Page 1

DC-190

ULTRA COUNT

Counting Scale

Version 4.0

Installation Manual

Page 2

1.0 Introduction

The DC-190 Ultra Count counting scale offers practical

solutions for a full range of precision counting applications.

Models with an internally mounted load cell are available in

capacities of 1.0 to 100 pounds. Models with external

platforms are available in capacities of 1.0 to 50,000 pounds.

An ultra-high-resolution force balance can also be used as a

sample scale.

Features include 200 item code storage, over/under weight

and quantity checking capability based on programmable

setpoints, and an optional internal battery for standalone applications. The enhanced DC-190 Ultra Count

software provides features not found in the standard DC-190 counting scale, including:

• Separate tare registers for each channel

• Selectable fields for RS-232 output

• 32-character ID Code, part name, and lot

number fields

• 32-character operator identification can be held

through ID Code changes (SPEC-selectable)

•Teraoka Code and numeric input without SPEC

change

• Supports unit weight per piece and unit weight

per 1000 (SPEC-selectable)

• Supports CR or CR/LF delimiter

• Supports output on stable (SPEC-selectable),

output on stable and

and

in target window (over/under) or

target window (SPEC-selectable)

• Supports simultaneous connection to two

printers

• Eltron 27xx series printers can use downloaded

label format or fixed format installed in 190

• Code 128 support for Eltron and BCP-30 printers

• BCP-300 company name output can be edited or

removed.

• Full barboard support

≥

setpoint, output on stable

not

in

Trademark Note:

trademark of Seiko Epson Corporation. PSC® and QuickScan® are registered trademarks of PSC Inc.

Eltron® and Zebra® are registered trademarks of Zebra Technologies Corporation. Epson® is a registered

Page 3

1.1 Unpacking and Inspection

Immediately after unpacking, visually inspect the DC-190 Ultra Count to ensure all components are included and

undamaged. If any items were damaged in shipment, notify Rice Lake Weighing Systems and the shipper

immediately.

Ensure all accessories are removed from the cartons, then replace all packing materials in the cartons and store in

a safe place. Use the original cartons whenever shipment of the scale is required.

1.2 Repacking

If the DC-190 counting scale must be returned for modification, calibration, or repair, it must be properly packed

with sufficient cushioning materials and the load cell must be locked to prevent damage to the load cell (see

Section 2.1 on page 6).

Whenever possible, use the original carton when shipping the DC-190. Damage caused by improper packaging is

not be covered by warranty.

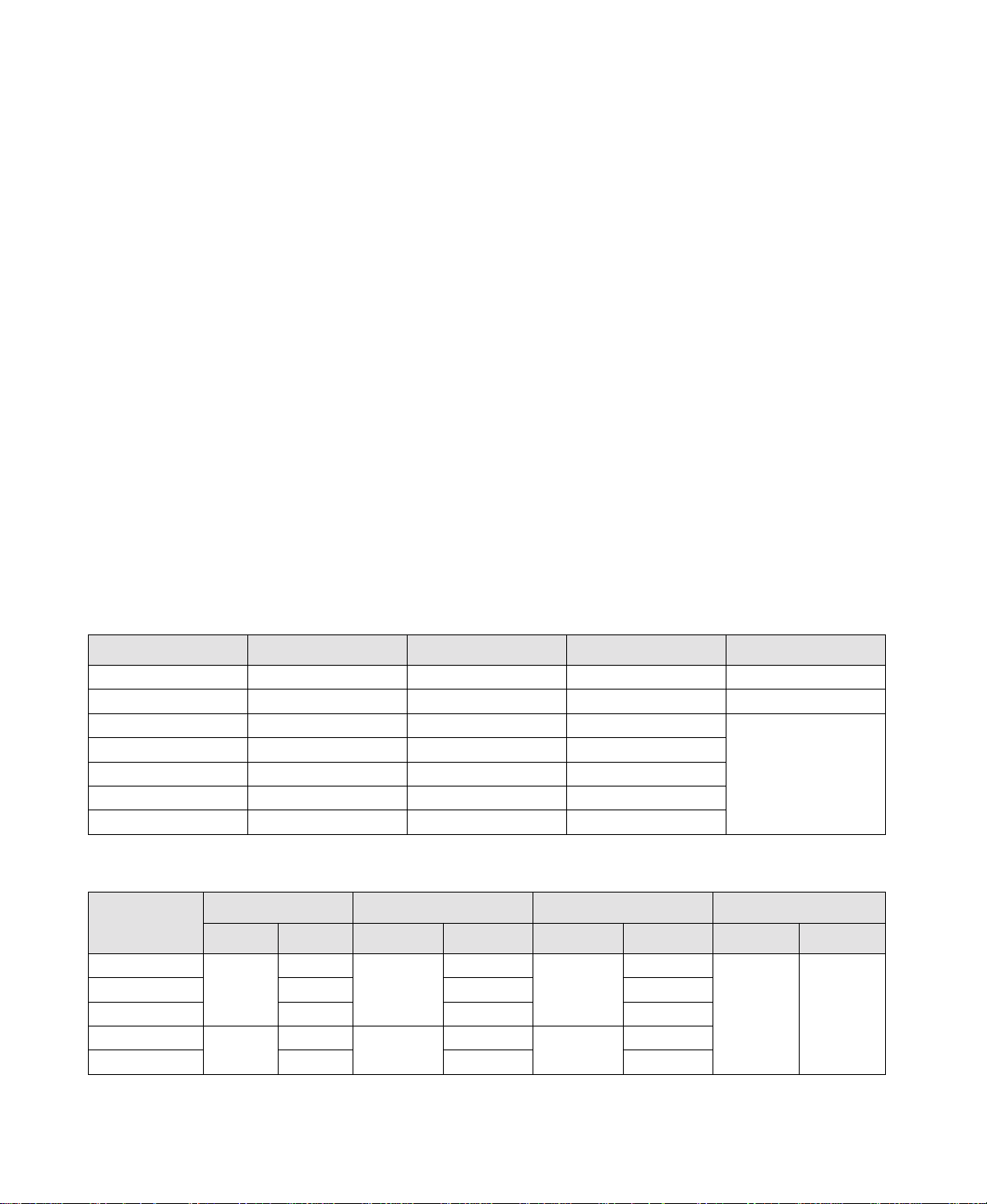

1.3 DC-190 Scale Capacities and Resolutions

Counting scales specify two types of resolution:

•Weight (or external) resolution

• Counting (or internal) resolution

Weight resolution is displayed in increments of the full scale capacity which is divided into weight increments.

For example, a 5-lb scale divided into 10,000 display divisions would display weight with 0.0005 lb divisions

(10,000 divisions x 0.0005 lb = 5.0 lb).

Counting resolution is based on the internal resolution of the scale. The weight and counting resolutions for the

DC-190 single- and dual-platform capacities are listed below.

Tables 1-1 through 1-3 list the scale capacities and resolutions for all models of the DC-190 counting scales.

Model

S-XL-1.0 1.0 0.0001 0.000001 6” x 8”

S-XL-2.5 2.5 0.0002 0.0000025 7” x 10”

S-XL-5.0 5.0 0.0005 0.000005 11” x 16”

S-XL-10 10.0 0.001 0.00001

S-XL-25 25.0 0.002 0.000025

S-XL-50 50.0 0.005 0.00005

S-XL-100 100.0 0.01 0.0001

Model

S-XD-1/10 1.0 10 0.0001 0.001 0.000001 0.00001 4” x 6” 9” x 12”

S-XD-1/25 25 0.002 0.000025

S-XD-1/50 50 0.005 0.00005

S-XD-2.5/25 2.5 25 0.0002 0.002 0.0000025 0.000025

S-XD-2.5/50 50 0.005 0.00005

Scale 1 Scale 2 Scale 1 Scale 2 Scale 1 Scale 2 Sample Bulk

Capacity (lb) Weighing Resolution (lb) Internal Resolution (lb) Platform Dimensions

Table 1-1. DC-190 S-XL Scale Capacities

Capacity (lb) Weighing Resolution (lb) Internal Resolution (lb) Platform Dimensions

Table 1-2. DC-190 S-XD Scale Capacities

Page 4

Model

S-SL-50 50 0.005 0.00005 13” x 17”

S-SL-100 100 0.01 0.0001

S-SL-250 250 0.02 0.00025

S-TL-100 100 0.01 0.0001 17” x 21”

S-TL-250 250 0.02 0.00025

S-TL-500 500 0.05 0.0005

S-UL-100 100 0.01 0.0001 24” x 28”

S-UL-250 250 0.02 0.00025

S-UL-500 500 0.05 0.0005

NOTE: Other platform sizes are available. Consult factory for more information.

Capacity (lb) Weighing Resolution (lb) Internal Resolution (lb) Platform Dimensions

Table 1-3. Other S-Series Remote Platforms

Page 5

IN

lb

kg

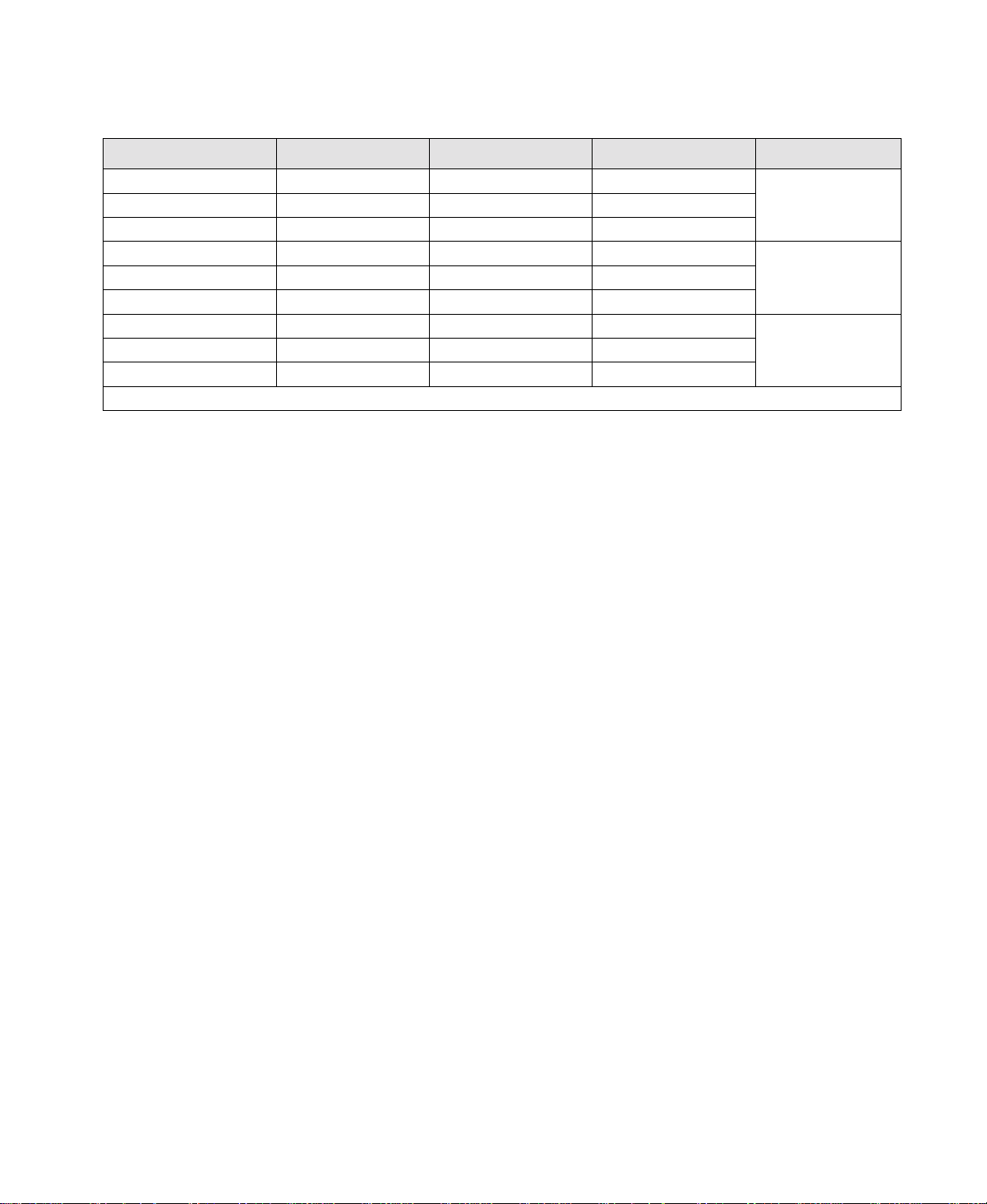

1.4 DC-190 Console

Figure 1-1 shows the DC-190 console with annunciators and numeric keypad. Annunciators are described in

Section 1.4.1; Section 1.4.2 describes the DC-190 keypad.

Figure 1-1. DC-190 Keypad and Displays

1.4.1 Annunciators

Table 1-4 shows a list of the annunciators that the DC-190 uses to provide additional information about the value

being displayed. The annunciators are illuminated when the specific function is being performed.

Annunciator

ZERO

NET

GROSS

INSUFF

RECOM

BATT

MEMORY

OUT

UW/1000 Pcs

MODE

Gross weight is at center of zero

Display shows net weight (when tare weight is entered or recalled)

Display shows gross weight

Net weight is below specified percentage of scale capacity

Unit weight recomputing is possible

Battery power level is low

Quantity being accumulated or memory overflow error

Inventory out

Inventory in

UNIT-WEIGHT display value is equal to the weight of one piece, not 1000 pieces. Otherwise

referred to as average piece weight (A.P.W.)

In programming mode

Annunciator Meaning

SCALE NO. (1–4)

Item weighed in lb units

Item weighed in kg units

Values shown in WEIGHT, UNIT-WEIGHT, and QUANTITY displays are for indicated scale.

Table 1-4. DC-190 Panel Annunciators and Function

Page 6

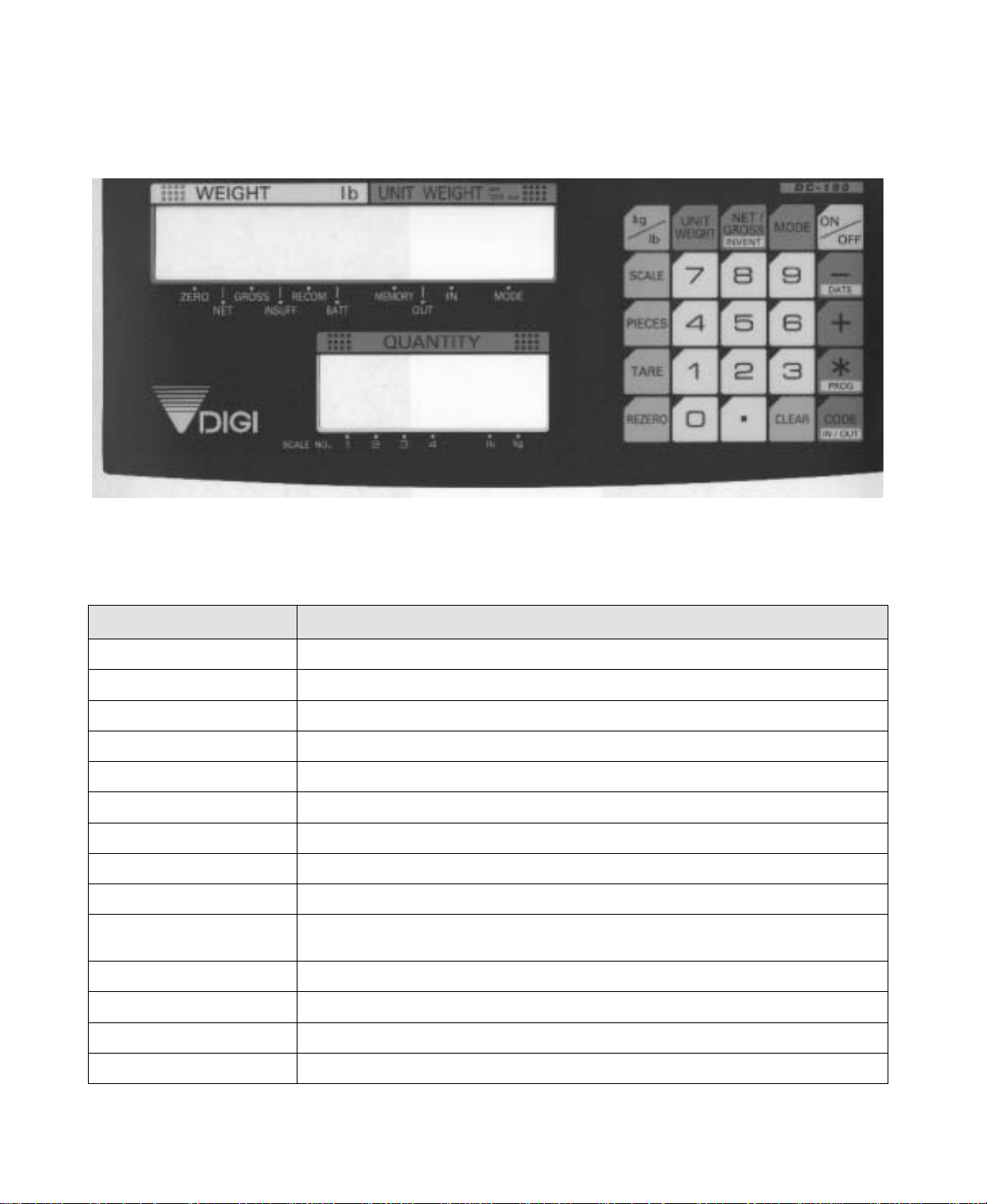

1.4.2 DC-190 Keypad

Table 1-5 lists the keys and key functions of the DC-190 Ultra Count keypad (see Figure 1-1 on page 4).

Key

Description

through Used to enter numeric values. When using the scale, first enter a numeric value, then press the

appropriate function key.

0

9

Used to enter numeric values containing a decimal point. NOTE: A numeric value must be entered

before the decimal point. For example, .250 would be entered as 0.250. In normal mode, pressing

the decimal key without entering a numeric value allows you to recall an item code from memory

using the Teraoka Code (see Section 10.8 on page 58).

CLEAR

Clears keyed-in data from the display starting with the last digit entered or clears keyed-in data all

at once (depends on SPEC 6, bit 2 setting). In normal weighing mode, can be used to clear the

unit weight with a unit weight already entered. When using a recalled item code, press CLEAR to

clear both the unit weight and the tare weight.

kg

lb

Switches display between pound (lb) and kilogram (kg). The scale powers up in the pound mode.

Used to cycle through Scales 1 through 4.

SCALE

Used to compute unit weight by sampling. Press the PIECES key after placing a 10-piece sample

PIECES

on the platform, or after using the numeric keypad to enter the sample size. On multichannel units,

the scale used must be selected.

TARE

Used to set and clear tare weights in the normal weighing mode.

Used to reset the scale to zero. Also used in conjunction with other keys to enter the maintenance

REZERO

mode. The REZERO key will not function when the scale is in motion.

UNIT

WEIGHT

NET/

GROSS

INVENT

MODE

ON

OFF

-

DATE

+

PROG

*

CODE

IN / OUT

Used to enter a known unit weight using the numeric keypad.

Switches between net weight and gross weight display modes. Also used as an inventory key

(depends on SPEC 2, bit 0 setting).

Used to enter the program mode. The MODE annunciator is illuminated when the scale is in

program mode and the WEIGHT display reads ProG . The quantity display shows the letter C and

the number of item codes in memory.

Powers the scale on or off.

Used to operate the reduction function and to move between specification numbers (high to low)

in SPEC setting mode. Also used to program part number in programming item codes. In

programming mode, it can be used for viewing or setting date/time.

Used to operate the accumulation function and to move between specification numbers (low to

high) in SPEC setting mode. Also used to program set points in programming item codes.

Used to store specification data in SPEC setting and program modes. Also used as a print key to

transmit weight information.

Used to recall item code data and to switch between item code inventory IN and OUT modes.

Also used to program commodity name in programming item codes.

Table 1-5. DC-190 Keypad Keys and Functional Descriptions

Page 7

2.0 Installation

This section describes the procedure for the

installation and setup of the DC-190 counting scale.

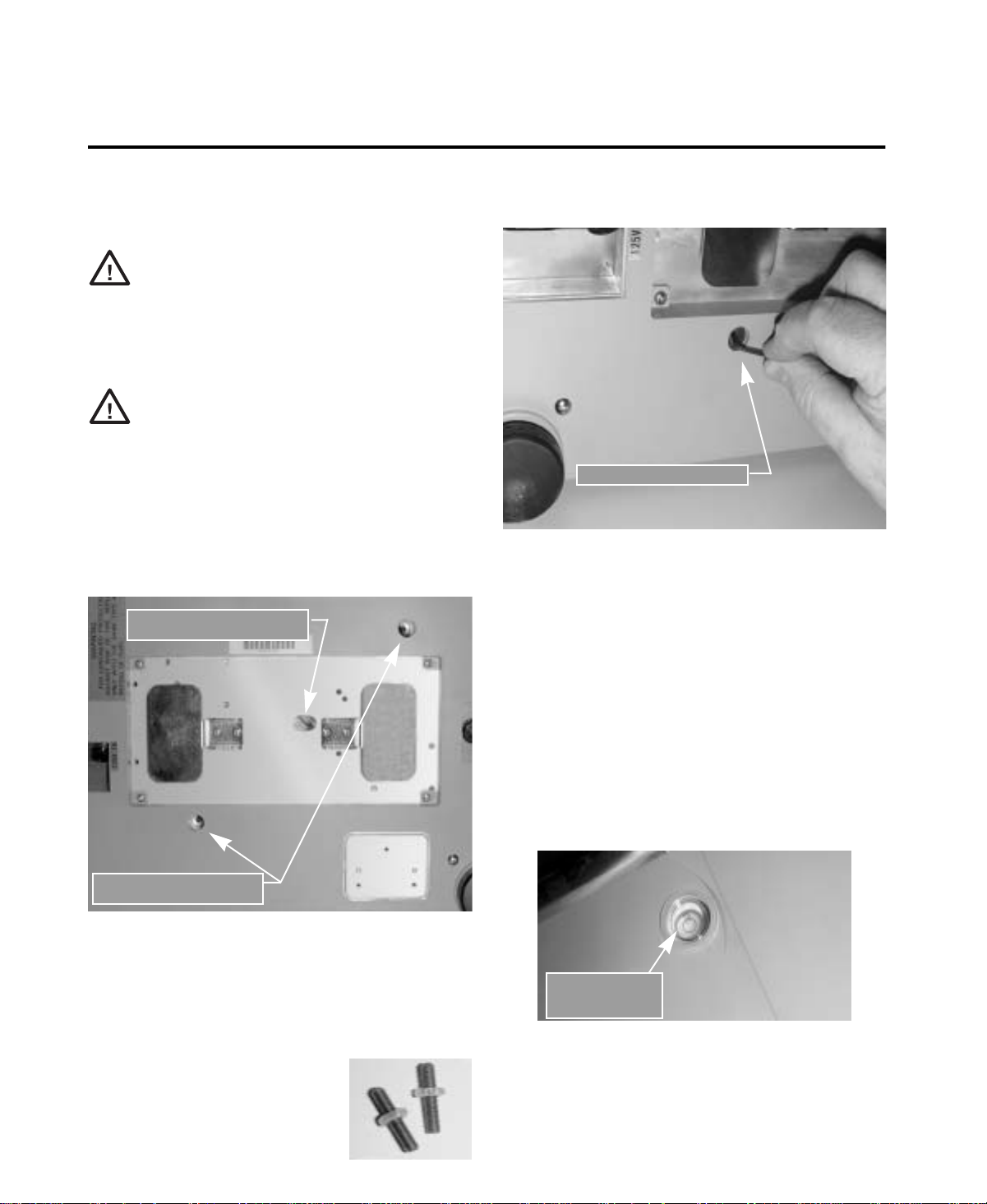

2.1 Locking and Unlocking

Do not turn scale upside down. Always

Caution

The DC-190 counting scale is delivered in a locked

position to prevent damage to the load cells during

shipment.

Caution

The scale uses either one setscrew for the single-platform

scale or two setscrews for the dual-platform scale. The

setscrews are located on the bottom of the base and must

be removed before the scale is put into service. Use the

following procedure to unlock your DC-190 counting

scale.

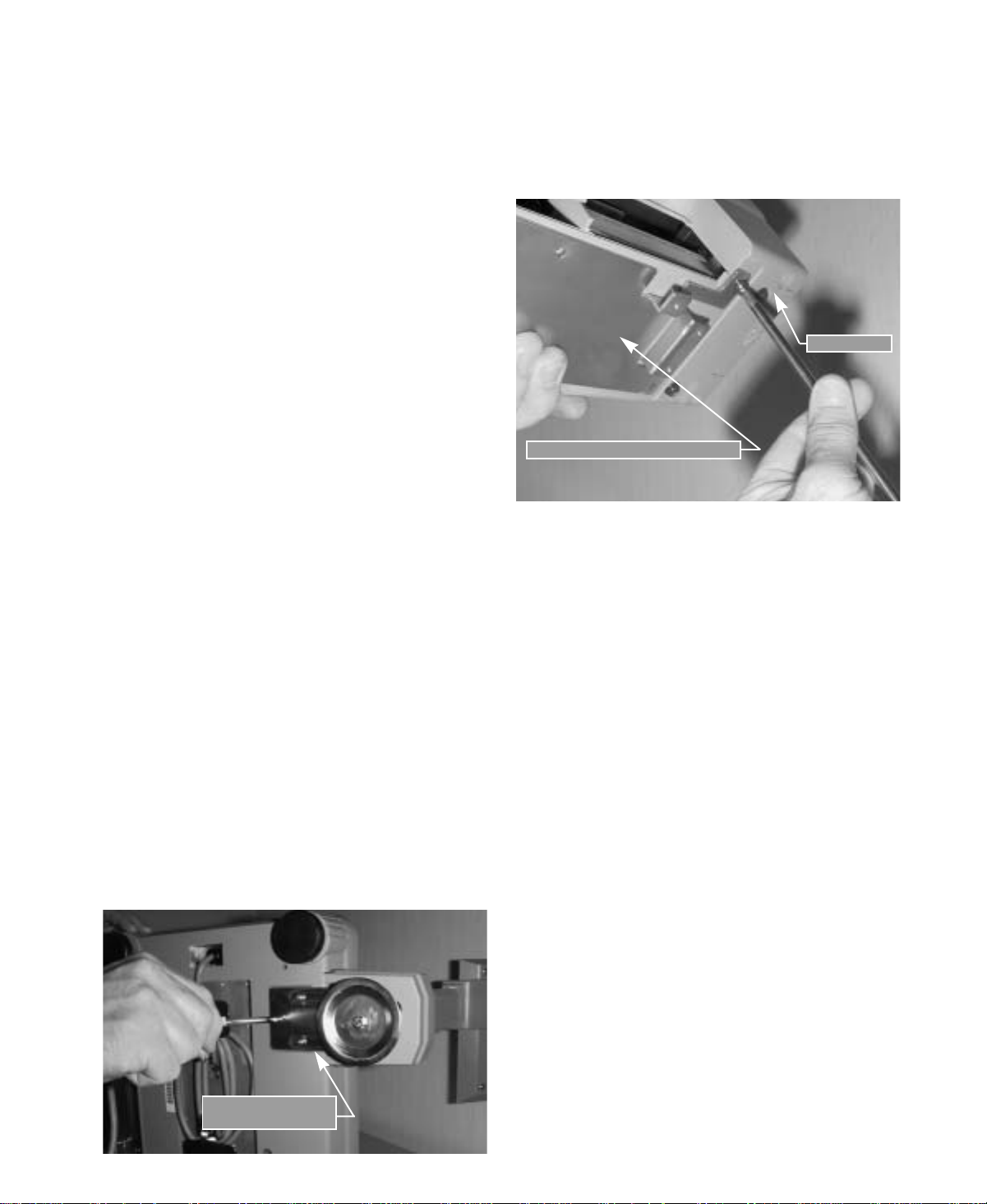

1. Turn scale on side. Loosen locknut 1/4 turn (see

Figure 2-1).

SINGLE-PLATFORM LOAD

CELL SETSCREW

work with scale on its side! Damage to

the load cell can occur if the scale is

turned upside down.

To prevent damage to the load cells,

scale must be locked prior to shipment.

NOTE:

will replace the hex head types, and will no longer require

the 2mm hex wrench for removal.

Beginning in 2003, setscrews with slotted heads

LOAD CELL SETSCREW

Figure 2-2. Setscrew Removal

3. Tape setscrews to the bottom of the scale or

store in a safe location for possible future use.

2.2 Setting Up

Place the scale on a solid, level surface away from

fans, breezes, and sources of electrical interference.

Level the scale by turning the four adjustable legs

located on the bottom of the scale while referencing

the bubble level located on the back of the scale (see

Figure 2-3).

DUAL-PLATFORM LOAD

CELL SETSCREWS

Figur e 2-1. Location of Load Cell Setscr e ws for Single- and

Dual-Platform Scales

2. Remove load cell setscrew (see Figure 2-2)

using the 2 mm hex wrench provided with

scale.

NOTE:

approximate original position on the

setscrew to prevent damage to load

cell when reinstalling.

Keep locknut in the

NOTE:

To ensure greater scale stability, turn in all

four adjustable legs before leveling. Turn out

adjustable legs to level as needed.

BUBBLE LEVEL

Figure 2-3. Bubble Level

Page 8

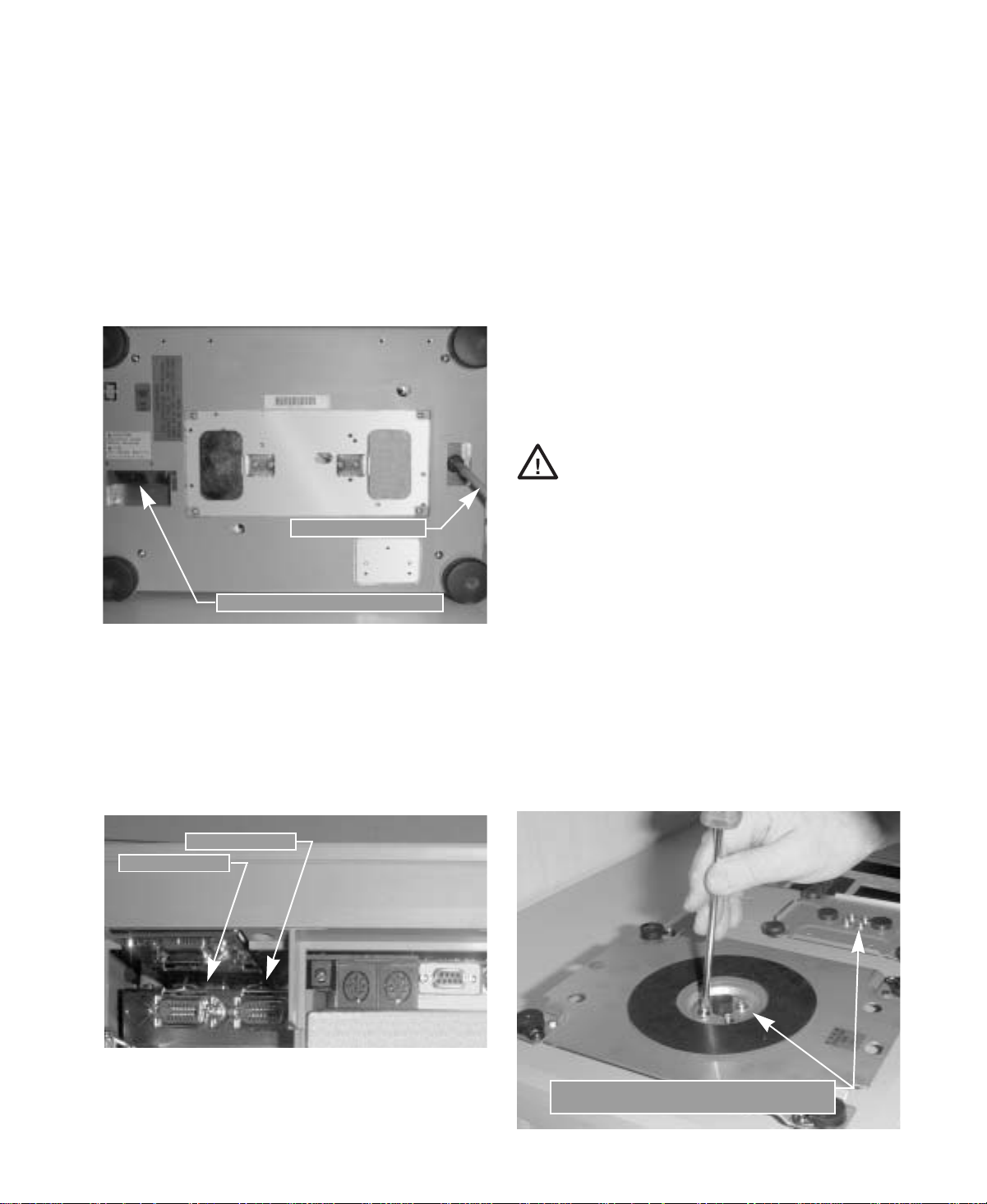

2.3 Powering Up the DC-190

The DC-190 can be operated either from an AC power

source or with an optional rechargeable battery pack

(DC power). The DC power allows the unit to be

completely portable. Instructions for DC operation are

contained in Section 2.3.3.

2.3.1 AC Power Source

To power-up the DC-190 using the AC power cord:

1. Connect female end of AC power cord

(Figure 2-4) under scale base.

LOAD CELL CABLE

AC POWER CORD RECEPTACLE

Figure 2-4. Location of AC Power Cord Receptacle and

Load Cell Cable

2. Connect load cell cable from scale to Cable

Port 1 in the back of the keyboard

(Figure 2-5).

3. Plug the AC power cord into a grounded 115

VAC receptacle.

If the scale is connected to AC power while in the

OFF condition, no warm-up is necessary.

NOTE: If the scale displays erratic data, it may be

caused by a power transient. Turn the scale off and

momentarily unplug it from the wall outlet. Then

restart by plugging the scale back in and pressing ON/

OFF key. The scale will go through a display check;

no warm up is needed.

2.3.2 DC Battery Pack Replacement/Installation

An optional DC battery pack is available and may be

purchased from RLWS to ship with the scale or

retrofit in the field.

The battery pack is located in the bottom of the scale

base and partial disassembly is required to install or

replace it. Use the following procedure to install or

replace the battery pack.

To prevent load cell damage, reinstall

Caution

setscrews before replacing battery.

1. Unplug scale from power source.

2. Remove scale platter.

3. Remove the four platform support screws

from the left-hand platform support assembly

(shown in Figure 2-6). Remove the four

screws from the right-hand platform support

assembly.

4. Remove both platform support assemblies

and set aside.

NOTE: The single-platform scale has four

platform support (spider) screws while the

dual-platform scale has four screws for each of the

two platform supports.

CABLE PORT 2

CABLE PORT 1

Figure 2-5. Scale Base Connector Ports

4. Press ON/OFF and allow scale to warm up for

10 minutes. The display momentarily shows

the revision number , sho ws all digits from 0 to

9 in a count-up mode, goes blank, shows all

8s, and then enters normal weighing mode.

REMOVE PLATFORM SUPPORT SCREWS

(DUAL-PLATFORM INSTALLATION)

Figure 2-6. Removing Platter Support Screws and Platter

Support on a Dual-Platform Scale

Page 9

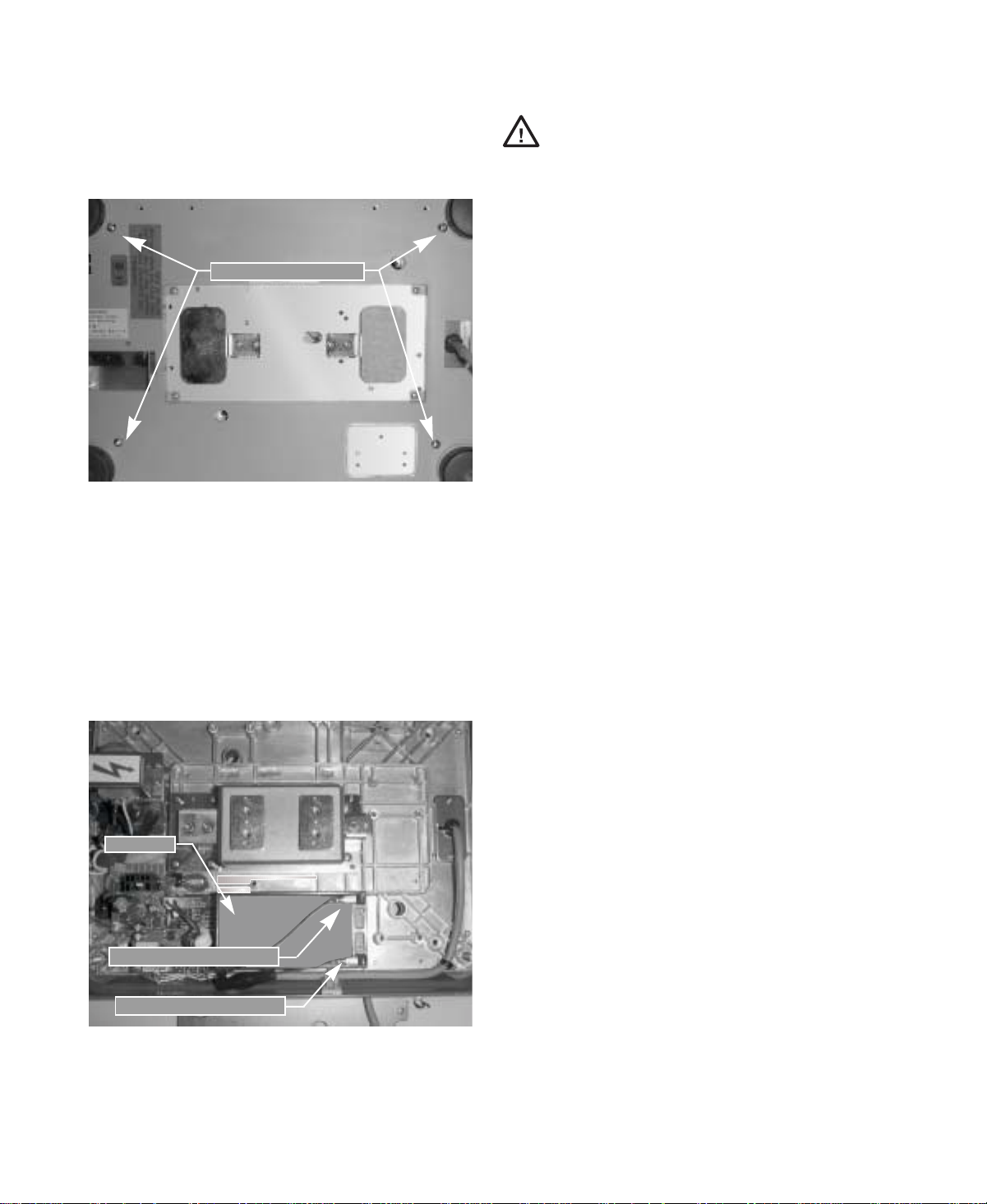

5. Place scale on side. Remove four top cover

screws (shown in Figure 2-7). Set scale on

legs and remove top cover.

TOP COVER SCREWS

Caution

that they do not make contact with each other or any part

of the scale frame or any sensitive electronic components.

2.3.3 DC Battery Operation

If the DC-190 scale is operated with the

battery pack removed, isolate the

positive (+) and negative (–) leads so

To power-up the DC-190 using the optional battery:

1. Remove AC power cord from bottom of scale.

2. Turn battery switch to ON (located on the

bottom left-hand side of the scale base).

Figure 2-7. Location of Top Cover Screws

6. Disconnect black (–) and red (+) electrical

leads from battery (see Figure 2-8). Remove

existing DC battery pack. Attach red lead to

positive (+) side of battery.

7. Attach black lead to negative (–) side of

battery.

8. Place new DC battery pack in battery

compartment.

BATTERY

POSITIVE (+)

NEGATIVE (-) TERMINAL

TERMINAL

Figure 2-8. Battery Installation

9. Reassemble scale in the reverse order that it

was disassembled.

10. Remove setscrew to unlock scale before

placing the scale into service.

3. Press

ON/OFF and allow scale to warm up for

10 minutes. The display momentarily shows

revision number, shows all digits from 0 to 9

in a count-up mode, goes blank, shows all 8s,

and then enters normal weighing mode.

2.3.4 Battery Charging

A fully charged battery allows for approximately 4

hours of continuous use. Refer to SPEC 1 (Power Auto

Off function) for extended hours of use. It will take

approximately 8 hours to fully recharge a battery that

has been completely dissipated. The console must be

connected to the base during the recharge cycle and

the AC power cord must be plugged in.

NOTE: Do not store the scale without turning off the

battery power switch! When the battery switch is ON and

the AC is not connected, a low level battery current will flow

even if the display is OFF. To prevent battery discharge

when stored, turn the battery switch OFF whenever the unit

is not in use.

2.4 Setting Time and Date

You can set the time and date printed on DC-190 print

tickets. SPEC 5, bits 0 and 1 list three sequence

variations of year, month, day that are available to

enter dates into the DC-190 counting scale. Printed

dates always appear in mmddyy format.

To set the date (month, date, and year) and time:

1. Press the

2. Press the

date, day, and time.

3. Press the

year (mmddyy) on the keypad.

4. Press the

1=Tue…6=Sun.

5. Press the

using the 24-hour clock. For example, enter

1:35 p.m. as 1335.

6. Press the

press the

time and date.

MODE key.

–/DATE key. The displays shows the

–/DATE key again. Enter month, day ,

–/DATE key. Enter the day (0=Mon,

–/DATE key. Enter the time of day

*/PROG key to store the setting, or

–/DATE key to exit without saving

Page 10

2.5 Installing Cable Strain Relief

To prevent load cell or peripheral cable damage from

bending and twisting, cable strain reliefs are used in

the back of the DC-190 keyboard. Each DC-190

counting scale comes equipped with these rubber

strain reliefs and should be installed on initial scale

setup.

1. Remove the three 4 mm x 8 mm panhead

screws securing the bracket to the back of the

keyboard.

2. Remove rubber strain relief covering the two

14-pin load cell cable ports. If any peripheral

devices are installed at this time, remove the

rubber strain relief covering the peripheral

cable access ports.

3. Route load cell and/or any peripheral device

cables through opening in bracket. Connect

cables to proper ports.

4. Install rubber strain relief over load cell/

peripheral cables and position into cavity.

Gently pull cables to take up any slack.

5. When rubber strain reliefs are securely

mounted, reinstall bracket using the three 4

mm x 8 mm panhead screws previously

removed.

5. Route load cell and peripheral device cables

through center of pole mount assembly.

6. Mount keyboard on bracket using six 4 mm x

10 mm machine screws (Figure 2-10).

KEYBOARD

KEYBOARD MOUNT BRACKET

Figure 2-10. Attach Keyboard to Pole Mount Assembly

7. Attach load cell cable to Cable Port 1. If any

other scales or peripheral devices are to be

installed, remove plastic knockout from

plastic shroud as required. Install plastic cover

using two 4 mm x 8 mm panhead screws.

2.6 Pole Mounting Instructions

1. Disconnect AC power cord from the bottom

of the scale. Remove platform.

2. Remove the plastic cover from the upper

mounting bracket.

NOTE: As a precaution, install load cell setscrew.

3. Turn scale on side.

4. Attach pole mount assembly to base using

three 4 mm x 10 mm machine screws (shown

in Figure 2-9).

POLE ASSEMBLY

MOUNT BRACKET

8. Install plastic cover over base of pole mount

assembly.

9. Remove the load cell setscrew previously

installed.

Figure 2-9. Attach Pole Mount Assembly to Base

Page 11

3.0 Scale Setup

This section provides information about attaching scales and serial devices to the DC-190. Information presented

describes both physical connections and values that must be specified when configuring the DC-190 (see

Section 4.0). If you know what scales and serial devices will be connected to the DC-190, you can use the SPEC

Code Worksheets Section 10.1 on page 50 to record these values for later configuration.

3.1 Scale Configurations

The DC-190 can be connected to up to three analog scale bases using the load cell ports (PORT 1 and PORT 2

shown in Figure 3-1). An Ohaus

232/PRINTER serial port for a total of four scale channels.

PORT 1 PORT 2

®

Explorer force balance can also connected to either the FORCE BALANCE or

Figure 3-1. DC-190 Scale Ports and Connectors

Attach SX-L single and SX-D dual scale platforms to PORT 1 (left connector); attach external scale base to

PORT 2 (right connector). For three-scale configurations using either an SX-L and two external bases or three

external bases, an optional Y-cable must be used to connect two of the bases to POR T 1. (A wiring diagram of the

Y-cable is shown in Section 10.5 on page 55.)

3.1.1 Configuring SPECs 16 and 17

SPECs 16 and 17 are used to assign the annunciators for each of the four scale channels (Scale No. annunciator

on the DC-190 console).

All scale channels must be assigned, regardless of the actual number of scales attached.

Table 3-1 shows the values and default bit configurations for SPECs 16 and 17.

SPEC Default Setting Bits 3 and 2 Bits 1 and 0

16 0001 Scale 1

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

17 1011 Scale 3

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

Table 3-1. Specifications 16 and 17 Default Settings

Scale 2

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

Scale 4

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

When configuring SPECs 16 and 17, use the following rules:

• If a force balance is attached, it must be configured as Scale 1. That is, SPEC 16, bits 3 and 2, (Scale 1)

must be set to Force Balance (11).

• Scales attached to Port 1 are configured as

Internal Scale 1 and Internal Scale 2, regardless of whether the

actual scale base is internal (SX-L, SX-D) or external.

Page 12

• The scale attached to Port 2 is configured as External Scale.

• All Scales (1–4) must be configured, and the value of each bit pair must be unique: each Scale (1–4)

must have a different value. For example, do not attempt to configure two or more scales as

Scale; doing so will cause the DC-190 to lock up with an all 888888s display. See Section 10.7 on

External

page 57 for information about clearing this error condition.

SPECs 16 and 17 do not turn on the additional scales; by default, only one scale is enabled. Scales 2 and 3 are

turned on and off using SPEC 25, bit 1 (Scale Type, single or dual) and SPEC 32, bit 0 (Scale Connected to Port

2). The force balance is turned on and off in SPEC 8, bit 3 (Force Balance on RS-232C port); the port used by the

force balance is selected in SPEC 13, bits 2, 1, and 0 (RS-232 Connectors).

When adding a second or third platform to the DC-190, plug in the remote scale (or

Caution

dummy plug) before connecting AC power to the DC-190 and before enabling the added

scales in the configuration SPECs. Do not unplug a remote scale while the DC-190 is

powered on.

3.1.2 Scale Configurations, No Force Balance Attached

Table 3-2 lists several scale configurations for single, dual, and console-only models of the DC-190 with no force

balance attached. Required values for each configuration are shown for SPECs 16 and 17 (including Scale No.

assignments), SPEC 25 (bit 1), and SPEC 32 (bit 0). Because no force balance is attached, SPEC 8, bit 3, must be

set to 0 for all listed configurations.

DC-190 Model PORT 1 Connector PORT 2 Connector SPEC 16 SPEC17 SPEC 25 SPEC 32

S-XL platform (SCALE 1) — 0001 1011 xx0x xxx0

S-XL platform (SCALE 1) External scale (SCALE 2)

See note below

S-XL platform (SCALE 1)

External scale (SCALE 2)

Requires Y-cable

S-XD, small platform (SCALE 1)

S-XD, large platform (SCALE 2)

S-XD, small platform (SCALE 1)

S-XD, large platform (SCALE 2)

External scale (SCALE 1) — 0001 1011 xx0x xxx0

External scale (SCALE 1) External scale (SCALE 2)

External scale (SCALE 1)

External scale (SCALE 2)

Requires Y-cable)

NOTES:

• SPEC 8, bit 3, must be set to 0 (0xxx) if no force balance is connected to the DC-190. Setting this bit to 1 with no force

balance connected will cause the scale to lock up.

• Console-only configurations require external AC adapter.

• If an external scale is attached to PORT 2 and only one scale is attached to the PORT 1 connector, the external scale is

configured using Scale 3 parameters (SPECs 33, 36, and 37).

External scale (SCALE 3) 0001 1011 xx1x xxx1

— 0001 1011 xx1x xxx0

External scale (SCALE 3) 0001 1011 xx1x xxx1

See note below

External scale (SCALE 3) 0001 1011 xx1x xxx1

0010 0111 xx0x xxx1

0010 0111 xx0x xxx1

Table 3-2. DC-190 Scale Configurations (No Force Balance Connected)

Page 13

4.2 Customer Specification (141 Settings)

To configure customer specifications, press and hold the REZERO key and enter 141 using the numeric keypad.

SPC00 appears in the WEIGHT display and configuration of four bits (for SPEC 0) appears in QUANTITY display.

Follow the procedure described in Section 4.1 on page 17 to update the SPEC settings for the 141 access code.

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

0 0000 Transfer Tare Weight

0: No (hold tare)

1: Yes (transfer tare)

1 0000 Power Auto Off Function: Function used to preserve and extend battery life. All four bits are used to

specify the number of minutes (binary) before the scale enters autopower off mode.Examples below show

the binary code, time delay, and description. Settings can range from 0–15 minutes in 1-minute

increments.

Binary Code

8421

Time (min) Description

0000 0 Autopower off is disabled.

0111 7 If net weight is zero and no motion for 7 minutes, scale goes into autopower off mode.

1111 15 If net weight is zero and no motion for 15 minutes, scale goes into autopower off mode.

NOTE: Powering down means that accumulated value is lost and not retained upon power up. However,

all total inventory values stored with item codes are retained.

2 1000 Scale Specification

00: Gram (no units switching) 01: Kg

10: Lb 11: Not used

NOTE: Values 01 and 10 allow Lb/Kg units

switching if SPEC 2, bit 1 is set 0.

3 0000 RS-232 Port Commands (D-sub)

00: Standard RS-232 (PC, force balance)

01: TM-U295 ticket printer

10: TM-U200 (with or without cutter)

11: TM-U200 (with feed for tear-off)

4 1001 Set New Item Code

During Normal Mode

0: Yes

1: No

5 1011 Sampling Time for Unit

Weight Calculations

0: 10 times

1: 5 times

6 1001 Display Accuracy of

Unit Weight

0: No

1: Yes

Tare Accumulation

0: No (overwrite tare)

1: Yes (add to existing

tare)

Insufficient Sample Level

00: 0.1%

01: 0.2%

10: 0.0%

Unit Weight

Auto-Recomputing

0: Press PIECES key

after adding number of

pieces

1: Scale automatically

recomputes after

adding number of

pieces without pressing

PIECES key

Clear Key Operation

0: Clear all data

1: Clear last character

Terminator (RS-232 only)

0: Carriage return

1: Carriage return +

linefeed

Kg/Lb Lamp Enable

0: Yes

1: No

Print Commands (8-pin DIN)

00: BCP-30 (barcode printer, force balance)

01: TM-U295 ticket printer

10: TM-U200 (with or without cutter)

11: TM-U200 (with feed for tear-off)

Date Order

00: Year, Month, Day

01: Day, Month, Year

11: Month, Day, Year

RS-232 Continue

Sending Rate to PC

0: High

1: Low

Piece Weight Selection

0: Unit wt per 1000

1: Average piece wt

(APW)

Inventory Display by Net/

Gross Key

0: No (Net/Gross toggle)

1: Yes (INVENT key

shows inventory quantity)

Negative Counting

0: No

1: Yes

Auto Shift to Next

Character After T wo Digits

of Teraoka Code Entry

0: No (requires

1: Yes

+ key)

Table 4-1. DC-190 141 Settings

Page 14

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

7 0000 Setpoint Buzzer

0: Yes

1: No

NOTE: See Section 3.2.2 on page 16 for more information about configuring SPECs 8–11

8 0010 Force Balance

Attached

0: No

1: Yes

9 0111 RS-232C Stop Bits

0: 1 bit

1: 2 bits

10 0111 Printer or PC Attached

0: No

1: Yes

11 0100 RS-232C Stop Bits

0: 1 bit

1: 2 bits

12 1000 RS-232 (PC/PRN) Output

00: Not available

01: When counting condition (PC)

10: By

11: In both cases

NOTE: See Section 3.2.1 on page 15 for more information about configuring SPEC 13

13 0001 RS-232 PC Header

0: Header codes

1: Field titles

NOTE: See Section 10.10 on page 60 for PSC QuickScan 6000 scanner setup information (SPECs 14 and 15).

14 1010 RS-232C Connection

(Barcode pen)

0: No

1: Yes

* key (printer and PC)

Setpoint Latch

0: Latching

1: Non-latching

RS-232C Data Length

0: 7 bits

1: 8 bits

Force Balance Type

0: Not used

1: Ohaus Explorer

RS-232C Data Length

0:7 bits

1: 8 bits

Printer Driver

0: Eltron printer driver

or comma-delimited

file

1: BCP30, BCP-300,

or Epson printer

RS-232 Connectors

If only one RS-232 device (printer or PC) is connected to the scale, select one of

the four settings below:

DIN-8 (FORCE BALANCE) D-Sub (232C/PRINTER)

000: Force Balance (SPEC 8, 9 Printer (SPEC 10, 11)

001: Printer (SPEC 10, 11) Force Balance (SPEC 8, 9)

100: Force Balance (SPEC 8, 9 PC (SPEC 10, 11)

101: PC (SPEC 10, 11) Force Balance (SPEC 8, 9)

If two RS-232 devices (printer and PC) are connected to the scale, select one of

the two settings below:

DIN-8 (FORCE BALANCE) D-Sub (232C/PRINTER)

010: PC (SPEC 8, 9) Printer (SPEC 10, 11)

011: Printer (SPEC 10, 11 PC (SPEC 8, 9)

RS-232C Data Length

(Barcode pen)

0: 7 Bits

1: 8 Bits

Setpoint Type

00: % Quantity 01: % Weight

10: Quantity 11: Weight

RS-232C Baud Rate

00: 1200 01: 2400

10: 4800 11: 9600

RS-232C Parity Bit

00: No 01: Odd

10: Not used 11: Even

RS-232C Baud Rate

00: 1200 01: 2400

10: 4800 11: 9600

RS-232 Parity Bit

00: No 01: Odd

10: Not used 11: Even

Eltron Format

0: Eltron fixed label

format (also for

BCP30, BCP300)

1: Custom download

format

RS-232C Baud Rate (Barcode pen)

00: 1200 01: 2400

10: 4800 11: 9600

RS-232C PC Data Sent

with Header Codes

0: Yes

1: No

Table 4-1. DC-190 141 Settings (Continued)

Page 15

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

15 0011 RS-232C Stop Bits

(Barcode pen)

0: 1 Bit

1: 2 Bits

NOTE: All scale channels must be assigned in SPECs 16 and 17, regardless of the actual number of scales attached. See

Section 3.1.1 on page 12 for detailed information about configuring these SPECs.

16 0001 Scale 1

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

17 1011 Scale 3

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

18 0000 Setpoint TTL Output

0: Active low (0V)

1: Active high (+5V)

19 1000 Display “not F”

Message for Items not

Stored in Memory

0: Yes

1: No

RS-232C with Header

(Barcode pen)

0: Yes (first character

recognized as

header)

1: No (every bar code

treated as ID code)

Number of Setpoints. Values for 3–6 setpoints are valid only if SPEC 7, bits 0

and 1, are set to 10 or 11 (Quantity or Weight).

000: 2 setpoints

001: 3 setpoints

010: 4 setpoints

011: 5 setpoints

100: 6 setpoints

Link to IMS (US version)

0: No

1: Yes

RS-232C Parity Bit (Barcode pen)

00: No 01: Odd

10: Not used 11: Even

Scale 2

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

Scale 4

00: Internal Scale 1

01: Internal Scale 2

10: External Scale

11: Force Balance

Type of Force Balance

(Japan version only)

0: SHG-300

1: HR-60

Print when Pressing

– Key in Add Mode

0: Yes

1: No (print only with *)

+ or

Table 4-1. DC-190 141 Settings (Continued)

Page 16

4.3 Weight and Measurement Specifications (142 Settings)

To configure weight and measurement specifications, press and hold the REZERO key and enter 142 using the

numeric keypad.

QUANTITY display. Follow the procedure described in Section 4.1 on page 17 to update the SPEC settings for the

142 access code.

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

20 none Minimum Display (PORT 1, Scale 1)

21 none Eltron Printer Selection

22 none Not used Weight Decimal Point Position (PORT 1, Scale 2)

23 0000 Display Resolution for Scales 1, 2, 3, and 4.

24 0000 Masked Display at

25 00_0 Scale Starting Method

26 0000 Zero Tracking When

SPC20 appears in WEIGHT display and configuration of four bits (for SPEC 20) appears in

Minimum Display (PORT 1, Scale 2)

MUST BE SET PRIOR TO CALIBRATION!

00: 2 01: 1

10: 5 11: 10

Weight Decimal Point Position (PORT 1, Scale 1)

0: Eltron Model 2722

1: Eltron Model 2742

or 2642

NOTE: Must be set to

0 if an Eltron printer is

not being used.

(Specify Not Used for force balance.)

00: 1/10000 01: 1/5000

10: 1/2500 11: Not used

Minus Weight

0: Gross

1: Net

0: Automatic

1: Manual (must

press REZERO key

on startup)

Tare Is Present

0:Yes

1:No (zero tracking is

off with tare in system)

MUST BE SET PRIOR TO CALIBRATION!

000: 00000 011: 00.000

001: 0000.0 100: 0.0000

010: 000.00 101: .00000

MUST BE SET PRIOR TO CALIBRATION!

000: 00000 011: 00.000

001: 0000.0 100: 0.0000

010: 000.00 101: .00000

Display at Minus Weight

0: Minus display

1: Masked

Internal Resolution

Protected by Span

Switch

0: No (internal

resolution can be

viewed by pressing

REZERO * * +)

1: Y es (protected until

internal span

switch pressed)

Rezero with a Tare

Weight

0: Yes

1: No

MUST BE SET PRIOR TO CALIBRATION!

00: 2 01: 1

10: 5 11: 10

Zero Setting Range

00: +Unlimited/–10% FS 01: ±2% FS

10: ±10% FS 11: Not used

Zero Lamp Lighting

Method

0: Gross

1: Net

Scale Type

0: Single scale

1: Dual scale

NOTE: If you are not

connected to a

dual-platform scale, or

do not have two scales

wired into Cable PORT

1, set this bit to 0 (single

scale). Selecting 1 (dual

scale) can damage the

console’s electronic

components.

Initial Start Range

00: +Unlimited/–10% FS 01: ±2% FS

10: ±10% FS 11: Not used

Low Battery (turn off

display when low battery)

0: No

1: Yes

Gross Mode Available

0: Yes (allows gross

mode selection from

keypad)

1: No (inhibits gross

mode; switching not

allowed)

Table 4-2. DC-190 142 Settings

Page 17

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

27 0100 Comma Display

0:No

1:Yes

28 0000 Auto Tare Clear when

Rezeroed

0: No

1: Yes (REZERO

clears tare value)

29 0000 Digital Tare Rounding

0:Tare exactly

1:Round to nearest

increment

30 none Load Cell Sensitivity Selection (mV/V)—PORT 1, Scale 1

Load cell sensitivity is automatically set at calibration. Manual adjustments can be made to reduce noise.

Spec

0000: 3.46 4.00

0001: 3.00 3.46

0010: 2.59 3.00

0011: 2.25 2.59

31 none Load Cell Sensitivity Selection (mV/V)—PORT 1, Scale 2

Load cell sensitivity is automatically set at calibration. Manual adjustments can be made to reduce noise.

Spec

0000: 3.46 4.00

0001: 3.00 3.46

0010: 2.59 3.00

0011: 2.25 2.59

32 1010 Calibration Mode

Protected by Span

Switch

0:Yes (span switch

1:No

33 0___ Over Weight Mask at:

0:+1d

1:+9d

34 0000 Not used A/D Output (PORT 1,

Min Max

Min Max

must be pressed

before calibration)

Keypad Entry of Tare

0: No

1: Yes

Automatic Unit Weight Clear Condition

00: Over net 5d and gross 21d, weight stable

01: Greater than or equal to net 1d, weight stable

10: Greater than or equal to net 1d, quantity > 0,

weight stable

Tare Value Exchange

with TARE key

0: Yes (allow tare

addition/subtraction)

1: No

Spec

0100: 1.95 2.25

0101: 1.69 1.95

0110: 1.46 1.69

0111: 1.27 1.46

Spec

0100: 1.95 2.25

0101: 1.69 1.95

0110: 1.46 1.69

0111: 1.27 1.46

Low Battery

Annunciator Enabled

0: Yes

1: No

Weight Decimal Point Position (PORT 2, Scale 2 or 3)

MUST BE SET PRIOR TO CALIBRATION!

000: 00000 011: 00.000

001: 0000.0 100: 0.0000

010: 000.00 101: 0.00000

Scale 1)

0: For std/normal load

1: For abnormal load

Min Max

Min Max

cell (≤ 18 mV)

cell with too large

offset (> 18mV)

Tare Range

00: 100% FS 01: 50% FS

10: 5% FS 11: Not used

Tare Addition

0:Yes (new tare weight

added to existing tare)

1:No

Spec

1000: 1.09 1.27

1001: 0.95 1.09

1010: 0.82 0.95

1011: 0.71 0.82

Spec

1000: 1.09 1.27

1001: 0.95 1.09

1010: 0.82 0.95

1011: 0.71 0.82

Auto Exit from Part

Accumulation and

Reduction Mode

0:No (must press

1:Yes (exits to counting

A/D Filtering (PORT 1, Scale 1)

00: Normal

01: Protect from small vibration/fast change in

10: Protect from medium vibration

11: Protect from large vibration, slow change in

Min Max

Min Max

CLEAR to perform

another accumulation)

mode after three

seconds)

display

display

Automatic Unit Weight

Clear

0: No

1: Yes

Tare Subtraction

0: Yes (new tare weight

subtracted from

existing tare)

1: No

Spec

1100: 0.61 0.71

1101: 0.53 0.91

1110: 0.46 0.53

1111: 0.40 0.46

Spec

1100: 0.61 0.71

1101: 0.53 0.91

1110: 0.46 0.53

1111: 0.40 0.46

Scale Connected to

PORT 2

0: No

1: Yes

CAUTION: If you are not

connecting a scale to this

connector, select 0.

Selecting 1 can damage

the console’s electronic

components.

Min Max

Min Max

Table 4-2. DC-190 142 Settings (Continued)

Page 18

SPEC Default Bit 3 Bit 2 Bit 1 Bit 0

35 0000 Not used A/D Output (PORT 1,

Scale 2)

0: For std/normal load

cell (≤ 18 mV)

1: For abnormal load

cell with too large

offset (> 18mV)

36 __00 Minimum Display (PORT 2, Scale 2 or 3)

MUST BE SET PRIOR TO CALIBRATION!

00: 2 01: 1

10: 5 11: 10

37 1001 Load Cell Sensitivity Selection (mV/V)—PORT 2, Scale 2 or 3

Load cell sensitivity is automatically set at calibration. Manual adjustments can be made to reduce noise.

Spec

0000: 3.46 4.00

0001: 3.00 3.46

0010: 2.59 3.00

0011: 2.25 2.59

38 0010 A/D Output (Scale 3)

0: For std/normal load

1: For abnormal load

39 0010 Set SPEC 39 to 0010

Min Max

cell (≤ 18 mV)

cell with too large

offset (> 18mV)

Spec

0100: 1.95 2.25

0101: 1.69 1.95

0110: 1.46 1.69

0111: 1.27 1.46

Digital Tare with Weight

on Scale

0: Yes

1: No

Min Max

A/D Filtering (PORT 1, Scale 2)

00: Normal

01: Protect from small vibration/fast change in

display

10: Protect from medium vibration

11: Protect from large vibration, slow change in

display

A/D Filtering (PORT 2, Scale 2 or 3)

00: Normal

01: Protect from small vibration/fast change in

display

10: Protect from medium vibration

11: Protect from large vibration, slow change in

display

Spec

1000: 1.09 1.27

1001: 0.95 1.09

1010: 0.82 0.95

1011: 0.71 0.82

Internal Count

0: 500,000

1: 1,000,000

Min Max

Spec

1100: 0.61 0.71

1101: 0.53 0.91

1110: 0.46 0.53

1111: 0.40 0.46

Stability Check When

Changing Scale

0: Yes

1: No

Min Max

Table 4-2. DC-190 142 Settings (Continued)

Page 19

4.4 RS-232 Specifications (143 Settings)

To configure RS-232 specifications, press and hold the REZERO key and enter 143 using the numeric keypad.

SPC40 appears in WEIGHT display and configuration of four bits (for SPEC 40) appears in QUANTITY display.

Follow the procedure described in Section 4.1 on page 17 to update the SPEC settings for the 143 access code.

SPECs 40–42 and SPEC 43, bits 0–2, represent the selectable RS-232 output fields.

SPECs 46–59 are not used. All bits for these SPECs must be set to 0.

SPEC Bit 3 Bit 2 Bit 1 Bit 0

40 Lot Number

0: Yes

1: No

41 Net Weight

0: Yes

1: No

42 Date and Time

0: Yes

1: No

43 Autoprint within Setpoints

0: No

1: Yes

44 Clear Operator Name

Each Use (BCP-300)

0: No (operator name held

in register for multiple

inputs)

1: Yes

45 Not used Not used Print with Zero Quantity

46–59 Not used: set to 0 Not used: set to 0 Not used: set to 0 Not used: set to 0

Memo (Part Name)

0: Yes

1: No

Gross Weight

0: Yes

1: No

Quantity & Total Quantity

0: Yes

1: No

Non-stable Ouput

0: No

1: Yes (allow serial output

with scale in motion)

Company Name

(BCP-300)

0: Default only

1: Input with bar board

Alternative Part Number

0: Yes

1: No

Setpoint

0: Yes

1: No

Unit Weight

0: Yes

1: No

Status Output

0: Yes

1: No

Manual Print with Setpoints

0: Yes

1: No

0: No

1: Yes

ID Code

0: Yes

1: No

Inventory

0: Yes

1: No

Tare Weight

0: Yes

1: No

Scale Number

0: Yes

1: No

Autoprint Overrange

Setpoint

0: No

1: Yes

Batch Print Once

0: No

1: Yes

Table 4-3. DC-190 143 Settings

Page 20

6.0 Scale Operations

The following sections contain detailed operator instructions for the DC-190 counting scale. Included are

instructions to enter tare weights, toggle between net and gross weight, enter unit weights, perform inventory

accumulation and reduction, and toggle between scales. All operator functions are conducted with the scale in the

weighing or normal mode. See Section 7.0 on page 30 for information about scale programming.

Counting scale accuracy is primarily determined by the following factors:

• Sample size (number of pieces)

•Total sample size as a percentage of full scale capacity

• Piece-to-piece weight variation

As a general rule when determining sample size of fairly uniform pieces, the larger the sample size the greater

the total sample weight, therefore, the better the counting accuracy. Selecting the smallest capacity scale that can

obtain the highest counting resolution should be considered, but should not sacrifice the capacity required for the

heaviest container of parts. For this specific application, a dual-platform scale may be the best selection.

There is a direct relationship between piece-to-piece weight variation (non-uniformity) and counting accuracy

Therefore, elimination of the piece-to-piece weight variations can be accomplished by:

1. Isolating the sample used to calculate the unit weight and use the same sample to re-check the scale.

2. Recalculating the unit weight from lot-to-lot of parts. Parts manufactured on one machine may vary

slightly from another machine relative to weight.

3. Tightening the manufacturing tolerances on the parts reduces piece weight v ariations and increases count

accuracy.

6.1 Entering Tare Weights

Tare weights can be entered in the scale by one of two methods: one-touch tare or digital tare.

NOTES:

• SPEC 27, bit 2 (Digital Tare Setting) must be a 1 to allow digital tare.

• SPEC 27, bits 0 and 1 (Tare Range) must be set to the appropriate tare range value. Default is 00, 100 percent of full

scale.

.

One-Touch Tare, Tare Weight Unknown

1. If the tare weight value is not known, place the container, box, or item to be tared on the scale and press

TARE. The WEIGHT display should now show 0 and the NET annunciator should illuminate.

2. Remove the container, box, or item from the scale. The

WEIGHT display should show a negative weight

value (weight of the tared container, box, or item).

3. Press

Digital Tare, Tare Weight Known

TARE to reset tare to zero.

1. If the tare weight value is known, use the numeric keypad to key in the value and then press TARE.

2. Press

NOTE: For digital tare entry, the decimal must be in the appropriate place as it would be displayed in the WEIGHT

display. For example, .250 would be entered as 0.250, not .250. The WEIGHT display shows weight entered with a

negative sign indicating that it is a tare weight.

TARE to reset tare to zero.

Page 21

6.2 Toggle Between Scales

To switch the displays from Scale 1 through Scale 4, press the SCALE key when in weighing mode. Only scales

present are selected. For example, a two-scale system switches between Scale 1 and Scale 2 only. In a four-scale

configuration, the

1. Press

2. Press

3. Press

4. Press

NOTE: Scale number assignments are set using SPECs 16 and 17.

SCALE key functions as follows:

SCALE key to change from Scale 1 to Scale 2.

SCALE key to change from Scale 2 to Scale 3.

SCALE key to change from Scale 3 to Scale 4.

SCALE key to change from Scale 4 to Scale 1.

6.3 Toggling Between Net and Gross Weight

To toggle between net and gross weight, a tare value must be entered into the scale (see Section 6.1). NOTE:

SPEC 25, bit 0 (Gross Mode Available) must be set to 0 (default) to enable gross mode.

After a tare value is entered into the scale, items placed on the scale will cause the

and allow toggling between net weight and gross weight.

An example of toggling between net weight and gross weight is shown below:

1. Place 0.5 lb weight on the scale and then press

2. Place another 0.5 lb weight on the scale. The scale

TARE once. The WEIGHT display should show 0.000 lb.

WEIGHT display should now show 0.500 and the NET

annunciator should be illuminated.

3. Press

NET/GROSS. The WEIGHT display should show 1.000 and the GROSS weight annunciator is

illuminated. The UNIT-WEIGHT and the QUANTITY displays go blank.

4. Press

NET/GROSS. The WEIGHT display now shows 0.500 and the NET weight annunciator is

illuminated.

NET annunciator to illuminate

6.4 Entering Unit Weights

Entering unit weights can be done either by sampling, as described in Section 6.4.1, or by key entry as described

in Section 6.4.2.

SPEC 0, bit 0 (

specifies that the

Setting bit 0 to 1 specifies that the unit weight value shown is per one piece (A.P.W.).

NOTE: SPEC 4, bits 1 and 2 (Insufficient Sample Level) control unit weight sampling. The default value is 0.1 percent.

6.4.1 Unit Weight Operation by Sampling

Unit weight operation by sampling is accomplished by placing a known quantity of pieces to be sampled on the

scale and then pressing the

compared to the weight of the sample.

1. Press

2. Place 10 pieces of the item to be sampled on the scale.

3. Press

(

display shows the unit or per 1000 weight for the 10 sample pieces (depending on the value of SPEC 0,

bit 0, as described above); the

If the weight of the sample is insufficient (

until the INSUFF annunciator goes off.

• If SPEC 5, bit 2 (unit weight auto-recomputing), is set to 1, place required pieces on the scale. The

• If SPEC 5, bit 2, is set to 0, use the keyboard to enter the new number of sample pieces then press the

Piece Weight Selection) works in conjunction with the UNIT-WEIGHT display. Setting the bit to 0

UNIT-WEIGHT value shown is per 1000 pieces and the UNIT WT PER 1000 annunciator is lit.

PIECES key. The scale calculates a unit weight based on the capacity of the scale

REZERO to zero scale.

PIECES key then wait a few seconds for the computation. If the sample weight is sufficient

INSUFF annunciator is off), the WEIGHT display shows the total sample weight; the UNIT-WEIGHT

QUANTITY display shows the number of pieces (10).

INSUFF annunciator is on), add pieces to the initial sample

scale automatically recomputes the unit weight.

PIECES key again to recompute the unit weight.

Page 22

6.4.2 Unit Weight Operation by Key Entry

Unit weight operation by key entry is accomplished by using the numeric keypad to enter the known value of the

unit weight and then pressing the

UNIT WEIGHT key. An example of unit weight operation by key entry is shown

below:

1. With the display in the weighing mode, use the keyboard to enter the known unit weight, for example,

200.00.

NOTE: The setting for SPEC 0, bit 0, determines whether the value entered is per piece (A.P.W., if set to 1)

or per 1000 pieces (if set to 0).

2. Press UNIT WEIGHT key to enter the unit weight.

3. Place a 2 lb. weight on the scale. The scale displays the quantity for the weight placed on the scale. For

example, the

WEIGHT display reads 2.000, the UNIT-WEIGHT display reads 200.00 (per 1000 pieces),

and the QUANTITY display reads 10).

6.4.3 Clearing Unit Weight

To clear a unit weight:

1. Remove weight from scale.

2. Press the

CLEAR key.

6.5 Part Accumulation and Reduction–Without Recalling an Item Code

The DC-190 counting scale is capable of part number inventory tracking and maintenance using the stored item

code function of the scale software (see Section 7.0 on page 30). Additionally, the scale has the capability to

acquire the total number of parts using the accumulation or reduction function of the scale (similar to the add/

subtract functions of a calculator).

6.5.1 Part Accumulation

To find the total accumulated quantity of similar containers filled with parts, use the accumulation procedure

detailed below. Six containers are used in this example procedure; it is assumed that all containers are of the

same weight.

1. Conduct a sampling process (see Section 6.4) to determine the unit weight of the pieces.

2. Enter known tare weight, or place empty container on scale to perform tare function (see Section 6.1).

3. Place Container 1 (full of parts) on the scale.

4. Press the

+ key to store the total in Container 1. The MEMORY annunciator lights. The WEIGHT display

briefly shows totAL and the QUANTITY display shows the total pieces in the first container.

5. Remove Container 1 and place Container 2 (full of parts) on the scale.

6. Press the

+ key (total is equal to Container 1 plus Container 2).

7. Continue with the remainder of the containers in the same accumulation method. The total number of

parts stored in all six containers will then be stored in the accumulation register.

8. To view the total, make sure that the scale platter is empty and press the

9. To clear the total, press the

NOTE: If SPEC 32, bit 1 (Auto Exit from Part Accumulation and Reduction Mode) is set to 0, the scale will not auto

exit from displaying the total amount. To return to the weighing mode, press the

6.5.2 Part Reduction

* key. The MEMORY annunciator is not illuminated.

+ or – key.

CLEAR key.

Part reduction can be also be done by using the – key while the scale is in the weighing mode and the MEMORY

annunciator is on.

1. Conduct a sampling process (Section 6.4) to determine the unit weight of the pieces.

2. Place container to be tared on scale and enter the tare weight (Section 6.1).

3. Place Container 1 (full of parts) on the scale.

4. Press the

+ key to store the total in Container 1. The MEMORY annunciator lights. The WEIGHT display

briefly shows totAL and the QUANTITY display shows the total pieces in the container.

5. Remove a number of parts from the container and press the

– key. The MEMORY annunciator is

Page 23

illuminated and the display shows the quantity of parts remaining.

6. Remove a number of parts from the container and press the

– key again. The MEMORY annunciator is

illuminated and the display shows the quantity of parts remaining.

NOTE: If SPEC 32, bit 1 (Auto Exit from Part Accumulation and Reduction Mode) is set to 0, the scale will not auto

exit from displaying the total amount. To return to the weighing mode, press the

6.5.3 Clearing Accumulated Data

CLEAR key.

To clear accumulated data, press the * key.

6.6 Other Operations

The following operations, added in software Version 4.02 and 4.04, can all be performed while the DC-190 Ultra

Count is in normal mode.

6.6.1 Set New Vendor Name

In software Version 4.02 or later, a new vendor (company) name can be scanned into the DC-190 Ultra Count by

doing the following:

1. Scan the

2. Use the alphanumeric bar codes to scan up to 48 characters for the vendor name.

3. When complete, scan the

SPEC 44, bit 2, (input company name with bar board) must be set to 1 to use this function (see page 24).

6.6.2 Set New Operator Name

In software Version 4.02 or later, a new operator name can be scanned into the DC-190 Ultra Count by doing the

following:

1. Scan the

2. Use the alphanumeric bar codes to scan up to 32 characters for the operator name.

3. When complete, scan the

SPEC 44, bit 3, specifies whether the operator name is held in memory or is cleared after each use (see page 24).

VENDOR NAME barcode using the bar code board (see Section 10.9 on page 59).

ENTER bar code.

OPERATOR NAME barcode using the bar code board (see Section 10.9 on page 59).

ENTER bar code.

6.6.3 Set New Batch Print Quantity

In software Version 4.04 or later, the number of labels printed for a batch can be changed by doing the following:

1. Press and hold the

REZERO key and enter 111 using the numeric keypad.

2. The display shows the batch print quantity. Use the numeric keypad to enter the number of labels to

print.

3. Press the

* key to store the batch print quantity, then press MODE to exit programming mode and return

to weighing mode.

Batch print quantity can also be set using a scanner and the

6.6.4 Set New Sequence Number

BATCH PRINT barcode (see Section 10.9 on page 59).

In software Version 4.04 or later, the sequence number can be reset by doing the following:

1. Press and hold the

REZERO key and enter 112 using the numeric keypad.

2. The display shows the sequence number. Use the numeric keypad to enter the new sequence number.

3. Press the

* key to store the sequence number, then press MODE to exit programming mode and return to

weighing mode.

Page 24

7.0 Scale Programming

7.1 Item Code Storage

Code numbers allow you to store information for the parts that are counted most frequently. This eliminates the

need for re-entering data for each of these parts during part count. Up to 200 item code numbers can be

programmed in the DC-190 counting scale; with IMS software, the number of item codes is unlimited.

The procedures for storing the unit weight, tare weight, quantity, part number, part name, setpoints, and lot

number with an item code are described below. You can enter all of this information for each item code or only

the data pertinent to your application. For example, if you only want to store only the unit and tare weights, you

can bypass Steps 5 through 13 and go to Step 14.

Program Unit Weight, Tare Weight, Quantity, Part Number, Part Name, Setpoints, and Lot Number

1. Press MODE key to enter program mode. The MODE annunciator will light, the WEIGHT display will

read ProG, and the QUANTITY display will read C XX (XX represents the number of item codes stored in

the DC-190 memory).

2. Enter the item code number (up to 32 digits) then press the

you want the item to be alphanumeric then you will need to press the

characters using the Teraoka Code (see Section 10.8 on page 58). After entering all of the characters,

press the

NOTE: If the QUANTITY display shows CLEAr, the code number is already stored in memory. Press the CODE key

a second time to modify the stored data or press the

CODE key to store the item code.

CLEAR key to delete the item code and stored data.

3. Enter tare weight (see Section 6.1 on page 26).

4. Enter unit weight value (see Section 6.4 on page 27).

5. Press

NET/GROSS key to enter initial quantity in stock for this item. The QUANTITY display will prompt

InVEnt and UNIT-WEIGHT display will sho w 0. Using the numeric k e ypad, enter the number of pieces that

the initial inventory will contain and then press the

information.

6. Press the

– key to enter the part number (32 characters maximum).

7. Use the Teraoka Code to enter the part number. Press the

8. Press

CODE key to enter the part name (32 characters maximum).

9. Use the Teraoka Code to enter the part name. Press the

10. Press the

+ key to check Setpoint 1. The WEIGHT display will prompt SEt 1; the QUANTITY display

shows the value of Setpoint 1.

NOTE: The DC-190 can store up to six setpoints which are determined by SPEC 18, bits 0 through 2.

11. Enter setpoint value and press + key to save.

CODE key. All displays will show zeros. If

. (decimal) key to enter the

NET/GROSS key a second time to store the

* key to store the part number.

CODE key to store the part number.

NOTES:

• When entering weight setpoints, be sure that you enter in the weight values with decimal point and trailing zeros.

• All percentage values must be rounded to the nearest whole number, fractional percentages are not allowed.

• SPEC 7, bits 0 and 1 (Setpoint Type) determine what kind of value you have entered. (See Table 7-1.)

12. Repeat Steps 10 and 11 for Setpoints 2 through 6.

13. Press the

CLEAR key to enter the lot number. Use the Teraoka Code to enter the lot number. Press the *

key to store the lot number.

14. Press

15. Press

* key to store all of the data entered with this item code. The display will go back to Step 1 but the

number in the

MODE key to exit the program mode.

QUANTITY display will have been incremented by one.

Page 25

SPEC 7,

bits 0,1

00 Percent quantity Setpoint 1: Quantity

01 Percent weight Setpoint 1: Weight

10 Upper and lower

11 Upper and lower

NOTES:

• All weight-based setpoint values must be entered with a decimal and all trailing zeros. All percentage-based

setpoint values must be entered to the nearest whole number (no fractional percentages).

• The DC-190 can program up to six setpoints by repeating Steps 2 through 6, SPEC 18, bit 0 through 2 (Number of

Setpoints) determines the number of setpoints. The six setpoints are TTL output for quantity or weight, but not

percent quantity or percent weight. These values may be programmed 1 through 6 low to high or 1 through 6 high to

low.

Setpoint Type Setpoint Designation

The quantity value can be no greater than 999999.

Setpoint 2: Percent of Setpoint 1

The percentage value can be no greater than 999%. The value for Setpoint 2 is calculated

by multiplying the value for Setpoint 1 by the percentage value entered for Setpoint 2.

NOTES:

• If Setpoint 1 is equal to 999999, then Setpoint 2 must be set less than or equal to

100%.

• Setpoints 3–6 are not available when Setpoint 2 is a percent setpoint.

The quantity value can be no greater than 999999.

Setpoint 2: Percent of Setpoint 1

The percentage value can be no greater than 999%. The value for Setpoint 2 is calculated

by multiplying the value for Setpoint 1 by the percentage value entered for Setpoint 2.

NOTE:

• If Setpoint 1 is equal to 999999, then Setpoint 2 must be set less than or equal to

100%.

• Setpoints 3–6 are not available when Setpoint 2 is a percent setpoint.

Setpoint 1: Quantity

quantity limit

weight limit

Setpoint 2: Quantity

Setpoints 3–6: Quantity

Setpoint 1: Weight

Must be a weight value less than or equal to the capacity of the scale.

Setpoint 2: Weight

Must be a weight value less than or equal to the capacity of the scale, but must be less

than Setpoint 1 value.

Setpoints 3–6: Weight

Must each specify a weight value less than the value of the preceding setpoint.

Table 7-1. Setpoint Programming for Quantity and Weight

7.2 Item Code Maintenance

Item code maintenance includes viewing item codes in memory and deleting item memory.

View Item Codes in Memory

The following procedure allows viewing all of the item codes stored in memory but will not change any of the

information (unit weight, tare weight, part number, quantity, part name, setpoints, and lot number) stored with

these codes.

1. Press the

2. Press the

memory, example:

3. Press the

MODE key. The WEIGHT display shows ProG and the QUANTITY display shows C XX.

CODE key. The QUANTITY display shows the first item code programmed and stored in

Id 123.

+ key to view the next item in memory and continue pressing the + key until the DC-190 beeps.

Page 26

NOTE: When you hear the beep, the display shows the last item code in memory . Press the – key to review the

item codes in reverse order.

4. Press the MODE key to return to Step 1.

5. Press the

Delete Item Memory

MODE key again to return to weighing mode.

The following procedure describes the steps used to delete all information stored within each item code (unit

weight, tare weight, part number, quantity, part, setpoints, and lot number) or any specific information stored

within each item code. It also explains the keystrokes required for resetting the sequence number, or deleting all

setpoints, global to the scale, but not tied to a specific item code.

1. Press the

2. While pressing the

MODE key. The WEIGHT display will show ProG and the QUANTITY display shows C XX.

REZERO key, enter the sequence as shown in Table 7-2 to delete the specified

information. The table shows the prompting that will take place on the weight and quantity displays to

ensure that the proper keystrokes have been performed.

NOTE: If an error was made entering data and the display is prompting you to clear information that is not to be

cleared, press the

MODE key and return to Step 1.

3. Press the CLEAR key to delete the information.

4. Press

Delete all memories ••0 ALL CLEAr

All item quantity in stock ••1 InVEnt CLEAr

All item unit weights ••2 UnIt u

All item tare weights ••3 TArE CLEAr

All item part numbers ••4 P-no CLEAr

All item setpoints ••5 P-SP CLEAr

All item names ••6 P-nAmE CLEAr

Reset SEQ numbers ••7* SEQ no CLEAr

Delete all setpoints (global) ••+ SEt P CLEAr

*Use for BCP-30 printer

MODE to exit programming mode.

Delete Item Memory Sequence WEIGHT Display QUANTITY Display

CLEAr

Table 7-2. Deleting Item Codes in Memory

7.3 Using Item Code in Normal Mode

The following paragraphs describe the procedure to recall item codes, recompute item code unit weights, set new

item codes, and inventory operations related to the item code quantity. All storage operations are done while the

scale is in the normal mode.

Recalling Numeric Item Codes using Item Code Number

1. Enter item code number using numeric keypad.

2. Press the

return to the normal mode.

Recalling Alphanumeric Item Codes using Teraoka Code

1. Press the . (decimal) key. The WEIGHT display prompts t-C 01, the QUANTITY display shows CodE, and

the

2. Enter the values equivalent to the digits to be entered using the Teraoka Code. For example, to recall

Item Code 123, enter: [

3. Press the

return to the normal mode.

CODE key. The scale will recall all information stored with the item code and automatically

UNIT-WEIGHT display prompts 00-.

31], [32], [33], [01], [02], [03] = 123ABC.

CODE key. The scale will recall all information stored with the item code and automatically

Page 27

Re-Computing Item Code Unit Weight

1. Recall item code from memory (see Section or Section ).

2. Place items to be counted on the scale.

3. Press the

4. Press the

Set New Item Code with Tare and Unit Weight

NOTE:

This can only be conducted if SPEC 4, bit 3 is 0 (Yes).

PIECES key for recomputing the unit weight.

UNIT WEIGHT key to store the new unit weight into memory.

1. Enter the item code using the numeric keypad or Teraoka Code (see Section , Step 2).

2. If the code is not currently stored in memory and SPEC 19, bit 3 is 0 (Yes), the

QUANTITY display shows

the message not F. If a new item code does not need to be stored into memory, press the CLEAR key to

exit to the normal mode. Otherwise, continue by pressing the

CODE key. This will set the new item code

number into memory.

3. If the code is not currently stored in memory and SPEC 19, bit 3 is 1 (No), the

not show the

not F message to alert you that the item code is not stored. Press the CODE key to set the

QUANTITY display does

new item code number into memory.

4. Enter tare weight and press the

TARE key. Press the TARE key again to store the tare weight into the item

code memory.

5. Place sample on the scale and press the

value (see Section 6.4 on page 27). Press the

PIECES key or use the numeric keypad to enter known weight

UNIT WEIGHT key a second time to store the weight value

into the item code memory.

7.3.1 Inventory Operations Related to the Item Code Quantity Value

The following procedure is used to add inventory to and remove inventory from an item code memory.

NOTE: The IN and OUT functions allow you to maintain the inventory (quantity) of a specific item in memor y. Pressing the

CODE key while in the normal mode enables the IN and OUT annunciators.

If neither annunciator is illuminated, press the

the

OUT annunciator on; press the CODE key a third time to turn both annunciators off.

CODE key once to turn the IN annunciator on. Press the CODE key again to turn

To Add Inventory to an Item Code Memory–IN Mode

1. Press the CODE key one time. The IN annunciator illuminates.

2. Recall the item code from memory.

3. Place the container of parts to add to memory on the scale platter.

4. Press the

* key to add the quantity shown on the display to the amount already stored under the item code

memory.

To Remove Inventory to an Item Code Memory–OUT Mode

1. Press the CODE key two times. The OUT annunciator illuminates.

2. Recall the item code from memory.

3. Place the container of parts to remove from memory on the scale platter.

4. Press the

* key to remove the quantity shown on the display to the amount already stored under the item

code memory.

NOTE: If at any time you would like to verify the quantity of parts under a specific item code, you can press the

NET/GROSS key and the inventory amount will be displayed in the UNIT-WEIGHT display. However, you must

have SPEC 2, bit 0 (Inventory Display by Gross Key) set to 1 (Yes).

Page 28

7.4 Global Setpoint Programming– Setpoints Not Tied to an Item Code

The DC-190 provides the flexibility to use the setpoint programming for parts counting applications that are

based on weight or quantity. SPEC 7 and SPEC 18 are used for configuring the setpoint type, latching, buzzer,

TTL outputs, and the number of setpoints.

The eight-pin DIN connector designation for the setpoint configuration is shown in Table 7-3. See Section 10.3

on page 52 for connector pinout information.

Pin Number Setpoint Configuration

1 SP-1

2 SP-2

3 SP-3

4 SP-4

5 SP-5

6 SP-6

7 +5 Vdc (external power supply)

8 GND

Table 7-3. Pin Out for Setpoint Configuration

The available setpoint types are quantity, weight, percent quantity, and percent weight. The following procedure

is the same for each type; however, the type of setpoint selected determines the values being entered. Table 7-1

details the values for each setpoint and the values they represent.

7.4.1 Procedure

The following steps present the procedure for setpoint programming by percent quantity, percent weight, upper

and lower quantity limit, and upper and lower weight limit.

1. Press the

display shows ProG, and the QUANTITY display shows C XX.

2. Press the

display shows the value for Setpoint 1.

3. Enter the setpoint value using numeric keys.

4. Press the

5. Press the

NOTES:

• The DC-190 can program up to six setpoints by repeating Steps 2 through 4. SPEC 18, bits 0, 1, and 2

(Number of Setpoints) determine the number of setpoints used. The six setpoints are TTL output for

quantity or weight, but not percentage quantity or percentage weight. These six values may be

programmed 1 through 6 (low-to-high) or 1 to 6 (high-to-low).

• If you recall an item code, those values stored with the item are used. Item setpoints take priority.

MODE key to go into the programming mode. The MODE annunciator illuminates, the WEIGHT

+ key to enter global setpoint values. The WEIGHT display shows Set 1, and the QUANTITY

+ key to store the value and move to the next setpoint.

MODE key to exit the programming mode and return to the weighing mode.

Page 29

10.3 Connector Pinouts

The DC-190 provides CTS/RTS hardware handshaking lines on both the 8-pin DIN and 9-pin D-Sub connectors.

For devices that do not require hardware handshaking, short the CTS/RTS lines on the scale side of the cable.

8-Pin DIN Female

Figure 10-1. 8-Pin DIN Female

Pin

Number

1 DTR DTR

2 SIGNAL GND SIGNAL GND

3 DSR DSR

4 RXD RXD

5 TXD TXD

6 CTS CTS

7RTS RTS

8 Vcc (5 V) N/C

Scanner DIN

Connector

Force Balance DIN

Connector

Table 10-6. Eight-Pin DIN Connector Pin Assignments

14-Pin Amphenol

9-Pin D-Sub Female

Figure 10-3. 9-Pin D-Sub Female

Pin Number Description

1 DCD

2 RXD

3 TXD

4 DTR

5 SIGNAL GND

6 DSR

7RTS

8 CTS

9RI

Table 10-8. 9-Pin D-Sub Connector Pin Assignments

Setpoint Mini DIN

Figure 10-2. 14-Pin Amphenol Female

Pin Number

Remote Platform Connector

1 Not used

2

3 +EXCITATION

4 –EXCITATION

5 SHIELD*

6 +SIGNAL

7 –SIGNAL

8 GROUND*

9 through 14 Not used

* When using the Y cable, use pin 5 instead of pin 8 as

ground.

Description

Table 10-7. Remote Platform Pin Assignments

Figure 10-4. Setpoint Mini DIN Female

Pin Number Setpoint Configuration

1 SP-1

2 SP-2

3 SP-3

4 SP-4

5 SP-5

6 SP-6

7 +5V

8 GND

Table 10-9. Setpoint Configuration Pin Assignments

Page 30

10.6 DC-190 Messages

Message Contents

ACC Accuracy

---Add XX Sampling quantity is insufficient

ALL All memory

C XX Number of items in memory

CH XXX Checking item code

ALL CLEAr Clear memory

dFt SPC Default spec

EntEr tIñE Enter time from 0000 to 2400

EntEr y-ñ-d Enter year, month, and day

Fb CoñErr Force balance communication error

Frl Friday

FULL Memory full

InVEnt Inventory

Lo-Err Span is out of range (on the low side)

Lot-no Lot number

ñon Monday

ñon-SUn 0-6 Mon=0, Tue=1, Wed=2, Thu=3, Fri=4, Sat=5, Sun=6

not F Item not found

OF Overflow

P-nAñE Part name

P-no Part number

PrESS CodE Calibration mode: Press code key to auto find zero number

ProG Programming mode

P-SP Item setpoint

rS232 CoñErr RS232 communication error (PC/printer)

S-on Span switch is ON

Sat Saturday

SEt P Setpoint

SEt X Setpoint number

SPCXX Specification number

SUn Sunday

TArE Tare

tArE oFF LoAd Tare is not allowed because weight is greater than zero

t-C XX XX-XX Teraoka Code I Character Position I Character Code Character - Character

THU Thursday

TotAL XXXXXXX Accumulation or subtraction operation

TUE Tuesday

UF Underflow

Unit u

UP-Err Span out of range (on the high side)

VEr X.XX Version number

ED Wednesday

U

Unit weight

Table 10-15. DC-190 Messages

Page 31

10.7 Clearing Locked-Up Scale (888888 Error)

Several configuration errors can result in the scale locking up with a display that sho ws all 888888s. These errors

include the following:

• If no force balance is connected to the DC-190, SPEC 8, bit 3, must be set to 0 (0xxx).

• If a force balance is attached, SPEC 8, bit 3 must be set to 1 (1xxx) and SPEC 9, bit 2 (force balance

type), must be set to 1 (x1xx, Ohaus Explorer).

• If no printer is attached to the DC-190, SPEC 10, bit 3, must be set to 0 (0xxx).

• SPEC 16 and SPEC 17 must assign a different location for each scale, whether it is present or not. These

bits must be configured to show scale assignments for

and Force Balance. See example below.

The following configuration for SPECs 16 and 17 contains duplicate entries for both Internal Scale 1

Caution

SPEC Setting Bits 2 and 3 Bits 0 and 1

and External Scale.

lockup condition will result if this configuration is selected.

Do NOT set SPECs 16 and 17 to a configuration such as that shown below: a

Internal Scale 1, Internal Scale 2, External Scale,

16 0010 Scale 1

00: Internal Scale 1

17 1000

Scale 3

10: External scale

Scale 2

10: External scale

Scale 4

00: Internal Scale 1

Should the DC-190 become locked up in all 888888s as a result of invalid specification settings, an authorized

service technician can perform the following procedure:

1. Unplug scale from AC outlet.

2. Press and hold the

3. The display shows

4. Press and hold

3 and 9 keys while plugging AC cord into outlet.