Page 1

Models 600 / 850

Series A - D Compressor Dehydrator

Instruction and operation manual

IB - 268 Rev. I Part Number 48248

Page 2

Notes, Cautions, and Warnings herein this manual

are used to prevent personal injury.

Warning: To reduce the risk of fire or electric shock, do not expose this equipment to rain or mois-

ture. For Indoor use only.

Warning: If the equipment is used in a manner not specified herein, the protection provided by the

equipment may be impaired.

Warning: Turn off Power, Isolate power by unplugging or by locking separate disconnect before

servicing.

Warning!: High Voltage Disconnect Power before working within

Caution: This Unit may start automatically at any time

NOTE: All machinery must be fitted with means to isolate it from electrical energy sources. The isola-

tor must be capable of being locked, when the operator is unable from any of the points to which

he/she has access, to check that the energy is off!

Caution: Use care when lifting compressor as compressor weight exceeds 12.3 lbs. ( 5.6 kg)

ATTENTION: Observe Precautions for Handling Electrostatic Sensitive Devices

Important Safety Instructions

1. Read and follow all instructions

2. Keep these instruction with the equipment

3. Heed all warnings, cautions and notes.

4. Do not block any ventilation openings.

5. Install in accordance with SPX Dielectric instructions

6. Do not defeat the safety purpose of the grounding type plug

7. Protect the power cord from being walked on or pinched.

8. Use Wrist Strap when handling ESD Sensitive Circuit Boards

WARNING! Risk of Electrocution

Isolate power by unplugging or by locking separate disconnect.

CAUTION - REFER TO ACCOMPANYING

WARNING - RISK OR ELECTROCUTION

WARNING - HOT SURFACE

DOCUMENTS

ATTE NTION - ELECTROSTATIC SENSITIVE

DEVICE

OBSERVE PRECAUTIONS FOR HANDLING

CAUTION - LIFTING HAZARD

PROTECTIVE CONDUCTOR TERMINAL

Page 3

TABLE I

TABLE OF CONTENTS

SECTION TITLE PAGE

1.0 INTRODUCTION 1

1.3 Before Installing 1

2.0 PRINCIPLE of OPERATION 1

3.0 SITE REQUIREMENTS 3

4.0 INSTALLATION 3

5.0 STARTUP OF THE MODEL 600 AND 850 3

6.0 ADJUSTMENTS 4

6.1 Outlet Pressure Regulator Adjustment 5

6.2 Back Pressure Regulator Adjustment 5

6.3 Outlet Pressure Alarm Switch Adjustment 5

6.4 Start / Stop Pressure switch Adjustment 5

7.0 MAINTENANCE 5

8.0 COMPRESSOR MAINTENANCE 6

9.0 TROUBLE SHOOTING 6

9.1 Outlet Air Pressure Alarm 6

9.2 Humidity Alarm 6

9.3 Excess Run Alarm 7

10.0 SERV ICE INFORMATION 7

LIST of TAB LES

TABLE DESCRIPTION PAGE

I TABLE OF CONTENTS i

II TABLE OF LEADING PARTICULARS ii

III MODEL 600 & 800 OPTION DESIGNATIONS iii

IV LIST OF COMMON SPARE PARTS 13

V LIST OF PARTS ON ALL MODELS 14

VI GLOSSARY OF TERMS 22

LIST OF ILLUSTRATIONS

FIGURE DESCRIPTION PAGE

1 DRY- PAK CYCLE 2

2 FLOW SCHEMATIC MODEL “A” DRYERS 8

3 FLOW SCHEMATIC MODEL “B” DRYERS 9

4 FLOW SCHEMATIC MODEL “C” & “D” DRYERS 10

5 FRONT VIEW 11

6 FRONT VIEW (COVER REMOVED) 11

7 SIDE VIEW (COVER REMOVED) 12

8 BACK VIEW 12

9 DESICCANT DRYER ASSY. 14

10 SOLENOID VALVE EXPLODED VIEW 15

11 COMPRESSOR - EXPLODED VIEW 15

12 “A” SERIES 115V WIRING SCHEMATIC 16

13 “A” SERIES 230V WIRING SCHEMATIC 17

14 “B” SERIES 115V WIRING SCHEMATIC 18

15 “B” SERIES 230V WIRING SCHEMATIC 19

16 “C & “D”” SERIES 115V WIRING SCHEMATIC 20

17 “C & “D”” SERIES 230V WIRING SCHEMATIC 21

i

Page 4

Tab le II

TABLE OF LEADING PARTICULARS

CHARACTERISTIC MODEL 600 A to D MODEL 850 A to D

NORMAL CAPACITY

EMERGENCY CAPACITY

WEIGHT

ELECTRICAL OPTIONS

AIR COMPRESSOR SIZE

COMPRESSOR CIRCUIT PROTECTION

CONTROL CIRCUIT PROTECTION

600 SCFD

750 SCFD

85 LBS

115VAC, 5.5A 50/60Hz 1ph

208-230VAC, 2.5A 60Hz 1ph

220-240VAC, 3.3A 60Hz 1ph

1/4 HP Piston

10 Amps(115V) 5 Amps(230V)

0.8 Amps(115V) 0.5 Amps(230V)

850 SCFD

1080 SCFD

85 LBS

115VAC, 6.5A 50/60Hz 1ph

208-230VAC, 2.7A 60Hz 1ph

220-240VAC, 3.5A 60Hz 1ph

1/4 HP Piston

10 Amps(115V) 5 Amps(230V)

0.8 Amps(115V) 0.5 Amps(230V)

DRY AIR DEWPOINT . . . . . . . . . . . . . . . .

DESICCANT DRYER TYPE . . . . . . . . . . .

OPERATING PRESSURE . . . . . . . . . . . . .

TANK PRESSURE RANGE . . . . . . . . . . .

AIR COMPRESSOR TYPE . . . . . . . . . . . .

REGULATED LINE PRESSURE . . . . . . .

HUMIDITY ALARM . . . . . . . . . . . . . . . . .

LOW LINE PRESSURE ALARM . . . . . . .

HIGH LINE PRESSURE ALARM . . . . . .

EXCESS RUN ALARM . . . . . . . . . . . . . . .

POWER ALARM . . . . . . . . . . . . . . . . . . . .

CABINET DIMENSIONS . . . . . . . . . . . . .

AIR TANK . . . . . . . . . . . . . . . . . . . . . . . . .

AIR TANK RELIEF VA LVE . . . . . . . . . . .

Below -40°F. (below -40°C.)

DRY-PAK® twin-tower heatless dryer. Efficient, internal check-ball valving, purge controlled by Four-way solenoid valves.

DRY-PAK® and compressor 45 PSIG (310 kPa), independent of tank pressure.

20 PSIG (137 kPa) (compressor start) to 45 PSIG (310 kPa) (compressor stop).

Piston oilless

Adjustable 2 TO 15 PSIG (14 - 103 kPa) on Models A,B, and C

Adjustable 0.1 TO 2.0 PSIG (0.7 - 14 kPa) on Models D

Color Change Humidity Indicator on Model A

Solid state Humistat on Models B,C, and D

Adjustable from 2 to 15 PSIG (14 - 103 kPa) on Models A, B, and C

Adjustable from 0.1 to 2.0 PSIG (.07 - 14 kPa) on Model D

Adjustable from 2 to 15 PSIG (14 - 103 kPa) on Models C

Adjustable from 0.1 to 2.0 PSIG on Model D

Solid state timer, fix set @ 10 min.

Active in event of service interruption, compressor or control-circuit breaker overload or

unit turned off manually.

H 15.5in. x W 17.5 in. x D 17.5 in. (39.3 cm x 44.5 cm x 44.5 cm)

0.37 cu/ft (10 L) - Mechanical 2nd agency rated

Pop-off 60-75 PSIG (413 - 517 kPa)

ii

Page 5

TABLE III

MODEL 600 / 850 OPTION DESIGNATIONS

OPTIONS ARE KEYED TO LAST LETTER OF MODEL DESIGNATION

LETTER

-A The output pressure regulator allows adjustment of the output pressure from 2 to 15 PSIG. This

unit comes equipped with a color-change Humidity Indicator, an adjustable Low Output Pressure Alarm, Power

Off Alarm, Power On indicator light, and Summary Alarm Terminal Board. Both “Closed in Alarm” and “Open

in Alarm” conditions can be monitored from the alarm terminal board.

-B The output pressure regulator allows adjustment of the output pressure from 2 to 15 PSIG. This

unit is equipped with an Electronic Humidity Alarm factory preset to alarm at 2% RH (-20° dew point). Other

standard features include an adjustable Low Output Pressure Alarm, and Power Off Alarm Power-On Indicator

Light and a Summary Alarm Terminal Board. Both “Closed in Alarm” and “Open in Alarm” conditions can be

monitored from the alarm terminal board.

-C The output pressure regulator allows adjustment of the output pressure from 2 to 15 PSIG.

This unit is equipped with an Electronic Humidity Alarm, factory preset to alarm at 2% RH (-20° dew point),

and a Humidity Bypass with automatic reset. Other standard features include an adjustable Low Output Pressure Alarm, adjustable High Output Pressure Alarm, Excessive Operation Alarm, and Power Off alarm. Front

Panel indicator lights provide confirmation of alarm status and a segregated Alarm Terminal Board provides

for remote recognition of 5 separate alarm conditions or a single “Summary” alarm condition. Both “Closed in

Alarm” and “Open in Alarm” conditions can be monitored from the alarm terminal board.

-D A precision low pressure regulator allows adjustment of the output pressure from 0.1 to 2.0

PSIG. This model is equipped with an Electronic humidity alarm, factory preset to alarm at 2% RH (-20° dew

point), and a Humidity Bypass with automatic reset. Other standard features include adjustable Low Output and

High Output Pressure Alarms, Excessive Operation Alarm, and Power Off Alarm. Front panel indicator lights

provide verification of alarm status and a Segregated Alarm Terminal Board provides remote recognition of

five separate alarm conditions or a single “Summary” alarm condition. Both “Closed in Alarm” and “Open in

Alarm” conditions can be monitored from the alarm terminal board.

iii

Page 6

1.0 INTRODUCTION

1.1.1 This manual covers installation, operation, and

maintenance of the Model 600 and 850 Series Compressor

Dehydrators. These units are capable of years of troublefree service when properly installed, operated and maintained.

1.1.2 The Model 600 and 850 air dryers from Dielectric

feature a reliable heatless dryer and a long life compressor well suited to high altitude operation. These models

benefit from more than 45 years of dehydrator design and

manufacturing experience, while incorporating the most

advanced and reliable components available today. Cabinet flow through forced air ventilation and sophisticated

vibration isolation optimize service life. Special consideration has been given to accessibility and ease of service, to

provide a versatile, full featured, yet cost effective pressurization package.

1.1.3 Equipment options: The Model 600 and 850 are offered in two voltage options with the 115V/50-60Hz being

standard. Each of these is available in any of four output/

alarm option groups. Each output/alarm option group is signified by a suffix letter (A through D) following the model

number. As an example: “Model 600 C, 115 VAC/60-50

HZ”, in which the “C” designates the output pressure range

and types of alarms included in the air dryer. A full description of electrical and output/alarm option groups is shown

in Table 3.

1.2 Before Installing

upon receipt and inspect the contents for hidden damage.

If damage is evident, promptly file a hidden damage claim

with the delivering transportation company.

2.0 PRINCIPAL OF OPERATION

2.1.1 Ambient airflows through the intake filter into

the compressor and is compressed to 45 PSIG operating

pressure, which is controlled by the adjustable back pressure regulator. The compressed air is cooled by the heat

exchanger which causes water droplets to form in the air

stream.

2.1.2 The cooled, compressed air is directed by the Dryer

Control Solenoid Va lve to either the left or right desiccant

tower of the dryer. Any water droplets are trapped at the

solenoid valve and do not enter the desiccant towers, where

gaseous moisture is absorbed by molecular sieve. A solid

state timer causes the Dryer Control Solenoid Va lve to alternate tower selection every thirty seconds of compressor

operation. Air leaving the dryer is at -40°F (-40°C) or lower

in dew point.

2.1.3 Air leaving the dryer passes through a Humidity

Sensor Block and back pressure regulator before entering

the dry air storage tank. Note: Humidity Sensor Block is

not on “A” models. On model “A” air passes through the

back pressure regulator and a humidity indicator located on

the front panel before entering the dry air storage tank. On

models “C” and “D” air flows through a Wet Air Bypass

Solenoid Valve before entering the dry air storage tank.

Moist air of 2% RH or more will be bypassed before storage of air.

1.2.1 READ THE MANUAL THOROUGHLY, then with

the manual as a reference, examine the air dryer. Learn to

recognize the various components and the full function

performed by each.

1.2.2 The installation environment can impact the performance and serviceability of the compressor/dehydrator, and

therefore, the performance and reliability of the systems

which it serves. Careful consideration should be given to

the parameters outlined in section 3.0 of this manual, so

that the best utilization of available space may be made.

1.3 Receiving

WARNING!

LIFTING HAZARD - This unit weighs 85 lbs. Use the

appropriate number of people to lift and position.

1.3.1 Shipping damage is unusual but not totally avoidable. Do not accept delivery of containers which show

shipping damage. Open acceptable containers immediately

2.1.4 Air pressure within the dry air storage tank is monitored by a gauge on the front panel and controlled by the

Start/Stop Pressure Switch. The pressure switch causes the

compressor to start when the tank pressure falls to 20 psig

and to stop when 45 psig is reached.

2.1.5 The dry air flows from the storage tank to the line

pressure regulator, which is adjustable from 2 to 15 psig.

The regulated pressure is indicated on the front panel Outlet Pressure Gauge and monitored by the Pressure Alarm

Switch or Switches. The dry, regulated air next flows to the

Dry Air Outlet. Note: All models are provided with a Low

Output Pressure Alarm Switch. A High Output Pressure

Alarm Switch is provided on “C” and “D” models. Note, on

“D” models the line pressure regulator is adjustable from

0.1 to 2.0 PSIG.

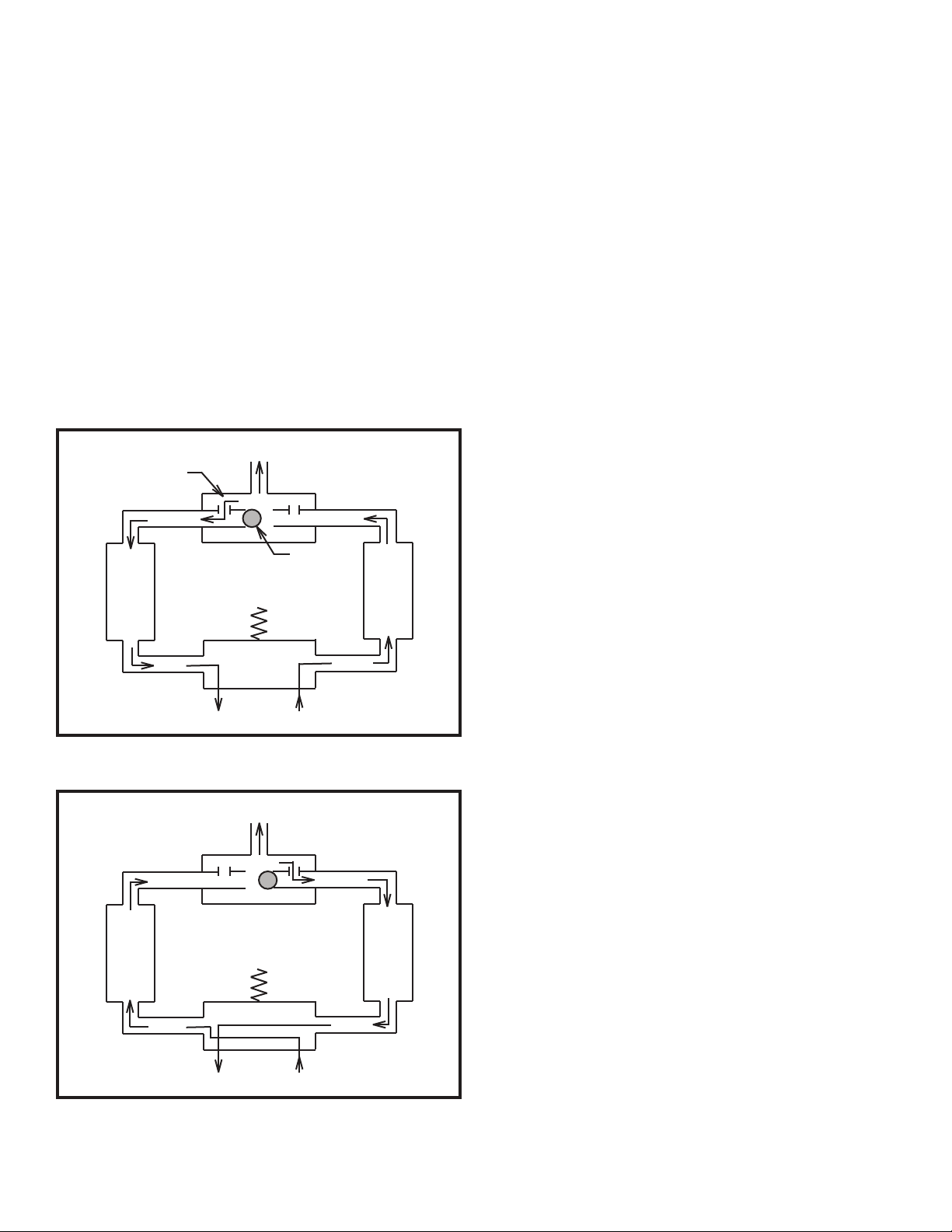

2.2 Operating Cycle Of The Desiccant Dryer

2.2.1 There are two phases of the one minute dryer cycle.

The cycle is interrupted when the compressor is not operat-

1

Page 7

ing and resumes when the compressor restarts. The cycle

is controlled by a solid state timer with a memory feature

which is active whenever the power is on.

The timer memory insures that the dryer cycle will resume

at exactly the point at which it was interrupted by the Start/

Stop Pressure Switch. This feature provides for a balanced

work load in the drying towers, regardless of the frequency

or duration of compressor operation.

PHASE ONE: Right desiccant tower is in dehydration

mode and left desiccant tower is in purge mode. Duration is

30 seconds for this phase.

The Dryer Control Solenoid Va lve is energized by the

timer, venting the left tower to atmosphere via the exhaust

port. Compressed air is directed to the right tower to be

dried. The ball check valve prevents higher pressure air

OUTPUT

C

in the right tower from flowing to the left tower. A small

portion of dry air from the right tower passes through a

purge control orifice and to the left tower, where it expands

at lower pressure. The expanded air picks up the moisture

deposited in the tower in the previous cycle and carries it

to atmosphere via the exhaust port of the Dryer Control

Solenoid Valve.

PHASE TWO: Left desiccant tower is in dehydration

mode and right desiccant tower is in purge mode. Duration

is 30 seconds for this phase.

The Dryer Control Solenoid Va lve is de-energized by the

timer, venting the right tower to atmosphere via the exhaust port. Compressed air is directed to the left tower to

be dried. The ball check valve prevents higher pressure air

in the left tower from flowing to the right tower. A small

portion of dry air from the left tower passes through a purge

control orifice to the right tower, where it expands at lower

pressure. The expanded air picks up the moisture deposited

in the tower in the previous cycle and carries it to atmosphere via the exhaust port of the Dryer Control Solenoid

Va l ve.

E

B A

D

CYL B

EXH IN

PHASE 1

OUTPUT

B A

D

CYL B

EXH IN

CYL A

CYL A

At the completion of phase two the cycle timer proceeds to

phase one, and so forth.

2.3 Alarms

2.3.1 Humidity Alarm

On the “A” model only a color change humidity indicator

is provided for visual indication of dry air. When indicator

is pink in color the outlet air is above 10% RH. When the

indicator is blue in color the outlet air is below 10% RH.

On the “B”, ”C” and “D” models a solid state humidistat

is provided that will alarm at 2% RH. The humidistat has a

test switch and two LEDs on the dryer option panel, which

provide a means of alarm verification. A glowing red LED

indicates a high humidity alarm. The amber LED indicates

an open circuit alarm. The humidity alarm function can be

tested by moving the test toggle lever, whether in test alarm

or test clear. A humidity alarm causes the alarm light to

glow and provides a dry contact short at the alarm terminal

board at the rear of the enclosure. On “C” and “D” models

a Wet Air Bypass Solenoid Va l ve will exhaust to the atmosphere when the humistat is in alarm.

2.3.2 Outlet Pressure Alarms

PHASE 2

Figure 2

Dry-Pak Dryer Cycle

On all models, an adjustable low outlet pressure alarm

switch, preset to close at 3.0 psig on decreasing pressure is

located on the dryer option panel. The alarm provides a dry

2

Page 8

contact short at the alarm terminal board at the rear of the

enclosure. Note: on “D” models preset at 0.2 psig. On “C”

and “D” models an adjustable high output pressure alarm

switch, preset to open at 11.0 psig on increasing pressure is

located on the dryer option panel. The alarm provides a dry

contact short at the alarm terminal board at the rear of the

enclosure. Note: on “D” models preset at 1.5 psig.

4.3 Provide a 3/8” o.d. tube from the user system, but

do not connect to the dehydrator Dry Air Outlet until performing step 5.5 below.

4.4 Be sure the front panel power switch is off and

connect the dehydrator power cord to an electrical outlet

which complies with the equipment nomenclature plate.

2.3.3 Excess Run Alarm

On “C” and “D” models a fixed ten minute timer will

provide an alarm if the unit runs for more then ten minutes

without the compressor being allowed to stop. The alarm

provides a dry contact short at the alarm terminal board at

the rear of the enclosure.

2.3.4 Power Failure Alarm

All models provide a power failure alarm at the terminal

board on the rear of the enclosure.

3.0 SITE REQUIREMENTS

3.1 The Models 600 and 850 require a firm, level surface with a minimum of 3” clearance at the rear and top for

ventilation. Provide space on the sides as well if possible,

so that the cover may be easily removed for yearly compressor servicing, without relocating the unit.

3.2 The site must not be subject to freezing or extremely high temperatures. The allowable temperature range for

operation is 33°F to 100°F. A reasonably clean location

with a temperature range of 60 to 90° F will enhance the

service life of the air dryer.

4.5 If the equipment is used in a manner not specified

by the manufacturer, the protection provided by this equipment may be impaired.

5.0 START-U P OF THE MODEL 600 and 850

WARNING!

RISK OF ELECTROCUTION - All machinery must be

fitted with a means to isolate it from electrical energy

sources. The isolator must be capable of being locked

where an operator is unable, from any of the points to

which he/she has access, to check that the energy is still

cut off!

5.1 Remove the front cover of the dehydrator. Turn on

the On/Off Power switch on the front panel. After the compressor has run for a minute, check the system back pressure regulator setting to assure that the system is operating

at 45 psig on the back pressure gauge. The regulator has a

locking adjusting knob. Pull the knob out carefully a 1/4

inch to unlock.

5.2 Turn the Outlet Pressure Regulator knob counterclockwise so that no air flows from the Dry Air Outlet. The

regulator has a locking adjusting knob. Pull the knob out

carefully a 1/4 inch to unlock.

3.3 Be sure to connect the power cord only to an

electrical outlet which complies with the electrical specifications of the dryer. The grounding of this equipment is

important and this product is not to be operated with

the ground bypassed. The power cord must be placed not

in an inaccessible manner, so that the power cord can be

used as a disconnect device. Check the nomenclature plate

on the front panel for the electrical characteristics. Units

powered by 230 VA C ,60/50 HZ. will require the addition of

an electrical plug purchased locally.

4.0 INSTALLATION

4.1 Mount the Model 600 or 860 per section 3.

4.2 Provide remove alarm wires for later connection to

the alarm terminal board on the rear of the enclosure. The

alarm circuit device must have its own power source (normally 24 or 48 volts DC).

5.3 Observe the Tan k Pressure Gauge on the front panel of the dehydrator. The compressor should stop when 45

psig is reached. Turn the Outlet Pressure Regulator clockwise until air flows from the Dry Air Outlet. The compressor should start to operate when the Tan k Pressure Gauge

reaches 20 psig. If the limits are more than 2 psig outside of

those specified, adjustment to the start/stop pressure switch

will be required. Refer to section 6.4

5.4 The air dryer may exhibit a higher than normal

moisture content when it is started after a period of inactivity. If high moisture content is evident, do not connect the

Dry Air Outlet fitting to the user system until corrective

action is taken as follows:

5.4.1 Models 600A and 850A only: An outlet air moisture indicator changes color to signify higher than normal

outlet air relative humidity. This indicator will be light pink

when moist, blue when dry. If the indicator is not blue,

adjust the Outlet Pressure Regulator so that outlet air flows

through the indicator and out the Dry Air Outlet fitting.

3

Page 9

Unlock the regulator and turn the knob clockwise to cause

maximum air flow through the outlet fitting to atmosphere.

Operation of several hours may be necessary in severe

cases, to restore the indicator to a blue color.

5.4.2 Models 600B and 850B only: This unit is equipped

with a solid state humistat. On the humistat, a red LED

indicates a humidity alarm when lit. If the outlet air relative humidity is above 2% the humistat will be in alarm. If

the humistat is showing a humidity alarm, adjust the Outlet

Pressure Regulator so that air is flowing out the Dry Air

Outlet fitting. Operation for an hour or more may be necessary in severe cases, to clear the humidity alarm.

5.4.3 Models 600C/D and 850C/D only: These units are

equipped with a solid state humistat. On the humistat, a red

LED indicates a humidity alarm when lit. A wet air bypass

solenoid valve operates automatically with the humistat

when in a humidity alarm. This prevents any moist air from

entering the storage tank. The tank pressure will increase

only after the humidity alarm has automatically cleared.

Operation for an hour or more may be necessary in severe

cases, to clear the humidity alarm.

5.4.4 All Models: If high humidity is indicated, but the

dryer is operational, the condition will clear itself after an

extended period of operation. Ignore any alarms which are

present at start up.

5.5 Connect a 3/8” plastic tube from the Dry Air Outlet

fitting on the rear of the enclosure to the user system. If

more then one system is to be supplied, the use of check

valves is recommended.

5.6 Alarm connection for Models A and B only: These

units are equipped with a three place terminal board on the

rear of the enclosure for remote alarm connection. Dry contact terminals with a five amp rating will send out a summary alarm in either “CLOSED IN ALARM” OR “OPEN

IN ALARM”. Connect one alarm wire to the board labeled

“COMMON” and select the manner of receiving the summary alarm either “CLOSE IN ALARM” or “OPEN IN

ALARM” and connect the other wire to the terminal board.

5.7 Alarm Connections for Models C and D only:

These units are equipped with a Segregated Alarm terminal board (located on the rear of the enclosure) for remote

alarm connection. Dry contact terminals having a five amp

rating are provided. The alarm terminals related to each

alarm function are labeled “COMMON”, “CLOSED IN

ALARM” and “OPEN IN ALARM”. There are four alarm

output wiring options available. Selection of an alarm output characteristic is made by positioning the jump wires on

the segregated alarm terminal board in one of the following

options.

5.7.1 Alarm output option 1 :

A summary closed in alarm remote warning that one or

more of the alarm circuits is active. To utilize this option

leave the terminal board configured as received from the

factory. Yel low jump wires connect “common” terminals in

series, blue jump wires connect “closed in alarm” terminals

in series. Connect your remote alarm pair to terminals #1

and #15.

5.7.2 Alarm output option 2 :

Segregated alarms using a single common provide discrete

indication of each alarm circuit, either closed in alarm or

open in alarm, but all at one potential. To utilize this option remove the blue jump wires from the terminal board,

leave the yellow jump wires that connect the commons in

series in place. Connect your remote alarm common wire

to terminal #1 and your remaining remote wires to selected

“CLOSED IN ALARM” or “OPEN IN ALARM” terminals

as you prefer.

5.7.3 Alarm output option 3 :

A summary open in alarm remote warning that one or more

of the circuits are active. To utilize this option move only

one end of each yellow jump wire from its location in a

“common” terminal to the adjacent “open in alarm” terminal as follows: yellow jump wire #1 to #4 becomes #2 to

#4 and move the remaining yellow jump wires to connect

#5 to #7, #8 to #10 and #11 to #13. Remove the blue jump

wires from the terminal board. Connect your remote alarm

pair to terminals #1 and #14.

5.7.4 Alarm output option 4:

A completely segregated alarm output wherein a separate

voltage or frequency may be used for any or each alarm

function. Remove both the yellow and blue jump wires

from the alarm terminal board. Connect your remote alarm

wires to each function terminal set to obtain “OPEN IN

ALARM” output as you prefer.

5.8 Make final verification of the outlet pressure

regulator adjustment and verify that the adjustment knob is

locked. This completes the start up procedure.

6.0 ADJUSTMENTS

6.1 Outlet Pressure Regulator Adjustment

6.1.1 The Outlet Pressure Regulator on the front panel

of models A, B and C has a locking adjuster knob. Carefully pull out the knob a 1/4 inch to unlock. Adjust the

regulator to the desired pressure, as shown on the Outlet

Pressure Gauge. Lock the regulator knob when adjustment

is complete. On “D” models the outlet pressure regulator

has a locking nut, after all outlet pressure adjustments are

made just tighten the nut with a 7/16 inch wrench.

4

Page 10

6.2 Back Pressure Regulator Adjustment

6.2.1 The Back Pressure Regulator which is located after

the dryer assembly has a locking adjuster knob. Carefully

pull out the knob a 1/4 inch to unlock. Adjust the regulator

to the desired operating pressure using the back pressure

gauge . Recommended back pressure for these dryer is 45

PSIG. Lock the regulator knob when adjustment is complete.

6.3 Outlet Pressure Alarm Switch Adjustment

6.3.1 Adjustment of the Outlet Pressure Alarm

Switch on all models is accomplished by removing the

front cover. Located on the dryer option panel that is

mounted on the tank, use a 1/8” flat blade screw driver to

turn the slotted plastic adjuster. Screw gently clockwise to

increase or counterclockwise to decrease the adjuster of the

low output pressure or high output pressure alarm switches.

Ve r ify the adjustment by decreasing and increasing the

outlet air pressure to activate and to deactivate the alarms.

6.4 Start / Stop Pressure Switch Adjustment

WARNING!

RISK OF ELECTROCUTION - Before performing this

procedure: Disconnect from the electrical power source.

Turn the dehydrator off and disconnect from the external

power source before performing the following procedures.

6.4.1 Before adjusting the start/stop pressure switch, observe the pressure shown on the Tan k Pressure Gauge when

the compressor starts and when it stops. Make note of the

amount of change required in psig to obtain the desired setting. The compressor should start at 20 psig and stop at 45

psig +/-2 psig.

6.4.2 The Start/Stop Pressure Switch can be accessed by

first removing the screws which retain the front cover and

the top cover.

6.4.3 Mounted on the storage tank in the center of the

unit. Remove the gray plastic pressure switch cover using a

5/16” wrench. Note the two adjuster nuts of the Start/Stop

Pressure Switch. The center adjuster controls the entire

range of the pressure switch. The side adjuster controls

only the stop pressure. TURN ONLY THE CENTER ADJUSTER.

6.4.4 Each full revolution of the adjuster nut changes the

range by 2 psig. Clockwise raises, counterclockwise lowers

the amount of differential or range. Use a 3/8” open end

wrench to reach the new stop pressure (the start pressure

changes also).

6.4.5 Connect the power cord to the electric outlet and

restart the dehydrator. Again check the Stop Pressure to

verify the Start/Stop Pressure Switch adjustment. If the

desired change is complete, turnoff the dehydrator, disconnect from the electrical power source, reinstall the pressure

switch cover. Install the top cover and front cover to the

dehydrator. Finally Reconnect the power and turn on the

panel power switch.

7.0 MAINTENANCE

7.1 At 6 month intervals verify that the dryer purges

every 30 seconds when the compressor is running.

7.1.1 Verify that the adjustment of the Start/Stop Pressure Switch is correct. The compressor should start when

tank pressure declines to 20 +/-2 psig and should stop at 45

+/-2 psig. If outside of this range, refer to section 6: ADJUSTMENTS.

7.1.2 Ve r ify the Outlet Pressure alarm switches by raising and then lowering the Outlet Pressure Regulator. Return

the regulator to the normal outlet pressure setting. If pressure settings need adjustment refer to section 6: ADJUSTMENT.

7.1.3 While operating at normal outlet pressure, verify

that the compressor does not run more than 70% of the

time. If operating time exceeds this limit check the inlet

filter element of the compressor to see if it is very dirty.

Replace the filter element if indicated. If excess operation

continues, check for leaks throughout the air system.

IF THE COMPRESSOR CONTINUES TO RUN MORE

THAN 70% OF THE TIME, PERFORM THIS TEST:

Turn the power switch off and let the tank pressure reach

0 psig as indicated by the Tan k Pressure Gauge. Turn the

outlet air regulator knob fully counterclockwise to prevent

outlet air flow. Turn the power switch on and measure the

time required to reach 15 psig tank pressure. A capable

compressor, absent any air leaks, should accomplish this in

two minutes or less when operating on 60 HZ current. With

50 HZ current the maximum time would be about three

minutes. If the unit takes longer than this, a compressor

overhaul may be required. Refer to section 8.0

7.2 After each twelve months of operation, again

perform maintenance outlined in section 7.1. Install a

compressor maintenance kit (refer to compressor exploded

view fig 8) and to section 8.0 COMPRESSOR MAINTENANCE.

7.3 It is recommended that the Purge Valve be serviced

after 12 months of operation and performed at the same

5

Page 11

time as the Compressor Maintenance. Reference Purge

Va l ve Repair Kit P/N 46037.(fig 10) See manufacture’s

instructions provided with repair kit.

7.4 After 24 months, it is recommended that the Humidty

Sensor , Plug and Gasket be changed out. (Model Ve rsions

B, C, and D) . With the unit shut off , using the Test Valve,

Relieve the pressure from the Humidity Manifold until the

gauge show zero. Disconnect the Electrical Connector and

remove the Nut. Pull out the Humidly plug with the Sensor

attached. Replace with new Sensor Plug and Gasket and

secure with Nut finger tight and reattached connector. (see

fig 7)

7.5 After 24 months , it is recommended to replace the

Humidity Bypass Solenoid Va lve. ( Model Ve rsions C and

D only) With the Unit Shut off and Power Cord Disconnected, remove the 3 Electrical Connections ( note where

the Green Wire ground is connected ) . Remove the two

tubes by pressing in on the Collar and pulling the ¼ inch

tubing straight out of the fitting. Remove the two ¼-20

Phillip Head screws holding the mounting plate to the Tan k

Bracket. Pull the panel away from the tank and remove the

two M5 Phillip head screw holding the Bypass Va lve. Note

the positioning of the #1 and #2 Ports. Remove the fittings

and reinstall in the new Va lve. Reattached the Val ve to

the plate with #2 Port on the left side then reassembly in

reverse order.

8.0 COMPRESSOR MAINTENANCE.

(see manufacture’s instructions provided with service kit)

NOTE

Do not lubricate the compressor. Do not allow petroleum

products, caustics or solvents to contact any part of the

compressor. Parts may be cleaned with soap and water

followed by wiping down with a dampened cloth.

WARNING!

RISK OF ELECTROCUTION - Before performing this

procedure: Disconnect from electrical power source.

WARNING!

RISK OF BURNS - Normal compressor operation will

cause head temperature to exceed 212 °F (100 °C). Be

careful when handling a hot compressor.

8.1 When replacing the compressor air filter, first remove the outer cap from the filter housing, discard the old

filter and clean the housing with a rag. Install the new filter

and replace the cap.

8.2 DISASSEMBLY: It is not necessary to remove

the filter from the cylinder head as metal chips could be

dislodged and enter the unit. Remove the shroud, cylinder

head, and valve components. Do not rearrange the valve

components. Remove the cylinder and rings. Make sure

all parts are clean before reassembling. DO NOT use any

chlorinated solvents to clean valves, or any liquids to

flush units. THE STAINLESS STEEL VALVE S MAY BE

CLEANED WITH WAT E R. All parts, except the valves,

can be cleaned with any industrial, nonflammable, nontoxic, cleaning solvent.

8.3 ASSEMBLY: Install piston seals, piston rings, and

rider rings on the piston. Locate ring joints approximately

opposite each other. Attach cylinder to bracket with the

cylinder screws and lock washers. Tighten screws finger

tight. Move pistons to top dead center position. Adjust

cylinder flush with top of piston and torque cylinder screws

to 150-160 in. lbs. Tor que second time. Stack the valve

components in order as shown in figure 8. Install the cylinder head, lock washers, and head screws. The exhaust ports

in the cylinder head have been marked by omitting the ends

of two fins. Tor que head screws to 150-160 in.-lbs. Tor que

head screws again after running for 10 minutes.

9.0 TROUBLE SHOOTING

9.1 Outlet Air Pressure Alarm

Be sure the Outlet Pressure Gauge indicates the desired

pressure. If the gauge reliability is in question, it can be

verified by connecting a test gauge to the test valve labeled

line pressure, on the control panel. Replace the gauge if

indicated. The line pressure alarm switches are labeled.

For outlet pressure alarm switch adjustment refer to section 6.3.

9.2 Humidity Alarm

A list of conditions which can cause a high humidity alarm

(a Humidity Alarm on models with suffix B, C and D) and

the order in which to proceed follows:

a: Faulty alarm circuit (9.2.1)

b: Dryer not cycling (9.2.2)

c: Plugged purge outlet (9.2.3)

d: Low Back Pressure (9.2.4)

e: Infrequent operation (9.2.5)

f: High temperature (9.2.6)

g: Desiccant towers (9.2.7)

h: Needs time to clear (9.2.8)

NOTE: Model 600A and 850A are equipped with a color

change moisture indicator. If excessive outlet air moisture

is indicated (pink in color ) proceed to section 9.2.2.

9.2.1 Humidistat Operational Tes t

9.2.1.1 Excessive moisture will cause the Alarm Light on

the control panel to glow. Determine which LED on the

6

Page 12

humidistat is lit, amber or red.

9.2.8 Dry-Down After Repair

9.2.1.2 If the humidity alarm is active and the amber

LED is lit, VERIFY THE ALARM by moving the test

toggle to “Test Clear”. If this action clears the alarm

temporarily, the humidistat is working properly and there

is an open condition in the sensor circuit. Check for a

loose connection between the humidistat and sensor. If

connections are ok, the sensor itself has an open circuit

and must be replaced. If the test toggle will not temporarily clear the amber LED when it is lit, replace the

humidistat.

9.2.1.3 If the humidity alarm is active and the red LED

is lit: VERIFY THE ALARM by moving the test toggle

to “Test Clear”. If this action clears the alarm temporarily, the humidistat is working properly. Perform the

corrective action indicated in the following paragraphs.

If all operational checks reveal no reason for the alarm

condition, but the alarm persists, replace the sensing element.

9.2.2 If the dryer does not cycle (does not purge audibly each 30 seconds of compressor operation), replace

the dryer solenoid valve. If the condition persists, replace

the cycle timer.

9.2.3 A restricted exhaust port on the dryer solenoid

valve can cause excessive pressure in the desiccant towers while purging. This can cause a humidity condition.

Be sure that the exhaust port is not plugged.

9.2.4 If the system back pressure setting falls below

43 psig. re-adjust the back pressure setting to the correct

setting of 45 psig +/-2 psig.

9.2.5 If the user system requires so little air that the

compressor operates less frequently than once each 45

minutes, it is recommended that an external fixed air

leak is added to the unit. This leak will allow the unit to

operate more frequently.

9.2.6 Be sure that the dehydrator is not located where

the temperature rises above 100° F.

9.2.7 The desiccant used in the drying towers is

molecular sieve, which has a normal useful life equal

to the dehydrator. Reduced service life can occur due

to air borne contaminants (hydrocarbons, acids etc.)

which may plug or degrade the desiccant. This is seldom

the cause of a high humidity condition, but if all other

possible causes for a high humidity condition have been

ruled out, and especially after years of service, replacement of the desiccant towers is indicated.

If a malfunction of the timer, dryer solenoid valve or a low

back pressure setting caused a humidity condition, the unit

must operate after repairs are completed for about an hour

in order to dry the desiccant towers and clear the humidity

alarm. If (not applicable to models with suffix A) a defective sensor element was the cause of alarm, it will normally

clear after 15 minutes of operation or less with a new sensor in place.

9.3 Excess Run Alarm

Check the duration of time the compressor starts to when

it stops. This time should be less than seven (7) minutes

without any short-term humidity problem. If the duration

of time is higher than seven minutes check for any air leaks

within the unit and outlet fitting. Check the user system for

higher than normal flow requirements. If the unit has no air

leaks or high flow requirements and the excess run alarm

clears after restarting the unit, a compressor overhaul kit

should be installed. If the excess run alarm does not cause

an alarm after eleven minutes of compressor run time replace the excess run timer. If the excess run alarm does not

clear or is in alarm after less than ten minutes of run time,

replace the excess run timer. The excess run timer should

be 10 minutes +/- 2 minutes.

10.0 Service Information

Should you need to contact us please call our Customer

service department on (207) 655-8525 or Tol l Free at (877)

247-3797

When returning a unit for factory service, Call the customer service department for a service return authorization

number (SRA). The device should be boxed securely and

contain contact information, contact telephone number, billing information, and return shipping information. If device

is being sent to the factory for service, a written statement

of the problem of symptoms should be included. The SRA

number must be on the outside of the package or indicated

on the shipping label.

NOTE: Do not ship equipment contaminated with any type

of hazardous/harmful substance.

SPX Dielectric

28 Tower Road, Raymond Maine. 04071

Phone (207) 655-8525 Toll Free: (877) 247-3797 Fax:

(207) 655-8535

Email: rd.sales.us@spx.com

7

Page 13

15

TP

14

TP

13

12

1

2

3

10

7

11

4

9

8

5

6

COMPONENT LIST

1. Intake Filter 8. Color Change Humidity Indicator

2. Compressor 9. Air Storage Tank

3. Heat Exchanger 10. Stop / Start Pressure Switch

4. Purge Solenoid Val ve 11. Tank Pressure Gauge

5. Dryer Assembly 12. Outlet Pressure Regulator

6. Back Pressure Regulator 13. Outlet Pressure Gauge

7. Back Pressure Gauge 14. Low Outlet Pressure Alarm

15. Outlet Air Fitting

Figure 2

Flow Schematic for Model “A” Dryers

8

Page 14

16

TP

15

TP

14

13

1

2

3

11

9

5

10

8

7

6

12

4

COMPONENT LIST

1. Intake Filter

2. Compressor 10. Air Storage Tank

3. Heat Exchanger 11. Stop / Start Pressure Switch

4. Purge Solenoid Val ve 12. Tank Pressure Gauge

5. Dryer Assembly 13. Outlet Pressure Regulator

6. Humidity Sensor Manifold 14. Outlet Pressure Gauge

7. Humidity Sensing Element 15. Low Outlet Pressure Alarm

8. Back Pressure Regulator 16. Outlet Air Fitting

9. Back Pressure Gauge

Figure 3

Flow Schematic for Model “B” Dryers

9

Page 15

16

18

TP

17

TP

15

14

1

2

3

13

4

12

9

11

10

5

8

7

6

COMPONENT LIST

1. Intake Filter 10. Humidity Bypass Valve

2. Compressor 11. Air Storage Tank

3. Heat Exchanger 12. Stop / Start Pressure Switch

4. Purge Solenoid Val ve 13. Tank Pressure Gauge

5. Dryer Assembly 14. Outlet Pressure Regulator

6. Humidity Sensor Manifold 15. Outlet Pressure Gauge

7. Humidity Sensing Element 16. High Output Pressure Alarm

8. Back Pressure Regulator 17. Low Outlet Pressure Alarm

9. Back Pressure Gauge 18. Outlet Air Fitting

Figure 4

Flow Schematic for Model “C & “D”” Dryers

10

Page 16

21,22

9

7

6

6

8

3

4

16

13

5

Figure 5

Front View

17

27

15

31

32

30

Figure 6

Front View (Cover removed)

11

Page 17

33

34

35

36

9

10

11

19

23

2

18

1

28

27

20

12

Figure 7

Side View (Cover removed)

26

24, 25

Figure 8

Back View

12

Strip insulation off wire

Insert tip of screwdriver blade

Push down and insert wire the release

Page 18

TABLE IV

LIST OF COMMON SPARE PARTS

ITEM NO. DESCRIPTION QTY. PART NO.

1. Spare 600 Compressor 115Vac 1 48163

Spare 600 Compressor 230Vac 1 48164

Spare 850 Compressor 115Vac 1 48165

Spare 850 Compressor 230Vac 1 48166

1a. Compressor Service Kit for 600 and 850 models 0046789501

2. Storage tank 1 39530

3. Line Pressure Gauge (A, B and C) 1 0017221016

Line Pressure Gauge (D only) 1 41776

4. Tank Pressure Gauge 1 0017221018

5. Circuit Breaker 115Vac 1 13281

Circuit Breaker 230Vac 1 30172

6. Power On Light 115Vac 1 13226

Power On Light 230Vac 1 41136

7. Alarms Light 115Vac 1-3 13225

Alarms Light 230Vac 1-3 41135

8. Line Regulator (A,B and C) 1 40328

Line Regulator (D only) 1 10814

9. Test Valves 3 0017495001

10. Back Pressure Regulator 1 0020523003

11. Back Pressure Gauge 1 0017221028

12. Cabinet feet 4 39959

13. Relay 115Vac 1-3 14126

Relay 230Vac 1-3 14127

14. Compressor contactor 115Vac 1 47052

Compressor contactor 230Vac 1 47053

15. Outlet Alarm Pressure Switch (on A, B and C ) 46752

Outlet Alarm Pressure Switch (on D only) 46753

15A Barb Fitting (part of switch) 1 36696

15B Gasket (part of switch) 1 40679

16. Solid State Timer 115Vac 1 48540

Solid State Timer 230Vac 1 48541

17. Start/Stop Pressure Switch 1 0060353003

18. Spare (complete) Dryer Solenoid Va l ve 115Vac 1 48178

Spare (complete) Dryer Solenoid Va l ve 230Vac 1 48179

18A Spare Dryer Solenoid Coil 115Vac 1 0019525001

Spare Dryer Solenoid Coil 230Vac 1 0019525002

18B Repair Kit Solenoid Val ve 1 46037

19. Spare Complete 600 Dryer 1 48169

Spare Complete 850 Dryer 1 48170

20. Spare Power Cord 115Vac 1 48172

Spare Power Cord 230Vac 1 67452

21. Fuse Holder 2/3 48061

22. Fuse .8 amp for 115Vac 52528

Fuse 1/2 amp for 230Vac 43803

23. Spare Heat Exchanger Assy. 1 48174

24. Alarm Terminal Block 0060192006

25. Alarm Terminal end 0060192005

26. Outlet Fitting 1 0016853013

27. Ventilation Fan 115Vac 1 39957

Ventilation Fan 230Vac 1 35066

28. Shock Mounts 4 44390

13

Page 19

TABLE V

LIST OF PARTS ON ALL MODELS

LIST OF PARTS ON MODEL A

ITEM NO. DESCRIPTION QTY. PART NO.

29. Humidity Indicator 1 39962

LIST OF PARTS ON MODELS C AND D

ITEM NO. DESCRIPTION QTY. PART NO.

30. Excess Run Timer 115Vac 1 17107

Excess Run Timer 230Vac 1 33384

31. 3 Way Bypass Solenoid Va l ve 115Vac 1 39984

3 Way Bypass Solenoid Va l ve 230Vac 1 34724

LIST OF PARTS ON MODELS B, C AND D

ITEM NO. DESCRIPTION QTY. PART NO.

32. Humidistat 1 14701

33. Humidity Sensor Element 1 15688

34. Humidity Sensor Shield 1 30986

35. Gasket 1 89795

PARTS LIST FOR DESICCANT DRYER

ITEM PART NO. DESCRIPTION

REF. 48169 DESICCANT DRYER ASSY, MODEL 600

REF. 48170 DESICCANT DRYER ASSY, MODEL 850

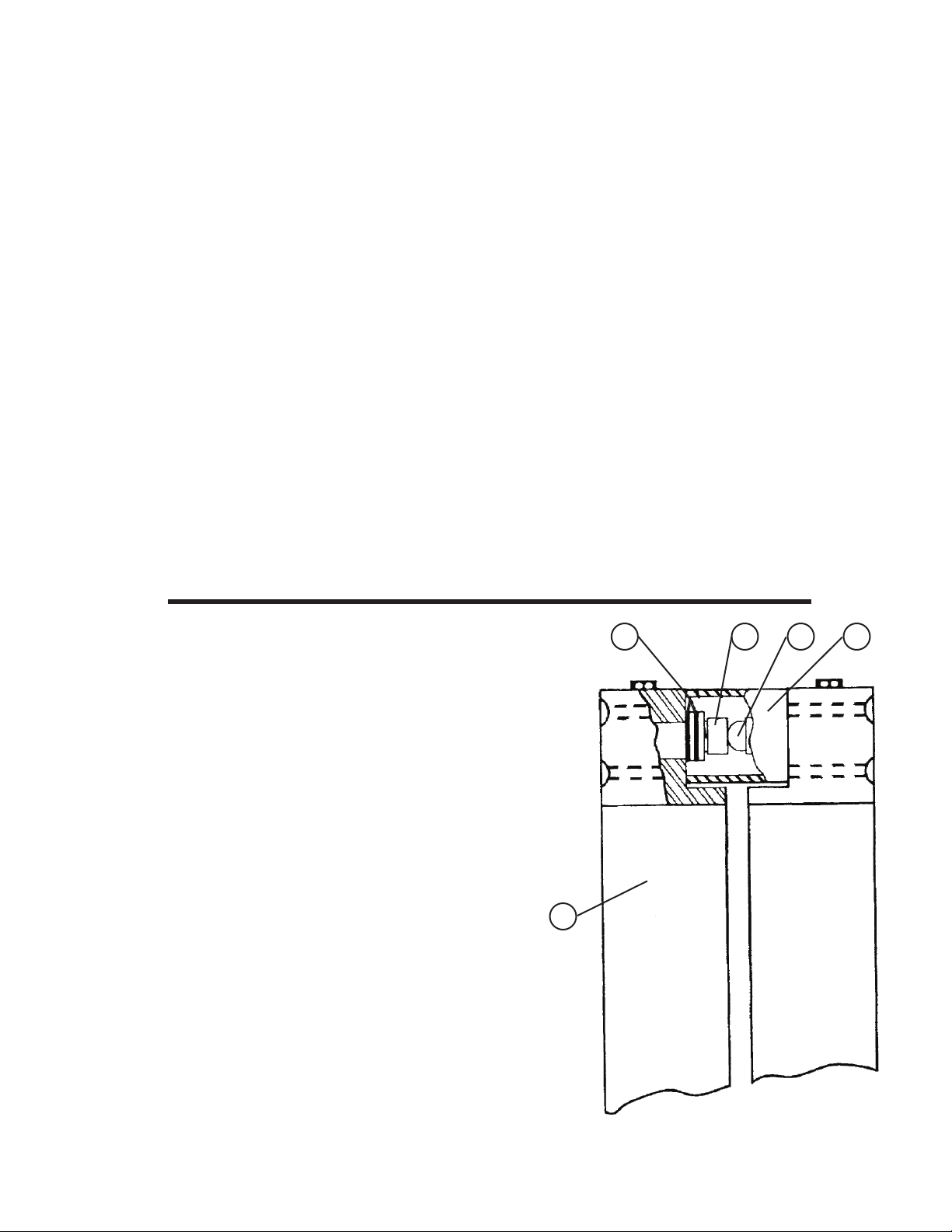

1. 47728 MODEL 600 & 850 DESICCANT CHAMBER

2. 47725 CENTER MANIFOLD BLOCK

3. 41548 BALL SEAT MODEL 600

3a 104292 BALL SEAT MODEL 850

4. 0015903005 BALL CHECK

5. 0014000017 O-RING SEAL

5 3 4

1

2

14

Figure 9

Desiccant Dryer Assembly

Page 20

Figure 10

Solenoid Valve- Exploded View

List of Compressor Parts

Ref. No. Description Qty

1 Filter Muffler Element 1

2* FilterFelt 1

3 Safety Val ve 1

4 Cylinder Feed 1

5* Head Gasket 1

6* Valve, Outlet 1

7 Valve Plate 1

8* Valve, Inlet 1

9* Cylinder Gasket 1

10 Cylinder 1

11* Piston Ring 2

12* Piston Seal 2

13* Rider Ring 1

Figure 11

Compressor - Exploded View

14 Piston Rod Assy 1

15 Counter Weights 1

16 Flat Key 1

17 Fan 1

18 Shroud 1

Dots(*) indicate items contained in Service kit

Use service kit P/N 46789-501 for Models 600 & 850

15

Page 21

Figure 12

“A” Series, 115V Wiring Schematic

16

Page 22

Figure 13

“A” Series, 230V Wiring Schematic

17

Page 23

Figure 14

“B” Series, 115V Wiring Schematic

18

Page 24

Figure 15

“B” Series, 230V Wiring Schematic

19

Page 25

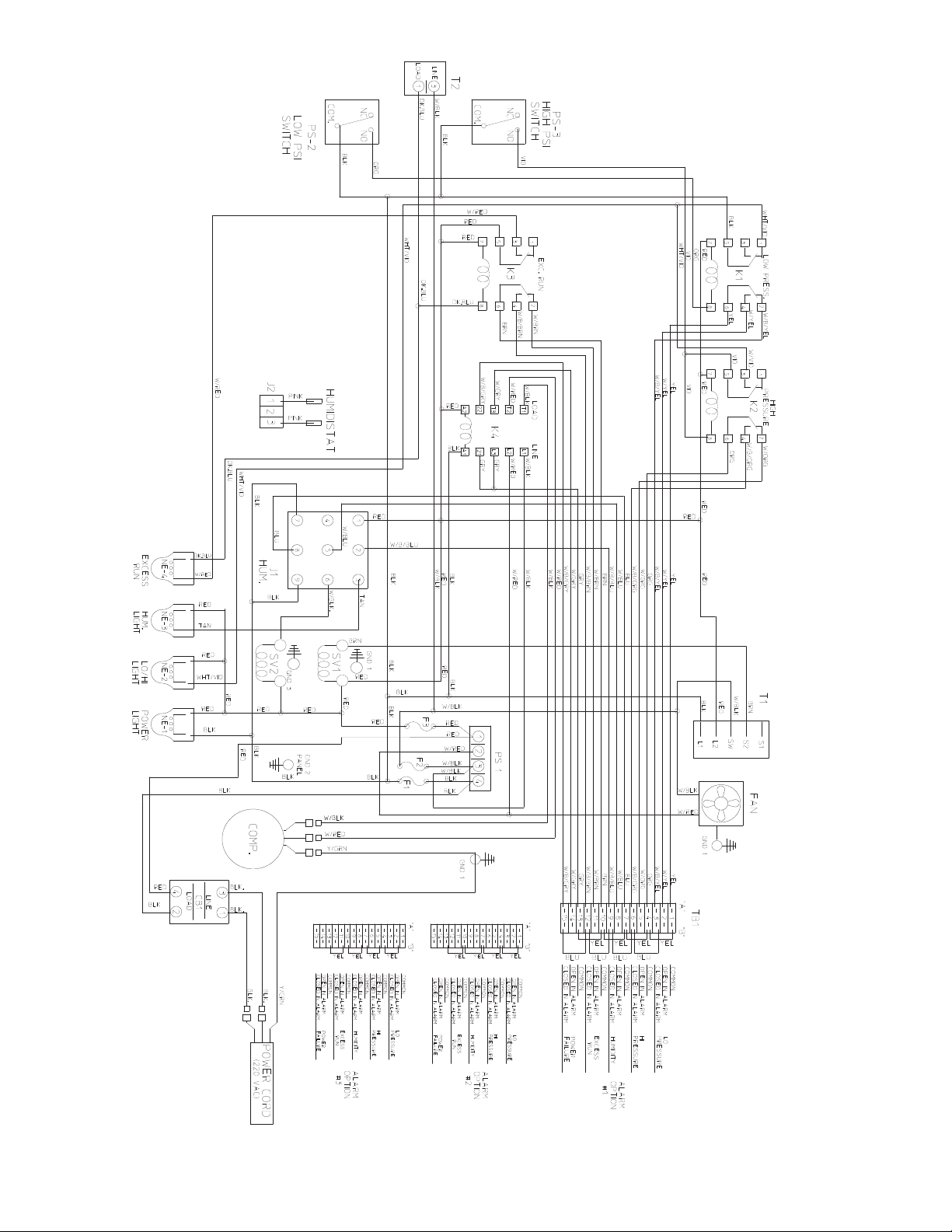

Figure 16

“C” & “D” Series, 115V Wiring Schematic

20

Page 26

Figure 17

“C” & “D” Series, 230V Wiring Schematic

21

Page 27

TABLE VI

GLOSSARY OF TERMS

Altitude: The distance which the installation is above sea level expressed in feet/meters, used interchangeably with elevation.

Ambient: The environment surrounding the dehydrator. Ambient factors which can influence a dehydrator include the

temperature, the relative humidity, the atmospheric pressure and quantity of various pollutants which are present.

Desiccant: The component within the dryer towers which is used alternately to retain, then to expel moisture from the

process air. SPX Radiodetection dryers employ desiccant which is totally inert, that is; it undergoes no chemical or physical change in normal use.

Dew Point: Expressed in °F., the temperature at which dew or frost would form at 14.7 PSIA. The dew point of a given

air sample rises with increased pressure. In 1943 SPX Dielectric established a dew point of -400F. as standard for their

compressor / dehydrators and for the pressurization of the communications equipment which is produced at SPX Radiodetection. NOTE: -400 is the one point at which the Fahrenheit and Celsius scales are numerically equal.

Dry-Pak: A patented dryer design and registered trade mark of SPX Radiodetection which describes the most simple and

efficient heatless air dryer. A Dry-Pak consists of two desiccant towers, two maintenance free ball checks and two direct

acting solenoid valves controlled by a solid state timer. The main air flow is handled by the ball checks without measurable pressure loss. Only the purge air flows through the two way solenoid valves, providing high efficiency and long

trouble free service.

Elevation: The distance which the installation is above sea level expressed in feet/meters, used interchangeably with

altitude.

Line Pressure: The pressure of the low pressure outlet system, which is controlled by the adjustment of the Line Pressure Regulator, is displayed on the Line Pressure Gauge, and is monitored by the adjustable Low and High Pressure Alarm

Switches.

PSIA/kPaa: Pounds per Square Inch Absolute / kilo pascal Absolute. The measure of the pressure of a gas or liquid,

expressed in pounds per square inch, relative to a total vacuum. Standard atmosphere at sea level equals 14.7 PSIA (approx.). / 101 kPaa (approx)

PSIG/kPa: Pounds per Square Inch Gauge. The measure of the pressure of a gas or liquid within a component or system,

to the degree it is greater than that of the surrounding atmosphere, expressed in pounds per square inch. The internal pressure as shown on the gauges used on air dryers.

SCFD/SCMD: Standard Cubic Feet per Day. A rate of air flow measured in cubic feet at 14.7 PSIA and 680 F. One

SCFD when subjected to 10 PSIG (without temperature change) would occupy a space equivalent to 0.6 cubic feet.

Segregated Alarm: An alarm circuit which provides separate terminations for each alarm function within the dehydrator.

Segregated alarms can provide to a remote location the information necessary for establishment of maintenance priorities.

Alarm terminations which either close in alarm or open in alarm, or dual function terminations may be available, dependent on design parameters.

Std. conditions: Standard operating conditions imply a reasonably clean environment at 70°F.(21°C.) and sea level. Ambient conditions impact dryer maintenance needs.

Summary Alarm: An alarm which does not identify an individual condition, but which can indicate an active state of one

or more alarm sensors within the dehydrator. Alarm terminations which either close in alarm or open in alarm, or dual

function terminations may be available, dependent on design parameters.

System Pressure: The pressure at which the compressors and the drying towers (desiccant towers) operate. System

Pressure determines the quantity of compressed air flow, the quantity of purge air and the moisture load on the desiccant

towers.

22

Page 28

WARRANTY

The Manufacturer warrants that all goods supplied hereunder, whether or not of its own manufacture, will be of the kind described

herein or in any specication and drawing approved by the Manufacturer and free from defects in material or workmanship

under normal use and prescribed maintenance for a period of one (1) year, with the exception of air dryers utilizing water sealed

compressors as well as the compressors themselves which shall be for two (2) years. Neither this warranty nor any other, expressed

or implied, shall apply to goods delivered hereunder which have been damaged or subjected to alteration or negligence after

delivery. The Manufacturer’s only obligation for breach of this warranty shall be the repair, without charge, or the furnishing EX Works

Raymond Maine, of a similar part to replace any part which within one (1) year, with the exception as noted above, from date of

shipment is proven to have been defective, provided that (i) the Purchaser shall have notied the Manufacturer within ten (10) days

of the discovery of such defect and not later than ten (10) days after the last day of this warranty, and (ii) the Manufacturer shall have

the option of requiring the return of the defective material (transportation prepaid) to establish the claim. The Manufacturer shall not in

any event be liable for the Purchaser’s manufacturing costs, loss of prots, good will or any other special, consequential, incidental,

or other damages resulting from such defects. THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, WHICH

EXTEND BEYOND THE WARRANTY SET FORTH HEREIN.

Radiodetection (USA) 28 Tower Road, Raymond, Maine 04071, USA

Tel: +1 (207) 655 8525 Toll Free: +1 (877) 247 3797 Fax: +1 (207) 655 8535 rd.sales.us@spx.com www.radiodetection.com

Radiodetection Ltd. (UK) Western Drive, Bristol BS14 0AF, UK

Tel: +44 (0) 117 976 7776 Fax: +44 (0) 117 976 7775 rd.sales.uk@spx.com www.radiodetection.com

© 2017 Radiodetection Ltd. All rights reserved. Radiodetection is a subsidiary of SPX Corporation. Dielectric is a trademark of Radiodetection in the United States and/or other countries.

Due to a policy of continued development, we reserve the right to alter or amend any published specification without notice. This document may not be copied, reproduced, transmitted,

modified or used, in whole or in part, without the prior written consent of Radiodetection Ltd.

Loading...

Loading...