CONTENTS

INTRODUCTION.......................................................................................................................... 1

A. SYSTEM OVERVIEW ......................................................................................................................................... 1

B. SWITCH OVERVIEW ......................................................................................................................................... 1

ON OFF ............................................................................................................................................................................... 2

ALARM............................................................................................................................................................................... 2

SETUP .................................................................................................................................................................................. 2

MIN AVG MAX SCAN ................................................................................................................................................. 2

SELECT ROW ................................................................................................................................................................... 2

SELECT ............................................................................................................................................................................... 2

SE T ....................................................................................................................................................................................... 2

START STOP RESET .................................................................................................................................................... 3

BACK ................................................................................................................................................................................... 3

OPERATE 1....................................................................................................................................................................... 3

OPERATE 2....................................................................................................................................................................... 3

OPERATE 3....................................................................................................................................................................... 3

SYSTEM INSTALLATION ......................................................................................................... 5

A. CONSOLE MOUNTING ..................................................................................................................................... 5

B. CONSOLE HARNESS INSTALLATION ....................................................................................................... 6

C. IMPLEMENT HARNESS/MODULE/SENSORS .......................................................................................... 9

SETUP MODE ............................................................................................................................... 19

A. SETUP CONSTANTS ............................................................................................................................................ 1 9

1 . Population Hi Limit ....................................................................................................................................................... 2 0

2 . Population Lo Limit ....................................................................................................................................................... 2 0

3 . Row Width ........................................................................................................................................................................ 2 1

4 . Implement Width ............................................................................................................................................................ 2 1

5 . Ground Speed Source .................................................................................................................................................... 2 2

6 . Distance Calibration ...................................................................................................................................................... 2 2

7 . Automatic Configuration.............................................................................................................................................. 2 3

8 . Split Row Configuration ............................................................................................................................................... 2 4

9 . Number of Seed Modules ............................................................................................................................................. 2 5

10. Number of Seed Sensors Per Module ....................................................................................................................... 2 5

11. Row Status......................................................................................................................................................................... 2 6

12. Total Number Of Rows Configured ......................................................................................................................... 2 7

13. Number of Fan Speed Sensors .................................................................................................................................... 2 7

14. Fan Speed Sensor Constant .......................................................................................................................................... 2 8

15. Fan Speed Sensor Hi Limit .......................................................................................................................................... 2 8

16. Fan Speed Sensor Lo Limit .......................................................................................................................................... 2 9

17. Number of Shaft Speed Sensors .................................................................................................................................. 2 9

18. Shaft Speed Sensor Constant ....................................................................................................................................... 3 0

19. Shaft Speed Sensor Hi Limit ....................................................................................................................................... 3 0

20. Shaft Speed Sensor Lo Limit ....................................................................................................................................... 3 1

21. Number of Hopper Level Sensors .............................................................................................................................. 3 1

22. Number of Pressure Sensors ........................................................................................................................................ 3 2

23. Pressure Sensor Hi Limit .............................................................................................................................................. 3 2

24. Pressure Sensor Lo Limit.............................................................................................................................................. 3 3

25. Blockage Mode Configuration .................................................................................................................................... 3 3

26. Population Filter.............................................................................................................................................................. 3 4

27. Population Scaling Factor............................................................................................................................................. 3 4

28. Sensor/Module Self-Test ............................................................................................................................................... 3 5

2 9 English/Metric Units ...................................................................................................................................................... 3 6

B.CUSTOMER SETUP CONSTANTS ..................................................................................................................... 3 6

1 . Boot Version Number ................................................................................................................................................... 3 6

2 . Flash Version Number .................................................................................................................................................. 3 7

OPERATE MODE ........................................................................................................................ 39

A. OPERATE MODE .............................................................................................................................................. 3 9

B. RUN HOURS ....................................................................................................................................................... 3 9

C. POPULATION ...................................................................................................................................................... 40

1 . Population SCAN ........................................................................................................................................................ 4 1

2 . Population MIN AVG MAX ................................................................................................................................... 4 1

3 . Population SELECT ROW ....................................................................................................................................... 4 2

4 . Seed Spacing ................................................................................................................................................................. 4 2

5 . Ground Speed ............................................................................................................................................................... 4 3

6 . Fan Speed ....................................................................................................................................................................... 4 3

7 . Shaft Speed .................................................................................................................................................................... 4 4

8 . Pressure .......................................................................................................................................................................... 4 4

9 . Area Accumulator ....................................................................................................................................................... 4 5

10. Seed Count .................................................................................................................................................................... 4 5

11. Distance Accumulator ............................................................................................................................................... 4 6

12. Speed Area Mode ........................................................................................................................................................ 4 6

ALARMS......................................................................................................................................... 4 9

1 . All Rows Failed ........................................................................................................................................................... 5 1

2 . Rows Failed ................................................................................................................................................................... 5 1

3 . Distance Sensor Failed ............................................................................................................................................... 5 1

4 . Population Hi Limit Warning .................................................................................................................................. 5 2

5 . Population Lo Limit Warning ................................................................................................................................. 5 3

6 . Fan Speed Hi Limit Warning ................................................................................................................................... 5 3

7 . Fan Speed Lo Limit Warning................................................................................................................................... 5 4

8 . Shaft Speed Hi Limit Warning ................................................................................................................................54

9 . Shaft Speed Lo Limit Warning ................................................................................................................................55

10. Pressure Hi Limit Warning....................................................................................................................................... 5 5

11. Pressure Lo Limit Warning ...................................................................................................................................... 5 6

12. Hopper Lo Warning .................................................................................................................................................... 5 6

13. Battery Voltage Warning .......................................................................................................................................... 5 7

SELF TEST ERROR CODES .................................................................................................... 59

TROUBLESHOOTING .............................................................................................................. 61

A. MONITOR DEAD .............................................................................................................................................. 61

B. BATTERY SYMBOL APPEARS ON DISPLAY ........................................................................................ 61

C. ERROR CODE E00 ........................................................................................................................................... 62

D. ERROR CODE E01 ........................................................................................................................................... 62

E. ERROR CODE E10 ........................................................................................................................................... 6 2

F. ERROR CODE E11 ........................................................................................................................................... 63

G. ERROR CODE E20 ........................................................................................................................................... 63

H. ERROR CODE E21 ........................................................................................................................................... 64

I. ERROR CODE E30 X ...................................................................................................................................... 64

J. ERROR CODE E31 X ......................................................................................................................................65

K. ERROR CODE E40 ........................................................................................................................................... 65

L. ERROR CODE E41 ........................................................................................................................................... 6 6

M. ERROR CODE E50 ........................................................................................................................................... 66

N. ERROR CODE E51 ........................................................................................................................................... 66

O. ERROR CODE E70 ........................................................................................................................................... 67

P. ERROR CODE E71 ........................................................................................................................................... 6 7

Q. ERROR CODE E98 E99............................................................................................................................... 67

CONNECTOR PIN OUTS ........................................................................................................................................... 68

SETUP RECORD SHEET ........................................................................................................................................... 69

OPERATOR'S MANUAL

INTRODUCTION

A. SYSTEM

OVERVIEW

The Seed Manager® SE System offers

features such as the ability to monitor up

to ninety six (96) seed or material flow

rows, two (2) Fan (RPM) inputs, three (3)

Shaft Speed (RPM) inputs, two (2)

Pressure inputs, seven (7) hopper level

inputs, and a Ground Speed input. It is

compatible with DICKEY-john Standard

and Hi-Rate seed sensors and Recon

Flow sensors. The monitor will store all

implement configuration data in nonvolatile memory, retaining information even

when disconnected from the tractor

battery. Figure 1 shows the Seed

Manager® SE console.

Figure 1

B. SWITCH

OVERVIEW

The switches are used to control system

power, select the mode of operation, and

enter implement configuration constants.

To help distinguish between switch

names and display messages in the text

of this manual, switch names are always

shown in italicized print. An overview of

the switches follows:

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

Seed Manager® SE Console

1 2 3 . . .

l l l l

SELECT

SET

1 2 3 ...

1 2 3 4 5

®

START

STOP

RESET

INTRODUCTION/ 1

OPERATOR'S MANUAL

ON OFF

Pressing this switch applies power to the

monitor. Upon power up, the monitor

performs internal diagnostic checks,

illuminates all segments of the LCD,

sounds the alarm, and determines what

sensors are connected to the system.

Depressing the ON OFF switch for at

least one (1) second causes the system to

power down.

ALARM

Momentarily pressing this switch silences

the alarm and acknowledges the alarm

condition. Additionally, holding the

switch pressed for more than one (1)

second allows the volume level of the

alarm to be adjusted. As the switch is

held pressed, the alarm sounds continu-

ously and the volume level slowly

decreases to a minimum, then increases

to a maximum. Releasing the switch

establishes the desired volume level.

MIN AVG MAX SCAN

This switch is pressed to toggle between

the MIN AVG MAX and SCAN options

for Population and Spacing.

1 2 3 . . .

SELECT ROW

Pressing this switch while in Population

or Spacing functions freezes the display

on the current row data. Successive

depressions then cause stepping from

one row to the next. In the Setup Mode,

this switch allows stepping through the

rows while entering Row Status.

SELECT

SELECT

This switch is used to change constants in

the Setup Mode as explained in the

Setup Mode chapter. To move the

selected digit to the next digit, press the

SELECT switch.

2/ INTRODUCTION

SETUP

This switch is pressed for one (1) second

to enter the Setup Mode and to step

from one Setup constant to the next as

detailed in the Setup Mode Chapter.

SET

SET

This switch is used to change constants in

the Setup Mode as explained in the

Setup Mode chapter. To increase the

selected digit by one press the SET

switch. SET can also toggle a selection

between ON and OFF for example.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

START

STOP

RESET

START STOP RESET

This switch is used in multiple modes for

multiple purposes. Some examples are

as follow: It is used in the Operate

Mode Seed Count and Distance

Accumulator functions to start or stop

the accumulations. It is also used in

Setup Mode Distance Calibration,

Automatic Configuration, and Sensor

Self Test functions to start or stop the

test. Other functions include: Clearing

the Run Hours, Area Accumulators,

Seed Count, Distance Accumulator, and

simply clearing digits when editing Setup

constant values.

l l l l

OPERATE 1

This switch is used to select Population,

Spacing, or Ground Speed Mode.

Pressing the switch repeatedly, will

change to the next mode.

OPERATE 2

This switch is used to select Fan Speed,

Shaft Speed, or Pressure Mode (if

available on system). Pressing the switch

repeatedly, will change to the next mode.

1 2 3 ...

1 2 3 4 5

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

BACK

This switch is used in multiple modes for

multiple purposes. Some examples are

as follow: It is used in the Operate

Mode Population and Spacing functions

to step to the previous row display. It is

also used in Setup Mode to return to the

previous Setup Mode screen.

OPERATE 3

This switch is used to select Area, Seed

Count, or Distance Accumulator Mode.

Pressing the switch repeatedly, will

change to the next mode.

INTRODUCTION/ 3

OPERATOR'S MANUAL

4/ INTRODUCTION

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

SYSTEM INSTALLATION

A. CONSOLE

MOUNTING

The console should be mounted inside

the tractor cab in a location accessible to

the operator but does not obstruct the

driving view.

Refer to Figure 2 for a typical console

mounting using the U-bracket and

hardware. Install as follows:

STEP 1

Verify the rear side of the selected

mounting surface is free of wiring or

other obstructions and is accessible for

inserting and tightening the mounting

bolts.

STEP 2

Use the U-shaped mounting bracket as a

template to mark the two outside holes of

the bracket on the selected location and

drill two 9/32 inch ( 7 mm ) holes. An

alternate mounting method, which allows

the console to swivel, requires drilling the

center bracket hole only.

STEP 3

Attach the mounting bracket to the

mounting surface using the ¼ - 20 x ½

inch bolts, lockwashers, flatwashers, and

nuts.

STEP 4

Secure the console to the mounting

bracket using the two knob screws.

Insert the two rubber washers between

the bracket and console.

STEP 5

Tilt console so that the J1 connector on

the rear of the console is accessible.

Temporarily tighten the two knob screws.

Warning:

The console must not obstruct the view or

interfere with the operation of the tractor.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

Figure 2

Display Console Mounting

U-Bracket

1/4

-20 Nuts

and Lockwasher

U-Bracket

Knob

Screw

Console

Rubber

Washer

Knob

Screw

1/4-20 x 3/4 Inch

Hex Bolts &

Flat washers

Rubber

Washer

(Preferred Mounting

U-Bracket

Position)

INSTALLATION/ 5

OPERATOR'S MANUAL

B. CONSOLE

HARNESS

INSTALLATION

The J1 connector on the back of the

console connects all input and output

signals to the Seed Manager® SE

console.

The primary tractor harness is shown in

Figure 3. This harness contains connectors for a ground speed sensor (digital),

a ground speed sensor (reluctance),

system power, and P1 and P2 Bus

connectors. A secondary module

harness is used to connect to P1 and/or

P2.

For systems that contain a J2 connector, a

separate accessory harness will contain a

RS-232 connector for PC/GPS applica-

tions.

The following procedures describe

installing the primary (J1) harness from

the rear of the console to the tractor

hitch:

STEP 1

Route the primary harness from J1 on

the console rear to the rear of the

tractor, near the hitch. Route it on the

Figure 3

Primary Tractor Harness

46682-0132

Mates with Reluctance

Ground Speed Sensor

6/ INSTALLATION

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

side of the tractor opposite the alternator

and spark plugs. Locate the harness to

prevent being pinched, cut, or stepped

on and secure it with wire ties.

STEP 2

Install or connect an existing ground

speed sensor. The ground speed sensor

may be one of three types radar,

reluctance, or Hall Effect. A radar

sensor or reluctance sensor connects

directly to the designated connector on

the primary harness. A Hall Effect

sensor may require an adapter harness

to connect to the primary harness.

Sensor mounting instructions accompany

the sensor. Select the mounting location

and install as the instructions describe.

STEP 3

Follow instructions to install Module and

Sensor Harnessing in Implement

Harness section.

STEP 4

The power connections are made last to

avoid accidental shorts during harness

installation.

The Seed Manager® SE System

operates on 12 volts DC only. The

battery connections on the primary

harness consist of two wires, each

terminated with a ring terminal.

Before making the battery connections,

determine the tractor battery arrange-

ment from Figures 4, 5, and 6, found on

page 8. After the 12 volt source is

known, connect the black wire directly to

the negative (-) terminal of the battery.

The red wire (containing the fuse link)

connects directly to the positive (+)

battery terminal. Make sure the connections are clean and tight. Do not route

these wires in close proximity to the

existing battery cables. Secure the battery

wires with wire ties.

If your tractor battery arrangement

differs from those shown in Figures 4, 5,

and 6, or if in any doubt exists about

how to connect to the battery, use a

voltmeter first. Verify 11 to 14 volts

across the battery connection points. On

Tractors using two batteries, be sure to

make connections to the grounded

battery.

Note: Due to the power requirements for the Seed Manager® SE

system, the battery connections must

be made directly to the tractor

battery.

WARNING:

Before welding on the frame or chassis, be

certain to disconnect battery leads.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

INSTALLATION/ 7

OPERATOR'S MANUAL

r

e

Figure 4

12 Volt Battery Source Connections

Vehicl

Ground

12V

Vehicle

Ground

Figure 5

24 Volt Battery Source Connections

Red

Black

Power

Cable

6V

6V

Black

Red

Powe

Cable

8/ INSTALLATION

Figure 6

Negative or Positive Sources Connections

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

C. IMPLEMENT

HARNESS /

MODULES /

SENSORS

The Seed Manager® SE system uses any

combination of three basic module types,

each with their own specific harness

configurations. There are 12 Row

Material Flow Modules, 16 Row Material

Flow Modules, and Shaft Speed

Modules. A single Bus cable connects to

each module, then serially (daisy chains)

connects to following modules. The

primary harness divides into two halves

at the implement hitch (P1 and P2). The

following requirements must be ob-

served when connecting modules to the

bus:

1. A maximum of six Material Flow

Modules can be connected to the bus.

3. No more than three Material Flow

Modules can be connected to P1 or P2.

4. Any combination of 12 Row or 16 Row

Material Flow Modules may be used.

The order in which the Material Flow

Modules are connected and their

position on the toolbar or implement is

important to note. The Material Flow

Modules are identified by the console as

b1, b2, . . . bn (where n is the total

number of Material Flow Modules

connected). The order in which the

console identifies the modules depends

upon how they are connected to the bus.

The following figures show example

system configurations and how the

Console identifies the modules connect-

ed for each configuration. Note order of

the modules in relation to how they

connect to the bus.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

2. Only one Shaft Speed Module may be

connected to the bus. The Shaft Speed

Module may be connected anywhere on

the bus that is convenient. It can be

connected to either P1 or P2.

INSTALLATION/ 9

OPERATOR'S MANUAL

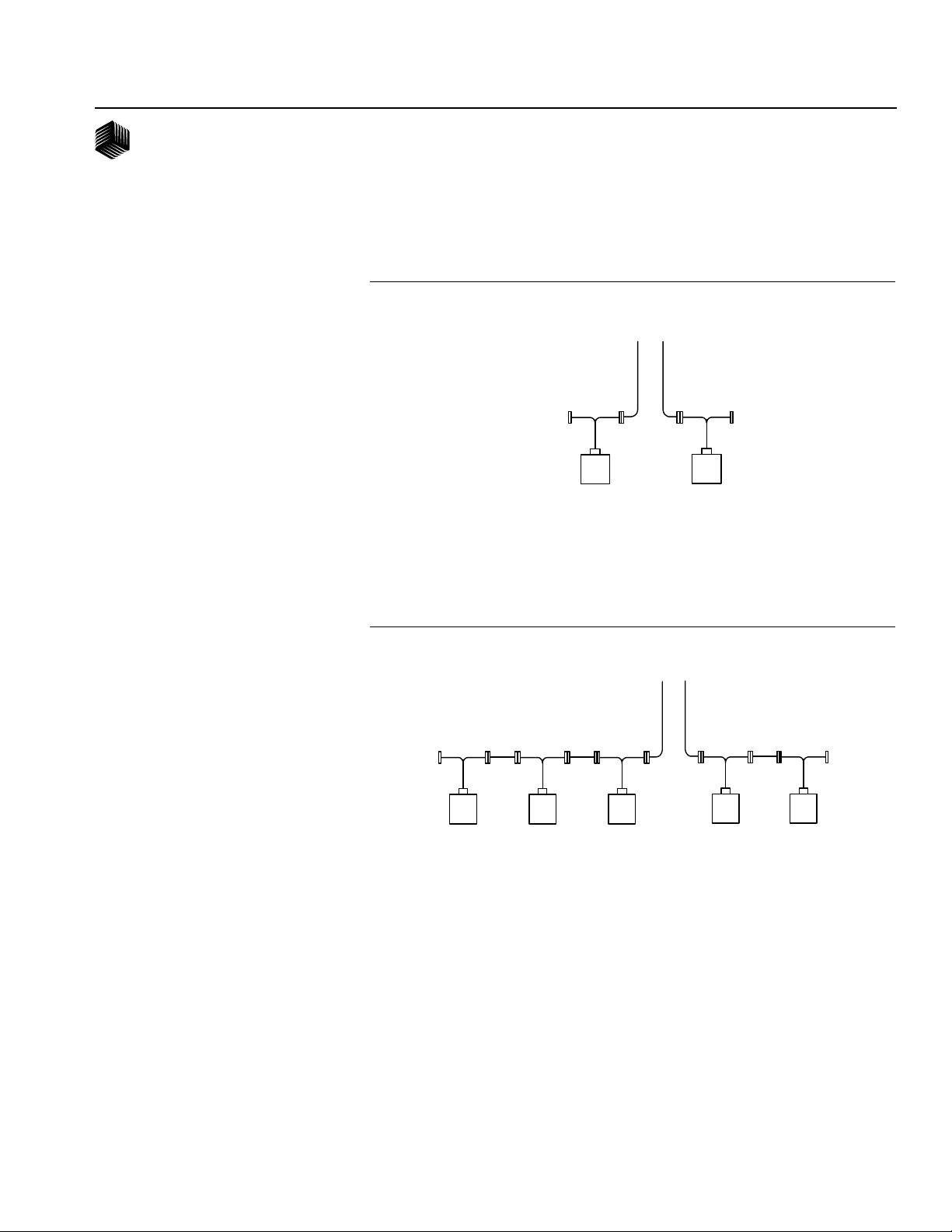

In this four module setup, two modules are connected to P1 and two to P2.

Figure 6A

Four module setup

P1

InOutInOut In Out In Out

P2

b1 b2 b3 b4

In this three module setup, all modules are connected to P1.

Figure 6B

Three module setup

P1

InOutInOut

b1 b2

InOut

b3

In this three module setup, one module is connected to P1 and two are connected to

P2.

Figure 6C

Three module setup

P1

P2

InOutInOut

InOut

10/ INSTALLATION

b1

b2

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

b3

OPERATOR'S MANUAL

In this two module configuration, one module is connected to both P1 and P2.

Figure 6D

Two module setup

P1

InOut

b1

P2

InOut

b2

In this five module configuration, three modules are connected to P1 and two are

connected to P2.

Figure 6E

Five module setup

P1

InOut

InOut InOut

P2

In Out In Out

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

b1 b2 b3 b4 b5

As the previous examples show, b1 is always identified as the LAST module connected

to P1. The remaining modules on P1 are number sequentially, along with any

modules connected to P2.

INSTALLATION/ 11

OPERATOR'S MANUAL

When connecting sensors to the Material Flow Modules, the following requirement

must be observed:

1. All seed sensors installed on a Material Flow Module must be connected sequential-

ly starting with Row 1 as shown below.

Figure 6F

Correct Install

CORRECT

RS-485 IN RS-485 OUT

Row1Row2Row

3

Row

Row

4

9

Row6Row7Row8Row

5

Row

10

Row

11

Row

12

In the event that not all row inputs on a module will be used, the unused row inputs

must be last as shown in the following eight row module setup:

Figure 6G

Correct Install

CORRECT

RS-485 IN RS-485 OUT

Row1Row2Row

3

Row

4

Row

Row6Row7Row8Row

5

Row

Row

9

10

Row

11

12

12/ INSTALLATION

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

There can be no skips in the row inputs on a Material Flow Module. The following

shows the previous eight row module setup incorrectly:

Figure 6H

Incorrect Install

INCORRECT

RS-485 IN RS-485 OUT

Row1Row2Row

3

Row

Row

4

9

Row6Row7Row8Row

5

Row

10

Row

11

Row

12

Follow the same examples on all Material Flow Modules used in the system. When

correctly connected, row 1 sensor should be connected to the Row 1 input on b1. The

monitor will then number the sensors from 1 to n starting on b1, then b2, and so on.

Hopper level sensors can be connected to 12 Row Material Flow Modules. Hopper

sensors can be connected to either of the hopper inputs on a Material Flow Module.

The monitor will identify the number of hopper sensors connected to each Material

Flow Module and will number them from 1 to n starting with any sensors connected to

b1. If no sensors are connected to b1, the number starts from b2 and so on.. In the

event that two hopper sensors are connected to a given module, the sensor connected

to input 1 is numbered before the sensor connected to input 2. The following shows

an example configuration with hopper sensors connected and how they would be

identified by the console.

Figure 6I

P1

Hop 1 Hop 2

P2

Hop 3 Hop 4

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

InOutInOut In Out In Out

b1 b2 b3 b4

INSTALLATION/ 13

OPERATOR'S MANUAL

When hopper level sensors are connected to a Shaft Speed Module, they are num-

bered relative to the position of the Shaft Speed Module on the bus. If the Shaft

Speed Module is connected to the RS-485 Out of b1, the numbering of the hopper

sensors starts with this module, then continues with any hopper sensors connected to

b1, b2, etc. If the Shaft Speed Module is connected between Material Flow Modules,

any hopper sensors connected are numbered in the order in which they are detected

as shown below.

Figure 6J

P2

P1

Hop 1 Hop 2 Hop 3

InOutInOut In Out In Out

Hop 4

b1

SHAFT

b2 b3

Shaft, fan, and pressure sensors can only be connected to the Shaft Speed Module.

These sensors are identified by the monitor according to what input they are connected

to regardless of the position of the Shaft Speed Module on the bus.

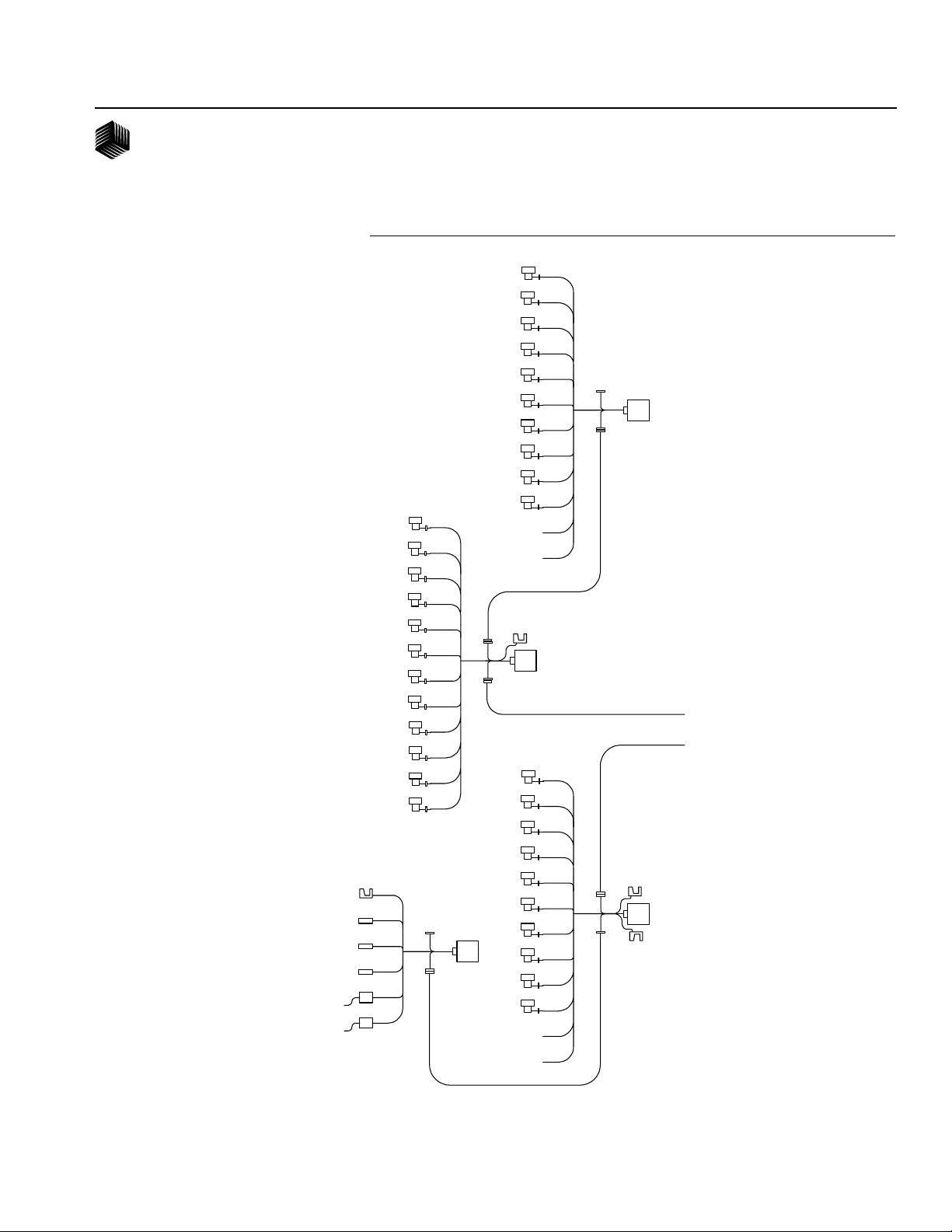

Figure 6K shows a complete example system setup and how each connected sensor

would be identified.

Installation Steps

STEP 1

Mount each of the modules to the toolbar or implement from in a location that will

minimize vibration and will allow for easy access to harness hookup.

STEP 2

Lay out each module harness along the frame of the implement to each of the seed

rows (or appropriate sensors). Secure the harness to the toolbar.

STEP 3

Install and/or connect each of the seed sensors (or appropriate sensor). Sensor

mounting instructions accompany the sensor. Select the mounting location and install

as described in the instructions.

14/ INSTALLATION

STEP 4

Connect each module together with a bus harness. Finally, connect the Tractor

Harness P1 and P2 connectors to the bus harness. Coil and secure existing cables

with wire ties to avoid pinching or damage to the harness.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 6K

R11 R12 R13 R14 R15 R16 R17 R18 R19 R20 R21 R22

Hop

4

Fan

1

Shaft

1

Shaft

2

Press

1

Press

2

Row

1

Row

2

Row

3

Row

4

Row

5

Row

6

Row

7

Row

8

Row

9

Row

10

Row

11

Row

12

RS-485 INRS-485 OUT

RS-485 INRS-485 OUT

Shaft

R1 R2 R3 R4 R5 R6 R7 R8 R9 R10

R23 R24 R25 R26 R27 R28 R29 R30 R31 R32

Row

1

Row

2

Row

3

Row

4

Row

5

Row

6

Row

7

Row

8

Row

9

Row

10

Row

11

Row

12

Hop

1

b1

RS-485 INRS-485 OUT

b2

P1

P2

Row

1

Row

2

Row

3

Row

4

Row

5

Row

6

Row

7

Row

8

Row

9

Row

10

Row

11

Row

12

RS-485 IN

RS-485 OUT

3

Hop

2

b3

Hop

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

INSTALLATION/ 15

OPERATOR'S MANUAL

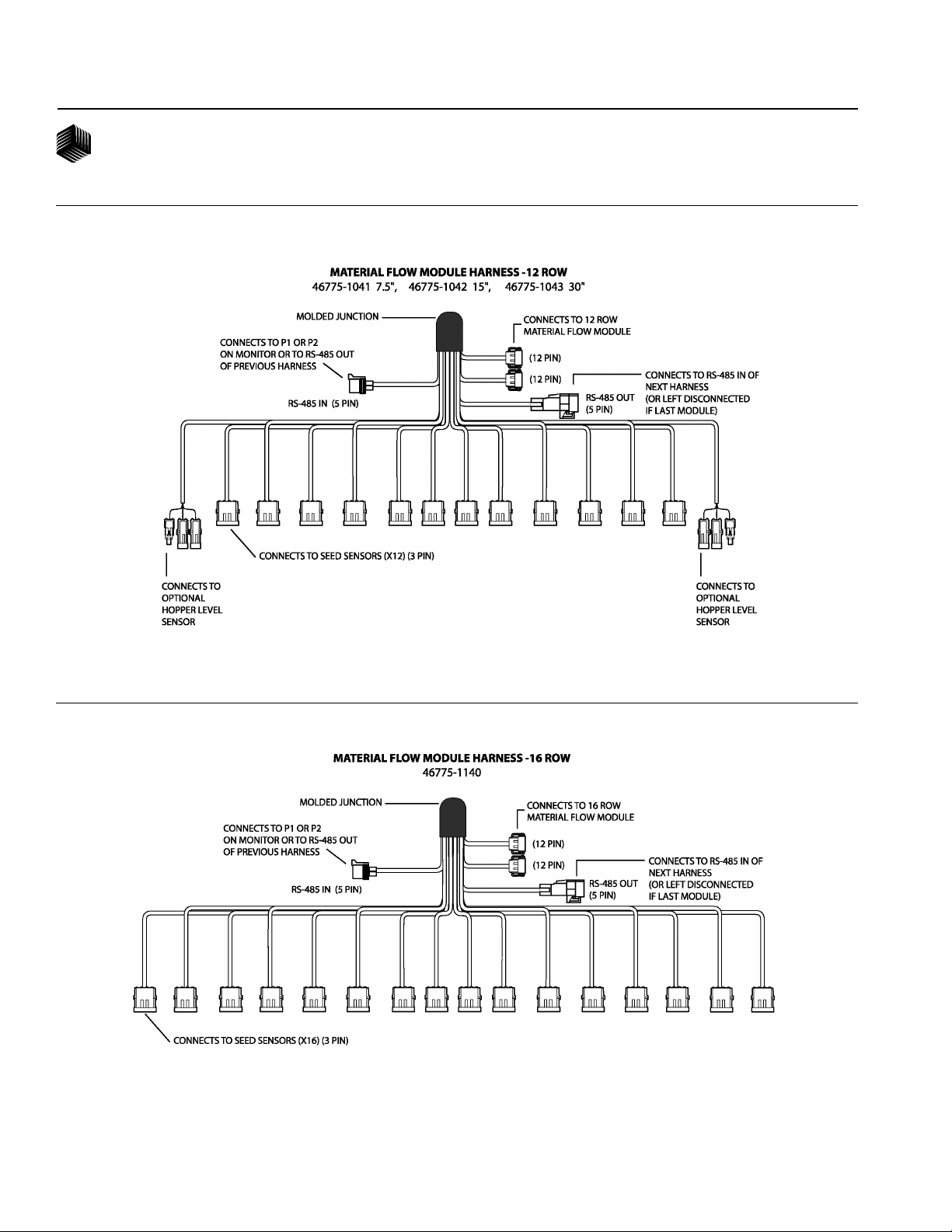

Figure 6L

12 Row Harness

Figure 6M

16 Row Harness

16/ INSTALLATION

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 6N

Shaft Speed Module Harness

Figure 6O

RS-485 Extension Harness

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

INSTALLATION/ 17

OPERATOR'S MANUAL

18/ INSTALLATION

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

SETUP MODE

A. SETUP

CONSTANTS

The Setup Mode is used to enter the

implement configuration constants,

which are listed in Figure 7, in the order

of their presentation. Depressing the

Setup switch for one (1) second, places

the console in the Setup Mode, which is

identified by the SETUP message on the

display. Additional messages uniquely

identify the constant displayed.

Each constant has a fixed number of

digits. Leading zeroes are displayed.

When it is desired to change the value of

a constant, use the SELECT, SET, and

START STOP RESET switches as

follows:

Pressing START STOP RESET zeroes

the digit. Each depression of the

SELECT switch makes the next digit to

the right the selected digit.

When the desired value is entered (or

there is no change from the original

value), press the Setup switch to store the

value and advance to the next constant

on the list. To return to the previous

constant on the list, press the BACK

switch. If a value is entered which

exceeds the minimum or maximum

shown for that constant in Figure 7, the

alarm sounds for one (1) second, the

value of the exceeded limit appears on

the screen, and the advance to the next

constant is aborted.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

Initially, the left most digit flashes on and

off indicating it is the selected digit.

Each depression of the SET switch

increases the selected digit by one count.

After reaching the maximum value of

nine (9), the digit rolls over to zero (0).

CAUTION: To allow rapid recovery

from an entry error, it is important to

record all values of constants on the

SETUP RECORD sheet on the last page

of this manual, immediately after console

entry.

SETUP/ 19

OPERATOR'S MANUAL

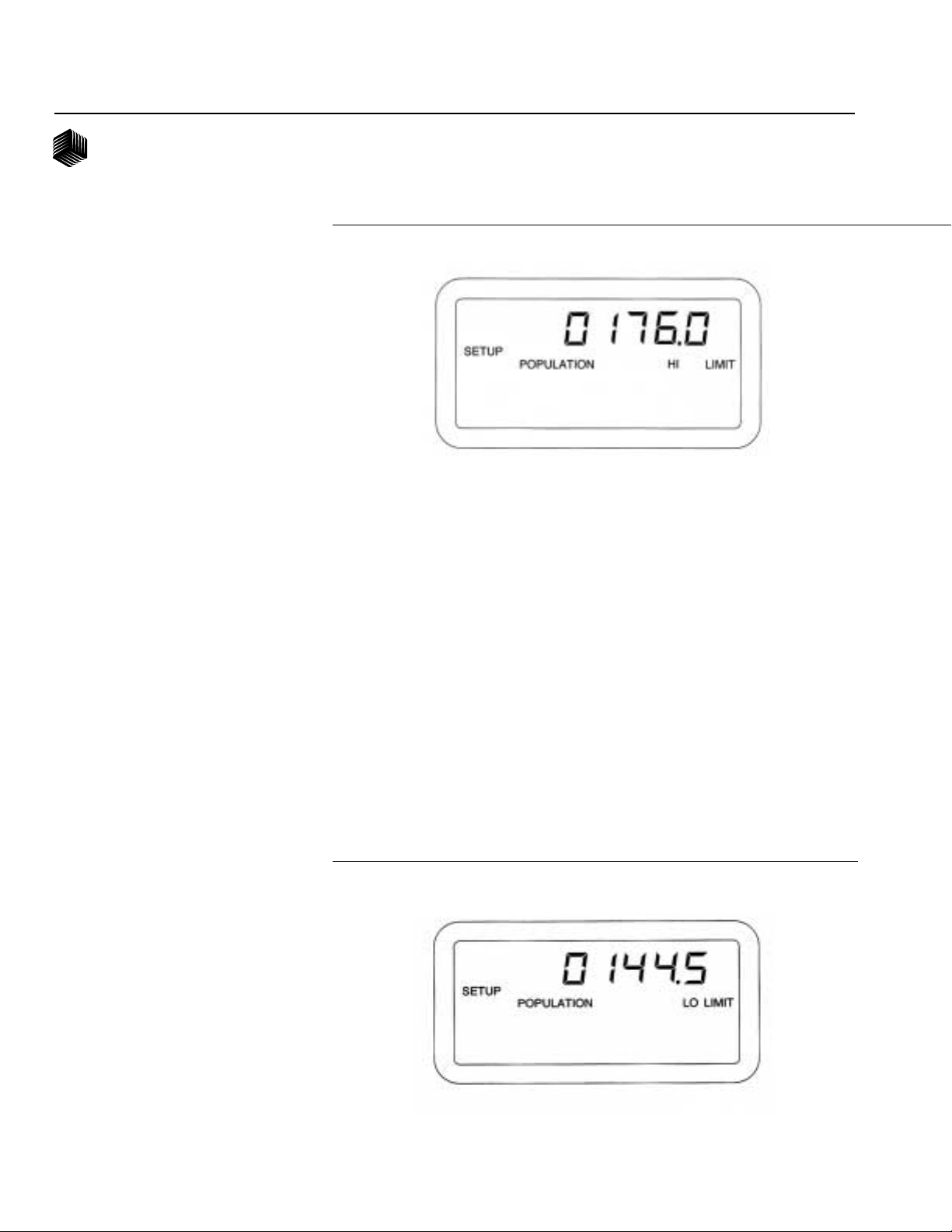

Figure 8

POPULATION HI LIMIT Display

To exit the Setup Mode, press any of the

three Operate switches. Exiting automat-

ically stores the last constant changed.

The first parameter displayed after

entering the Setup Mode is the Population Hi Limit. Definitions and consider-

ations when entering values for each

constant are as follows:

1. Population Hi Limit

When the population on any row

exceeds the value entered for this

constant, in thousands of seeds per acre

Figure 9

POPULATION LO LIMIT Display

(hectare), the alarm sounds, as indicated

under the heading ALARMS, POPULATION HI LIMIT WARNING.

Figure 8 shows the display for a limit of

176,000 seeds/acre.

2. Population Lo Limit

When the population on any row falls

below the value entered for this constant,

in thousands of seeds per acre (hectare),

the alarm sounds, as indicated under the

heading ALARMS, POPULATION

LO LIMIT WARNING. Figure 9

shows the display for a limit of 144,500

seeds/acre.

20/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 10

ROW WIDTH Display

3. Row Width

This is the distance in inches (centime-

ters) between rows, with a resolution of

0.1. Figure 10 shows a Row Width of

38.0 inches.

Figure 11

IMPLement WIDTH Display

4. Implement Width

This is the seeding width of the imple-

ment in inches (centimeters) with a

resolution of 0.1. It is automatically

calculated when either the Number of

Modules, Number of Rows per Module,

or the Row Width is changed and can be

edited for special applications such as

skip row seeding. Figure 11 shows an

Implement Width of 720.0 inches.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 21

OPERATOR'S MANUAL

Figure 12

Ground Speed Sensor Type Display

5. Ground Speed Source

Pressing the Set switch causes the lower

right display to toggle between d1, r1,

or d2. If a digital (radar or Hall Effect)

type ground speed sensor is used, and is

connected directly to the Seed Manager®

Console, press the SET switch until d1

appears. If a digital (radar or Hall Effect)

type ground speed sensor is used, and is

connected to a Shaft Speed Module, press

the SET switch until d2 appears. If a

reluctance type ground speed sensor is

used press the SET switch until r1

appears. Figure 12 shows a configuration

for a digital 1 ground speed source.

Figure 13

Distance Calibration Display

6. Distance Calibration

The Distance Calibration constant is the

number of pulses generated by the

ground speed sensor while traveling a

distance of 400 feet (122 meters). Figure

13 shows the display with the SETUP,

SPEED, and COUNT messages and the

default value of 6096, which is the

nominal pulse count for the radar

ground speed sensor. A smaller

number, typically 3100, results with a

reluctance ground speed sensor.

22/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

To perform the Distance Calibration:

STEP 1

Carefully measure a 400 foot (122 meter)

course, plainly marking the start and finish

points.

STEP 2

With the tractor moving between 2 and 5

MPH (3.2 and 8 Km/h), press the START

STOP RESET switch when the tractor is

exactly even with the start marker. The

display showing the Distance Calibration

constant zeroes, then counts the ground

speed pulses.

STEP 3

When the tractor is even with the finish

marker, press the START STOP RESET

switch.

STEP 4

To ensure best accuracy, perform this

procedure at least three (3) times. Record

the count each time, then enter the average

as the Distance Calibration constant, using

the SELECT and SET switches.

7. Automatic Configuration

To begin the Automatic Configuration,

press the START STOP RESET switch.

The TEST message flashes while the

Automatic Configuration is running.

Configuration is complete when the TEST

message disappears. The Automatic

Configuration will automatically detect how

many Seed Modules are connected to the

system, how many Seed Sensors are

connected to each Module, how many

Hopper Sensors are connected in the

system, and how many Pressure Sensors

are connected in the system. Note: Fan

Speed Sensors and Shaft Speed Sensors

are not automatically configured and will

need to be setup manually by the user.

When Automatic Configuration is run, the

number of seed modules, number of seed

sensors, number of hopper sensors, and

number of pressure sensors is configured

to be whatever the results of Automatic

Configuration detects in the system. Verify

the detected configuration by reviewing the

setup constants for the number of seed

modules, number of seed sensors,

number of hopper sensors, and number

of pressure sensors before beginning

operation of the implement. Figure 14

shows the Automatic Configuration

screen.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

Figure 14

Automatic Configuration Display

SETUP/ 23

OPERATOR'S MANUAL

8. Split Row Configuration

For users that utilize split, twin, or skip

row type seeding implements, this feature

will allow easy configuration for setting

up the correct row pattern that is used.

Reference Figure 15 for a listing of all of

the row patterns that can be applied to

selected, all of the rows are automatically

turned ON or OFF according to the

pattern. The user can still edit individual

rows in the Row Configuration Screen,

but it can only be done after a pattern is

selected. Figure 16 shows a row pattern

of 01 being selected.

the system. When a row pattern is

Figure 15

Split Row

Configuration Description/Example

00 All Rows On

01 Every other Row Off, with first Row On (OXOXOX)

02 Every other Row Off with first Row Off (XOXOXO)

03 Every Third Row On (OXXOXXOXX)

04 Every Third Row On (XXOXXOXXO)

05 Every Third Row On (XOXXOXXOXX)

06 Every Third Row Off (OOXOOXOOX)

07 Every Third Row Off (OXOOXOOXOO)

08 Every Third Row Off (XOOXOOXOO)

09 Every Fourth Row On (OXXXOXXXOXXX)

10 Every Fourth Row On (XXXOXXXOXXXO)

11 Every Fourth Row On (XXOXXXOXXXOXXX)

12 Every Fourth Row On (XOXXXOXXXOXXX)

13 Twin Rows (OOXXOOXXOOXX)

14 Twin Rows (OXXOOXXOOXXOO)

15 Twin Rows (XXOOXXOOXXOO)

16 Twin Rows (XOOXXOOXXOOXX)

17 Every Fourth Row Off (OOOXOOOXOOOX)

18 Every Fourth Row Off (OOXOOOXOOOXOOO)

19 Every Fourth Row Off (OXOOOXOOOXOOO)

20 Every Fourth Row Off (XOOOXOOOXOOO)

24/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

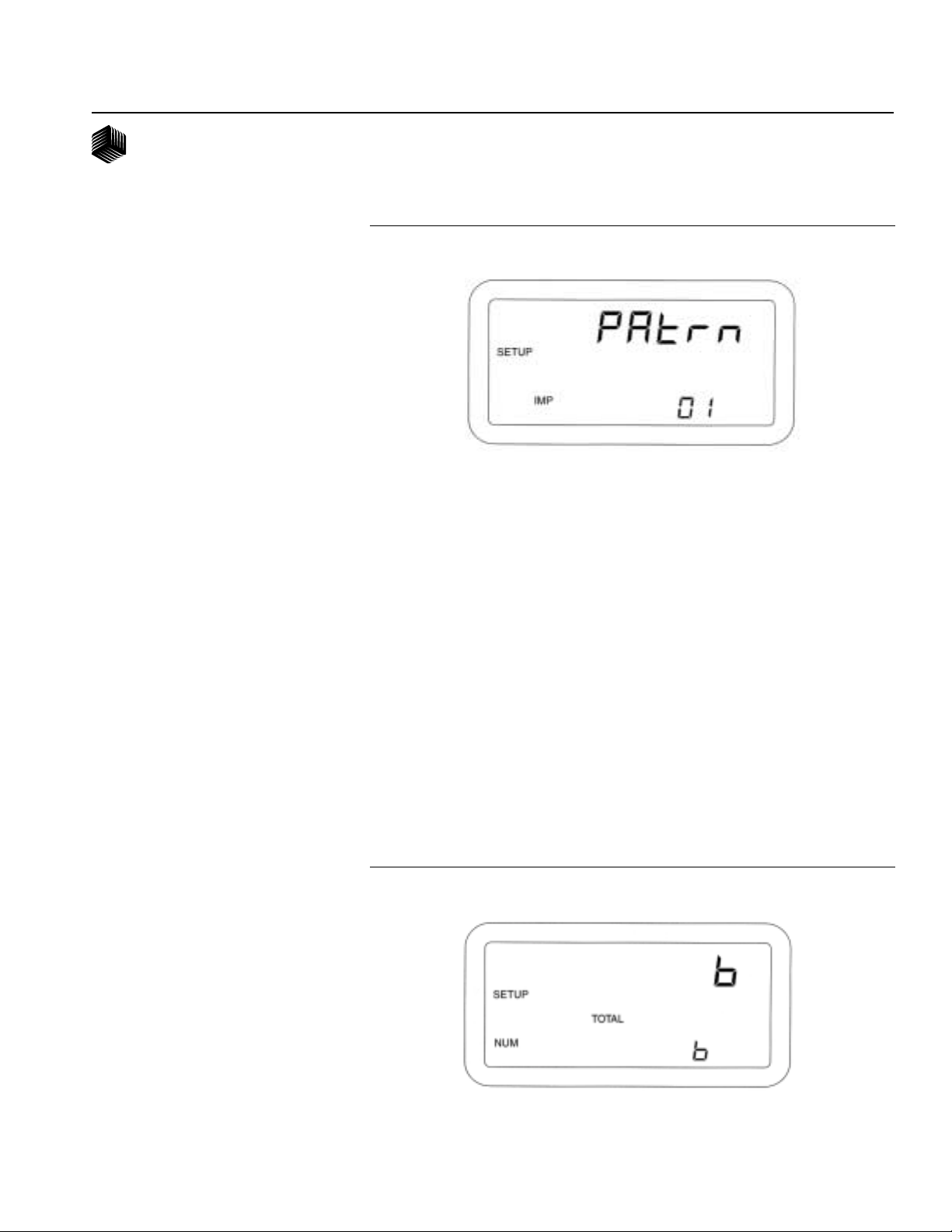

Figure 16

Pattern Select Display

9. Number of Seed Modules

This is the actual number of Seed

Modules that are connected to the

system. Note: This does not include the

Shaft Speed Module if one is available

on the system. This parameter will be

checked as part of the Sensor/Module

Self-Test, and Error codes will be

generated if this value does not match the

actual number of Seed Modules. Figure

17 shows a configuration for six (6)

modules.

Figure 17

Seed Modules Display

10. Number of Seed Sensors Per

Module

For each Seed Module that is configured

on the previous Setup Screen, there will

be a Number of Seed Sensors Per

Module screen. This is the actual number

of Seed Sensors that are connected to the

particular Module. The Modules are

Numbered from the far left of the

implement (end of P1) to the far right of

the implement (end of P2). This parame-

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 25

OPERATOR'S MANUAL

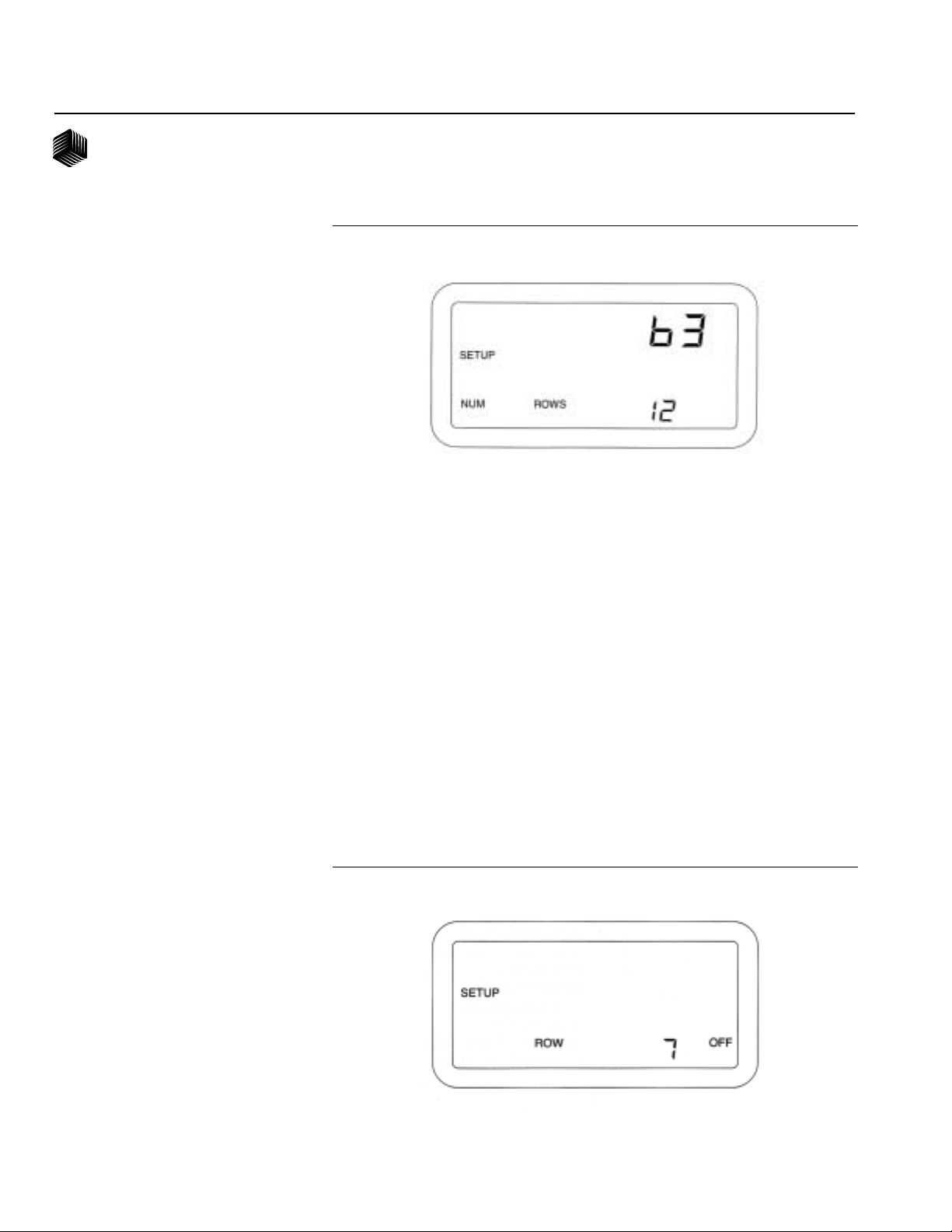

Figure 18

Sensors Per Module Display

ter will be checked as part of the Sensor/

Module Self-Test and Error codes will be

generated if this value does not match the

actual number of Seed Sensors. Figure 18

shows twelve (12) seed sensors configured

on Module 3.

11. Row Status

This parameter allows placing individual

seed sensors in ON or OFF staus. For

those situations where it is necessary to

turn off certain rows on the implement,

OFF status turns off the related sensors

so alarms do not occur.

Figure 19

Row Status Display

The display initially shows the messages

SETUP, ROW, 1, and the status of row

1. Figure 19 shows row 7 status set to

OFF. Press the SET switch to toggle

between ON and OFF the sensors.

Press the SELECT ROW switch to

advance to the next row. When the

status of all rows is correctly entered,

press SETUP to advance to the next

Setup constant.

26/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 20

Rows Configured Display

12. Total Number Of Rows

Configured

This parameter is used to calculate

Implement Width and is used in

checking the number of seed sensors

detected upon system power up. This

value is displayed for confirmation only

and can only be altered by changing the

Number of Seed Modules or Number

of Seed Sensors Per Module parame-

ters. Figure 20 shows the display for

sixteen (16) rows.

Figure 21

Fan Speed Sensor Display

13. Number of Fan Speed Sensors

This is the actual number of Fan Speed

Sensors that are connected to a Shaft

Speed Module on the system. For each

Fan Speed Sensor that is configured

here there will be an operate screen

generated. Fan Speed Sensors are not

Self-Tested and will not generate any

error codes except for operational error

codes for Hi and Lo Limit warnings.

Figure 21 shows a configuration of two

(2) Fan Speed Sensors.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 27

OPERATOR'S MANUAL

Figure 22

Fan Speed Constant Display

14. Fan Speed Sensor Constant

The Fan Speed Constant is the number

of pulses the Fan Speed Sensor gener-

ates in one revolution of the monitored

fan. This is typically the number of teeth

(sense points) on the fan. The Fan

Speed Constant can be entered as a

decimal with 0.01 resolution. Entering a

value of zero (000.00) disables the Fan

Speed function. The Fan Speed Sensor

Constant is accessible only if the

Number of Fan Speed Sensors has a

value other than 0. Figure 22 shows the

display with a Fan Speed Constant of

34.00 pulses per revolution.

Figure 23

Hi Limit Fan Speed Display

15. Fan Speed Sensor Hi Limit

This constant is the highest Fan Speed

(RPM) allowed before sounding a

warning alarm. The Hi and Lo warning

limits are accessible only if the Number

of Fan Speed Sensors has a value other

than 0. The warning is enabled or

disabled by selecting the ON or OFF

message. Use the SELECT switch to

advance one step to the right of the right

most digit, then press the SET switch to

toggle between ON and OFF. Figure 23

shows a Hi limit of 500 RPM with the

warning enabled.

28/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 24

Lo Limit Fan Speed Display

16. Fan Speed Sensor Lo Limit

This constant is the lowest Fan Speed

(RPM) allowed before sounding a

warning alarm. The Hi and Lo warning

limits are accessible only if the Number

of Fan Speed Sensors has a value other

than 0. The warning is enabled or

disabled by selecting the ON or OFF

message. Use the SELECT switch to

advance one step to the right of the right

most digit, then press the SET switch to

toggle between ON and OFF. Figure 24

shows a Lo limit of 25 RPM with the

warning disabled.

Figure 25

Shaft Speed Sensor Display

17. Number of Shaft Speed

Sensors

This is the actual number of Shaft Speed

Sensors that are connected to a Shaft

Speed Module on the system. For each

Shaft Speed Sensor that is configured

here, there will be an operate screen

generated. Shaft Speed Sensors are not

Self-Tested and will not generate any

error codes except for operational error

codes for Hi and Lo Limit warnings.

Figure 25 shows a configuration of three

(3) Shaft Speed Sensors.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 29

OPERATOR'S MANUAL

Figure 26

Shaft Speed Constant Display

18. Shaft Speed Sensor Constant

The Shaft Speed Constant is the number

of pulses the Shaft Speed Sensor

generates in one revolution of the

monitored shaft. This is typically the

number of teeth (sense points) on the

gear attached to the monitored shaft.

The Shaft Speed Constant can be

entered as a decimal with 0.01 resolution.

Entering a value of zero (000.00) disables

the Shaft Speed function. The Shaft

Speed Sensor Constant is accessible only

if the Number of Shaft Speed Sensors

has a value other than 0. Figure 26

shows the display with a Shaft Speed

Constant of 26.00 pulses per revolution.

Figure 27

Hi Limit Shaft Speed Display

19. Shaft Speed Sensor Hi Limit

This constant is the highest Shaft Speed

(RPM) allowed before sounding a

warning alarm. The Hi and Lo warning

limits are accessible only if the Number

of Shaft Speed Sensors has a value other

than 0. The warning is enabled or

disabled by selecting the ON or OFF

message. Use the SELECT switch to

advance one step to the right of the right

most digit, then press the SET switch to

toggle between ON and OFF. Figure 27

shows a Hi limit of 65 RPM with the

warning enabled.

30/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 28

Lo Limit Shaft Speed Display

20. Shaft Speed Sensor Lo Limit

This constant is the lowest Shaft Speed

(RPM) allowed before sounding a

warning alarm. The Hi and Lo warning

limits are accessible only if the Number

of Shaft Speed Sensors has a value other

than 0. The warning is enabled or

disabled by selecting the ON or OFF

message. Use the SELECT switch to

advance one step to the right of the right

most digit, then press the SET switch to

toggle between ON and OFF. Figure 28

shows a Lo limit of 12 RPM with the

warning disabled.

Figure 29

Hopper Level Display

21. Number of Hopper Level

Sensors

This is the actual number of Hopper

Level Sensors that are connected to all

modules in the system. This parameter

will be checked as part of the Sensor/

Module Self-Test and Error codes will

be generated if this value does not match

the actual number of Hopper Level

Sensors. Figure 29 shows a configura-

tion of five (5) Hopper Sensors.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 31

OPERATOR'S MANUAL

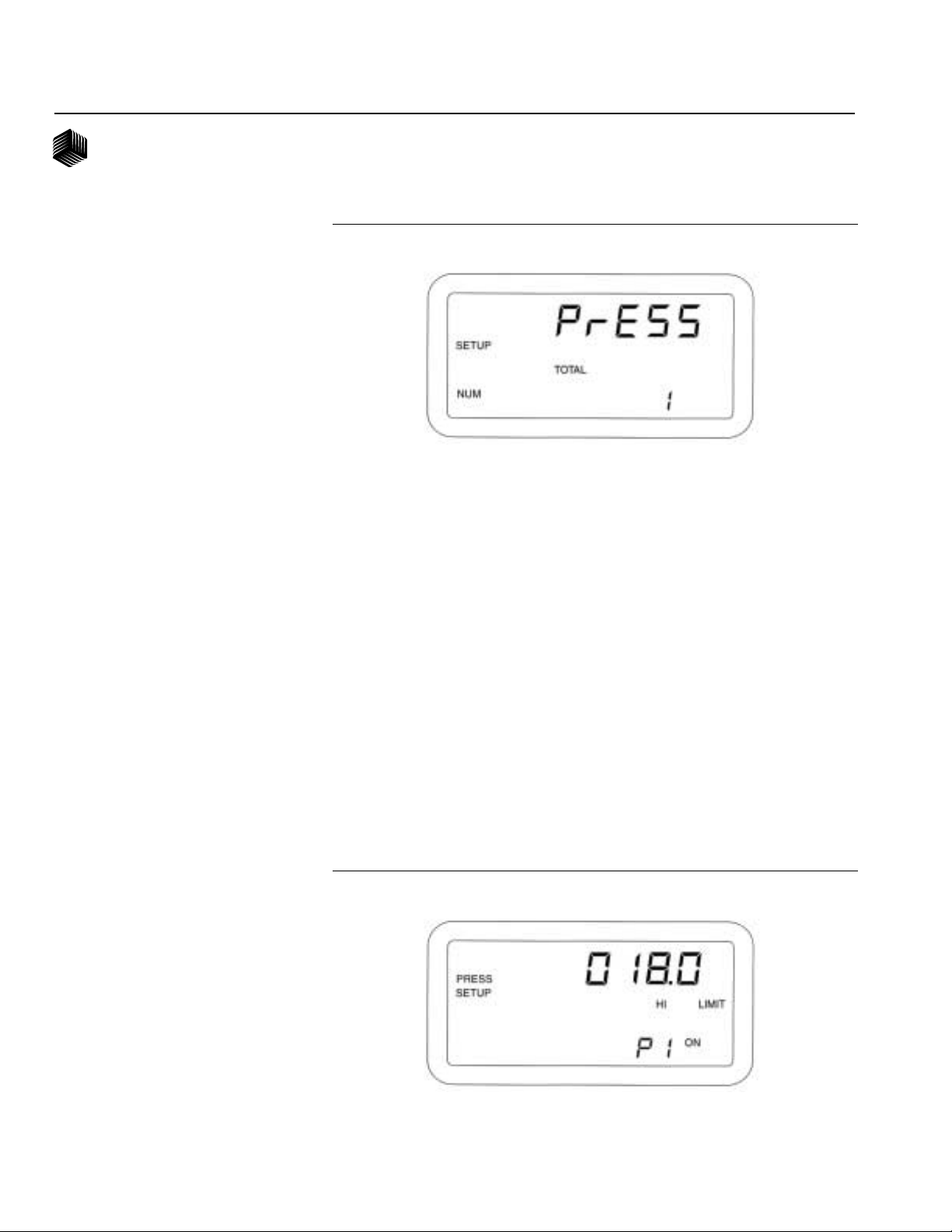

Figure 30

Pressure Sensor Display

22. Number of Pressure Sensors

This is the actual number of Pressure

Sensors that are connected to a Shaft

Speed Module on the system. This

parameter will be checked as part of the

Sensor/Module Self-Test, and Error

codes will be generated if this value does

not match the actual number of Pressure

Sensors. Figure 30 shows a configuration of one (1) Pressure Sensor.

23. Pressure Sensor Hi Limit

The Pressure Sensor Hi Limit Warning

is entered in oz/in2 (kPa). The Hi and

Lo warning limits are accessible only if

Figure 31

Hi Limit Pressure Display

the Number of Pressure Sensors has a

value other than 0. Setting the Pressure

Sensor Hi Limit will cause the audible

alarm to sound when the pressure

exceeds the value that has been entered.

Use the SET and SELECT switches to

adjust the Pressure Sensor Hi Limit

value. The Pressure Sensor Hi Limit

can be enabled or disabled by selecting

the ON or OFF symbol after the

rightmost digit. Pressing the SET switch

will toggle the status of the warning

between ON and OFF. Figure 31 shows

a Pressure Sensor Hi Limit of 18.0 with

the warning enabled.

32/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 32

Lo Limit Pressure Display

24. Pressure Sensor Lo Limit

The Pressure Sensor Lo Limit Warning

is entered in oz/in2 (kPa). The Hi and

Lo warning limits are accessible only if

the Number of Pressure Sensors has a

value other than 0. Setting the Pressure

Sensor Lo Limit will cause the audible

alarm to sound when the pressure falls

below the value that has been entered.

Use the SET and SELECT switches to

adjust the Pressure Sensor Lo Limit

value. The Pressure Sensor Lo Limit

can be enabled or disabled by selecting

the ON or OFF symbol after the

rightmost digit. Pressing the SET switch

Figure 33

Blockage Configuration

Blockage

Mode Description

will toggle the status of the warning

between ON and OFF. Figure 32 shows

a Pressure Sensor Lo Limit of 3.8 with

the warning disabled.

25. Blockage Mode Configuration

This configuration will select one of

three different modes according to the

Table in Figure 33. If Mode 0 or Mode

1 is selected, the Operate screens will

cycle through the Population Rows only.

If Mode 2 is selected, The Population

and Spacing Operate screens will show a

series of 5 dashes to represent no data.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

0 All Rows are configured for displaying Population

1 First Row of each Module is configured for displaying

Population – All other rows are configured for

Blockage Only .

2 All Rows are configured for Blockage Only

SETUP/ 33

OPERATOR'S MANUAL

Figure 34

Blockage Mode Display

In all modes Row failures will be

displayed according to the details in the

ALARMS section of this document.

Figure 34 shows a Blockage Mode

Configuration of 0.

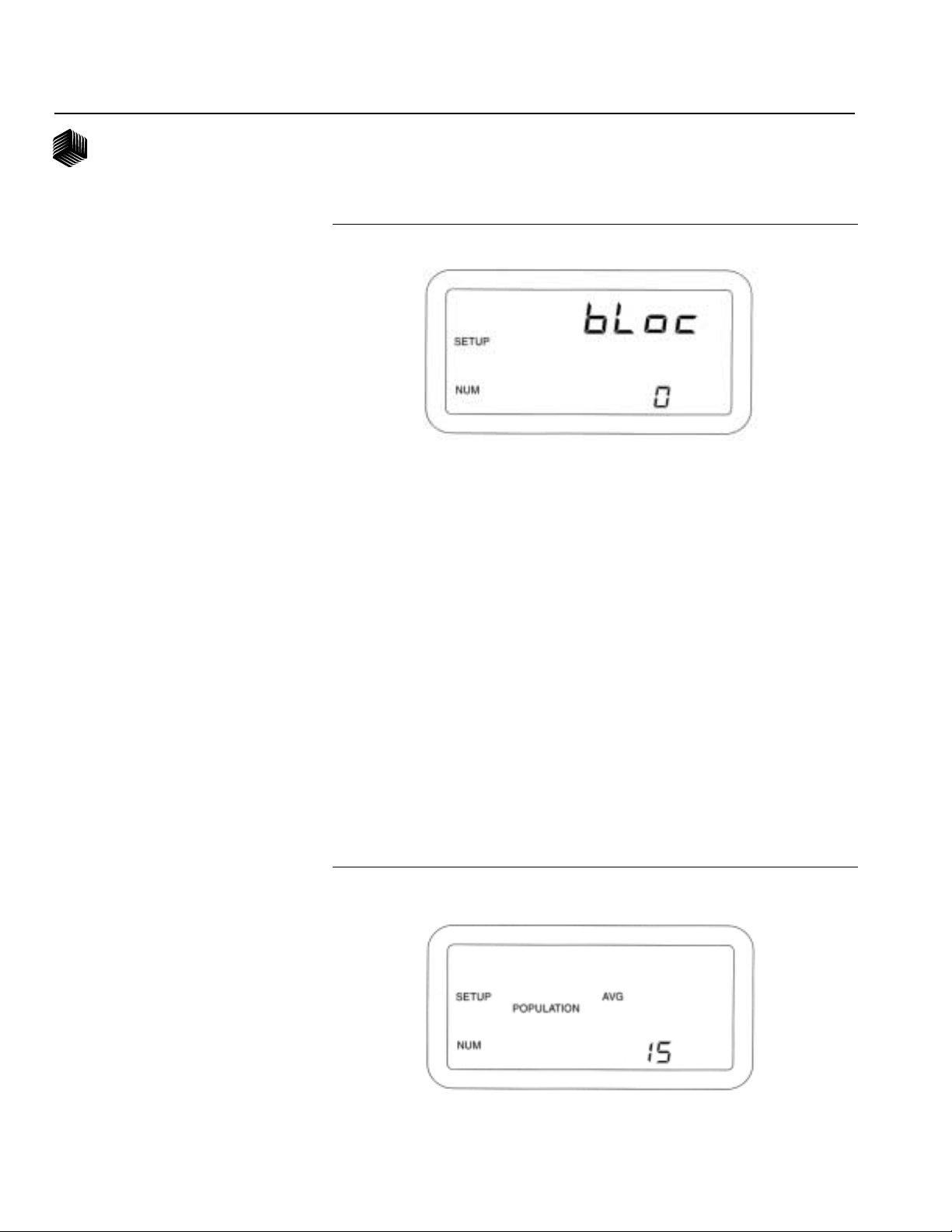

26. Population Filter

In certain applications, the Seed

Manager® SE, due to its rapid update

rate, might exhibit fluctuations in

population and spacing that are undesir-

able to the operator. The population

filtering option applies an averaging filter

to the population and spacing calcula-

Figure 35

Population Filter

tions. The filter values range from 0 to

99, with 0 having no filtering effect, and

99 being the maximum filtering value.

Use the SET and SELECT switches to

adjust the filtering value. Figure 35

shows a Population Filter of 15.

27. Population Scaling Factor

The population scaling factor allows the

operator to make fine adjustments in the

readout of population and spacing on a

percentage basis. This value is adjust-

able from 1% to 999% with the factory

default being 100%. Use the SET and

34/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 36

Population Scaling Display

SELECT switches to adjust to the

desired population scaling factor. Figure

36 shows a Population Scaling of 105%.

28. Sensor/Module Self-Test

Start the test by pressing the START

STOP RESET switch. The TEST

message flashes while the test is executing

(Note: This is the same test that is

performed automatically during console

power up). When the test is complete

the display will show either PASSED

(and scroll through all available seed

Figure 37

Sensor Self-Test Display

rows), or show FAILED and display the

appropriate error code(s). If multiple

errors exist, the E in the error code will

be flashing. To view the next error code,

press the Alarm switch. For a full

description of all the error codes and

their meanings, see the ERROR CODES

chapter. Figure 37 shows the Sensor/

Module Self Test Screen.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 35

OPERATOR'S MANUAL

Figure 38

Units Selection Display

29. English/Metric Units

The user selects the system of units with

this constant. The SET switch is used to

toggle between English and Metric units.

Figure 38 shows the display when Metric

units are selected. The METRIC

message is absent when English units are

selected.

CUSTOMER SETUP

CONSTANTS

The Customer Setup Constants are

entered by holding the SETUP switch

depressed, while powering on the

console and continuing to hold it

depressed until the Display Test begins.

A flashing SETUP message indicates the

console is in the Customer Setup

Constants. Press the SETUP switch to

advance to the next Customer Setup

Constant. To exit the Customer Setup

Constants, power off the console. The

different Customer Setup Constants are

listed as follows:

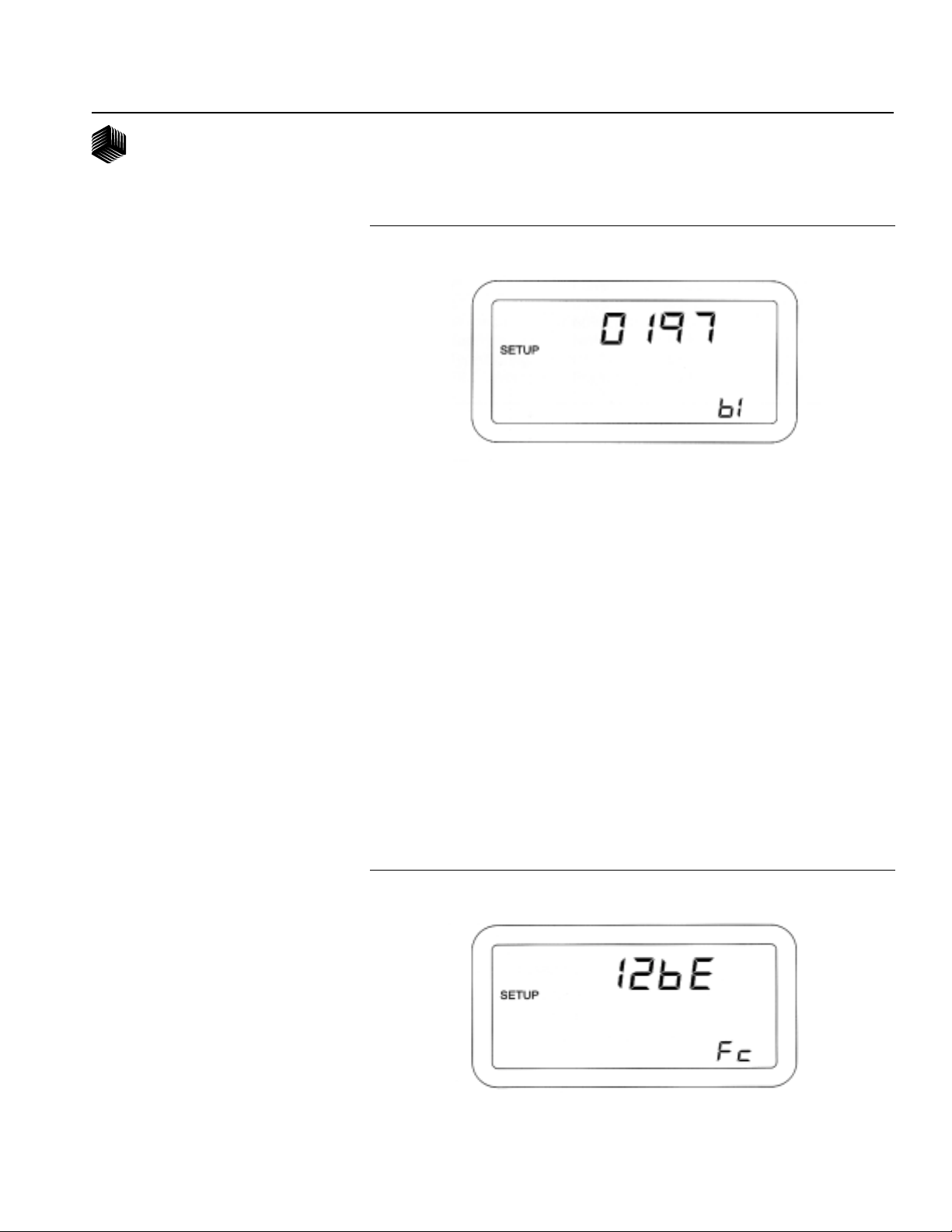

1. Boot Version Number

DICKEY-johns Service Department

may request the customer to observe and

record the four (4) different 4-digit

numbers (to identify the boot memory

software version) in the unlikely event

field problems occur.

The first 4-digit number shows on the

upper numeric display at the same time a

b1 identifier appears on the lower

numeric display. Record this number,

then press and release the SELECT

switch to step to the b2, b3, and bc

numbers, recording each 4-digit number

along with its identifier. To return to

b1 again press the SELECT switch.

Press SETUP to advance to the next

constant. Figure 39 shows 0197 for

b1, the first Boot Version Number.

36/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 39

Boot Number

2. Flash Version Number

DICKEY-johns Service Department

may request the customer to observe and

record the four (4) different 4-digit

numbers (to identify the flash memory

software version) in the unlikely event

field problems occur.

The first 4-digit number shows on the

upper numeric display at the same time a

F1 identifier appears on the lower

Figure 40

Flash Version Number

numeric display. Record this number,

then press and release the SELECT

switch to step to the F2, F3, and Fc

numbers, recording each 4-digit number

along with its identifier. To return to

F1 again press the SELECT switch.

Press SETUP to advance to the next

constant. Figure 40 shows 12bE for

Fc, the first Boot Version Number.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

SETUP/ 37

OPERATOR'S MANUAL

38/ SETUP

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

OPERATE MODE

A. OPERATE MODE

Performance of the following Operate

Mode functions assumes the console has

been properly installed and setup as

detailed in the INSTALLATION and

SETUP MODE chapters respectively.

Figure 41 lists all Operate Mode

functions and shows which are available

in the Speed Area Mode (defined later

in this chapter). Notice, this list includes

all the function names on the three (3)

Operate Mode switches, plus the Run

Hours function, which is performed

automatically.

Figure 41

Operate Mode Function Name Available in Speed Area Mode

B. RUN HOURS

This is defined as the total number of

accumulated hours, in 0.1 hour increments, the console has been powered.

Run Hours are not accumulated during

an ALL ROWS FAILED condition or if

a lift switch is installed and the implement

is in the up position. The Run Hours

total is displayed for five (5) seconds

immediately following the power up

sequence. The SETUP switch or any of

the three Operate Mode switches can be

pressed during the display of the Run

Hours to advance immediately to the

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

Run Hours Yes

Population No

Seed Spacing No

Ground Speed Yes

Fan Speed Y es

Shaft Speed Y es

Pressure Yes

Area Accumulator Y es

Seed Count No

Distance Accumulator Y es

OPERATE/ 39

OPERATOR'S MANUAL

Figure 42

Run Hours Display

desired function. Otherwise the

Population function is automatically

selected. To zero the accumulated Run

Hours, press the START STOP

RESET switch for one (1) second while

Run Hours are displayed. Figure 42

shows Run Hours of 47.5.

C. POPULATION

This is the amount of seeds, in thou-

sands of seeds per acre (hectare), sown

in a given row based, upon the most

recent sampling of the seeding rate for

that row. The Population function is

selected automatically upon power up or

by pressing the OPERATE 1 switch until

the POPULATION message appears

on the display. Only the seed rows that

have their row status set to ON will be

displayed in the Population function. If

the Blockage Mode is set to All Rows

Blockage, the upper numeric display will

show a series of five (5) dashes and no

population values will be available. The

Population display has several different

modes based upon the Setup configuration and the scan mode that is selected.

A short description of each mode is

described as follows.

40/ OPERATE

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

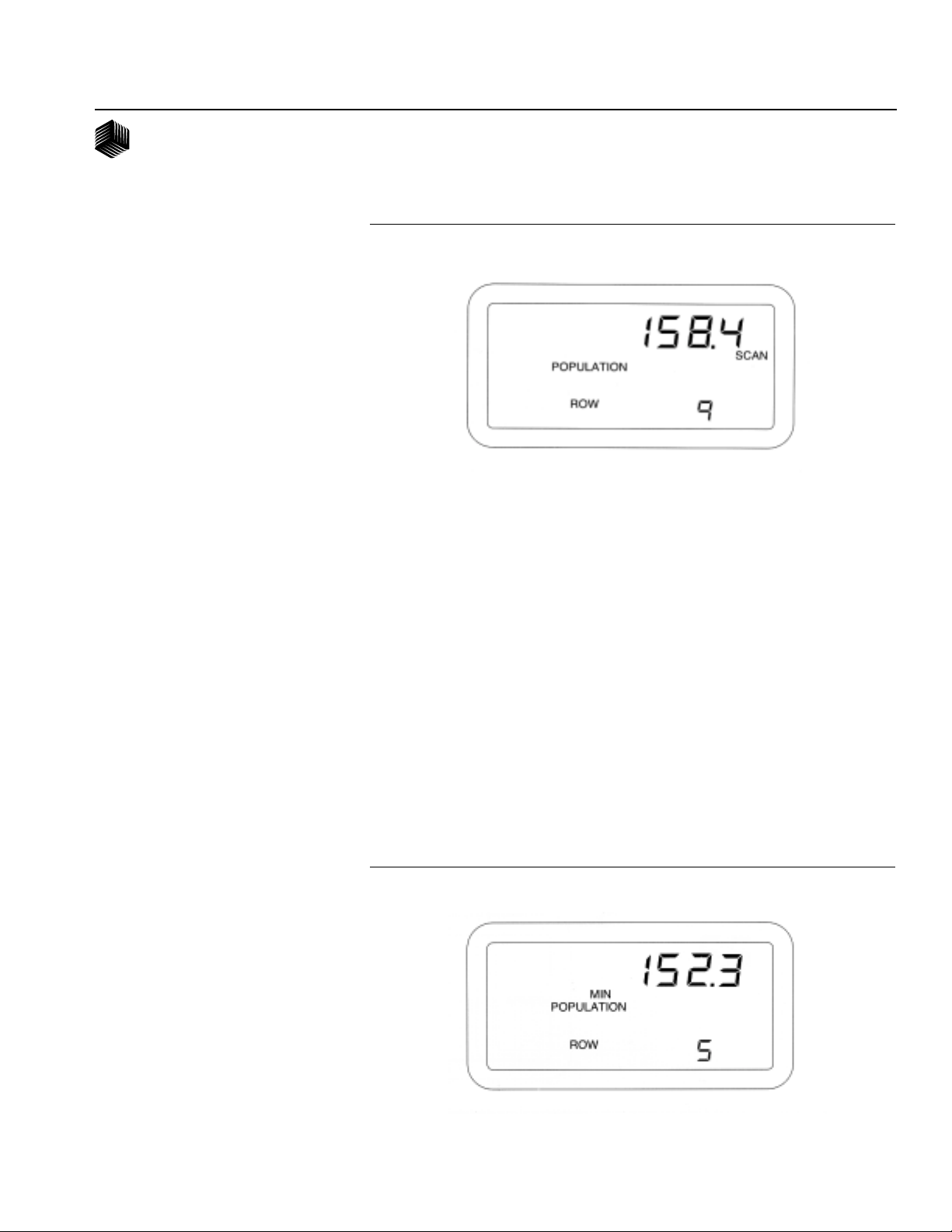

Figure 43

Population SCAN Display

1. Population Scan

This mode will display the population of

each valid row for two (2) seconds, then

advances to the next row. After the last

row population is displayed, the average

seeding population (for all valid popula-

tion rows) is displayed, identified by the

AVG message. Population Scan mode is

selected automatically upon powerup or

can be selected by pressing the MIN

AVG MAX SCAN switch until the

SCAN message is displayed while in

Population function. Figure 43 shows a

population of 158,400 seeds/acre on row

nine (9) while in Population Scan.

Figure 44

Population MIN-AVG-MAX Display

2. Population Min Avg Max

This mode will display the seeding row

with the minimum population, the

average seeding population, and the

seeding row with the maximum popula-

tion in cyclic fashion, dwelling on each

for three (3) seconds. This option is

selected by pressing the MIN AVG

MAX SCAN switch while in the Popula-

tion function. Figure 44 shows a

minimum population of 152,300 seeds/

acre on row five (5).

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATE/ 41

OPERATOR'S MANUAL

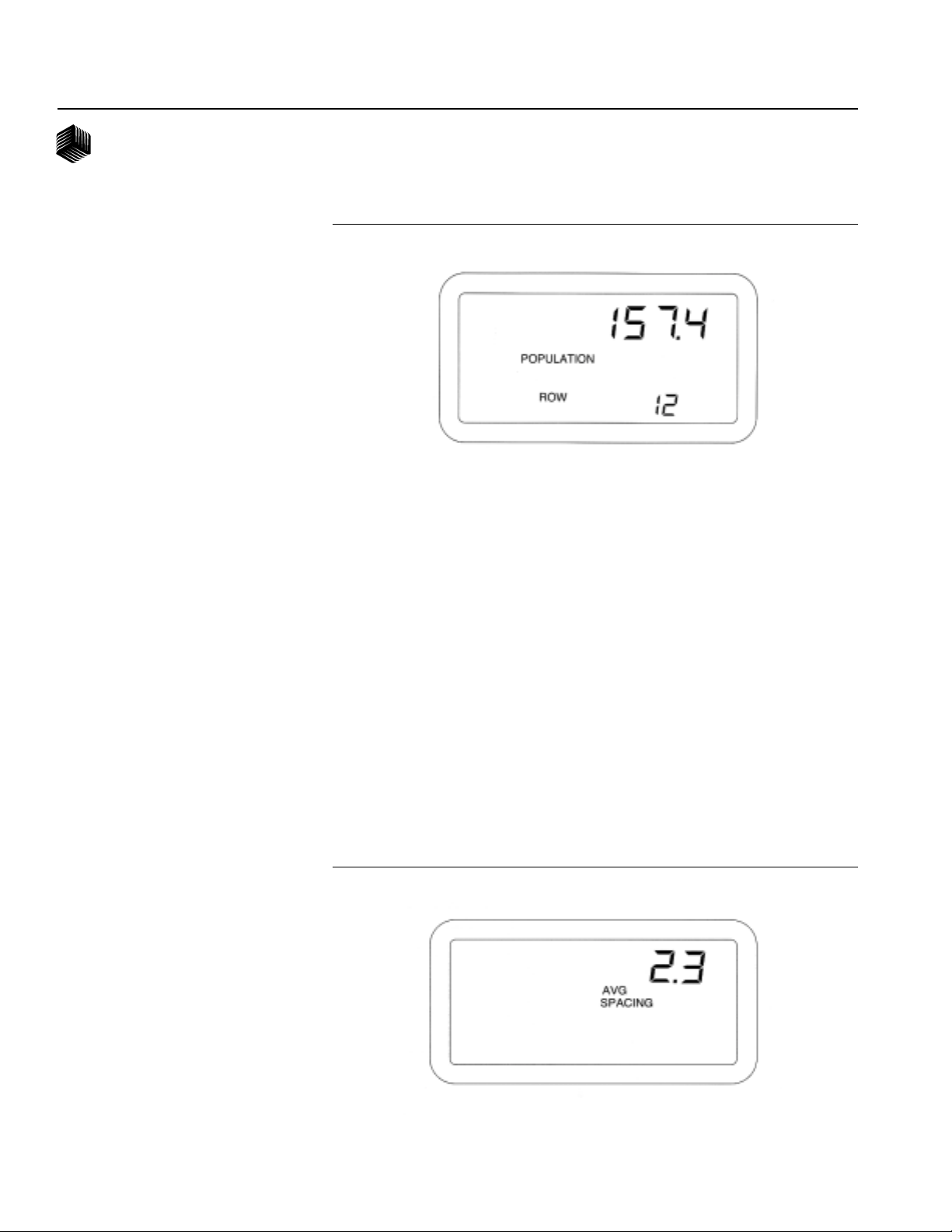

Figure 45

Population SELECT ROW Display

3. Population Select Row

Depressing the SELECT ROW switch

while in either Population Scan or

Population Min Avg Max freezes the

population display on the current row or

the implement average. Pressing the

SELECT ROW switch again, causes the

display to advance to the next valid

population row. Pressing the BACK

switch, will cause the display to return to

the previous valid population row.

Figure 45 shows a population of 157,400

seeds/acre on row twelve (12) while in

Population Select Row.

Figure 46

Seed spacing average Display

4. Seed Spacing

This is the calculated average spacing

between seeds in the furrow, in inches

(centimeters). The resolution is in 0.1

inches (centimeters). This function is

selected by pressing the OPERATE 1

switch until the SPACING message

appears on the display. The Seed

Spacing display has several different

modes based upon the Setup configura-

tion and the scan mode that is selected.

They are the same modes as in the

Population function. Figure 46 shows an

implement average seed spacing of 2.3

inches between seeds.

42/ OPERATE

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 47

Ground Speed Display

5. Ground Speed

This is the ground speed in MPH (Km/

h), with 0.1 resolution, as measured by

the ground speed sensor. This function

is selected by pressing the OPERATE 1

switch until the SPEED message appears

on the display. The ground speed

sensor can be either radar, Hall Effect,

or reluctance type. Figure 47 shows a

ground speed of 5.6 MPH.

Figure 48

Fan Speed Display

6. Fan Speed

This is the rotational speed of any Fan

the user wishes to monitor. A Hall

Effect type sensor senses points on a fan

to a resolution of 0.1 RPM. This

function is selected by pressing the

OPERATE 2 switch until F1 or F2 is

displayed in the lower numerical display.

Figure 48 shows a fan speed of 275.8

RPM.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATE/ 43

OPERATOR'S MANUAL

Figure 49

Shaft Speed Display

7. Shaft Speed

This is the rotational speed of any shaft

the user wishes to monitor. A Hall

Effect type sensor senses a multi-toothed

gear mounted on the shaft, to a resolu-

tion of 0.1 RPM. Typically, a shaft

driving the seeding mechanism is

monitored. This function is selected by

pressing the OPERATE 2 switch until

S1, S2, or S3 is displayed in the

lower numerical display. Figure 49

shows a shaft speed of 53.0 RPM.

Figure 50

Pressure Display

8. Pressure

This is the pressure in oz/in2 (kPa), as

measured by a pressure sensor, to a

resolution of 0.1 oz/in2 (kPa). This

function is selected by pressing the

OPERATE 2 switch until P1 or P2 is

displayed in the lower numerical display.

Figure 50 shows a pressure of 12.3 oz/

in2 .

44/ OPERATE

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATOR'S MANUAL

Figure 51

Area Accumulator 1 Display

9. Area Accumulator

Area Accumulator 1 and 2 are intended

to be used as field area accumulators,

displaying acres with 0.1 resolution

(hectares with 0.01 resolution). Area

Accumulator 3 is intended to be used as

a total area accumulator with the same

resolution as Area Accumulator 1 and 2.

The area calculations are based on the

Implement Width and distance traveled.

Area does not accumulate during an

ALL ROWS FAILED condition, i. e.,

when the implement is raised. This

function is selected by pressing the

OPERATE 3 switch until the AREA

message appears and a 1, 2, or 3 is

shown in the lower right corner of the

display. Area Accumulator 1 and 2 is

reset by pressing the START STOP

RESET switch for at least one (1)

second. Area Accumulator 3 is reset by

pressing the START STOP RESET

switch for at least three (3) seconds.

When a total of 9999.9 acres (999.99

hectares) is exceeded, the decimal point

shifts to the right one place. When a

total area of 99999 acres (hectares) is

exceeded, it will roll over to zero (0).

Figure 51 shows Area Accumulator 1

with 1674.3 acres.

10. Seed Count

This function is used to count the

number of seeds passing through each

seed sensor. This function is selected by

pressing the OPERATE 3 switch until

the COUNT message appears.

Press the START STOP RESET switch

to start the measurement, then press it

again to stop. The ON and OFF messages on the display indicate the Seed Count

function status. To zero the accumulated

seed count on the selected row, press

and hold the START STOP RESET

switch until a beep occurs (approximately

one (1) second). To zero the seed count

for all rows, press and hold the START

STOP RESET switch for at least three

(3) seconds. When a total of 99999

counts are exceeded, the count rolls over

to zero (0). Depress the SELECT ROW

switch to advance the display to the next

row. Depress the BACK switch to

return to the previous row.

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A

OPERATE/ 45

OPERATOR'S MANUAL

Figure 52

Seed Count Display

46/ OPERATE

Any other Operate Mode function can

be selected while Seed Count is running

without affecting the actual seed counts.

Figure 52 shows a stopped seed counter

with 1693 seeds counted on row fourteen

(14).

11. Distance Accumulator

This function is used to measure distances

in feet (meters), with 0.1 resolution. It can

only be used after the Distance Calibra-

tion Constant has been accurately

established (See the SETUP MODE

chapter for details). This function is

selected by pressing the OPERATE 3

switch until the DISTANCE and ACC

messages appear on the display.

Press the START STOP RESET switch

to start the measurement, then press it

again to stop. The ON and OFF messag-

es on the display indicate the Distance

Accumulator function status. To zero

the distance accumulator, press and hold

the START STOP RESET switch until a

beep occurs (approximately one (1)

second). When a total of 9999.9 feet

(meters) are exceeded the accumulator

rolls over to zero (0).

Any other Operate Mode function can

be selected while Distance Accumulator

is running without affecting the actual

distance accumulation. Figure 53 shows

a running distance accumulator with

783.6 feet measured.

12. Speed Area Mode

The Speed Area Mode is used to monitor

non-seeding operations like cultivating.

Only the Speed, Fan Speed, Shaft Speed,

Pressure, Area, and Distance Accumulator functions are available in this mode.

Figure 41 shows this function availability

in chart form. The console display for

these functions is identical in the Speed

Area and Operate Modes.

Enter the Speed Area Mode as follows:

A lift switch (Implement status switch) must

be connected to a Shaft Speed Module

that is connected to the system. No seed

sensors can be connected at this time.

Power down, then power up the console

(wait a minimum of 10 seconds before

re-powering the system).

Dj SEED MANAGER® SE PLANTER MONITOR

BENCHMARK Series® 11001-1218-200112 Rev A