Page 1

DC-530

Counting Scale

Counting Scale

Operation Manual

Version 2.01

95145

Page 2

Page 3

Contents

1.0 Introduction.................................................................................................................................. 1

1.1 Capacities and Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Keyboard and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.3 Display Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.4 Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Installation ................................................................................................................................... 6

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Powering Up the DC-530 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 AC Power Cord and On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 Start-Up Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Scale Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 Configuration Settings ............................................................................................................... 10

3.1 Configuring Customer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Configuring Weight and Measurement Specifications (Dealer/Technician Maintenance) . . . . . . . . . . 13

4.0 Calibration ................................................................................................................................. 20

5.0 Scale Operations........................................................................................................................ 22

5.1 Factors Affecting Counting Scale Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Teraoka Error Prediction (TEP) Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 The Mode Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Tare Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.1 One-Touch Tare, Tare Unknown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.2 Digital Tare, Tare Weight Known . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4.3 Tare Value Accumulation and Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4.4 Tare Accumulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.5 Tare Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Operations in Normal Counting Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.1 Normal Counting Mode - Unit Weight Operation by Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.2 Normal Counting Mode - Unit Weight Operation by Key Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5.3 Normal Counting Mode - Part Accumulation and Part Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.5 Normal Counting Mode - Part Subtraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5.6 Normal Counting Mode - Negative Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5.7 Counting Out of a Full Container - See Total Amount Remaining in the Container . . . . . . . . . . . . . . . . 30

5.5.8 Negative Counting - Total Removed Displayed at the End. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5.9 Normal Counting Mode - Clearing Accumulated Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.6 Operations in TEP (Teraoka Error Prediction) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.6.1 TEP Mode - Unit Weight Operation by Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.6.2 TEP Mode - Unit Weight Operation by Key Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.6.3 TEP Mode - Parts Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.6.4 TEP Mode - Part Accumulation and Part Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.6.5 TEP Mode - Negative Counting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.6.6 TEP Mode - Clearing Accumulated Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.7 Toggle Between Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.8 Recalling Item Codes in Counting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Page 4

5.9 Sample, Count and Print a Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.10 Scan ID Bar Code, Count and Print a Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.0 Scale Programming................................................................................................................... 37

6.1 Programming a New Item Code (Item Registration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Updating the Record of an Existing Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.1 Update the Unit Weight of an Existing Item From the Counting Mode . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.2 Update the Tare Weight of an Existing Item From the Counting Mode. . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.3 Update an Existing Item From the Programming Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.3 Deleting Item Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.1 Clearing an Individual Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.2 Deleting a Single Item Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.3 Deleting All Item Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4 Setting a General Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.0 External Devices: Printers, PCs, Scanners and Scales ............................................................ 46

7.1 Printer Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1.1 Zebra LP2824. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.1.2 Epson TM-U220 Tape Printer or Epson TM-U295 Ticket Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2 Printer Label Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.1 No Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.2 ZEBRA LP2844 Barcode Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.3 Epson TM-U220 Tape Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2.4 Epson TM-U295 Ticket Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Connecting to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.1 Setting the Scale Specifications for Communication to a PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.2 Communication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.4 Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.5 Output Data Formats With Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.6 Output Data Formats Without Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4 Setpoint Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.5 Bar Code Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.6 Remote Scale Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.1 Setting the Specifications for Scale 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.6.2 Remote Platforms Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.0 Appendices ................................................................................................................................ 55

8.1 Error Message List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.0 DC-530 Limited Warranty........................................................................................................... 58

2

Page 5

About This Manual

This manual contains operating procedures for the DC-530 counting scale and provides the user with all the

information necessary for its setup and operation. It is organized based on the procedures you will likely follow

when setting up and using your counting scale. This manual applies to Version 2.01 of the DC-530 counting scale

series.

Some procedures described in this manual require work inside the scale base. These procedures are to

#AUTION

be performed by qualified service personnel only.

Authorized distributors and their employees can view or download this manual from the

DIGI distributor site at www.ricelake.com.

1.0 Introduction

The DC-530 is high-precision counting scale that offers practical solutions for a full range of counting

applications. With an internal counting resolution of 1/1,000,000, the UniBloc one-piece force cell design

provides quick response, stability against temperature change, and outstanding durability on top of maximum

counting precision and accuracy. Its high-visibility full dot color LCD display enables operators to easily see

weights and quantities. Counting and weighing operations are greatly speeded by the DC-530’s ability to store

and recall the item code, tare weight, unit weight, and three setpoint values for 200 of your pieces, parts, or items.

The RS-232 ports allow you to connect to a printer, PC, or barcode scanner, while the optional remote scale

channel lets you add another weighing platform.

The DC-530 Counting Scale includes the DIGI TEP (Teraoka Error Prediction) Function which detects weight

variances in sample quantities and calculates the maximum quantity of that piece that can be counted without

introducing error. To make the operator’s job easier, the scale’s display will change from green to yellow or red

when the maximum safe quantity has been exceeded. This function works by performing a series of sampling

operations which the scale uses to plot the weight variances of the pieces being weighed. By then accumulating

counting results within the calculated safe quantity, the counting operation can be completed without a counting

error.

1.1 Capacities and Resolutions

Table 1-1 lists the scale capacities, minimum graduations, and tare ranges for all models of the DC-530 counting

scales. The internal count span and display resolution can be set by the user in the weight and measurement

specifications (See Section 3.X). Weight units can also be set between lb and kg using the scale’s weight and

measurement specifications.

DC-530 Single Scale

DC-530 Capacity Minimum Graduation Platter Size

10 lb 0.0001 lb 13” x 9.3”

20 lb 0.0002 lb 13” x 9.3”

Table 1-1. DC-530 Capacities, Minimum Graduations and Platter Sizes

Introduction 1

Page 6

1.2 Modes of Operation

The DC-530 has four modes of operation that are accessed from the MODE key:

• Counting Mode – where all weighing, counting and printing operations take place.

• Program Mode – where item data can be programmed into the memory of the scale and edited.

• Date & Time - where you can set the date and time used in printing on labels and reports.

• Set Point Setting - where you can program general set points.

1.3 Keyboard and Display

Figure 1-1 shows the DC-530 console with its indicator lamps, the main function keys and the numeric keypad.

Indicator lamps are described in Section 1.3.2. Section 1.3.3 shows the two main counting displays (Normal and

TEP); while Section 1.3.4 describes the DC-530 keys and keypad.

Figure 1-1. DC-530 Display

1.3.1 Display Specifications

Weight display 6 digits

Unit Weight display 5 digits

Quantity display 7 digits

Table 1-2. DC-530 Display Specifications

1.3.2 Indicator Lamps

Table 1-3 shows a list of the indicator lamps that the DC-530 uses to provide additional information about the

value being displayed. The indicator lamps are illuminated when the specific function is being performed.

Indicator Lamp Function or Meaning

Zero

STABLE

NET

INSUFF

ACC

RECOM

On when the gross weight is at zero and is stable

On when the weight on the platter is stable.

On when the display shows net weight (when a tare weight is entered or recalled)

On when the net weight is below the specified percentage of scale capacity

Indicates that an accumulated quantity is stored in memory.

On when unit weight recomputing is possible

Table 1-3. DC-530 Indicator Lamps and Function

2 DC-530 Operation Manual

Page 7

1.3.3 Display Elements

The DC-530’s display shows different elements depending on whether it is in “Normal Counting Mode” or “TEP

(Teraoka Error Prediction) Counting Mode”.

Figure 1-2. Normal Counting Mode Display Elements

Figure 1-3. TEP Counting Mode Display Elements

Introduction 3

Page 8

1.3.4 Key Functions

The DC-530 features many functions for managing item information and scale operation. Table 1-4 lists the keys

and key functions of the DC-530 keyboard and keypad.

Some keys have different functions depending on what mode or function you are in.

Key Description

ON/OFF - Turns the scale display on or off.

REZERO key - Used to reset the weight display to zero.

SCALE key - Used to select between Scale 1 and Scale 2 if an external scale is connected.

TEP key - Used to toggle between “Normal Counting Mode” and “Teraoka Error

Prediction (TEP) Counting Mode”.

+ (Plus) key -

Counting Mode - Used to accumulate quantity data. Also prompts printing of a label if an

external printer is connected.

Program Mode - Used to navigate to the next editable data in all modes except Normal and

TEP counting modes.

- (Minus) key -

Counting Mode - Used to subtract a quantity during accumulation.

Program Mode - Used to navigate to the previous editable data in all modes except Normal

and TEP counting modes.

* PRINT key -

Counting Mode - Used to output data to print a label when an external printer is connected.

Used to show and then clear accumulated TOTAL data when doing

accumulation.

Program Mode - Used to save changes in data in all mode operations except Normal and

TEP Counting modes.

MODE key - Used to access the MODE menu for Program Mode, Date & Time Setting,

and Set Point Setting.

to

Numeric keys - Used to enter numeric values. When using the scale, first enter a numeric

DECIMAL key - Used to set the decimal point.

PCS key - Used for computing Unit Weight by sampling.

TARE key -

Counting Mode - Used to set or clear the tare value.

Program Mode - Used to store SPEC changes and escape to the Weighing Mode when

Maintenance Mode - Used to escape to the Weighing Mode from the Maintenance Mode.

4 DC-530 Operation Manual

value, then press the appropriate function key.

programming specifications.

Table 1-4. DC-530 Key Functions

Page 9

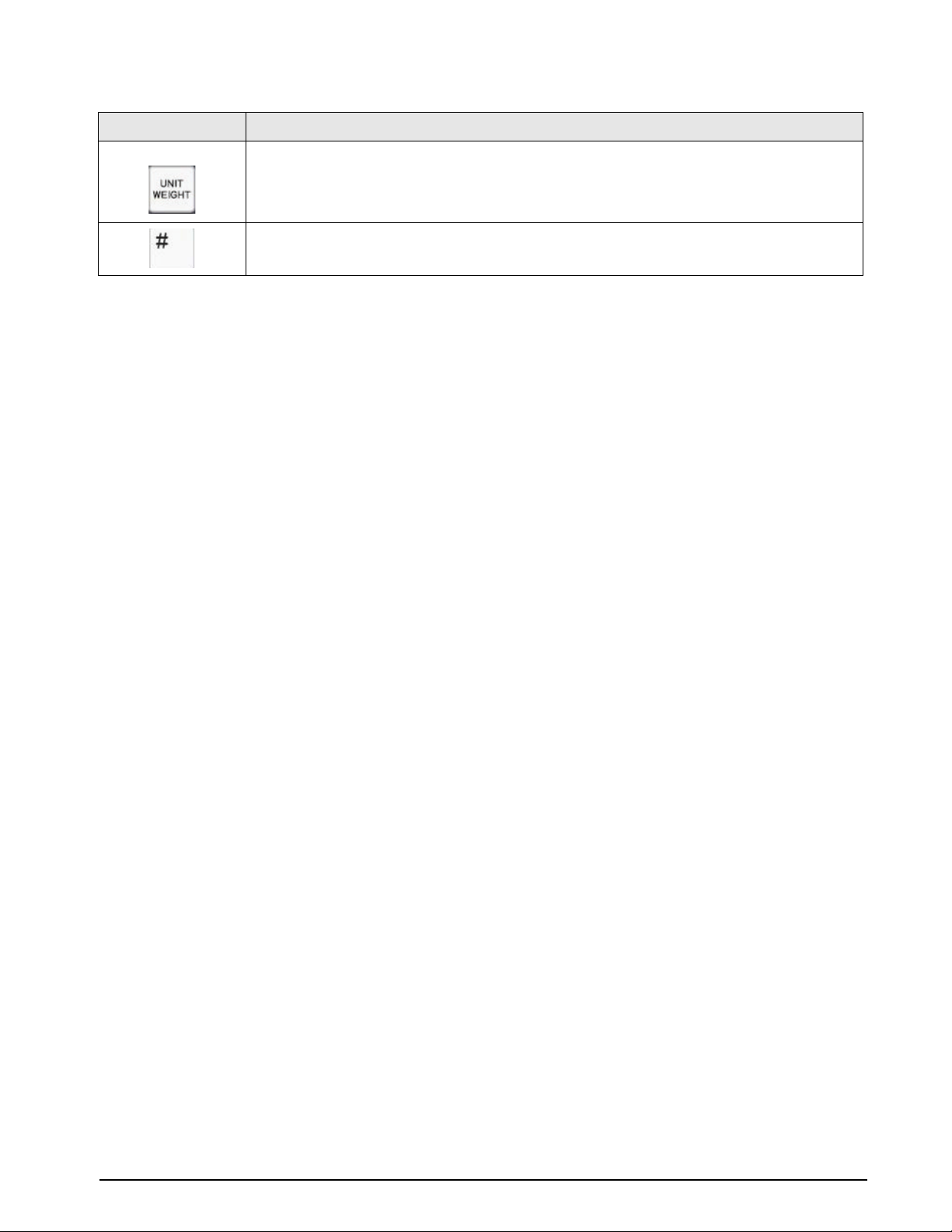

Key Description

UNIT WEIGHT key -

Counting Mode - Used to set the Unit Weight.

Program Mode - Used to register an item code being entered into memory.

POUND key- Used to call up or recal an item code from memory.

Table 1-4. DC-530 Key Functions

Introduction 5

Page 10

2.0 Installation

This section describes the procedure for the installation and setup of the DC-530 counting scale.

2.1 Unpacking

Do not turn scale upside down. Always work with scale on its side! Damage to the load cell can occur if

#AUTION

1. Immediately after unpacking, visually inspect the DC-530 counting scale to ensure all components are

included and undamaged. If any were damaged in shipment, notify Rice Lake Weighing Systems and the

shipper immediately.

2. The DC-530 counting scale is carefully packed for protection during shipping. After opening the box,

remove all the components. Check the insides of the box carefully to make sure you have all of the

pieces. The package should include the following:

• DC-530 counting scale

• Platter support

• 4 rubber caps

• 4 screws for platter support

• Stainless steel platter

• AC power cord

• Operation Manual

• Warranty card

the scale is turned upside down.

3. Remove the bag protecting the scale and the protective film covering the front panel and platter.

4. Put the 4 supplied rubber caps on the ends of the platter support.

5. Set the platter support on the scale, lining up the screw holes on the support with the corresponding holes

on the scale. Use the 4 screws supplied to fix the platter support to the scale, taking care not to put strong

pressure down on the platter support while screwing it down to avoid damage to the force balance.

6. Seat the stainless steel platter on the platter supports, making sure that the rubber caps are completely

seated in the corners of the platter.

7. Connect the AC power cord to the plug on the bottom right-hand side of the scale.

8. Store the DC-530 scale box for possible future use.

2.2 Repacking

If the DC-530 counting scale must be returned for modification, calibration or repair, it must be properly packed

with sufficient cushioning materials. Whenever possible, use the original carton when shipping the DC-530.

Damage caused by improper packaging is not covered by the warranty.

6 DC-530 Operation Manual

Page 11

2.3 Setting Up

Place the scale on a solid, level surface away from fans, breezes, and sources of electrical interference or

magnetic fields. The installation location should also be free from high humidity, direct sunlight, or excessive

dust. The operating temperature is 0 - 40º C.

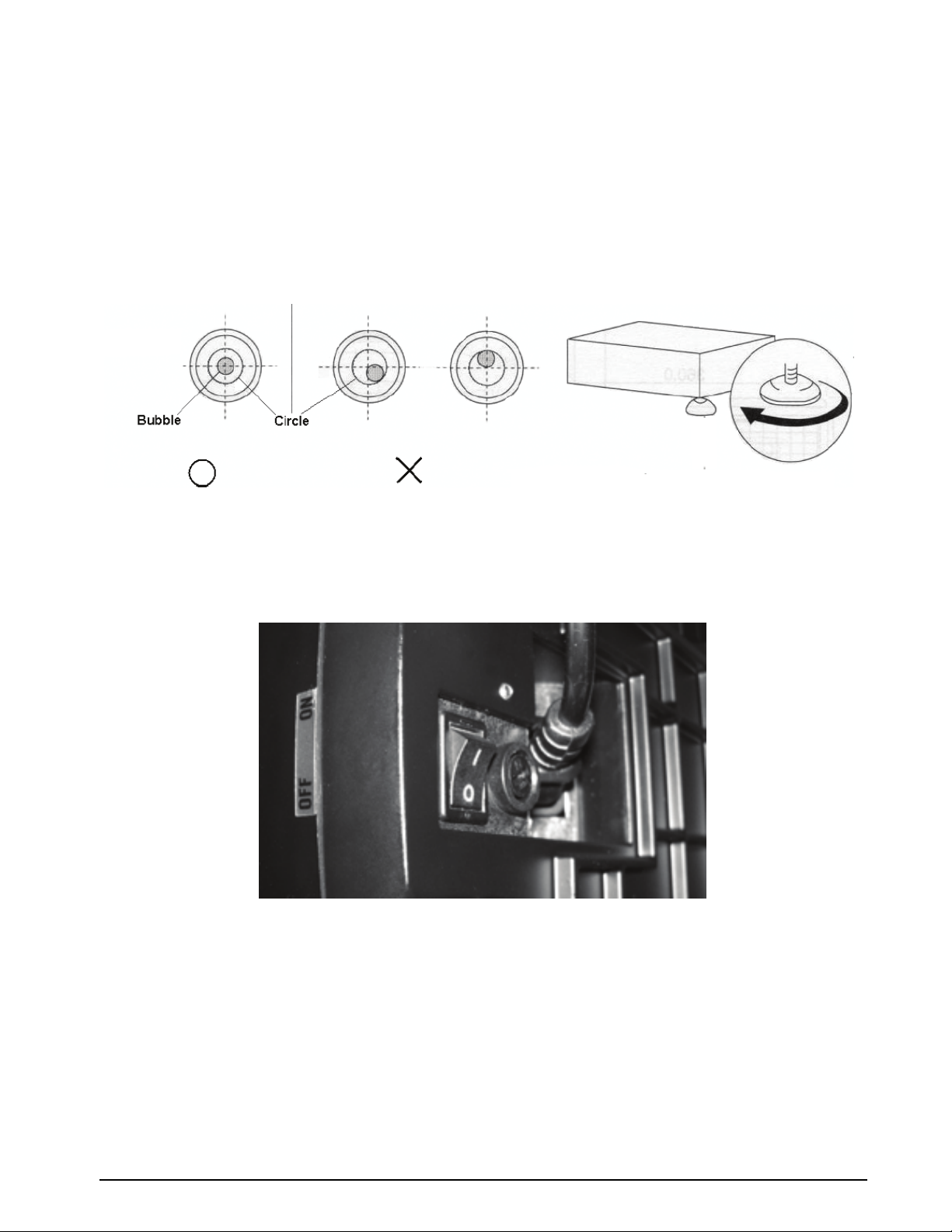

Level the scale by turning the four adjustable legs located on the bottom of the scale while referencing the bubble

level located on the front of the scale (see

NOTE: To ensure a higher degree of scale stability, turn all four adjustable legs al the way in before leveling. Turn the adjustable

legs out to level as needed.

Figure 2-1).

Figure 2-1. Leveling Bubble

2.4 Powering Up the DC-530

2.4.1 AC Power Cord and On/Off Switch

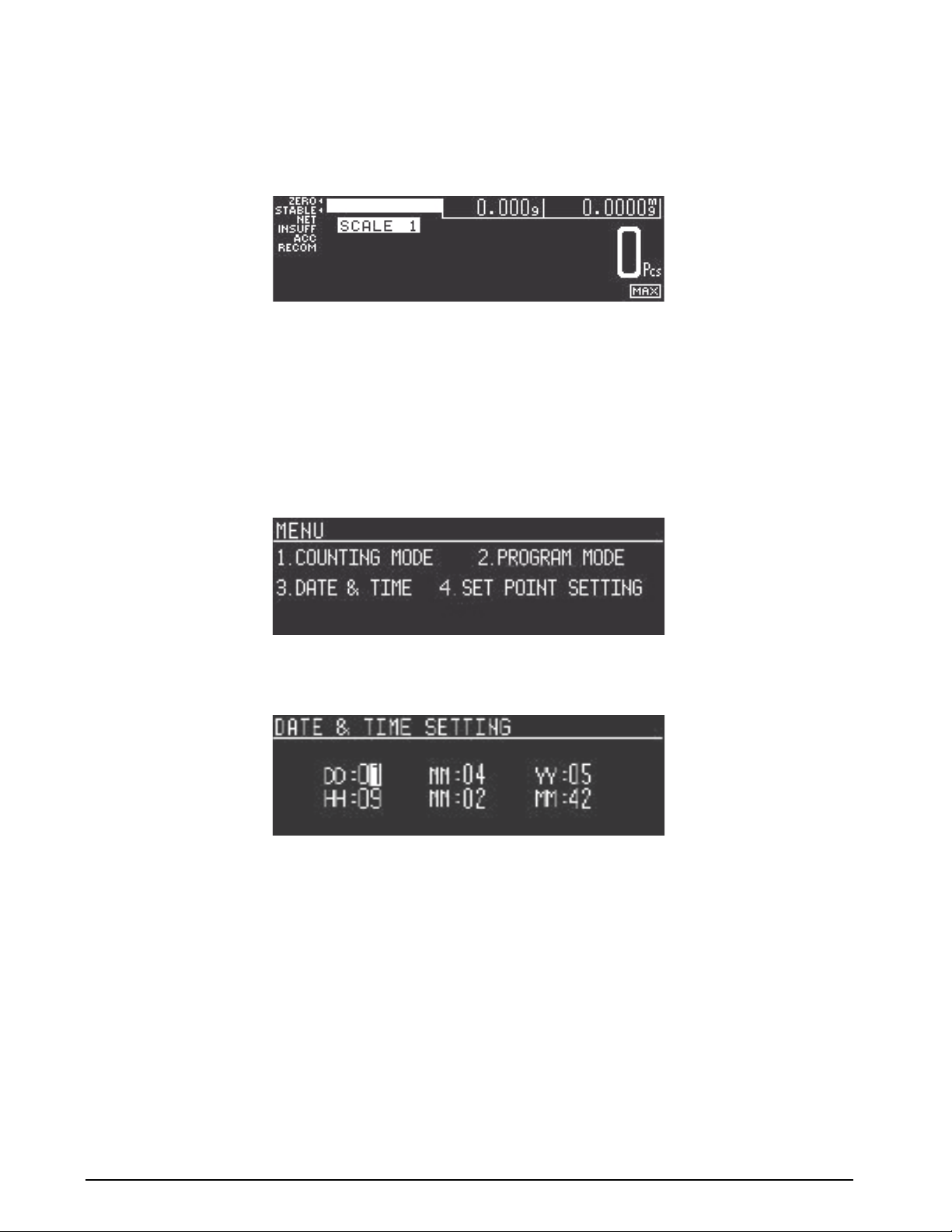

1. Connect the AC power cord under the scale base as shown in Figure 2-2.

Figure 2-2. AC Plug-in and ON/OFF Switch Location on Underside of DC-530

2. Plug the AC power cord into a grounded 115 VAC receptacle and switch the ON/OFF rocker switch on

the bottom right-hand side of the scale to the “On” position.

3. Press the ON/OFF key located on the front of the scale. This key turns the scale display on and off. To

turn AC power to the scale on and off, use the

ON/OFF rocker switch.

Installation 7

Page 12

2.4.2 Start-Up Screens

1. When powering up, the DC-530 will display the model number and firmware version.

2. Next, the scale tests the color modes of the display and says SEARCHING SCALE before bringing you to the

Normal Counting Mode screen

.

3. If there is anything on the platform(s) and it exceeds the scale start range, the display will show the error

message Out of start range. If this error appears, remove the weight from the platform and the scale

will continue its startup sequence.

2.5 Setting the Date and Time

Once the date and time have been set, the internal clock will be maintained by the main board battery even when

the DC-530 is not plugged in or turned off. The procedure below can also be used to adjust the time when

moving from Standard to Daylight Savings Time or when the scale is moved to a new facility in a different time

zone.

1. Press the MODE key until the display shows the Menu Screen.

2. Press the 3 key to enter the Date and Time Setting Screen.

(NOTE: The order in which the day/month/year fields appear on the screen may vary depending on how you scale is

programmed.).

3. Use the numeric keypad to enter the current date (2 digit format). Then press the + (Plus) key to move to

the setting of the month.

4. Use the numeric keypad to enter the current month (in 2 digit format). Continue forward to the other

fields by pressing the + (Plus) key. To move backwards to a modify a previous field, press the [-]

(minus)

key. To move to the next field without making any change, simply press the + (Plus) key

without entering data.

5. When all the date and time fields have been entered, press the * PRINT key to save the date and time

setting. To exit without saving the changes, press the TAR E key to return to the Mode Menu screen.

6. Press the [1] key to exit the menu and return to the Counting Mode Screen.

8 DC-530 Operation Manual

Page 13

2.6 Replacement Parts

The following table lists the part numbers and descriptions of replacement parts available for the DC-530

Counting Scale.

RLWS Part Number Description

97002 Platter

97003 Platter Support (without rubber stops)

97004 Rubber Stops for Platter Support (97003)

97005 Overlay

97006 Overlay Lens

97007 Display Board

97008 Loadcell Block, 10 lb

97009 Loadcell Block, 20 lb

97010 A/D Assembly

97011 Power Supply

97012 Main CPU Board

15438 Power Cord

Table 2-1. DC-530 Replacement Parts

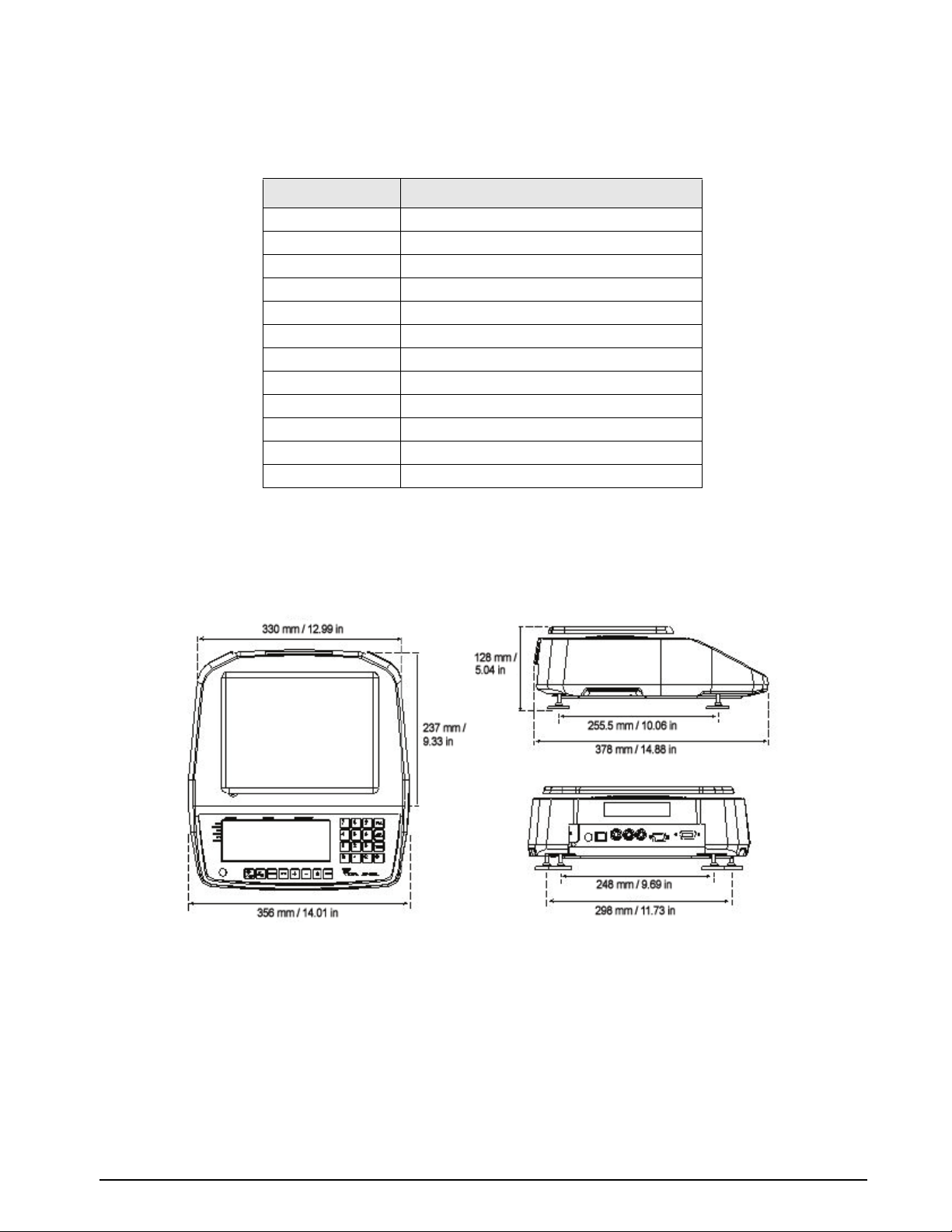

2.7 Scale Dimensions

The following diagram illustrates the external dimensions of the DC-530 Counting Scale.

Installation 9

Page 14

3.0 Configuration Settings

This section presents the setup and configuration of the DC-530 Counting Scale to be used specifically by

distributors and service technicians. Configuring these specifications allow you to tailor the DC-530 to your

specific applications.

Setting the specifications allows you to modify the functionality of the DC-530. Use the tables in this section to

view the options you can modify. For example, if you want to deactivate the DC-530’s ability to enter Tare

weights digitally, refer to the specification table and locate SPEC 35, Bit 2. The default for SPEC 35 is 1, which

means it is enabled. To turn it off or disable it, change the SPEC setting to 0: No.

The following tables list the DC-530 specifications and their corresponding default values. The default values are

automatically set when the scale’s memory is initally set by the dealer.

SPEC 00 through SPEC 12, and SPEC 51 through SPEC 55 (Table 3-1) are Customer Specifications while SPEC

20 through SPEC 49 (Tab le 3-2) are Weight and Measurement specifications. In programming specifications, the

+ (Plus) and – (minus) keys allow you to move to the next or previous specification while saving changes to the

SPEC code you were just in. To exit from a specification without saving your changes, press the TARE key. To

save the changes when exiting, press the

3.1 Configuring Customer Specifications

1. To configure customer specifications, press the MODE key to enter the Menu Screen.

* PRINT key.

2. In the Mode Menu Screeen, hold down the REZERO key while entering 141 from the numeric keypad.

The first SPEC code,

3. Press the + (Plus) key until the specification you want to modify is displayed. (You can use the (Minus) key to move backwards through the list.)

4. Enter the new value for the specification. You must enter values for all four bits of this specification

even if you are only changing one of the bits, so your entry must be 4 digits long. Your new entry will be

displayed in the

5. Once you have entered your change, you have the following options:

• press the + (Plus) key to temporarily store the change and move to the next specification, then press

* PRINT key to permanently record the change and leave the SPEC setting mode.

the

• Press the TARE key to exit without saving the change.

SPEC 00 is displayed along with its OLD SETTING meaning its current setting.

NEW SETTING field.

10 DC-530 Operation Manual

Page 15

6. To change another SPEC code before exiting, repeat Steps 3 and 4.

If you power off the scale while the saving process in going on, you can clear the entire memory of the

scale! Wait until the scale has returned to the Menu Screen before performing any other functions.

#AUTION

7. After returning to the Normal Weighing Mode, power the scale down completely by using the ON/OFF

rocker switch on the bottom of the scale to complete the registering of the changes.

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

00

01 Set Point Operation

00: No Operation [DEFAULT]

01: Common Setpoint

10: Item Setpoint

11: Not Used

02 Buzzer Output Type

Setpoint Selection

Setpoint Buzzer Output

LAN

[not currently used - for

future expansion]

0: Disable [DEFAULT]

1: Enable

Setpoint Range

03

RS232B for

Printer

04

RS232A for

Scanner

05

RS232C for PC

06

RS232C Output

07

RS232C1 Force

Balance

08

RS232C1 Force

Balance

0: Proper [DEFAULT]

1: Scare/Over

Printer Model

00: No Connection [DEFAULT]

01:DIGI TVP1000/ Zebra LP2824

10: EPSON CTM290/TM-U295/TM-U220

11: FL-2

Output Protocol

00: No Output

01: Continuous (this affects the printer output)

10: Manual [by key press] Key [DEFAULT]

11: Not Used

Baud Rate

000: 19200

001: 9600

010: 4800 [DEFAULT]

011: 2400

100: 1200

Parity

00: Even [DEFAULT]

01: Odd

10: None

11: None

0: Pieces [DEFAULT]

1: Weight

Connection Type

00: No Connection [DEFAULT]

01: Barcode Scanner

Connection Type

00: No Connection [DEFAULT]

01: PC

0: No

1: Yes [DEFAULT]

Header Type

NOTE: The header type SPEC only affects output

to a PC, not communication to a printer.

00: No Header

01: Code [DEFAULT]

10: Title

11: Not Used

Stop Bit

0: 1 [DEFAULT]

1: 2

0: Negative

1: Positive [DEFAULT]

Data Length

0: 7 [DEFAULT]

1: 8

Table 3-1. DC-530 Customer Specifications

Configuration Settings 11

Page 16

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

09

RS232C2

10

RS232C2

11

RS232C3

12

RS232C3

13 - 19 not currently in use

51 Insufficient Range for Load Cell

Baud Rate

000: 19200

001: 9600 [DEFAULT]

010: 4800

011: 2400

100: 1200

Parity Bit

00: Even

01: Odd

10: None [DEFAULT]

11: None

Baud Rate

000: 19200

001: 9600 [DEFAULT]

010: 4800

011: 2400

100: 1200

Parity Bit

00: Even

01: Odd

10: None [DEFAULT]

11: None

Stop Bit

0: 1 [DEFAULT]

1: 2

Stop Bit

0: 1 [DEFAULT]

1: 2

Insufficient Sample

Data Length

0: 7

1: 8 [DEFAULT]

Data Length

0: 7

1: 8 [DEFAULT]

Insufficient Range for

Force Balance

00: 0.1% of Full Scale [DEFAULT]

01: 0.2% of Full Scale

10: None

11: None

52 Unit Weight Sampling

Times

0: 5 times [DEFAULT]

1: 10 times

53 Gross Weight Output

0: Display [DEFAULT]

1: Internal

54 Wait for Stable Weight

During Unit Weight

Calculating

0: No [DEFAULT]

1: Yes

Table 3-1. DC-530 Customer Specifications

Change Scale When

Weight Stable

0: No [DEFAULT]

1: Yes

Normal Counting Mode

Auto Re-Computing

0: Manual

1: Automatic [DEFAULT]

Work Filter Function

0: No

1: Yes [DEFAULT]

0: Disable

1: Enable [DEFAULT]

Negative Counting

0: No

1: Yes [DEFAULT]

Exit the Total Mode

0: Manual

1: Automatic [DEFAULT]

Uni Bloc Average Sample (filter function)

00: 16 samples

01: 32 samples

10: 64 samples [DEFAULT]

11: 128 samples

0: 0.01% of Full Scale

[DEFAULT]

1: 0.1% of Full Scale

Sampling Times

0: 5 times

1: 10 times [DEFAULT]

TEP Sampling Method

0: Manual

1: Automatic [DEFAULT]

12 DC-530 Operation Manual

Page 17

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

55 Scan Quantity Type

Buzzer at Error

(activates the buzzer

when an operational

error is performed)

USA Pharmacy

Download Print Format

When Power On

0: Item Quantity

[DEFAULT]

1: Accumulate Quantity

56 - 59 not currently in use

0: Open [DEFAULT]

1: Close

0: Disable [DEFAULT]

1: Enable

NOTE: This SPEC must

be enabled for use in

pharmaceutical

applications. When this

SPEC is enabled, if the

Unit Weight is less than

3d or the sample size is

less than 10 the error

message “UNIT WEIGHT

BELOW LIGHT RANGE,

PLEASE RESAMPLE”

will appear.

0: No

1: Yes

Table 3-1. DC-530 Customer Specifications

3.2 Configuring Weight and Measurement Specifications (Dealer/Technician Maintenance)

1. To configure customer specifications, press the MODE key to enter the Menu Screen.

2. In the Mode Menu Screeen, hold down the REZERO key while entering 142 from the numeric keypad.

The first SPEC code, SPEC 20 is displayed along with its OLD SETTING meaning its current setting.

3. Press the + (Plus) key until the specification you want to modify is displayed. (You can use the -

(Minus)

key to move backwards through the list.)

4. Enter the new value for the specification. You must enter values for all four bits of this specification

even if you are only changing one of the bits, so your entry must be 4 digits long. Your new entry will be

Configuration Settings 13

Page 18

displayed in the NEW SETTING field.

5. Once you have entered your change, you have the following options:

• press the + (Plus) key to temporarily store the change and move to the next specification, then press

the * PRINT key to permanently record the change and store it and leave the SPEC setting mode.

• Press the TARE key to exit without saving the change.

6. To change another SPEC code before exiting, repeat Steps 3 and 4.

If you power off the scale while the saving process in going on, you can clear the entire memory of the

scale! Wait until the scale has returned to the Menu Screen before performing any other functions.

#AUTION

7. After returning to the Normal Weighing Mode, power the scale down completely by using the ON/OFF

rocker switch on the bottom of the scale to complete the registering of the changes.

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

20 Minimum Display (Uni Bloc)

00: 1 [DEFAULT]

01: 2

10: 5

11: 10

Display Resolution (Uni Bloc)

(when internal count span is 500,000)

00: 1/10,000

01: 1/5,000 [DEFAULT]

10: 1/2,500

11: 1/12,500

(when internal count span is 1,000,000)

00: 1/100,000

01: 1/50,000 [DEFAULT]

10: 1/25,000

11: 1/20,000

21 Internal Count Span (Uni

Bloc)

0: 500,000

1: 1,000,000 [DEFAULT]

22 not currently in use

Weight Decimal Point Position (Uni Bloc)

(when internal count span is 500,000)

000: 00000

001: 0000.0 [DEFAULT]

010: 000.00

011: 00.000

100: 0.0000

Weight Decimal Point Position (Uni Bloc)

(when internal count span is 1,000,000)

000: 000000

001: 00000.0 [DEFAULT]

010: 0000.00

011: 000.000

100: 00.0000

101: 0.00000

Table 3-2. DC-530 Weight and Measurement Specifications

14 DC-530 Operation Manual

Page 19

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

23 Minimum Display (Load Cell 1)

00: 1

01: 2

10: 5

11: 10

24 Internal Count Span

(Load Cell 1)

Weight Decimal Point Position (Load Cell 1)

(when internal count span is 500,000)

Display Resolution (Load Cell 1)

(when internal count span is 500,000)

00: 1/10,000

01: 1/5,000 [DEFAULT]

10: 1/2,500

11: 1/12,500

(when internal count span is 1,000,000)

00: 1/100,000

01: 1/50,000 [DEFAULT]

10: 1/25,000

0: 500,000 [DEFAULT]

1: 1,000,000

25 Weight Stable Condition for Load Cell 1 - waiting time 0.5 seconds to 10 seconds

0000: 0.5 seconds 1000: 4.5 seconds

0001: 1.0 seconds 1101: 5.0 seconds

0010: 1.5 seconds 1010: 5.5 seconds

0011: 2.0 seconds [DEFAULT] 1011: 6.0 seconds

0100: 2.5 seconds 1100: 7.0 seconds

0101: 3.0 seconds 1101: 8.0 seconds

0110: 3.5 seconds 1110: 9.0 seconds

0111: 4.0 seconds 1111: 10.0 seconds

26 Weight Stable Condition for Load Cell 1 - Limit No Check to ± 10.0d

000: 00000

001: 0000.0 [DEFAULT]

010: 000.00

011: 00.000

100: 0.0000

Weight Decimal Point Position (Load Cell 1)

(when internal count span is 1,000,000)

000: 000000

001: 00000.0 [DEFAULT]

010: 0000.00

011: 000.000

100: 00.0000

101: 0.00000

0000: No Check 1000: ± 5.0d

0001: ± 0.1d 1001: ± 10.0d

0010: ± 0.2d

0011: ± 0.3d

0100: ± 0.4d

0101: ± 0.5d [DEFAULT]

0110: ± 1.0d

0111: ± 2.0d

Table 3-2. DC-530 Weight and Measurement Specifications

Configuration Settings 15

Page 20

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

27 Minimum Display (Load Cell 2)

00: 1 [DEFAULT]

01: 2

10: 5

11: 10

28 Internal Count Span

(Load Cell 2)

Weight Decimal Point Position (Load Cell 2)

(when internal count span is 500,000)

Display Resolution (Load Cell 2)

(when internal count span is 500,000)

00: 1/10,000

01: 1/5,000 [DEFAULT]

10: 1/2,500

11: 1/12,500

(when internal count span is 1,000,000)

00: 1/1,000,000

01: 1/50,000 [DEFAULT]

10: 1/25,000

0: 500,000 [DEFAULT]

1: 1,000,000

29 Weight Stable Condition for Load Cell 2 - waiting time 0.5 seconds to 10 seconds

0000: 0.5 seconds 1000: 4.5 seconds

0001: 1.0 seconds 1101: 5.0 seconds

0010: 1.5 seconds 1010: 5.5 seconds

0011: 2.0 seconds [DEFAULT] 1011: 6.0 seconds

0100: 2.5 seconds 1100: 7.0 seconds

0101: 3.0 seconds 1101: 8.0 seconds

0110: 3.5 seconds 1110: 9.0 seconds

0111: 4.0 seconds 1111: 10.0 seconds

000: 00000

001: 0000.0 [DEFAULT]

010: 000.00

011: 00.000

100: 0.0000

Weight Decimal Point Position (Load Cell 2)

(when internal count span is 1,000,000)

000: 000000

001: 00000.0 [DEFAULT]

010: 0000.00

011: 000.000

100: 00.0000

101: 0.00000

30 Weight Stable Condition for Load Cell 2 - Limit No Check to +/- 10.0d

0000: No Check

0001: ± 0.1d

0010: ± 0.2d

0011: ± 0.3d

0100: ± 0.4d

0101: ± 0.5d [DEFAULT]

0110: ± 1.0d

0111: ± 2.0d

1000: ± 5.0d

1001: ± 10.0d

31 - 34 not currently in use

Table 3-2. DC-530 Weight and Measurement Specifications

16 DC-530 Operation Manual

Page 21

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

35 Enble Tare

Digital Tare Setting

Tare R a n ge

0: No

1: Yes [DEFAULT]

36 Weight Stable Timeout

37 Digital Tare Rounding

00: As Entered

01: Round to Nearest Increment [DEFAULT]

10: Not Used

11: Not Used

38 Digital Tare When

Loaded

0: No

1: Yes [DEFAULT]

39 Rezero on Power-Up

0: No

1: Yes [DEFAULT]

00: 2 10:6

01: 4 11:8 [DEFAULT]

This SPEC sets how many seconds it is before the

scale sounds its error buzzer if the weight does not

stabilize within that time after a function key (TARE,

REZERO, PCS, * PRINT, + (plus), - (minus).

Auto Tare Weight Clear

0: No [DEFAULT]

1: Yes

Condition of Auto Item Clear

00: 100% of Full Scale [DEFAULT]

01: 50% of Full Scale

10: 5% of Full Scale

Zero Reset When Scale

Change

0: No

1: Yes [DEFAULT]

NOTE: If both this SPEC

and SPEC 37 BIT 1 Clear Tare When ReZero Operation are set to

1: Yes, the tare value will

be changed when

changing scales even if

SPEC 45 Bit 1 - Clear

Tare on Scale Change

and SPEC 47 Bit 0 Keep Tare are both set to

0: No.

Clear Tare When ReZero Operation

0: No [DEFAULT]

1: Yes

NOTE: If both this SPEC

and SPEC 36 BIT 0 Zero Reset When Scale

Change are set to 1: Yes,

the tare value will be

changed when changing

scales even if SPEC 45

Bit 1 - Clear Tare on

Scale Change and SPEC

47 Bit 0 - Keep Tare are

both set to 0: No

Zero Tracking With Tare

0: No

1: Yes [DEFAULT]

Clear Unit Weight on

Scale Change

0: No [DEFAULT]

1: Yes

Zero Tracking

0: No

1: Yes [DEFAULT]

Auto Item Clear in

Normal Counting Mode

0: No

1: Yes [DEFAULT]

Table 3-2. DC-530 Weight and Measurement Specifications

00: >=Net 5d & gross 21d [DEFAULT]

01: >=Net 1d & stable

10: >=Net 1d & stable & quantity=0

NOTE: For auto tare clear, 10: >=net 5d & stable

0: No [DEFAULT]

1: Yes

Configuration Settings 17

Page 22

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

40 Load Cell 1 Sensitivities Selection (mV/V)

1000(8 H): 2.08

1001(9 H): 1.84

1010(A,H):1.60

1011(B H): 1.36

1100(C H): 1.12 [DEFAULT]

1101(D H): 0.88

1110(E H): 0.64

1111(F H): 0.40

41 Load Cell 2 Sensitivities Selection (mV/V)

1000(8 H): 2.08

1001(9 H): 1.84

1010(A H): 1.60

1011(B H): 1.36

1100(C H): 1.12 [DEFAULT]

1101(D H): 0.88

1110(E H): 0.64

1111(F H): 0.40

42 Scale 4 Connection

Scale 3 Connection

Scale 2 Connection

Scale 1 Connection

0: Not Connected

[DEFAULT]

1: Connected

43 SCALE 1

00: UniBloc [DEFAULT]

01: Load Cell 1

10: Force Balance

11: Load Cell 2

44 SCALE 3

00: UniBloc

01: Load Cell 1

10: Force Balance

11: Load Cell 2 [DEFAULT]

45 Tare Decrease

0: No

1: Yes [DEFAULT]

0: Not Connected

[DEFAULT]

1: Connected

Item Tare Subtraction

0: No

1: Yes [DEFAULT]

0: Not Connected

[DEFAULT]

1: Connected

SCALE 2

00: UniBloc

01: Load Cell 1 [DEFAULT]

10: Force Balance

11: Load Cell 2

SCALE 4

00: UniBloc

01: Load Cell 1

10: Force Balance [DEFAULT]

11: Load Cell 2

Clear Tare on Scale

Change

0: No

1: Yes [DEFAULT]

NOTE: Even if this SPEC

is set to 0: No to keep

the tare value, the tare

value will be changed

when changing scales if

SPEC 36 Bit 0 - Zero

Reset When Scale

Change and SPEC 37

Bit 1 - Clear Tare When

Re-Zero Operation are

both set to 1: Yes

0: Not Connected

1: Connected [DEFAULT]

Do Tare Operation When

No Stability

0: No

1: Yes [DEFAULT]

Table 3-2. DC-530 Weight and Measurement Specifications

18 DC-530 Operation Manual

Page 23

SPEC No Bit 3 Bit 2 Bit 1 Bit 0

46 Tare Increase

Weight Unit

Overwrite the Tare Value

Do Tare Operation When

No Stability

0: No

1: Yes [DEFAULT]

47 Minus Mask Limit

0: Gross Weight

[DEFAULT]

1: Net Weight

48 Rezero Operation Range

0: kg

1: g [DEFAULT]

NOTE: This SPEC does

not affect the units

displayed unless SPEC

49 Bit 1 - Weight Base is

set to 0: Kg/g.

Minus Display

0: Mask

1: Minus [DEFAULT]

0: No

1: Yes [DEFAULT]

Zero Lamp Condition

0: Gross [DEFAULT]

1: Net

Scale Start Range

0: No [DEFAULT]

1: Yes

Keep Tare When

Changing Scale

0: No [DEFAULT]

1: Yes

NOTE: Even if this SPEC

is set to 1: Yes to keep

the tare value, the tare

value will be changed

when changing scales if

SPEC 36 Bit 0 - Zero

Reset When Scale

Change and SPEC 37

Bit 1 - Clear Tare When

Re-Zero Operation are

both set to 1: Yes

00: 100% of Full Scale [DEFAULT]

01: 10% of Full Scale

10: 2% of Full Scale

49 Disable Scale

Connection Check

0: No [DEFAULT]

1: Yes

50 not currently in use

Too Light Range for

Sampling

0: No [DEFAULT]

1: Yes

00: 100% of Full Scale [DEFAULT]

01: 10% of Full Scale

10: 2% of Full Scale

Weight Base

0: kg/g

1: lb [DEFAULT]

Table 3-2. DC-530 Weight and Measurement Specifications

Mask Condition at

Overflow

0: 1d

1: 9d [DEFAULT]

Configuration Settings 19

Page 24

4.0 Calibration

The DC-530 Counting Scale is a high-precision instrument. Although the scale needs very little maintenance,

you may want to check the calibration after every month or so of normal usage. To do this you will need to have

a test weight of approximately the total capacity of the scale (i.e. a 10 lb weight if you have a 10 lb capacity

scale). After the scale is initially installed, put the weight on the platform and record the weight displayed. Then

every month or so put the same weight on the scale and verify that it still reads the same.

Many facilities have a technician come in and check their units with certified test weights four times a year. If

you are ISO certified, you will want to check to see if your certification specifies more stringent requirements in

order to stay in compliance. Your Rice Lake Weighing Systems scale dealer has the calibrated test weights,

expertise and experience to perform this task for you as well as to check other operating parameters of your scale

and help you effectively integrate scales into your operations. If you do not know who your local Rice Lake

Weighing Systems dealer is, call us at 1-715-736-0002 and we will help you find someone who can provide you

with on-site support.

Follow the instructions below to calibrate your DC-530 scale to ensure its continued accuracy.

NOTE: You can exit the Maintenance Mode and return to the Counting Mode at any time by pressing the TAR E key.

1. Ensure that there is no weight on the platter and turn the scale on. It will display the model number and

current firmware version number.

2. With the scale in the Counting Mode, press the MODE key to go to the Mode Menu.

3. While at the Mode Menu, press and hold the REZERO key while entering 8715 from the numeric

keypad to enter the calibration mode.

4. You can select which scale you are calibrating, Scale 1 or Scale 2, by pressing the SCALE key. (If a 2nd

scale is not installed and set in the specifications, pressing the

5. The scale display will ask you to make sure that there is no weight on the platter then press the #

[CODE] key to set the zero point..

6. The scale will briefly flash the message ZERO POINT SETTING, please WAIT...Once the zero point is set, the

display returns to the Calibration Screen.. Press the * PRINT key to move to the span weight calibration.

The display will change to the following:

SCALE key has no effect.)

7. Place a reference weight on the platform. It is preferable to calibrate the scale using a weight equal to the

20 DC-530 Operation Manual

Page 25

full capacity of the scale (i.e. a 10 lb weight for 10 lb capacity scale, etc.) If the reference weight is not

equal to the full capacity of the scale, it must at least be greater than 10% of the full scale capacity.

Enter the value of the weight placed on the platter using the numeric keys before pressing the # [CODE]

key. The weight you enter will appear at the bottom of the display. Press the # [CODE] key.

8. The display will flash briefly again as the span settings for calibration of the scale are being saved, then

the display will return to Mode Menu.

9. Press 1 exit the Mode Menu and return to the Counting Mode.

Calibration 21

Page 26

5.0 Scale Operations

The following sections contain detailed operator instructions for the DC-530 counting scale. Included are

instructions on how to enter tare weights, accumulate tare weights, establish unit weights, accumulate item

counts, perform negative counting, and count parts in both Normal Counting Mode and TEP (Teraoka Error

Prediction) Mode.

When performing all weighing and counting operations, the scale must be stable before it will accept an entry.

The scale will indicate that the weight reading or count is stable by illuminating the Stable indicator lamp. If you

press a function key when the scale is not stable you will hear a double beep indicating that the function cannot

be performed yet. Once the Stable indicator lamp is lit, then perform the function.

Figure 5-1. DC-530 Counting Scale

5.1 Factors Affecting Counting Scale Accuracy

Counting scale accuracy is primarily determined by the following factors:

• Sample size (number of pieces)

• Total sample size as a percentage of full scale capacity

• Piece-to-piece weight variation

As a general rule, when determining sample size of fairly uniform pieces, the larger the sample size the greater

the total sample weight and therefore the better the counting accuracy. Selecting the smallest capacity scale that

can obtain the highest counting resolution should be considered, but should not sacrifice the capacity required for

the heaviest container of parts. For some applications, a dual-platform scale utilizing the DC-530’s optional

capability to connect a second scale may be the best selection.

There is a direct relationship between piece-to-piece weight variation (non-uniformity) and counting accuracy.

Therefore, elimination of the piece-to-piece weight variations will greatly improve accuracy. This can be

accomplished by:

• Isolating the sample used to calculate the unit weight and use the same sample to re-check the scale.

• Recalculating the unit weight from lot to lot of parts. Parts manufactured on one machine may vary

slightly from another machine relative to weight.

• Tightening the manufacturing tolerances on the parts reduces piece weight variations and increases

count accuracy.

22 DC-530 Operation Manual

Page 27

5.2 Teraoka Error Prediction (TEP) Function

The DC-530 counting scale includes the DIGI TEP (Teraoka Error Prediction) Function which detects weight

variances in sample quantities and calculates the maximum quantity of that piece that can be counted without

introducing error. To make the operator’s job easier, the scale’s display will change from green to yellow or red

when the maximum safe quantity has been exceeded. This function works by performing a series of sampling

operations which the scale uses to plot the weight variances of the pieces being weighed. By then accumulating

counting results within the calculated safe quantity, the counting operation can be completed without a counting

error. Although the TEP Function can be used at any time the scale owner or operator deems it appropriate, the

extra sampling involved to derive the plot make it most logical for high-value items.

Coupled with the DC-530’s internal counting resolution of 1/1,000,000, the TEP Function assures your precise

counting of high-value items.

5.3 The Mode Menu Screen

The starting point for using the DC-530 scale is the Mode Menu Screen. From this screen you have four options

to choose from:

1. Counting Mode - to enter the Counting Mode Screen on which weights and counts are displayed;

2 - Program Mode - to enter the Program Mode Screen where you will be able to further choose between

editing and deleting items in memory;

3 - Date and Time - to enter the Date and Time Setting Screen; and

4 - Set Point Settings - to enter the General Set Point Setting Screen in which you can establish set points

not associated with specific items in memory.

Figure 5-2. Mode Menu Screen

To select the option desired, simply press the number key for the corresponding number on the numeric keypad.

The display will change to the screen for that option.

5.4 Tare Operation

Tare weights can be entered in the scale by one of two methods: one-touch tare or digital tare. Digital tare is used

when the tare weight is already known, while one-touch tare is used when the tare weight is unknown. If you call

up an Item Code already programmed into the DC-530’s memory and you have a Tare Weight stored for that

Item Code, the Tare Weight stored with the Item Code will override one entered digitally or by using the TARE

key. The procedures illustrated below are the same for the Normal Counting Mode and the TEP Counting Mode

although only Normal Counting Mode displays are shown in the examples.

NOTES:

• SPEC 35, Bit 2 DIGITAL TARE SETTING must be a “1: YES” to allow digital tare.

• SPEC 35, Bits 1 and 0 TARE RANGE must be set to the appropriate tare range value. The default is “00: 100 PERCENT OF

FULL SCALE”.

• SPEC 37, Bits 3 an 2 DIGITAL TARE ROUNDING determines if a digital tare is stored as entered or rounded to the nearest

increment. The default is “01: Round to Nearest Increment.”

• SPEC 47, Bit 1 ZERO LAMP CONDITION determines whether the zero indicator lamp lights when a gross weight is being

displayed or a net weight. The default is “0: GROSS”.

5.4.1 One-Touch Tare, Tare Unknown

1. Press the REZERO key to zero the scale.

2. If the tare weight value is not known, place the container, box, or item to be tared on the scale and press

Scale Operations 23

Page 28

the TA R E key. The weight display will now show 0 and the Net and Zero indicator lamps will

illuminate.

3. Remove the container, box, or item from the scale. The weight display should show a negative weight

value (weight of the tared container, box, or item).

4. To clear the tare weight, press the TARE key. The Net indicator lamp will no longer be illuminated.

5.4.2 Digital Tare, Tare Weight Known

1. Press the REZERO key to zero the scale.

2. If the tare weight value is known, use the numeric keypad to key in the value and then press the TARE

key. The Tare Weight value must be entered without a decimal point. The Weight field is 5 digits long

and the placement of the decimal point is determined by Bits 2, 1, and 0 of Specification 21 - Weight

Decimal Point Position. The digits you enter for the tare weight will fill the field starting from the right.

(Example: if the decimal point is set as 0.0000 and you enter the digits 125, the net weight will show as

0.0125.) The Net indicator lamp will illuminate.

3. To reset the tare to zero, press the TARE key again.

5.4.3 Tare Value Accumulation and Subtraction

Tare weights can be accumulated or subtracted using the TARE key by the One Touch Tare method. Tare

weights can also be accumulated using the Digital Tare method, but not subtracted.

NOTES:

• SPEC 35, Bit 2 DIGITAL TARE SETTING must be a “1: YES” to allow digital tare.

• SPEC 35, Bits 1 and 0 TARE RANGE must be set to the appropriate tare range value. The default is “00: 100 PERCENT OF

FULL SCALE”.

• SPEC 37, Bits 3 an 2 DIGITAL TARE ROUNDING determines if a digital tare is stored as entered or rounded to the nearest

increment. The default is “01: Round to Nearest Increment.”

• SPEC 38, Bit 3 DIGITAL TARE WHEN LOADED must be set to “1: YES” in order for bo t h O n e To u c h Ta r e a n d D i g it a l Ta r e

functions to be used at the same time.

• SPEC 46, Bit 3 TARE INCREASE and SPEC 46, Bit 1 OVERWRITE THE TARE must both be set to “1: YES” to allow

24 DC-530 Operation Manual

Page 29

accumulation of tare values. To allow Tare Subtraction, SPEC 45, Bit 3 TARE DECREASE must be set to “1: YES”.

5.4.4 Tare Accumulation

1. Press the REZERO key to zero the scale.

2. At the Counting Mode Screen, place the container, box or item to be tared on the platform and press the

TARE key. The Weight Display should now show 0 and the NET indicator lamp will illuminate. If you

enter the Tare Weight digitally and press the TARE key, the Tare Weight will show in the Weight

Display with a minus sign in front of it and the NET indicator lamp will illuminate.

3. Place another item to be tared on the platform and press the TA R E key again. This will add the two tare

weights together (Tare Accumulation). When using Digital Tare entry, the next tare weight value should

not be lower than the previous one. If you enter another tare weight digitally and press the TARE key,

the Weight Display will show the accumulated Tare Weight.

4. Repeat Step 2 until you have accumulated all the tare weights necessary for your weighing and counting

operation.

5. If you remove all the tare weights from the platter, the Weight Display will show the accumulated Tare

Weight.

6. To clear the accumulated tare weights, press the TARE key after removing all the tare weights from the

platter. The NET indicator lamp will no longer be illuminated.

5.4.5 Tare Subtraction

1. Press the REZERO key to zero the scale.

2. At the Counting Mode Screen, place the container, box or item to be tared on the platform and press the

TARE key. The weight display should now show 0 and the NET indicator lamp will illuminate. Tare

subtraction cannot be done digitally.

3. Remove the amount of the tare that you want to subtract and press the TAR E key to subtract it.

4. Repeat Step 3 to subtract more tare weights until you have the desired tare weight.

5. To clear all the tare weight, remove all tare weights from the platter and press the TARE key. The NET

indicator lamp will no longer be illuminated

5.5 Operations in Normal Counting Mode

Unit Weight Entry, Counting Operations, and Accumulation and Subtraction can be done either in Normal

Counting Mode or in TEP (Teraoka Error Prediction) Mode. This section (

the Normal Counting Mode. For operations under TEP Mode, see Section 5.6.

5.5.1 Normal Counting Mode - Unit Weight Operation by Sampling

Entering unit weights can be done either by sampling, as presented in Section 5.5.1, or by manual key entry as

described in Section 5.5.2.

NOTE: SPEC 53, Bit 2 NORMAL COUNTING MODE AUTO-RECOMPUTING controls whether or not you have to push the PCS

key to recompute the Unit Weight after resampling. The default is “1: Auto” which means that you do not have to press the PCS

key except after placing the very first sample in the sampling process.

Unit Weight operation by sampling is accomplished by placing a 10 piece sample on the scale and then pressing

PCS key. The scale calculates a Unit Weight based on the capacity of the scale compared to the weight of the

the

sample.

1. Press REZERO to zero the scale.

2. Place a number of pieces of the item to be sampled on the scale. The DC-530 assumes that you are using

a 10 piece sample unless you indicate otherwise in the next step. For maximum accuracy, count the

sample into your hand and then add the entire sample to the bin at one time, instead of adding them one

or two at a time.

3. If you are using a 10 piece sample, simply press the PCS key. The scale will display the total Weight,

Unit Weight, and number of Pieces. If you are using a sample size other than 10 pieces, enter the sample

Section 5.5) will cover operations in

Scale Operations 25

Page 30

quantity using the numeric keypad before pressing the PCS key.

4. To improve the accuracy of the Unit Weight calculation, add another sample of the same pieces. This

second sample should be of a number of pieces equal to or fewer than the first one. Press the

(NOTE: If Specification 53, Bit 2 is set to the default setting of 1: Automatic, the scale will automatically begin

recomputing.)

PCS key.

The scale display will display RECOMPUTING for a few seconds, then automatically display the new total

Weight, Unit Weight, and number of Pieces.

NOTE: If you place too large a second sample on the platform, the error message OUT OF RECOMPUTE RANGE, PLEASE

REDUCE SAMPLES

the bar graph along the bottom of the display. When it reaches all the way to the

side of the display, you have reached the maximum. Remove some of the pieces in the second sample until the number

of pieces is below that of the first sample.

will appear. You can also tell if you are under the maximum recomputing sample size by observing

MAX marker on the bottom right-hand

If you place too small a sample on the platform for the scale to accurately calculate a Unit Weight, the

INSUFF indicator lamp will illuminate and the display will indicate how many more pieces have to be

added to the sample in order to be able to calculate the Unit Weight. Add the necessary pieces to the

sample until the scale returns you to the Normal Counting Mode screen. The screen will then show

RECOMPUTING before showing the Unit Weight.

5. If you wish to continue to refine the Unit Weight, repeat Step 4, adding another sample.

6. When done with calculating the Unit Weight you can begin counting operations by placing a quantity of

the pieces to be counted on the platform. The scale will display the number of pieces as well as the Total

Weight, based on the Unit Weight established by the sampling process. To store this Unit Weight in the

DC-530’s memory associated with an Item Code so that you can recall it in the future, see

Section 6.2.

7. To clear the Unit Weight, remove all weight from the scale platter and press the C (Clear) key.

5.5.2 Normal Counting Mode - Unit Weight Operation by Key Entry

Unit weight operation by key entry is accomplished by using the numeric keypad to enter the known value of the

Unit Weight and then pressing the

UNIT WEIGHT key. An example of Unit Weight operation by key entry is

shown below:

1. Press the REZERO key to zero the scale.

2. With the display in the Normal Counting Mode, enter the known Unit Weight using the keyboard, for

example, 200.00.

(NOTE: the Unit Weight is entered and displayed per 1000 pieces. To enter a Unit Weight of 0.0125 lbs, for example,

multiply 0.0125 x 1000 = 12.5. For a Unit Weight of 0.0125, therefore, you would enter 12.5 on the numeric keypad.

When entering Unit Weights you must enter the decimal point where appropriate.)

3. Press UNIT WEIGHT key to enter the Unit Weight.

26 DC-530 Operation Manual

Page 31

4. You can now begin counting operations by placing a quantity of the pieces to be counted on the

platform. The scale will display the number of pieces as well as the Total Weight, based on the Unit

Weight you keyed in. To store this Unit Weight in the DC-530’s memory associated with an Item Code

so that you can recall it in the future, see

Section 6.2.1.

5. To clear the Unit Weight, remove all weight from the scale platter and press the C (Clear) key.

5.5.3 Normal Counting Mode - Part Accumulation and Part Subtraction

Once a Unit Weight has been established for an part, the DC-530 Counting Scale has the capability to

accumulate and subtract total item quantities by using its accumulation memory.

5.5.4 Normal Counting Mode - Part Accumulation

To find the total accumulated quantity of similar containers filled with parts, use the accumulation procedure

detailed below.

1. Conduct a sampling process (Section 5.5.1) to determine the Unit Weight of the pieces and enter a

known tare weight, or place the empty container on the scale to perform the tare function ().

Alternatively, you can enter the Item Code of an item previously programmed into memory and press the

# [CODE] key to recall the data. If you enter an Item Code that is not currently programmed into the

scale’s memory, the message ITEM NOT FOUND will appear at the bottom of the display. For more

information on how to program item data into the DC-530’s memory, see Section 6.1.

2. Place Container 1 (full of parts) on the scale.

3. Press the + (Plus) key to store the total in Container 1. The Acc (Accumulation) indicator lamp will now

be illuminated. The display will show the total quantity of pieces accumulated for 3 seconds, then return

to the Counting Mode screen.

4. Remove Container 1 and place Container 2 (full of parts) on the scale.

5. Press the + (Plus) key (the total displayed is equal to Container 1 plus Container 2, etc).

6. Continue with the remainder of the containers to be counted. The total number of parts stored in all the

containers will be stored in the accumulation register.

Scale Operations 27

Page 32

7. To print a label showing the total, press the * PRINT key.

Figure 5-1. Total Accumulation Label Sample

8. This will also clear the accumulation register. The ACC (Accumulation) indicator lamp will no longer

be illuminated.

9. To clear the Unit Weight, remove all weight from the scale platter and press the C (Clear) key.

5.5.5 Normal Counting Mode - Part Subtraction

Just as you can accumulate total quantities by adding parts to the scale, you can also count by removing parts

from the scale, subtracting them from the total you began with.

1. Conduct a sampling process (Section 5.5.1) to determine the Unit Weight of the pieces and enter a

known tare weight, or place the empty container on the scale to perform the tare function (Section 5.4).

Alternatively, you can enter the Item Code of an item previously programmed into memory and press the

# [CODE] key to recall the data. If you enter an Item Code that is not currently programmed into the

scale’s memory, the message

ITEM NOT FOUND will appear at the bottom of the display. For more

information on how to program item data into the DC-530’s memory, see Section 6.1.

2. Place Container 1 (full of parts) on the scale and press the + (Plus) key to store the total in Container 1.

The Acc (Accumulation) indicator lamp will now be illuminated. The display will show the total

quantity of pieces accumulated for 3 seconds, then return to the Normal Counting Mode screen.

.

28 DC-530 Operation Manual

Page 33

3. Remove Container 1 from the platform.

4. Place Container 2 (full of parts) on the scale.

5. Press the - (Minus) key to subtract the new quantity from the total. The display will show the total

which will be the difference between Container 1 and Container 2, then return to the Normal Counting

Mode screen.

6. Repeat steps 4 and 5 for all the containers to be subtracted from the total.

7. To print a label showing the total after all the subtractions, press the * PRINT key.

Figure 5-2. Total After Subtraction Sample Label

This will also clear the accumulation register. The ACC (Accumulation) indicator lamp will no longer be

illuminated.

8. To clear the Unit Weight, remove all weight from the scale platter and press the C (Clear) key.

5.5.6 Normal Counting Mode - Negative Counting

There are two ways to do this depending on whether at the end you want to see the total amount remaining in the

container or the total amount removed from the container.

Scale Operations 29

Page 34

NOTE: To perform Negative Counting, SPEC 52, Bit 1 must be set to 1: Yes. This is the default setting.

5.5.7 Counting Out of a Full Container - See Total Amount Remaining in the Container

To carry out this operation you must know the tare weight ahead of time.

1. Press the REZERO key to zero the scale.

2. Place the full container on the scale. Press the TAR E key.

3. Remove a 10 piece sample from the container and press the PCS key. After the Unit Weight has been

calculated, return the 10 piece sample to the container.

4. Remove a number of parts from the container and press the + (Plus) key. The memory indicator lamp

(ACC) is illuminated and the display shows the quantity of parts taken out.

5. Remove a number of parts from the container and press the + (Plus) key again. The memory indicator

lamp (ACC) will be illuminated and the display shows the quantity of parts removed.

6. If at the end of the procedure, if you want to see how many parts are still in the bin you first have to know

the tare weight of the bin or container. After removing the parts you want to take out of the bin, simply

digitally enter the tare weight of the bin and press the TA RE key. The scale will display how many parts

were left in the bin. To print a label to put on the bin showing the new, lower, total quantity in the bin ,

press the

5.5.8 Negative Counting - Total Removed Displayed at the End

+ (Plus) key.

With this procedure you can count accurately out of a full container for kitting, shipping, etc. without having to

know the tare weight of the container.

1. Press the REZERO key to zero the scale.

2. Place a full container on the scale and press the TA RE key.

3. Remove a 10 piece sample from the container and press the PCS key. After the Unit Weight has been

calculated, return the 10 piece sample to the container.

4. Remove the number of pieces you need for kitting, shipping, etc. The amount removed will be

displayed. If you need a label for each kit or container, press the + (Plus) key after removing each batch

of pieces. Then press the

TAR E key.

5. When you have removed the last batch of pieces, press the * PRINT key to show the total number of

pieces you have counted out of the full container.

5.5.9 Normal Counting Mode - Clearing Accumulated Data

To clear accumulated data, press the * PRINT key.

5.6 Operations in TEP (Teraoka Error Prediction) Mode

Unit Weight Entry, Counting Operations, Accumulation and Subtraction can be done either in Normal Counting

Mode or in TEP (Teraoka Error Prediction) Mode. This section (

For operations under Normal Counting Mode, see Section 5.5.

The TEP Counting Mode is generally used for high-value parts for which you want to avoid even the generally

very small counting errors introduced by sample variances. A repeated sampling procedure allows the DC-530

scale to develop weight variance plots and thereby calculate a maximum safe quantity that can be counted

without error. The extra sampling effort required has to be balanced against the need for the greatest possible

accuracy.

5.6.1 TEP Mode - Unit Weight Operation by Sampling

Entering unit weights can be done either by sampling, as presented in Section 5.6.1, or by manual key entry as

described in Section 5.6.2.

NOTE: SPEC 53, Bit 0 TEP SAMPLING METHOD controls whether or not you have to push the PCS key to recompute the Unit

Weight after resampling. The default is “1: Automatic” which means that you do not have to press the PCS key except after

placing the very first sample in the sampling process.

Unit Weight operation by sampling is accomplished by placing a sample on the scale, entering the sample

quantity, and then pressing the

PCS key. The scale calculates a Unit Weight based on the capacity of the scale

compared to the weight of the sample.

Section 5.6) will cover operations in TEP Mode.

30 DC-530 Operation Manual

Page 35

1. Press REZERO to zero the scale.

2. Press the TEP key to enter the Teraoka Error Prediction Mode.

3. Count out a number of parts to be sampled and place them on the scale (for example 10 pieces). For

maximum accuracy, count the 10 piece sample into your hand and then add the entire sample to the bin

at one time, instead of adding them one or two at a time.

4. Enter the sample quantity using the numeric keypad, then press the PCS key. (Unlike in Normal

Counting Mode, the scale does not assume that the sample size is 10 pieces. You must enter the sample

quantity.) The scale will display the total Weight, Unit Weight, and number of Pieces and will indicate

that you have performed

SAMPLING 1 TIMES.

5. To improve the accuracy of the Unit Weight calculation, add another sample of the same pieces

according to the number indicated on the display (10 Pcs and below in the example above). Press the

PCS key. (If the Auto-Recomputing SPEC is set to 1: Auto, the scale will automatically begin

recomputing.)

As you add parts for the next sample, the scale display will indicate how many more pieces can be added

before reaching the maximum allowable for the resampling. If you add more pieces in the next sample

than the scale requests for its resampling, the scale display will turn red and the message

ITEMS

will appear, along with the number of items it suggests that you remove from the sample.

PLEASE REDUCE

If you add too few items for the scale to recompute the Unit Weight, the display will not change. Once

you add enough parts for another sample, the recomputing will take place. You can also gauge whether

your sample size is too small or too large by watching the bar graph at the bottom of the scale display. If

you add a sample and it does not register on the graph, it is too small. If you add a sample and the bar

graph goes all the way to the

MAX marker on the bottom right-hand side of the display you have exceeded

the maximum and need to remove some parts.

Scale Operations 31

Page 36

6. When the sample weight is within the required range, the scale will recompute the Unit Weight and

return to the TEP Sampling screen. The scale display will show the new total Weight, Unit Weight, and

number of Pieces. It will also now indicate that you have been

SAMPLING 2 TIMES.

7. Continue resampling by repeating Step 5, adding another sample below the amount shown on the TEP

Mode display. If the Auto-Recomputing SPEC is not set to 1: Auto, you will need to press the PCS key

to recompute the Unit Weight after each sample is added. Repeat the procedure until the scale reads

SAMPLING 9 TIMES.

8. As you continue sampling, at the bottom of the display the DC-530 will show a bar graph of the Unit

Weight curve it is developing. After the ninth sample, the scale’s display will turn red indicating that the

sampling operation is complete.

9. Remove all the sample parts from the platter. The DC-530 will now calculate and display the maximum

Safe Quantity Limit that can be counted without error in the Limit field.

10. You can now begin counting operations by placing a quantity of the pieces to be counted on the

32 DC-530 Operation Manual

Page 37

platform. The scale will display the number of pieces as well as the Total Weight, based on the Unit

Weight established by the sampling process. To store this Unit Weight in the DC-530’s memory

associated with an Item Code so that you can recall it in the future, see

Section 6.2.1.

If you press the TEP key to exit the TEP Mode after having established a Unit Weight and Safe Limit

Quantity, the scale will display the following message:

Enter 1 to clear the Safe Limit Quantity that you have established and go to Normal Counting Mode.

Enter 9 to keep the Safe Limit Quantity and stay in TEP Mode.

11. To clear the Unit Weight, remove all weight from the scale platter and press the C (Clear) key.