Page 1

CCCCoooouuuunnnnttttiiiinnnngggg SSSSccccaaaallllee

ee

DC-180

OO

OO

pp

pp

ee

ee

rr

rr

aa

aa

ttiiii

oo

tt

oo

MM

MM

nn

nn

aa

aa

&&

&&

nn

nn

uu

uu

SS

SS

aallll

aa

ee

ee

rr

rr

vviiii

vv

cc

cc

ee

ee

73349

Page 2

Page 3

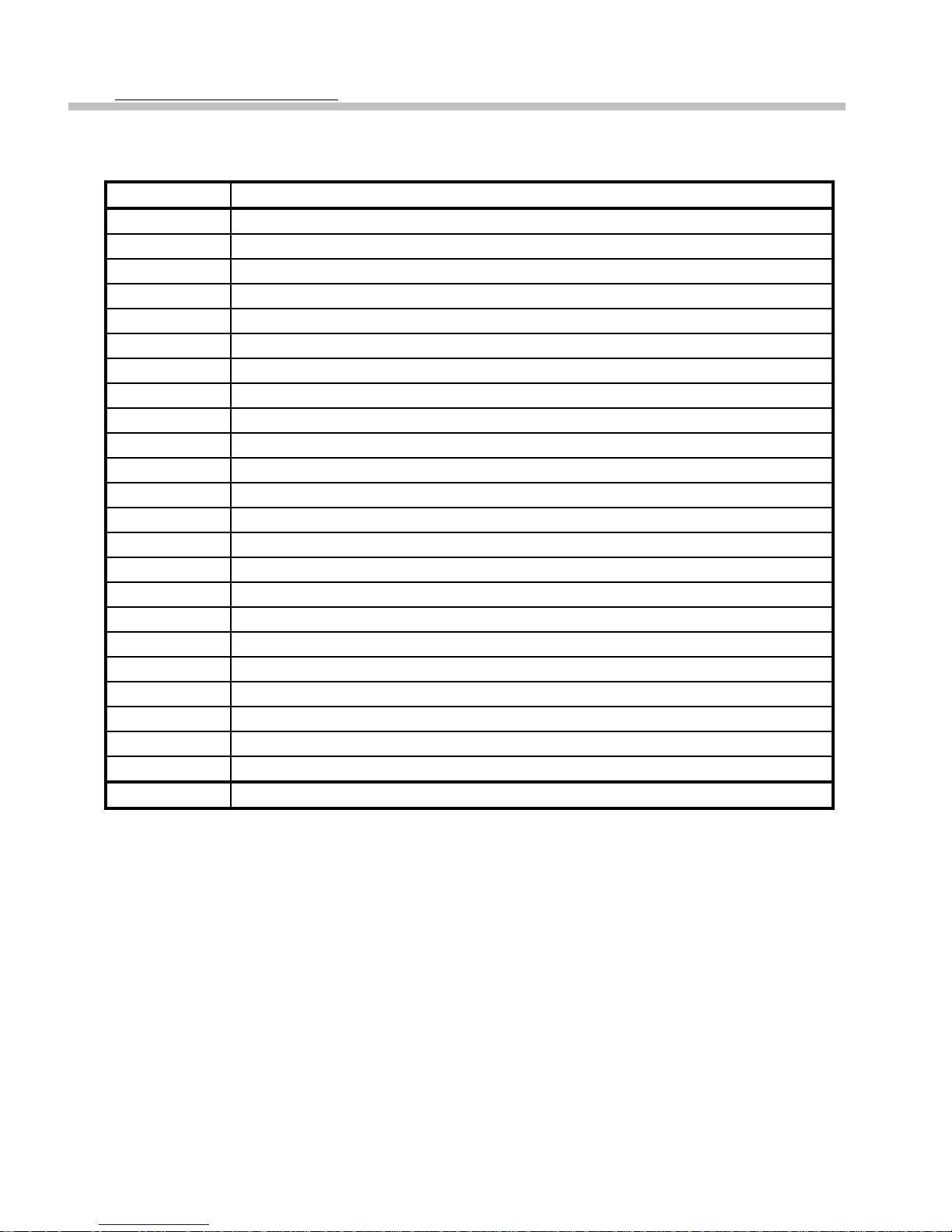

DC-180 SERIES OPERATING MANUAL

INDEX

SECTION PAGE

NUMBER

1.0 GENERAL 4-7

1.1. Description 4

1.2. Keyboard & Display Layout 5

1.3. Indicator Lamp Information 6

1.4. Key Switch Information 7

2.0 SPECIFICATIONS 8

2.1 Capacities 8

3.0 INSTALLATION

3.1 Un-packing

3.2 Inspection

3.3 Re-packing

3.4 Un-locking Procedure

4.0 ELECTRICAL 12

4.1. DC-180 AC / BATTERY OPERATION 12

5.0 DC-180 OPERATIONAL PROCEDURES 13-17

5.1. Tare Reducton 13-14

5,1,1, One Touch Tare 13

5.1.2. Digital Tare 13

5.2. Net / Gross 13

5.3. Unit Weight 14

5.3.1. Unit Weight by Sampling 14

5.3.2. Unit Weight by Key Entry 14

5.4. Accumulation 15

5.5. Subtraction / Reduction 15

5.6. Clearing of Accumulated Data 16

5.7. Clearing Unit Weight 16

5.8. Scale 1 ←→ 2 Operation 16

5.9. Recall Item From Memory: 17

9-11

9

9

9

9-11

6.0. PROGRAM MODE 18-20

6.1. Set Point Programming 18-19

6.1.1. Set Point Programming by % Quantity 18

6.1.2. Set Point Programming by % Weight 18

6.1.3. Set Point Programming by Upper & Lower Limit Quantity 19

6.1.4. Set Point Programming by Upper & Lower Limit Weight 19

6.2. Programming Id Code (30 Item Memory) 20

7.0. MAINTENANCE MODE 21-26

7.1. Scale Calibration 21

7.2. Internal Count and A/D Count Display 21

7.3. Spec Setting 1 - 4 -1 22

7.4. Spec Setting 1 - 4 -2 22

7.5. Spec List 23-25

7.6. Platform Wiring 25

7.7. Shop Notes 26

3

Page 4

1.0. GENERAL

1.1. Description

The DC-180 counting scale offers a practical solution to a full range of precision

counting applications. There are a variety of models available ranging from a weight

capacity of 0.5 lb. through 100 lb. utilizing an internally mounted load cell and a full

range of capacities from 0.5 to 50,000 lb. utilizing an external second platform. A

console model is also available with 1 external platform in any of the above mentioned

capacities in any combination.

This manual will provide the user with information necessary to operate and program the

DC-180. Included in this manual are descriptions, specifications, operating instructions

and service guide.

4

Page 5

1.3. Keyboard & Display Panel Layout

5

Page 6

1.4. Indicator Lamp Informaton

LAMP “ON”

Zero When the gross weight is zero.

Tare When tare weight is set.

Gross When [Gross/Net] key is pressed.

Insuff When the net weight is below a specific percentage of capacity weight.

Recomp When unit weight recomputing is possible.

Memory When quantity is being accumulated or when memory overflows.

Prog When in the programming mode with [mode] key pressed.

Kg When the item is weighed in Kg. unit with [Kg/Lb] key pressed.

Lb When the Item is weighed in Lb. unit with [Kg/Lb] key pressed.

Batt When battery’s power level is low.

Scale 1 When built-in platform is used.

Scale 2 When remote platform is connected and used.

6

Page 7

1.5. Key Switch Information

KEY FUNCTIONS

On/Off For turning the machine ON and OFF.

0 to 9 Numeric Keys.

.

Rezero Used to reset the scale to zero.

Tare Used for setting and clearing tare weight.

Kg/Lb Used to change the weighing unit between Kilogram and Pound.

C Used to clear the key entries and unit weight.

Net/Gross Used to change between Gross and Net.

Unit Weight Used to enter the unit weight using numeric key board.

Mode Used for entering programming mode from weighing mode.

Scale 1 __

__

2 Used to switch between Built-in Platform and Remote Platform.

+

Decimal Point.

Used to enter the maintenance mode along with other keys

Used for Accumulation function and for incrementing SPEC

numbers in SPEC setting mode.

-

*

#

PIECES Used for computing unit weight by sampling.

Used for Subtraction function and for decrementing SPEC

numbers in SPEC setting mode.

Used for storing the specification data and used to print out weight

information when printer is connected.

PLU key, for calling out PLU data.

7

Page 8

2.0. SPECIFICATIONS

This section includes a detailed listing of all pertinent specifications and parameters for the

DC-180 counting scales. The system weighing accuracy is 0.02 % . All models meet or

exceed the requirements of OIML, Class III, and NIST Handbook, Number 44.

2.1. CAPACITIES

The following resolution specifications apply to all models of DC-180 counting scales:

DC-180 SINGLE SCALE

Capacity Mounting

Internal/External

0.5 lb. Both 0.0001 0.000002 6” x 8”

1.0 lb. Both 0.0001 0.000002 6” x 8”

2.5 lb. Both 0.0002 0.000005 7” x 10”

5.0 lb. Both 0.0005 0.00001 9” x 12”

10.0 lb. Both 0.001 0.00002 9” x 12”

25.0 lb. Both 0.002 0.00005 9” x 12”

50.0 lb. Both 0.005 0.0001 9” x 12”

Weight

Resolution

Counting

Resolution

Platform Dimension

DC-182L REMOTE PLATFORMS

Platform capacity Weight

Resolution

100.0 lb. 0.01 0.0002 13” x 17”

250.00 0.02 0.0005 17” x 21” **

500.00 0.05 0.001 17” x 21” **

1000.0 0.1 0.002 24” x 28” **

2500.0 0.2 0.005 36” x 36” or 48” x 48”

5000.0 0.5 0.01 48” x 48” **

10000 1.0 0.02 48” x 48” or 60” x 60”

25000 2.0 0.05 48” x 72” or 60” x 84”

50000 5.0 0.1 60” x 84” **

Counting

Resolution

Platform

Dimensions

** Other platform sizes are available; consult factory for more information.

* Units are selectable from lb. to kg. and can be programmed to weigh in other primary

Units ; lb., kg., g., oz., or dwt.

8

Page 9

3.0. INSTALLATION

This section provides the information required for installing this counting system

For operation. The following steps accomplish installation.

1. Unpacking

2. Set-up Procedure

3.1. UNPACKING

Each component of the DC-180 system is packed in a specially designed carton.

Remove each component from its carton, separate the component from its

polystyrene shell assembly and set aside. Inspect the carton interior to be sure

that all accessories have been removed from the carton. Inspect the carton inner

panels for accessories.

NOTE: Be sure to repack all materials within the carton set. Store the cartons in

A secure area so they can be available whenever future shipment of the scale is

required.

3.2. INSPECTION

Immediately after unpacking, a visual inspection of the scale should be performed.

If any damage has been incurred during transportation notify the shipper and DIGI

MATEX, Inc. immediately. Instructions for assessment of damage and further

procedures will then be determined.

3.3. REPACKAGING

If, at anytime, the DC-180 counting scale must be returned for modification,

calibration, or repair, be sure that it is properly packed with sufficient cushioning

materials.

Whenever possible, the original carton assembly should be retained for this

purpose. Any damage caused by improper packaging will not be covered by

warranty.

3.1. UNPACKING

The unlocking procedure is included on the next page. The DC-180 should

be properly locked whenever it is being transported.

9

Page 10

3.4. Unlocking Procedure (Continued) for 5LB. To 50LB. Scales

INITIAL SET-UP PROCEDURES

Before setting up the scale, remove the load cell locking screws

located at the bottom of the scale as shown in the diagram below.

Warning!

Do Not Turn Scale Upside Down.

To Lock Scale for shipping:

1. Install cap screw finger tight.

2. Install allen screw finger tight,

3. Then install nut, just snug.

Do the following steps before scale calibration.

A) Place the platter on the platter support of the scale.

B) Turn on the power and check that the scale is functioning.

C) For calibration of the scale, use a thin rod to enable the span switch.

Refer to the diagram above for the location of the span switch.

D) Please refer to instructions for Span Adjustment for more detail.

Note: For DC-180 with a remote scale, connect the remote scale before plugging the A/C.

10

Page 11

Do not unplug remote scale from the DC-180 while the DC-180 is powered.

3.4. Unlocking Procedure (Continued) for 1LB. and 2.5LB. Scales

The above drawing is for illustration

purpose only.

Warning!

Do Not Turn Scale Upside Down.

SET UP PROCEDURES

Do the following steps before

scale calibration or operation.

1. Take off nut (A) and four screws (C), then take off plate.

2. Loosen nut (B) and screw (D) , then take off screw (D) , nut (B) and insert.

3. Take off screw (E) and stopper, then take off screw (F).

4. Install platter support and platter.

(Please pay attention to installation direction of support.)

11

Page 12

4.0. DC-180 AC / BATTERY OPERATION

The DC-180 can be operated with AC power or with the optional internal

battery. The battery will automatically charge whenever the scale is

plugged into AC power. The charging current is regulated by a battery

monitor circuit, so that the battery can not be overcharged.

The DC-180 system is powered internally at a low power level whenever

the scale is plugged into the AC line or the battery switch is in the “ON”

position. The battery power switch is located on the right side of the rear

panel. The front panel “ON/OFF” switch enables the display and

primary power.

When the battery switch is “ON” and the AC is not connected, a low level

battery current will flow even if the display is “OFF”. To prevent battery

discharge when stored turn the battery switch to “OFF” whenever unit is

not used.

Do not store the scale without turning off the battery power switch.

To Install Battery Option

1. Turn Scale On Side.

2. Remove Battery Compartment Cover.

3. Connect The Red Lead To (+ ) Positive Terminal Of Battery.

4. Connect The Black Lead To ( −)Terminal Of Battery.

5. Place Battery Into Compartment & Replace Battery Compartment Cover.

CHARGING TIME: FOR OPTIMUM USE AND BATTERY LIFE, THE DC-180 BATTERY

SHOULD BE FULLY CHARGED BEFORE EACH OPERATING RUN.

NOTE: Short Cycle Charging Will Reduce The Normal Use Time And Can Drastically

Reduce Battery Life.

The BP-180 battery is a sealed lead acid battery which needs to be charged

periodically, similar to a car battery, if the BP-180 is left on the shelf for several

months without being charged it will eventually drain to point that it can no longer be

charged!

12

Page 13

5.0. Operation Guide in Weighing Mode

5.1. Tare Reduction :

5.1.1. One Touch Tare Operation :

1 Display in the weighing mode

2 Place 0.5 Lb weight on the platter. (Example : of a .5lb tare)

3 Press the [TARE] key to tare the weight on the platter

4 Remove the weight from the platter

Note : The tare operation is valid up to the 4th digit of the weight column. For Example ;

when we attempt to tare a weight of 1.0000 lb, on a 5.0000 lb machine, the error buzzer

comes on. So, the maximum permissible tare value is 0.9995 lb. But for a 10.000 lb

machine, the maximum permissible tare value (for 100 % FS setting) is 9.998 lb.

5.1.2. Digital Tare Operation :

1 Display in the weighing mode.

2 Enter [0][.][5][0][0][0] (Example : of a .5lb tare)

3 Press the [TARE] key to tare the weight entered by keyboard.

Note : The same note as in One Touch Tare applies for Digital Tare as well.

5.2. Net/Gross Operation :

1 Display in the weighing mode.

2 Place 0.5 Lb. weight on the platter.

3 Press the [TARE] key to tare the weight on the platter.

4 Place an additional 0.5 Lb. on the platter.

5 Press the [NET / GROSS] key. 1.0000 lb is the Gross Weight.

6 Press the [NET / GROSS] key. 0.5000 lb is the Net Weight.

13

Page 14

5.3. Unit Weight Operation :

5.3.1. Unit Weight Operation by Sampling :

1 Display in the weighing mode

2 Place 10 pcs of the item to be sampled on the platter.

3 Press the [PIECES] key. Please wait for a few seconds for the computation.

4 The Unit Weight Display shows the Unit Weight of the samples (1.255/1000 pieces) and the

Quantity Display shows the Quantity of the pieces i.e. 10 in this case.

Note : When the samples are placed on the platter, if the insufficient lamp is “ON”, then add

few more samples until the insufficient lamp is “OFF. Now, before pressing the [PIECES]

Key, enter the no. of samples using the key board and then press the [PIECES] Key. For e.g. :

After putting ten pieces of the sample, if the insufficient lamp is “ON”, then add few more

samples (say 3) until the insufficient lamp is “OFF”. Now using the key board, enter [1] [3] and

then press the [PIECES] Key to compute the Unit weight of the samples.

5.3.2. Unit Weight Operation by Key Entry :

This following procedure is used if the unit weight is already known.

1 Display in the weighing mode

2 Enter the known Unit Weight using the keyboard. [2][.][8][7]

3 Press the [UNIT WEIGHT] key to enter the unit weight.

4 Place 2 lb weight on the platter. The scale displays the quantity for the weight placed on the

platter.

14

Page 15

5.4. Accumulation Operation :

This following procedure is used if the unit weight is already known.

1 After Unit Weight entry. (See 4.3)

2 Press the [++++] key. The Total is displayed in the Quantity Display.

3 The memory lamp will glow. After a moment the scale will resume operation mode.

4 Put 1.0lb on the platter

5 Press the [++++] key. The Total is displayed in the Quantity Display.

6 The memory lamp will glow. After a moment the scale will resume operation mode.

7 The previous total of 25 and the present quantity of 15 are added and the Total Of 40 is

displayed in the Quantity Display.

8 The memory lamp will glow. After a moment the scale will resume operation mode.

9 Pressing the [++++] key makes the total 15 + 40 = 55, displayed in the Quantity Display.

5.5. Subtraction/Reduction Operation :

1 Display in the weighing mode with memory lamp glowing.

From previous operation (See 4.4.)

2 Press the [++++] key. The Total Is Displayed in the Quantity Display.

3 Remove the 2.0 lb. Weight from platter

Leave only the 1.0lb weight on the platter.

4 Pressing the [−−−−] key deducts the quantity of 5 in the Quantity Display from the

previous Total of 70 to give us a total of 65.

5 The memory lamp will glow. After a moment the scale will resume operation mode.

6 Press the [−−−−] key. The total quantity after subtracting is shown in the Quantity

Display. 65 -5 =60

7 The memory lamp will glow. After a moment the scale will resume operation mode.

15

Page 16

5.6. Clearing of Accumulated Data :

1 From previous operations (See 4.4. & 4.5.)

2 Pressing the [∗∗∗∗] key, clears the accumulated total.

5.7. Clearing Unit Weight :

1 Remove weight.

2 Pressing the

5.8. Scale 1__

To change between Scale 1 (Built-in) and Scale 2 (Remote), please make sure that bit 1 of Spec 25 in

Weight and Measures specification is set to 1. Switch off the scale and turn it on again after setting

this spec. Or else you might notice a shift in the zero point, when changing between scales. The scale

change operation cannot be performed if there is any [Numeric] Key entry.

[C] key, clears the unit weight.

__

2 Operation :

Display in the weighing mode

Pressing [SCALE] key changes from Scale 1 to Scale 2.

Pressing the [SCALE] key again changes back to Scale 1

Note :- The unit weight computed on Scale 1 can be transferred to Scale 2 and vice versa.

16

Page 17

5.9. Recall Item From Memory:

Version 1.13 and above ID CODE (30 ITEM MEMORY)

OPERATION EXAMPLE : Recall Item From Memory:

Task Procedure

1. Select Scale And Reset Zero Point Press [SCALE 1 , 2 ] Key And Press

[REZERO] Key.

2. Enter ID Code Type ID Code (Up To Four Digits) Example

[1] [2] [3] [4], Then Press[CODE] Key.

3a. Enter Tare Value (One Touch Tare) Place Empty Container On Platter And Press

[TARE] Key.

3b. Enter Tare Value (Digital Tare) Place Full Container On Platter And Keyboard

Enter The Known Tare Weight. (Example

Press: [0] [•] [2] [5] [5], Then Press [TARE]

Key.

4. Accumulate Quantity With The First Quantity On Scale, Press [+]

Key. Remove Them And Press [C] Key. The

Display Returns To Weighing Mode . Place

The Second Quantity On Scale And Count

Them. Repeat The Procedure Until All Parts

Have Been Counted. If A Mistake Is Made

During Accumulation, Press [-] Key.

5. End Accumulation Press [∗] Key.

!!

!!

Note: If no Unit Weight has been programmed into the memory, it will be necessary to

enter a Unit Weight using one of the following steps:

""

a""

Compute Unit Weight

When sample size is insufficient the number of pieces to be added appears in display

This procedure may be skipped by pressing [pieces] key without adding additional pieces,

however it may affect accuracy to use an insufficient sample size

The accuracy of the computation can be improved by increasing the sample size

""

b""

Recompute Unit Weight

or

""

c""

Enter Unit Weight

Place 10 Pieces On Scale, Press [PIECES]

key.

Add Additional Pieces, Press[PIECES] Key.

Press [1] [•] [7] [2] [6] [6], Press [UNIT

WEIGHT] key.

17

Page 18

6.0. PROGRAMMING MODE:

6.1. Set Point Programming :

6.1.1. Set Point Programming by % Quantity

Set Point 1 : Quantity (See Note Below) , Set Point 2 : % Quantity (See Note Below)

Set bit 0 and 1 of Spec 7 to 00

1 Display in the weighing mode

2 Press the [MODE] key to go into the programming mode.

3 Press [++++] key to go into Set Point Programming Mode.

4 Enter the Quantity for Set Point 1 using the [Numeric] keys. Example type [1][0][0][0][0]

5 Press [++++] key to go to Set Point 2.

6 Enter the new Set Point 2 value using the [Numeric] keys. Example type [7][5]

7 Pressing the [++++] key exits from the Set Point Programming mode, but remains in the

Programming mode.

8 Pressing the [MODE] key exits from Programming mode and returns to Weighing mode.

NOTE: Using the [C] key clears the key entry.

Note : Set Point 1 : Must be a quantity value up to 999999.

Set Point 2 : Percentage value up to 999%, but set according to Set Point 1 value. Ex: Suppose

Set Point 1=999999, Set Point 2 cannot be set more than 100%.

6.1.2. Set Point Programming by % Weight

Set Point 1 : Weight (See Note Below), Set Point 2 : Weight (See Note Below)

Set bit 0 and 1 of Spec 7 to 01

1 Display in the weighing mode

2 Press the [MODE] key to go into the programming mode.

3 Press [++++] key to go into Set Point Programming Mode.

4 Enter the Weight value for Set Point 1 using the [Numeric] keys depending on the capacity of the

scale. Please see the note below. Example type [3][.][0][0][0][0]

5 Press the [++++] key to program Set Point 2.

6 Enter the percentage value for Set Point 2 using [Numeric] keys. Please see the note below. [7][5]

7 Pressing the [++++] key exits from the Set Point Programming mode, but remains in the Programming

mode.

8 Pressing the [MODE] key exits from Programming mode and returns to Weighing mode.

Note : Set Point 1 : Must be a weight value depending on the capacity of the scale.

Set Point 2 : Percentage value up to 999%, but set according to Set Point 1 value. Ex: Suppose Set

Point 1=5.0000 (capacity of the scale), Set Point 2 cannot be set more than 100%.

18

Page 19

6.1.3. Set Point Programming by Upper and Lower Limit of Quantity

Set Point 1 : Quantity (See Note Below), Set Point 2 : Quantity (See Note Below)

Set bit 0 and 1 of Spec 7 to 10

1 Display in the weighing mode

2 Press the [MODE] key to go into the programming mode.

3 Press [++++] key to go into Set Point Programming Mode.

4 Enter the Quantity value for Set Point 1 using the [Numeric] keys. Example: type

[2][0][0][0][0] Please see the note below.

5 Press the [++++] key to program Set Point 2.

6 Enter the Set Point 2 value using the [Numeric] keys. Example: type [1][0][0][0][0]

Please see note below.

7 Pressing the [++++] key exits from the Set Point Programming mode, but remains in the Programming

mode.

8 Pressing the [MODE] key exits from Programming mode and returns to Weighing mode.

Note : Set Point 1 : Must be a quantity value up to 999999

Set Point 2 : Quantity value up to 999999, but Set Point 2 value must always be less

than Set Point 1 value.

6.1.4. Set Point Programming by Upper and Lower Limit of Weight

1 Display in the weighing mode

2 Press the [MODE] key to go into the programming mode.

3 Press [++++] key to go into Set Point Programming Mode.

4 Enter the Weight value for Set Point 1 using the [Numeric] keys depending on the capacity of the

scale. Example: type [3][.][0][0][0][0] Please see the note below.

5 Press the [++++] key to program Set Point 2.

6 Enter the weight value for Set Point 2 using [Numeric] keys. Example: type [2][.][0][0][0][0]Please

see the note below.

7 Press the [++++] key exits from the Set Point Programming mode but remains in the Programming

mode.

8 Pressing the [MODE] key exits from Programming mode and returns to Weighing mode.

Note : Set Point 1 : Must be a weight value depending on the capacity of the scale.

Set Point 2 : Weight value up to the capacity of the scale, but Set Point 2 value

must be less than Set Point 1 value.

19

Page 20

6.2. PROGRAMMING ID CODE (30 ITEM MEMORY)

Version 1.13 and above PROGRAMMING ID CODE (30 ITEM MEMORY)

Task Procedure

1. Enter PROGRAM Mode. Press [MODE] key.

2. Enter ID Code Type ID Code (Up To Four Digits) Example [1] [2] [3] [4],

Then Press[CODE] Key.

3a. Compute Unit Weight Place 10 Pieces On Scale, Press [PIECES] key.

When sample size is insufficient the number of pieces to be added appears in display

This procedure may be skipped by pressing [pieces] key without adding additional pieces however

it may affect accuracy to use an insufficient sample size

The accuracy of the computation can be improved by increasing the sample size

3b. Recompute Unit Weight Add Additional Pieces, Press[PIECES] Key.

or

3c. Enter Unit Weight Press [1] [•] [7] [2] [6] [6], Press [UNIT WEIGHT] key.

4. Enter Set Point Mode Press [+] key.

5. Enter Setpoint 1 Enter Setpoint 1 (Example 1000) Type [1] [0] [0] [0],

Press [+] Key.

6. Enter Setpoint 2 Enter Setpoint 2 (Example 90.00) Type [9] [0] [•] [0] [0],

Press [+] Key.

7. Store Data Press [∗] Key To Store Data.

8. Exit Program Mode. Press [MODE] Key.

Item # 3 A, B, & C Or Item # 4, 5, & 6 May Be Omitted To Fit Your Needs.

Item # 1, 2, 7 & 8 Are Necessary To Program ID Code Into Memory.

NOTE: DELETE ALL ITEM MEMORY……….. PRESS AND HOLD REZERO WHILE

PRESSING [••••] [••••] [0], THEN RELEASE THE REZERO THE DISPLAY WILL SHOW

[ ALL CLEAr ] . PRESS CLEAR KEY TO CLEAR ITEMS

20

Page 21

7.0. MAINTENANCE MODE:

y

y

i

e

7.1. Scale Calibration :

Prior to the calibration of the scale, please note that the SPEC settings

corresponding to Minimum Display, Weight Decimal Point Position and Load Cell Sensitivity

for that particular scale have to be correctly set. Ensure that the[SPAN] Switch is ON.

See page 10 for lacation of the span switch

S/No. OPERATION

1 Press the [SPAN]

Switch

2 [REZERO]

[8] [7] [1] [5]

3 [REZERO]

4 [++++]

5

6 [REZERO]

7 Place 5 lb weight on the

platter.

8 [5][.][0][0][0][0]

9 [❋]

10

11

12 [MODE]

13 Push the [SPAN]

Switch.

REMARKS

The [SPAN] Switch is located at the bottom of the machine.

Enter [8] [7] [1] [5] while depressing the [REZERO] Key. The displa

will show weight in the Weight Window and zero count in the Quantit

Window. If the zero count is 50,000_10,000, ( 100,000±10,000 for

version 1.06 software) then proceed to step 5.

Press the [REZERO] Key to zero the weight in the Weight Window.

Press the [+] Key in order to compute the zero point. It takes a few

seconds for the zero calibration.

After computing the zero point, the Quantity Window shows the Zero

Counts. Ensure that the counts are 50,000 _ 10000,

(100,000±10,000 for Version 1.06 software). If not, repeat Step 3 unt

the Counts are in the above range.

Press [REZERO] Key to zero the weight before span calibration.

Place capacity weight of 5 lb or any weight on the platter. In this

illustration, capacity weight is taken as an example.

Enter the weight placed on the platter using the [Numeric] Keys.

Press the [❋] Key to start span calibration.

After a few seconds, the display shows the counts for the weight on th

platter in the Weight/Unit Weight Window and the Quantity Window

shows the internal count with the zero point counts added to it.

Removing the weight, the Unit Weight Window should indicate zero

and the Quantity Window the zero starting point i.e. 50,000,

(100,000±10,000 for version 1.06 software) If the zero point has

changed, please carry out the calibration procedure again.

Pushing the [MODE] Key shows the S-On display

Pushing the [SPAN] Switch returns the scale to the Weighing Mode.

21

Page 22

7.4. Internal Count And A/D Count Display :

If the SPEC 25, bit 2 is set, then the [SPAN] Switch must be "ON" to enter this mode.

1

Enter [0] [0] [9] while depressing the [REZERO] Key. Unit Weight Window will display

the Internal Count and the Quantity Window will display the A/D Count.

2

3

Press [MODE] Key to exit from Program Mode to Weighing Mode.

Depressing the [SPAN] Switch returns scale to the Weighing Mode.

7.2. Spec 141 Setting

Spec 141 Setting:

Spec 141(Customer Specifications) can be accessed from the weighing mode.

1. Enter [1][4][1] while depressing the [REZERO] key.

2. [++++] key increases to the next SPEC number and also stores temporarily the SPEC data in the RAM location.

3. Enter 1011 as the new value for SPEC01 using the [Numeric] keypad

4. [C] key clears the [Numeric] entry.

5. [++++] key increases to the next SPEC number.

6. [−−−−] key decreases to the previous SPEC number.

7. [−−−−]key decreases from SPEC 01 to SPEC 00.

8. [−−−−] key decreases the SPEC number from SPEC00 to SPEC18

9. [❋] stores the new SPEC values to the NOV-RAM and exits from the SPEC setting mode.

10. Press [MODE] key to escape from maintenance mode to weighing mode.

7.3. Spec 142 Setting

Spec 142 Setting: To access the Spec 142 (W & M Spec) mode the [SPAN] Switch must be "ON".

The rest of the procedure is the same as Spec 141 setting.

See page 10 for location of the span switch

1 Depress the [SPAN] Switch. The S-On message comes on.

2 Enter [1][4][2] while depressing the [REZERO] key.

3 [++++] key increases to the next SPEC number and also stores temporarily the SPEC data in the RAM location.

4 Enter, (example, 1011) as the new value for SPEC21 using the [Numeric] keypad

5 [C] key clears the [Numeric] entry.

6 [++++] key increases to the next SPEC number.

7 [−−−−] key decreases to the previous SPEC number.

8 [−−−−]key decreases from SPEC 21 to SPEC 20.

9 [−−−−] key decreases the SPEC number from SPEC20 to SPEC36

10 [❋ PROG] key stores the new SPEC values to the NOV-RAM and exits from the SPEC setting mode.

11 Press [MODE] Key to exit from Spec Setting mode. The display shows S-On indicating that the [SPAN]

Switch is ON.

12 Depressing the [SPAN] Switch returns scale to the Weighing Mode.

22

Page 23

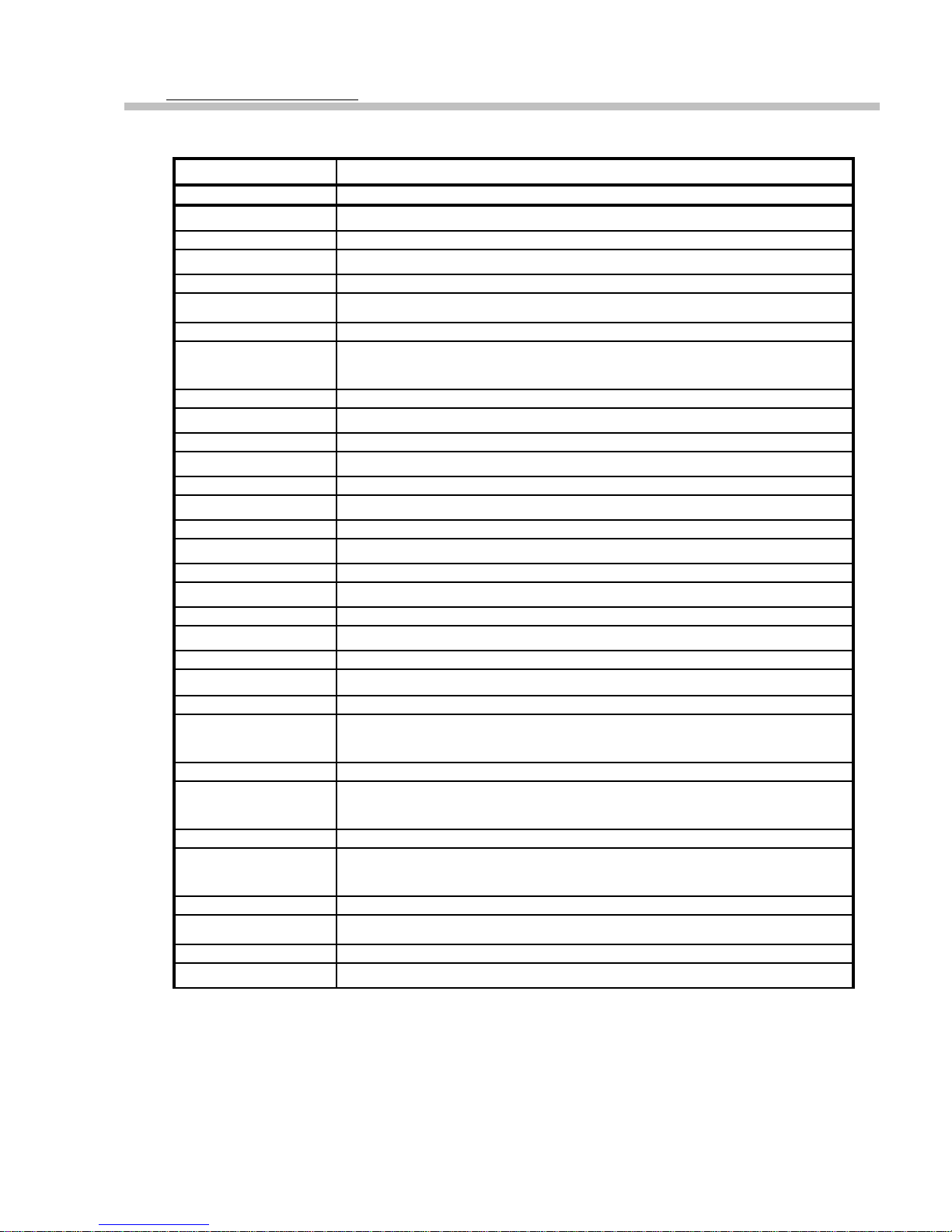

7.5. DC-180 Spec. List Rev. 7

g

p

Operation Specifications : To enter this mode, enter the numeric keys 1,4,1 while pressing the Rezero

Key.

Spec No. Bit 3 Bit 2 Bit 1 Bit 0

0

1 Power Auto Off Function

0000 : Auto Power Off Disable when Net Wt. = 0

0001 ~ 1111 : Time duration to activate Power Off, equal to the

decimal no. converted from the 4 binary digits

2 Scale Specification

00 : Gram 01 : Kg

10 : Lb 11 : not used

3 Not used Not used Not used Not used

4 Auto Scale Switching

0 : No 1 : Yes

(ver 1.25)

5 Sampling time for Unit

Weight Calculation

0 : 10 times

1 : 5 times

6 Display Accuracy of Unit

Weight

0 : No1 : Yes

7 Set Point Buzzer

0 : Yes 1 : No

8-9 Not used Not used Not used

10 RS-232C Connection

0 : No

1 : Yes

(ver 1.07)

11 RS-232C

Stop Bit

(Optional)

0 : 1 bit

1 : 2 bits

(ver 1.07)

12 RS-232C Output

(Optional)

00 : Not Available

01 : When Counting Condition

∗∗

10 : By ∗∗

11 : In Both Cases

(ver 1.07)

13-17 Not used Not used Not used Not used

18 Set Point TTL Output

0: Active Low

1: Active High

(ver 1.08)

Key

Extent of insufficient samples

00 : 0.1 %

01 : 0.2%

10 : 0.0%

Unit Wt. Auto

Recomputing

0 : No

1 : Yes

Varying levels for the control of FIP Brightness.

000 : Highest Brightness Level

111 : Lowest Brightness Level

RS-232C

Data Length

(Optional)

0 : 7 bits

1 : 8 bits

(ver 1.07)

Not used Not used Not used

/Lb Lam

K

Inhibit

0 : No 1 : Yes (ver 1.04)

Negative

Counting

0 : No

1 : Yes

FIP Brightness Levels

Set Point Type

00 : %Quantity 10 : Quantity

01 : %Weight 11 : Weight

Not used

(ver 1.06)

RS-232C Baud Rate

00 : 1200 10 : 4800

01 : 2400 11 : 9600

(ver 1.07)

RS-232C Parity Bit

00 : No 10 : Not Used

01 : Odd 11 : Even

(ver 1.07)

RS-232C

Communication

0 : With

Handshaking

1 : Without

Handshaking

(ver 1.12)

(ver 1.06)

(Optional)

(Optional)

RS-232C Header

0 : With

Header

1 : Without

Header

(ver 1.12)

23

Page 24

Weight and Measures Specification :

y

To enter this mode, enter the numeric keys 1,4,2

while pressing the Rezero Key. The Span Switch must be “ON” to enter this mode.

Spec No. Bit 3 Bit 2 Bit 1 Bit 0

20 Minimum Display ( Scale 1)

00 : 2 10 : 5

01 : 1 11 : 10

21 Not used Weight Decimal Point Position (Scale 1)

000 : 00000 011 : 00.000

001 : 0000.0 100 : 0.0000

010 : 000.00

22 Not used Weight Decimal Point Position (Scale 2)

000 : 00000 011 : 00.000

001 : 0000.0 100 : 0.0000

010 : 000.00

23 Display Resolution

00 : 1/10,000 10 : 1/2,500

01 : 1/5,000 11 : Not Used

24 Masked Display

at Minus Wt.

0 : Gross

1 : Net

25 Scale Starting

Method

0 : Automatic

1 : Manual

26 Zero Tracking

When Tare

0 : Yes

1 : No

27 Comma Displa

0 : No

1 : Yes

28 Auto Tare clear

when Rezero

0 : No

1 : Yes

29 Digital Tare

Rounding

0 : Tare

Exactly

1 : Round to

Nearest

Increment

Display at

Minus Wt.

0 :Minus

Display

1 :Masked

IR Mode

protected by

Span Switch

0 : No

1 : Yes

Weight Reset

when Tare

0 : Yes

1 : No

Digital Tare

Setting

0 : No

1 : Yes

Automatic Unit Weight Clear

Condition

00 : Over Net 5d and Gross 21d

and Weight Stable

01 : >= Net 1d and Weight Stable

10 : >= Net 1d and Quantity >0

and Weight Stable

Tare Value

Exchange

0 : Yes

1 : No

Minimum Display (Scale 2)

00 : 2 10 : 5

01 : 1 11 : 10

Zero Setting Range

00 : Unlimited 10 : +- 10% FS

01 : +- 2% FS 11 : Not Avail.

Zero Lamp

Lighting

Method

0 : Gross

1 : Net

Scale Type

0 : Single

Scale

1 : Double

Scale

Initial Start Range

00 : Unlimited 10 : +- 10% FS

01 : +- 2% FS 11 : Not Avail.

00 : 100%FS 10 : 5% FS

01 : 50%FS 11 : Not Available

Tare Addition

0 : Yes

1 : No

Display Mask When

Battery Low

0 : Yes

1 : No

Gross Mode

Available

0 : Yes

1 : No

Tare Range

Automatic Unit

Weight Clear

0 : No

1 : Yes

Tare Subtraction

0 : Yes

1 : No

24

Page 25

Spec No. Bit 3 Bit 2 Bit 1 Bit 0

30 Load Cell Sensitivities Selection (mV/V) (Scale 1)

Spc Min Max Spc Min Max Spc Min Max Spc Min Max

0000

0001

0010

0011

31 Load Cell Sensitivities Selection (mV/V) (Scale 2)

0000

0001

0010

0011

32 Keyboard & Display Type

00 : EX type

01 : AA type

10 : U1 type - U.S. use only

11 : EX type

33 Over Weight Mask at

0 : +1d 1 : +9d

34 Not used (For Scale 1)

35 Not used (For Scale 2)

36 Not used Not used Not used Not used

3.46

3.00

2.59

2.25

Spc Min Max Spc Min Max Spc Min Max Spc Min Max

3.46

3.00

2.59

2.25

4.00

3.46

3.00

2.59

4.00

3.46

3.00

2.59

0 :For Std / Normal Load Cell

1: For abnormal load cell with

too large offset.

(ver 1.06)

0 :For Std / Normal Load Cell

1: For abnormal load cell with

too large offset.

(ver 1.06)

0100

0101

0110

0111

0100

0101

0110

0111

1.95

1.69

1.46

1.27

1.95

1.69

1.46

1.27

Not used Not used Not used

2.25

1.95

1.69

1.46

2.25

1.95

1.69

1.46

1000

1001

1010

1011

1000

1001

1010

1011

Auto Exit from Add

Mode

0 : No

1 : Yes

00 : Normal

01 : Prevent from Small vibration/ fast change in display

10 : Prevent from Medium vibration

11 : Prevent from Large slow change in display

(ver 1.06)

00 : Normal

01 : Prevent from Small vibration/ fast change in display

10 : Prevent from Medium vibration

11 : Prevent from Large slow change in display

(ver 1.06)

1.09

0.95

0.82

0.71

1.09

0.95

0.82

0.71

1.27

1.09

0.95

0.82

1.27

1.09

0.95

0.82

A/D Board (Scale 1)

A/D Board (For Scale 2)

1100

1101

1110

1111

1100

1101

1110

1111

5-Digit Tare

0 : No

1 : Yes

(ver 1.26)

0.61

0.53

0.46

0.40

0.61

0.53

0.46

0.40

0.71

0.91

0.53

0.46

0.71

0.91

0.53

0.46

7.6. Platform Wiring

D I GI R EMOTE

PLA TFOR M WI R I N G

PI N 3 ( + ) EX C I TA TI ON

PI N 4 ( −−

−−

) EX CI TA TI ON

PI N 5 S HI ELD

PI N 6 ( + ) SI GN A L

PI N 7 ( −−

−−

) S I GN A L

25

Page 26

7.7. Shop Notes:

26

Page 27

DC-180 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed

by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects

in materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications

authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If

any equipment fails to conform to these warranties, RLWS will, at its option, repair or replace such goods

returned within the warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a detailed explanation

of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent electrostatic

discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, “Protecting Your Components

From Static Damage in Shipment,” available from RLWS Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair or improper testing; RLWS shall be the sole

judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping charges

both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT,

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER

IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS

WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any legal effect unless

made in writing and signed by a corporate officer of RLWS and the Buyer.

© 2002 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

• 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

1

Loading...

Loading...