Page 1

CCCCoooouuuunnnnttttiiiinnnngggg SSSSccccaaaallllee

ee

DC-688

When Accuracy Counts

OO

OO

pp

pp

ee

ee

rr

rr

aa

aa

ttiiii

tt

oo

oo

nn

nn

MM

MM

aa

aa

nn

nn

uu

uu

aallll

aa

73353

Page 2

Page 3

DC- 688 SERIES OPERATING MANUAL

SECTION INDEX

NUMBER

PAGE

1.0. GENERAL

1.1. Unlocking Procedure and location of span (calibration) switch 2

2.0. DC-688 USER’S TECHNICAL GUIDE 3

2.1. Display & Keyboard Panels 3

2.1.1. Location of Keys 3

2.1.2. Location of Indicator Lamps 3

2.2. Setting up 3

2.3. Indicator Lamps 4

2.4. Key Functions 5

3.0. OPERATION MODE 6

3.1. One Touch Tare 6

3.2. Digital Tare 6

3.3. Unit Weight Entry 6

3.3.1. Unit Weight Entry By Sampling 6

3.3.2. Digital Unit Weight Entry 7

3.3.3. Assign Unit Weight To Preset Key 7

3.4. Clearing Unit Weight 7

3.5. Gross Weight Operation 7

3.6. Counting And Accumulation 8

3.7. Operation Example 8

4.0. MAINTENANCE MODE 9

4.1. Specification List 9-11

4.2. Specification Setting 12-13

4.3. Internal Count 13

4.4. Span Adjustment 14

4.5. Maintenance, Calibration, Test Procedure & Service 15

4.6. Shop Notes

5.0

The DC-688 counting scale offers a practical solution to a full range of precision counting applications. There

is a variety of models available ranging from a weight capacity of 6 lb. through 60 lb.

This manual will provide the user with information necessary to operate and program the DC-688. Included in

this manual are examples, descriptions, specifications, operating instructions and service guide.

QUICK GUIDE

16

17-18

1

Page 4

1.0. GENERAL

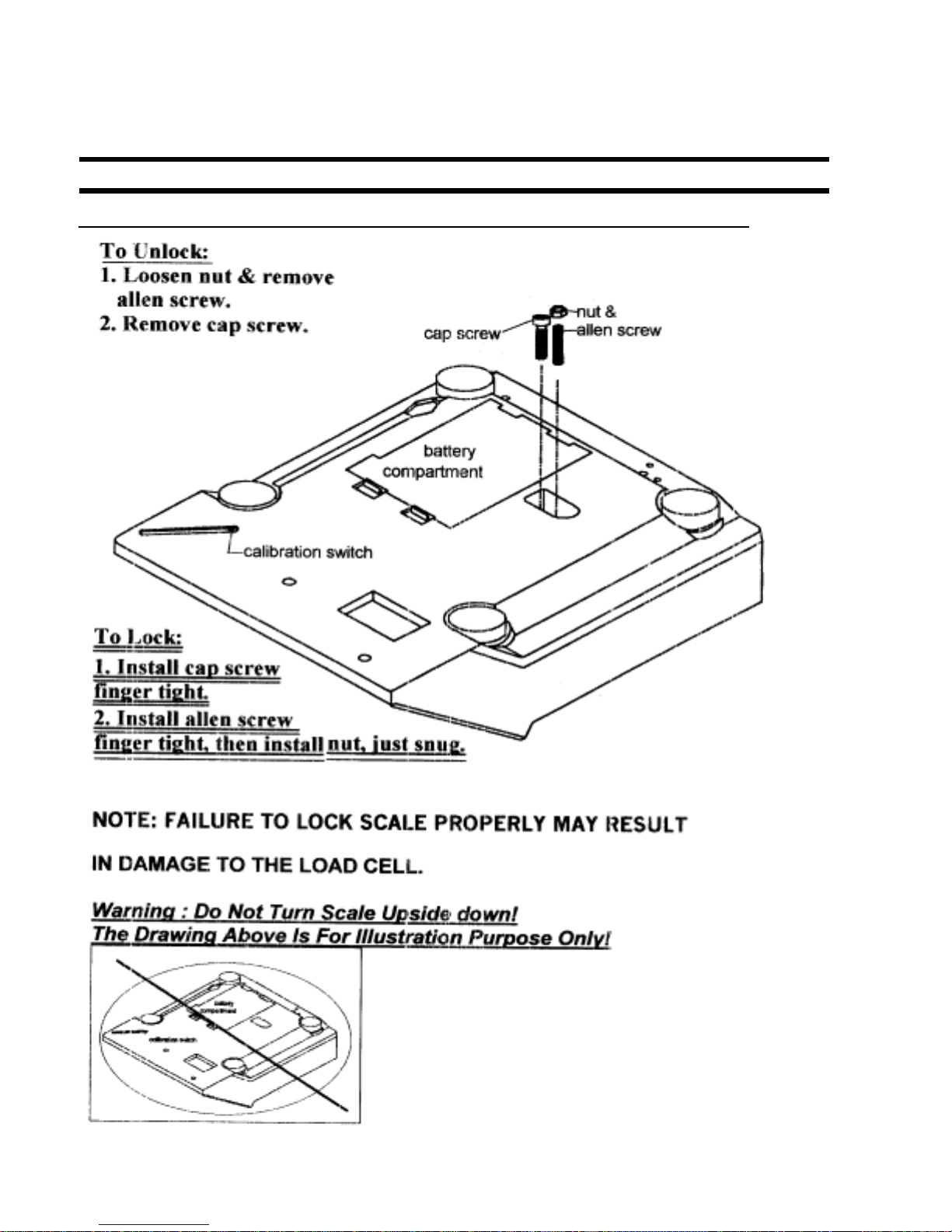

1.1. UNLOCKING PROCEDURE & SPAN SWITCH LOCATION:

NOTE: Turn Scale On Side, Do Not Turn Scale Upside DOWN!

2

Page 5

g

DC-688 USER’S TECHNICAL GUIDE

2.1. DISPLAY & KEYBOARD PANELS:

2.1.1. LOCATION OF KEYS:

(1) ON/OFF key : Turn display ON/OFF. (7) Net/Gross Key : Switch between Net and Gross

(2) Preset Keys : Recall Unit Weight data. weight display.

(3) Plus Key : Add parts in total accumulation. (8) Re-zero Key : Reset weight display to zero.

(4) Minus Key : Subtract parts in total accumulation. (9) Tare Key : Set or clear tare value.

(5) Enter Key : Clear data in total accumulation. (10) Pieces Key : Enter unit weight by sampling.

(6) Unit Weight Key : Set unit weight after numeric data entry. (11) Numeric Keys : Input Numeric data.

(12) Clear Key : Clear the entry data or unit weight.

2.1.2. LOCATION OF INDICATOR LAMPS:

! Zero Lamp : Light on when zero point is " Insufficient Lamp : Light on when sampling

adjusted and weight is stable. quantity is too small

# Net Lamp : Light on when tare $Recomputin

weight is present Recalculated by pressing PIECES key.

% Gross Lamp : Light on when Gross weight is & Memory Lamp : Light on when accumulated data is

displayed. in memory.

Lamp : Light on when Unit Weight may be

2.2. SETTING UP:

2.2.1. See Page 2 For Unlocking Procedure

2.2.2. Level Adjustment:

a. Place scale on firm and flat base.

b. Level the scale by turning adjusting legs until

air bubble is at the center of the Level Indicator.

Not Level Level

2.2.3. Place the platter onto scale:

a. Place the platter on the scale. Ensure that the platter

is properly aligned.

2.2.4. Power Supply:

a. Connect to power supply. Or install 6 pcs of “D” cell

Battery (DC1.5V)

b. With nothing placed on the platter, depress ON/OFF key.

c. Scale is ready for operation after segment checking.

3

Page 6

2.3. INDICATOR LAMPS:

LAMP “ON”

Zero When the gross weight is zero.

Tare When tare weight is set.

Gross When [Gross/Net] key is pressed.

Insuff When the net weight is below a specific percentage

of capacity weight.

Recomp When unit weight recomputing is possible.

Memory When quantity is being accumulated or when

memory overflows.

Batt When battery’s power level is low.

4

Page 7

2.4. KEY FUNCTIONS:

KEY FUNCTIONS

[0] to [9] Numeric Keys.

For turning the machine ON and OFF.

[.]

[RE-ZERO] Used to reset the scale to zero.

[TARE] Used for setting and clearing tare weight and used to exit

[C] Used to clear the key entries and unit weight.

[NET/GROSS] Used to change between Gross and Net.

[UNIT WEIGHT] Used to enter the unit weight using numeric key board.

[+]

[−−−−]

Decimal Point.

Used to enter the maintenance mode along with other keys

SPEC setting mode and save spec changes.

Used for Accumulation function and for incrementing SPEC

numbers (without changing the spec data) in SPEC setting

mode.

Used for Subtraction function and for decrementing SPEC

numbers in SPEC setting mode.

['''']

[PIECES] Used for computing unit weight by sampling.

Used for clearing accumulated quantity and for storing new

specification data when making spec changes .

5

Page 8

3.0. OPERATION MODE:

3.1. TARE SUBTRACTION:

3.1.1. One Touch Tare:

Display in the weighing mode

1. Place the container on scale.

2. Press [TARE] key to subtract the container (tare) weight.

Note () To clear tare value, press [TARE] key after removing the tare.

3.1.2. Preset (Digital) Tare:

Display in the weighing mode

1.

Enter the known weight of the container. Example: Press [ 0 ] [ •••• ] [ 2 ] [ 3 ]

2. Press [TARE ] key.

3.2. UNIT WEIGHT ENTRY:

3.2.1. Unit Weight Entry by sampling:

Display in the weighing mode

1. Place sample on scale. example. 45 pcs.

2. Enter a sample number with numerical keys. [ 4 ] [ 5 ]

3. Press [ PIECES ] key. To compute Unit weight.

When sample pieces are not sufficient, step 4 & 5 are required.

The number of pieces to be added appears in display. *(2

4. Add the required sample.

Press [ PIECES ] key. To compute Unit Weight with sufficient sample

The accuracy of the computation can be improved by increasing the sample size with the

following procedure.

5. Re-compute Unit Weight. (note *

pieces on the scale. Press [PIECES] key.

Note *1() If using a sample of 10 pcs., press [PIECES ] key without entering a number of sample

pieces.

Note *2() This procedure can be skipped by pressing [PIECES] key without adding additional parts.

However, it may affect counting accuracy to use an insufficient number of samples.

Note *3() Re-computing function is available when RECOMP lamp is on.

Note 4() A unit weight up to 4 decimal places is determined by sampling. To display the

complete unit weight, press [UNIT WEIGHT] key.

(3) Add approximately double the number of

6

Page 9

3.3.2. Digital Unit Weight Entry:

Display in the weighing mode

1. Press [ 1 ] [ •••• ] 7 ] [ 2] [ 6 ] [ 6 ] to enter Unit Weight.

2. Press [ UNIT WEIGHT ] key

Note ((((: Unit weight per 1,000 pieces should be entered and displayed in the Unit Weight display

window.

3.3.3. ASSIGN UNIT WEIGHT TO PRESET KEY:

Unit weight can be assigned to each preset key. The programmed value can be re-called in

Operation Mode

by pressing the preset key. Assign unit weights, which will be used frequently.

Display in the weighing mode

1. Enter Unit Weight by any means. (see 3.21. & 3.2.2.)

2. Press [ UNIT WEIGHT ] key. to store displayed Unit Weight.

3.

Press [ P1 ] to assign the data to Preset key. e.g. P1

3.4. Clearing Unit Weight :

Display in the weighing mode

1. Press [ 1 ] [ •••• ] 7 ] [ 2] [ 6 ] [ 6 ] to Enter Unit Weight. Example only 1.7266

2. Press [ UNIT WEIGHT ] key.

3. Press [ C ] key to Clear Unit Weight.

3.5. GROSS WEIGHT OPERATION:

Display in the weighing mode

1. Place the empty container on scale.

2. Press [TARE ] key to subtract the tare weight of the container

3. Place Sample on platter.Example: 1.00 lb.

4. Press [NET/GROSS] key to change to Gross display.

5. Press [NET/GROSS] key to return to Net weight display.

Note ((((: Counting operation is not available in Gross Weight display.

7

Page 10

3.6. COUNTING AND ACCUMULATION:

3.6.1. Single counting:

Display in the weighing mode

1. Enter the unit weight by any methods in section 3.

2. Place parts on platter, the quantity will be displayed.

3.6.2. Quantity Accumulation:

Display in the weighing mode

1. Enter the unit weight by any methods in section 3.

2. Place parts on platter, the quantity will be displayed.

3. Press [ + ] key to accumulate the data.

4. Remove the parts, the display will clear the total display.

5. Place parts on platter, the quantity will be displayed.

6. Press [ + ] key to accumulate the data.

7. Remove the parts, the display will clear the total display.

8. Place parts on platter, the quantity will be displayed.

9. Press [ −−−− ] key to subtract the data.

10. Press [ ∗∗∗∗ ] key clear total quantity.

Note((((: See spec 16 page 11, Exit From Accumulate Mode, for the method that fits the

application.

3.7. OPERATION EXAMPLE:

TASK PROCEDURE

1. Enter Tare value, Place an empty container on platter and press [TARE] key.

2. Compute Unit Weight, Place a number of pieces on platter, enter the quantity of samples

and press [PIECES] key.

3. Re-compute Unit Weight, Add a number of pieces to the samples and press [PIECES]

key.

4. Accumulate quantity, With the first quantity on platter, press [ + ] key. Remove them and

the display returns to the weighing mode. Place the second quantity on platter , press [ + ]

key and count them. Repeat the same procedure until all items have been counted. If a

mistake is made during the accumulation, press [ −−−− ] key with the over count on the scale.

5. Clear Accumulated data, Press [ ∗∗∗∗ ] key.

8

Page 11

4.0. MAINTENANCE MODE:

4.1.1. For The Customer - (1 4 1)

SPEC No. BIT 3 BIT 2 BIT 1 BIT 0

0

0 0 0 0

1

Power Auto Off function (for no key operation & weigh operation)

0000 - Auto power off disable when scale is not in use

0001 - 3 minute

0010 - 10 minutes

0011 - 30 minutes

0100 - 1 hour

0101 - 3 hours

0110 ~ 1111 - Not used

Buzz

Error Beep

Not used

Not used

0 0 0 0

2

0 - On

1 - Off

Sampling time

for Unit Weight

0 - On

1 - OFF

Negative

Counting

0

Unit Weight

Rounding

0

Not used

Calculation

0

0 - 10 times

1 1 0 0

3

0 0 0 0

Default Specs

[re-zero] [1] [4] [1] [re-zero] [1] [4] [2]

Spec 0 0 0 0 0 to 0 1 0 1 Spec 8 0 0 0 1

Spec 1 0 0 0 0 Spec 9 1 1 0 1 1 1 0 1 1 1 0 1 1 0 0 1

Spec 2 0 1 1 0 Spec 10 0 0 0 1 0 0 1 1 0 1 0 1 0 0 0 1

Spec 3 0 0 0 0 Spec 11 1 1 0 0

1 - 5 times

Not used

0

0 - NO

1 - YES

Not used

0

Capacity 6 lb. 15 lb. 30 lb. 60 lb.

Spec 12 0 0 0 0

Spec 13 0 0 0 0

Spec 14 1 0 0 0

Spec 15 0 0 1 1

Spec 16 1 1 1 0

Spec 17 0 1 0 0

Spec 18 0 0 0 1

Spec 19 0 0 0 0

0 - NO

1 - YES

Not used

Not used

0

0

9

Page 12

4.1.2. FOR WEIGHT & MEASURE - (1 4 2)

* NOTE((((: It can only work when the SPAN Switch is on (Enable)

SPEC NO. BIT 3 BIT 2 BIT 1 BIT 0

8

0 0 0 1

9

ZERO Lamp

Scale Start

"ON"

0 - Gross 0

1 - Net 0

0 - Automatic

1 - Manual

Decimal Point Position On Weight

Display

00 - No decimal point

01 - Not used

10 - 3rd digit (000.00)

11 - 4th digit (00.000)

Selection Of

Selection Of Model

Segment-Check

Style

0 - Fast

0 - DC-685

1 - DC-688

1 - Standard

Negative Weight Display Mask

00 - Minus gross > 9e

01 - Minus gross Weight

10 - Minus Net Weight

11 - Not used

10

11

1 0 0 0

12

0 0 0 0

Selection Of Capacity

B3 B2 B1 B0 Capacity Increment (Single/Multi-

Interval)

0 0 0 1

0 0 1 1

0 1 0 1

Selection Of Resolution

00 - Single Interval

01 - Multi Interval

10 - 1/7500 Or 1/6000

11 - Not Used

(6.000lb, 60.00lb)

(15.000lb)

(30.000lb)

1

2

5

Multi-Interval

Setting

0 - Net MultiInterval

1 -Gross Multi-

View Internal

Count Protected

By SPAN SW

0 - NO

1 - YES

Interval

Manual Tare

Cancellation

1 - NO

0 - YES

Tare Subtraction

1 - NO

0 - YES

Tare

Accumulation

1 - NO

0 - YES

Tare Value

Exchange

1 - NO

0 - YES

10

Page 13

4.1.3. WEIGHT & MEASURE - (1 4 2) CONTINUED

SPEC NO. BIT 3 BIT 2 BIT 1 BIT 0

13

Digital Tare

Accumulation

When Tare

Zero Tracking

When Tare

Weight Reset

When Tare

0 0 0 0

14

1 0 0 0

15

0 0 1 1

16

1 1 1 0

17

1 - NO

0 - YES

AUTO Tare Clear

When Rezero

0 - NO

1 - YES

Accumulation

Using [+] Key

1 - NO

0 - YES

Exit From

Accumulation

Mode After 15

Sec Time Out

0 - NO

1 - YES

Gross Mode

1 - NO

0 - YES

Tare AUTO Clear

0 - NO

1 - YES

Subtraction

Using [−−−−] Key

1 - NO

0 - YES

Exit From

Accumulation

Mode When

Weight Change

0 - NO

1 - YES

Tare Range

1 - NO

0 - YES

Unit Weight

AUTO Clear

0 - NO

1 - YES

Accumulation

Number Display

0 - NO

1 - YES

NO Quantity

Accumulation

Without

Removing

Weight

0 - NO

1 - YES

Not used

1 - NO

0 - YES

AUTO Clear

Condition

0 - >= Gross 21e

& >= Net 5e

1 - >=Net 1e

& Quantity > 10

WT Data

Synchronization

(+ Key only)

0 - NO

1 - YES

NO Quantity

Accumulation

Without Change

Weight

for >= +/- 10e

0 - NO

1 - YES

Not used

0 1 0 0

18

0 - YES

Not used

0

1 - NO

0 0 0 0

19

Not used

0

0 0 0 0

0 - 50% of F.S.

1 - 100% of F.S.

Not used

0

Not used

0

11

Not used

Not used

0

0

Not used

0

0

Not used

0

0

Page 14

4.2.1. Spec 141 Setting:

Spec 141 Setting: Spec 141(Customer Specifications)

can be accessed from the weighing mode.

1

Display in the weighing mode

2

Enter [1] [4] [1] while pressing the [REZERO] Key.

3

4

5

6

7

8

9

10

11

Press the

[++++] Key increases to the next SPEC number without

changing spec data.

Enter 1011 as the new value for SPEC01 using the [Numeric] Keys

as example only enter : 1011

Press the

Press the

[C] Key clears the [Numeric] Entry.

[∗∗∗∗] Key increases to the next SPEC number. and also stores

temporarily the SPEC data in the RAM location.

Press the

Press the

Press the

[−−−−] Key decreases to the previous SPEC number.

[−−−−] Key decreases from SPEC 01 to SPEC 00.

[−−−−] Key decreases the SPEC number from SPEC00 to

SPEC03

Press the

[TARE] Key stores the new SPEC values to the EEPROM

and exits from the SPEC setting mode.

Scale returns to Weighing Mode.

12

Page 15

4.2.2. SPEC 142 SETTING:

((

((

: Spec 142 Setting: To access the Spec 142 (W & M Spec) mode the [SPAN] Switch

must be "ON". The rest of the procedure is the same as Spec 141 setting.

1 Display in the weighing mode

2 Press the [SPAN] Switch. The S-On message comes on.

3 Enter [1] [4] [2] while depressing the [REZERO] Key.

4

[∗∗∗∗] Key increases to the next SPEC number and also stores temporarily the SPEC data

in the RAM location.

5

6 Press the [C] Key clears the [Numeric] Entry.

7

8

9

10

11

[1][0][1][1] as the new value for SPEC09 using the [Numeric] Keys

Enter

as example only enter : 1011

Press the [++++] Key increases to the next SPEC number without making any changes to

spec data.

Press the [−−−−] Key decreases to the previous SPEC number.

Press the [−−−−] Key decreases from SPEC 09 to SPEC 08.

Press the [−−−−] Key decreases the SPEC number from SPEC08 to SPEC19

Press the

[TARE] Key stores the new SPEC values to the EEPROM and exits

from the SPEC setting mode.

12

Scale returns to the Weighing Mode.

4.3. INTERNAL COUNT AND A/D COUNT DISPLAY :

((

((

:If the SPEC 11, bit 0 is set to 1, then the [SPAN]

Switch must be "ON" to enter this mode.

1

2

3

Display in the weighing mode

Enter [0] [0] [9] while pressing the [REZERO] Key. Unit Weight Window will

display the Internal Count and the Quantity Window will display the A/D Count.

Press [TARE] Key to exit from Internal Count Mode.

13

Page 16

4.4. SCALE CALIBRATION :

Prior to the calibration of the scale, please note that the SPEC settings

corresponding to Minimum Display, Weight Decimal Point Position for

that particular scale have to be correctly set. Ensure

is ON.

1 Display in the weighing mode

1

Press the [SPAN] Switch which is located at the bottom of the machine.

See page 2 for details.

2

Enter [8] [7] [1] [5] while depressing the [REZERO] Key. The

display will show CAL00

3

Press the [∗∗∗∗] Key in order to compute the zero point. It takes a

few seconds for the zero calibration.

5

7.1.

After computing the zero point, the Weight Window shows CALSP

Place capacity weight of 60 lb on the platter. In this illustration,

capacity weight of 60 lb is taken as an example.

--- OR ---

OR

that the [SPAN] Switch

7.2.

Using less than capacity weight .Enter the weight placed on the

platter using the [Numeric] Keys. Example: enter [5][0][••

8

Press the [∗∗∗∗] Key to start span calibration.

14

••

][0][0]

Page 17

4.5. MAINTENANCE, CALIBRATION, TEST PROCEDURE & SERVICE

This section contains information and instructions concerning maintenance of the DC-688 Counting

Scale. Preventive maintenance consists of periodically cleaning the external surfaces of the

instrument and should be performed as often as operating conditions warrant. The calibration

procedure is designed to be an aid in maintaining the scale accuracy within specifications. The

calibration procedure may also serve as a performance test procedure.

CAUTION: DO NOT ATTEMPT ANY SERVICE WHILE THE

INSTRUMENT IS CONNECTED TO THE POWER LINES.

4.5.1. MAINTENANCE PROCEDURES

4.5.1.1. EXTERIOR MAINTENANCE

The exterior surfaces of the counting scale can be easily cleaned using soap and water. However,

extreme caution should be used so that there is no possibility of water penetration into the scale

electrical or mechanical sections. A damp cloth or sponge is suggested. NEVER USE ACETONE,

MEK, OR SIMILAR SOLVENTS ON THE PLASTIC HOUSING AS THEY WILL ETCH THESE

SURFACES. For grease or other difficult spots, a chlorothane or naptha based cleaner may be used.

Never use any solvents on the front or rear panels. Accumulations of dust or direct particles between

the pins of the connectors may be removed by using dry forced air or a small dry brush.

4.5.1.2. INTERNAL MAINTENANCE

Internal maintenance is not normally required and if it is, should not be attempted except by a

qualified, authorized

service technician.

4.5.2. CALIBRATION

The following procedure should be followed periodically (every six to twelve months is suggested) to

determine that the scale is functioning in all modes.

a. Electrical

Follow section 4.0 through all its steps

b. ACCURACY

Weighing: The scale weighing accuracy can be determined by applying various known

weights to the platform. Because of the scale's very high accuracy, only weights that are

certifiably more accurate than the scale's specifications should be used in testing for accuracy.

(NBS class "F" or higher) Since the scale owner does not normally have such certifiable

weights available to him, it is suggested that the customer call their authorized DIGI dealer.

4.5.3. SERVICE & REPAIR

No service or repair should be attempted except by qualified personnel, and not until it has

been positively determined that the counting scale requires such service. All service should be

done in a clean, dry, dust-proof area.

15

Page 18

5.0. QUICK GUIDE

OPERATION PROCEDURE

Tare out an empty container Place an empty container on the scale, press [TARE] key

Enter a known tare Enter the tare weight as it would appear in the window,

press [TARE] key.

Change to gross weight display

Change back to net wt.

Compute a unit weight Place 10 pieces on scale, press [PIECES] key

Re-compute a unit weight (only as long

as the RECOMP light is on after pcs. are

added)

Enter a known unit weight Enter the weight /1000 pcs, press

Accumulate a quantity

(temporary memory)

Press [NET/GROSS] key

Press [NET/GROSS] key again

or

Place an arbitrary number of pieces on the scale, enter

the number of pieces and press the [PIECES] key.

Add a number of pieces to the sample and press the

[PIECES] key.

[UNIT WEIGHT] key.

With first quantity on the scale, press [++++] key. When

display returns to normal, remove parts from the scale

and count second quantity. Repeat until all items have

been counted. Press [∗∗∗∗] key to end accumulation. (((( If a

mistake is made during accumulation, press [−−

−−]]]]

key to

Clear a unit weight in the display Press [CLEAR] key.

Clear a tare weight in the display Press [TARE] key.

delete that quantity.

or

Enter [0], then press the [UNIT WEIGHT] key.

or

Press the [REZERO] key. ((((1 (See note 1 below.)

16

Page 19

5.1. OPERATION

QUICK GUIDE DC-688

Sample & Count

A.

Sampling Procedure (To develop the Unit Weight with Negative Counting)

1. Press [REZERO] & [TARE] keys to set up the procedure.

2. Press [CLEAR] key to clear unit weight.

3. Place full container onto scale platform; press [TARE] key.

(The weight display will zero)

4. Remove 10 piece sample from container; press [PIECES] key.

The unit weight will be computed, and shown in the unit

weight window.

5. For increased sampling accuracy, you can re-compute unit weight by

removing additional pieces (about 10-20 at a time)

from the container. If the “RECOMP” indicator is “on”, then pressing

[PIECES] key will recalculate the unit weight. It is not necessary to

hand count the additional pieces. (You may re-compute again and

again if the parts are not very uniform. )

6. Place the sample pieces back into the container.

B. Counting Procedure ( To count the in parts the full container)

7. Key in the known tare weight. Press the [TARE] key.

The net weight of the container will be displayed, and the total

Quantity in the container will be shown in the quantity window.

17

Page 20

DC-688 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed

by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects

in materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications

authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If

any equipment fails to conform to these warranties, RLWS will, at its option, repair or replace such goods

returned within the warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a detailed explanation

of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent electrostatic

discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, “Protecting Your Components

From Static Damage in Shipment,” available from RLWS Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair or improper testing; RLWS shall be the sole

judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping charges

both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT,

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER

IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS

WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any legal effect unless

made in writing and signed by a corporate officer of RLWS and the Buyer.

© 2002 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

• 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Loading...

Loading...