34H) Represents TARE

A (41H) Represents GROSS WEIGHT

* Data

− (2DH) : Represents minus. (plus=0 )

• (2EH) : Represents decimal point.

* Terminal Code

CR (0DH) : Represents data terminate code.

LF (0AH) : Represents text end code.

4. Location Of Connector And Pin Assignment.

pin 1 SP-1 (LO)

pin 2 COM (GND)

pin 3 SP-2 (OK)

pin 4 RXD

pin 5 TXD

pin 6 CTS

pin 7 RTS

pin 8 SP-3 (HI)

*SP-1,SP-2 AND SP-3 ARE SETPOINT OUTPUT with 5V

5.4. AC / DC ADAPTER

The specifications for the AC/DC adapter are as follows:

* Input voltage to your needs

* Output volyage 12V

* Output current 1.0 A (minimun)

* Type of connector see below

Center Electrode Is Negative (−)

Outer Electrode Is Positive (+)

D 1 D 2 L

5.5 mm 2.1 mm 9.5 mm

30

Page 32

6.0. MAINTENANCE, CALIBRATION, TEST PROCEDURE & SERVICE

This section contains information and instructions concerning maintenance of the DI-10

weighing Scale.

Preventive maintenance consists of periodically cleaning the external surfaces of the instrument

and should be performed as often as operating conditions warrant.

The calibration procedure is designed to be an aid in maintaining the scale accuracy within

specifications. The calibration procedure may also serve as a performance test procedure.

CAUTION: DO NOT ATTEMPT ANY SERVICE WHILE THE INSTRUMENT

IS CONNECTED TO THE POWER LINES.

6.1. MAINTENANCE PROCEDURES

6.1.1. EXTERIOR MAINTENANCE

The exterior surfaces of the counting scale can be easily cleaned using soap and

water. However, extreme caution should be used so that there is no possibility of

water penetration into the scale electrical or mechanical sections. A damp cloth or

sponge is suggested. NEVER USE ACETONE, MEK, OR SIMILAR

SOLVENTS ON THE PLASTIC HOUSING AS THEY WILL ETCH THESE

SURFACES.

For grease or other difficult spots, a chlorothane or naptha based cleaner may be

used. Never use any solvents on the front or rear panels.

Accumulations of dust or direct particles between the pins of the connectors may

be removed by using dry forced air or a small dry brush.

6.1.2. INTERNAL MAINTENANCE

Internal maintenance is not normally required and if it is, should not be attempted

except by a qualified, authorized service technician.

31

Page 33

Page 34

6.4. ERROR MESSAGE LIST

The following error messages will appear when an incorrect operation is taken :

Add OF Whwn accumulated weight total exceeds 6 digits.

When quantity displayed exceeds 6 digits.

OF When displayed weight exceeds scale capacity.

Spn Er When weight value entered during calibration

procedure is not in proper range .

− − − − − −

When zero calibration is not correct during calibration

procedure.

Please try Zero and Span calibration.

8 8 8 8 8 8 When zero calibration is not correct when in weighing

mode.

Please try Zero and Span calibration

Add X X When sample weight is an insufficient sample size.

Please place X X more pcs on scale press [PCS] key

SP Err

When an incorrect setpoint value is entered ↓ (Err)

(ex.SP1 = 2.00[LO] SP2 = 4.00[OK] SP3= 0.00[HI] )

Sub UF When total weight is minus.

F F F F F F When quantity result exceeds 6 digits.

33

Page 35

Page 36

6.5.2 SPEC. LIST

Function Table Of 141

SPEC #

Bit 3 Bit 2 Bit 1 Bit 0

& standard setting

Spec 00

0 0 0 0

Spec 01

0 0 0 0

Spec 02

0 0 0 0

not used Setpoint Function

0 = yes

1 = no

Key-In Wt. Print

0 = yes

1 = no

Print out by ∗ key

when “0” weight

0 = no

1 = yes

Date & Time Print

0 = no

1 = yes

Net/Gross

Display Change

0 = yes

1 = no

Negative Wt. Acc.

0 = yes

1 = no

Data Output Serial I / F

Weighing Unit

Change

0 = yes

1 = no

Spec 03 -Spec 06 not used

Spec 07

0 0 1 0

Spec 08

1 1 0 0

Setpoint Out &

Display

0 = only + weight

1 = only − weight

Print Code #

0 = no

1 = yes

Setpoint Out &

Display

0 = absolute value

1 = sign selectable

Filling Display

0 = no

1 = yes

Date Order

00 = yy.mm.dd

01 = dd.mm.yy

10 = mm.dd.yy

Insufficient Sample Range

00 = 0.1 % of scale capacity

01 = 0.2 % of scale capacity

10 = 0.3 % of scale capacity

11 = 0.4 % of scale capacity

Spec09 Automatic Power OFF Timer

1 0 1 0

0 0 0 0 = none

0 0 0 1 = 1 min.

0 0 1 0 = 2 min

0 0 1 1 = 3 min

0 1 0 0 = 4 min

0 1 0 1 = 5 min

0 1 1 0 = 6 min

0 1 1 1 = 7 min

1 0 0 0 = 8 min

1 0 0 1 = 9 min

1 0 1 0 = 10 min

1 0 1 1 = 11 min

Note : Wt = Weight

∗ key = Print key

Specifications in bold print were newly added from Ver 3.00

Specifications from Spec.03 to 06 are deleted from Ver. 3.00

Printer Connection

0 = no

1 = yes

0 = no

1 = yes

Automatic Print

0 = no

1 = yes

yy = year

mm = month

dd = day

1 1 0 0 = 12 min

1 1 0 1 = 13 min

1 1 1 0 = 14 min

1 1 1 1 = 15 min

35

Page 37

6.5.3 SPEC.LIST (continued)

Function Table Of 142

SPEC #

Bit 3 Bit 2 Bit 1 Bit 0

& standard setting

Spec 13

0 0 0 0

Spec 14

0 0 0 0

Spec 15

0 0 0 0

Spec 16

0 0 0 0

Spec 17

0 0 0 0

Spec 18

0 0 0 0

Zero Tracking

During Tare

Reduction

0 = yes

1 = no

Manual Tare

Clear

0 = yes

1 = no

NTEP

0 = no

1 = yes

Auto Tare

Clear

0 = no

1 = yes

Decimal Point

0 = period

1 = comma

Zero

Suppress

Code # Print

0 = no

1 = yes

Re-Zero Key

During Tare

Reduction

0 = yes

1 = no

Tare Decrease

0 = yes

1 = no

When Net Weight

is Below “0”

0 = minus

1 = blank

A.T.C. condition

0 = net 21d

1 = net 1d

Non-Stable

Output

0 = no

1 = yes

Add Function

When Auto

Print

0 = no

1 = yes

Scale Start Range

0 = 10 % of cap

1 = 5 % of cap

Tare Increase

0 = yes

1 = no

When Gross Weight

Is Below “0”

0 = minus

1 = blank

Digital Tare

0 = yes

1 = no

Negative Total

0 = yes

1 = no

Scale Start

0 = auto

1 = by RE-ZERO

Spec 19 Senseitivity Of Load Cell To Be Used

1 0 0 1

0 0 0 0 = 3.46 − 4.00mV/V

0 0 0 1 = 3.00 − 3.46mV/V

0 0 1 0 = 2.59 − 3.00mV/V

0 0 1 1 = 2.55 − 2.59mV/V

0 1 0 0 = 1.95 − 2.55mV/V

0 1 0 1 = 1.69 − 1.95mV/V

0 1 1 0 = 1.46 − 1.69mV/V

0 1 1 1 = 1.27 − 1.46mV/V

1 0 0 0 = 1.09 − 1.27mV/V

1 0 0 1 = 0.95 − 1.09mV/V

1 0 1 0 = 0.82 − 0.95mV/V

1 0 1 1 = 0.71 − 0.82mV/V

1 1 0 0 = 0.61 − 0.71mV/V

1 1 0 1 = 0.53 − 0.61mV/V

1 1 1 0 = 0.46 − 0.53mV/V

1 1 1 1 = 0.40 − 0.46mV/V

NOTE: IR. = Internal Count.

FS. = Full Scale.

Cap. = Scale Capacity.

Specifications in bold print were newly added from Ver. 3.00

Specifications from spec. 10 to 12 were deleted from Ver. 3.00

Weighing Unit

(Display/Print)

0 = yes

1 = no

Tare Limit

0 = 100 % of FS.

1 = 5 % of FS.

Zero Lamp Range

0 = gross 0 ±1/4d

1 = net 0 ±1/4d

Print Limit

0 = below 0 d

1 = below 20 d

Double Print

0 = yes

1 = no

Tare Exchange

0 = yes

1 = no

36

Page 38

Page 39

Page 40

NOTES:

39

Page 41

DI-10 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed

by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects

in materials and workmanship for one (1) year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications

authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If

any equipment fails to conform to these warranties, RLWS will, at its option, repair or replace such goods

returned within the warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a detailed explanation

of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent electrostatic

discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, “Protecting Your Components

From Static Damage in Shipment,” available from RLWS Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair or improper testing; RLWS shall be the sole

judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping charges

both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT,

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER

IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS

WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any legal effect unless

made in writing and signed by a corporate officer of RLWS and the Buyer.

© 2002 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

• 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Loading...

Loading...