Page 1

DC-100

Counting Scale

Counting Scale

Operation Manual

Version 1.27

Disponible

en Español

Visite ricelake.com/spanish

para ver todos los materiales

RLWS disponibles en Español

To be the best by every measure

82311

Page 2

Page 3

Contents

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Capacities and Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Description of Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Keyboard and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.1 Annunciators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.0 Installation ................................................................................................................................... 8

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Powering Up the DC-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Battery Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Start-Up Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Setting Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.0 Configuration Settings ............................................................................................................... 14

3.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard . . . . . . . . . . . . . . . . . . . . 14

3.1.1 Customer Specification (141 Settings). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.2 Weight and Measurement Specification (142 Settings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.0 Calibration ................................................................................................................................. 25

5.0 Scale Operations........................................................................................................................ 28

5.1 Weight Unit Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Entering Tare Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.1 One-Touch Tare, Tare Unknown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.2 Digital Tare, Tare Weight Known . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.3 Tare Addition or Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2.4 Tare Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Toggling Between Gross and Net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.4 Entering Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.1 Unit Weight Operation by Sampling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4.2 Unit Weight Operation by Key Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.5 Part Accumulation and Negative Counting – Without Recalling an Item Code. . . . . . . . . . . . . . . . . . 33

5.5.1 Part Accumulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5.2 Negative Counting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5.3 Clearing Accumulated Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.6 Toggle Between Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.7 Adding Parts To and Subtracting Parts From Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.7.1 Adding Parts to Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.7.2 Subtracting Parts From Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.7.3 Sample, Count and Print a Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.7.4 Scan ID Bar Code, Count and Print a Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.0 Scale Programming................................................................................................................... 36

6.1 Item Code Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.1.1 Checking Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1.2 Program ID Code, Unit Weight, Tare Weight, Label Format, Part Name, Part Number, Lot Number, Location, Inventory Quantity, Threshold, and Setpoints 37

6.1.3 Delete Item Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2 Using Item Codes in Normal or Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Page 4

6.2.1 Recalling Numeric Item Codes using Item Code Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.2 Re-Computing Item Code Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.3 Quick Add Item to Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.4 Tare Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.5 Inventory Operations Related to the Item Code Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.2.6 Delete Item Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3 Setting Tare in Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.1 One Touch Tare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.2 Digital Tare (When Tare Weight is Known in Advance). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3.3 Tare Value Exchange (Tare Addition or Subtraction) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4 Setting a Lot Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.5 Setting a Sequence Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.0 External Printers, Barcode Scanners, Keyboards and Platforms ............................................. 44

7.1 Connecting External Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.1 SPEC Settings for External Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.2 Connecting the Printer to the RS-232C Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1.3 Eltron Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.4 Epson Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

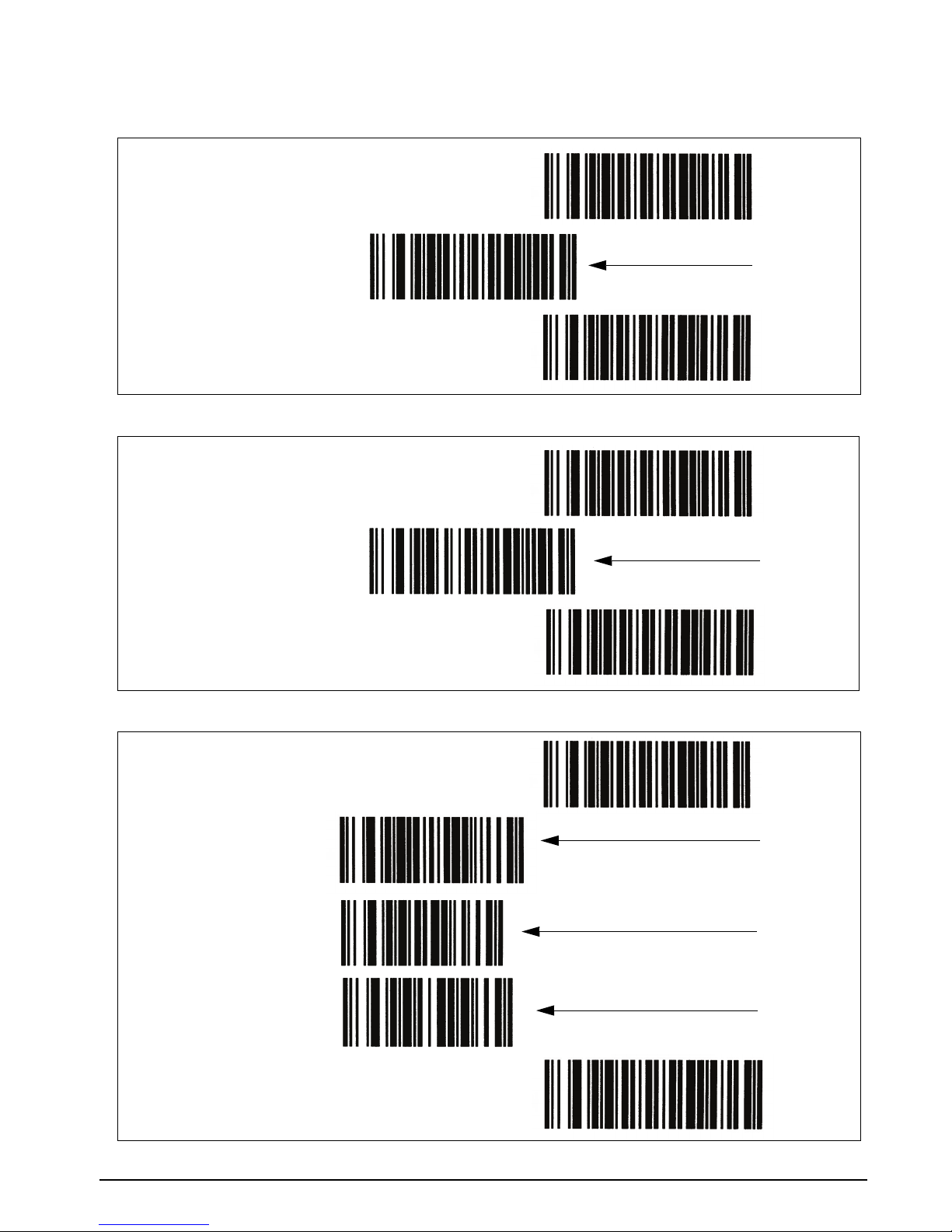

7.2 Connecting a Barcode Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.1 Header Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2.2 Z Commands via Barcodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.3 Configuring the RS232C Port for a Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.4 Connecting the Scanner to the RS232C Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2.5 Configuring the Keyboard Port for a Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

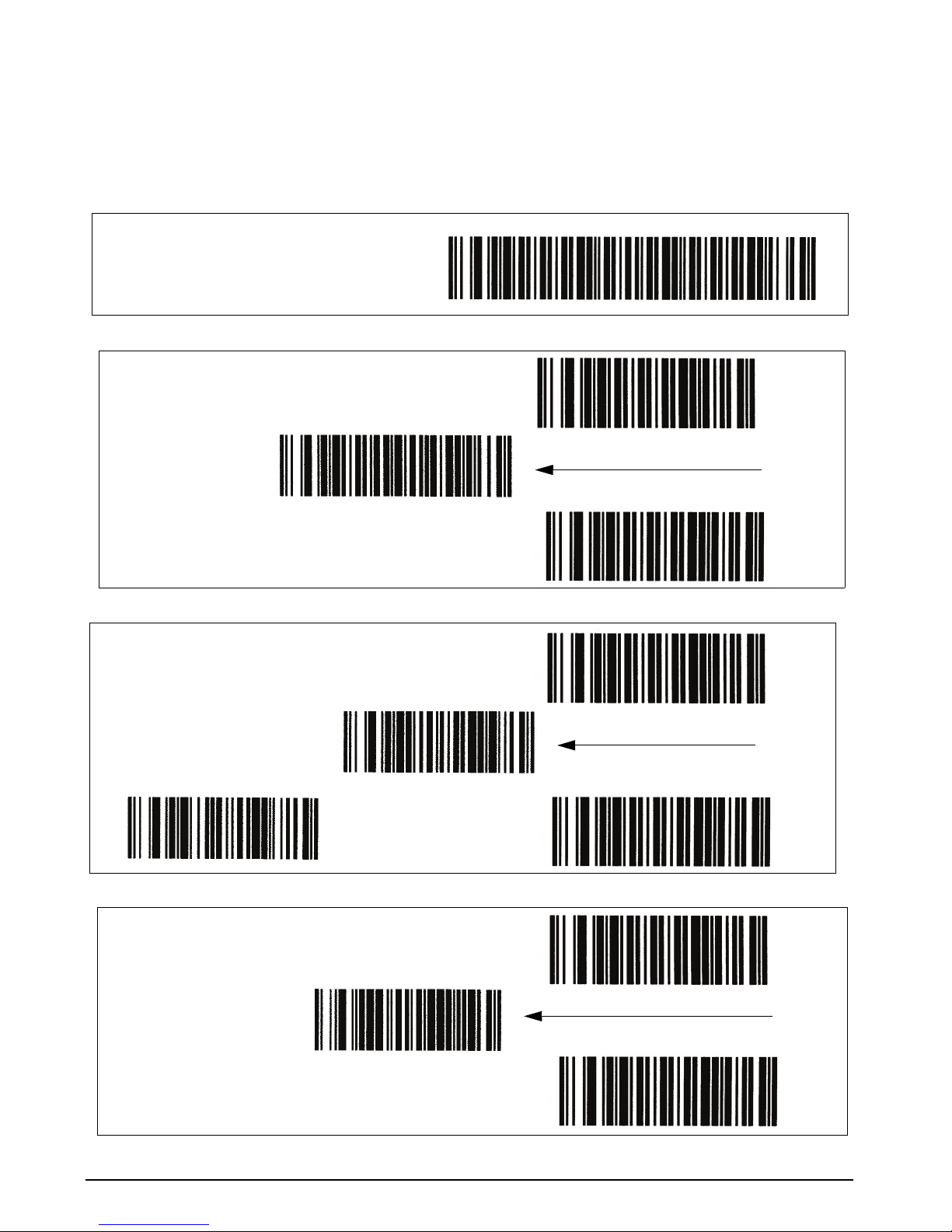

7.2.6 Programming the QSC-6000 Plus Quickscan RS232C Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2.7 Programming the QuickScan Keyboard Wedge Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3 Connecting the IBM Keyboard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4 Connecting an External Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.0 Job Sequence Programming ..................................................................................................... 57

8.1 General Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2 Example of Job Sequence Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.3 Modifying a Job Sequence Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.4 Deleting a Job Sequence Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.0 Password Protecting the Programming Functions ................................................................... 60

9.1 How to Program a Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.2 How to Use a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3 How to Change or Delete a Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.0 DC-100 Error Message List ........................................................................................................ 62

11.0 DC-100 Limited Warranty........................................................................................................... 64

2 DC-100 Operation Manual

Page 5

About This Manual

This manual contains operating procedures for the DC-100 counting scales and provides the user with all the

information necessary for setup and operation. It is organized based on the procedures you will likely follow

when setting up and using your counting scale. This manual applies to Version 1.27 of the DC-100 counting

scale series.

Some procedures described in this manual require work inside the scale base. These procedures are to

#AUTION

be performed by qualified service personnel only.

Authorized distributors and their employees can view or download this manual from the

DIGI distributor site at www.DigiScales.com.

1.0 Introduction

The DC-100 counting scale offers practical solutions for a full range of precision counting applications. A bright

dot matrix LCD display enables operators to easily view quantities, and a second line of alphanumeric text

messaging displays operator prompts and part numbers to enable job sequencing. Two thousand item memory

and an RS-232 port enable the DC-100 to provide real-time data collection and position it for the future growth

of your business. Multiple scales can be connected to the DC-100, as well as a bar code scanner, external printer

or keyboard. When portability is required, choose the battery operation option of the DC-100 for over 30 hours of

continuous use for mobile workstations, outdoor applications, and rental fleets. It’s built to withstand transport

from one area of the plant to another or from one business to the next. Simply connect a printer via RS-232 for

labeling tasks.

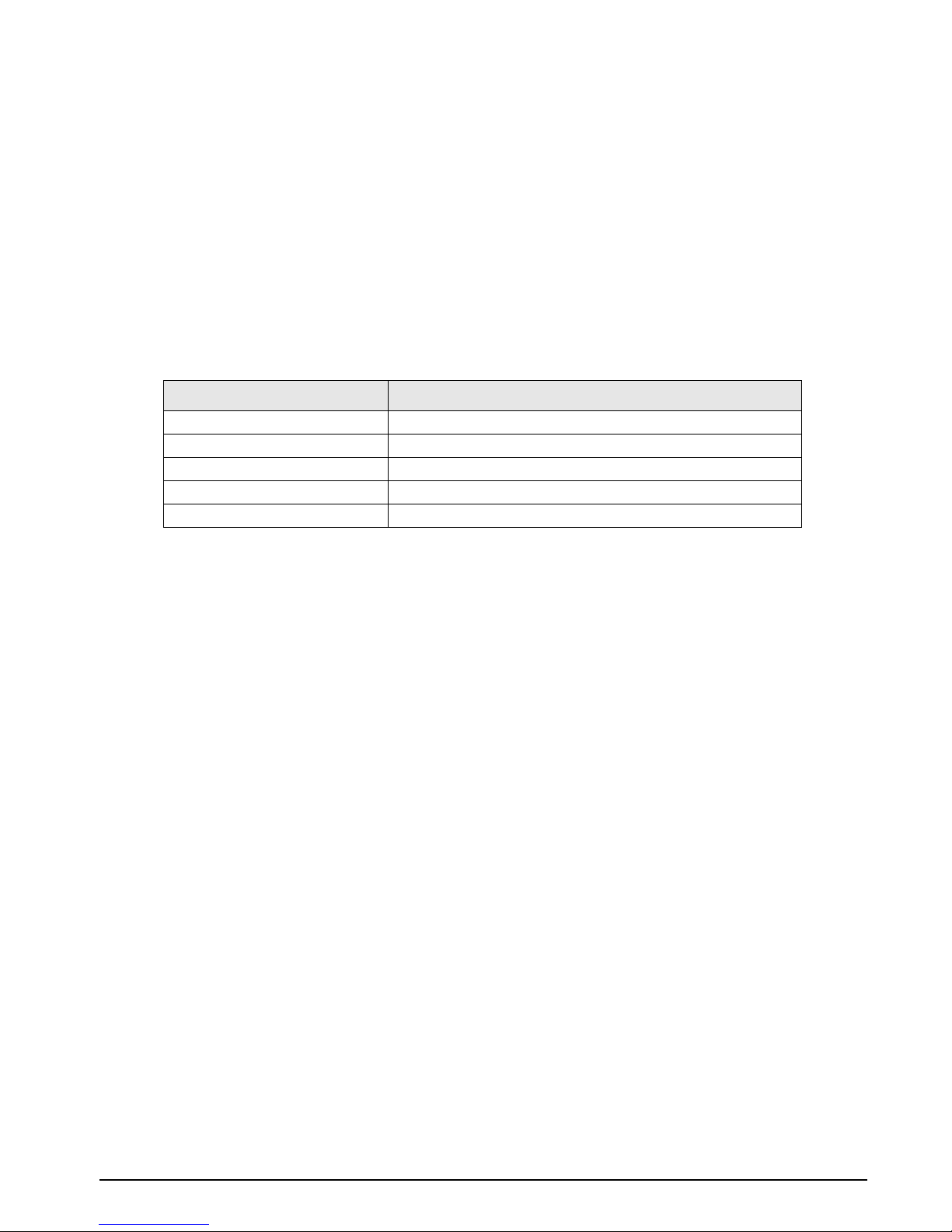

1.1 Capacities and Resolutions

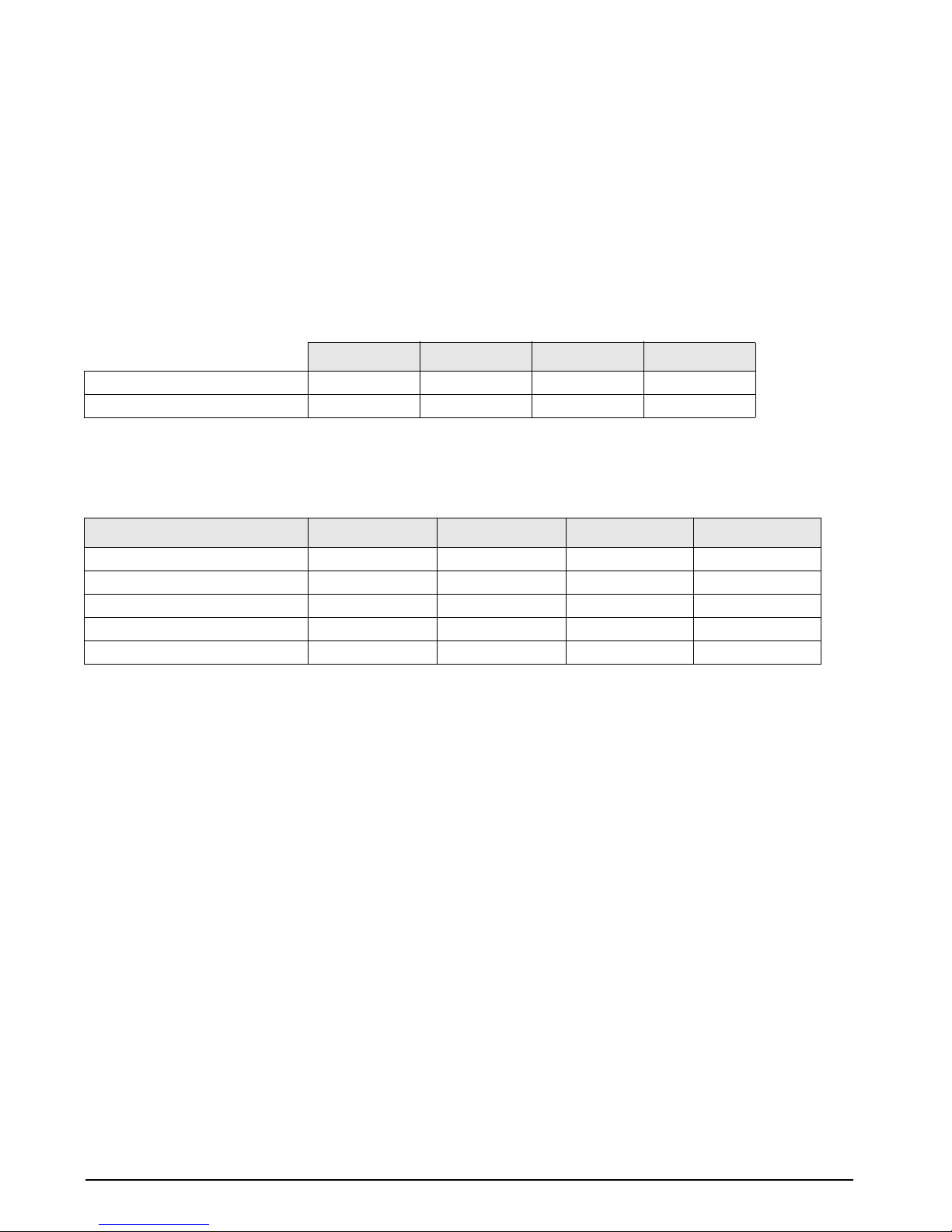

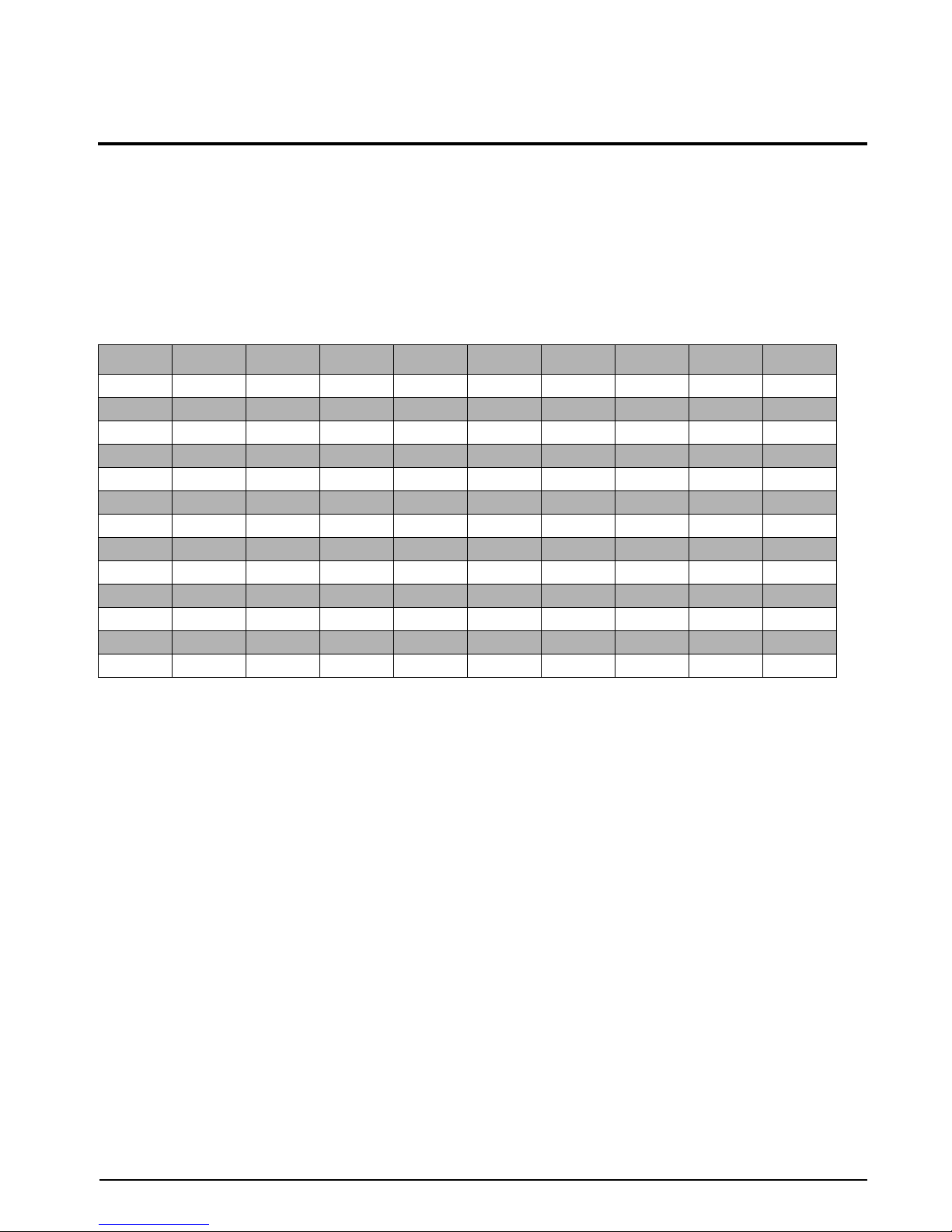

Table 1-1 and Table 1-2 list the scale capacities and resolutions for all models of the DC-100 counting scales.

The system weighing accuracy is 0.02 percent.

Counting scales specify two types of resolution:

• Weight (or external) resolution

• Counting (or internal) resolution

Weight resolution is displayed in divisions of the full scale capacity which is divided into weight increments. For

example, a 5-lb scale divided into 10,000 display divisions would display weight with 0.0005 lb divisions

(10,000 divisions x 0.0005 lb = 5.0 lb).

Counting resolution is based on the internal resolution of the scale. The weight and counting resolutions for the

DC-100 capacities are shown on the next page.

Introduction 1

Page 6

DC-100 Single Scale

Note: Units are selectable from lb to kg and can be programmed to weigh in other primary units: lb, kg, g.

Capacity Mounting Internal/External Weight Resolution Counting Resolution Platform Dimension

1.0 lb Both 0.0001 0.000001 6" x 8"

2.5 lb Both 0.0002 0.000002 7" x 10"

5.0 lb Both 0.0005 0.000005 12" x 14"

10.0 lb Both 0.001 0.00001 12" x 14"

25.0 lb Both 0.002 0.00002 12" x 14"

50.0 lb Both 0.005 0.00005 12" x 14"

Table 1-1. DC-100 Single Scale Capacities

DC-100 Remote Platforms

Platform Capacity Weight Resolution Counting Resolution Platform Dimensions

100.00 0.01 0.0001 13" x 17"

(DIGI S-SL Platform)

250.00 0.02 0.0002 17" x 21" *

(DIGI S-TL Platform)

500.00 0.05 0.0005 17" x 21" *

(DIGI S-TL Platform)

1500.0 0.2 0.001 24" x 28" *

(DIGI S-UL Platform)

2500.0 0.2 0.002 36" x 36” or 48" x 48" *

(DIGI Summit 3000 Platform)

5000.0 0.5 0.005 48" x 48" *

(DIGI Summit 3000 Platform)

10000.0 1.0 0.01 48" x 48" or 60" x 60" *

(DIGI Summit 3000 Platform)

25000.0 2.0 0.02 42" x 72" or 60" x 84" *

(DIGI Summit 3000 Platform)

50000.0 5.0 0.05 60" x 84" *

(DIGI Summit 3000 Platform)

*Note: Other platform sizes are available; consult the factory or your dealer for more information. Units are selectable from lb to

kg and can be programmed to weigh in other primary units: lb, kg, g.

Table 1-2. DC-100 External Platform Capacities

2 DC-100 Operation Manual

Page 7

1.2 Modes of Operation

1.2.1 Description of Modes of Operation

• Operation Mode – where all the basic weighing and counting operations are performed (also called the

Registration Mode).

• Report Mode – the report mode is not used in the DC-100

• Program Mode –where item data, factory name, and other data can be programmed into the memory of

the scale.

• Password Mode – where you can set passwords that will be required for a scale operator to use certain

functions of the scale.

A fifth mode of operation, Service Mode, is used by your DIGI Dealer or authorized service technician to

perform initial programming and troubleshooting operations.

Which mode you are in is displayed on the right-hand side of the display panel by the following codes:

Mode Annunciator

Operation Mode Default mode, no letter displayed

Report Mode X

Program Mode S

Password Mode The code for the mode you are password protecting is displayed

Service Mode Z

Table 1-3. DC-100 Modes of Operation

Introduction 3

Page 8

DC-100 Mode Flowchart

The chart below shows the functions under each of the DC-100 modes. Use the Mode key to switch between

modes. Once you are in a particular mode, use the

+ and – keys to move between the different functions for that

mode.

7%)'().'-/$%

ANNUNCIATOR!

2%0/24-/$%

ANNUNICATOR8

02/'2!--/$%

ANNUNICATOR3

3%26)#%-/$%

ANNUNICATOR:

0!337/2$-/$%

)TEM2EPORT

/NE)TEM0RINT

!LL)TEM0RINT

)NVENTORY2EPORT

4HRESHOLD0RINT

)N/UT#OUNT2EPORT

#LEAR)N/UT#OUNT2EPORT

3HELF,OCATION0RINT

)TEM#ODE0ROGRAMMING

&ACTORY0ROGRAMMING

0ROGRAM*OB3EQUENCE

0ROGRAM$ATE

!DDRESS0ROGRAMMING

4EXT0ROGRAMMING

)TEMS0ROGRAMMED)TEMS!VAILABLE

8-ODE0ASSWORD

3-ODE0ASSWORD

:-ODE0ASSWORD

07$-$0ASSWORD

4 DC-100 Operation Manual

Figure 1-1. DC-100 Mode Flowchart

Page 9

1.3 Keyboard and Display

Figure 1-2 shows the DC-100 console with annunciators, function keys and the numeric keypad. Annunciators

are described in Section 1.3.1. Section 1.3.2 describes the DC-100 function keys and keypad.

Figure 1-2. DC-100 Display

1.3.1 Annunciators

Table 1-4 shows a list of the annunciators that the DC-100 uses to provide additional information about the value

being displayed. The annunciators are illuminated when the specific function is being performed.

Annunciator Annunciator Meaning

→ 0 ←

NET

RECOM

INSUFF

²

IN

OUT

R

S

X

Z

Gross weight is zero

Display shows net weight (when tare weight is entered or recalled)

Unit weight is recomputing is possible

Net weight is below specified percentage of scale capacity

Memory indicator showing quantity accumulation is being done

Inventory IN (for counting mode)

Inventory OUT (for counting mode)

Scale is in Registration Mode, also referred to as Operation Mode. (see Section 1.2 for description of modes)

Scale is in Programming Mode. (see Section 1.2 for description of modes)

Scale is in Report Mode. (see Section 1.2 for description of modes)

Scale is in Service Mode. (see Section 1.2 for description of modes)

Table 1-4. DC-100 Annunciators and Function

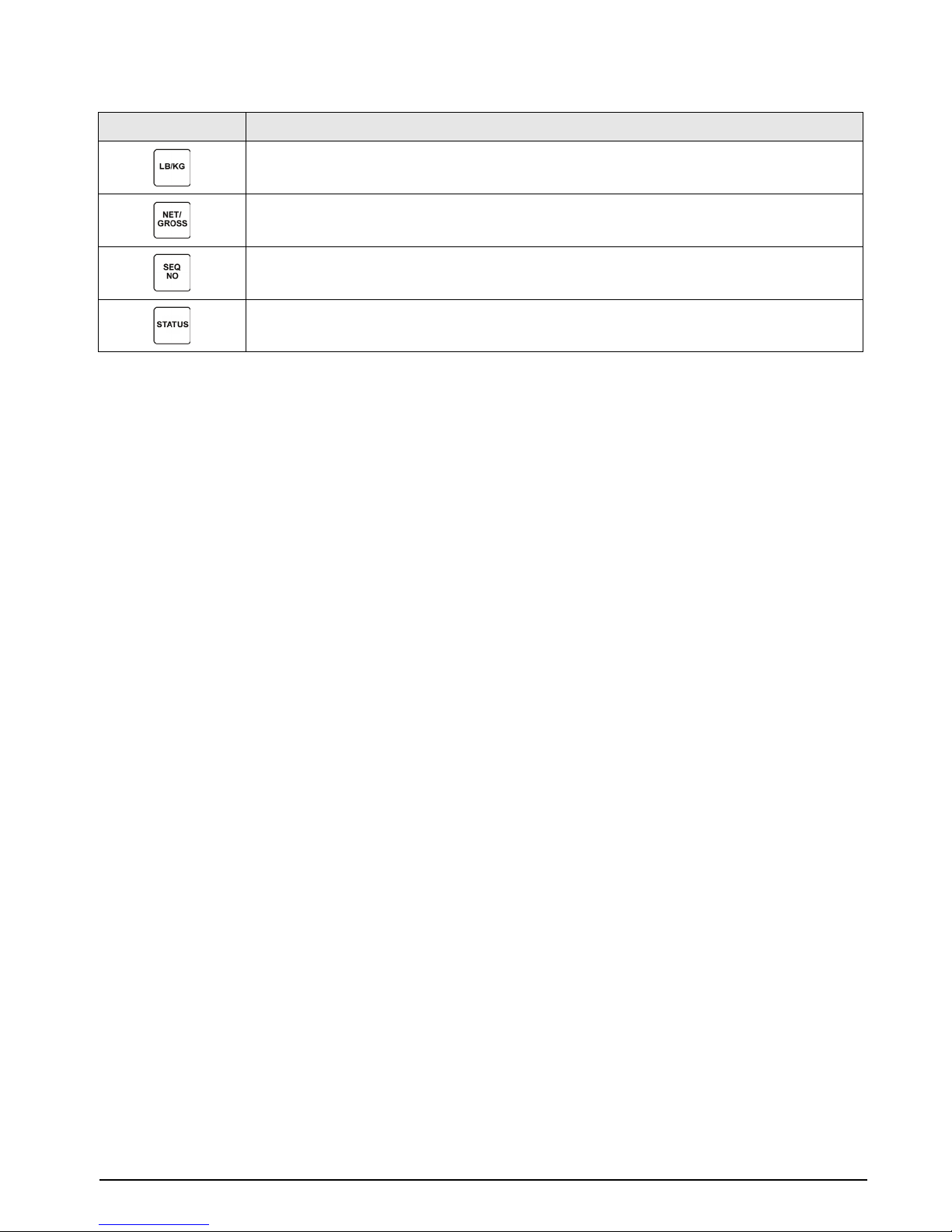

1.3.2 Key Functions

Table 1-5 lists the keys and key functions of the DC-100 keyboard and keypad (see Figure 1-2 above).

Note: Some keys have different functions depending on what mode you are in, so be sure to check which mode is selected

before using them.

Introduction 5

Page 10

.

Key Description

Turns the scale display on or off

to

Used to enter numeric values. When using the scale, first enter a numeric value, then press the

appropriate function key.

Allows cycling between the different modes:

• Operation Mode – weighing and counting operations

• Report Mode – this mode is not used with the DC-100

• Program Mode – entering item data, factory name

• Password Mode – password protecting certain operations

• Service Mode -setup and troubleshooting by an authorized dealer or technician

• Operation Mode – set and clear tare weights

• Other Modes – used to select “No”

• Operation Mode – clear keyed-in data from the display starting with the last digit entered

• Other Modes – used to select “Yes”

Used to reset the scale to zero. Also used in conjunction with other keys to enter the maintenance

mode. The REZERO key does not function when the scale is in motion.

• Operation Mode - compute unit weight by sampling. Press the PIECES key after placing a sample

on the platform, or after using the numeric keypad to enter the sample size. On multi-channel

units, ensure that the correct scale is selected.

• Other Modes - escape the programming screen without saving data

Used to enter a known unit weight using the numeric keypad

• Program Mode – select an item to be programmed such as item code, factory name, or cycle

through set-point modes

• SPEC Setting – move between SPEC numbers (low to high)

• Program Mode –- select programming item such as item code, factory name

• Other Modes – enter the delete function

• SPEC Setting – move between SPEC numbers (high to low)

• Operation Mode – call up stored item code information and switch between item code inventory

IN and OUT modes

• Program Mode – store the programmed data

Enter numeric values containing a decimal point

Note: A numeric value must be entered before the decimal point. For example, .250 would be

entered as 0.250.

Cycle between Scales A through D when using the DC-100 as a multi-scale system.

• Operation Mode – print a label or report

• Program Mode – enter information about an item into temporary memory

Move the cursor. Change the entry to the right. Also used to cycle forward between choices in SPEC

setting mode.

Move the cursor. Change the entry to the left. Also used to cycle backward between choices in

SPEC setting mode.

6 DC-100 Operation Manual

Table 1-5. DC-100 Key Functions

Page 11

Key Description

Changes the weighing units between lb and kgs.

Changes the display between net weight and gross weight.

Adds an incrementing Sequence Number to the transaction.

Toggle between Inventory In, Inventory Out, and Non-add to Inventory functions.

Table 1-5. DC-100 Key Functions

Introduction 7

Page 12

2.0 Installation

This section describes the procedure for the installation and setup of the DC-100 counting scale.

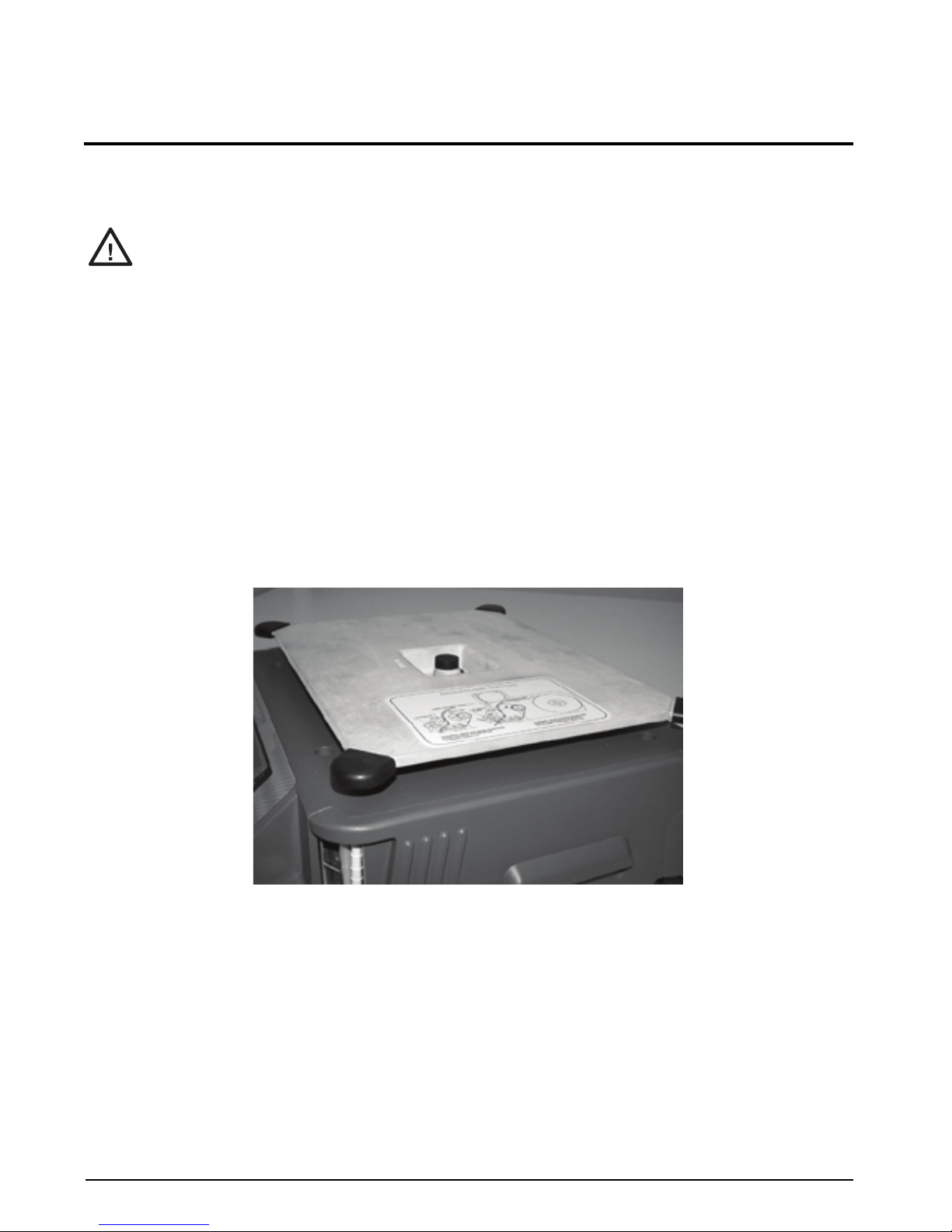

2.1 Unpacking

Do not turn scale upside down. Always work with scale on its side! Damage to the load cell can occur if

#AUTION

Immediately after unpacking, visually inspect the DC-100 counting scale to ensure all components are included

and undamaged. If any were damaged in shipment, notify Rice Lake Weighing Systems and the shipper

immediately.

The DC-100 counting scale is packed in custom-fitted foam. After opening the box, remove all the components.

Check the insides of the box carefully to make sure you have all of the pieces. The package should include the

following:

• DC-100 counting scale

• Stainless steel platter

• AC power cord

• DIGI certificate of quality

• Spare keysheet label

the scale is turned upside down.

Remove the bag protecting the scale and the dessicant bag. Next remove the protective film covering the front

panel and the foam spacers between the scale case and the platform spider. Finally, place the stainless steel

platter on top of the scale and seat it securely on the rubber stops.

After insuring that all the parts are present, store the original box in a safe location for possible future use. You

will want the original packaging if you ever need to transport the scale or send it for servicing.

8 DC-100 Operation Manual

Figure 2-1. DC-100 Unpacked

Page 13

2.2 Repacking

If the DC-100 counting scale must be returned for modification, calibration or repair, it must be properly packed

with sufficient cushioning materials. Whenever possible, use the original carton when shipping the DC-100.

Damage caused by improper packaging is not covered by the warranty.

2.3 Setting Up

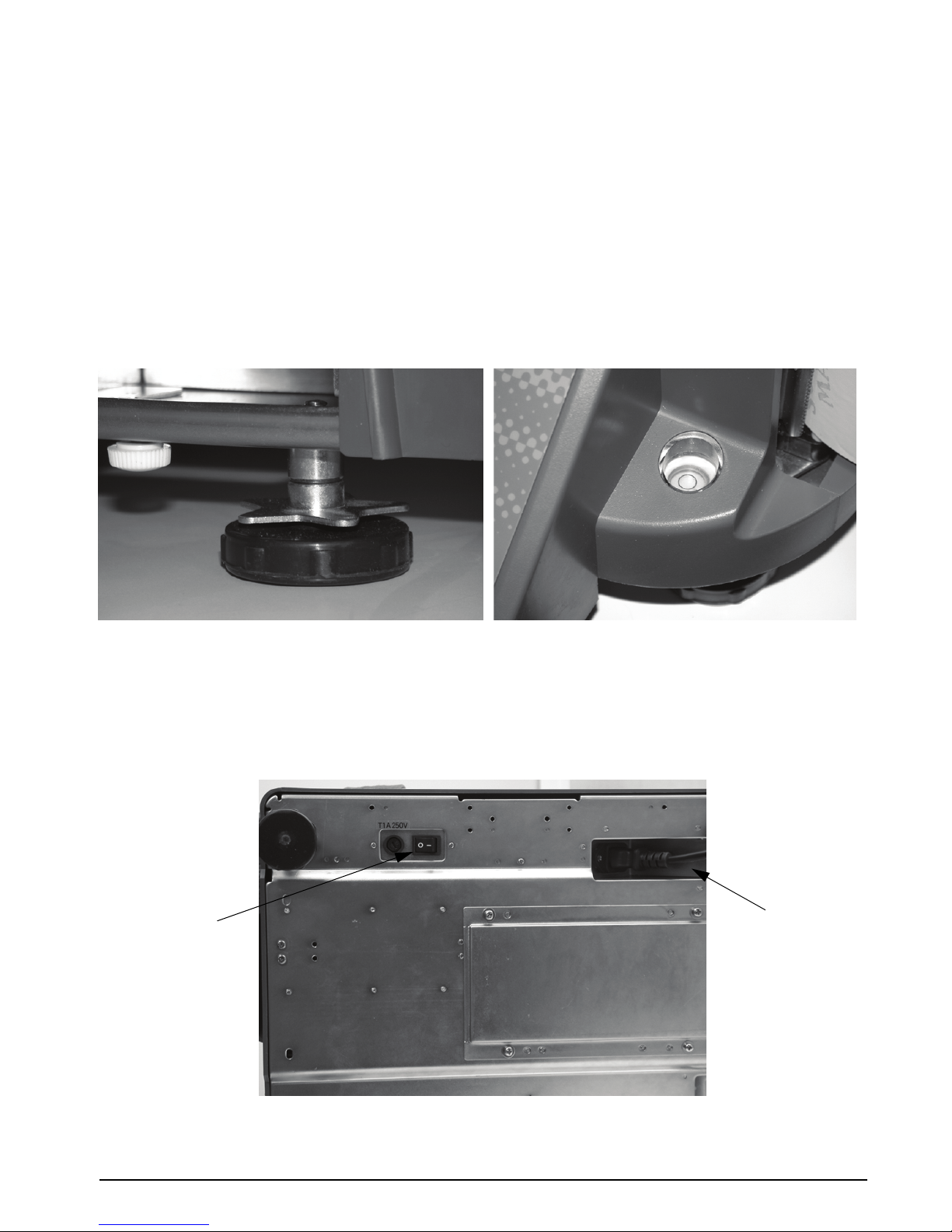

Place the scale on a solid, level surface away from fans, breezes, and sources of electrical interference.

Level the scale by turning the four adjustable legs located on the bottom of the scale while referencing the bubble

level located on the front of the scale (see

Note:To ensure a higher degree of scale stability, turn in all four adjustable legs before leveling. Turn out adjustable legs to level

as needed.

Figure 2-2).

Figure 2-2. Leveling Feet and Bubble

2.4 Powering Up the DC-100

After plugging the power cord into the socket on the bottom of the scale (Figure 2-3) turn the power switch on

the back of the bottom of the scale to the ON position. Generally when starting up the scale, if the power switch is

currently

but the display has been powered down by pressing the

pressing the

Power switch

location

OFF, turning it to the ON position powers up the scale. If the power switch is already in the ON position

ON/OFF key on the front, the scale can be reactivated by

ON/OFF key again.

Power cord

location

Figure 2-3. Power Switch and Power Cord Location

Installation 9

Page 14

2.5 Battery Installation

This section covers the installation of the DC-100’s optional battery into the battery compartment. Use the

following steps to install a battery into the DC-100.

Do not turn the scale upside down. Always work with the scale on its side! Damage to the load cell can

#AUTION

1. Turn the DC-100 on its left side.

2. Unscrew the three screws holding on the side cover to the battery compartment.

3. Remove the side cover enclosing the battery compartment.

occur if the scale is turned upside down.

Screw Location

Figure 2-4. DC-100 Screw Location

Side Cover

Figure 2-5. Side Cover Location

4. Remove the battery slot screw holding in place the battery holder bracket, and then remove the bracket.

Battery Holder

Bracket

Location

Figure 2-6. Battery Holder Bracket Location

10 DC-100 Operation Manual

Page 15

5. Slide the faston connectors on the battery cables onto the faston tabs on the battery, being careful to

match the wire color with the colored tag by the faston tabs to insure correct polarity.

Figure 2-7. Faston Tabs

6. Place the battery inside the battery compartment. Then replace the battery holder bracket and secure it

with the battery slot screw.

Figure 2-8. Battery Holder Bracket

7. Replace the side cover to the scale case and secure it with the three screws on the bottom of the scale.

Installation 11

Page 16

2.6 Start-Up Screens

1. As the scale powers up it will display the current version of the firmware it is using. It also shows that the

scale is currently being operated as a stand-alone unit.

2. After a test of the different elements of the display, the scale takes you to the stand-by screen in the

Operation Mode. At the stand-by screen the

and the annuciator for the platform you are using is illuminated (A, B, C or D).

From this stand-by screen all of the basic weighing, counting and inventory operations can be performed.

Also, if any job sequence instructions have been programmed into the scale, the first operator instruction

will be displayed on the second line of the display (

3. If there is anything on the platform(s) and it exceeds the scale start range, a beep sounds, and the

following error message appears.

Note: The Initial Start Range settings are controlled by SPEC 631. The default setting is 0: +UNLIMITED TO 10% OF FULL

.

SCALE

WEIGHT, UNIT WEIGHT and QUANTITY displays show zeroes

See Section 8.0 on page 56).

Remove the weight from the platform and press the CLEAR key to exit.

12 DC-100 Operation Manual

Page 17

2.7 Setting Time and Date

Once you set the internal clock for the correct day and time it will continue to keep them, even when the scale is

off, using the internal battery on the main board. The procedure below can also be used to adjust the time when

moving from Standard to Daylight Savings Time or when the scale is moved to a new facility in a different time

zone.

Note: SPEC 05 - DATE ORDER and SPEC 06 - TIME FORMAT allow you to set the format for date and time that you prefer the

scale to display. The defaults are Month/Date/Year for date and 12 hour for time. To change these specifications, see

Section 3.0 on page 14.

1. Press the MODE key twice until the display shows ITEM CODE PROGRAMMING. The S annunciator,

indicating the Programming Mode, will illuminate.

2. Press the + (plus) or – (minus) keys to scroll through the programming options until you see the

PROGRAM DATE screen. Enter the current date using the numeric keypad. For months or days from 1 to 9,

enter a leading zero. (Ex. In a MM-DD-YY format, May 8, 2003 would be entered as 050803.) Press the

REPRINT * key to store the data in temporary memory and move to the time programming mode.

3. Enter the current time using the numeric keypad. For numbers from 1 to 9, enter a leading zero. (Ex. In a

12 hour format, 3:06 pm would be entered as 0306.) If SPEC 06 - TIME FORMAT is set to a 12 hour

format, you use the

4. Press the CODE key to save the data or press the PIECES key followed by the CLEAR key to exit without

saving the data.

5. To return to the Stand-by Screen in the Operation Mode, press the MODE key three times.

<< and >> keys to toggle between AM and PM.

Installation 13

Page 18

3.0 Configuration Settings

This section presents the setup and configuration of the 920i counting scale to be used specifically by distributors

and service technicians. Configuring these specifications allow you to tailor the

applications.

Setting the specifications allows you to modify the functionality of the 920i. Use the tables in this section to view

the options you can modify. For example, if you want to activate the DC-100’s Job Sequence function, refer to

the DC-100 specification table and locate

SPEC 13 - Job Sequence. The default for SPEC 13 is 0 which means it is

disabled. To turn it on or enable it, change the SPEC setting to 1: Enable.

3.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard

The following tables list the 920i specifications and their corresponding default values. The default values are

automatically set when the scale’s memory is set by the dealer for the country of operation.

SPEC 00 through SPEC 65 (Table 3-1) are customer specifications and use the 141 access code, while SPEC 600

through SPEC 646 (Table 3-2) are weight and measurement specifications, and use the 142 access code. In

programming specifications, the * PRINT and – (minus) keys allow you to move to the next or previous

specification without saving changes to the SPEC code you were just in.

3.1.1 Customer Specification (141 Settings)

1. To configure customer specifications, press and hold the REZERO key and enter 141 using the numeric

keypad. The first SPEC code, SPEC 0 is displayed, with

line of the weight display and its current setting (ex. 00>0: Disable) appearing in the second line.

If this is the SPEC that you want to modify, press >> or << keys to scroll through the possible settings.

When the setting you want to store is displayed, press the + (plus) key to enter the change into temporary

memory and move to the next SPEC code.

2. If you want to modify a SPEC other than SPEC 00 and you know the number of that SPEC code, enter

the number of the SPEC code on the numeric keypad and press the * PRINT key. Otherwise, you can use

the + (plus) and – (minus) keys to scroll through the specifications until you find the one you want. Then

make your changes per the instructions in Step 1.

3. To change another SPEC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPEC settings currently in temporary memory and exit to the Operation Mode,

press the CODE key. You will hear a long beep to confirm that the scale is saving the change. The saving

of the configuration file takes about 10 seconds, after which the scale will return to the Stand-By mode.

To exit to the Operation Mode without saving the changes, press the

If you power off the scale while the saving process in going on, you can clear the entire memory of the

#AUTION

scale! Wait until the scale has returned to the Stand-by screen before performing any other functions.

SP0: AUTO POWER SAVING appearing in the first

TARE key.

920i to your specific

5.Power down scale using the power switch on the back of the bottom of the scale, not the

ON/OFF key on the keyboard.

6. Power scale on to re-initialize the new specification settings.

14 DC-100 Operation Manual

Page 19

SPEC Description

00 Auto Power Saving When No Weight Change & No Key Press

0: Disable (DEFAULT)

1: 1 minute

2: 2 minutes

3: 3 minutes

4: 4 minutes

5: 5 minutes

6: 6 minutes

7: 7 minutes

8: 8 minutes

9: 9 minutes

10: 10 minutes

11: 11 minutes

12: 12 minutes

13: 13 minutes

14: 14 minutes

15: 15 minutes

01 Power Saving Type

When set to 0, the backlight turns off when the scale goes into power-saving mode. When set to 1,

the scale turns off entirely

0: Backlight Off (DEFAULT)

1: Power Off

02 Negative Counting

0: No

1: Yes (DEFAULT)

03 Extent of Insufficient Samples

Sets the percentage of the full scale capacity that the initial counting sample has to exceed, otherwise

the INSUFF lamp lights.

0: 0.1% (DEFAULT)

1: 0.2%

2: 0.0%

04 Set New Item Code During Registration (Operation) Mode

This allows you to add item codes while weighing in the operation mode without having to switch to

the programming mode. These item codes can then be saved to the scale’s Item Code memory (0:

Allow -Save); or you can enter Item Codes, Part Names, and Lot Numbers that will print on labels but

not be saved to the Item Code Memory (1: Allow - Not Save); or (2: Not Allow) item codes and item

information to be set unless you are in the programming mode.

0: Allow (Save) (DEFAULT)

1: Allow (Not Save)

2:Not Allow

05 Date Order

0: Month/Day/Year (DEFAULT)

1: Day/Month/Year

2: Year/Month/Day

06 Time Format

0: 24 hour (DEFAULT)

1: 12 HOUR (am/pm)

07 Unit Weight Auto Recomputing

0: No (DEFAULT)

1: Yes

Table 3-1. DC-100 (141) Settings

Configuration Settings 15

Page 20

SPEC Description

08 Sampling Times for Unit Weight Calculation

Higher number samples improve accuracy in environments of higher vibration or breeze but also

increase the time required to compute the unit weight.

0: 15 times (DEFAULT)

1: 20 times

09 Display Accuracy Unit Weight Calculation During Recomputing

0: No (DEFAULT)

1: Yes

10 Set Point Buzzer

0: Buzzer on (DEFAULT)

1: Buzzer off

11 Clear All Input Key in One Touch

0: Yes

1: No (DEFAULT)

12 Keep Lot Number in Registration (Operation) Mode

0: Allow (DEFAULT)

1: Inhibit

13 Job Sequence

0: Disable (DEFAULT)

1: Enable

14 Auto Exit From Add Mode

0: No

1: Yes (DEFAULT)

15 SIO Select Job

Defines what the primary or standard input/output port on the scale is connecting to.

0: No operation (DEFAULT)

1: Not Used

2: PC

3: Printer

4: Bar Code Scanner

16 RS-232C Baud Rate (SIO - Standard Input/Output Port)

0: 1200 baud

1: 2400 baud

2: 4800 baud

3: 9600 baud (DEFAULT)

4: 19200 baud

5: 38400 baud

17 RS-232C Data Length (SIO - Standard Input/Output Port)

0: 7 bits

1: 8 bits (DEFAULT)

18 RS-232C Parity Bit (SIO - Standard Input/Output Port)

0: None (DEFAULT)

1: Odd

2: Even

19 RS-232C Stop Bit (SIO - Standard Input/Output Port)

0: 1 bit (DEFAULT)

1: 2 bits

20-30 Specifications 20-30 are not used by the DC-100

16 DC-100 Operation Manual

Table 3-1. DC-100 (141) Settings

Page 21

SPEC Description

31 PC/PRN Output Data Method

0: No operation

1: Counting

2: By +/-/Print Key (PC/PRN) (DEFAULT)

3: For both classes 1 & 2

32 Select External Printer Type

0: Eltron/TVP (DEFAULT)

1: SE520

2: DP122 (Japan)

3: Epson

33 External Eltron/TVP Printer Download Label Format

0: Enable (DEFAULT)

1: Disable

34 Print When Press +/- Key

0: Disable (DEFAULT)

1: Enable

35 PC Data With Header

0: Yes (DEFAULT)

1: No

36 PC Data Header Type

0: Code 9 - numeric headers (DEFAULT)

1: Title - alphabetic headers

37 IBM Keyboard Port

0: IBM Keyboard

1: Barcode Scanner

38 Barcode Scanner (BCS) With Header

0: Yes (DEFAULT)

1: No

39 Track Nprint (TNP) Time Out

0: 2 seconds (DEFAULT)

1: 8 seconds

2: 32 seconds

40-49 SPEC 40-49 are not used by the DC-100.

50 Selection of Label and Receipt Printing Operation

0: All operation (in/out/non-add) (DEFAULT)

1: Out (shipping operations)

2: In (receiving operations)

3: In and out

4: No printing

51-58 SPEC 51-58 are not used by the DC-100

59 Selection of Barcode Type

0: Code 128A

1: Code 128B

2: EAN 128A

3: EAN 128B

4: CODE 39 (DEFAULT)

60 Auto Print Function

0: Between set point 1 and set point 2

1: Disable (DEFAULT)

61 Not used by the DC-100

Table 3-1. DC-100 (141) Settings

Configuration Settings 17

Page 22

SPEC Description

62 RS232 - XON/XOFF

0: Disable

1: Enable

63 Sample Quantity

Determines the number of pieces the scale assumes are on the platter when you press the PIECES

key to calculate the Unit Weight.

0: 10 pieces (DEFAULT)

1: 25 pieces

2: 50 pieces

3: 100 pieces

64 Scale A <-> B

Sets whether the unit weight determined by sampling on Scale A is automatically transferred to Scale

B or not.

0: Manual (DEFAULT)

1: Auto

65 Unit of Pcs Weight

Sets whether the units weights are displayed per 1000 pieces or per 1 piece. For a further discussion

of the benefits of each option, please see Section 5.5.

0: 1000 pieces (DEFAULT)

1: 1 piece

66 - 67 Not used by the DC-100

68 Epson II

Changes the Epson label format from the default (all item information fields) to an abbreviated format

with only selected fields.

0: Disable (DEFAULT)

1: Enable

69 4 Lot Number

If disabled, allows a single lot number to be entered during weighing operations. If enabled, allows up

to 4 lot numbers to be entered. These lot numbers are not written to the item database.

0: Disable (DEFAULT)

1: Enable

70 Upload Lot and Part Number

If disabled, lot numbers and part numbers entered during weighing operations are not uploaded to the

item database. If enabled, lot numbers and part numbers entered during weighing operations

overwrite the information previously stored with the item code in the scale memory. (In the DC-100,

Part Numbers cannot be entered in the weighing or operation mode.) Not also that if this specification

is set to 1: Enable, Spec 04 - Set New Item Code During Registration must be set to 0: Allow (Save).

0: Disable (DEFAULT)

1: Enable

71 Text 11-16 in Titles

Allows you to use text fields 11-16 on total labels that include them rather than just item labels, if you

have an external printer attached.

0: Disable (DEFAULT)

1: Enable

72 Comma in Quantity

Enabling this option prints a comma after the first three places in a Quantity field on a

user-programmed label format. This allows large quantity numbers to be read more easily at a glance.

Does not fit on the standard label format so is only used on custom formats.

0: Disable (DEFAULT)

1: Enable

18 DC-100 Operation Manual

Table 3-1. DC-100 (141) Settings

Page 23

SPEC Description

73 Print Barcode

This option allows you to print barcodes on labels with all the headers printed, with no headers

printed, or with all the headers except the header for the Quantity barcode on label formats with

barcode headers included.

0: With Header (DEFAULT)

1: All Without Header

74 Overwrite Unit Weight

Allows you to protect the Unit Weight so that it cannot be overwritten by the operator. Note that

SPEC 04 - Set New Item Code During Registration Mode must be set to 0: Allow (Save) for the new

Unit Weight to overwrite the Unit Weight stored in memory with the Item Code. If SPEC 04 is set to 1:

Allow (Not Save), this SPEC will allow you to enter or change a Unit Weight in operation mode but

does not change the Unit Weight stored in memory.

0: No (DEFAULT)

1: Yes (If Unit Weight = 0)

Table 3-1. DC-100 (141) Settings

3.1.2 Weight and Measurement Specification (142 Settings)

1. Press and hold the REZERO key and enter 142 using the numeric keypad. SP600 appears in weight display

and its current setting (ex. 2>2: LB) appearing in the second line. If this is the SPEC that you want to

modify, press the

>> or << keys to scroll through the possible settings. When the setting you want to

store is displayed, press the + (plus) key to enter the change into temporary memory and move to the next

SPEC code.

2. If you want to modify a SPEC other than SPEC 600 and you know the number of that SPEC code, enter

the number of the SPEC code on the numeric keypad and press the

*PRINT key. Otherwise, you can use

the + (plus) and – (minus) keys to scroll through the specifications until you find the one you want. Then

make your changes per the instructions in Step 1.

3. To change another SPEC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPEC settings currently in temporary memory and exit to the Operation Mode,

press the

CODE key. To exit to the Operation Mode without saving the changes, press the TA RE key.

5. Power down scale using the power switch on the back of the bottom of the scale, not the ON/OFF key on

the keyboard.

6. Power scale on to re-initialize the new specification settings.

Spec Description

600

601

602

603

Scale Unit Specification

0: Gram

1: Kg

2: Lb (DEFAULT)

Display Resolution

0: 1/10000 (DEFAULT)

1: 1/5000

2: 1/2500)

Internal Count

0: 500,000

1: 1,000,000 (DEFAULT)

Minimum Display (Increment) for Scale A

0: 2 (DEFAULT)

1: 1

2: 5

3: 10

Table 3-2. DC-100 (142) Settings

Configuration Settings 19

Page 24

Spec Description

604

Weight Decimal Point Position for Scale A

0: 0

1: 0.0

2: 0.00

3: 0.000 (DEFAULT)

4: 0.0000

605

Load Cell Sensitivity Selection in mV/V for Scale A

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V (DEFAULT)

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

606

Load Cell Type for Scale A

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

607

A/D Board Type for Scale A

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

608

External Scale B Connection

0: Disable (DEFAULT)

1: Enable

609

Minimum Display (Increment) for Scale B

0: 2 (DEFAULT)

1: 1

2: 5

3: 10

610

Weight Decimal Point Position for Scale B

0: 0

1: 0.0

2: 0.00

3: 0.000

4: 0.0000 (DEFAULT)

20 DC-100 Operation Manual

Table 3-2. DC-100 (142) Settings

Page 25

Spec Description

611

Load Cell Sensitivity Selection in mV/V for Scale B

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V (DEFAULT)

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

612

Load Cell Type for Scale B

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

613

A/D Board Type for Scale B

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

614

External Scale C Connection

0: Disable (DEFAULT)

1: Enable

615

Minimum Display Increment for Scale C

0: 2

1: 1 (DEFAULT)

2: 5

3: 10

616

Weight Decimal Point Position for Scale C

0: 0 (DEFAULT)

1: 0.0

2: 0.00

3: 0.000

4: 0.0000

Table 3-2. DC-100 (142) Settings

Configuration Settings 21

Page 26

Spec Description

617

Load Cell Sensitivity Selection in mV/V for Scale C

0: 4.00 mV/V

1: 3.76 mV/V

2: 3.52 mV/V

3: 3.28 mV/V

4: 3.04 mV/V

5: 2.80 mV/V

6: 2.56 mV/V

7: 2.32 mV/V

8: 2.08 mV/V

9: 1.84 mV/V (DEFAULT)

10: 1.60 mV/V

11: 1.36 mV/V

12: 1.12 mV/V

13: 0.88 mV/V

14: 0.64 mV/V

15: 0.40 mV/V

618

Load Cell Type for Scale C

0: Standard / Normal load cell (DEFAULT)

1: Abnormal load cell with large offset

619

A/D Board Type for Scale C

0: Normal (DEFAULT)

1: Prevent from small vibration / fast change in display

2: Prevent from medium vibration

3: Prevent from large vibration / slow change in display

620

Tare Range Settings

0: 100% full scale (DEFAULT)

1: <50% full scale

2: <5% full scale

621

Digital Tare Setting

0: Disable

1: Enable (DEFAULT)

622

Tare Accumulation

0: No (DEFAULT)

1: Yes

623

Digital Tare When Loaded

0: Allow (DEFAULT)

1: Inhibit

624

Tare Subtraction (for Load Tare Only)

0: Yes (DEFAULT)

1: No

625

Tare Addition (for Load Tare Only)

0: Yes

1: No (DEFAULT)

626

Tare Value Exchange (for Load Tare)

0: Yes (DEFAULT)

1: No

627

Zero Tracking When Tare

0: Yes (DEFAULT)

1: No

628

Tare When Scale Change

0: Old Tare (DEFAULT)

1: New Tare

22 DC-100 Operation Manual

Table 3-2. DC-100 (142) Settings

Page 27

Spec Description

629

Weight Reset When Tare

0: Yes (DEFAULT)

1: No

630

Auto Clear Tare When Rezero

0: No (DEFAULT)

1: Yes

631

Initial Start Range Settings

0: +/- 2% full scale

1: +/- 10% full scale

632

Zero Range Settings

0: +/- 2% full scale

1: +/- 10% full scale2:

633

Zero Lamp Lighting Method

0: Gross weight (DEFAULT)

1: Net weight

634

Rezero When Changing Scale

0: No rezero (DEFAULT)

1: Rezero

635

Stability Check When Changing Scale

0: Stability check (DEFAULT)

1: No stability check

636

Internal Count Resolution (IR) Protected by Span Switch

0: No (DEFAULT)

1: Span switch protect

637

638

NOT USED

Display at Minus Weight

0: Minus display (DEFAULT)

1: Masked display

639

Masked Display at Minus Weight

0: Gross weight (DEFAULT)

1: Net weight

640

Overweight Masked

0: At +1D (DEFAULT)

1: At + 9D

641

Selection of Scale Starting Method

0: Auto start (DEFAULT)

1: Manual start

642

Weight Unit Convert

0: Yes (DEFAULT)

1: No

643

Gross Mode Display

0: Yes (DEFAULT)

1: No

644

Selection of Decimal Point Type

Sets whether the decimal point is displayed as a period (U.S. usage) or a comma (European, Latin

American, Asian usage)

0: Period display (DEFAULT)

1: Comma display

645

NOT USED

Table 3-2. DC-100 (142) Settings

Configuration Settings 23

Page 28

Spec Description

646

Automatic Unit Weight Clear Conditions

0: Disable (DEFAULT)

1: Over net 5D & gross 21D & weight stable

2: >=net 1D & weight stable

3: >=net 1D & quantity > 0 & weight stable

Table 3-2. DC-100 (142) Settings

24 DC-100 Operation Manual

Page 29

4.0 Calibration

The DC-100 counting scale is a high-precision instrument. Although the scale needs very little maintenance, you

may want to check the calibration after every month or so of normal usage. To do this you will need to have a test

weight of approximately the total capacity of the scale (i.e. a 10 lb weight if you have a 10 lb capacity scale).

After the scale is initially installed, put the weight on the platform and record the weight displayed. Then every

month or so put the same weight on the scale and verify that it still reads the same.

Many facilities have a technician come in and check their units with certified test weights four times a year. If

you are ISO certified, you will want to check to see if your certification specifies more stringent requirements to

stay in compliance. Your DIGI scale dealer has the calibrated test weights, expertise and experience to perform

this task for you as well as to check other operating parameters of your scale and help you effectively integrate

scales into your operations. If you do not know who your local DIGI dealer is, call us at 1-715-736-0002 and we

will help you find someone who can provide you with on-site support.

Follow the instructions below to calibrate your DC-100 scale to ensure its continued accuracy.

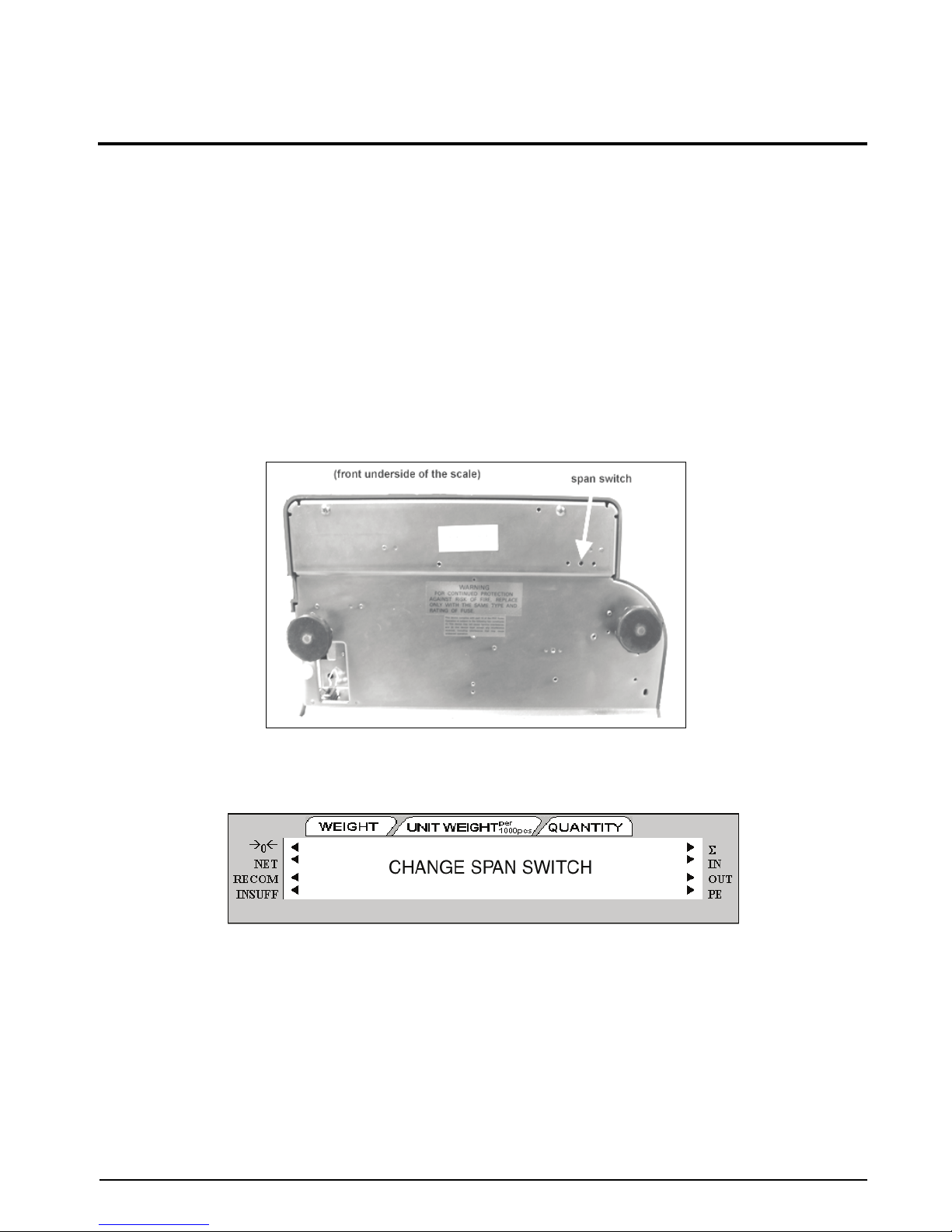

1. Make sure the scale is turned off. Then press the span switch to reset it. (See Figure 4-1 for location of

Span switch).

2. Turn the scale back on. The scale displays the message CHANGE SPAN SWITCH.

3. While pressing the REZERO key, enter 8715 from the numeric keypad to enter the calibration mode.

Figure 4-1. Location of Span Switch

Calibration 25

Page 30

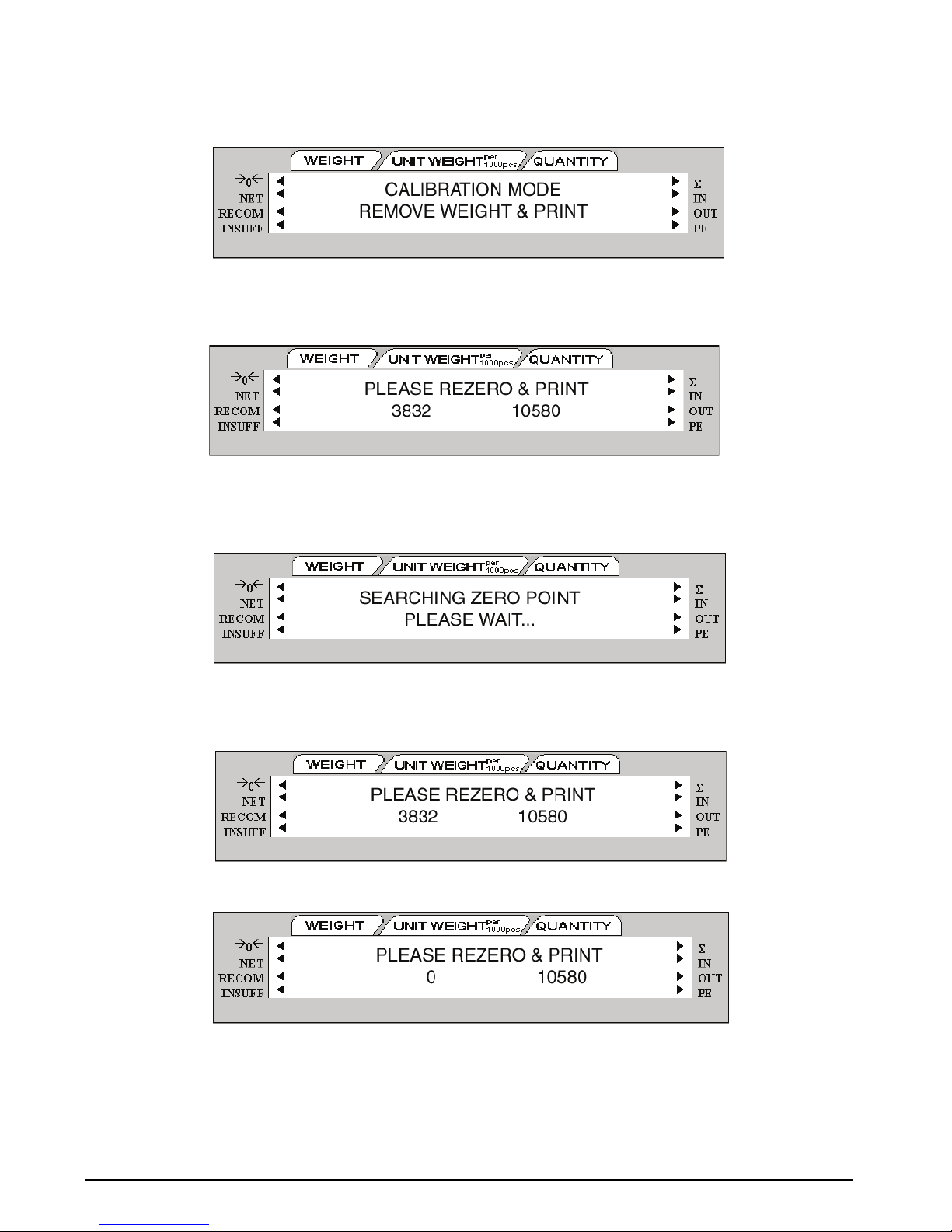

4. The scale display confirms that you are in the Calibration Mode.

5. Next, press the * REPRINT key to enter the zero setting mode.

6. Choose which scale platform you are calibrating. The scale defaults to platform A. To choose another

scale platform, press the SCALE key until the platform you want to calibrate is displayed.

7. Make sure that nothing is on the scale platform and press the CODE key to have the scale automatically

search for the zero point.

8. The scale displays the zero point in the quantity window. It should be a value between 9000 and 11000.

If the scale does not catch that range, you will need to call your local DIGI dealer or call us at

1-715-736-0002 for service assistance.

9. Press the REZERO key to clear the Internal Count shown in the weight window.

26 DC-100 Operation Manual

Page 31

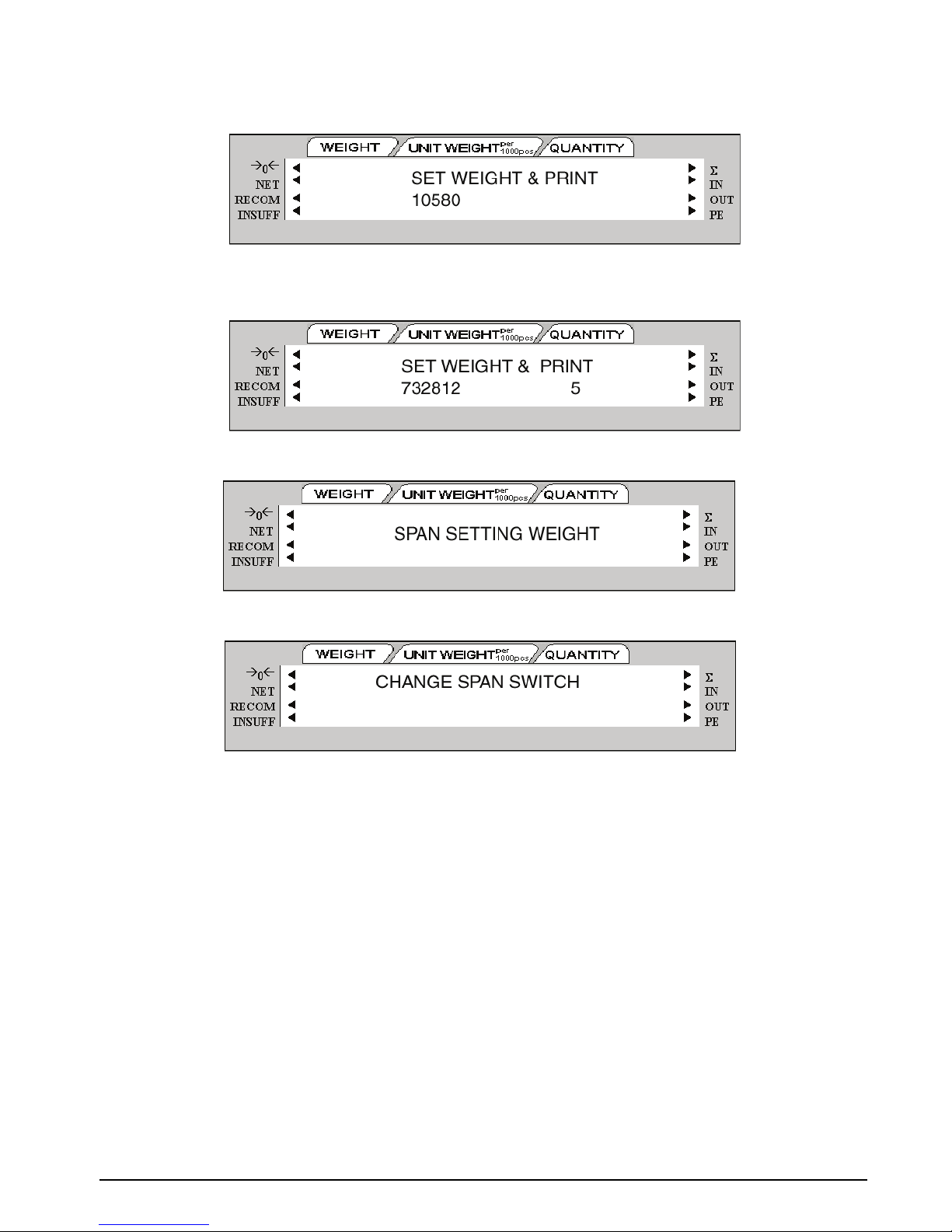

10. Press the * REPRINT key to enter the weight calibration setting.

11. Put a calibrated weight on the platform equal to the total capacity of the scale (Example, for a 25 lb scale,

place a 25 lb weight on the scale). Alternatively, you can enter the weight from the numeric keypad. The

weight appears in quantity window. Press the

* REPRINT key to save the calibration data.

The display confirms that the span settings for calibration of the scale are being saved

Finally the screen returns to the initial CHANGE SPAN SWITCH.

12. Once the span switch is turned off, the scale automatically returns to operation mode. The scale should

now be powered off and restarted for the new settings to take effect.

Calibration 27

Page 32

5.0 Scale Operations

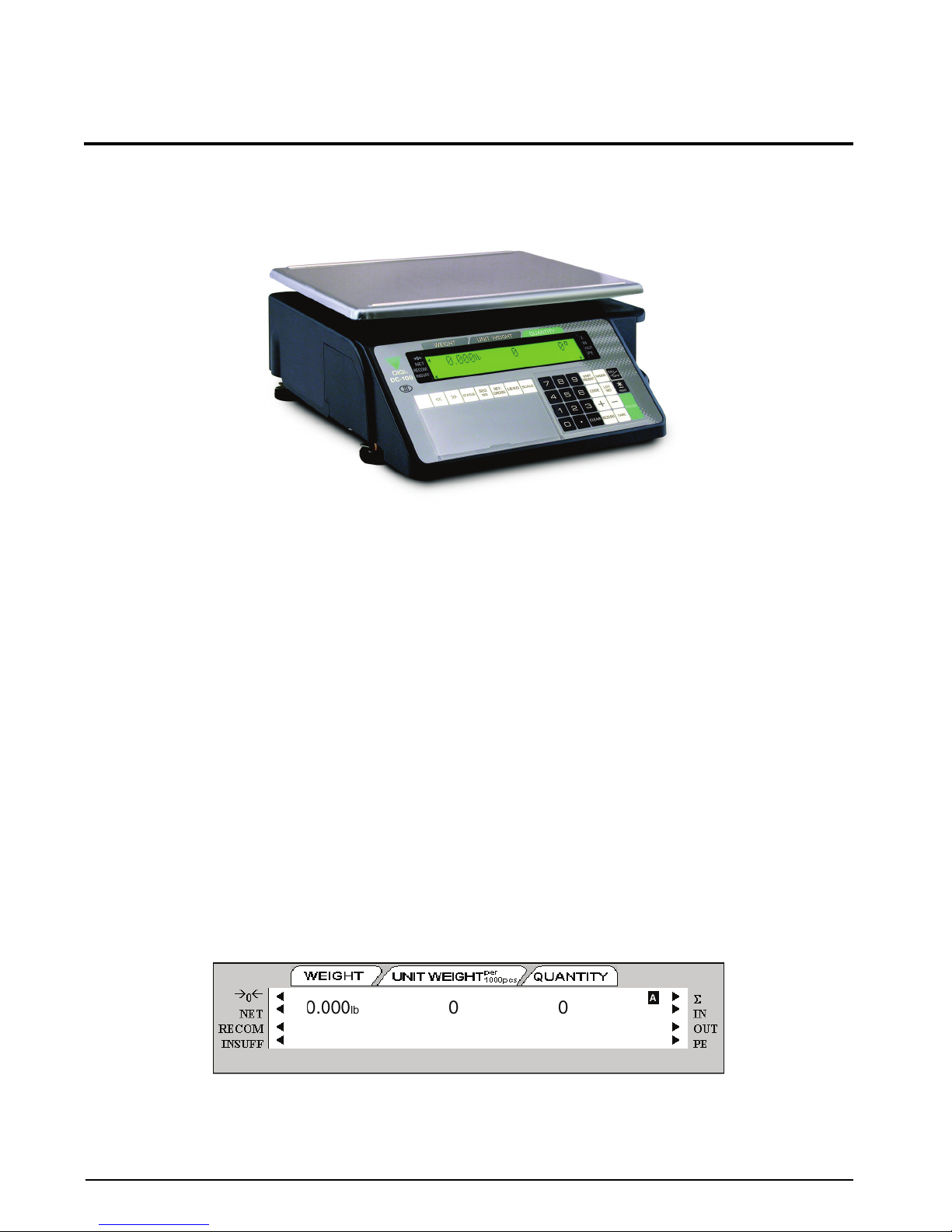

The following paragraphs contain detailed operator instructions for the DC-100 counting scale (see Figure 5-1).

Included are instructions to enter tare weights, toggle between net and gross weight, enter unit weights, perform

inventory accumulation and reduction, and toggle between scales. All operator instructions are conducted with

the scale in the operation mode that is the weighing or normal mode.

Figure 5-1. DC-100 Counting Scale

Counting scale accuracy is primarily determined by the following factors:

• Sample size (number of pieces)

• Total sample size as a percentage of full scale capacity

• Piece-to-piece weight variation

As a general rule when determining sample size of fairly uniform pieces, the larger the sample size the greater

the total sample weight, therefore, the better the counting accuracy. Selecting the smallest capacity scale that can

obtain the highest counting resolution should be considered, but should not sacrifice the capacity required for the

heaviest container of parts. For this kind of application, a dual-platform scale may be the best selection.

There is a direct relationship between piece-to-piece weight variation (non-uniformity) and counting accuracy.

Therefore, elimination of the piece-to-piece weight variations can be accomplished by:

1. Isolating the sample used to calculate the unit weight and use the same sample to re-check the scale.

2. Recalculating the unit weight from lot-to-lot of parts. Parts manufactured on one machine may vary

slightly from another machine relative to weight.

3. Tightening the manufacturing tolerances on the parts reduces piece weight variations and increases count

accuracy.

The Stand-By Screen

The starting point for using the scale in operation mode is the stand-by screen. At the stand-by screen the WEIGHT,

UNIT WEIGHT,

and QUANTITY displays show zeroes and the annuciator for the platform you are using is illuminated

(A, B, C or D).

From the stand-by screen you can perform all of the basic weighing, counting and inventory operations of the

scale.

28 DC-100 Operation Manual

Page 33

5.1 Weight Unit Switching

Notes:

• SPEC 600 SCALE UNIT SPECIFICATION sets the default weight unit to Grams, Kgs or Lbs.

• SPEC 642 WEIGHT/UNIT CONVERT must be set to “0: YES” in order for you to be able to switch weight units during weighing

operations.

The weight units displayed can be changed between Kg and Lb during weighing operations by pressing the LB/

KG

key.

5.2 Entering Tare Weights

Tare weights can be entered in the scale by one of two methods: one-touch tare or digital tare. Digital tare is used

when the tare weight is already known while one-touch tare is used when the tare weight is unknown. If you call

up an Item Code already programmed into the DC-100’s memory and you have a Tare Weight stored for that

Item Code, the Tare Weight stored with the Item Code will override one entered digitally or by using the

key.

Notes:

• SPEC 621 DIGITAL TARE SETTING must be a “1: ENABLE” to allow digital tare.

• SPEC 620 TARE RANGE must be set to the appropriate tare range value. Default is “0: 100 PERCENT OF FULL SCALE”.

5.2.1 One-Touch Tare, Tare Unknown

1. If the tare weight value is not known, place the container, box, or item to be tared on the scale and press

TARE. The weight display should now show 0 and the Net annunciator should illuminate.

2. Remove the container, box, or item from the scale. The weight display should show a negative weight

value (weight of the tared container, box, or item).

3. To clear the tare weight, press TAR E. The Net annunciator will no longer be illuminated.

TARE

5.2.2 Digital Tare, Tare Weight Known

1. If the tare weight value is known, use the numeric keypad to key in the value and then press TA RE . The

Net annunciator will illuminate.

2. To reset the tare to zero, press TA RE again.

Note: For digital tare entry, the decimal must be in the appropriate place as it would be displayed in the weight display. For

example, .250 would be entered as 0.250, not .250. The weight display shows weight entered with a negative sign indicating that

it is a tare weight.

Scale Operations 29

Page 34

5.2.3 Tare Addition or Subtraction

Two tares can be accumulated or subtracted using the TARE key as well. Tare weights cannot be accumulated or

subtracted by digital entry, although you can do tare exchange by digital entry (

Notes:

• SPEC 620 TARE RANGE must be set to the appropriate tare range value. Default is “0: 100 PERCENT OF FULL SCALE”.

• SPEC 621 DIGITAL TARE SETTING must be set to “1: ENABLE” to allow digital tare

• SPEC 622 DIGITAL TARE ACCUMULATION must be set to “1: YES” to enable these functions.

• S PEC 62 3 DIG I TAL TAR E WHEN LOAD ED, SPEC 624 TARE SUBTRACTION FOR LOAD TARE ONLY, SPEC 625 TARE

ADDITION FOR LOAD TARE ONLY, and SPEC 626 TARE VALUE EXCHANGE (FOR LOAD TARE) must all be set to 0:ALLOW or

YES to enable these functions.

Tare Value Addition or Subtraction by One Touch Tare

Section 5.2.4)

1. Place the container, box or item to be tared on the platform and press the TARE key. The weight display

should now show

0 and the net annunciator will illuminate.

2. Place another tare weight on the platform and press the TA RE key again. This will add the two tare

weights together (Tare Addition).

3. Tare weights can be subtracted individually by removing one from the platform and pressing the TA RE

key again. To clear all the tare weights and return to the Operation Mode, remove all the tare weights and

press the TARE key. The net annuciator will no longer be lit.

5.2.4 Tare Exchange

A tare weight that has been stored in the scale, either by digital entry or one-touch using the TAR E key, can be

changed during the operation mode. The new tare entered will overwrite the previous tare.

1. Remove any bin or container from the scale.

2. If the tare weight value is known, use the numeric keypad to key in the value and then press TA RE . The

weight display will now show the new tare as a negative number and the NET annunciator will

illuminate.

If the tare weight value is not known, put the container to be tared out on the platter and press the TAR E

key. The new tare will be entered, the weight display will show 0.000 lb and the NET annunciator will

illuminate.

5.3 Toggling Between Gross and Net

To toggle between net and gross weight, a tare value must be entered into the scale. Follow Section 5.2 to enter a

tare value.

Note: SPEC 643 GROSS MODE DISPLAY must be set to 0: YES (which is the default) to enable gross mode.

After a tare value is entered into the scale, items placed on the scale will cause the net annunciator to illuminate

and allow toggling between net weight and gross weight. An example of toggling between net weight and gross

weight is shown below:

1. Place 0.5 lb weight on the scale and then press TARE once. The weight display should show 0.000 lb.

2. Place another 0.5 lb weight on the scale. The scale weight display should now show 0.500 and the net

annunciator should be illuminated.

3. Press the NET/GROSS key. The weight display should show 1.000 GROSS WEIGHT, the net annunciator

will no longer be illuminated. The unit weight and the quantity displays go blank.

4. Press the NET/GROSS key. The weight display should now show 0.500 and the net weight annunciator is

illuminated again.

30 DC-100 Operation Manual

Page 35

5.4 Entering Unit Weights

Entering unit weights can be done either by sampling, as presented in Section 5.4.1, or by key entry as described

in Section 5.4.2.

Note: SPEC 03 EXTENT OF INSUFFICIENT SAMPLES controls unit weight sampling. The default setting for the SPEC is 0.1

percent.

Note: SPEC 63 SAMPLE QUANTITY determines the number of peices the scale assumes are on the platter when you press the

PIECES key to calculate the unit weight. The default setting for the SPEC is 0: 10 pieces.

Note: SPEC 64 SCALE A <–> B sets whether the unit weight determined by sampling is automatically transferred from Scale A

to Scale B. The default setting for the SPEC is 0: MANUAL.

When you have a procedure that involves sampling an item’s unit weight on the DC-100’s built-in platform and then want to go

immediately to weighing and counting boxes or bins on a floor scale or other external scale, set SPEC 64 to 1: AUTO. If the

external Scale B is not necessarily going to be used for weighing the same item as is being sampled on Scale A, set SPEC 64 to

0: MANUAL.

Note: SPEC 65 UNIT OF PCS WT controls whether the unit weight is displayed per 1000 pieces or per 1 piece. The default

settings for this SPEC is 0: 1000 pieces.

Unit Weight per 1000 Pieces vs. Unit Weight per 1 Piece

The scale’s internal microprocessor calculates unit weights to 7 or 8 decimal places. However, the scale display

generally can only show Unit Weight to 5 characters. If this Unit Weight is recorded from the scale display and

entered by key entry, this can introduce errors in the Unit Weight and consequently in the counts. This error

increases as the Unit Weight of the parts being counted decreases.

Example: A sample of 10 zener diodes is placed on the scale. The Unit Weight is computed to be 0.0006536 lbs.

However, the scale has a 5 character display for Unit Weight so the scale can only display .0065 as the Unit

Weight. If this Unit Weight were recorded and keyboard entered in future counting operations, the resulting error

would be: 00065 .55%

.0006536

On the other hand, with entry of the Unit Weight as “weight per 1000 pieces” the decimal place is, in effect,

moved three places to the right, allowing 3 more decimal places of accuracy. In this example, the entry would be

made as 0.6536 per 1000 pieces, eliminating the error.

As a practical note, entering unit weights per 1000 pieces also lessens the chances of entering the wrong number

of zeros when keying in weights with many leading zeros. Misentry of unit weights is a common cause of

inaccurate counting.

When might you want to use unit weight per 1 piece? Generally in one of two cases:

1. If you are working with other existing systems or procedures that are already set up to record unit weight

per piece (inventory systems, labeling requirements, etc).

2. If the unit weight or your pieces is more than 100 lbs, the number of digits in the scale’s Quantity display

will not be able to fully display counts of omore than 100 pieces.

=

5.4.1 Unit Weight Operation by Sampling

Unit weight operation by sampling is accomplished by placing a 10 piece sample on the scale and then pressing

PIECES key. The scale calculates a unit weight based on the capacity of the scale compared to the weight of

the

the sample. The following paragraphs detail the procedure with SPEC 7 - UNIT WEIGHT

AUTO-RECOMPUTING either set at 0 or 1.

SPEC 7 - Unit Weight Auto-Recomputing Set to “0: No” (Default)

1. Press REZERO to zero scale.

2. Place 10 pieces of the item to be sampled on the scale.

3. Press PIECES key. If the sample weight is sufficient (INSUFF annunciator is off), the display shows a unit

weight for 10 pieces. However, if the weight of the sample is insufficient (

display will show

---ADD XX PIECES. Add the indicated number of pieces to the initial sample and then

press the PIECES key again.

4. The display shows the total weight, unit weight and the quantity of the sample.

INSUFF annunciator is on) the

Scale Operations 31

Page 36

SPEC 7 - Unit Weight Auto-Recomputing Set to “1: Yes”

1. Press REZERO key to zero scale.

2. Place 10 pieces of the item to be sampled on the scale.

3. Press the PIECES key. If the weight of the sample is sufficient (INSUFF annunciator is off), the display

shows a unit weight for 10 pieces. However, if the weight of the sample is insufficient (

INSUFF

annunciator is on) the display will show ---ADD XX PIECES. Add the indicated number of pieces to the

initial sample. The display then automatically recomputes the sample size and displays the unit weight

and quantity of the sample.

5.4.2 Unit Weight Operation by Key Entry

Unit weight operation by key entry is accomplished by using the numeric keypad to enter the known value of the

unit weight and then pressing the

UNIT WEIGHT key. An example of unit weight operation by key entry is shown

below:

1. With the display in the weighing mode, enter the known unit weight using the keyboard, for example,

200.00.

2. Press UNIT WEIGHT key to enter the unit weight.

3. Place a 2 lb. weight on the scale. The scale displays the quantity for the weight placed on the scale, for

example, the weight display reads 2.000, the unit weight display reads 200.00, and the quantity display

reads 10).

32 DC-100 Operation Manual

Page 37

5.5 Part Accumulation and Negative Counting – Without Recalling an Item Code

The DC-100 counting scale is fully capable of part number inventory tracking and maintenance using the stored

item code function internal to the scale software.

on page 39. Additionally, the scale has the capability to acquire the total number of parts using the accumulation

or reduction function of the scale (similar to the add/ subtract functions of a calculator).

5.5.1 Part Accumulation

To find the total accumulated quantity of similar containers filled with parts, use the accumulation procedure

detailed below. This does not affect the inventory quantity for this item in the scale’s memory. To add or

subtract from inventory, (see Section 6.2.5).

1. Conduct a sampling process (Section 5.4.1) to determine the unit weight of the pieces.

2. Enter known tare weight, or place the empty container on scale to perform tare function (Section 5.2).

3. Place Container 1 (full of parts) on the scale.

4. Press the STATUS key. The IN annunciator will illuminate, showning that you are now in accumulation

mode.

5. Press the + key to store the total in Container 1. The memory annunciator S is now illuminated. The

weight display briefly shows

Note: If SPEC 31 PC/PRN OUTPUT is set to “2: BY +/-/PRINT KEY”, and you have an external printer connected, a label will be

printed when you press the + key. If no external printer is connected, the error message “PAPER END” will appear, followed by

the display of the total. The label will show the quantity in the container currently on the platform, not the accumulation. If SPEC

14 AUTO EXIT FROM ADD MODE is set to “0: NO”, the scale will not automatically exit from displaying the total amount. To

return to the weighing mode, press the CLEAR key.

totAL and the quantity display shows the total pieces in the first container.

6. Remove Container 1 and place Container 2 (full of parts) on the scale.

7. Press the + key (total is equal to Container 1 plus Container 2, etc).

8. Continue with the remainder of the containers to be counted. The total number of parts stored in all the

containers will be stored in the accumulation register.

9. To print a label in the default label format showing the total, press the * REPRINT key. This will also clear

the accumulation register. The memory annunciator

See “Inventory Operations Related to the Item Code Quantity”

S is no longer illuminated.

5.5.2 Negative Counting

Just as you can count by adding parts to the scale, you can also count by removing parts from the scale. This is

called “negative counting” because a negative weight is displayed while counting. Contrary to what may seem

intuitively logical, you do not use the (

-) key to do negative counting. The (-) key is only used to delete an entry

in accumulation mode that you want to erase. This procedure does not affect the inventory quantity for this item

stored in the scale. To reduce inventory,

See “Inventory Operations Related to the Item Code Quantity” on

page 39.

Note: To utilize the Negative Counting feature, SPEC 2 - NEGATIVE COUNTING must be set to “1: YES”.

There are two ways to do this depending on whether, at the end, you want to see the total amount remaining in

the container or the total amount removed from the container.

Counting Out of a Full Container - See Total Amount Remaining in the Container

To carry out this operation you must know the tare weight ahead of time.

1. Place the full container on the scale. Press the TARE key.

2. Remove a 10 piece sample from the container and press the PIECES key. After the unit weight has been

calculated, return the 10 piece sample to the container.

3. Remove a number of parts from the container and press the + key. The memory annunciator Σ

annunciator is illuminated and the display shows the quantity of parts taken out.

4. Remove a number of parts from the container and press the + key again. The memory annunciator Σ will

be illuminated and the display shows the quantity of parts removed.

5. If at the end of the procedure, if you want to see how many are still in the bin, you first have to know the

tare weight of the bin or container. After removing the parts you want to take out of the bin, simply

digitally enter the tare weight of the bin and press the

TARE key. The scale will display how many parts

were left in the bin. To print a label to put on the bin showing the new, lower, total quantity in the bin,

Scale Operations 33

Page 38

press the + key.

Note: If SPEC 14 AUTO EXIT FROM ADD MODE is set to “0: No”, the scale will not auto exit from displaying the total amount. To

return to the weighing mode, press the CLEAR key.

Negative Counting - Total Removed Displayed at the End

With this procedure you can count accurately out of a full container for kitting, shipping, etc. without having to

know the tare weight of the container.

1. Place a full container on the scale and press TARE .

2. Remove a 10 piece sample from the container and press PIECES. After the unit weight has been

calculated, return the 10 piece sample to the container.

3. Remove the number of pieces you need for kitting, shipping, etc. The amount removed will be displayed.

If you need a label for each kit or container, press the

press the

TARE key.

+ key after removing each batch of pieces. Then

4. When you have removed the last batch of pieces, press the * REPRINT key to show the total number of

pieces you have counted out of the full container.

5.5.3 Clearing Accumulated Data

To clear accumulated data, press the * REPRINT key.

5.6 Toggle Between Scales

To toggle between Scales A through D, press the SCALE key. The indicator lamp for the appropriate scale lights

on the display.

Pressing the SCALE key rotates the scales available for selection as follows:

Only scales present will be selected (i.e. A two-scale system switches between Scale A and Scale B only.) If no

external scales are connected, this function will not work.

5.7 Adding Parts To and Subtracting Parts From Inventory

The DC-100 is a self-contained inventory control system, capable of tracking and reporting on the stock,

threshold and movement of up to 2,000 items. In order to track the inventory of an item, it must first have been

programmed into the DC-100’s memory (

5.7.1 Adding Parts to Inventory

1. Key in the item ID Code and press the CODE key.

2. If the tare weight and unit weight have already been associated with the ID Code in memory, you can go

to step 4. Otherwise, key in the known tare weight or scan the tare weight from a barcode or put the

empty bin the scale and press the

3. If the unit weight has already been associated with the ID Code in memory, you can go to step 4.

Otherwise, place a sample of 10 pieces in the bin on the scale. For accuracy it is best to put the pieces in

the same bin used to find the tare weight in step 2. Press the PIECES key.

4. Either pour into the bin the remaining pieces to be added to inventory or, if the tare weight and unit

weight of the item were already programmed into the scale, put the full container on the scale. The

DC-100 will display the quantity, unit weight and total weight of the pieces in the container.

5. Press the STATUS key once. The IN annunciator will be illuminated on the display.

6. Press the * REPRINT key to add the count to inventory.

Note: If SPEC 31 - PC/PRN OUTPUT is set to “2: By +/-/PRINT KEY”, a label will print when you hit the * REPRINT key (and if

you have an external printer connected), showing the count for this particular container in the default label format or the label

format preprogrammed to be associated with this particular item.

Section 6.1.2 on page 36).

TARE key.

34 DC-100 Operation Manual

Page 39

5.7.2 Subtracting Parts From Inventory

1. Key in the item ID Code and press the CODE key.

2. If the tare weight and unit weight have already been associated with the ID Code in memory, you can go

to step 4. Otherwise, key in the known tare weight or scan the tare weight from a barcode or put the

empty bin on the scale and press the

TARE key.

3. If the unit weight has already been associated with the ID Code in memory, you can go to step 4.

Otherwise, place a sample of 10 pieces in the bin on the scale. For accuracy it is best to put the pieces in

the same bin used to find the tare weight in step 2. Press the PIECES key.

4. Either pour into the bin the remaining pieces to be added to inventory or, if the tare weight and unit

weight of the item were already programmed into the scale, put the full container on the scale. The

DC-100 will display the quantity, unit weight and total weight of the pieces in the container.

5. Press the STATUS key once. The OUT annunciator will be illuminated on the display.

6. Press the * REPRINT key to subtract the count from inventory.

Note: If SPEC 31 - PC/PRN OUTPUT is set to “2: By +/-/PRINT KEY”, a label will print when you hit the * REPRINT key (if you

have an external printer connected), showing the count for this particular container in the default label format or the label format

preprogrammed to be associated with this particular item.

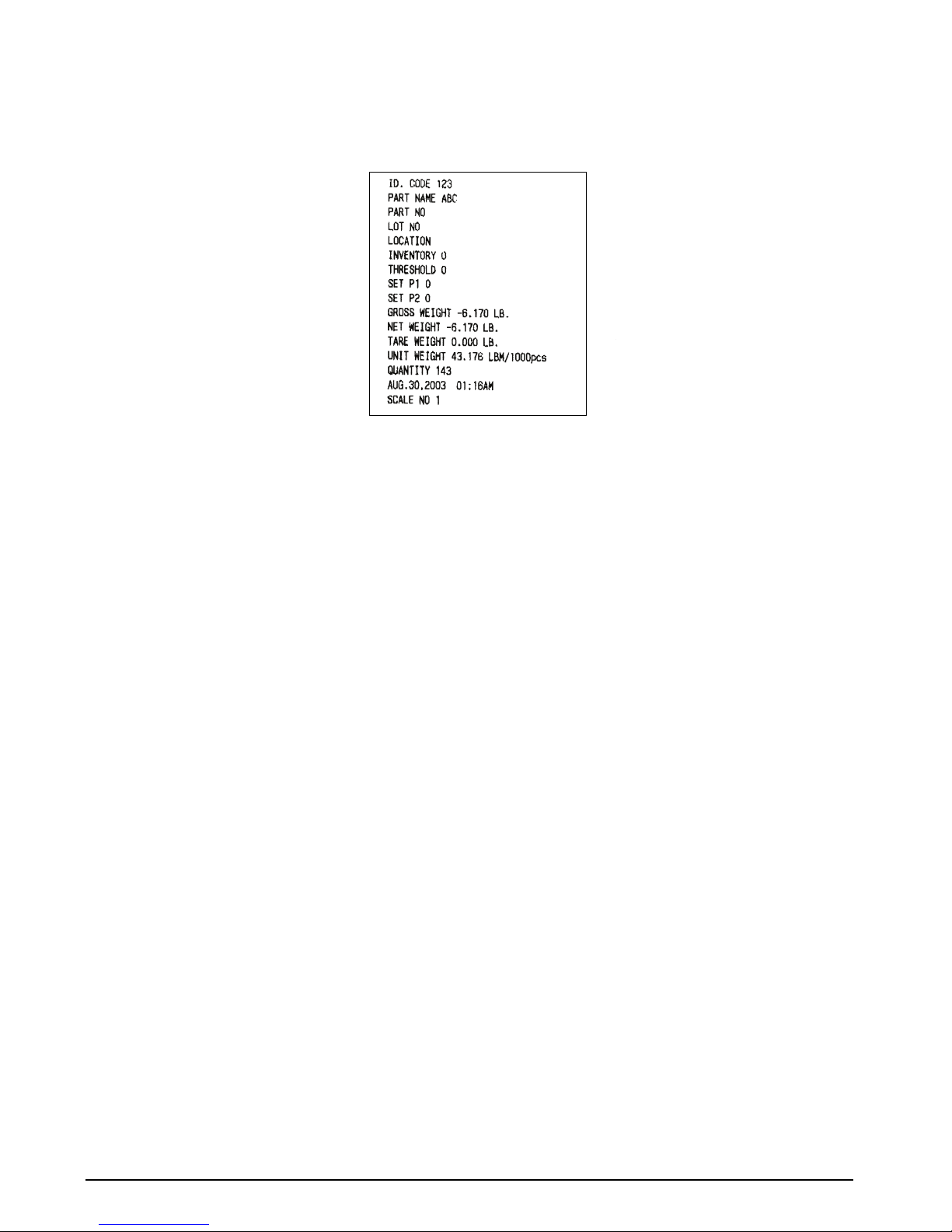

5.7.3 Sample, Count and Print a Label

Note: For this function to be used on the DC-100, an external printer must be connected to the scale.

1. Press the REZERO key to zero the weight display.

2. Place the empty bin on the scale and press the TARE key.

3. Place a 10 piece sample of the item in the bin and press the PIECES key. (For maximum accuracy, count