Page 1

Operation Manual for DC-788

Prepared : 8 July 2003

1st Amendment : : 11 November 2004

Issued by 2nd. R&D Dept., SHANGHAI TERAOKA ELECTRONIC CO., LTD.

Page 2

2

1. General Layout..................................................................................................................4

2. Purpose..............................................................................................................................

5

3. Features..............................................................................................................................

5

4. Operating Conditions ........................................................................................................

5

5. Charging Conditions (for Rechargeable battery only)......................................................

5

7. Display and Indicators.......................................................................................................

6

7.1. Display Specifications..................................................................................................................... 6

7.2. Indicators......................................................................................................................................... 6

8. Dimensions........................................................................................................................ 6

9. External Connectors ..........................................................................................................

7

10. Main Components ...........................................................................................................

7

11. Existing parts to be used..................................................................................................

7

12. Keysheet Layout..............................................................................................................

8

13. Key Functions..................................................................................................................

8

14. Notable differences from current Teraoka scales: ..........................................................

9

15. Block Diagram of Electrical Connection........................................................................

9

16. Physical layout of Electrical Connection......................................................................

10

17. Hardware Description....................................................................................................

11

17.1. Microcomputer............................................................................................................................ 11

17.2. Pin Assignment......................................................................................................... 11

18. Maintenance Mode........................................................ Error! Bookmark not defined.

18.1. SPAN Adjustment........................................................................Error! Bookmark not defined.

18.2. Escape from Maintenance mode..................................................Error! Bookmark not defined.

18.3. Specification Setting....................................................................Error! Bookmark not defined.

18.3.1. Specification Enter (141).................................................................Error! Bookmark not defined.

18.3.2. Specification Enter (142).................................................................Error! Bookmark not defined.

18.4. Internal Count & A/D Count Display..........................................Error! Bookmark not defined.

18.5. Operational Specification List .....................................................Error! Bookmark not defined.

19. Operations In Weighing Mode......................................................................................13

19.1. ON/OFF ...................................................................................................................................... 13

19.2. Tare Subtraction.......................................................................................................................... 13

19.2.1. One Touch Tare Subtraction ...........................................................................................................13

19.2.2. Digital Tare Subtraction..................................................................................................................

13

19.3. Unit Weight Entry Operation...................................................................................................... 13

19.3.1. By Sampling....................................................................................................................................13

19.3.2. Digital Unit Weight Operation........................................................................................................

14

19.4. Insufficient Sampling Weight Operation.................................................................................... 14

19.4.1. Add Samples ...................................................................................................................................14

19.4.2. Adopt Suggestion............................................................................................................................

14

19.4.3. Ignore Suggestion............................................................................................................................

14

19.5. Parts Counting Operation............................................................................................................ 15

19.5.1. Single Counting Operation..............................................................................................................15

19.5.3. Negative Counting Function ...........................................................................................................

15

19.6. Net/Gross Operation ................................................................................................................... 16

19.7. Item Code Call Up......................................................................................................................

17

19.7.1. Recall Numeric Item Code..............................................................................................................17

19.7.2. Recall Alphanumeric Item Code.....................................................................................................

17

Memory Field of Item Code........................................................................................................................

17

Page 3

3

20. Operations In Program Mode........................................................................................ 18

20.1. Program Item Code..................................................................................................................... 18

20.2. Delete Item Code in Memory...................................................................................................... 19

20.2.1. Delete a Certain Item Code.............................................................................................................19

20.2.2. Delete all Item Code........................................................................................................................

19

20.2.3. Delete all Inventory Value from Memory.......................................................................................

19

20.2.4. Delete all Unit Weight Value from Memory...................................................................................

19

20.2.5. Delete all Tare Weight Value from Memory ..................................................................................

20

20.2.6. Delete all Parts Numbers from Memory .........................................................................................

20

20.2.7. Delete all Setpoint Data from Memory...........................................................................................

20

20.2.8. Delete all Parts Name from Memory ..............................................................................................

20

20.2.9. Reset Sequence Number to 0...........................................................................................................

21

20.3. Review Item Code....................................................................................................................... 21

20.4. Program Setpoint to Operate all Items........................................................................................ 21

20.5. Date and Time............................................................................................................................. 21

Page 4

4

1. General Layout

Page 5

5

2. Purpose

To develop a low cost LCD display counting scale which caters to OIML, UL, EU Standard and meets requirement of

major customers.

3. Features

* Low cost counting scale.

* Quick response to weight changes.

* Capacity : 500g; 1kg; 2.5kg; 5kg; 10kg; 25kg; 50kg

* Resolution : Display Resolution 1/10,000.

Internal Resolution 1/1000,000.

* Rechargeable Battery backup for 24 hours of continuous usage (optional).

* Intelligent power control

A. When AC power is available, scale will use AC power only whatever rechargeable battery is installed or not.

When AC power is shut off, scale will use battery automatically.

B. When scale works on rechargeable battery, if the battery is weak, the battery indictor will light up.

When the power from battery becomes low such that the scale can not compute accurately, all Displays will

shut off except the Battery indicator. The power is then shut off completely after 1 minute.

C. Scale detects rechargeable battery voltage and control battery charge process automatically.

The battery charge indicator lights up when rechargeable battery is being charged.

* Calibration by software.

* Water proof keyboard and splash proof housing.

* 24 switch keys

- ON/OFF key.

- 10 Numeric keys.

- 13 Operational keys.

* Large platter : 340 x 243 mm.

* Plastic housing.

* 25 digits with 19 segments Back-light LCD Operat o r di spl ay s .

* RS-232C interface for data communication and printer connection.

- Gross Weight, Tare Weight, Net Weight, Unit Weight, Count, PLU code, Product Description, Product Lot No.,

Accumulated count.

* Two scale channels, one for built-in platform, another for remote platform.

* External printer connectible (RS-232C)

- Label printer : DIGI GP-460R

- Bar code printer : ZEBRA LP-2844

- Receipt printer :EPSON TM-U200

* 100 PLU, each PLU consists of Unit Weight, Tare Weight, Product Description(32 characters), Product Lot No.

(32 characters), Set point(Hi/OK/Low).

4. Operating Conditions

* Power Source : AC 240/230/220V, 117/100V.

: DC 6V 5Ah rechargeable battery (optional).

* Operating Temperature : -10℃ ~ +40℃ (OIML).

* Operating Humidity : 15 ~ 85% RH.

* Power Consumption : 18W when using AC power.

: 1W when using rechargeable battery.

5. Charging Conditions (for Rechargeable battery only)

* Power Source : AC 240/230/220V, 117/100V.

* Charge Current : 800 mA.

* Charge Time : 8 - 10 hours.

Page 6

6

6. Analog Specification

* Input sensitivity : 1mV/V.

* Zero adjust range : 0 ± 5mV.

* Zero balance range : 0 ± 0.5mV.

* L/C applied voltage : DC 5V.

* Speed of A/D conversion : 30 times/sec.

* Internal Resolution : 1000,000.

7. Display and Indicators

Type A(Standard type with NET/GROSS shift function)

Type B(Special type with kg/lb shift function)

Type B(Special type with WT/100 or APW function)

7.1. Display Specifications

* Tare Weight Display : 5 digits.

* Weight Display : 5 digits .

* Unit Weight Display : 5 digits.

* Quantity Display : 7 digits.

7.2. Indicators

* ZERO : On when zero point is adjusted and weight is stable.

* NET : On when tare subtraction is performed.

* kg : On when th e item is weigh ed in kg unit with [kg/lb] key pressed.(type B version only)

* lb : On when the item is weighed in lb unit with [kg/lb] key pressed. (type B version only)

* INSUFF : On when the net weight is below a specific percentage of capacity weight.

* GROSS : On when [Gross/Net] key is pressed. (type A version only)

*SCALE1 : On when the scale 1 is in use.

*SCALE2 : On when the scale 2 is in use.

* RECOMP : On when unit weight recomputing is enable.

* PROG : On when in the programming mode.

* WT/1000 : On when the display unit weight is 1000PCS base. (type B version only)

* APW : On when the display unit weight is one PCS base. (type B versio n only )

* Σ : On when quantity is accumulating.

*OUT : On when remove a quantity of parts to item inventory.

*IN : On when add a quantity of parts to item inventory.

* BATT : On when Battery is weak and needs to charge (only for rechargeable battery type).

* CHARGE : On when Battery is charging (only for rechargeable battery type)..

8. Dimensions

* Platter size : 340 x 243 mm.

* Overall size : 354 x 349 x 115 mm.

Page 7

7

9. External Connectors

* AC receptacle.

* RS-232C interface.

* 14 pin femal amphenol for external loadcell

10. Main Components

* Microcomputer : Hitachi HD64F73687(56K Flash) / HD64F3684(32K Flash) /

HD6433687(56K ROM) / HD6433686(48K ROM) ./ HD6433685(40K ROM) /

HD6433684(32K ROM) / HD6433683(23K ROM)

* Crystal Oscillator : 10 MHz.

* Display device : Back-light LCD.

* Loadcell :

Sensitivity 1~3mV/V

11. Existing parts to be used

* P type Loadcell (DS-788).

* Back-ligntLCD(SM-100).

* Housing and Mechanical Blocks (DS-788).

12. Capacity/Minimum Graduation/Tare range

Capacity Minimum Graduation Tare Rang

500g 0.1g (1e = 200IR) 0 - 249.9g

1kg 0.2g (1e = 200IR) 0 - 0.4998kg

2.5kg 0.5g (1e = 200IR) 0 - 0.9995kg

5kg 1g (1e = 200IR) 0 - 0.999kg

10kg 2g (1e = 200IR) 0 - 9.998kg

25kg 5g (1e = 200IR) 0 - 9.995kg

1lb 0.0001 lb (1e = 100IR) 0 - 0.4999 lb

2 lb 0.0002 lb (1e = 100IR) 0 - 0.9998 lb

5 lb 0.0005 lb (1e = 100IR) 0 - 0.9995 lb

10 lb 0.001 lb (1e = 100IR) 0 - 9.999 lb

20 lb 0.002 lb (1e = 100IR) 0 - 9.998 lb

50 lb 0.005 lb (1e = 100IR) 0 - 9.995 lb

Page 8

8

12. Keysheet Layout

Type A

Type B

13. Key Functions

: ON/OFF key. Turn the power ON or OFF.

to

: Numeric keys. Input numerical value.

: Decimal Point key. Set decimal point.

: CLEAR key. Clear numerical values.

: Sampling key. Used for computing unit weight by sampling.

: TARE key.Set or clear tare value.

: RE-ZERO key. Resets weight display to zero.

: PLU CODE key. Used to call out PLU data.

Page 9

9

: MINUS key. Correct operation on products.

: PLUS key. Used for accumulation.

: Data Setting key. Set up SPEC data or clear TOTAL data.

:Select 1

st

Scale or 2nd Scale

: MODE SET key. Used to enter programming mode from weighing mode.

: NET/GROSS change key. Used to change display between Gross and Net.(Only on

type A)

: kg/lb conversion key. Used to convert the weighing unit between kg and lb. (Only

on type B)

: UNIT WEIGHT key. Used to set unit weight and display All digits of Unit Weight.

14. Notable differences from current Teraoka scales:

* Low cost LCD display counting scale.

15. Block Diagram of Electrical Connection

Page 10

10

16. Physical layout of Electrical Connection

Page 11

11

17. Hardware Description

17.1. Microcomputer

The H8/3687 Series Microcomputer was chosen for the following reasons:

* Cheaper.

* High-speed CPU with sixteen 16-bit registers.

* 33 interrupt sources and efficient interrupt processing.

* Four versatile timers.

* Two on-chip serial communication interface channels.

* 8-channel 10-bit resolution A/D converter.

*I

2

C bus interface.

* Less chip count.

* Pin compatibility of similar package with difference ROM sizes.

* Instruction set is compatible with the H8/300 CPU.

* Good support.

17.2. Pin Assignment

Pin I/O Assignment Device Remark

P10/TMOW I -

P11/PWM I -

P12 I ACIN AC Power Detects AC Power

P14/IRQ0 I -

P15/IRQ1/TMIB1 I -

P16/IRQ2 I -

P17/IRQ3/TRGV I K0 Keyboard Key Return Line

P20/SCK3 O RTS MAX232 RS-232C

P21/RXD I RXD MAX232 RS-232C

P22/TXD O TXD MAX232 RS-232C

P23 I CTS MAX232 RS-232C

P24 O CVD R12 Device Power Control

P30 O T1 KEYBOARD Key Scanning Line

P31 O T2 KEYBOARD Key Scanning Line

P32 O T3 KEYBOARD Key Scanning Line

P33 O T4 KEYBOARD Key Scanning Line

P34 O T5 KEYBOARD Key Scanning Line

P35 O T6 KEYBOARD Key Scanning Line

P36 I -

P37 I -

P50/WKP0 I -

P51/ WKP 1 I -

P52/ WKP 2 O TBT R8 Controls BATT Detector

P53/ WKP 3 O CVAD R6 Controls BATT Power To A/D

P54 WKP 4 O BTPW R4 Controls BATT Power To M/B

P55/ WKP 5/ADTRG O BTCHG R2 Controls BATT Charger

P56/SDA I/O SDA AT24C128,HMS093AL EEPROM,LCM

P57/SCL O SCL AT24C128,HMS093AL EEPROM,LCM

P60/FTIOA0 O RTCCS 3511A Real Time Clock

P61/FTIOB0 O RTCSCK 3511A Real Time Clock

P62/FTOC0 I/O RTCSIO 3511A Real Time Clock

P63/FTIOD0 O CBUZZ R40 Buzzer Sounder

P64/FTIOA1 O ADCHAN A/D Board Controls A/D Channel

P65/FTIOB1 O ADSCLK A/D Board Controls A/ D C onver si o n

P66/FTIOC1 O ADSDI A/D Board Controls A/D Conversion

P67/FTIOD1 I ADSDO A/D Board Controls A/D Conversion

P70/SCK3_2 I -

P71/RXD_2 I -

P71/TXD_2 I -

P74/TMRIV O EEPWP AT24C128 EEPROM

P75/TMCIV I -

P76/TMOV I -

Page 12

12

Pin I/O Assignment Device Remark

P85 I/O JUMPER&E7 JUMPER&E7 MODE SELECT

P86 I/O E7 E7 MODE SELECT

P87 I/O E7 E7 MODE SELECT

PB0/AN0 I -

PB1/AN1 I K1 Keyboard Key Return Line

PB2/AN2 I K2 Keyboard Key Return Line

PB3/AN3 I K3 Keyboard Key Return Line

PB4/AN4 I K4 Keyboard Key Return Line

PB5/AN5 I -

PB6/AN6 I BTV Battery Detects Battery Voltage

PB7/AN7 I -

NMI I - JUMPER MODE SELECT

OSC1 I - Oscillator 10 MHz Crystal

OSC2 O - Oscillator 10 MHz Crystal

X1 I - Oscillator 32.768 kHz Crystal

X2 O - Oscillator 32.768 kHz Crystal

AVCC - - - Analog power supply

VCL - - - Connected to VSS PIN

VCC - - - Power supply

VSS - - - Ground

TEST I - - Connected to VSS PIN

RES I - Reset device System Reset

Page 13

13

19. Operations In Weighing Mode

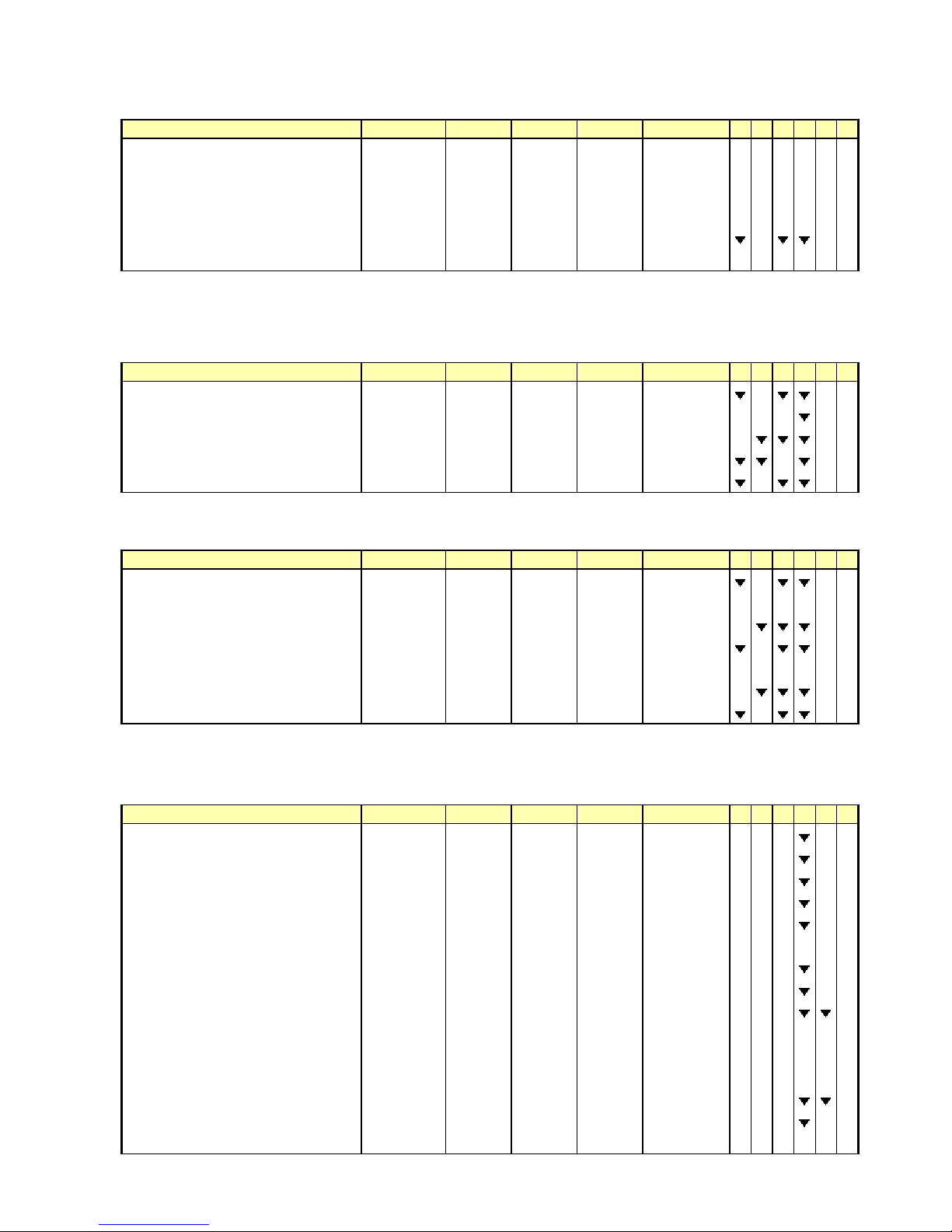

19.1. ON/OFF

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 - MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Display for 1.5 seconds.

*Note1

[ON/OFF] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

Blank for 1.5 seconds.

Display for 1.5 seconds. 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

Blank for 1.5 seconds.

Weighing mode. 0.0 0 0 0.0 0 0 0 0

OFF [ON/OFF]

Note: 1) Power On Segment Check Style can be selected by setting SPEC08.0. In this example assume SPEC08.0 = 0.

19.2. Tare Subtraction

19.2.1. One Touch Tare Subtraction

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 - MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Put tare (e.g. 30 g) on platter 0.0 0 0 0.0 3 0 0 0

Subtract the tare weight. [T] 0.0 3 0 0.0 0 0 0 0

Remove the tare weight 0.0 3 0 - 0.0 3 0 0 0

Clear the tare weight. [T] 0.0 0 0 0.0 0 0 0 0

19.2.2. Digital Tare Subtraction

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Key in the tare weight. (e.g. 50g). [0] [.] [0] [3] 0.0 3

Subtract the tare weight. [T] 0.0 3 0 -0.0 3 0 0 0

Clear the tare weight. [T] 0.0 0 0 0.0 0 0 0 0

Key in the tare weight. (e.g. 2kg). [2] 2

Subtract the tare weight. [T] 2.0 0 0 -2.0 0 0 0 0

Clear the tare weight. [T] 0.0 0 0 0.0 0 0 0 0

19.3. Unit Weight Entry Operation

19.3.1. By Sampling

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put 10 pieces of samples on platter 0.0 0 0 0.0 9 6 0 0

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.0 9 6 9.6 3 6 6 1 0

Clear unit weight. [C] 0.0 0 0 0.0 9 6 0 0

Put 15 pieces of samples on platter 0.0 0 0 0.1 4 4 0 0

Input sampling quantity. [1] [5] 1 5

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.0 9 6 9.6 3 2 6 1 5

Put some more pieces of samples on platter

(e.g. 5pcs)

Re-compute function enabled while

RECOMP lamp is on.

0.0 0 0 0.1 9 2 9.6 3 2 6 20

Re-compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

The accuracy of unit weight can be

improved after re-computing.

0.0 0 0 0.1 9 2 9.6 2 9 8 20

Page 14

14

19.3.2. Digital Unit Weight Operation

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put weight on platter 0.0 0 0 0.5 2 8 0 0

Key in unit weight. [5] [.] [2] [5]

[7] [8]

5.2 5 7 8

Set unit weight. [UNIT

W

EIGHT]

0.0 0 0 0.5 2 8 5.2 5 7 8 1 0 0

Clear unit weight. [C] 0.0 0 0 0.5 2 8 0 0

19.4. Insufficient Sampling Weight Operation

19.4.1. Add Samples

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put 10 pieces of samples on platter 0.0 0 0 0.0 1 6 0 0

Add samples till the INSUFF lamp is "OFF"

(e.g. 2)

0.0 0 0 0.0 2 0 0 0

Input sampling quantity before [1] [2] 1 2

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.0 2 0 1.7 0 0 0 12

19.4.2. Adopt Suggestion

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put 10 pieces of samples on platter

The INSUFF lamp is "ON" when sampling

weight is under a certain level.

0.0 0 0 0.0 1 6 0 0

[Pcs] - - - - - - - - - - - - - - - - - - - - -

Giving a suggestion. A d d 1 0

Add exactly 10 more pieces of samples A d d 0

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.0 3 2 1.6 0 0 0 2 0

19.4.3. Ignore Suggestion

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put 10 pieces of samples on platter

The INSUFF lamp is "ON" when sampling

weight is under a certain level.

0.0 0 0 0.0 1 6 0 0

[Pcs] - - - - - - - - - - - - - - - - - - - - -

Giving a suggestion. A d d 1 0

Ignore the suggestion. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.0 1 6 1.5 9 0 2 1 0

Page 15

15

19.5. Parts Counting Operation

19.5.1. Single Counting Operation

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Enter Unit weight by any means of 19.3

Unit Weight Entry Operation

0.0 0 0 0.0 0 0 0.5 0 0 2 0

Put bulk quantity on platter 0.0 0 0 0.4 0 0 0.5 0 0 2 8 0 0

[*] 0.0 0 0 0.4 0 0 0.5 0 0 2 8 0 0

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [*] key.

19.5.2. Accumulation & Subtraction Operation

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Enter Unit weight by any means of 19.3

Unit Weight Entry Operation

0.0 0 0 0.0 0 0 0.5 0 0 2 0

Put product on platter 0.0 0 0 0.4 0 0 0.5 0 0 2 8 0 0

Accumulate the data. [+] t O t A L 1 8 0 0

Return to Weighing mode. [C] 0.0 0 0 0.4 0 0 0.5 0 0 2 8 0 0

Remove product from platter 0.0 0 0 0.0 0 0 0.5 0 0 2 0

Put product on platter 0.0 0 0 0.2 5 0 0.5 0 0 2 5 0 0

Subtract the data. [-] C o r r 0 3 0 0

Return to Weighing mode. [C] 0.0 0 0 0.2 5 0 0.5 0 0 2 5 0 0

Remove product from platter 0.0 0 0 0.0 0 0 0.5 0 0 2 0

Clear unit weight. [C] 0.0 0 0 0.0 0 0 0 0

Display total when unit weight is 0. [+] t O t A L 0 3 0 0

Return to Weighing mode. [C] 0.0 0 0 0.0 0 0 0 0

[1] [0] [0] 1 0 0

Accumulate the data. [+] t O t A L 1 4 0 0

Return to Weighing mode. [C] 0.0 0 0 0.0 0 0 0 0

[3] [7] 3 7

Subtract the data. [-] C o r r 1 3 6 3

Return to Weighing mode. [C] 0.0 0 0 0.0 0 0 0 0

[*] 0.0 0 0 0.0 0 0 0 0

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [+], [-] and [*] key.

19.5.3. Negative Counting Function

1 - ZERO 2 - NET 3 - INSUFF 4 – SCALE1 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put container with parts on platter 0.0 0 0 1.2 5 5 0 0

Subtract the tare weight. [T] 1.2 5 5 0.0 0 0 0.0 0 0 0

Take 10 pcs of parts from container 1.2 5 5 - 0.0 2 5 0 0

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

:

1.2 5 5 - 0.0 2 5 2.4 7 8 10

Take bulk number from container 1.2 5 5 - 0.0 9 9 2.4 7 8 40

[*] 1.2 5 5 - 0.0 9 9 2.4 7 8 40

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [*] key.

Page 16

16

19.6. Net/Gross Operation

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – MEMORY

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put product on platter 0.0 0 0 0.4 0 0 0 0

Read out Gross weight [Gross] 0.4 0 0

Return to Weighing mode. [Gross] 0.0 0 0 0.4 0 0 0 0

Subtract the tare weight. [T] 0.4 0 0 0.0 0 0 0.0 0 0 0

Read out Gross weight [Gross] 0.4 0 0

Put more product on platter 0.6 5 0

Return to Weighing mode. [Gross] 0.4 0 0 0.2 5 0 0 0

Note: 1) Only type A have Net/Gross function to shift display between Net weight and Gross weight.

19.7. kg/lb Operation

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - kg 6 – lb

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Put product on platter 0.0 0 0 0.4 0 0 0 0

Shift to lb mode [kg/lb] 0.0 0 0 0.8 8 0 0 0

Return to kg mode [kg/lb] 0.0 0 0 0.4 0 0 0 0

[kg/lb] 0.0 0 0 0.8 8 0 0.0 0 0 0

Compute unit weight. [Pcs] - - - - - - - - - - - - - - - - - - - - -

0.0 0 0 0.8 8 0 8 7.9 9 2 1 0

Note: 1) Only type B have kg/lb fuction to shift weight unit between kg and lb.

19.8. Select 1

st

Scale or 2nd Scale Operation

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 – Scale1 6 – Scale2

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Select 1st Scale or 2nd Scale key

[Scale] 0.0 0 0 0.0 0 0 0 0

0.0 0 0 0.0 0 0 0 0

Select 1st Scale or 2nd Scale key

[Scale] 0.0 0 0 0.0 0 0 0 0

0.0 0 0 0.0 0 0 0 0

Note: 1) This function available only when SPEC26 2nd Scale is enable.

Page 17

17

19.9. Item Code Call Up

19.9.1. Recall Numeric Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - IN 6 – OUT

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter item code. [1] [0] [0] 1 0 0

Call up item code. [CODE] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Select “In-Out” status. [IN/OUT] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Put bulk parts on platter. 0.0 0 0 0.1 4 5 1.6 9 8 0 8 4

[*] 0.0 0 0 0.1 4 5 1.6 9 8 0 8 4

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [*] key .

And inventory value will update according to the IN/OUT status and Accumulation when quantity is accumulating.

Subtract from inventory when OUT status. Accumulate inventory when IN status.

19.9.2. Recall Alphanumeric Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - IN 6 – OUT

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

ASCII enter mode. [.] A S C 0 1 0 0 0 - CODE

Call up PLU. [8] [0] A S C 0 1 0 8 0 - P CODE

“+” key to move cursor ahead. [+] A S C 0 2 0 0 0 - CODE

“-” key to move cursor back. [-] A S C 0 1 0 8 0 - P CODE

“C” key to delete character. [C] A S C 0 2 0 0 0 - CODE

[6] [5] A S C 0 1 0 6 5 - A CODE

[+] [6] [6] A S C 0 2 0 6 6 - b CODE

Call up item code “ABC10”. [CODE] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Select “In-Out” status. [IN/OUT] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Put bulk parts on platter. 0.0 0 0 0.1 4 5 1.6 9 8 0 84

[*] 0.0 0 0 0.1 4 5 1.6 9 8 0 84

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [*] key .

And inventory value will update according to the IN/OUT status and Accumulation when quantity is accumulating.

Subtract from inventory when OUT status. Accumulate inventory when IN status.

19.9.3. Review Current PLU Contents

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - IN 6 – OUT

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter item code. [1] [0] [0] 1 0 0

Call up item code. [CODE] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Select “In-Out” status. [IN/OUT] 0.0 0 0 0.0 0 0 1.6 9 8 0 0

Put bulk parts on platter. 0.0 0 0 0.1 4 5 1.6 9 8 0 8 4

Review PLU contents[Scale] [Scale] ICODE 100

[Scale] Pno 123A

[Scale] Pname SCREW

[Scale] Lnum 2

[Scale] INVENT 4012

[Scale]

0.0 0 0 0.1 4 5 1.6 9 8 0 8 4

Note: 1) If DC-788 is connected to printer/PC, the data is printed/output by pressing [*] key .

Page 18

18

Memory Field of Item Code

• Memory Field

Parameters Max. length

Item Code 10 digits numeric data or Alphanumeric data

Parts No. 16 digits Alphanumeric data

Parts Name 32 Alphanumeric data

Lot Number 32 Alphanumeric data

Tare Weight 5 digits + Decimal figure

Unit Weight 5 digits + Decimal figure

Inventory 8 digits

Setpoint Value 2 points

20. Operations In Program Mode

20.1. Program Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. The total number

of item codes in memory appears in QTY

column.

[MODE] P r o G C 0

To program Item Code. *Note1 [1] [0] [0] 1 0 0

[CODE] 0.0 0 0 0.0 0 0 0 0

To program Tare Weight.

Enter tare WT by any means of 19.2.

0.1 2 0 - 0.1 2 0 0 0

To program Unit Weight.

Enter unit WT by any means of 19.3.

0.1 2 0 0.1 4 5 1.6 9 8 0 84

Store the data to program Inventory. [INVENT] 0 INVENT

[6] [0] [0] 6 0 0 INVENT

Store the data to program Parts Number. [*] A S C 0 1 0 0 0 - P- No

e.g. Parts No is TA12. [8] [4] A S C 0 1 0 8 4 - T P- No

[6] [5] A S C 0 2 0 6 5 - A P- No

[4] [9] A S C 0 3 0 4 9 - 1 P- No

[5] [0] A S C 0 4 0 5 0 - 2 P- No

Store the data to program Parts Name. [*] A S C 0 1 0 0 0 - P-NAME

e.g. Parts Name is SCREW. [8] [3] A S C 0 1 0 8 3 - S P-NAME

[6] [7] A S C 0 2 0 6 7 - C P-NAME

[8] [2] A S C 0 3 0 8 2 - R P-NAME

[6] [9] A S C 0 4 0 6 9 - E P-NAME

[8] [7] A S C 0 5 0 8 7 - W P-NAME

Store the data to program Lot Number. [*] A S C 0 1 0 0 0 - LOt NO

e.g. Lot Number is LT68. [7] [6] [7] [6] A S C 0 1 0 7 6 - L LOt NO

[8] [4] A S C 0 2 0 8 4 - T LOt NO

[5] [4] A S C 0 3 0 5 4 - 6 LOt NO

[5] [6] A S C 0 4 0 5 6 - 8 LOt NO

Store the data to program Setpoint 1. [*] SET 1 0

e.g. Setpoint 1 value is 100pcs. [1] [0] [0] SET 1 100

Store the data to program Setpoint 2. [+] SET 2 0

e.g. Set point2 value is 50%. [5] [0] SET 2 50

Store the data. [*] P r o G C 1

Quit to Weighing mode. [MODE] 0.0 0 0 0 0

*Note1: To enter alphanumeric character to item code, press [•] key to change the screen to the display of alphanumeric entry.

Page 19

19

20.2. Delete Item Code in Memory

20.2.1. Delete a Certain Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

To program Item Code. [1] [0] [0] 1 0 0

1 0 0 CLEAr

Delete item code. [C] P r o G C 1 9

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.2. Delete all Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [0 ]

Enter . . 0 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [0]

ALL CLEAr

Delete all item code. [C] P r o G C 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.3. Delete all Inventory Value from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [1 ]

Enter . . 1 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [1]

INVENT CLEAr

Delete all invent value. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.4. Delete all Unit Weight Value from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 - PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [2 ]

Enter . . 2 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [2]

UNITW CLEAr

Delete all Unit Weight value. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

Page 20

20

20.2.5. Delete all Tare Weight Value from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [3 ]

Enter . . 3 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [3]

TAREW CLEAr

Delete all Tare Weight value. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.6. Delete all Parts Numbers from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [4 ]

Enter . . 4 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [4]

PARTSNo CLEAr

Delete all Parts Number. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.7. Delete all Setpoint Data from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [5 ]

Enter . . 5 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [5]

SetPOINT CLEAr

Delete all Setpoint Data. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.2.8. Delete all Parts Name from Memory

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [6 ]

Enter . . 6 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [6]

PName CLEAr

Delete all Parts Name. [C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

Page 21

21

20.2.9. Reset Sequence Number to 0

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

[RE-ZERO] [RE-ZERO] 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8 8

[RE-ZERO] + [.] [.] [7 ]

Enter . . 7 while pressing. [RE-ZERO]

[RE-ZERO] +

[.] [.] [7]

SN CLEAr

Reset Sequence Number

[C] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Note: *1) Press [MODE] key to go back to weighing mode without clearing.

20.3. Review Item Code

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

[MODE] [MODE] P r o G C 2 0

[CODE] CH1 1 0 0

[+] [+] CH2 1 2 3

[-] [-] CH1 1 0 0

Quit to Program mode. [MODE] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

20.4. Program Setpoint to Operate all Items

General setpoint value can be programmed to operate on all items. This value is enabled when no code number is selected or

the item code re-called in operation mode has no setpoint data.

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

Setpoint Program mode. [+] SET 1 0 0

[1] [0] [0] SET 1 0 1 0 0

Store Setpoint 1 value. [+] SET 2 0 0

[5] [0] SET 2 0 5 0

Store Setpoint 1 value. [+] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

20.5. Date and Time

1 - ZERO 2 - NET 3 - GROSS 4 - INSUFF 5 - RECOMP 6 – PROG

OPERATION

Key-in

TARE WEIGHT U.Weight QTY. 1 2 3 4 5 6

Weighing mode. 0.0 0 0 0.0 0 0 0 0

Enter into Program mode. [MODE] P r o G C 2 0

Display current date & time. [-] 2 6 - 0 8 0 3 TUE 1 5 - 2 8

[-] EntEr D-M-Y 2 6 0 8 0 3

[2] [8] [0] [8]

[0] [3]

EntEr D-M-Y 2 8 0 8 0 3 2 6 0 8 0 3

Store date setting. [*] EntEr TIME 1 5 - 2 8

[1] [5] [2] [5] EntEr TIME 1 5 2 5 1 5 - 2 8

Store time setting. [*] P r o G C 2 0

Quit to Weighing mode. [MODE] 0.0 0 0 0.0 0 0 0 0

Page 22

22

21. Error Massage List

The following error message will appear when an incorrect operation is performed.

Message Remarks Appropriate Operation

O F

When displayed weight exceeded capacity+9d, or some t hing

is on the platter when power on.

Remove the item on the platter.

U F

When displayed minus weight >= 9d. REZERO or ON/OFF again.

E r r o r

When calibration operation is not correct, when A/D fault, or

when an error occurs in RS-232C communication.

Repeat calibration operation.

8 8 8 8 8

When scale is not steady when power on. Place scale on firm, flat base.

Total

FULL

When current Total overflow. Clear current Total.

Loading...

Loading...