ADDENDUM (GAC® 2500 UGMA/INTL)

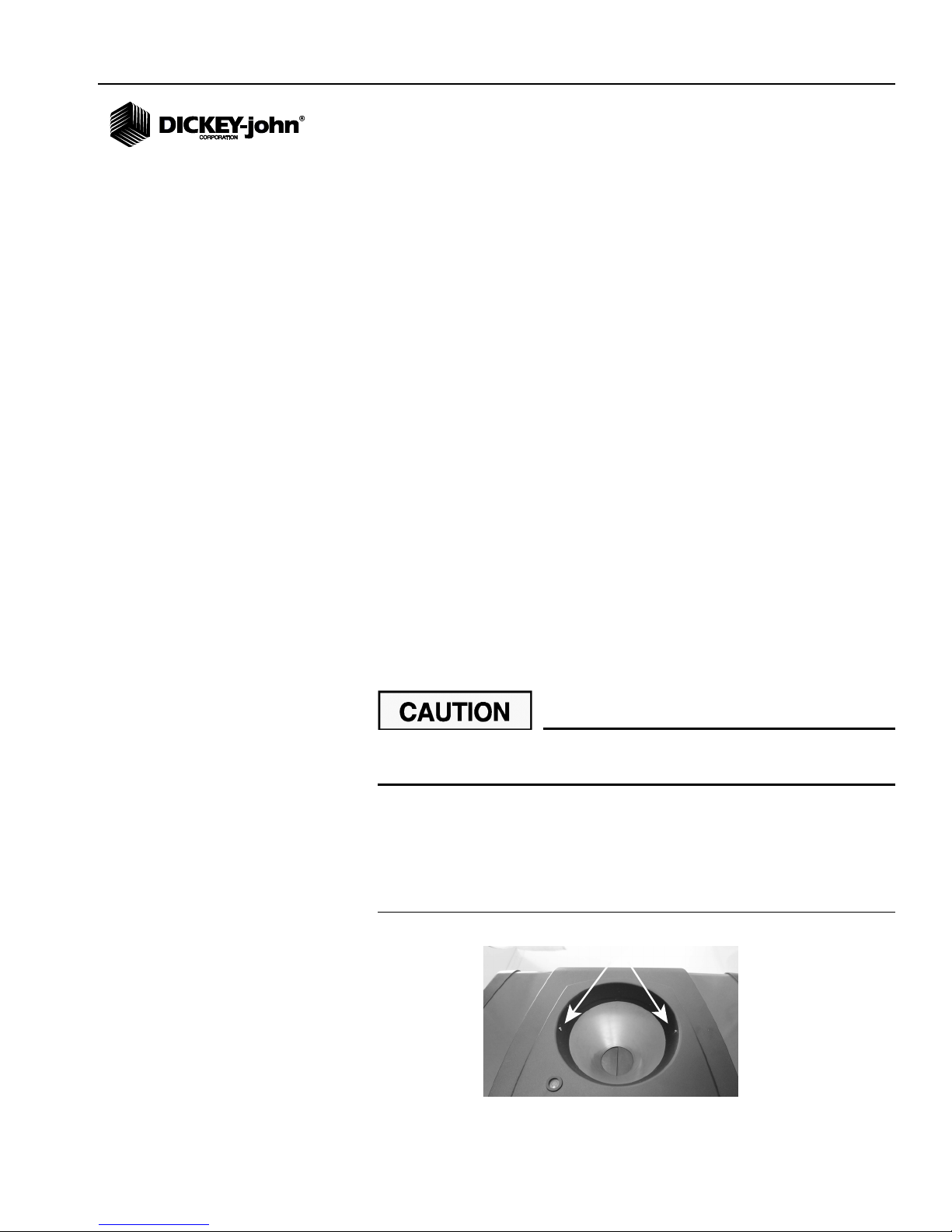

Upper grain

hopper sensors

MAINTENANCE

This Addendum updates the Maintenance section of the GAC® 2500

(UGMA & INTL) operator’s manual (11001-1505F and all other preceding

manuals).

NOTE: For customers that require a

more extensive cleaning

procedure with debris buildup in

the cell, contact and schedule

your instrument for cleaning

with your dealer or authorized

service center.

IMPORTANT: It is highly recommended the unit be regularly inspected

and cleaned to ensure continued and consistent results.

For optimum performance, extensive cleaning should be performed

weekly or more often based on surrounding environment conditions.

Factors such as dust, temperature extremes, grain dust, and external

humidity vary from location to location. If there are any questions

about the cleanliness or instrument performance, contact your local

authorized service center.

Note: The following recommendations are provided as a guideline to

maintain a robust and quality operating instrument. It should not be

interpreted as an exhaustive maintenance program. Dust and debris may

periodically accumulate in areas not specified in this manual. The owner is

responsible for ensuring overall equipment cleanliness. If any questions

arise regarding the maintenance or performance of the instrument, contact

your dealer or local authorized service center.

EXTERNAL CLEANING

The LCD display may require periodic cleaning. Use a commercial cleaner

for glass lenses to remove dust.

Do not apply water, organic solvent or chemicals, such as acid

and alkali to the LCD display.

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

The GAC® 2500 surface can be cleaned with any cleaner designed for

plastic and stainless steel surfaces.

Periodically use a rag to wipe the grain hopper and the (2) upper grain

hopper sensors.

Figure 1

Grain Hopper Sensors

MAINTENANCE / 1

ADDENDUM (GAC® 2500 UGMA/INTL)

Instrument Information

S/N: 1807-00005

Software Versions:

IP Address: 169.254.0.37

Las t Serv ice: 1/1/2014

4.2.0.0, 2.4, 2.2

NTEP COC:

10-038

Model:

GAC2500

-

DICKEY-

john Cor poratio n

Analyze

Current User: Guest

SetupResults

Cleaning Cell

Setting Instrument to Cleaning Mode

Please wait...

GAC2500-UGMA

GAC2500-UGMA

GAC2500-UGMA

Directive No: 9180.61 05-01-13

INTERNAL CLEANING

Performing continuous tests can result in material accumulation around the

critical internal components and adversely affect the measurement.

Two types of cleaning are recommended on an as needed basis:

• Daily clean

• Extensive clean

DAILY CLEAN METHOD

A daily clean method allows cleaning the cell and door using an automated

process. During the cleaning sequence, the hopper door automatically

opens. Instruments with version 2.4 grain handler firmware, the trap door

opens automatically also.

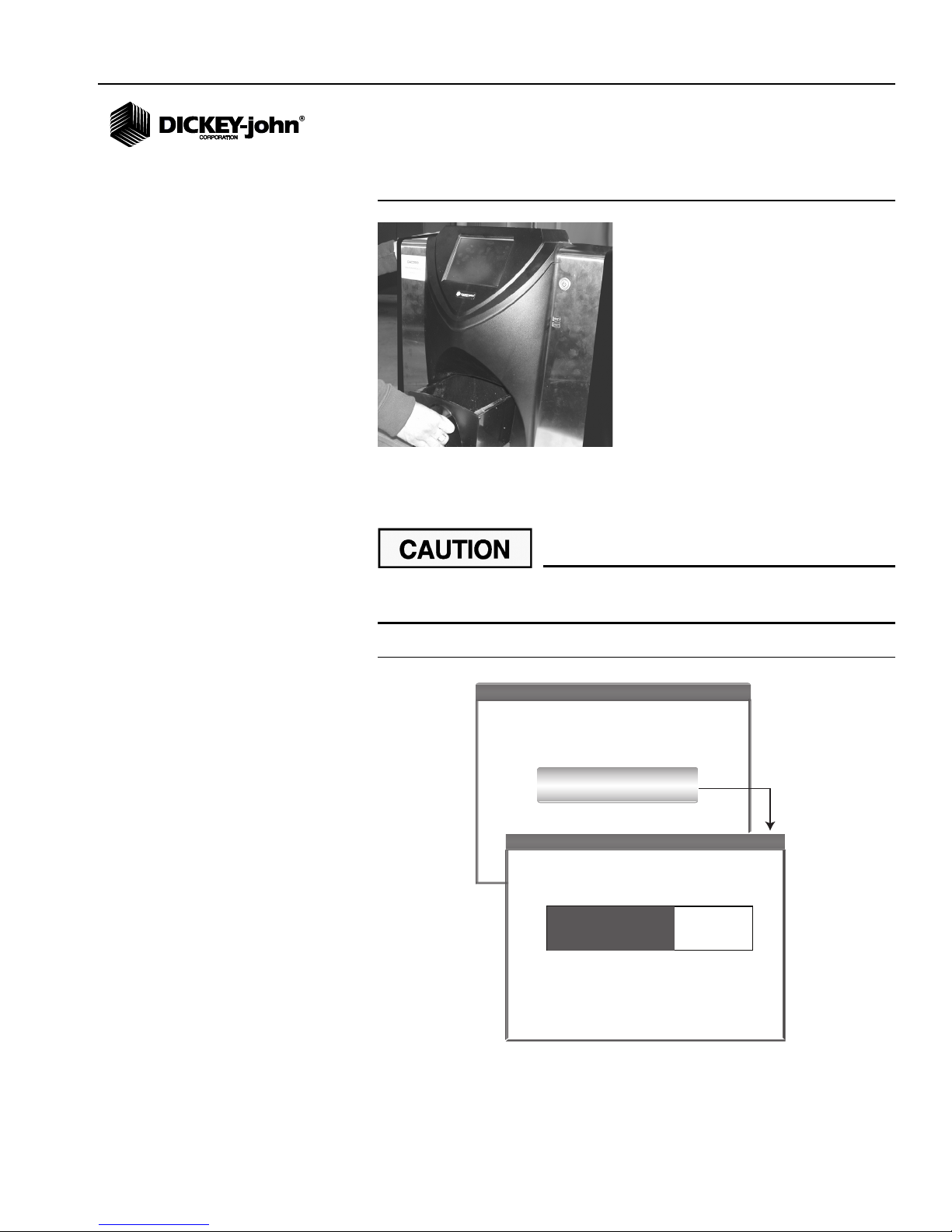

To start the cleaning process:

1. At the Main Menu screen, press the Instrument Information button.

2. At the Instrument Information screen, press the Clean button.

– Pressing the Clean button automatically begins the cleaning

sequence and opens the hopper door and the trap door (version 2.4

grain handler firmware).

Figure 2

Daily Clean Method

2/MAINTENANCE

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

ADDENDUM (GAC® 2500 UGMA/INTL)

Clean Cell

Clean Cell

Ok

GAC2500-UGMA

Clean Cell and Press Ok when complete

Cleaning Cell-

Cleaning Cell

Returning System to Normal Operation

Please wait...

GAC2500-UGMA

3. Remove the grain drawer.

Figure 3

Remove Grain Drawer

4. Using the supplied brush, manually remove any loose or stuck grain or

dust from the measuring cell.

5. Press the OK button to return instrument to normal operation.

Hands should be clear from inside the instrument before pressing

the OK button.

Figure 4

Cleaning Sequence

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

6. Insert grain drawer.

MAINTENANCE / 3

ADDENDUM (GAC® 2500 UGMA/INTL)

EXTENSIVE CLEANING METHOD

NOTE: For customers that require a

more extensive cleaning

procedure with buildup in the

cell, contact and schedule your

instrument for cleaning with

your dealer or authorized

service center.

The daily cleaning method should be performed first before proceeding to

the extensive cleaning method.

IMPORTANT:

Extensive cleaning should be performed weekly or more often based

on surrounding environment conditions. Factors such as dust,

temperature extremes, grain dust, and external humidity vary from

location to location. If there are any questions about the cleanliness or

instrument performance, contact your local authorized service center.

Tools required for internal mechanism cleaning:

• Brush p/n 206410003 (included with instrument)

Extensive cleaning of the instrument involves two steps to ensure optimum

instrument performance:

1. Internal mechanism cleaning

2. Temperature sensor probe cleaning

To Clean the Instrument:

1. Power down the instrument.

Figure 5

Power Down

4/MAINTENANCE

2. Unplug power cord.

Figure 6

Unplug Power Cord

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

ADDENDUM (GAC® 2500 UGMA/INTL)

3. Remove other accessory cords (USB and printer).

Figure 7

Remove Accessory Cords

4. Remove grain drawer.

Figure 8

Remove Grain Drawer

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

5. Place the unit on its back side.

Figure 9

Place Unit on Back Side

MAINTENANCE / 5

ADDENDUM (GAC® 2500 UGMA/INTL)

6. Manually pull down on trap door.

Figure 10

Pull Down on Trap Door

7. Clean surfaces around measurement cell including hinge, trap door,

and edge of cell with the supplied brush.

Figure 11

Clean Surface Area Around Cell, Hinge, Trap Door, Edge of Cell

8. Close the trap door and clean hinge under trap door with brush.

Figure 12

Clean Under Trap Door

9. Proceed to instruction for cleaning the temperature sensor probe.

6/MAINTENANCE

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

ADDENDUM (GAC® 2500 UGMA/INTL)

CLEANING THE TEMPERATURE SENSOR PROBE

IMPORTANT: Any particles in front of the sensor’s optics can affect

measurement performance. Therefore it is crucial to

sufficiently clean the sensor. For excessive dust and/or

foreign material buildup on or around the temperature

sensor, it is recommended the instrument be returned to

DICKEY-john Service or authorized service center.

The temperature sensor may require cleaning due to dust buildup and/or

foreign material that has collected around the sensor that could potentially

cause temperature error readings during analysis. It is important the

temperature sensor is visually inspected and cleaned each time a regular

maintenance check of the instrument is conducted.

Tools required for cleaning the temperature sensor probe:

1. One of the below cotton swabs:

– Standard 6” long cotton swab (i.e. McMaster-Carr p/n 7074T12) for

flush sensor

– 6” long, tapered tip cotton swab (i.e. McMaster-Carr p/n 71035T54)

for embedded sensor

Figure 13

Recommended Cotton Swab for Flush Sensor

Figure 14

Recommended Cotton Swab for Embedded Sensor

2. 99% Isopropyl Alcohol

Figure 15

99% Isopropyl Alcohol

3. 10” flat head screw driver (only for instruments with flush sensor/brush

bracket)

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

Figure 16

10” Flat Head Screw Driver

MAINTENANCE / 7

ADDENDUM (GAC® 2500 UGMA/INTL)

Enlarged view of

ush sensor

OR

Enlarged view of

embedded sensor

[

Brush and

Bracket

Assembly

(ush sensor)

TEMPERATURE SENSOR TYPE

The GAC 2500 is equipped with one of two different sensor types. The

cleaning method is similar for both types however the cotton swab for

cleaning varies based on the sensor type.

• older instruments may include an embedded sensor on the circuit

board (recommended cotton swab McMaster-Carr p/n 71035T54)

• newer instruments include a flush sensor on the circuit board and a

brush bracket (recommended cotton swab McMaster-Carr p/n

7074T12 )

TEMPERATURE SENSOR LOCATION

With the instrument placed upside down and looking inside the instrument,

the sensor probe is located in the middle of the instrument toward the top

and front attached to a circuit board.

Figure 17

Sensor Probe Location

8/MAINTENANCE

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

ADDENDUM (GAC® 2500 UGMA/INTL)

To Clean the IR Temperature Sensor:

1. Gently place instrument upside down.

Figure 18

Place Instrument Upside Down

2. Visually inspect the IR temperature sensor to determine the type of

sensor installed.

3. For instruments with the flush sensor and brush bracket, the following

procedure can be utilized to remove particles from the brush. Carefully

place the head of the screw driver (10” length recommended) at the

bristles and use a sweeping side-to-side motion through the entire

length of the bristles no fewer than three times.

Figure 19

Cleaning the Brush Assembly

4. Select the appropriate cotton swab as described. Wet one end of the

cotton swab with 99% Isopropyl alcohol.

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

MAINTENANCE / 9

ADDENDUM (GAC® 2500 UGMA/INTL)

Flush sensorEmbedded sensor

Figure 20

Wet Swab with Alcohol

5. Swab method for cleaning sensor:

– For embedded sensors, the sensor is located inside the black tube.

Insert the swab inside the black tube and gently clean the IR

temperature sensor with the wet end of the cotton swab as depicted

in (Figure 21).

– For flush sensors, gently clean the entire IR temperature sensor

surface with the wet end of the cotton swab as depicted in

(Figure 21).

Figure 21

Magnified View of Proper Cleaning with Cotton Swab

10/MAINTENANCE

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

ADDENDUM (GAC® 2500 UGMA/INTL)

Funnel

Place Q-tip

on either side

of funnel

to reach

sensor

The IR temperature sensor can be cleaned with the Q-tip by placing the

Q-tip through the funnel or on the outside of the funnel as depicted in

(Figure 22).

Figure 22

Cleaning the Sensor with Cotton Swab

6. Allow the temperature sensor to dry for 90 seconds then gently clean

with the dry end of the cotton swab.

7. Visually inspect the temperature sensor as well as all other areas

cleaned to ensure the instrument is free from debris. If there is any

question about the cleanliness of the instrument, it should be returned

to a dealer or authorized service center.

8. If cleaning is acceptable, return instrument to upright position and

replace the drawer.

9. Reconnect power cable and accessory cords.

10. Power on instrument.

IMPORTANT: The foregoing recommendations are provided as a

guideline to maintain a robust and quality operating

GAC 2500. It should not be interpreted as an exhaustive

maintenance program. Dust and debris may periodically

accumulate in areas not specified in this manual. The

owner is responsible for ensuring overall equipment

cleanliness. If any questions arise regarding the

maintenance or performance of the instrument, contact

your dealer or local authorized service center.

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

MAINTENANCE / 11

ADDENDUM (GAC® 2500 UGMA/INTL)

12/MAINTENANCE

GAC® 2500 Models (UGMA & INTL)

11001-1646A-201409

Loading...

Loading...