Page 1

OPERATION MANUAL

Model : DC-150

Edition

Month Year

3rd August 1996

TERAOKA SEIKO CO., LTD.

13-12 Kugahara 5-chome, Ohta-ku

Tokyo 146 Japan

TEL: +81-3-3752-2131

FAX: +81-3-3752-2801

Page 2

1. SET UP

1

Page 3

1.2 OVERALL VIEW------------------------------------------------5

1.2a Name Of Each Parts-------------------------------------------------------------5

1.2b Display & Keys--------------------------------------------------------------------6

1.3 LABEL FORMAT AND LABEL SET UP ---------------10

1.3a Specification of Labels and Receipt --------------------------------------- 10

1.3b Standard Print Formats ------------------------------------------------------- 10

1.3c How to set paper--------------------------------------------------------------- 11

1.4 OPERATION FLOW CHART-----------------------------12

2

Page 4

1.1 Specifications

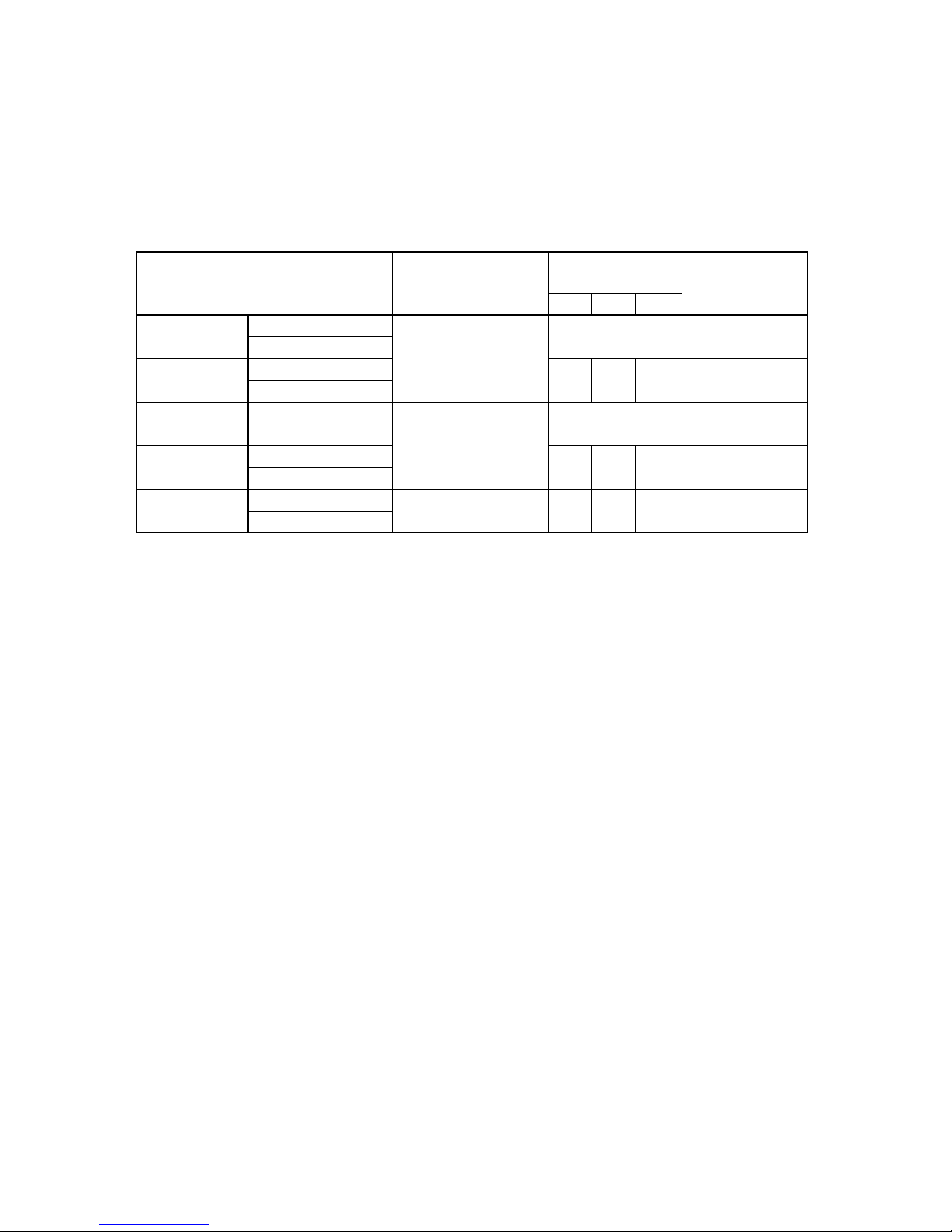

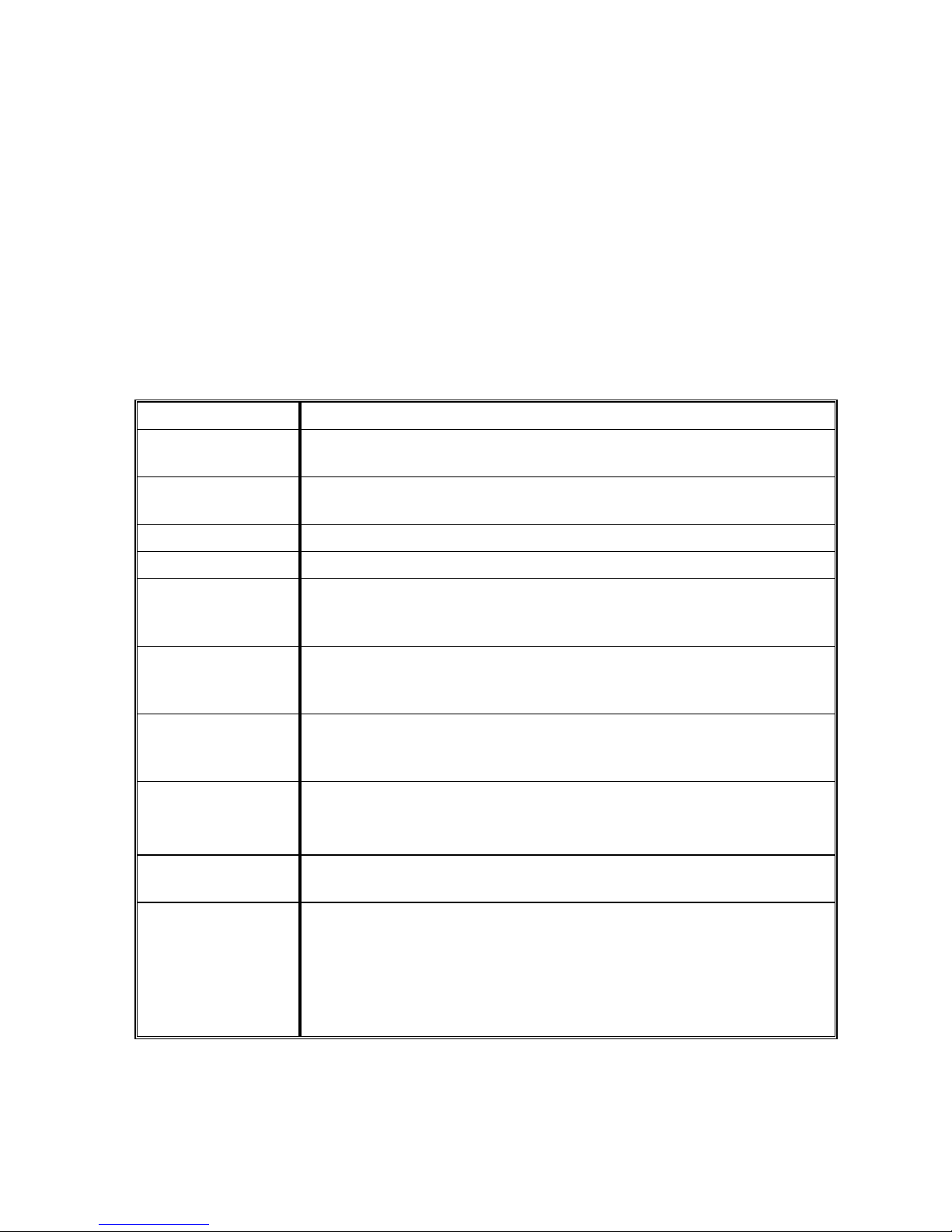

1 MODEL VARIATION

Model

Built-in scale I/F for External

Scale

Optional I/F for

peripherals

#1 #2 FB

DC-151S

DC-151S-64KB 500g,1kg, 2.5kg, 5kg

NO NO

DC-151S-518KB 10kg, 25kg, 50kg

DC-153SI

DC-153SI-64KB (1lb, 2.5lb, 5lb, 10lb

{ { {

YES

DC-153SI-518KB 25lb, 50lb 100lb)

DC-152D

DC-152D-64KB 500g/2.5kg,500g/5kg

NO NO

DC-152D-518KB 1kg/5kg, 1kg/10kg

DC-153DI

DC-153DI-63KB (1lb/5lb, 1lb/10lb,

{

X

{

YES

DC-153DI-518KB 2.5lb/10lb,2.5lb/25lb)

DC-152CFX

DC-152CI-64KB no scale

{ { {

YES

DC-152CI-518KB

2 SCALE SPECIFICATIONS

* WEIGHING DEVICE : LOAD CELL

* DISPLAY DEVICE : Fluorescent Display

* INTERNAL RESOLUTION : 1/500,000

* DISPLAY RESOLUTION : 1/10,000 or 1/5,000 or 1/2,500

3 MEMORY SPECIFICATIONS

* 64kb (STANDARD) for 385 ITEM MEMORY.

* 512kb (Expand Version) for 3,080 ITEM MEMORY.

3

Page 5

4 INTERFACE

* INTERFACES FOR PERIPHERALS

INTERFACE PURPOSE REMARKS

RS-232C-1(8PIN) MODEM, FL-1 STANDARD

TTL SERIAL I/F (8PIN) or RS-232C-2 (8PIN) BAR-CODE SCANNER

TTL OUTPUT (8PIN) or RS-422 (8PIN) SET POINT OUTPUT OPTION

KEY BOARD I/F IBM-AT COMPATIBLE

KEYBOARD

* EXTERNAL SCALE INTERFACES

INTERFACE

RS-232C FOR FORCE BALANCE

EXTERNAL SCALE INTERFACE (SCALE 1)

EXTERNAL SCALE INTERFACE (SCALE 2)

5 DISPLAY SPECIFICATION

* 20 DIGITS ( 5 X 7 DOTS) Fluorescent Display

* WEIGHT : 6 DIGITS

* UNIT WEIGHT : 5 DIGITS

* QUANTITY : 6 DIGITS

6 PRINTER

* THERMAL PRINT

* 0.135 mm x 0.135 mm (Square Dot)

* 448 Dots / Line

7 ELECTRICAL REQUIREMENT

* OPERATION VOLTAGE : 100, 117, 220, 230, 240 Vac

* OPERATING FREQUENCY : 50 or 60Hz

* POWER CONSUMPTION : 15Wz

8 ENVIRONMENT

* OPERATING TEMPERATURE : 0 ~ 40C ( -4F ~ 104F)

* OPERATING HUMIDITY : 15% TO 85%RH

9 DIMENSION

* OVERALL WIDTH x HEIGHT x DEPTH : 410(W) x 498 (D) x 158 (H) mm

16.14(W) x 16.06 (D) x 6.2 (H) inches

* TOTAL WEIGHT : 11.2kg (124.lb.)

4

Page 6

1.2 Overall View

1.2a Name Of Each Parts

1. MAIN SWITCH 7. PORT PANEL A. MODEM /FL-1

2. SCALE 1 B. SET POINT OUTPUT

3. SCALE 2 C. PEN /REWAIND SCANNER

4. DISPLAY WINDOW D. IBM KEY BOARD

5. OPERATION KEYS E. FORCE BALANCE

6. PRINTER F. EXTERNAL SCALE I/F -1

G. EXTERNAL SCALE I/F -2

5

Page 7

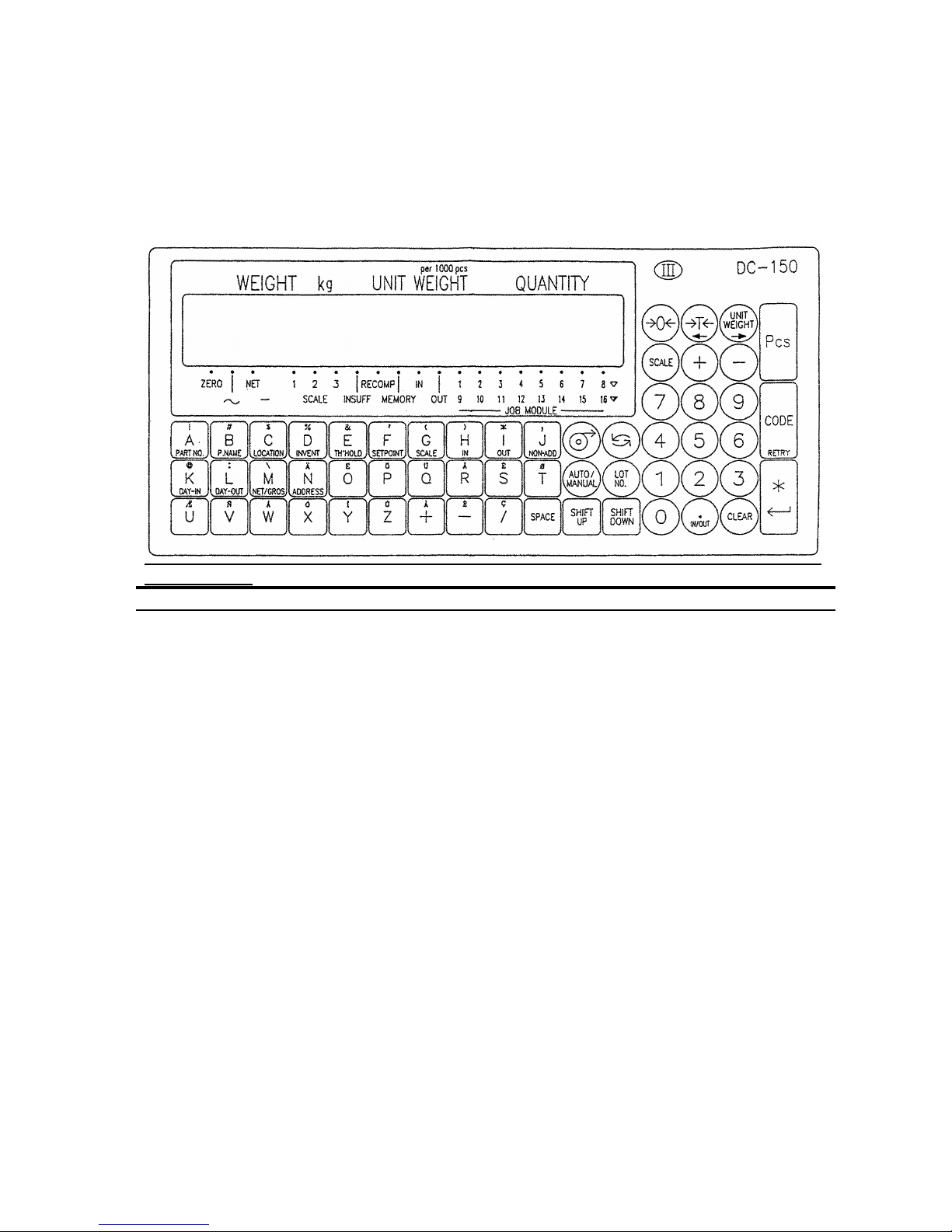

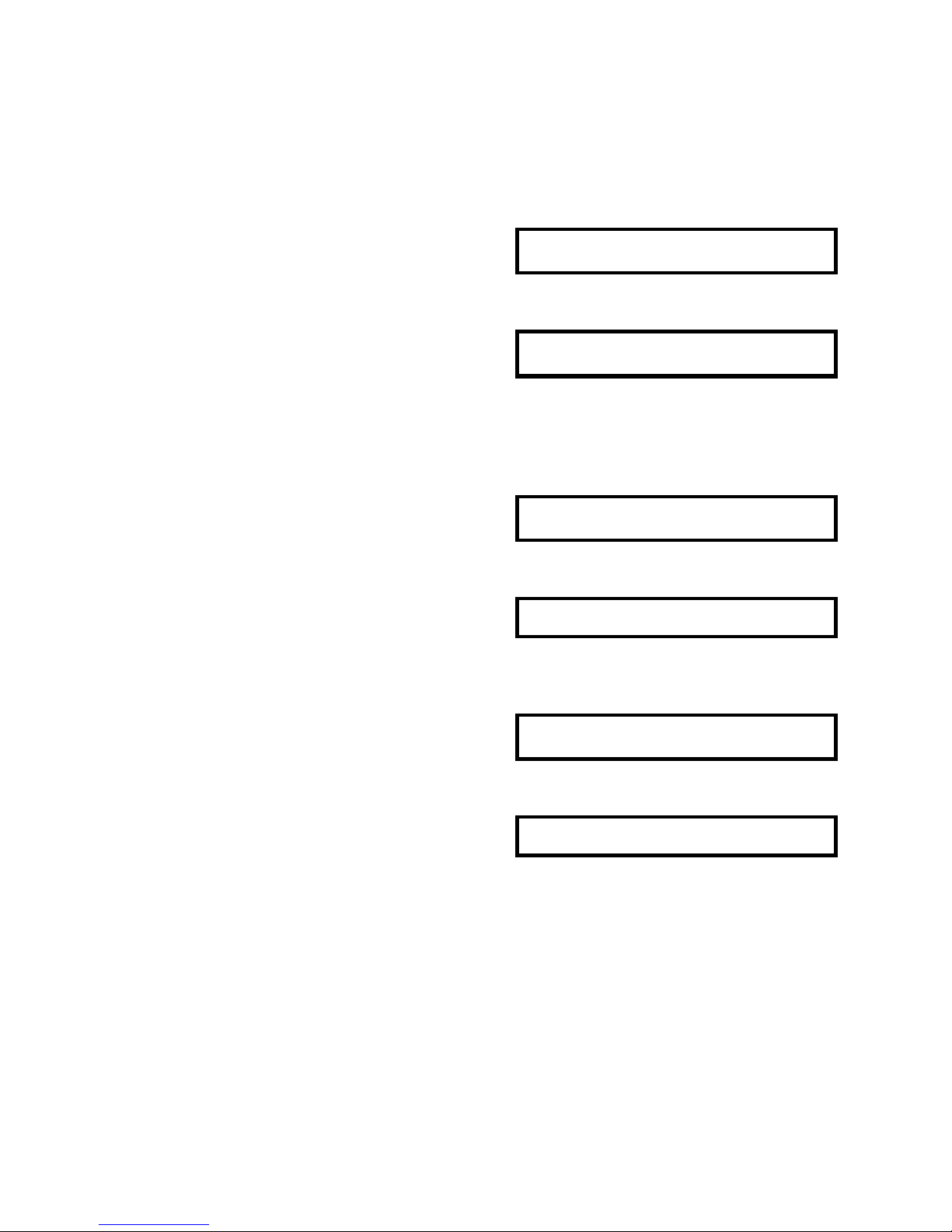

1.2b Display & Keys

INDICATORS

INDICATORS MEANINGS

ZERO Weight is zero

STABLE Weight is stable

NET Presence of a tare weight

kg Scale weighing in kg base. (available in lb. version only)

SCALE 1~3 Scale is in use

INSUFF Sample size is too small to calculate

RECOMP. Unit weight may be recalculated by pressing PIECES key.

MEMORY An accumulated total is in memory

IN Quantities being added to inventory and movement data

OUT Quantities being removed to inventory and movement data

JOB NODULE 1~8 JOB instruction is in the process of Auto job operation

(9~16) (9~16 will flash on and off)

6

Page 8

FUNCTION OF KEYS

0 ~ 9 NUMERIC KEYS

Key numerical values into the system.

•

I N/OUT

DECIMAL POINT

Enter decimal point when entering data

Toggle between receiving, shipping, Non-add operation together with

[SHIT DOWN] key in operation mode.

CLEAR

CLEAR

Clear keyed-in data from display.

Delete the data in memory file.

Æ

FEED

Feed paper.

MODE

MODE

Toggle between modes.

Exit modes without saving data.

AUTO

MANUAL

AUTO / MANUAL

Toggle between Auto Job Operation and Manual Operation in Operation mode.

Back to the precious screen in programming data.

LOT

NO.

LOT NUMBER

Enter the key-in data to LOT No. in OPR mode.

RE ZERO

RE-ZERO

Eliminate weight from the weight dispaly with no tare and causes it to show a true

zero.

TARE

←

TARE

Enter a tare value into the system.

Toggle the data files to program or access

Move the triangle cursor to Right.

7

Page 9

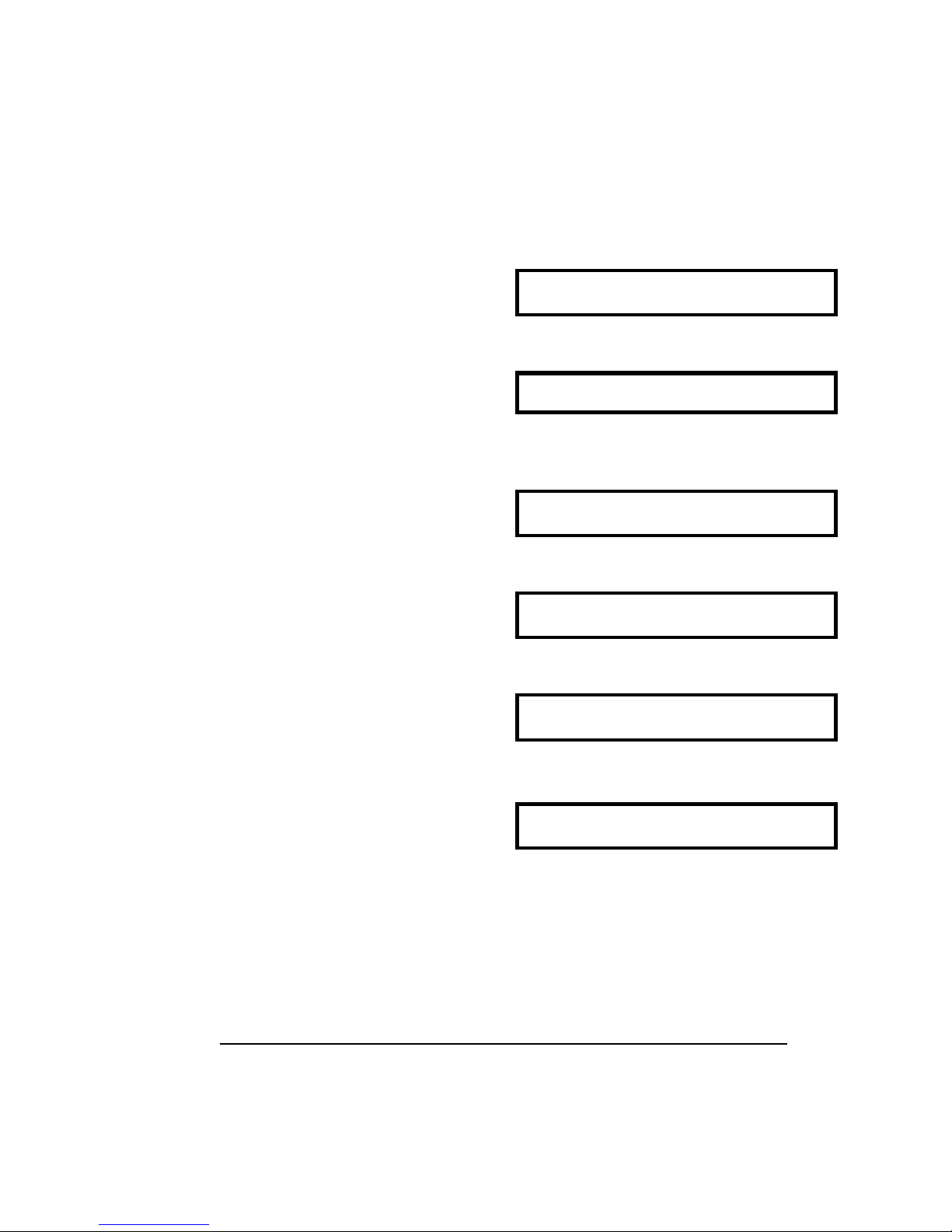

UNIT

WEIG HT

→

UNIT WEIGHT

Enter weight per 1000 count of pieces.

Toggle the data files to program or access.

Move the triangle cursor to Left.

SCALE

SCALE

Toggle between the scales, if the system is with pural scales.

+

PLUS

Weight data addition and print out.

In Maintenance mode, advantage to the next choice, when the triangle cursour is

blinking.

_

MINUS

Weight data subtraction and print out.

In Maintenance mode, moves back to the previous choice, when the triangle

cursour is blinking.

PIECES

PIECES

Sample entry in counting mode to accumulate UNIT WEIGHT.

CODE

RETRY

CODE

Call ITEM data from memory file.

Reprint the same label without saving inventory total in OPR. mode.

Print TEST LABEL (TOTAL LABEL) in programming FREE FORMAT.

ENTER

ENTER

Print total accumulation in OPR. mode.

Enter set up choices and advantages to next choice. Then, at the end of

choices,store the data into memory files.

A ~ Z

+ , − , /

ALPHABET / PLUS / PLUS / MINUS / SLASH

Key alphabetical data into the system.

Assign the data to ITEM FILES together with [SHIFT DOWN] key.

NOTE * [Y] key is used for executing the deletion in the deletion screen.

* [N] key is used for escaping the deletion screen.

* [M] key is used for test printing (gross label) in free format setting.

8

Page 10

SPACE

lb/kg

SPACE

Enter SPACE in alphabetical data entry.

Toggle the display between pound (lb) and kirogram (kg). This function is available

in LB version.

Print TEST LABEL (ITEM LABEL) in programming FREE FORMAT

SHIFT

DOWN

SHIFT DOWN

Change the key functions to the lower line of Alphabet keys.

SHIFT

UP

SHIFT UP

Change the key functions to the special charactors in the upper line of Alphabet

keys.

9

Page 11

1.3 Label format and label set up

1.3a Specification of Labels and Receipt

Outer diameter : 105mm

Inner diameter : 40mm

Width of Receipt Roll : 40mm or 66 mm

Width of label roll : 42mm or 66 mm

1.3b Standard Print Formats

DC-150 has 7 standard label formats and the memory area for 2 free label formats. The

format can be selected in PRINT SPEC in maintenance mode.

Also, 3 types of labels can be printed by the following applications in operation mode.

ITEM LABEL ...... Issued in single operation in OPERATION MODE

TOTAL LABEL ...... Issued in multiple operation in OPERATION MODE

GROSS LABEL ...... Issued in gross weight operation in OPERATION MODE

NOTE) Refer to APPENDIX Ι to see the sample of standard format.

10

Page 12

1.3c How to set paper

1. Remove front panel of printer.

2. Open thermal head by pulling down the lever.

3. Open the side panel in right side of printer block.

4. Slide out label cassette from the main unit.

5. Twist the roll holder s 45 degree to clockwise and pull it out.

6. Take out the empty roll core and place a new stock roll.

7. In case of label, take several labels from the end of the label stock and run it above

the guides o

and through dispenser p and set back paper on take up reel q with

paper clampr.

8. Push roll holder s

to set reeln with the same direction as drawing, until it stops.

9. Set the label and receipt switch on the left side of label cassette.

[LEFT (label) ↔ RIGHT(receipt)]

10.Slide label cassette back into the main unit, along with the metal shaft under the

thermal head block.

11.Close the thermal head by pushing the top of thermal head.

12.Close the side panel and put the front panel of printer back.

13.Depress [FEED] Key to have paper tension.

14. In case of receipt, set receipt roll as the same as label stock

15. Fold the end of the receipt roll and hook the fold on dispenser p

as drawing A.

16. Set the cassette into the main unit and close the thermal head as the same as label.

17. Depress [FEED] key.

DRAWING

11

Page 13

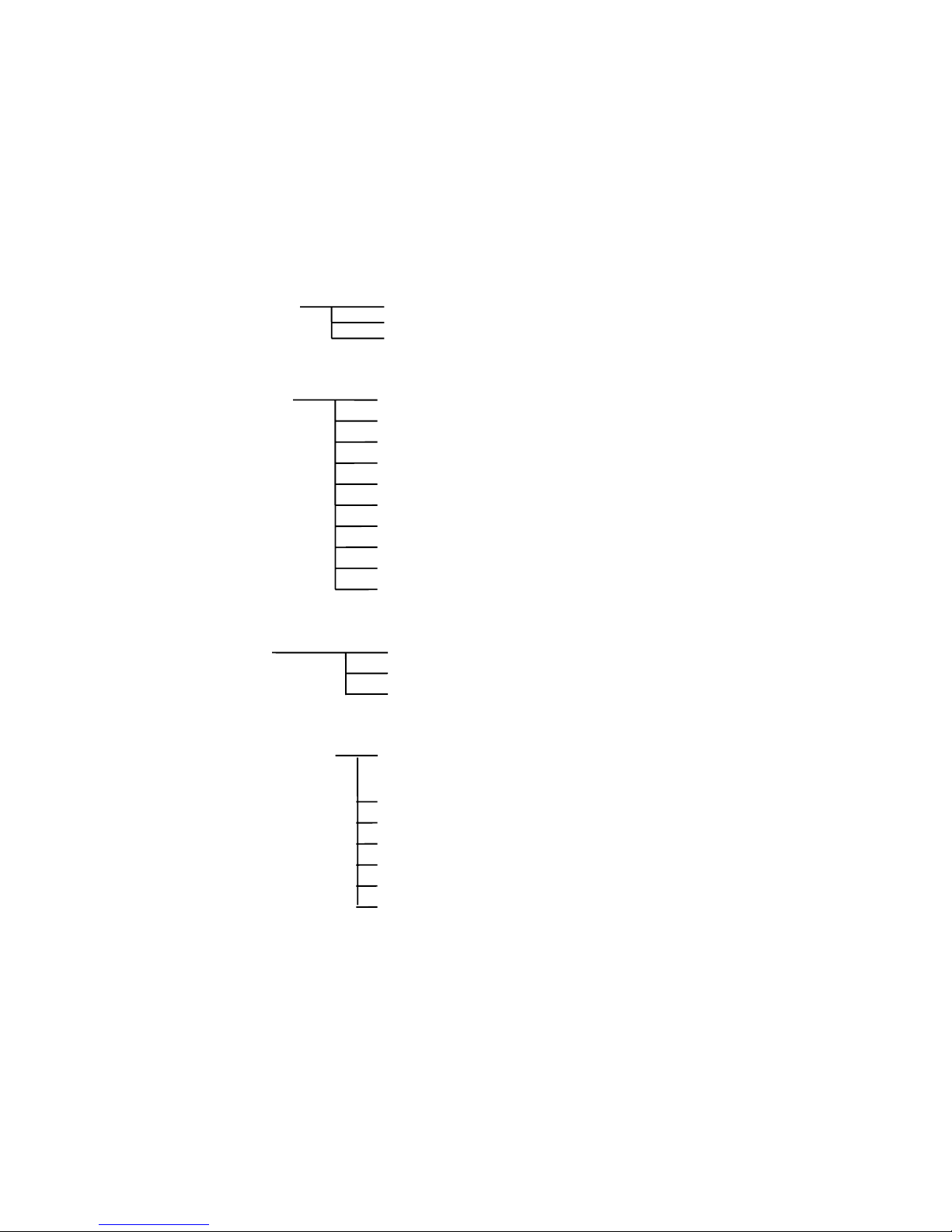

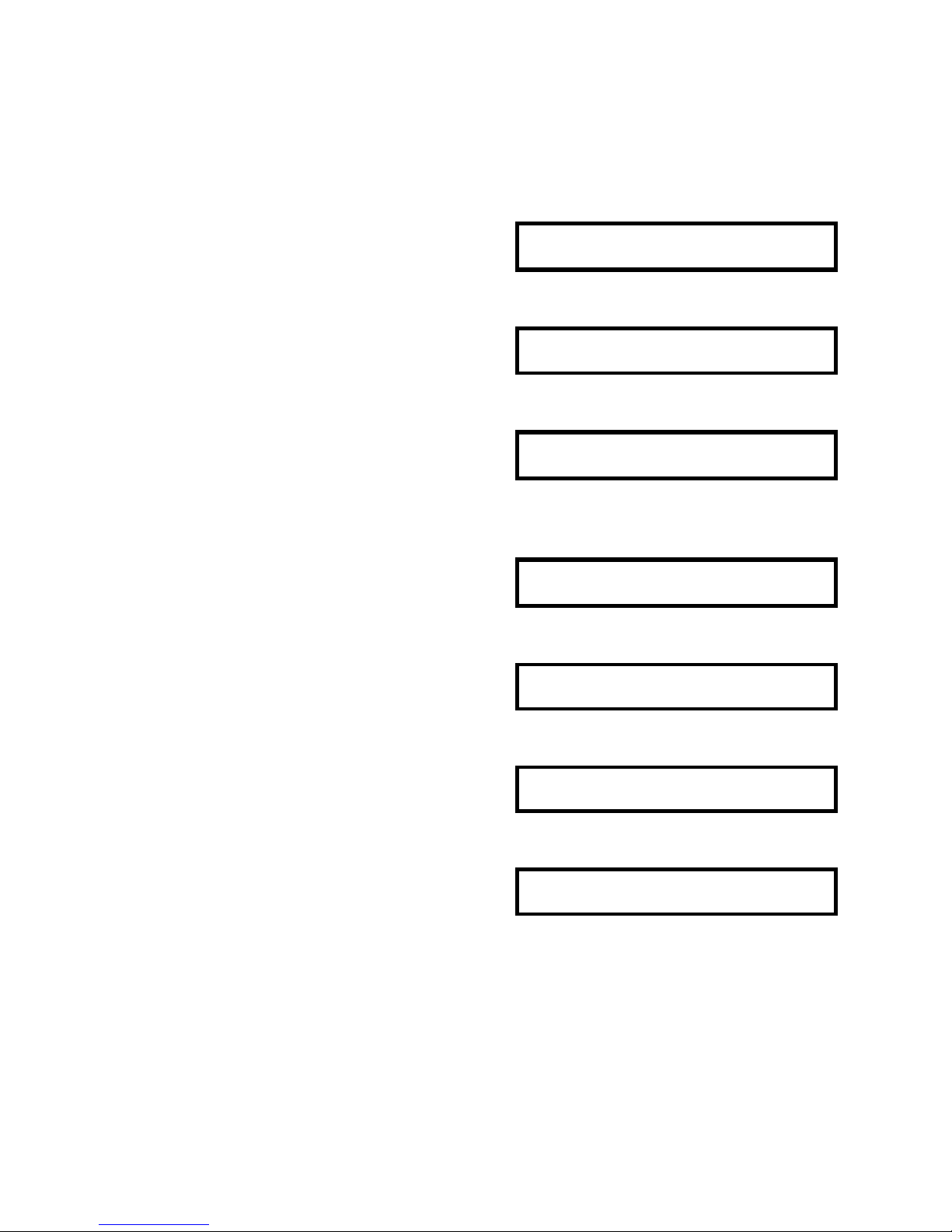

1.4 Operation Flow Chart

OPERATION MODE Receiving Operation (Manual / Auto Job Operation)

Shipping Operation (Manual / Auto Job Operation)

Non-add Operation (Manual / Auto Job Operation)

PROGRAM MODE I.D. Code Setting

Date / Time Setting

Set Point Setting

Title Contents Setting (No.1 ~ No.16)

Preprinting Setting (No.1 ~ No..3)

Format Copy

Free Format Setting (Max. 2 Format)

Shelf Location Format Setting

Shelf Location Limit Setting

Address Setting

CHECK MODE Memory Contents Check

Inventory Data Check

Shelf Location No. Check

MAINTENANCE MODE SPEC Setting (Display/ Report/ Printing/ Outside

Apparatus/ Others)

Deletion of programmed data (Free format/I.D. data)

Print Adjustment

Auto job operation number setting

Saving or loading data with FL-1

Saving or loading data through Modem

Printing SPEC List

12

Page 14

13

2. PROGRAM MODE

Page 15

14

2.1 GENERAL INFORMATION--------------------------------17

2.1a How To Enter Program Mode ----------------------------------------------- 17

2.1b Data Files and Function List-------------------------------------------------

18

2.1c Key Function In Program Mode--------------------------------------------

19

2.2 I.D. CODE SETTING----------------------------------------20

2.2a Item data in I.D. Code -------------------------------------------------------- 20

2.2b The maximum length of data -----------------------------------------------

21

2.2c Programming I. D. Code. -----------------------------------------------------

22

2.2d Delete Programmed ID code and Item Data-----------------------------

28

2.3 DATE/TIME SETTING---------------------------------------30

2.4 SET POINT OUTPUT SETTING-------------------------

31

2.5 TITLE CONTENTS SETTING -----------------------------

33

2.5a Defult data list------------------------------------------------------------------- 33

2.5b Programming Title Contents-------------------------------------------------

34

2.5c Delete Title Contents Data ---------------------------------------------------

35

2.6 PRE-PRINT DATA SETTING------------------------------36

2.6a Programming Pre-print Contents------------------------------------------- 37

2.6b Delete Pre-Print Contents Data---------------------------------------------

38

2.6c Print Position & Character Size of Pre-Print Data ---------------------

39

2.6d Programming Print Position & Character Size of Pre-Print Data---

40

Page 16

15

2.7 COPYING STANDARD FORMAT------------------------42

2.8 FREE FORMAT SETTING ---------------------------------

43

2.8a Label Size------------------------------------------------------------------------ 43

2.8b Programmable Item Data for Each Type of Label----------------------

44

2.8c Data Type ------------------------------------------------------------------------

45

2.8d Printing Position----------------------------------------------------------------

46

2.8e Label Angle And Bar-Code Angle -----------------------------------------

47

2.8f Character Size and Magnifications ----------------------------------------

47

(Height of Bar-code)------------------------------------------------------------------

47

2.8g Programming Screen----------------------------------------------------------

48

2.8h Function Key---------------------------------------------------------------------

49

2.8i Programming Operation -------------------------------------------------------

50

2.8 j Programming Procedure-----------------------------------------------------

56

2.9 SHELF LOCATION LABEL SETTING------------------58

2.9a Label Size------------------------------------------------------------------------ 58

2.9b Programmable Item Data for Shelf Location Label --------------------

58

2.9c Data Type ------------------------------------------------------------------------

58

2.9d Printing Position----------------------------------------------------------------

59

2.9e Label Angle And Bar-Code Angle -----------------------------------------

59

2.9f Character Size and Magnifications ----------------------------------------

59

(Height of Bar-code)------------------------------------------------------------------

59

2.9g Programming Screen----------------------------------------------------------

59

Page 17

16

2.9h Function Key--------------------------------------------------------------------- 59

2.8i Programming Operation -------------------------------------------------------

59

2.9j Program Procedure-------------------------------------------------------------

61

2.10 SHELF LOCATION LIMIT SETTING ------------------63

2.10a Genral Explanation for SHELF LOCATION No.----------------------- 63

2.10b Shelf Location Limit ----------------------------------------------------------

64

2.10c Programming Operation-----------------------------------------------------

64

2.11 ADDRESS CONTENTS SETTING ---------------------65

2.11a Programming Operation----------------------------------------------------- 65

2.6b Delete Pre-Print Contents Data---------------------------------------------

67

Page 18

17

2.1 General Information

2.1a How To Enter Program Mode

When powered on, the scale always gets into Operation Mode.

WEIGHT UNIT WEIGHT QUANTITY

0 . 0 0 0 . 0

∇ ∇ ∇ ∇ ∇

• • • • • • • • • • • • • • • • • • • •

ZERO NET 1 2 3 RECO IN OUT 1 2 3 4 5 6 7 8

(SCALE) JOB MODULE

STABLE KG INSUFF MEMORY

1. Change to PRG mode by depressing

[MODE] key.

PROGRAM MODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7

8

2. Enter PRG mode by depressing [ENTER]

key.

PRG: ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7

8

3. Select each file in Programming Mode by

depressing

[TARE←] or [UNIT WEIGHT→] key.

PRG: FREE FORMAT SET

* Refer to 2.1b Data files and Function List.

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7

8

4. Enter the displayed mode by depressing

[ENTER] key

F.F= FREE FORMAT 1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7

8

Note) Each file is changed in loop routine with [TARE←] or [UNIT WEIGHT→] key.

Page 19

18

2.1b Data Files and Function List

The main data listed below is programmed in Program Mode.

Chapter #

Data File Remarks

2.2 I.D. Code File Programming ID code data in Memory

2.3 Date / Time Setting the internal clock.

2.4 Set Point Output File Programming Set Point value.

2.5 Title Contents File Programming text massage (title) on formats.

2.6 Preprint data File Programming text and position of Pre-print data.

2.7 Copy Format Function Copying a standard format to Free format.

2.8 Free Format File Programming Free format.

2.9 Shelf Location Format File Programming Shelf Location Format.

2.10 Shelf Location Limit File Setting Shelf Location Limit.

2.11 Address Data File Setting Address data.

Page 20

19

2.1c Key Function In Program Mode

[MODE] Key

To return to the initial screen of each modes without saving programmed data.

[AUTO/MANUAL] key

To return to the previous screen in programming.

[ENTER] key

To enter the next screen in each file.

To enter the programmed data into memory file.

[CLEAR] key

To clear mis-set data.

To enter the deletion screen of programmed data.

[TARE (←)] and [UNIT WEIGHT (→)] key

To select the headings in loop routines.

To move the cursor to left/right when there are purl cursors in a display.

[PLUS +] and [MINUS -] key

To select the data, when cursor of triangle indicator is blinking.

CURSORS

The cursors appear when programming data. The cursor shows not only the maximum

number of digits, but also the characteristic of the entering data.

1.) Light cursor ..... The numeric data should be entered with numeric keys.

2.) Blinking cursor .... The data should be selected with [ + ] or [ − ] key

Page 21

20

2.2 I.D. Code Setting

2.2a Item data in I.D. Code

ID code is used as the recognize code in calling part item in OPR mode and in various

reports. ID code allows to store item data in memory though program mode. The

following data can be programmed.

I.D. Code ID code is the recognize code of item data.

Unit Weight Unit weight can be entered by using sample counting or direct key

entry when unit weight is known.

Tare Weight Tare weight can entered by one touch tare entry or direct key entry

when unit weight is known.

Parts No. Parts number is usually used as production number.

Parts Name Parts name can also be changed in operation mode temporary.

Shelf Location No. Shelf location number can be programmed. According to the

range of shelf location number, the available data to enter for each

digit are changed. (Ref. to 2.7 Setting Shelf Location Limit)

Inventory After you set up the initial quality of stock, the data is renewed

along with receiving or shipping value. The accurate quantity of

stock in your warehouse can be handled with this number.

Threshold Threshold is the ideal quantity of stock. By comparing with the

actual quantity of inventory, lack or excess of stock can be

checked.

Set Point Output Set Point Output function alerts the operator to a predetermined

weight or quantity with alarm or external equipment.

(Ref to 2.4 Setting Set Point Output)

Scale According to the value of unit weight, the applicable capacity of

scale can be selected.

Auto Job No. Auto Job Operation number programmed in maintenance mode

can be selected for receiving/ shipping/ checking operation for

each parts item independently.

If Auto Job operation number is not assigned for ID code, Auto

Job Operation number programmed in Address 04/05/06

(OTHERS SPEC) are circulated.

Page 22

21

2.2b The maximum length of data

The maximum length of data will vary with each line of data from one digit to 32 digits.

Item Data Max. Length Available character

I.D. Code 16 digits Alpha-Numeric Data / Period

Unit Weight 5 Digits Numeric data / Decimal Point

Tare Weight 6 Digits Numeric data / Decimal Point

Parts No. 32 Digits Alpha-Numeric Data / Period / Space

Parts Name 32 Digits Alpha-Numeric Data / Period / Space

Shelf Location No. 8 Digits Alpha-Numeric Data

Inventory 8 Digits Numeric data and Minus

Threshold 8 Digits Numeric data

Set Point 7 Digits Numeric Data and decimal Point

Scale No. 1 Digit 0 ~ 3

Auto Job No. (Shipping) 1 Digit 1 ~ 5

Auto Job No. (Receiving) 1 Digit 1 ~ 5

Auto Job No. (Non-add) 1 Digit 1 ~ 5

Page 23

22

2.2c Programming I. D. Code.

1. Select ID code file in Program Mode and

depress [ENTER] key.

ID= ENTER ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Enter I.D. Code.

Ex.) ABC-100#125 *1

ID= ABC-100#125

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [CODE] key to enter the screen to

set each data. *2

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

PART NUMBER ENTRY

4. Enter Parts Number.

Ex.) H2-1357E-01

(13) H2-1375E-01

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depress [SHIFT DOWN] key then [A/ PART

NO.

] key within 3 seconds.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

PART NAME ENTRY

6. Enter Parts Name.

Ex.) Capacitor 1211E1

(16) C A P A C I T E R 1 2 1 1 E 1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [SHIFT DOWN] key then

[B/ PART NAME ] key within 3 seconds.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) When entering a special character above alphabet key, depress [SHIFT UP]

key then alphabet key.

Note: *2) Item data can be entered in this screen. The programming order can be

proceeded at random. It is possible to omit any item data, if these are not

necessary to enter.

Page 24

23

Shelf Location no. entry

8. Enter location number.

Ex.) 01-15-07-1-E

(8) 0115071E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

9. Depress [SHIFT DOWN] key then [C

LOCATION] key within 3 seconds. *1

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Inventory entry

10. Enter Inventory data.

Ex.) 5000 Pcs.

(4) 5000

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

11. Depress [SHIFT DOWN] key then [D/

INVENT ] key within 3 seconds.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Threshold Entry

12. Enter Threshold data.

Ex.) 5100 Pcs.

(4) 5100

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

13. Depress [SHIFT DOWN] key then [E/

TH’HOLD ] key within 3 seconds.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) you cannot assign the data to the location number,the entered value might be

out of shelf location limit. Refer to 2.9 Setting Shelf Location Limit.

Page 25

24

Set Point entry

14. Depress [SHIFT DOWN] key then [F

/SETPOINT] key within 3 seconds. *1

S.P= 0 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

Ex.) Set Point 1=200 Set Point 2=250

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

15. Enter Set Point 1 and depress then [F

/SETPOINT] key.

S.P= 200 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

16. Move the cursor to right by pressing

[UNIT WEIGHT →].

S.P= 200 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7

8

17. Enter Set Point 2 and depress then [F

/SETPOINT] key.

S.P= 200 / 250

∇ ∇ ∇ ∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

18. Press [F /SETPOINT] key.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Scale No. Entry

19. Enter Scale No.

Ex.) Scale 1

(1) 1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

20. Depress [SHIFT DOWN] key then [G/ SCALE

] key within 3 seconds.

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) The setpoint value can be programmed to operate an item being weighed or

counted. Refer to 2.4 Setting Set Point Output.

Page 26

25

Auto Job No. Entry

21. Enter Scale No.

Ex.) Auto Job No. 1 for Receiving

(1) 1

Operation

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

22. Depress [SHIFT DOWN] key then [H/ IN ]

key within 3 seconds. *1

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Tare Entry

ONE TOUCH TARE

23. Place a container on the scale when

stable. Ex.) 0.0120kg

* 0.0120 0. 0

∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

24. Depress [TARE] key. *2

* 0.0000 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

DIGITAL TARE

23’. Enter Tare Weight value by numeric keys.

Ex.) 0.0120kg

(6) 0.0120

∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

24’. Depress [TARE] key. *2

* - 0.0120 0. 0

∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) Auto Job no. can be selected from 5 patterns which are programmed in

Maintenance Mode.

Auto Job no. for shipping and non-add operation can be selected with the same

operation as the receiving except using [I/OUT] or [J/NON-ADD]] key instead of [H]

key

Note: *2) To clear tare value, press [0] then [TARE] key.

Page 27

26

Unit Weight Entry

DIGITAL ENTRY

25. Enter Unit Weight Value with numeric

keys Ex.) 3.756kg/1000pcs.

(5) 3.756

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

26. Press [UNIT WEIGHT] key. *1

* 0.0000 3.7560 0

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

UNIT WEIGHT SAMPLING

25’. Place sample pieces on scale.

Ex.) 0.015kg

* 0.0150 0. 0

∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

26’. Enter sample number with numeric keys.

*2 Ex) 15

(2) 15

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

27’. Press [PIECES] key. *3

---ADD 12

(The number of pieces needed appears in

display.)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

28’. Add the required pieces more and press

[PIECES] key again.

* 0.0270 0.9970 27

∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) The unit weight value should be Unit Weight/1,000.

Note: *2) If using a sample of 10 pcs., press PIECES key without entering a number of

sample.

Note:*3) To have accurate unit weight calculation, the sample weight must be more

than the insufficient range of the scale. (Insufficient range = 0.0% ~ 0.7 % of

scale capacity) If sample weight is less than the range, the number of pieces

required for accurate sampling would be displayed in PROCEDURE 27.

The procedure on 27 and 28 will be skipped if sample weight is sufficient.

Page 28

27

29’) Add more pieces 1 to 3 times as many as

the first sample. *1

* 0.0835 0.9970 84

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

30’) Press [PIECES] key.

* 0.0835 0.9917 84

∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

NOTE: *1) When the unit weight is developed though sampling, the accuracy can be

improved by increasing the sample size using recomputing feature. This

function works only when the “RECOMP” sign lit.

After you set all the item data and ID code, depress [ENTER] key to enter the data

into MEMORY FILE. The display is back to the initial screen of ID code entry.

Page 29

28

2.2d Delete Programmed ID code and Item Data

Delete ID code

1. Select ID code file in Program Mode and

depress [ENTER] key.

ID= ENTER ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Enter I.D. Code which is in memory file.

Ex.) ABC-100#125

ID= ABC-100#125

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [CODE] key. * 1

DEL A B C - 1 0 0 # 1 2 5

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Press [Y] key to delete the data. *2

ID= ENTER ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) If the entering ID code exists on ID memory file, the deletion screen appears

automatically.

Note: *2) To escape from the deletion screen, press [N] key. The screen to set Item

data will appear.

Delete Item data on ID code

1. Select ID code file in Program Mode and

depress [ENTER] key.

ID= ENTER ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Enter I.D. Code which is in memory file.

Ex.) ABC-100#125

ID= ABC-100#125

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 30

29

3. Depress [CODE] key. * 1

DEL A B C - 1 0 0 # 1 2 5

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Press [N] key to enter Item Setting Screen.

* 0.0000 0.9917 0

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Select the item data to delete. (Depress

[SHIFT DOWN] then [B] key.)

P . N A=C A P A C I T O R 1 2 1 1 E 1

Ex.) Parts Name

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Press [CLEAR] key to enter the deletion

screen.

D E L C A P A C I T O R 1 2 1 1 E 1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Press [Y] key to delete.

* 0.0000 0.9917 0

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 31

30

2.3 Date/Time Setting

The built-in clock automatically up-dates date/time once they are set. The present date

and time are printed on labels and reports.

Date (Month / Day / Year ) ----- 2 digits for each part

Time -------------------------------- 4 digits

The date format can be selected in Specification Setting.

1. Enter Program Mode.

PRG: ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select DATE/TIME file with [UNIT WEIGHT

→].

PRG: DATE/ TIME

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Press [ENTER] key.

D/T= 1 8 - 0 6 - 9 6 / 2 0 : 3 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Enter date and time.

Ex.) July 20, 1996 PM 19:56

D/T= 2 0 0 7 9 6 2 1 5 6

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depress [ENTER] key.

PRG: DATE/ TIME

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 32

31

2.4 Set Point Output Setting

2 target values can be programmed for all items being weighed or counted in this file.

Beep sounds let operator know when the counting weight value is equal to ( or over) the

target value, so that operator can check the external or lack of its approach.

The setpoints can be set to each code number in programming I.D. code. (Refer to

2.2C Programming I.D. code) If no data programmed in I.D. code, the general setpoint

in this file is enabled.

The combination of Setpoint 1 and Setpoint 2 can be selected as following in

Maintenance Mode.

COMBINATION SETPOINT 1 SET POINT 2

Q’TY & % Q’TY % of SETPOINT 1

Q’TY & % (To Stop Buzzer,

Recomputing Process Is Required.)

Q’TY % of SETPOINT 1

WEIGHT & % WEIGHT % of SETPOINT 1

LOW WEIGHT & HIGH WEIGHT LOW WEIGHT HIGH WEIGHT

LOW Q’TY & HIGH Q’TY LOW Q’TY HIGH Q’TY

Example) Combination is Quantity & Percentage.

(Setpoint 1= 2,000 Pcs / Setpoint 2 = 80%)

0 80% 2000 Pcs

Intermittent Buzzer Continuous Buzzer

1. Enter Program Mode.

PRG: ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select DATE/TIME file with

[UNIT WEIGHT →] twice.

PRG: SET POINT

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 33

32

3. Press [ENTER] key.

S.P= 0 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Enter Setpoint value 1 and depress [F

SETPOINT] key.

S.P= 2 0 0 0 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

Setpoint 1 = 2,000 Pcs.

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Move the cursor to Setpoint 2 by pressing

[Unit Weight →] key.

S.P= 2 0 0 0 / 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Enter Setpoint value 2 and depress [F

SETPOINT] key.

S.P= 2 0 0 0 / 8 0 . 0

∇ ∇ ∇ ∇ ∇ ∇ ∇

Setpoint 2 = 80%

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [ENTER] key.

PRG: SET POINT

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 34

33

2.5 Title Contents Setting

The title contents is the text data (the fixed data) on label format, such as “Tare”, “QTY”

as the following table. Because the tile contents are the common with all the formats

(standard formats and Free formats), if the defult contents is changed, the text contents

in standard formats are changed, too.

Printing position and character size of title contents can be programmed in Free Format

File. (Ref. to 2.8 Setting Free Format). 16 kinds of title contents can be programmed.

The maximum digits for each contents are 16 digits.

2.5a Defult data list

CONTENTS NO. DEFAULT DATA PRINT STATUS

Item Label

Total Label

Gross Label

T# 1 GROSS X X

{

T# 2 NET X X

{

T# 3 TARE X X

{

T# 4 P.NAME

{ { {

T# 5 P.NO.

{ { {

T# 6 ID CODE

{ { {

T# 7 LOT NO.

{ { {

T# 8 QTY

{ {

X

T# 9 W/1000

{ { {

T# 10 SEQ NO.

{ { {

T# 11 UW/

{ { {

T# 12 QTY

{ {

X

T# 13 TARE

{ { {

T# 14 GROSS

{ { {

T# 15 NET

{ { {

T# 16 TARE

{ { {

Page 35

34

2.5b Programming Title Contents

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select Title Contents with [ Unit Weight →]

key three times.

PRG : T I T L E C O N T E N T S

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key.

TITLE CONTENTS = N O . 1

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

4. Select Title Contents No. with [+] and [-]

key. Ex.) Title Contents No. = 3

TITLE CONTENTS = N O . 3

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depres [ENTER] key.

(The defult data appears.)

T3 = TARE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Enter the data.

Ex.) Title 3 = Unit Weight

T3 = UNIT WEIGHT

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [ENTER] key to store the data into

memory.

TITLE CONTENTS = N O . 3

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 36

35

2.5c Delete Title Contents Data

1. Select Title Contents with [ Unit Weight →]

key three times.

PRG : T I T L E C O N T E N T S

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Depress [ENTER] key.

TITLE CONTENTS = N O . 1

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

3. Select Title Contents No. to delete.

Ex.) Title Contents No. = 3

TITLE CONTENTS = N O . 3

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Depres [ENTER] key.

(The defult data appears.)

T3 = TARE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Enter the deletion screen by pressing

[CLEAR] key.

DEL TARE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Depress [Y] to delete data. * 1

T16=

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) To escape from the deletion screen, press [N] key.

Page 37

36

2.6 Pre-print Data Setting

The item data cannot be print on the bottom 10mm of the label for peeling the label off

smoothly.

In the area, the fixed (pre-printing) data, such as vendor name or company motto, can

be printed. The contents and the print position of preprint data should be programmed

for printing. Up to 3 contents can be printed in this area. One contents can be

programmed 32 digits at maximum.

Back paper

PREPRINTING AREA

10mm

Page 38

37

2.6a Programming Pre-print Contents

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select Title Contents with [ Unit Weight →]

key four times.

PRG :P R E . P R I N T E D C O N T

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key.

PRE= P R I N T C O N T E N T S

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Depress [ENTER] key to program the Pre-

print Contents.

CONTENTS = N O . 1

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

5. Select Contents No. with [+] and [-] key.

Ex.) Contents No. = 2

CONTENTS = N O . 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Depres [ENTER] key.

C2=

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Enter the data.

Ex.) Contents = Teraoka Seiko

(13) T E R A O K A S E I K O

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

8. Depress [ENTER] key to store the data into

memory.

CONTENTS = N O . 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 39

38

2.6b Delete Pre-Print Contents Data

1. Select Pre-Print Contents with [ Unit Weight

→] key Four times.

PRG : P R E . P R I N T E D C O N T

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Depress [ENTER] key.

PRE= P R I N T C O N T E N T S

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key delete the Pre-print

Contents.

CONTENTS = N O . 1

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

4. Select Contents No. with [+] and [-] key.

Ex.) Contents No. = 2

CONTENTS = N O . 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depres [ENTER] key.

C2= T E R A O K A S E I K O

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Depres [CLEAR] key to enter the deletion

screen.

DEL T E R A O K A S E I K O

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [Y] to delete data. * 1

C2=

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note: *1) To escape from the deletion screen, press [N] key.

Page 40

39

2.6c Print Position & Character Size of Pre-Print Data

PRINT POSITION

Printing position of preprinting data is decided with X and Y value. The X and Y value is

the interval from the fundamental point (X=0, Y=0) to where to print data. The both

values are graduated by unit “DOT”. (one dot is X=0.135mm, Y=0.135mm)

Y

ITEM DATA AREA

x PREPRINT DATA

y

X

(0,0)

⇓

Label Printing Direction

CHARACTER SIZE

Please refer to size of character and the magnification on APPENDEX II to select

Character Size.

DISPLAY OF PROGRAMMING SCREEN

C1 = X. 0. / Y. 0. / S. 0 / M. 0

* Printing position (X value, horizontal)

Numeric key entry

* Printing position (Y value, vertical)

Numeric key entry

* Character size

Selection from S.0 ~ S.5 with [+],[-] keys

* Magnification of character Size

Selection from M.0 ~ M.2 with [+],[-] keys

Note) In order not to print the data, set the printing position with 0 vale for X and Y.

Page 41

40

2.6d Programming Print Position & Character Size of

Pre-Print Data

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select Title Contents with [ Unit Weight →]

key four times.

PRG : P R E . P R I N T E D C O N T

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key.

PRE= P R I N T C O N T E N T S

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Select Print Coordinate with [ Unit Weight

→] key.

PRE= P R I N T C O O R D I N A T E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depress [ENTER] key to program the print

position & character size of Pre-print

C O O R D I N A T E = N O . 1

♦♦♦♦♦

Contents.

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

6. Select Contents No. with [+] and [-] key.

Ex.) Contents No. = 2

C O O R D I N A T E = N O . 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depres [ENTER] key.

C2= X. 0 / Y. 0 / S.0 / M.0

∇∇∇∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

∇= Lits Cursor

Page 42

41

8. Enter X value and depress[UNIT WEIGHT

→] key to move cursor to reight.

C2= X. 2 / Y. 0 / S.0 / M.0

∇∇∇∇

Ex.) X=2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

∇= Lits Cursor

9. Enter Y value and depress[UNIT WEIGHT

→] key to move cursor to reight.

C2= X. 2 / Y. 10 / S.0 / M.0

♦♦

Ex.) Y=10

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

10. Select character size by depressing [+] or

[-] key and depress [UNIT WEIGHT] key

C2= X. 2 / Y. 10 / S.2 / M.0

♦♦

to move cursor to right.

Ex.) Character Size = S2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

11. Select character size by depressing [+] or

[-] key.

C2= X. 2 / Y. 10 / S.2 / M.1

♦♦

Ex.) Magnification = M1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

12. Depress [ENTER] key to store data.

C O O R D I N A T E = N O . 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Example)

Contents #1 = TERAOKA SEIKO (X=120 / Y=33 / S.2 / M.1)

Contents #2 = TEL(81)-3-3753-2131 (X=100 / Y=16 / S.0 / M.1)

Contents #3 = OFFICE HOURS 9:00 - 17:50 (X=80 / Y= 1 / S.0 / M.1)

Page 43

42

2.7 Copying Standard Format

If what label format you need to make is a similar to a standard format, you can make a

new format easily by copying the standard format then arranging print data.

When you select the standard format to be copied to, refer to the list of standard format

in APPENDEX I.

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select Title Contents with [ Unit Weight →]

key five times.

PRG : C O P Y F O R M A T

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key.

CPY= ST NO. 1 → FR NO. 1

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Select a standard format to be copied from

by pressing [ + ] or [ - ] key.

CPY= ST NO. 5 → FR NO. 1

♦♦♦♦♦

Ex.) Format No. = 5

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Move cursor to right by pressing [ Unit

Weight →] key.

CPY= ST NO. 5 → FR NO. 1

♦♦♦♦♦

Ex.) Free Format No. = 2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

6.Select Free Format No. to be copied to by

pressing [ + ] or [ - ] key.

CPY= ST NO. 5 → FR NO. 2

♦♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Dpress [ENTER] key to copy the format.

PRG : C O P Y F O R M A T

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 44

43

2.8 Free Format Setting

DC-150 has 7 types of standard format, so that the suit label format for the system can

be used. Moreover, in the case that any types of standard format is not suit for what

required, “FREE FORMAT” can create your own label (item label, total label, and gross

label) by setting up printing angle, direction and size of the print items.

Accroding to the usage of the machine, DC-150 can print 3 types of labels: ITEM

LABEL, TOTAL LABEL and GROSS LABEL. The data base of one label format has all

3 type of labels. When you make a new label format, the format data for Item, Total,

and Gross labels are saved as one data base.

In Free Format Set Up

• 2 Free Format can be programmed.

• One item label, total label and gross label are avaialble to be set for each Free

Format number.

• Label size should be pre-set in Maintenance Mode.

2.8a Label Size

You can select label size from 11 size in Address 34 (PRINT SPEC)

64 x 40, 64 x 55, 64 x 77.5, 64 x 92, 64 x 120, 40 x 23, 40 x 28, 40 x 46, 40 x 62.5, 40 x

77.5, 40 x 92

Page 45

44

2.8b Programmable Item Data for Each Type of Label

This chart shows which data fields are printed on the three (3) standard types of labels.

ITEM DATA ITEM LABEL

TOTAL LABEL GROSS

LABEL

DATA TYPE

ID CODE

| | |

TYPE 1

PART NO.

| | |

TYPE 2

PARTS NAME

| | |

TYPE 2

LOT NO.

| | |

TYPE 2

WEIGHT

|

X X TYPE 1

WEIGHT UNIT (g/ LB)

|

X X TYPE 1

“/” MARK FOR WEIGHT

|

X X TYPE 1

UNIT WEIGHT

|

X X TYPE 1

UNIT WEIGHT UNIT (g/ lb)

|

X X TYPE 1

“-” MARK FOR QTY

|

X X TYPE 1

QUANTITY

| |

X TYPE 1

QUANTITY UNIT (symbol)

| |

X TYPE 1

DATE

| | |

TYPE 1

TIME

| | |

TYPE 1

TASK CONTENTS

| |

X TYPE 1

SUM TOTALING

X

|

X TYPE 1

SUM COUNT

X

|

X TYPE 1

GROSS WEIGHT

|

X X TYPE 1

GROSS UNIT (g/lb)

|

X X TYPE 1

NET WEIGHT

|

X X TYPE 1

NET UNIT (g/lb)

|

X X TYPE 1

TARE WEIGHT

|

X X TYPE 1

TARE UNIT (g/lb)

|

X X TYPE 1

SEQUENCE NO. DATA

| |

X TYPE 1

BAR-CODE (ID)

| | |

TYPE 3

BAR-CODE (PART NO)

| | |

TYPE 3

BAR-CODE (LOT NO.)

| | |

TYPE 3

BAR-CODE (QTY)

| |

X TYPE 3

BAR-CODE (TARE)

|

X

|

TYPE 3

BAR-CODE (UNIT WEIGHT)

|

X X TYPE 3

BAR-CODE (GROSS WEIGHT)

|

X

|

TYPE 3

BAR-CODE (NET WEIGHT)

|

X

|

TYPE 3

TITLE CONTENTS #1 ~ 3

X X

|

TYPE 1

TITLE CONTENTS #4 ~ 7

| | |

TYPE 1

TITLE CONTENTS #8

| |

X TYPE 1

- Continue -

Page 46

45

- Continued -

ITEM DATA ITEM LABEL

TOTAL LABEL GROSS

LABEL

DATA BASE

TITLE CONTENTS #9 ~11

| | |

TYPE 1

TITLE CONTENTS #12

| |

X TYPE 1

TITLE CONTENTS #13 ~16

| | |

TYPE 1

GROSS WEIGHT (GROSS)

X X

|

TYPE 1

GROSS UNIT (GROSS)

X X

|

TYPE 1

UNIT WEIGHT (GROSS)

X X

|

TYPE 1

NET WEIGHT (GROSS)

X X

|

TYPE 1

NET UNIT (GROSS)

X X

|

TYPE 1

TARE WEIGHT (GROSS)

X X

|

TYPE 1

TARE UNIT (GROSS)

X X

|

TYPE 1

ADDRESS CONTENTS #1~ 5

| | |

TYPE 1

NOTE: 1) In minus transaction, item label issued along with using [-] keys. Minus mark

is printed on label.

NOTE: 2) TASK CONTENTS is “IN”, “OUT”, “NON-ADD”.

2.8c Data Type

Every filed can have different characteristics, therefore, data can vary from label format

to label format. Three types of data can vary into accordance with the programming

parameters. By the divided types, the programming procedures are explained in 2.8

Programming Free Format.

TO SET FOR ITEM DATA

TYPE 1 TYPE 2 TYPE 3

X position

| | |

Y position

| | |

Character size

| |

X

Magnification of character

| |

X

Line number

X

|

X

Max. digits in the selected line

X

|

X

Height of bar-code

X X

|

Print angle of bar-code

X X

|

| = Required X = Not Required

Note:1) Bar-code is selectable in SPEC for print.

Page 47

46

2.8d Printing Position

Printing position of item data is decided with X and Y value. The X and Y value is the

interval from the fundamental point (X=0, Y=0) to print preprinting data. The both

values are graduated by one dot unit. (one dot is 0.135mm x 0.135mm)

Y

x ITEM DATA

(0,0)

y

X

PRE PRINTING AREA

10mm

⇓ label printing

direction

NOTE: 1) The item data can not be printed on the bottom 10mm of label.

NOTE: 2) The printing position of item data, which you need not to print, is to be set at

the start point where X=0 and Y=0.

Page 48

47

2.8e Label Angle And Bar-Code Angle

All item data except bar-codes can be printed in 4 different angles by changing label

angle. The printing position of item data differ among the different angles as the

following. The print angle of bar-code data can be programmed independently in each

data base.

y y

x ITEM DATA

x

(0,0) y

(0,0)

y

TERAOKA SEIKO (PRE-PRINT) TERAOKA SEIKO (PRE-PRINT)

0 degree 90 degree

y y

x

x

y

y

(0,0)

(0,0)

TERAOKA SEIKO (PRE-PRINT) TERAOKA SEIKO (PRE-PRINT)

180 degree 270 degree

(0,0)

2.8f Character Size and Magnifications

(Height of Bar-code)

• Refer to the list of character size in APPENDEX II to select the combination of

character size and magnifications for preprinting data.

• Height of bar-code can be selected from 10mm, 15mm, 20mm, 25mm, 30mm.

Page 49

48

2.8g Programming Screen

Programming screen for data type 1

C1 = X. 0. / Y. 0. / S. 0 / M. 0

* Printing position (X value, horizontal)

Numeric key entry

* Printing position (Y value, vertical)

Numeric key entry

* Character size

Selection from S.0 ~ S.5 with [+],[-] keys

* Magnification of character Size

Selection from M.0 ~ M.2 with [+],[-] keys

Note) In order not to print the data, set the printing position with 0 vale for X and Y.

Programming screen for data type 2

L.4 / D.08 / X. 467 / M. 0

* Line Number

Selection from L.1 ~ L.4 with [+] or [-]

key

* The number of digits in the line

Numeric key entry (0~8)

* Horizontal / Vertical Selection

Selection with [+] or [-] key. (X or Y)

* Printing position (X value or Y value)

Numeric key entry

* Character size / Magnification Selection

Selection with [+],[-] keys. (S or M)

* Character Size or Magnification Size

Selection with [+],[-] keys.

(S.=S.0~S.5/M.= M.0~M.2)

Page 50

49

Programming screen for data type 3

C1 = X. 0. / Y. 0. / H. 4 / A. 3

* Printing position (X value, horizontal)

Numeric key entry

* Printing position (Y value, vertical)

Numeric key entry

* Height of bar-code

Selection (H.0~H.4) with [+],[-] keys

* Printing angle of bar-code

Selection (A.0 ~ A.3)with [+],[-] keys

Note: 1) Selection of height of bar-code

H.0 = 10mm, H.1 = 15mm, H.2 = 20mm, H.3 = 25mm, H.4 = 30mm)

Note: 2) Selection of printing angle of bar-code

A.0 = 0 degree, A.1 = 90 degree, A-2 =180 degree, A.3 = 270 degree

2.8h Function Key

[UNIT WEIGHT←] key and [TARE→] key

To select item data in loop routine

To move the cursor in a display

[PLUS + ] and [MINUS - ] key

To select data when cursor of triangle indicator is blinking

[AUTO /MANUAL] key

To move back to the previous screen.

Page 51

50

2.8i Programming Operation

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select Free Formats with [ Unit Weight →]

key six times.

PRG : FREE FORMAT SET

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Depress [ENTER] key.

F. F = FREE FORMAT 1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Select FREE FORMAT # by depressing

[UNIT WEIGHT←] or [TARE→] key.

F.F = FREE FORMAT 2

Ex.) Format = no.2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Depres [ENTER] key.

FM2 = PRINT ANGLE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Depress [ENTER] key.

FM2 = ANGLE (°) 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Select label angle by depressing

[ + ] or [ - ] key..

FM2 = ANGLE (°) 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 52

51

8. Depress [ENTER] key.

(Ready for setting the print positions for

M2 = ID CODE

Item data)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

9. Select item data by depressing

[UNIT WEIGHT←] or [TARE→] key.

M2 = PART NAME

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Set Print Items in the procedure in 2.8I Item setting.

10. Store the data to F2 by pressing [ENTER]

key.

F.F = FREE FORMAT 2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note:) While programming print data, the programmed data may be printed in test label.

With uins this function, you can check if the print position is proper and adjust the

data accordingly.

In the selection screen for item data such as the screen in procedure 9, press the

following keys for test printing.

♦ [ SP kg/lb ] key ...... Test Printing of Item Label

♦ [ PEICES ] key ...... Test Printing of Item Label (on Minus transaction)

♦ [ CODE ] key ...... Test Printing of Total Label

♦ [M NET/GROSS] key ...... Test Printing of Gross Label

Page 53

52

Start for A. ITEM DATA SETTING ( DATA TYPE 1)

1. Select Print Item.

Ex.) ID code

FM2 = ID CODE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Press [ENTER] key.

ID= X. 0 /Y. 0. / S.0 / M.0

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Enter X value and press [U.W.→] key to

move the cursor to right.

ID= X. 52 /Y. 0. / S.0 / M.0

∇ ∇ ∇

Ex.) X value= 52

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Enter Y value and press [U.W.→] key to

move the cursor to right.

ID= X. 52 /Y. 15. / S.0 / M.0

♦♦

Ex.) Y value= 15

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

5. Select character size by depressing [+] or [-]

key and depress [U.W.→] key to move the

ID= X. 52 /Y. 15. / S.2 / M.0

♦♦

cursor to right. Ex.) S=2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

6. Select Magnification by depressing [+] or [-]

key.

ID= X. 52 /Y. 15. / S.2 / M.0

♦♦

Ex.) M=0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [ENTER] key to enter the data into

the memory file.

FM2 = PART NO

(Ready for setting the next item data)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 54

53

Repaet for B. ITEM DATA SETTING ( DATA TYPE 2)

1. Select Print Item.

Ex.) Part No.

FM2 = PART NO

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Press [ENTER] key.

P.N.O.= L.1 / D. 0 / X. 0/ S.0

♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Select Line no. by pressing [+] or [-] key

and press [U.W.→] key.

P.N.O.= L.1 / D. 0 / X. 0/ S.0

∇ ∇ ∇

Ex.) Line No.=1

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Enter the number of digits for the selected

line and press [U.W.→] key twice.

P.N.O.= L.1 / D. 8 / X. 0/ S.0

∇ ∇ ∇

Ex.) The number of Digits = 8

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Enter X value and press [TARE ←] key to

move the cursor to left.

P.N.O.= L.1 / D. 8 / X. 64/ S.0

♦

Ex.) X value= 64

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Press [+] or [-] key for Y value entry and

press [U.W.→] key to move the cursor to

P.N.O.= L.1 / D. 8 / Y. 123/ S.0

∇ ∇ ∇

left. Ex.) Y value = 123

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Enter Y value and press [U.W.→] key twice

to move the cursor to right.

P.N.O.= L.1 / D. 8 / Y. 123/ S.0

♦

Ex.) Y value= 15

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

8. Select character size by depressing [+] or [-]

key and depress [TARE ←] key to move the

P.N.O.= L.1 / D. 8 / Y. 123/ S.2

♦

cursor to left. Ex.) S=2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

- Continue -

Page 55

54

- Continue- Item data setting (data type 2)

9. Press [+] or [-] key for M value entry and

press [U.W.→] key to move the cursor.

P.N.O.= L.1 / D. 8 / Y. 123/ M.0

♦

Ex.) M=0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

10. Select Magnification value.

Ex.) M.=2

P.N.O.= L.1 / D. 8 / Y. 123/ M.2

♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

If you need to set the data for line 2 ~ 4, press [TARE ←] key to move cursor to line

no. selection and set the data as the same program procedure.

11. Depress [ENTER] key to enter the data

into the memory file.

FM2 = PART NAME

(Ready for setting the next item data)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 56

55

Repaet for C. ITEM DATA SETTING ( DATA TYPE 3)

1. Select Item Data.

Ex.) Bar-code (ID)

FM2 = BAR CODE (ID)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Press [ENTER] key.

ID= X. 0 /Y. 0. / H.0 / A.0

∇ ∇ ∇

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Enter X value and press [U.W.→] key to

move the cursor to right.

ID= X. 85 /Y. 0. / H.0 / A.0

∇ ∇ ∇

Ex.) X value= 85

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Enter Y value and press [U.W.→] key to

move the cursor to right.

ID= X. 85 /Y. 236. / H.0 / A.0

♦♦

Ex.) Y value= 236

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

5. Select height of bar-code by depressing [+]

or [-] key and depress [U.W.→] key to move

ID= X. 85 /Y. 236. / H.2 / A.0

♦♦

the cursor to right. Ex.) Height= 2

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

6. Select angle of barcode by depressing [+] or

[-] key.

ID= X. 85 /Y. 236. / H.2 / A.0

♦♦

Ex.) Angle of bar-code = 0 degree (0)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Depress [ENTER] key to enter the data into

the memory file.

FM2 = BAR CODE (PART NO)

(Ready for setting the next item data)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 57

56

2.8 j Programming Procedure

A. List up the print data.

B. Set up the label size in maintenance mode.

C. Copy the standard format in “copy of format” in program mode.

D. Change the format in “Free Format Program” in program mode.

A. LABEL FORMAT

⇒

Standard format #2 Free format #1

Page 58

57

B. THE LIST OF LABEL FORMAT TO CHANGE

DATA ACTION Digits no. X

position

Y position Ssize Msiz

e

ID CODE DELETE

0 ⇒ 0 162 ⇒ 0

S1 M2

P. NO.

(L1)

DELETE 32

0 ⇒ 0 210 ⇒ 0

S1 M1

LOT NO. (L1) DELETE 32

0 ⇒ 0 134 ⇒ 0

S1 M1

PART NAME(L1)

(L2)

CHANGE

ADD

32 ⇒ 16

0 ⇒ 16

0 ⇒ 0

0 ⇒ 0

238 ⇒ 275

0 ⇒ 230

S1

S1

M1

M1

BARCODE(ID) ADD

0 ⇒

100

0 ⇒ 150

H0 A0

TEXT 6 ADD

0 ⇒ 0 0 ⇒ 150

S1 M1

C. SET UP THE LABEL SIZE

Set “64mm x55mm” on address 34 (size of label format) in PRINT SPEC in

MAINTENANCE MODE. Refer to 3.3 METHOD OF PROGRAM.

D. COPY THE STANDARD FORMAT

Copy the standard format #2 to free format #1. Refer to 2.7 COPY OF STANDARD

FORMAT.

E. CHANGE THE FORMAT

Change the print data of label format data. Refer to 2.8 FREE FORMAT SETING.

E-1 Select free format ............... No.1.

E-2 Set angle of label format ...... 0 degree

E-3 Change the print position for ID code at (X=0, Y=0) to delete.

E-4 Change the print position for part no. at ( X=0, Y=0) to delete.

E-5 Change the print position for lot no at ( X=0,Y=0) to delete.

E-6 Change the data for part name. (L1/ D=16, X=0, Y=275, S1, M1)

(L2/ D=16, X=0, Y=230, S1, M1)

E-7 Change the data for barcode of ID code. ( X=100, Y=150, H=0, A=0)

E-8 Change the data for text 6. (X=0, Y=150, S1, M1)

NOTE) After changing each print data, we recommend, you would check with the

test print if the print position and character size are fit for the layout. If they

are not, adjust the print position in programming step.

Page 59

58

2.9 Shelf Location Label Setting

To konw the location of stock, each item code can be assigned shelf location number.

DC-150 can print the shelf location label for each item code in CHECK MODE to put on

the shelves where the stock is stored.

DC-150 has no standard format, use one free format for this shelf location label. The

label format is to be developed with the same programming steps as free format.

2.9a Label Size

You can select label size from 11 size in Address 34, which is in common with label size

of free format. (Ref. to 2.8.a Label Size in Free Format Setting)

2.9b Programmable Item Data for Shelf Location Label

This chart shows the data type in setting each Item data.

PRINTING FACTORS DATA BASE

ID CODE TYPE 1

PARTS NO. TYPE 2

PARTS NAME TYPE 2

UNIT WEIGHT TYPE 1

LOCATION NO. TYPE 1

THRESHOLD TYPE 1

DATE TYPE 1

TIME TYPE 1

BAR-CODE (ID) TYPE 3

BAR-CODE (PARTS NO.) TYPE 3

TITLE CONTENTS NO.1 ~ 16 TYPE 1

2.9c Data Type

The data type of item data on shelf location label is the same as free format.

(Refer to 2.8.c Data Type in Free Format Setting)

Page 60

59

2.9d Printing Position

The printing position of item data on shelf location label is the same as on free format.

(Ref. to 2.8d Printing Postion in Free Format Setting.)

2.9e Label Angle And Bar-Code Angle

Shelf location label and bar-code can be printed in 4 different angles in the same as free

format. (Ref. to 2.8e Label Angle and Bar-code Angle in Free Format Setting.)

2.9f Character Size and Magnifications

(Height of Bar-code)

Character size and magnification value in shelf location label is the same as in free

format. (Refer to 2.8f Character size and magnifications in Free Format Setting)

2.9g Programming Screen

The programming screens for item data are the same as free format.

(Refer to 2.8g Programming screen in Free Format Program)

2.9h Function Key

The function keys in programming Shelf Location Label are the same as free format.

(Refer to 2.8 Function Key in Free Format Program)

2.8i Programming Operation

1. Enter Program Mode.

PRG : I D C O D E

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Select S.Location Label with [ Unit Weight

→] key seven times.

PRG : S. LOCATION LABEL

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 61

60

3. Depress [ENTER] key.

S.L = PRINT ANGLE

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Depress [ENTER] key.

S.L = ANGLE (°) 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

5. Select label angle by depressing

[ + ] or [ - ] key.

S.L = ANGLE (°) 0

Ex.) Angle = 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Depress [ENTER] key.

(Ready for setting the print positions for item

S.L = ID CODE

data)

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

7. Select item data by depressing

[UNIT WEIGHT←] or [TARE→] key.

S.L = PART NAME

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Set Print Items in the procedure in 2.8I Item setting in Free Format Setting.

8. Store the data by pressing [ENTER] key.

PRG : S. LOCATION LABEL

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Note:) While programming print data, the programmed data may be printed in test label.

With uins this function, you can check if the print position is proper and adjust the

data accordingly.

♦ [ SP kg/lb ] key ...... Test Printing of Shelf Location Label

Page 62

61

2.9j Program Procedure

A. List up what print data would be required for shelf location label. Then, decide the

layout of the label roughly.

B. Set up the label size in maintenance mode.

C. Set the format in “Free Format Program” in program mode.

A. SAMPLE LABEL FORMAT

B. THE LIST OF LABEL FORMAT TO THE SAMPLE LABEL

DATA Digits no. X position Y position Ssize Msize

ID CODE 200 545 S2 M2

P. NO. (L1) 32 50 650 S1 M1

P NAME (L1) 32 100 650 S1 M1

LOCATION NO. 380 686 S1 M2

BARCODE(ID) 280 750 H0 A3

TEXT 4 100 750 S1 M2

TEXT 5 50 750 S1 M1

TEXT 6 200 50 S1 M2

Print angle = 270

Page 63

62

C. SET UP LABEL SIZE

Set “64mm x120mm” on address 34 (size of label format) in PRINT SPEC in

MAINTENANCE MODE. Refer to 3.3 METHOD OF PROGRAM.

D. SET ITEM DATA

Change the print data of label format data. Refer to 2.8 Free Format Setting.

E-1 Set angle of label format 270 degree

E-2 Set the data for ID code. (X=200, Y=200, S2, M2)

E-3 Set the data for part code. (L1/ D=32, X=50, Y=650, S1, M1)

E-4 Set the data for part name. (L1/ D=32,X=100, Y=650, S1,M1)

E-5 Set the data for location no. (X=380, Y=686, S1, M2)

E-6 Set the data for barocode of ID code ( X=280, Y=750, H0, A3)

E-7 Set the data for text 4. ( X=100, Y=750, S1, M2)

E-8 Set the data for text 5. (X=50, Y=750, S1, M1)

E-9 Set the data for text 6. (X=200, Y=50, S1, M1)

NOTE) After changing each print data, we recommend, you would check with the

test print if the print position and character size are fit for the layout. If they

are not, adjust the print position in programming step.

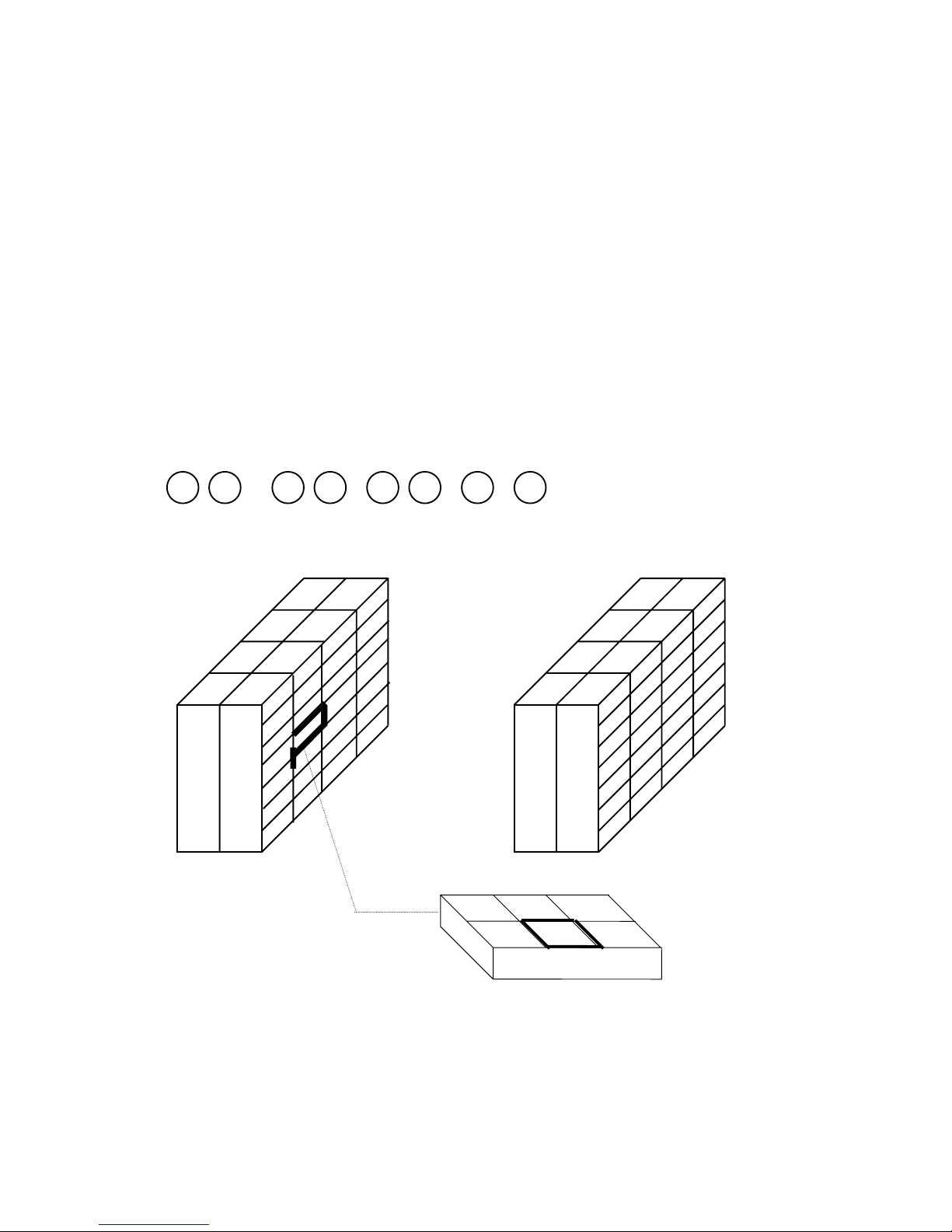

SAMPLE OF TEST LABEL

Page 64

63

2.10 Shelf Location Limit Setting

2.10a Genral Explanation for SHELF LOCATION No.

The shelf location number for each item can be programmed into DC-150 and can be

printed on tages for each shelf location. (Refer to 2.2 ID code setting.)

The location of parts can be discriminated by 8 digits. The first 2 digits are to be fiexed

for scale no. (The first 2 digits are printed on reports as scale no.)

The remaining 6 digits identify the following;

0 1 - 0 2 - 0 2 - 5 - E

SCALE - ROW - RACK - SHELF - BIN

1 2 3 4

A B C

D E F

Note: 1) The same shelf location number cannot be assigned in any other part.

Page 65

64

2.10b Shelf Location Limit

The maximum available character or number for each digit of shelf location number can

be set, according to your definition and the stock room.

By setting up the maximum limit of each digits which are composed of shelf location

number, when you miss-set the shelf location data which dose not exsit in your

definition, the erroe buzzer notice the miss-entry and the incalid data cannot be entered

in the momoey of ID data.

Programmable character and the available characters

Programmable

characters

available characters for a set

0 0

1 0, 1

9 0, 1, 2, 3, 4, 5 , 6, 7, 8, 9

A

0, 1, 2, 3, 4, 5, 6, 7, 8 , 9, A

Z 0, 1, 2, 3, 4, 5, 6, 7, 8 , 9, A ~ Z

2.10c Programming Operation

1. Enter Program Mode and select SHELF

LOCATION LIMIT.

PRG : S. LOCATION LABEL

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Depress [ENTER] key.

LIMIT = 00 - 00 - 00 - 0 - 0

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

3. Enter the data with numeric keys.

Ex.) 01-15-09-A-Z

LIMIT = 0 1 1 5 0 9 A Z

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

4. Depress [ENTER] key to store the data.

PRG : S. LOCATION LABEL

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 66

65

2.11 Address Contents Setting

Address data can be printed on a label which have printing area for address contents.

The data can be called in Operation Mode from the different data base from ID coode.

Address Contents can be programmed up to 10 (files) patterns. Also, the data base of

one file has 5 lines (32 characters/line) You can select address file no. on calling ID

code in OPR mode.

2.11a Programming Operation

1. Enter Program Mode and select Address

Contents.

PRG : ADDRESS CONTENTS

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

2. Depress [ENTER] key.

A.C = FILE NO. 1

♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

3. Select file no. by pressing [ + ] or [ - ] key.

Ex.) File No. = 3

A.C = FILE NO. 3

♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

4. Press [ENTER] key.

F3 = ADDRESS NO. 1

♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

♦ = Blinking Cursor

5. Select address no. by pressing [ + ] or [ - ]

key. Ex.) Address no. = 1

F3 = ADDRESS NO. 1

♦♦♦♦

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

6. Press [ENTER] key.

3.1 =

. . . . . . . . . . . . . . . . . . . .

Z S N K 1 2 3 I R M I O 1 2 3 4 5 6 7 8

Page 67

66

7. Enter the data.

Ex.) 13-12 Kugahara 5-Chome Ohta-ku

3.1=

. . . . . . . . . . . . . . . . . . . .