Page 1

DC-200/300

Counting Scale

Counting Scale

Service Manual

Version 1.37

Page 2

Page 3

Contents

1.0 Overview ............................................................................................................................................2

1.1 DC-200/300 Specifications ................................................................................................................. 2

1.2 Keyboard and Display ......................................................................................................................... 3

1.2.1 Annunicators .............................................................................................................................................. 4

1.2.2 Key Functions............................................................................................................................................. 4

1.3 Interface Ports ....................................................................................................................................7

1.4 Capacities and Resolutions................................................................................................................. 7

2.0 Installation......................................................................................................................................... 8

2.1 Unpacking .......................................................................................................................................... 8

2.2 Repacking .......................................................................................................................................... 9

2.3 Setting Up .......................................................................................................................................... 9

2.4 Powering Up the DC-200/300 ............................................................................................................ 9

2.5 Initialize Scale Specifications ............................................................................................................. 10

2.6 Start-Up Screens .............................................................................................................................. 11

2.7 Calibration (Span Adjustment) ........................................................................................................... 12

2.8 Setting Time and Date ...................................................................................................................... 15

2.9 Configuration Settings ....................................................................................................................... 15

2.9.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard ................................................15

2.9.2 Configuring Spec 141 and 142 Settings Using the Spec Upload Utility .....................................................27

2.10 Modes of Operation ........................................................................................................................ 36

3.0 Maintenance ....................................................................................................................................37

3.1 Hardware Testing ............................................................................................................................. 37

3.1.1 RAM and Communications Port Testing................................................................................................... 37

3.1.2 Internal Test Count ...................................................................................................................................41

3.1.3 Span Switch Status Test........................................................................................................................... 41

3.1.4 Voltage Checkpoints .................................................................................................................................41

3.2 Internal Printer Tests and Adjustments (DC-300 only)........................................................................ 42

3.2.1 Checking or Rezeroing the Thermal Head Usage Counter ........................................................................42

3.2.2 Adjusting the Printer Label Gap Sensor .....................................................................................................43

3.2.3 Adjusting the Printing Position................................................................................................................... 45

3.3 Clearing the Scale Memory ............................................................................................................... 45

3.4 Technical Drawings ........................................................................................................................... 47

3.4.1 DC-300 Exploded View ............................................................................................................................47

3.4.2 DC-300 Block Diagram .............................................................................................................................48

3.4.3 DC-200 Block Diagram .............................................................................................................................49

4.0 Assembly/Disassembly of the DC-200/300...................................................................................... 50

4.1 Removing the Main Cover .................................................................................................................50

4.2 Disconnecting the Display Board ...................................................................................................... 51

4.3 Disconnecting the Keyboard Circuit Board........................................................................................ 52

4.4 Removing the Interface Main Board .................................................................................................. 53

4.5 Removing the Printer Drawer Block (DC-300 only) ............................................................................54

4.6 Removing the Thermal Print Head (DC-300 only) .............................................................................. 55

5.0 Network and Interfaces: External Printers ......................................................................................57

5.1 Connecting an External Printer to the Scale ....................................................................................... 57

5.1.1 Spec Settings for External Printers............................................................................................................ 57

5.1.2 Connecting the Printer to the RS-232C Port .............................................................................................58

5.2 Eltron Printers ................................................................................................................................... 59

5.2.1 Set the Computer Serial Port ....................................................................................................................59

5.2.2 Designing a Label .....................................................................................................................................60

5.2.3 Saving the Label Format You Have Made .................................................................................................64

Page 4

5.2.4 Downloading the Label Format From the Computer to the Eltron Printer .................................................. 67

5.2.5 Predesigned Label Formats for Eltron Printers.......................................................................................... 68

5.2.6 Testing to See What Label Format or Graphic is in the Eltron Printer’s Memory ........................................ 73

5.2.7 Printing to the Eltron Printer from the DC-200/300 Scale.......................................................................... 75

5.3 Epson Printers ...................................................................................................................................76

6.0 Network and Interfaces: Connection to a PC ..................................................................................77

6.1 Ethernet Connection .........................................................................................................................77

6.1.1 Checking the Scale’s IP Address.............................................................................................................. 77

6.1.2 Machine Setup Utility................................................................................................................................ 77

6.1.3 Changing the IP Address Directly on the Scale ......................................................................................... 78

6.1.4 Ethernet Cable Connection Between the Scale and the Computer........................................................... 79

6.1.5 Setting the Computer’s Network Communication ..................................................................................... 79

6.1.6 Entering the Data Transfer Mode on the Scale.......................................................................................... 81

6.1.7 Exiting The Data Transfer Mode on the Scale........................................................................................... 82

6.1.8 Pinging the Scale to Test the Ethernet Connection ................................................................................... 83

6.2 RS-232 Connection ..........................................................................................................................84

6.2.1 Spec Settings for RS-232C Connection to a PC ....................................................................................... 84

6.2.2 Connecting the PC to the RS-232C Port .................................................................................................. 85

6.2.3 Configuring Communication Between the Scale and the Computer .......................................................... 86

6.2.4 Setting HyperTerminal to Capture Data Coming From the Scale................................................................ 86

6.2.5 Sending Data from the Scale to HyperTerminal ........................................................................................ 87

6.2.6 Scale Data Header Codes ........................................................................................................................ 87

6.2.7 Requesting Data From the Scale Using HyperTerminal ............................................................................. 88

7.0 Network and Interfaces: Scanners, Keyboards, Balances.............................................................. 89

7.1 Connecting an IBM Keyboard ...........................................................................................................89

7.2 Connecting a Barcode Scanner ........................................................................................................90

7.2.1 Header Codes.......................................................................................................................................... 90

7.2.2 Z Commands via Barcodes ...................................................................................................................... 91

7.2.3 Configuring the RS-232C Port for a Scanner ............................................................................................ 91

7.2.4 Connecting the Scanner to the RS-232C Port ..........................................................................................92

7.2.5 Configuring the Keyboard Port for a Scanner ........................................................................................... 92

7.2.6 Programming the QSC-6000 Plus Quickscan RS-232C Scanner ............................................................. 93

7.2.7 Programming the QuickScan Keyboard Wedge Scanner.......................................................................... 98

7.3 Connecting a Force Balance .............................................................................................................99

7.3.1 Spec Settings for Force Balance .............................................................................................................. 99

7.3.2 Connecting the Force Balance to the RS-232C Port .............................................................................. 100

8.0 Firmware Upgrade .........................................................................................................................101

8.1 Determining Your Current Firmware Version Number ...................................................................... 101

8.2 Installing the WinDload Software .....................................................................................................101

8.3 Setting Up the WinDload Software ..................................................................................................104

8.4 Connecting the DC-200/300 Scale to the Computer .......................................................................108

8.5 Downloading Firmware to the Scale ................................................................................................ 109

9.0 Appendix ........................................................................................................................................112

9.1 DC-200/300 Error Message List ......................................................................................................112

9.2 Appendix - Rezero Functions ..........................................................................................................114

9.3 Character Code Tables................................................................................................................... 116

9.3.1 ASCII Code ............................................................................................................................................ 116

9.3.2 Teraoka Codes ....................................................................................................................................... 118

Page 5

About This Manual

This manual contains technical instructions and procedures for servicing the DC-200/300 counting scale. It is for

the use of DIGI scale dealers and authorized technicians. The manual does not attempt to cover again all of the

operating procedures covered in the DC-200/300 operation manual nor does it cover every possible service

situation. If you have questions regarding this manual or a service-related situation not covered by this manual,

please contact the Service Department by calling 715-234-9171. This manual applies to Version 1.37 of the

DC-200/300 counting scale.

Some procedures described in this manual require work inside the scale base. These

Caution

procedures are to be performed by qualified service personnel only.

Authorized distributors and their employees can view or download this manual from the

DIGI distributor site at www.DigiScales.com .

Page 6

1.0 Overview

1.1 DC-200/300 Specifications

The following table illustrates all specifications associated with the DC-200/300 counting scale.

General Operating Specifications Weight Display Resolution 1/2,500

1/5,000

1/10,000

Counting (internal) Resolution 1/1,000.000

Power Source and Frequency AC 100-120V, 50/60 Hz

Battery (DC-200 only) 12V, 3.2 Ah/20hr

Power Consumption 50W

Operating Temperature -10 C to 40 C (14 F to 104 F)

Operating Humidity 15 to 85% RH Maximum

Dimensions Platter Size 360 x 275 mm / 14.17 x 10.83 in

Dimensions 410 mm (L) x 378 mm (W) x 140 mm(H)

16.14 in (L) x 14.88 in (W) x 5.52 in (H)

Analog Specifications Load Cell Excitation 12 VDC

Number of Load Cells four 350 ohm load cells maximum

Scale Channels Up to 3 scales including the built-in scale

Input Sensitivity 0.4 - 2.0mV/V

Digital Specifications Display LCD with backlight (136 x 16 dots w/ icon)

Weight: 5 digits

Unit Weight: 5 digits

Quantity: 7 digits

Memory 2 Mb standard (up to 5000 items)

Programmable Data per Item ID code (32 digits), Unit weight (5 digits), Part

number (32 digits), Part name (32 digits),

Location (32 digits), Inventory (8 digits),

Threshold (8 digits), Tare weight (5 digits),

Set point target data

Printing Items ID code, Lot number, Net weight, Gross

weight, Unit weight, Tare weight, Parts

name, Parts number, Quantity, Task

contents, Barcodes (code 39, code 128)

Mechanical Specifications Keyboard Keys Mechanical switch

Number of Preset Keys 32 preset keys

Printer Type (DC-300 only) Drawer type

Paper types: label and receipt

Paper width: for label - max. 60 mm, for

receipt - 40, 50, or 60 mm

Resolution: 8 dots/mm

Speed: For label - 80 mm/sec, for receipt -

100 mm/sec

Table 1-1. DC-200/300 Specifications

Page 7

Interfaces and Ports Amphenol one 14-pin interface to scale

RS-232C three RS-232C data ports (8-pin DIN) to PC,

printer, force balance or scanner

Ethernet one Ethernet port to PC, hub, or router

IBM Keyboard one IBM keyboard port

Electronic Components Main CPU Hitachi HD6413003RF16 (H8/3003)

Flash Memory MBM29F160BE-70

SRAM Hyundai HY628400ALLG-55 (Normal pin)

Mitsubishi MEM5408ART-55LL (Reverse pin)

Display Device IDW RD747SG-LG

Printing Head (DC-300) Kyocera KYT-56-8MPP1-TRS

DC Stepping Motor (DC-300) Minebea 17PM-K448-G5V

A/D Converter Teraoka TWB-09130 (AD Main Board)

Power Supply (DC-300) NEMIC Lambda ZD75-0524

Table 1-1. DC-200/300 Specifications

1.2 Keyboard and Display

Figure 1-1 shows the DC-200/300 console with annunciators, the alphanumeric keyboard and the numeric

keypad. Annunciators are described in Section 1.2.1. Section 1.2.2 describes the DC-200/300 keyboard and

keypad.

Figure 1-1. DC-200/300 Display

Page 8

1.2.1 Annunicators

Table 1-2 shows a list of the annunciators that the DC-200/300 uses to provide additional information about the

value being displayed. The annunciators are illuminated when the specific function is being performed.

Annunciator

→

0

←

NET

RECOM

INSUFF

∑

IN

OUT

PE

R

S

X

Z

Gross weight is zero

Display shows net weight (when tare weight is entered or recalled)

Unit weight is recomputing is possible

Net weight is below specified percentage of scale capacity

Memory indicator showing quantity accumulation is being done

Inventory IN (for counting mode)

Inventory OUT (for counting mode)

Paper end.

Scale is in Registration Mode, also referred to as Operation Mode. (see Section 2.10 for description

of modes)

Scale is in Programming Mode. (see Section 2.10 for description of modes)

Scale is in Report Mode. (see Section 2.10 for description of modes)

Scale is in Service Mode. (see Section 2.10 for description of modes)

Annunciator Meaning

Table 1-2. DC-200/300 Annunciators and Function

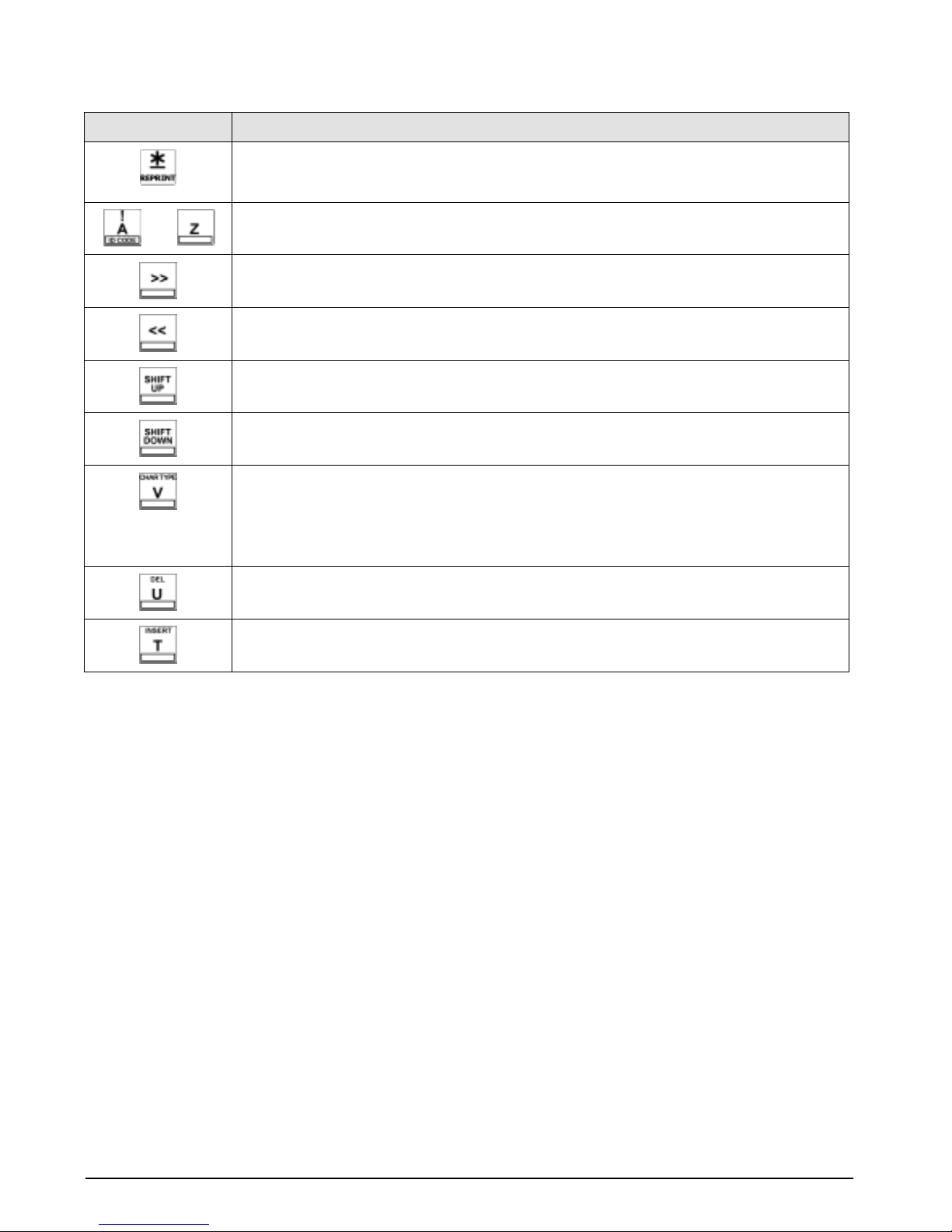

1.2.2 Key Functions

The DC-200/300 features a full alphanumeric keyboard with many functions for managing inventory information

and scale operation. Table 1-3 lists the keys and key functions of the DC-200/300 keyboard and keypad (see

Figure 1-1 on the previous page).

Note: Some keys have different functions depending on what mode you are in, so be sure to check which mode is

selected before using them.

Page 9

.

Key

to

Description

Turns the scale display on or off

Used to enter numeric values. When using the scale, first enter a numeric value, then press the

appropriate function key.

Allows cycling between the different modes:

• Operation Mode – weighing and counting operations

• Report Mode – print item, inventory, and shelf location reports

•Program Mode – entering item data, factory name

• Password Mode – password protecting certain operations

• Service Mode -setup and troubleshooting by an authorized dealer or technician

• Operation Mode – set and clear tare weights

•Program Mode – do an item test print

• Other Modes – used to select “No”

• Operation Mode – clear keyed-in data from the display starting with the last digit entered

• Other Modes – used to select “Yes”

Used to reset the scale to zero. Also used in conjunction with other keys to enter the maintenance

mode. The

• Operation Mode - compute unit weight by sampling. Press the

• Other Modes - escape the programming screen without saving data

Used to enter a known unit weight using the numeric keypad

REZERO

10-piece sample on the platform, or after using the numeric keypad to enter the sample size. On

multi-channel units, ensure that the correct scale is selected.

key does not function when the scale is in motion.

PIECES

key after placing a

• Operation Mode – accumulate the total quantity

•Program Mode – select an item to be programmed such as item code, factory name, or cycle

through set-point modes

• Report Mode – select the type of report to print

• SPEC Setting – move between SPEC numbers (low to high)

•Program Mode –- select programming item such as item code, factory name

• Report Mode – select report type

• Other Modes – enter the delete function

• SPEC Setting – move between SPEC numbers (high to low)

• Operation Mode – call up stored item code information and switch between item code inventory

IN and OUT modes

•Program Mode – store the programmed data

Enter numeric values containing a decimal point

Note: A numeric value must be entered before the decimal point. For example, .250 would be

entered as 0.250.

Feed label or receipt paper (DC-300 only)

Cycle between Scales A through D when using the DC-200/300 as a multi-scale system.

Table 1-3. DC-200/300 Key Functions

Page 10

Key Description

• Operation Mode – print a label or report

• Report Mode – print out a report

•Program Mode – enter information about an item into temporary memory

to

• Operation Mode – view item code data stored in memory

•Program Mode – enter alphabetic data

Move the cursor . Change the entry to the right. Also used to cycle forward between choices in

setting mode.

Move the cursor. Change the entry to the left. Also used to cycle backward between choices in

setting mode.

SPEC

Select the top function or character of a desired character key

Select the bottom function or character of a desired character key, generally to quickly view the

values in different registers

Shift between code type for keyboard entry. Options are:

•

P:KEY

•

A:KEY

•

T:KEY

Section 9.3 on page 116 - Character Code Tables

Delete data

Insert data

- enter the letter or number corresponding to the key pressed

ASCII code - select by entering the hex code for the character

Teraoka code - select by entering the numeric value for the character

SPEC

Table 1-3. DC-200/300 Key Functions

Page 11

1.3 Interface Ports

The DC-200/300 is equipped with a number of interface ports enabling it to be connected with other devices.

There are RS-232C ports that allow connection to bar code readers, printers or force balances. An IBM keyboard

interface permits connection to an external keyboard or wedge scanner. The Ethernet connection makes the

DC-200/300 a networkable workstation and allows you to use the Utility Transfer and Label Design programs.

Figure 1-2. DC-200/300 Interface Ports

1.4 Capacities and Resolutions

Table 1-4 lists the scale capacities and resolutions for all models of the DC-200/300 counting scales. The system

weighing accuracy is 0.02 percent.

Counting scales specify two types of resolution:

•Weight (or external) resolution

•Counting (or internal) resolution

Weight resolution is displayed in divisions of the full scale capacity which is divided into weight increments. For

example, a 5-lb scale divided into 10,000 display divisions would display weight with 0.0005 lb divisions

(10,000 divisions x 0.0005 lb = 5.0 lb).

Counting resolution is based on the internal resolution of the scale. The weight and counting resolutions for the

DC-200/300 capacities are shown below and apply to all models of DC-300 counting scales.

DC-200/300 Single Scale

Note: Units are selectable from lb to kg and can be programmed to weigh in other primary units: lb, kg, g.

Capacity

1.0 lb Both 0.0001 0.000001 6" x 8"

2.5 lb Both 0.0002 0.000002 7" x 10"

5.0 lb Both 0.0005 0.000005 12" x 14"

10.0 lb Both 0.001 0.00001 12" x 14"

25.0 lb Both 0.002 0.00002 12" x 14"

50.0 lb Both 0.005 0.00005 12" x 14"

Mounting Internal/External Weight Resolution Counting Resolution Platform Dimension

The external scale platform connector allows the DC-200/300 to connect with another larger capacity platform. A

third scale can be added by using the optional Y cable to connect to the external scale connector. with the ability

to add a force balance, barcode scanner, external printer and/or keyboard, your DC-200/300 becomes the hub of

a sophisticated weighing system with huge capacities for expandability and flexibility.

Table 1-4. DC-200/300 Single Scale Capacities

Page 12

2.0 Installation

This section describes the procedure for the installation and setup of the DC-200/300 counting scale.

2.1 Unpacking

Do not turn scale upside down. Always work with scale on its side! Damage to the load cell

Caution

Immediately after unpacking, visually inspect the DC-200/300 counting scale to ensure all components are

included and undamaged. If any were damaged in shipment, notify Rice Lake Weighing Systems and the shipper

immediately.

The DC-200/300 counting scale is packed in custom-fitted foam. After opening the box, remove all the

components. Check the insides of the box carefully to make sure you have all of the pieces. The package should

include the following:

• DC-200/300 counting scale

• Stainless steel platter

•AC power cord

• DC200/DC300 set-up tools CD-ROM

• Thermal head cleaning kit (DC-300 only)

• Thermal printer take-up reel (DC-300 only)

•DIGI certificate of quality

• Spare keysheet label

can occur if the scale is turned upside down.

Remove the bag protecting the scale and the dessicant bag. Next remove the protective film covering the front

panel and the foam spacers between the scale case and the platform spider. Finally, place the stainless steel

platter on top of the scale and seat it securely on the rubber stops.

After insuring that all the parts are present, store the original box in a safe location for possible future use. You

will want the original packaging if you ever need to transport the scale or send it for servicing.

Figure 2-1. DC-200/300 Unpacked

Page 13

2.2 Repacking

If the DC-200/300 counting scale must be returned for modification, calibration or repair, it must be properly

packed with sufficient cushioning materials. Whenever possible, use the original carton when shipping the

DC-200/300. Damage caused by improper packaging is not covered by the warranty.

2.3 Setting Up

Place the scale on a solid, level surface away from fans, breezes, and sources of electrical interference.

Level the scale by turning the four adjustable legs located on the bottom of the scale while referencing the b ubble

level located on the front of the scale (see Figure 2-2).

Note: To ensure a higher degree of scale stability, turn in all four adjustable legs before leveling. Turn out adjustable

legs to level as needed.

Figure 2-2. Leveling Feet and Bubble

2.4 Powering Up the DC-200/300

After plugging the power cord into the socket on the bottom of the scale (Figure 2-3) turn the power switch on

the back of the bottom of the scale to the

is currently

, turning it to the

OFF

position but the display has been powered down by pressing the

reactivated by pressing the

Power switch

location

ON/OFF

ON

position. Generally when starting up the scale, if the power switch

position powers up the scale. If the power switch is already in the

ON

ON/OFF

key on the front, the scale can be

key again.

Power cord

location

ON

Figure 2-3. Power Switch and Power Cord Location

Page 14

2.5 Initialize Scale Specifications

When first setting up the DC-200/300 scale, the specifications can all be set to their default values in one

procedure. The scale has three possible sets of default values: Japan, U.S.A., and Standard. If the scale will be

used in the United States, the best initial combination of settings will be the U.S.A. Remember that you can

customize many functions of the scale to fit your customer’s application by modifying these specification

settings. For more information on the default settings of each specification and their optional settings, see Section

3.0 of the DC-200/300 Operation Manual .

Note: This procedure clears the scale’s SDRAM before initializing the specification settings to their default values.

This means that all item code information, customized specification settings and custom free label formats will be

erased by performing this procedure.

1. Turn on the Span Switch and then power on the scale.

2. Press and hold and

Country Spec mode.

REZERO key while entering 124 from the numeric keypad to enter the Select

3. Use the

(USA), and 3-STD (Standard). When the display shows 1-US, press the

4. The scale will next move to the Select Scale Type mode. Use the

<< or >> key to scroll through the Country code options. (The options are 0-AA (Japan), 1- US

REPRINT key to select it.

<< or >> keys to select either 0 DC300

or 1 DC200.

Press the

REPRINT key to confirm your selection.

5. The scale will indicate that it is reading the default country specs for the country setting you selected in

Step 2 above.

6. The scale will next ask you if you want to clear all the SDRAM memory in the scale and intialize all the

files and specifications. Press the

TARE key to exit without reinitializing.

CLEAR key to clear the memory and intialize the specifications or the

Pressing the Clear key will also erase any item code files, inventory records, and custom label

Caution

formats you have programmed into the scale previously.

If you press the CLEAR key to reinitialize, the scale will display a message saying PLEASE WAIT..., while

Page 15

the procedure is taking place.

7. Once the settings are reinitialized, the scale will go through its normal start-up segment check and then

return to the Span Switch On Mode.

2.6 Start-Up Screens

The instructions below assume that you are using the scale as a stand-alone unit, with or without remote

platforms. For information on using the DC-200/300 as a network workstation, see Section 6.0.

1. As the scale powers up it will display the current version of the firmware it is using. It also sho ws that the

scale is currently being operated as a stand-alone unit.

2. After a test of the different elements of the display, the scale takes you to the stand-by screen in the

Operation Mode. At the stand-by screen the

WEIGHT, UNIT WEIGHT and QUANTITY displays show zeroes

and the annuciator for the platform you are using is illuminated (A, B, C or D).

From this stand-by screen all of the basic weighing, counting and inventory operations can be performed

(See Section 6.0 on page 77). Also, if any job sequence instructions have been programmed into the

scale, the first operator instruction will be displayed on the second line of the display (Section 8.0).

3. If there is anything on the platform(s) and it exceeds the scale start range, a beep sounds, and the

following error message appears.

Note: The Initial Start Range settings are controlled by SPEC 631. The default setting is 0: +UNLIMITED TO 10%

OF FULL SCALE.

Remove the weight from the platform and press the CLEAR key to exit.

Page 16

2.7 Calibration (Span Adjustment)

The DC-200/300 counting scale is a high-precision instrument. Although the scale needs very little maintenance,

you may want to check the calibration after every month or so of normal usage. To do this you will need to have

a test weight of approximately the total capacity of the scale (i.e. a 10 lb weight if you have a 10 lb capacity

scale). After the scale is initially installed, put the weight on the platform and record the weight displayed. Then

every month or so put the same weight on the scale and verify that it still reads the same.

Many facilities have a technician come in and check their units with certified test weights four times a year. If

you are ISO certified, you will want to check to see if your certification specifies more stringent requirements to

stay in compliance. Your DIGI scale dealer has the calibrated test weights, expertise and experience to perform

this task for you as well as to check other operating parameters of your scale and help you effectively integrate

scales into your operations. If you do not know who your local DIGI dealer is, call us at 1-715-736-0002 and we

will help you find someone who can provide you with on-site support.

Follow the instructions below to calibrate your DC-200/300 scale to ensure its continued accuracy.

1. Make sure the scale is turned off. Then press the span switch to reset it. See Figure 2-4 for location of

Span switch).

Figure 2-4. Location of Span Switch

2. Turn the scale back on. the scale displays the message, CHANGE SPAN SWITCH.

3. While pressing the

REZERO key, enter 8715 from the numeric keypad to enter the calibration mode.

Page 17

4. The scale display confirms that you are in the Calibration Mode.

5. Next, press the

REPRINT key to enter the zero setting mode.

6. Choose which scale platform you are calibrating. The scale defaults to platform A. To choose another

scale platform, press the

7. Make sure that nothing is on the scale platform and press the

SCALE key until the platform you want to calibrate is displayed.

CODE key to have the scale automatically

search for the zero point.

8. The scale displays the zero point in the quantity window. It should be a value between 9000 and 11000.

If the scale does not catch that range, you will need to call your local DIGI dealer or call us at

1-715-736-0002 for service assistance.

9. Press the

REZERO key to clear the Internal Count shown in the weight window.

Page 18

10. Press the REPRINT key to enter the weight calibration setting.

11. Put a calibrated weight on the platform equal to the total capacity of the scale (Example, for a 25 lb scale,

place a 25 lb weight on the scale). Alternatively, you can enter the weight from the numeric keypad. The

weight appears in quantity window. Press the

REPRINT key to save the calibration data.

The display confirms that the span settings for calibration of the scale are being saved

Finally the screen returns to the initial

CHANGE SPAN SWITCH.

12. Once the span switch is turned off, the scale automatically returns to operation mode. The scale should

now be powered off and restarted for the new settings to take effect.

Page 19

2.8 Setting Time and Date

Once you set the internal clock for the correct day and time it will continue to keep them, even when the scale is

off, using the internal battery on the main board. The procedure below can also be used to adjust the time when

moving from Standard to Daylight Savings Time or when the scale is moved to a new facility in a different time

zone.

Note: SPEC 05 - DATE ORDER and SPEC 06 -TIME FORMAT allow you to set the format for date and time that

you prefer the scale to display. The defaults are Month/Date/Year for date and 12 hour for time. To change these

specifications, see Section 2.9.1.

1. Press the MODE key twice until the display shows ITEM CODE PROGRAMMING. The S annunciator,

indicating the Programming Mode, will illuminate.

2. Press the

PROGRAM DATE screen. Enter the current date using the numeric keypad. For months or days from 1 to

9, enter a leading zero. (Ex. In a MM-DD-YY format, May 8, 2003 would be entered as 050803.) Press

the

REPRINT key to store the data in temporary memory and move to the time programming mode.

3. Enter the current time using the numeric keypad. For numbers from 1 to 9, enter a leading zero. (Ex. In a

12 hour format, 3:06 pm would be entered as 0306.) If SPEC 06 - TIME FORMAT is set to a 12 hour

format, you use the

4. Press the

saving the data.

5. To return to the Stand-by Screen in the Operation Mode, press the

+ (plus) or – (minus) keys to scroll through the programming options until you see the

<< and >> keys to toggle between AM and PM.

CODE key to save the data or press the PIECES key followed by the CLEAR key to exit without

MODE key three times.

2.9 Configuration Settings

This section presents the setup and configuration of the DC-200/300 counting scale to be used specifically by

distributors and service technicians. Configuring these specifications allow you to tailor the DC-200/300 to your

specific applications.

Setting the specifications allows you to modify the functionality of the DC-200/300. Use the tables in this section

to view the options you can modify. For example, if you want the function allowing you to print labels by

pressing the

specification table and locate

means that the

the SPEC setting to

2.9.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard

The following tables list the DC-200/300 specifications and their corresponding default values. The default

values are automatically set when the scale’s memory is set by the dealer for the country of operation.

SPEC 00 through SPEC 71 (Table 2-1) are customer specifications and use the 141 access code, while SPEC 600

through SPEC 646 (Table 2-2) are weight and measurement specifications, and use the 142 access code. In

programming specifications, the

specification without saving changes to the SPEC code you were just in.

Customer Specification (141 Settings)

1. To configure customer specifications, press and hold the REZERO key and enter 141 using the numeric

2. If you want to modify a SPEC other than SPEC 00 and you know the number of that SPEC code, enter

+/- keys as well as pressing the REPRINT key to work on the DC-200/300, refer to the DC-200/300

SPEC 34 - PRINT WHEN PRESS +/- KEY. The default for SPEC 34 is 0, which

PRINT WHEN PRESS +/- KEY function is turned off or disabled. To turn it on or enable it, change

1.

REPRINT and – (minus) keys allow you to move to the next or previous

keypad. The first SPEC code, SPEC 0 is displayed, with

first line of the weight display and its current setting (ex.

If this is the SPEC that you want to modify, press

>> or << keys to scroll through the possible settings.

SP0: AUTO POWER SAVING appearing in the

00>0: Disable) appearing in the second line.

When the setting you want to store is displayed, press the + (plus) key to enter the change into temporary

memory and move to the next SPEC code.

the number of the SPEC code on the numeric keypad and press the

REPRINT key. Otherwise, you can

Page 20

use the + (plus) and – (minus) keys to scroll through the specifications until you find the one you want.

Then make your changes per the instructions in Step 1.

3. To change another SPEC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPEC settings currently in temporary memory and exit to the Operation Mode,

press the

CODE key. You will hear a long beep to confirm that the scale is saving the change. The saving

of the configuration file takes about 10 seconds, after which the scale will return to the Stand-By mode.

To exit to the Operation Mode without saving the changes, press the TARE key.

If you power off the scale while the saving process is going on, you can clear the entire

Caution

memory of the scale. Wait until the scale has returned to the Stand-by screen before

performing any other functions.

5. Power down scale using the power switch on the back of the bottom of the scale, not the ON/OFF key on

the keyboard.

6. Power scale on to re-initialize the new specification settings.

Page 21

SPEC Description

00 Auto Power Saving When No Weight Change & No Key Press

0: Disable (DEFAULT)

1: 1 minute

2: 2 minutes

3: 3 minutes

4: 4 minutes

5: 5 minutes

6: 6 minutes

7: 7 minutes

8: 8 minutes

9: 9 minutes

10: 10 minutes

11: 11 minutes

12: 12 minutes

13: 13 minutes

14: 14 minutes

15: 15 minutes

01 Power Saving Type

When set to 0, the backlight turns off when the scale goes into power-saving mode. When set to 1,

the scale turns off entirely

0: Backlight Off (DEFAULT)

1: Power Off

02 Negative Counting

0: No

1: Yes (DEFAULT)

03 Extent of Insufficient Samples

Sets the percentage of the full scale capacity that the initial counting sample has to exceed, otherwise

the

INSUFF lamp lights.

0: 0.1% (DEFAULT)

1: 0.2%

2: 0.0%

04 Set New Item Code During Registration (Operation) Mode

0: Yes (DEFAULT)

1: No

05 Date Order

0: Month/Day/Year (DEFAULT)

1: Day/Month/Year

2: Year/Month/Day

06 Time Format

0: 24 hour (DEFAULT)

1: 12 HOUR (am/pm)

07 Unit Weight Auto Recomputing

0: No (DEFAULT)

1: Yes

08 Sampling Times for Unit Weight Calculation

Higher number samples improve accuracy in environments of higher vibration or breeze but also

increase the time required to compute the unit weight.

0: 15 times (DEFAULT)

1: 20 times

09 Display Accuracy Unit Weight Calculation During Recomputing

0: No (DEFAULT)

1: Yes

Page 22

SPEC Description

10 Set Point Buzzer

0: Buzzer on (DEFAULT)

1: Buzzer off

11 Clear All Input Key in One Touch

0: Yes

1: No (DEFAULT)

12 Keep Lot Number in Registration (Operation) Mode

0: Allow (DEFAULT)

1: Inhibit

13 Job Sequence

0: Disable (DEFAULT)

1: Enable

14 Auto Exit From Add Mode

0: No

1: Yes (DEFAULT)

15 SIO Select Job

Defines what the primary or standard input/output port on the scale is connecting to.

0: No operation (DEFAULT)

1: Force Balance

2: PC

3: Printer

4: Bar Code Scanner

16 RS-232C Baud Rate (SIO - Standard Input/Output Port)

0: 1200 baud

1: 2400 baud

2: 4800 baud

3: 9600 baud (DEFAULT)

4: 19200 baud

5: 38400 baud

17 RS-232C Data Length (SIO - Standard Input/Output Port)

0: 7 bits

1: 8 bits (DEFAULT)

18 RS-232C Parity Bit (SIO - Standard Input/Output Port)

0: None (DEFAULT)

1: Odd

2: Even

19 RS-232C Stop Bit (SIO - Standard Input/Output Port)

0: 1 bit (DEFAULT)

1: 2 bits

20 RS-232 Option Card

0: Not connected (DEFAULT)

1: Printer/Force balance

2: Force balance/Printer

3: Printer/PC

4: PC/Printer

5: PC/Force balance

6: Force balance/PC

21 RS-232 Baud Rate for 8 Pin DIN 1 Connector

0: 4800

1: 9600 (DEFAULT)

2: 19200

3: 38400

Page 23

SPEC Description

22 RS-232 Data Length for 8 Pin DIN 1 Connector

0: 7 bits

1: 8 bits (DEFAULT)

23 RS-232 Stop Bit for 8 Pin DIN 1 Connector

0: 1 bit (DEFAULT)

1: 2 bits

24 RS-232 Parity Bit for 8 Pin DIN 1 Connector

0: None (DEFAULT)

1: Odd

2: Even

25 RS-232 Baud Rate for 8 Pin DIN 2 Connector

0: 4800

1: 9600 (DEFAULT)

2: 19200

3: 38400

26 RS-232 Data Length for 8 Pin DIN 2 Connector

0: 7 bits

1: 8 bits (DEFAULT)

27 RS-232 Stop Bit for 8 Pin DIN 2 Connector

0: 1 bit (DEFAULT)

1: 2 bits

28 RS-232 Parity Bit for 8 Pin DIN 2 Connector

0: None (DEFAULT)

1: Odd

2: Even

29 RS-232 Connection to Force Balance (FB)

0: Disable (DEFAULT)

1: Enable

30 Type of Force Balance

0: Export (DEFAULT) 2:S-HG200

1: HR-603:S-HG300

31 PC/PRN Output Data Method

0: No operation

1: Counting

2: By +/-/Print Key (PC/PRN) (DEFAULT)

3: For both classes 1 & 2

32 Select External Printer Type

0: Eltron LP2622/LP2722 or TVP1000 (DEFAULT)

1: SE520

2: DP122 (Japan)

3: Epson output

33 External Eltron/TVP Printer Download Label Format

0: Enable (DEFAULT)

1: Disable

34 Print When Press +/- Key

0: Disable (DEFAULT)

1: Enable

35 PC Data With Header

0: Yes (DEFAULT)

1: No

36 PC Data Header Type

0: Code 9 - numeric headers (DEFAULT)

1: Title - alphabetic headers

Page 24

SPEC Description

37 IBM Keyboard Port

0: IBM Keyboard

1: Scanner

38 Barcode Scanner (BCS) With Header

0: Yes (DEFAULT)

1: No

39 Track Nprint (TNP) Time Out

0: 2 seconds (DEFAULT)

1: 8 seconds

2: 32 seconds

40 Selection of Network Interface

0: No network (RS-232) (DEFAULT)

1: Twisted Cable (Ethernet)

41 Port Number (IP Address)

The port number can be set anywhere in a range from 1 to 255 (DEFAULT = 001 for DC-300)

(DEFAULT = 002 for DC-200)

42 Set Scale Number

The scale number can be set anywhere in a range from 0 to 999999 (DEFAULT = 00001)

43 Select Receipt or Label Paper Printing

0: Print paper receipt

1: Print label paper (DEFAULT)

44 Printing Speed For Receipt

0: Slow

1: Normal (DEFAULT)

2: High

45 Printing Speed for Label

0: Slow

1: Normal (DEFAULT)

2: High

46 Label Printing Density

0: Low

1: Medium

2: Medium High (DEFAULT)

3: High

47 Label Type

0: Gap (DEFAULT)

1: No Gap

48 Peel Sensor Function

The peel sensor determines whether labels are set to be printed with the backing left on (0: disable) or

with the backing peeled part way so that an individual label can be removed easily from the backing

for immediate use (1: enable).

0: Disable

1: Enable (DEFAULT)

49 Number of Reprint Labels

0: No Label

1:1 Label (DEFAULT)

2:2 Labels

50 Selection of Label and Receipt Printing Operation

0: All operation (in/out/non-add) (DEFAULT)

1: Out (shipping operations)

2: In (receiving operations)

3: In and out

4: No printing

Page 25

SPEC Description

51 Human Readable Barcode Printing Format

0: No print (DEFAULT)

1: Print

52 Item Data Printing Format (DC-300 only)

Sets the justification for printing the data associated with item codes in memory such as ID codes,

part name, part number, and lot number

0: Centering

1: Start printing from the left (DEFAULT)

53 Date Title Print (DC-300 only)

0: No

1: Yes (DEFAULT)

54 Weight Data and Quantity Title Print (DC-300 only)

0: No print

1: Print (DEFAULT)

55 Printing of Factory Name on Label (DC-300 only)

0: No print

1: Print (DEFAULT)

56 Default Printing Label Factory Number (DC-300 only)

Can choose a factory number in a range from 0 to 32. (DEFAULT = 01)

57 Printing of Factory Name Format (DC-300 only)

0: No centering

1: Centering (DEFAULT)

58 Selection of Label Logo Printing Status (DC-300 only)

0: No print (DEFAULT)

1: Logo 1

2: Logo 2

3: Logo 3

4: Logo 4

59 Selection of Barcode Type

0: Code 128A

1: Code 128B

2: EAN 128A

3: EAN 128B

4: CODE 39 (DEFAULT)

60 Auto Print Function

0: Between set point 1 and set point 2

1: Disable (DEFAULT)

61 Ethernet Function

0: No operation

1: Track N Print

2: Data Transfer Mode

62 RS232 - XON/XOFF

0: Disable

1: Enable

63 Sample Quantity

Determines the number of pieces the scale assumes are on the platter when you press the

key to calculate the Unit Weight.

0: 10 pieces (DEFAULT)

1: 25 pieces

2: 50 pieces

3: 100 pieces

PIECES

Page 26

SPEC Description

64 Scale A <–> B

Sets whether the unit weight determined by sampling on Scale A is automatically transferred to Scale

B or not.

0: Manual (DEFAULT)

1: Auto

65 Unit of Pcs Weight

Sets whether the unit weights are displayed per 1000 pieces or per 1 piece. For a further discussion of

the benefits of each option, please see Section 5.4.

0: 1000 pieces (DEFAULT)

1: 1 piece

66 Not used

67 IMS

Determines whether or not the scale automatically queries the DIGI Inventory Management Software

(IMS) for all of the parameters associated with an Item Code when the

more information on this option, please see Section 6.3.1.

0: Disable (DEFAULT)

1: Enable

68 EPSON II

Changes the Epson label format from the default (all item information fields) to an abbreviated format

with only selected fields.

0: Disable (DEFAULT)

1: Enable

69 4 Lot No.

If disabled, allows a single lot number to be entered during weighing operations. If enabled, allows up

to 4 lot numbers to be entered. These lot numbers are not written to the item database.

0: Disable (DEFAULT)

1: Enable

70 Upload Lot and Part Number

If disabled, lot numbers and part numbers entered during weighing operations are not uploaded to the

item database. If enabled, lot numbers and part numbers entered during weighing operations

overwrite the information previously stored with the item code in the scale memory.

0: Disable (DEFAULT)

1: Enable

71 Text 11-16 TTL

Allows you to use text fields 11-16 on total labels rather than just item labels.

0: Disable (DEFAULT)

1: Enable

CODE key is pressed. For

Table 2-1. DC-200/300 (141) Settings

Page 27

Weight and Measurement Specification (142 Settings)

1. Press and hold the REZERO key and enter 142 using the numeric keypad. SP600 appears in weight

display and its current setting (ex. 2>2: LB) appearing in the second line. If this is the SPEC that you

want to modify, press the >> or << keys to scroll through the possible settings. When the setting you

want to store is displayed, press the + (plus) key to enter the change into temporary memory and mo v e to

the next SPEC code.

2. If you want to modify a SPEC other than SPEC 600 and you know the number of that SPEC code, enter

the number of the SPEC code on the numeric keypad and press the

use the

+ (plus) and – (minus) keys to scroll through the specifications until you find the one you want.

REPRINT key. Otherwise, you can

Then make your changes per the instructions in Step 1.

3. To change another SPEC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPEC settings currently in temporary memory and exit to the Operation Mode,

press the

5. Power down scale using the power switch on the back of the bottom of the scale, not the

CODE key. To exit to the Operation Mode without saving the changes, press the TARE key.

ON/OFF key on

the keyboard.

Power scale on to re-initialize the new specification settings.

Spec Description

600

601

602

603

604

Scale Unit Specification

0: Gram

1: Kg

2: Lb (DEFAULT)

Display Resolution

0: 1/10000 (DEFAULT)

1: 1/5000

2: 1/2500)

Internal Count

0: 500,000

1: 1,000,000 (DEFAULT)

Minimum Display (Increment) for Scale A

0: 2 (DEFAULT)

1: 1

2: 5

3: 10

Weight Decimal Point Position for Scale A

0: 0

1: 0.0

2: 0.00

3: 0.000 (DEFAULT)

4: 0.0000

Page 28

Spec Description

605

Load Cell Sensitivity Selection in mV/V for Scale A

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V (DEFAULT)

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

606

Load Cell Type for Scale A

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

607

A/D Board Type for Scale A

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

608

External Scale B Connection

0: Disable (DEFAULT)

1: Enable

609

Minimum Display (Increment) for Scale B

0: 2 (DEFAULT)

1: 1

2: 5

3: 10

610

Weight Decimal Point Position for Scale B

0: 0

1: 0.0

2: 0.00

3: 0.000

4: 0.0000 (DEFAULT)

611

Load Cell Sensitivity Selection in mV/V for Scale B

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V (DEFAULT)

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

Page 29

Spec Description

612

Load Cell Type for Scale B

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

613

A/D Board Type for Scale B

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

614

External Scale C Connection

0: Disable (DEFAULT)

1: Enable

615

Minimum Display Increment for Scale C

0: 2

1: 1 (DEFAULT)

2: 5

3: 10

616

Weight Decimal Point Position for Scale C

0: 0 (DEFAULT)

1: 0.0

2: 0.00

3: 0.000

4: 0.0000

617

Load Cell Sensitivity Selection in mV/V for Scale C

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V (DEFAULT)

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

618

Load Cell Type for Scale C

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

619

A/D Board Type for Scale C

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

620

Tare Range Settings

0: 100% full scale (DEFAULT)

1: <50% full scale

2: <5% full scale

621

Digital Tare Setting

0: Disable

1: Enable (DEFAULT)

Page 30

Spec Description

622

Tare Accumulation

0: No (DEFAULT)

1: Yes

623

Digital Tare When Loaded

0: Allow (DEFAULT)

1: Inhibit

624

Tare Subtraction (for Load Tare Only)

0: Yes (DEFAULT)

1: No

625

Tare Addition (for Load Tare Only)

0: Yes

1: No (DEFAULT)

626

Tare Value Exchange (for Load Tare)

0: Yes (DEFAULT)

1: No

627

Zero Tracking When Tare

0: Yes (DEFAULT)

1: No

628

Tare When Scale Change

0: Old Tare (DEFAULT)

1: New Tare

629

Weight Reset When Tare

0: Yes (DEFAULT)

1: No

630

Auto Clear Tare When Rezero

0: No (DEFAULT)

1: Yes

631

Initial Start Range Settings

0: +Unlimited to 10% full scale (DEFAULT)

1: +/- 2% full scale

2: +/- 10% full scale

632

Zero Range Settings

0: +Unlimited to 10% full scale (DEFAULT)

1: +/- 2% full scale

2: +/- 10% full scale

633

Zero Lamp Lighting Method

0: Gross weight (DEFAULT)

1: Net weight

634

Rezero When Changing Scale

0: No rezero (DEFAULT)

1: Rezero

635

Stability Check When Changing Scale

0: Stability check (DEFAULT)

1: No stability check

636

Internal Count Resolution (IR) Protected by Span Switch

0: No (DEFAULT)

1: Span switch protect

637

Calibration/Default SPEC/SPEC 142 Mode Protected by Span Switch

0: Span switch protection

1: No protection (DELETE)

Page 31

Spec Description

638

639

640

641

642

643

644

645

646

Display at Minus Weight

0: Minus display (DEFAULT)

1: Masked display

Masked Display at Minus Weight

0: Gross weight (DEFAULT)

1: Net weight

Overweight Masked

0: At +1D (DEFAULT)

1: At + 9D

Selection of Scale Starting Method

0: Auto start (DEFAULT)

1: Manual start

Weight Unit Convert

0: Yes (DEFAULT)

1: No

Gross Mode Display

0: Yes (DEFAULT)

1: No

Selection of Decimal Point Type

Sets whether the decimal point is displayed as a period (U.S. usage) or a comma (European, Latin

American, Asian usage)

0: Period display (DEFAULT)

1: Comma display

Selection of Scale Type

0: DC-300 scale

1: DC-200 scale

Automatic Unit Weight Clear Conditions

0: Disable (DEFAULT)

1: Over net 5D & gross 21D & weight stable

2: >=net 1D & weight stable

3: >=net 1D & quantity > 0 & weight stable

Table 2-2. DC-200/300 (142) Settings

2.9.2 Configuring Spec 141 and 142 Settings Using the Spec Upload Utility

The DC-300 Utility Program includes a module called “Spec Upload”. This handy program allows you to more

easily do four useful things:

• change one or any number of spec settings from your computer screen and then upload them to a

DC-200/300 rather than change them from the scale’s keyboard.

•save the spec setting currently programmed in the DC-200/300 to a named file on your computer from

which they can be restored to the same DC-200/300 later or uploaded to other DC-200/300s so that their

spec settings match.

•save spec settings optimized for a particular task, department or facility to a named file on the computer.

This complete set of spec settings can then be uploaded to a DC-200/300 whenever the scale’s use or

location changes, rather than have to go through and manually change each spec. It can also be used to

save a backup of your spec settings if you should need to send your scale to be serviced.

Return all the scale’s spec settings to the default settings by uploading the defaults from the computer to the

scale.

Note: For information on how to install the DC-300 Utility Program on your computer, Section 8.2 on page 101 If

you have not already set up your computer and the scale to be able to communicate to each other using the

DC-200/300’s Ethernet connection, please see Section 6.1. If you are unsure of how to work with TCP/IP

connections or have difficulties, see your Network Administrator for help.

Page 32

Change Spec Settings Using the Spec Upload Utility

1. With the scale turned on and at the Stand-by screen, press REZERO + SHIFT UP. The scale display will

indicate that it is changing to the data transfer mode.

2. The scale display will next indicate that it is ready for the data transfer mode after the scale is restarted.

Turn the scale off and then on again, using the on/off switch located on the bottom of the scale at the

back

3. After you restart the scale and it goes through its startup sequence, the scale will show that the data

transfer mode is ready.

4. On your computer, open the Spec Upload program.

Note: If you have not yet installed the DC-300 Utility Program, see Section 8.2.

At the opening screen of the Spec Upload program, you have the option to Load the Default Setting file; load

from a named, saved file on your computer; or read the spec settings from the DC-200/300 scale connected to

your computer.

Page 33

Select the radio button for Read From Scale. Also make sure that the Scale No. radio button for 192.168.0.1 (the

IP address of the DC-300) has been selected if you are using the DC-300 or 192.168.0.2 if you are using the

DC-200.

Figure 2-5. Read From Scale Screen

5. Click on the Next button at the bottom of the Spec Setting dialog box. The program will confirm Spec

reading in progress, please wait..., showing that it is uploading the current spec settings from the scale.

The Spec Upload program will next display the Spec Setting screen, showing the values of the first four

SPECs programmed in the scale.

6. To change the setting of one or more of the first four specs, use the pull down list box for that spec to

choose among the available settings for that specification. To move to the next four specifications, click

on the Next button at the bottom of the dialog box.

7. Once you have made all the needed changes to the specifications, you can upload the changed specs to

Figure 2-6. User Specification Screen

Page 34

the scale and also save the new configuration to a named file on your computer for future updating of this

scale or matching the specifications on another DC-200/300.

To save the new configuration settings, click on the

Save button at the bottom of the dialog box. You will

be prompted to give this configuration a file name. The next time you open the DC-300 Spec Upload

program, this file will show as one of the ones available to upload to any DC-200/300. After assigning a

file name, click on the Save button to save the file. You will be returned to the main Spec Upload Utility

screen.

8. To upload the changed spec settings to the DC-200/300 currently connected to your computer, click on

the

Upload button. The utility will ask you whether you want to update one specific spec or all the specs.

Figure 2-7. Upload Screen

To update only one spec, type its number into the box. To update all the specifications, select the radio

button for All Specifications. Click on the Upload button.

Page 35

9. The program will confirm with the message Successfully Sent while the scale display shows the

following.

If you power off the scale while the saving process in going on, you can clear the entire

Warning

memory of the scale!

Once the scale has completed the upload of the change(s), it will display the following:

The scale should be powered down and then powered back up to initialize the new changes. When the

scale is powered back up, it will still be in the

DATA TRANSFER MODE - READY state. To exit the Data

Transfer Mode, continue with the instructions below.

10. To exit the Data Transfer Mode on your DC-200/300 scale and return it to normal weighing mode, press

REZERO + SHIFT DOWN. The scale will briefly display a message saying that it is exiting the Data

Transfer mode.

11. Next you will be prompted to restart the scale.

Once you have restarted the scale, you will be returned to normal weighing operations.

Page 36

Uploading Saved Spec Configurations to a DC-200/300

To download the spec settings from a DC-200/300 to the computer, see Section 2.9. If you already have a saved

configuration file of spec settings, use the instructions below to upload the settings to a DC-200/300. This could

be to change the settings of a DC-200/300 to fit a particular task, department or facility or it could be to take the

spec settings configuration from one DC-200/300 and upload it to other DC-200/300’s so that their settings

match.

1. With the scale turned on and at the Stand-by screen, press

REZERO + SHIFT UP. The scale display will

indicate that it is changing to the data transfer mode.

2. The scale display will next indicate that it is ready for the data transfer mode after the scale is restarted.

Turn the scale off and then on again, using the on/off switch located on the bottom of the scale at the

back.

3. After you restart the scale and it goes through its startup sequence, the scale will show that the data

transfer mode is ready.

4. On your computer, open the Spec Upload program.

Page 37

Note: If you have not yet installed the DC-300 Utility Programs, see “Installing the DC-300 Utility Program”.

Figure 2-8. Load From File Screen

At the opening screen of the Spec Upload program, you have the option to Load the Default Setting file; load

from a named, saved file on your computer; or read the spec settings from the DC-200/300 scale connected to

your computer.

• to load the default specification settings to the scale, click the radio button next to

Load Default Setting.

When you installed the DC-300 Utility Program a file named Default.ini was copied into the Digisoft

folder on your computer. To see what the default settings are for the scale specifications, see Section 2.5.

• to load a specification file you have previously saved to your computer, select the radio button for

From File. If the named file you want to upload to the scale appears in the File Name box, click on it to

Load

select it. If the file you want does not appear in the File Name box, use the Drives and Folders explorer

windows to find the file you are looking for.

Once you have selected the spec configuration file to be uploaded and it appears under

File Name, click

on the Next button at the bottom of the screen to continue.

Page 38

5. In the next screen you have the option to change any of the spec settings saved in this file before

uploading.

Figure 2-9. User Specification Screen

To upload to the scale without making any changes, click on the Upload button. To change the setting of

one or more of the first four specs, use the pull down list box for that spec to choose among the available

settings for that specification. To mov e to the ne xt four specifications, press the Next button at the bottom

of the dialog box.

6. Once you have made all the needed changes to the specifications, you can upload the changed specs to

the scale and also save the new configuration to a named file on your computer for future updating of this

scale or matching the specifications on another DC-200/300.

To save the new configuration settings, click on the

Save button at the bottom of the dialog box. You will

be prompted to give this configuration a file name. The next time you open the DC-300 Spec Upload

program, this file will show as one of the ones available to upload to any DC-200/300. After assigning a

file name, click on the Save button to save the file. You will be returned to the main Spec Upload Utility

screen.

7. To upload the changed spec settings to the DC-200/300 currently connected to your computer, click on

the

Upload button. The utility will ask you whether you want to update one specific spec or all the specs.

To update only one spec, type its number into the box. To update all the specifications, select the radio

button for all specifications. Click the Upload button.

Figure 2-10. Upload Spec Settings

Page 39

8. The program will confirm with the message Successfully Sent while the scale display shows the

following.

If you power off the scale while the saving process in going on, you can clear the entire

Warning

9. Once the scale has completed the upload of the change(s), it will display the following:

memory of the scale!

The scale should be powered down and then powered back up to initialize the new changes. When the

scale is powered back up, it will still be in the

Transfer Mode, continue with the instructions below.

10. To exit the Data Transfer Mode on your DC-200/300 scale and return it to normal weighing mode, press

REZERO + SHIFT DOWN. The scale will briefly display a message saying that it is exiting the Data

Transfer mode.

11. Next you will be prompted to restart the scale.

DATA TRANSFER MODE - READY state. To exit the Data

Once you have restarted the scale, you will be returned to normal weighing operations.

Page 40

2.10 Modes of Operation

The DC-200/300 has four main modes of operation:

•Operation Mode – where all the basic weighing and counting operations are performed (also called the

Registration Mode).

•Report Mode – where item, inventory, and shelf location reports can be printed.

• Program Mode –where item data, factory name, and other data can be programmed into the memory of

the scale.

•Password Mode – where you can set passwords that will be required for a scale operator to use certain

functions of the scale.

A fifth mode of operation, Service Mode, is used by your DIGI Dealer or authorized service technician to

perform initial programming and troubleshooting operations.

Which mode you are in is displayed on the right-hand side of the display panel by the following codes:

Mode Annunciator

Operation Mode Default mode, no letter displayed

Report Mode X

Program Mode S

Password Mode The code for the mode you are password protecting is displayed

Service Mode Z

Table 2-3. DC-200/300 Modes of Operation

Page 41

3.0 Maintenance

The following section describes basic maintenance involved with the DC-200/300 counting scale.

3.1 Hardware Testing

3.1.1 RAM and Communications Port Testing

In the Service Mode you can cycle through a set of hardware tests that will check reading/writing to RAM, the

RS-232 and Ethernet ports, and the ROM Checksum. If any of these tests fails, contact Rice Lake Weighing

Systems for help in determining the problem.

RAM Test

1. From the Stand-by Screen press the MODE key until the display shows SERVICE MODE. The Z

annunciator, indicating that you are in the service Mode will illuminate.While holding down the

REZERO key, press 001 to enter the hardware testing mode.

2. The first test is the RAM Read/Write Test. While the test is under way, the following is displayed.

If reading and writing to the scale’s RAM test successfully, the display reads:

If the read/write test is unsuccessful, the display will read:

Page 42

RS-232 Main Port Test

In order to perform the RS-232 port testing, you will need to have or make two test connectors with pins 4 and 5

connected as follows:

Figure 3-1. Test Connector for RS-232 Ports

1. Press the + (plus) key. The display shows SIO LOOP BACK TEST.

2. Plug the test connector into the RS-232 port in the main interface board (the lower RS-232 port, next to

the IBM keyboard port.

Figure 3-2. DC-200/300 Interface Ports

If the port tests correctly, the following message is displayed.

If the loop back test of the port fails, you will see the following:

Page 43

RS-232 Option Card Test

Your DC-200/300 comes standard with the option board installed that gives you two additional RS-232 ports.

You will need the two test connectors described in the RS-232 Main Test Port section on the previous page in

order to perform this test.

1. Press the

+ (plus) key to move to the RS-232 Option Card test.

2. Plug the RS-232 test connectors into both of the ports on the option card (the two upper RS-232 ports

next to the Ethernet port marked SIO1 and SIO2).

Figure 3-3. Option Board RS-232 Ports

The scale will perform the test. If it completes successfully, you will see the following display:

If the test fails, the display will indicate which port(s) did not test successfully. If both ports fail, the

display will read as follows:

If only one port fails, the message will show which one was unsuccessful by displaying the following:

Page 44

Ethernet Port Test

1. Press the + (plus) key to move to a test of the Ethernet port. If the port tests successfully, the following

message is displayed.

If the test fails, the scale displays the following screen:

ROM Checksum Test

Press the + (plus) key to move to the ROM Checksum test for the firmware. While the test is being performed,

you will see;

When the test completes successfully, the scale display will switch to:

Exiting the Hardware Test Mode

At this point you can press the + (plus) key again to repeat the cycle of hardware test beginning with the RAM

test, or you can press the

TARE key to return to the Service Mode. Then press the MODE key twice to return to

the Stand-by screen.

Page 45

3.1.2 Internal Test Count

This test allows you to see more detail on the scale’s internal resolution than you can see on the weight and

counting display . It may allo w you to tell if there is a problem with the load cell being misaligned or if something

is rubbing against a load cell during weighing operations. If the scale constantly does not return to zero during

weighing, you can also rezero the internal counting using this procedure.

1. From the Stand-by screen, press the

MODE key until the display shows SERVICE MODE. The Z

annunicator, indicating that you are in the Service Mode, illuminates.

2. While holding down the

REZERO key, press 009 to start the Internal Count test. The scale display shows

the results of the test:

If the number on the left is not returning to zero, press the

REZERO key. Place a weight on the scale

platform. If the scale does not respond quickly and repeatedly by increasing the counts when you place a

weight on the scale, you may want to check the load cells.

3. Press the

TARE key to return to the SERVICE MODE. Then press the MODE key twice to return to the

Stand-by screen.

3.1.3 Span Switch Status Test

From the Stand-by screen, press the MODE key until the display shows SERVICE MODE. The Z annunicator,

indicates that you are in the Service Mode and illuminates.

1. While holding down the

REZERO key, press 284 to display the Span Switch status. The scale display

shows the current status of the Span Switch.

2. Press the

TARE key to return to the Service Mode. Then press the MODE key twice to return to the Stand-

by screen.

3.1.4 Voltage Checkpoints

There are four voltage checkpoints on the main board. Below are listed the reference voltage levels commonly

used.

Voltage Point Voltage Purpose

Vcc 5.0 V Provides voltage for most of the IC

TH 24 V Provides voltage primarily to the thermal print head

V

BB (off state) 2.5 V Provides backup voltage for the RAM IC when the power is off

V

BB (on state) 4.5 V Provides backup voltage for the RAM IC when the power is on

V

The tolerance of all the voltages shown is about ± 5%, except V

Table 3-1. Voltage Checkpoints

TH which is +2% and -5%.

Page 46

Figure 3-4. Voltage Checkpoints

3.2 Internal Printer Tests and Adjustments (DC-300 only)

The following sections describe internal printer tests and the appropriate adjustments.

3.2.1 Checking or Rezeroing the Thermal Head Usage Counter

The DC-300 maintains a usage counter for the thermal head of the built-in printer. It displays the usage in

thousands (incrementing 1 for every 1000 print operations). The counter can be rezeroed after the replacement of