®

SINCE 1966

GAC® 2100 GRAIN

ANALYSIS COMPUTER

MODELS BLUE, GRAY, AND AGRI

Operator’s Manual

OPERATOR’S MANUAL

Safety Notices ..................................................................................................... 1

Disclaimer ......................................................................................................................... 1

Introduction ......................................................................................................... 3

Accessories ....................................................................................................................... 3

Features ............................................................................................................................ 4

Specifications .................................................................................................................... 4

Access Codes ................................................................................................................... 5

External Communication Connections .............................................................................. 5

Printer ............................................................................................................................... 6

Unpacking the Instrument .................................................................................. 7

Disengage Shipping Brace ............................................................................................... 7

Instrument Placement.........................................................................................................8

Installation ......................................................................................................... 11

Connecting AC Power .................................................. .... ... ............................................ 11

Sample Drawer Bypass .................................................................................................. 12

Navigation .......................................................................................................... 13

Display Screen ................................................................................................................ 13

Adjust Screen Contrast ................................................................................................... 13

Keyboard Layout ............................................................................................................. 13

Alarm ............................................................................................................................... 14

Key Functions ................................................................................................................. 14

Menu Screens .................... .... ... ... ... ... .... ... ... ... ................................................................ 15

Startup Procedure ............................................................................................. 17

Test Samples (Quick Start)...............................................................................................18

Measure Moisture ...............................................................................................19

Basic Method .................................................................................................................. 20

Grain Sample ID Numbers .............................................................................................. 22

Enter Numbers and Alpha Characters ............................................................................ 22

ID Options .................................... ... ... .... ... ... ... .... ............................................................ 23

Factors (Labels) ........................................................................................................ .... .. 23

Next Page View ........................... ... ... .... ... ... ... .... ... ... ...................................................... 24

Grain Selection .................................................................................................. 25

Select Grain Menu .......................................................................................................... 25

Quick Keys ......................................................................................................................26

Calibrate Procedures ................................... ..... .... .... .... .... ..... .... ........ .... ..... .... .. 27

View Calibration Data (1 Key) ......................................................................................... 27

Enter/Change Calibration Values (2 Key) ....................................................................... 28

Print Calibration Grain List (3 Key) ................. ................................................................ 31

Obtain Basic Calibration Data (4 Key) ............................................................................ 32

Print Audit Memory Data (5 Key) ....... .... ... ... ... .... ... ......................................................... 34

Memory Full .............................. ............................................................ ......................................... 36

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

/I

OPERATOR’S MANUAL

Instrument Setup ..................... .... .... ..... .... .... .... .... ..... .... .... .... .... ..... .... .... .... .... .. 39

Clear Cycle Counter (1 Key) ........................................................................................... 39

ID Options (2 Key) .......................................................................................................... 40

Configure Output Options (3 Key) .................................................................................. 41

Change The Access Code (4 Key) ................................................................................. 44

Change Date, Time and Date Format (5 Key)..................................................................46

Change Labels (6 Key) ....... ............................................................................................ 48

Set Communications Port Parameters (7 Key) ............................................................... 51

Non-Active (5 Key from Communications Menu) ........................................................... 58

Service Menu (8 Key) ..................................................................................................... 58

Quick Keys Menu ........................................................................................................... 58

Test Weight Bias Adjustment ......................................................................................... 59

Test Weight Slope Adjustment ....................................................................................... 61

Moisture Bias Adjustment ................................................ ... ... .... ... ... ... ... .... ... ... ... .... ... ... .. 62

Moisture Slope Adjustment .......................... .... ... ... ... .... ... ... ... .... ... ... ............................... 64

Test Unit Performance ..................................................................................... 67

Non-Active Keys ............. .... ... ... ... .... .......................................................................... ... .. 67

View COM1 Port (2 Key) ....................................... ... .... ... ............................................... 67

View COM2 Transmit Port (3 Key) ................................................................................. 68

View Display Characters (5 Key) .................................................................................... 69

View Diagnostic Mode (6 Key) ....................................................................................... 70

Test Network Mode (7 Key) ............................................................................................ 72

View/Print Parameters (8 Key) ....................................................................................... 73

Operator Maintenance ..................................................................................... 77

Cell Cleaning - Daily ....................................................................................................... 77

Fuse Replacement ......................................................................................................... 77

Error Codes.........................................................................................................78

Appendix A: Communication Ports ................................................................ 79

COM1 Port options ......................................................................................................... 79

COM1 Pin Assignment Details ....................................................................................... 79

COM2 Pin Assignment Details ....................................................................................... 80

Warranty.............................................................................................................. 83

II /

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important safety messages in this

manual. When you see this symbol, carefully read the message that

follows. Be alert to the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoid ed, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

DISCLAIMER

DICKEY-john reserves the right to make engineering refinements or

procedural changes that may not be reflected in this manual. Material

included in this manual is for informational purposes and is subject to

change without notice.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

1

OPERATOR’S MANUAL

2 SAFETY NOTICES

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

INTRODUCTION

The DICKEY-john Grain Analysis Computer GAC® 2100 quickly tests grain

samples for moisture content and other profile information. T he unit loads a

sample, weighs and checks temperature, runs the test, displays the results,

and unloads the sample.

NOTE: Three models are addressed in

this manual and include the

GAC® 2100 Blue (BIAS9),

®

2100 AGRI (AGZ/AGIA),

GAC

and GAC® 2100 Gray (GZ/

GIA). Differences in models are

indicated.

Test results calculate automatically to display the moisture content. If

enabled, the temperature and approximate test weight (density) of the grain

sample will display. The product name, grain calibration date, and sample

ID numbers display for identification purposes.

An additional screen of information includes readings for conductance (D1),

capacitance (D2), weight (D3), and tempe rature (D4) values along with the

current date and time.

Figure 1

®

GAC

2100 Instrument

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

ACCESSORIES

• Drawer p/n 464220420BS1

• Null Modem Adapter DB9 Null Modem Adapter 9 pin p/n 220490001

(computer to unit connection)

• Communication software package to upload calibrations to unit via a

computer (available via email by contacting a DICKEY-john

representative).

INTRODUCTION 3

OPERATOR’S MANUAL

FEATURES

GAC 2100 features include:

• Memory storage for grain calibrations

– 64 grain calibrations (GAC 2100 Blue)

– 8 grain calibrations (GAC 2100 AGRI)

– 16 grain calibrations (GAC 2100 Gray)

• Keyboard entry or computer accessibility for updating grain

calibrations as revisions become necessary.

• Alpha/numeric sample identification numbers with automatic

sequential numbering for record keep in g pu rp os es .

• Automatic ranging by switching to predetermined calibrations when

moisture is above or below normal limits.

• Two RS-232 output ports (DCE and DTE) available for printer and

external computer/modem control.

• Capability to interface with a personal computer either directly or

through a modem (Blue model).

• Self-check mode to ensure proper continual operation.

• Error messages for out-of-limits moisture, grain weight, or grain

temperatures.

• Help screens to address operator issues.

• Quick keys (Blue model)

• Test weight slope and bias adjustment all grains

• Moisture slope and bias adjustment all grains

SPECIFICATIONS

• Supply Voltage and Frequency Limits:

– 85 Vac to 264 Vac 48-440 Hz at 1 Amp Max.

• Operating Temperature Range:

– 2° C (35.6° F) to 45° C (113° F) (Blue model)

o

C (41oF) to 45oC (113oF) (AGRI and Gray models)

–5

– If the instrument exceeds temperature ranges, an error displays.

• Grain Temperature Range:

– 0° C (32° F) to 45° C (113° F) (Blue model)

o

C (32oF) to 50oC (122oF) (AGRI and Gray models)

–0

If the grain temperature range is exceeded, an error message

displays.

• Unit T emperature and Grain Temperature Difference Limit: The

maximum allowable temperature differential between empty cell and

grain under test is 20° C (36° F). If exceeded, an error message

displays.

• Classes/Types of Grain or Seed: Refer to the latest Calibration

Bulletin.

• Weight: 11.8 kg (26 lbs) – Shipping Weight: 15.0 kg (33 lbs)

4 INTRODUCTION

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Access

Port

COM1

Port

COM2

Port

ACCESS CODES

An access code is necessary to gain access to certain screens. Whenever

the code is required, a screen appears stating ENTER ACCESS CODE.

The factory preset access code is set to “0”. T o change the access code for

security reasons, refer to “Changing the Access Code” in “Instrument

Setup” section.

EXTERNAL COMMUNICATION CONNECTIONS

GAC 2100 Blue

The GAC 2100 Blue is capable of communicating with a computer via a

direct connection using a null modem cable.

GAC 2100 AGRI and Gray

®

The GAC

(PC) using the COM1 or COM2 ports. The two communication ports are

located on the rear of the unit and are identified as Printer Output Port

(COM1) and Computer Output Port (COM2). Each must be properly

configured to communicate with external devices. Port configuration is

described in the Instrument Setup section.

2100 AGRI and Gray models can output to a personal computer

When using the COM2 port, a null cable or null adapter is required. A

null adapter is available from DICKEY-john.

Figure 2

Communication Ports

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

INTRODUCTION 5

OPERATOR’S MANUAL

Print Key

PRINTER

An optional printer connected to the instrument can print test data results.

The printout can include:

• Facility name and address

• Current date and time

• Sample ID number

• Product name

• Grain calibration date

• Percent moisture

• Test Weight

• Grain temperature

• Unit serial number

• D1 through D4 values

Data can automatically print at the end of each measurement cycle or

manually initiated by pressing the Print key.

6 INTRODUCTION

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Shipping Brace Transport Handle

Operate

position

Transport

position

UNPACKING THE INSTRUMENT

DISENGAGE SHIPPING BRACE

The shipping brace must be moved to the operate position before

applying power . Sinc e the gr ain test c ell cycle s through an unload

sequence during power up, damage may occur with the shipping

brace in the transport position.

The GAC 2100 is shipped with the grain test cell supported by an internal

shipping/transport brace. This brace supports the test cell whenever the unit

is transported. The position of the brace is controlled by a handle lo cated on

the rear panel behind the grain test cell (Figure 5). A small spool is placed

over the handle to prevent possible bumping and release of the handle

during shipment.

To Disengage Shipping Brace:

1. Remove spool and store with shipping materials.

2. Push the handle in to unlock position and rotate counterclockwise to

the locked operate position as indicated on th e ba ck panel.

– The movement of the brace is viewable through the front window of

the unit.

Figure 3

Disengaging Shipping Brace

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

UNPACKING THE INSTRUMENT 7

OPERATOR’S MANUAL

37.5 cm

(14.75 in.)

40.6 cm (16.00 in.)

38.7 cm (15.25 in.)

Front View

Top View

Side View

GRAIN ANALYSIS COMPUTER

GAC 2100

Rotate the brace back into supporting position before moving or

shipping the unit. If the cell is not adequat ely supporte d operat ing

performance may be adversely affected due to cell bouncing.

Some effort is required to move the brace back into position. It

may be helpful to reach inside the drawer front and lift up on the

cell while attempting to lock the brace into the transport position.

Place the spool over the handle to prevent the accidental release

of the shipping brace.

INSTRUMENT PLACEMENT

Choose a clean environment that is protected from rapid changes in

ambient temperature. Avoid a hazardous (classified) location as defined in

Article 500 of the NFPA Handbook of the National Electrical Code.

Instrument should be placed in a dry environment/area free to

standing water or dampness to avoid electrical shock.

Figure 4

GAC 2100 Dimensions

8 UNPACKING THE INSTRUMENT

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Rubber

Foot Pads

4. After adjustment, retighten nut up against

bottom panel.

1. Use wrench to loosen the upper nut

and then adjust height.

2. Ensure bottom nut is locked down

against rubber foot pad.

3. Use a Phillips screwdriver in center

of pad to change height and to hold

the screw from turning while tightening nuts.

To Level the Instrument:

1. Use the self-contained level on the panel top to position the GAC2100

on a flat level or nearly level surface.

2. Adjust the four rubber foot pads to level and stabilize the unit

(Figure 5). To adjust the foot pad height, unlock the upper nut from the

bottom panel of the selected foot pad and adjust height as required.

– All four leveling foot pads should be set to the lowest level possible

with one pad fully seated against the bottom panel. This ensures

minimum height above the counter top.

– When moving the instrument to a different location, re-leve ling may

be required.

3. After adjusting, use a Phillips screwdriver in the center of the foot pad

to hold the screw from turning and tighten the upper nut against the

bottom panel of the unit.

4. Ensure the lower nut remains tight against the foot pad.

Figure 5

Leveling With Rubber Foot Pads

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

UNPACKING THE INSTRUMENT 9

OPERATOR’S MANUAL

10 UNPACKING THE INSTRUMENT

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Verify Shipping

Brace Transport

Handle is in

Operate

position

Line

Cord

Connector

On/Off

Switch

Display

Contrast

Control

Fuse

Assembly

INSTALLATION

Before shipping, the GAC 2100 is inspected and tested for mechanical and

electrical defects. After unp acking, visually inspect for possible dam age that

may have occurred during transit. Save all packing materials until the

inspection is complete. If damage is found, immediately file a claim with the

carrier and notify your DICKEY-john representative.

CONNECTING AC POWER

1. Verify that the ON/OFF (I/O) switch is in the OFF (O) position and that

the shipping brace is in the OPERATE position.

2. Plug the line cord into the connector on the rear panel next to the ON/

OFF switch.

3. Plug the male end into an appropriate 3-wire (grounded) outlet.

The grounding pin on the line cord connects directly to the

GAC 2100 frame. When using an adapter with a grounding wire

ensure the grounding wire is connected properly to a good earth

ground to prevent a shock hazard.

Figure 6

Connecting Power

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

INSTALLATION 11

OPERATOR’S MANUAL

Tab

Tab

SAMPLE DRAWER BYPASS

Normal use of the sample drawer can be bypassed by removing the drawer

bottom and cutting a hole into the work counter to allow the tested grain

samples to fall through to a larger container below. The size of the hole

must be at least equal to the drawer dimension and located directly be neath

the grain sample drawer.

To Remove Sample Drawer Bottom:

1. To remove the bottom of the grain sample drawer, carefully lift the two

plastic tabs at the front of the drawer (Figure 7).

2. Using a small screwdriver, gently pry up on each tab and slide the

bottom panel out the rear of the drawer.

Use care when prying on tabs to prevent breakage.

3. When finished, slide the grain drawer back into position. This prevents

grain from spilling onto the work surface in front of the unit.

– If replacing the drawer bottom later, slide the bottom toward the

drawer front until it latches under the two plastic tabs.

Figure 7

Removing Drawer Bottom

12 INSTALLATION

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

7189

4

5

6

2

3

0

.

–

Keys 0, 1, 3, and 5

also function as

arrow keys to navigate

to certain screens.

NAVIGATION

DISPLAY SCREEN

The display screen is a graphics Liquid Crystal Display (LCD) and is

backlighted for low light level viewing.

ADJUST SCREEN CONTRAST

The Display Contrast Control is on the rear panel (Figure 6) immediately

above the COM1 and COM2 ports. The contrast control changes the

contrast between the displayed charact er s an d th e backg ro u nd . Adju st th e

control as necessary for a comfortable contrast level in varying light

conditions.

KEYBOARD LAYOUT

All operator controls, except the Power ON/OFF switch and Contrast

control, are located on the front panel. These two are on the rear panel.

The sealed membrane keyboard contains 20 pressure-sensitive keys

requiring light finger pressure to actuate each key. Valid key closures result

in short tone bursts while invalid keystrokes generate longer tone bursts.

The function of each key or key group is defined as follows and illustrated in

(Figure 8).

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

Numbers (0 through 9), Decimal point (.) and Minus (–) keys

All numeric keys perform dual functions, making menu selections, and

entering numeric values. The four numeric keys with small arrows ha ve the

additional function of screen navigation. When making a numeric entry, a

prompt on the display identifies the value entered and a cursor shows the

destination of each entry. The minus (-) sign is accepted at any point in the

entry and displays at the front of the entered str ing .

Figure 8

Keyboard Layout

Each entry immediately displays as the cursor moves to the right in

preparation for the next entry. Only the first entry of the decimal point is

acknowledged.

NAVIGATION 13

OPERATOR’S MANUAL

SELECT GRAIN

1: CORN 5: SOYBEANS

2: CORN HI MOIST 6: FESCUE

3: WHEAT HRW 7: BARLEY

4: OATS 8: RYE

PAGE 1 OF 8 <more>

Indicates

Additional Page

Indicates Number

of Pages

ALARM

An audible alarm is enabled for 0.5 seconds at the end of each grain

analysis or for an error condition. A shorter beep of 0.1 se conds soun ds fo r

each valid key stroke.

KEY FUNCTIONS

BACKSPACE KEY

Moves the cursor to the left to delete the last keystroke or to clear an entire

entry field.

NEXT PAGE KEY

Advances to the next page when the <more> prompt appears in the lower

right corner of the display. The Next Page key sequences the display

forward to additional pages of information. Th e total p age num ber and p age

count appear in the lower left corner of screen (i.e. PAGE 2 OF 8).

Figure 9

Typical Screen Indicating More Pages

14 NAVIGATION

PREVIOUS PAGE KEY

Sequences backward through previously displayed pages. Neither the

Previous Page or Next Page keys roll-over the pages to the beginning or

end.

ENTER KEY

Accepts the character string after an entry is complete.

LOAD KEY

Initiates a grain cell loading sequence to begin a test cycle.

HELP KEY

Provides context-sensitive help screens on the display. If the <more>

message appears at the lower right of the screen, additional pages are

accessible with the Next Page key. T o use th e HELP INDEX when in a Help

screen, select the 0 key and select the desired topic. To resume normal

operation, select the Help key a second time.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

1

3

&

5

0

&

MAIN MENU

1: MEASURE MOISTURE 3: CALIBRATION MENU

2: SELECT GRAIN 4: SETUP MENU

5: TESTS MENU

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

STATUS

CYCLE COUNTER: 435

THIS COUNTER INCREMENTS AFTER EACH

SAMPLE MEASUREMENT OR DATA COLLECTION

SEQUENCE IS SUCCESSFULLY COMPLETED

PRINT KEY

Initiates a printout of current information on the screen (e.g., grain moisture

analysis, calibrations data, etc.). If the automatic printout o ption is selected ,

the Print key initiates duplicate copies. Help information does not print.

COM SETUP options allows the Print key to transmit to either the printer

port or the communications/modem port. For example, the system may be

configured to automatically print results through the printer port while the

Print key transfers results to the computer port.

UNLOAD KEY

Dumps the contents from the test cell after a grain test.

LEFT AND RIGHT KEYS

Moves the cursor horizontally during alpha entries and certain functions

during the SETUP mode.

UP AND DOWN KEYS

Moves the cursor vertically during alpha entries and certain functions in the

SETUP mode.

MENU SCREENS

The Main menu displays once the start-up checks are successfully

completed. The Main menu is the “home” screen that all other screens are

accessed. The Main menu displays five major selections or categories.

A number appears next to each Main menu selection. Select the desired

number to access the appropriate menu. Refer to (Figure 11) for a general

configuration of the Menu Tree layout.

Figure 10

Main Menu Selections

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

NAVIGATION 15

OPERATOR’S MANUAL

<MORE>

<MORE>

<MORE>

<MORE>

<MORE>

<MORE>

<MORE>

SETUP MENU

MAIN MENU

1: MEASURE MOISTURE

2: SELECT GRAIN

SELECT ITEM NUMBER

(NEXT PAGE: STATUS)

3: CALIBRATION MENU

4: SETUP MENU

5: TESTS MENU

FILL SAMPLE HOPPER, ENTER ID NO. THEN

SETUP MENU

1: CLEAR COUNTER

2: ID OPTIONS

3: OUTPUT OPTIONS

4: EDIT ACCESS CODE

SELECT ITEM NUMBER

5: DATE/TIME MENU

6: LABELS MENU

7: COM MENU

8: SERVICE MENU

TESTS MENU

1: non-active

2: COM1

3: COM2 TRANSMIT

4: non-active

SELECT ITEM NUMBER

(NEXT PAGE: STATUS)

5: DISPLAY

6: DIAGNOSTIC MODE

7: TEST NETWORK MODE

8: PARAMETERS MENU

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER

(NEXT PAGE: STATUS)

<MORE>

PRESS LOAD TO BEGIN

CORN 91051

ID: 2

PAGE 8 OF 8

PAGE 7 OF 8

PAGE 6 OF 8

PAGE 5 OF 8

PAGE 4 OF 8

PAGE 3 OF 8

PAGE 2 OF 8

PAGE 1 OF 8

SELECT GRAIN

1: CORN

2: CORN HI MOIST

3: AMARANTH

4: BARLEY

5: SOYBEANS

4: DURUM

5: FESCUE

8: MILLET

GAC 2100 Blue

SELECT GRAIN

1: CORN

2: CORN HI MOIST

3. SOYBEANS

4: SORGHUM

5: WHEAT HRW

6: WHEAT HRS

7: WHEAT SRW

8: OATS

GAC 2100 AGRI

<MORE>

PAGE 2 OF 2

PAGE 1 OF 2

SELECT GRAIN

1: CORN

2: CORN HI MOIST

3: SOYBEANS

4: SORGHUM

5: WHEAT HRW

6. WHEAT HRS

7. WHEAT SRW

8: OATS

GAC 2100 Gray

Calibration Menu on the AGRI and Gray

instruments do not have

5. Print Audit Memory Data.

Figure 11

Menu Tree

16 NAVIGATION

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

1: *ENGLISH US

2: NEDERLANDS

3: FRENCH

4: DEUTSCH

5: ITALIANO

6: PORTUGUES

7: ESPANOL

8: ENGLISH

PLEASE WAIT

PERFORMING STARTUP TESTS

GAC2100 REV: 0798121009

LANG REV: 0798121009

Language Software

Number

Instrument

Software

Number

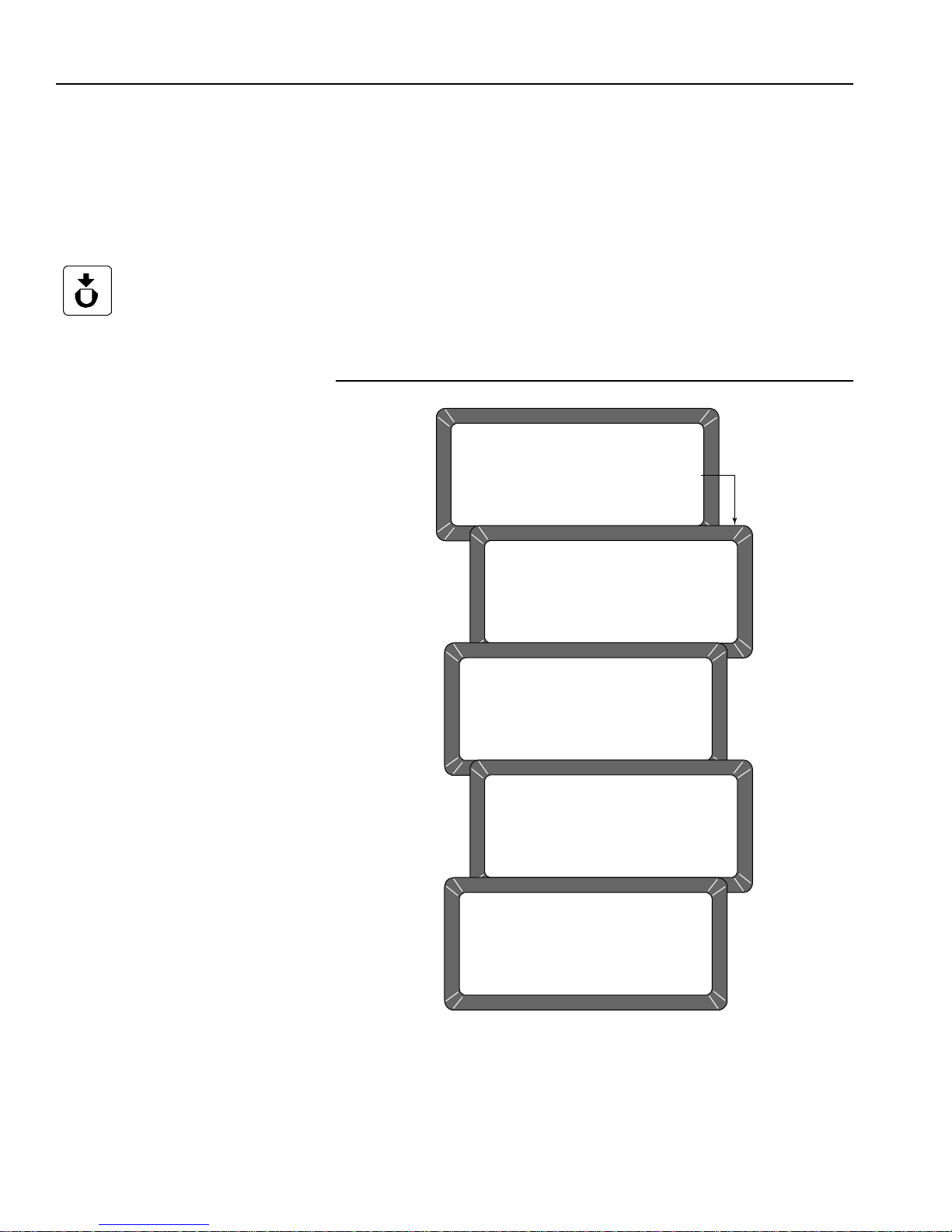

STARTUP PROCEDURE

Each time the GAC 2100 is powered on, the instrument performs a series of

self checks to determine the status of the following:

• Load/strike-off mechanism

• Unload function

• Empty test cell weight

• Conductance/capacitance measurement circuitry

Self-checks begin when the hopper doors open, the strike-off arm swings

across the cell and back again, and the cell dumps. When the cycle ends

(about 15 seconds), the Main Menu displays.

Before starting the following procedures, ensure the ON/OFF (I/O)

switch is in the OFF (O) position and that the shipping brace is in

the OPERATE position. These are both located on the rear of the

unit.

1. Turn the power switch ON. Initially, a language screen appears

showing eight choices (Figure 12). Two English selections are

available: English US and English.

– English US invokes parameters to display test weight for

NTEP-certified calibrations used in the United St ates and allows the

option of displaying test weight on the Analysis screen.

– English is for non-NTEP users that do not require test weight

parameters.

Figure 12

Start Up Screens

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

STARTUP PROCEDURE 17

OPERATOR’S MANUAL

2. Select a language by pressing the respective number on the keypad

next to the desired language.

– This screen only remains available for approximately 8 seconds.

– Once selected, an asterisk appears and remains in front of the

selection until changed again during another startup cycle.

3. Wait for the remaining portion of the cycle to finish. A second screen

displays PLEASE WAIT while the unit is performing self checks. The

bottom two lines of this screen display the software revision numbers

(Figure 12).

4. After the Main Menu displays proceed with general operation.

TEST SAMPLES (QUICK START)

Performing a grain sample analysis consists of six basic steps:

1. Select a grain for testing through keyboard entries.

2. Pour grain sample into the hopper (top of the unit) and enter a sample

ID number (optional).

3. Press the Load key. The sample automatically loads (drops) the grain

into the test cell and a strike-off arm levels and removes the excess.

4. Wait briefly for the test results to process. The moisture reading and

grain temperature display.

5. Print a hard copy of the test results.

– With an optional printer connected, the date and time with sample

identification number and all test information prints.

– By selecting the Print key, additional copies can be printed.

6. Press the Unload key to empty the test cell contents.

– The test cell rotates 180° (inverts) to dump the grain into a sample

drawer or into a larger container below the counter top.

– After the cell returns to the upright position, the instrument is ready

for the next test sample.

18 STARTUP PROCEDURE

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

MAIN MENU

1: MEASURE MOISTURE 3: CALIBRATION MENU

2: SELECT GRAIN 4: SETUP MENU

5: TESTS MENU

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

SELECT GRAIN

1: CORN 5: SOYBEANS

2: CORN HI MOIST 6: MILO

3: WHEAT HRW 7: BARLEY

4: AMARANTH 8: OATS

PAGE 1 OF 8 <more>

PLEASE WAIT

PERFORMING SELF-CHECKS

WHEAT HRW

ID: 14

960918

Sample ID Number

Selected Grain Type for Testing

MEASURE MOISTURE

The Main Menu appears immediately after all startup checks have

successfully concluded. The Main Menu displays five major selections for

categories.

To Measure Moisture:

1. Choose MEASURE MOISTURE (1 Key) from the Main menu to

display the Select Grain menu.

Figure 13

Moisture Testing Preparation

Next Page Key

Previous Page Key

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

2. Locate the grain type for testing and select the corresponding number

to the left.

– After selecting a grain, the unit cycles through self-check tests to

ensure the program memory and calibrations are valid.

– Subsequent moisture measurements default to the previously

selected grain.

– For models with multiple pages on grains, select the Next Page

key.

3. If a different grain is desired, press the Previous Page key to return to

the Main menu.

4. Select the option SELECT GRAIN (2 key) and choose a new grain

(refer to GRAIN SELECTION for additional information).

5. Enter a sample ID number. This number identifies the sample tested

on the paper printout. If the ENTER REQUIRED FOR ID is turned ON

(refer to CHOOSING ID OPTIONS in the ESTABLISHING

P ARAMETERS section), the Enter Sample ID screen displays and an

ID number is required. Other ID numbering options bypass this screen.

Details on how to use ID numbers are described later in this section.

MEASURE MOISTURE 19

OPERATOR’S MANUAL

ENTER SAMPLE ID

WHEAT HRW

ID:

960918

PRESS LOAD TO BEGIN

WHEAT HRW

ID:AD38

960918

FILL SAMPLE HOPPER AND

6. Use the Down Arrow key (0 key) to place the cursor next to the ID and

enter any number.

7. Press the Enter key.

Figure 14

Screen Sequence Using Enter Required For ID

Load Key

Enter Key

BASIC METHOD

After all calibration self-checks for the selected grain are complete

(approximately 10 seconds), the message FILL SAMPLE HOPPER,

ENTER ID NO. THEN…PRESS LOAD TO BEGIN displays (Figure 15).

To Measure Moisture:

1. Pour grain into the sample hopper. Fill the hopper until the grain is at

least 1.25 cm (1/2 inch) above the separation line between the hopper

top and hopper compartment (heap gr ain slightly). The exa ct volume is

unimportant, except enough grain must be present to overfill the cell

(approx 0.5 liter or 2 cups). Excess grain spills over the cell top and

falls into the grain drawer below.

2. If an ID number is not entered, enter a number or skip to step 3.

3. Press the Load key to begin the test cycle.

4. GAC 2100 Blue- If factors (a type of label) are enabled, a screen

displays the message ENTER RESULTS FOR THE FOLLOWING.

– Disregard this screen by entering a number and selecting the Enter

key. Refer to FACTORS for additional information.

5. Press the Load key, the hopper do ors open and drop the grain into th e

test cell. The cell fills and the striker arm swings across the top to

remove excess grain.

20 MEASURE MOISTURE

Do not insert fingers or other foreign objects into the opened

hopper doors.

6. Wait for the moisture test to complete (Figure 15). A screen displays

the message MEASURING - PLEASE WAIT.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

PLEASE WAIT

MEASURING

WHEAT HRW

960918

ID: AD38

PRESS LOAD TO BEGIN

FILL SAMPLE HOPPER, ENTER ID NO. THEN

WHEAT HRW

ID:AD1234

960918

MOISTURE

13.4%

WHEAT HRW

TEMP: 30 C

ID: AD38 <more>

960918

Press

the

Load Key

PLEASE WAIT

PERFORMING SELF CHECKS

WHEAT HRW

960918

Press

the

Dump Key

Figure 15

Basic Moisture Measuring Cycle

7. The grain name, moisture, sample ID and grain calibration issue date

Next Page Key

8. The option <more> displays on the lower right corner of the screen.

9. Press the Next Page key to view additional pages. The D1 through D4

10. Blue model-If the <more> prompt continues to display, press the Next

Enter Key

Unload Key

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

11. When the measurement is complete, select the Unload key. The test

12. Start a new moisture measurement for the same grain type. The

appears on the display along with the sample temperature and test

weight, if enabled.

values display along with the present date (lower left corner) and time

(lower right corner).

Page key again.

– This page is only available if FACTORS are used. FACTORS are a

type of label that allows entry of data for additional information on

the paper printout. Up to four user-defined factors (or labels) may

display and print as specified on the Setup menu. If this screen

displays, enter numbers as desired and select the Enter key. If no

factor names are specified, the screen will not display.

cell will invert dumping the grain and returning to the upright position.

GAC 2100 remembers the grain type until it is changed or power is

turned OFF. The Select Grain menu does not appear again until it is

selected.

MEASURE MOISTURE 21

OPERATOR’S MANUAL

ABCDEFGHIJKLMNOPQRSTUVQXYZ _ #$%&'( ) *,-.+

ÇOZÄ CÉLLS ÖÜ TLANZECAAES ADD Ë NIITUO ß ONSRUU

Y§R S1 S2 S3 S4 S5 S6 S7 S8 S9 S10

TEXT: -

“

“

´´´´´´´´´´´

ˆˆˆ°

~

±

1

3

&

5

0

&

Next Page Key

Left and Right Arrow Keys

GRAIN SAMPLE ID NUMBERS

Three sample ID options may be selected to number grain samples:

1. Automatic number sequencing (e.g., 1, 2, 3...)

2. Manual entry (numbers may be manually entered or skipped)

3. ENTER REQUIRED FOR ID (produces the Enter Sample ID screen)

which prompts a required entry before proceedin g. The ID field may be

either numeric or alphanumeric. If numeric only, the digits 0-9, the

decimal point, and the minus sign are entered with the keyboard. Other

characters are entered from an alpha screen.

ENTER NUMBERS AND ALPHA CHARACTERS

Entering alpha characters (letters) into certain screens, such as an ENTER

SAMPLE ID number, is accomplished through a special alpha screen.

To Access the Alpha Screen:

1. From the Enter Sample ID screen, press the Next Page key. The Next

Page key only functions if an alpha entry is possible.

To View and/or Use the Alpha Screen:

1. Prepare for a moisture test. When the PRESS LOAD TO BEGIN

message appears, stop and observe the screen. The ID field on the

lower left corner below the grain type appears and a small cursor will

blink. If necessary, use the Down Arrow key to position the cursor

next to the ID field (ID: _ ). Numbers are entere d dir ec tly fro m the

keypad and completed by selecting the Enter key.

2. To ente r letters, select the Next Pa ge key to ac cess the Alpha scr een.

The Alpha screen displays the alphabet, special characters, and a

string of S numbers (S1…S10). On the lower left corner, the word

TEXT displays (Figure 16).

Up and Down Arrow Keys

Enter Key

Backspace Key

22 MEASURE MOISTURE

Figure 16

Alpha Screen

3. Move the vertical pointer (center of screen) to the first letter. The small

vertical pointer identifies the selected character. The pointer is moved

around the screen by using the four arrow keys (Left/Right and Up/

Down).

4. After selecting a letter, press the Enter key. The letter appears next to

the word TEXT: on the lower corner. Repeat the process until the

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Previous Page Key

Backspace Key

phrase is complete. If an error is made, select the Backspace key and

re-enter the corrected character.

5. After completing the text string, select the Previous Page key . The text

string becomes part of the ID field on the Press Load To Begin

screen. Additional numbers can be inserted after the text string as

before. Deleting is accomplished by entering the alpha screen again

and using the Backspace key to delete letters.

– GAC 2100 Blue-Using the S1 through S10 character strings is

described in Instrument Setup. Character strings are predete rmined

phrases to insert into an alpha text line when needed (i.e.

BROWN).

ID OPTIONS

ID numbers typically identify grain samples. The numbers can be a simple

number (e.g., 1, 2, 3, etc.), a combination of letters and numbers (i.e.

operator’s initials plus sample number) or the customer’s name (i.e.

BROWN). The ID field can contain up to 16 alpha numeric characters.

The ID option is selected through the Setup menu, ID OPTIONS (refer to

Instrument Setup). ID numbers are added to each tested sample using one

of three methods:

1. Inserted Manually - Any ID field, including none at all, are assigned to

grain samples before each test. This flexibility allows the creation of

individualized numbering schemes.

2. Automatic Sequencing - Numbers can be sequentially assigned

automatically to each moisture test. For example, 1, 2, 3, etc. or

specific letters (i.e. initials) can be placed in front of the numbers (i.e.

JW12). Only the numbers at the end of the field change automatically.

3. Entry Required For ID - An ID field is required before each moisture

test can proceed. This method ensures each sample is properly

identified, typically for printer output. A screen displays before the

moisture test requests the user to ENTER SAMPLE ID. Alpha

characters can be used if desired.

FACTORS (LABELS)

Blue Model

Factors are predetermined labels that appear at the beginning of each

moisture test similar to sample ID numbers. Up to four factors display and

print as specified in the calibration. For each FACTOR specified, an entry

must be made before initiating the moisture measurement. Entries (numeric

only) can be up to six digits long (Figure 17). FACTORS are established on

the Setup menu (refer to Instrument Setup).

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

MEASURE MOISTURE 23

OPERATOR’S MANUAL

CUSTOMER ID 54

VEHICLE NUMBER 4

CODE 382

LOAD WEIGHT 19535

WHEAT HRW

ID: AB1234

ENTER RESULTS FOR THE FOLLOWING:

960518

D1: nnnn

D2: nnnn

D3: nnnn

D4: nnnn

TEST WEIGHT OFFSET: +0.4 LB/BU

DATE: 05/18/16

ID: 12

TIME: 16:42:20

Blue model

only

Next Page Key

Figure 17

Example of Factors

NEXT PAGE VIEW

After the grain analysis is complete and the moisture content displays,

<more> appears on the lower right corner of the screen indicating another

page is available.

Press the Next Page key to view the calculated values (D1, D2, D3 and D4)

determined from the grain measurement (Figure 18). These values are

relatively unimportant to the operator but are important to service

personnel. A general definition of each value is as follows:

D1 - Conductance measurement to indicate grain surface moisture.

D2 - Capacitance measurement to indicate inte rnal grain moisture.

D3 - Weight measurement to indicate grain weight.

D4 - Temperature to indicate grain temperature.

Blue model-

Below the D calculations, the TEST WEIGHT OFFSET (as applicable)

appears. This value is programmed on the Setup menu (refer to Instrume nt

Setup). The current date, time, and sample ID also display.

Figure 18

Next Page Typical Calculated D-Values

24 MEASURE MOISTURE

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

GRAIN SELECTION

The second item on the Main menu is the Select Grain menu to select

specific grain types for testing. The Select Grain menu automatically

displays for the first moisture test each time power is applied. It may also be

selected at any time to test different grain types. After the first test, the

Select Grain menu must be selected manually.

GAC 2100 Blue-One exception is through the use of QUICK KEYS.

However, these are limited to three grai n choices, usually the most common

grains. The use of QUICK KEYS allows a programmed grain to be selected

prior to loading the grain into the test cell (refer to ANALYZING GRAIN).

SELECT GRAIN MENU

Grain Calibration Storage

• GAC 2100 Blue-Stores up to 64 unique grain calibrations. The first 40

are restricted and can only be changed by authorized personnel. The

remaining 24 are less secure and can be changed using the access

code.

• GAC 2100 AGRI-Stores up to 8 different grain calibrations.

• GAC 2100 Gray-Stores up to 16 different grain calibrations.

To Select a Grain for Testing:

Next Page Key

Previous Page Key

1. Choose the Select Grain menu from the Main menu by selecting the 2

key.

– Blue and gray models - The first page of the Select Grain menu

displays the first eight grain calibrations available. The prompts on

each lower corner of the display indicate additional pages are

available (Figure 19).

2. Blue and Gray models - Press the Next Page key to advance to the

next page. The next eight grain calibrations will display. The Next

Page key allows access to all available eight pages. When the last

page displays, the <more> prompt no longer remains visible on the

screen.

– Press the Previous Page key to move backward. The Previous

Page key is the counterpart of the Next Page key.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

GRAIN SELECTION 25

OPERATOR’S MANUAL

PAGE 8 OF 8

PAGE 7 OF 8 <more>

PAGE 6 OF 8 <more>

PAGE 5 OF 8 <more>

PAGE 4 OF 8 <more>

PAGE 3 OF 8 <more>

PAGE 2 OF 8 <more>

SELECT GRAIN

1: CORN 5: SOYBEANS

2: CORN HI MOIST 6: MILO

3: WHEAT HRW 7: BARLEY

4: AMARANTH 8: OATS

PAGE 1 OF 8 <more>

SELECT GRAIN

1: CORN 5: WHEAT HRW

2: CORN HI MOIST 6: WHEAT HRS

3: SOYBEANS

4. SORGHUM

7: WHEAT SRW

8: OATS

SELECT GRAIN

1: CORN

2: CORN HI MOIST

3: SOYBEANS

4: SORGHUM

5: WHEAT HRW

4: WHEAT HRS

5: WHEAT SRW

8: OATS

PAGE 1 OF 2 <MORE>

1: BARLEY SIX ROWED

2: BARLEY TWO ROWED

3: WHEAT DURUM

4: SUNFLOWER OIL

5: MILLET

4: RAPE SEED

5: RYE

8: SAFFLOWER

PAGE 2 OF 2

Blue AGRI

Gray

Figure 19

Select Grain Menus

Load Key

3. Press the number key corresponding to the desired grain. After

selecting the grain, the GAC 2100 automatically enters the MEASURE

MOISTURE mode and retains the grain selection until a new grain is

selected again or the power is turned OFF.

QUICK KEYS

Blue Model

QUICK KEYS makes changing between frequently-used grains easier

during moisture measurements bypassing the Select Grain menu. Up to

three frequently used grains can be programmed for keyboard keys 1, 2,

and 3. The desired key (grain) changes the grain to be tested whenever the

1, 2, or 3 key is pressed on the Press Load to Begin screen.

26 GRAIN SELECTION

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

STATUS

CYCLE COUNTER: 435

THIS COUNTER INCREMENTS AFTER EACH

SAMPLE MEASUREMENT OR DATA COLLECTION

SEQUENCE IS SUCCESSFULLY COMPLETED

View and print

selected grain

calibrations only.

Enter new or

edit existing

grain calibrations.

Print a list of

grain calibrations.

Obtain data to

determine

calibration constants

for a specic grain.

Print and/or

clear Audit

trail information

(Blue model)

Represents the total count

of samples processed since

the counter was last reset.

CALIBRATE PROCEDURES

The Calibration menu allows authorized personnel to:

• view calibration constants of selected grains

• enter new or change existing calibrations

• print the entire list of stored grain calibrations

• obtain calibration data necessary to generate new calibrations

• print audit memory data (Blue model)

Choose a function by selecting the number key corresponding to the

desired function (Figure 20).

Figure 20

Calibration Menu With Status Page

Next Page Key

Print Key

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

VIEW CALIBRATION DATA (1 KEY)

The View Calibration menu allows for viewing and printing of a selected

grain calibration (Figure 21). Editing cannot be performed in this function.

To View Grain Calibrations:

1. From the Calibration menu, choose View Calibration by selecting the

1 key.

2. Choose a grain calibration to view from the grain list pages and then

select the corresponding number key.

–Use the Next Page key to view additional pages, if applicable.

3. The View Calibration screen displays the grain name, moisture range,

calibration issue date, and the nine calibration K values.

4. If a printer is connected, FACTORS (Blue model) are defined and

AUTO RANGE is specified in the calibration, this information also

prints. The lower right corner of the View Calibration screen indicates

<more> meaning another page is available.

5. Blue model-Press the Next Page key to display the Factors screen.

The Factors screen displays the grain name and up to four defined

factors. If the grain does not have defined factors, the labels are empty.

The <more> prompt also displays on this page.

CALIBRATE PROCEDURES 27

OPERATOR’S MANUAL

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

SELECT GRAIN TO VIEW

1: CORN 5: SOYBEANS

2: CORN HI MOIST 6: MILO

3: WHEAT HRW 7: BARLEY

4: AMARANTH 8: OATS

PAGE 1 OF 8 <more>

VIEW CALIBRATION

GRAIN: WHEAT HRW RANGE: 06 -20%

ISSUE: 960701

K1: 0433 K4: 2821 K7: 2006

K2: 3577 K5: 2500 K8: 0564

K3: 1368 K6: 2577 K9: 1044

<more>

VIEW CALIBRATION

GRAIN: WHEAT HRW

FACTOR 1: VEHICLE NUMBER

FACTOR 2:

FACTOR 3:

FACTOR 4:

<more>

VIEW CALIBRATION

AUTO RANGE FOR: WHEAT HRW

IF ABOVE MAX MOIST TRY: WHEAT HI MOIST

IF BELOW MIN MOIST TRY: WHEAT LO MOIST

Blue model

Next Page Key

6. Press the Next Page key to view the Auto Range screen. The Auto

Range screen displays grain name and calibrations automatically used

to extend the moisture range if the normal maximum and minimum

limits are exceeded. Separate grain calibrations or grains may be

referenced for each limit.

Figure 21

View Calibration Menu Showing Wheat HRW

28 CALIBRATE PROCEDURE S

ENTER/CHANGE CALIBRATION VALUES (2 KEY)

Blue model-This function enters or changes grain calibrations. Grains 1

through 40 are restricted to authorized personnel only. Grains 41 through 64

are considered “unofficial calibrations” and can be accessed by using the

Access Code. Changing calibrations is also possible through proper linking

with a computer (refer to the computer manual). The same security code

restrictions exist. After gaining access, changes to calibrations can be

accomplished (Figure 22).

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Next Page Key

Previous Page Key

Enter Key

To Enter/Change Calibration Values:

1. From the Calibration menu, press the 2 key to access Enter/Change

Calibration screen.

– (Blue model) PAGE 1 OF 8 of the Select Grain To Enter/Change

menu displays. The remaining pages are accessed by selecting the

Next Page and Previous Page keys.

2. Select the grain to be altered or locate an empty position to enter a

new calibration. Select the appropriate key corresponding to the listing.

A screen displays TO PROCEED, UNSEAL ACCESS PORT ON

REAR P ANEL and PRESS WHITE PUSHBUTTON.

– (Blue model) If the grain selected is on one of the first five grain

pages (5 x 8 = 40) changing the calibration is restricted to

authorized personnel only.

– (Blue model) If the grain selection is on pages 6, 7 or 8, these

calibrations can be altered after responding to the request to

ENTER ACCESS CODE.

– (Blue model) Enter the access code and select the Enter key to

proceed.

IMPORTANT: Unsealing the access port should only be performed by

an authorized user.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

CALIBRATE PROCEDURES 29

OPERATOR’S MANUAL

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

SELECT GRAIN TO ENTER/CHANGE

1: CORN 5: SOYBEANS

2: CORN HI MOIST 6: MILO

3: WHEAT HRW 7: BARLEY

4: AMARANTH 8: OATS

PAGE 1 OF 8 <more>

ENTER/CHANGE CALIBRATION

AUTO RANGE FOR: WHEAT HRW

IF ABOVE MAX MOIST TRY: WHEAT HI MOIST

IF BELOW MIN MOIST TRY: WHEAT LO MOIST

TO PROCEED

UNSEAL ACCESS PORT ON REAR PANEL

AND DEPRESS WHITE PUSHBUTTON

ENTER/CHANGE CALIBRATION

ENTER/CHANGE CALIBRATION

GRAIN: WHEAT HRW RANGE: 06 -20%

ISSUE: 960701

K1: 0433 K4: 2821 K7: 2006

K2: 3577 K5: 2500 K8: 0564

K3: 1368 K6: 2577 K9: 1044

Press to EDIT <more>

Press to SELECT GRAIN, 0 to DELETE

(Blue model)

Page #

varies based

on model

Figure 22

Changing Calibrations

Backspace Key

Next Page Key

NOTE: Selecting the Next Page key

instead of the Backspace key

(to change the large flashing

block to the cursor), advances

to the AUTO RANGE function.

30 CALIBRATE PROCEDURE S

3. If selecting an existing calibration, a large flashing block appears on

the grain selection.The screen displays the current K values for that

grain. The large flashing block signifies that alpha characters can be

entered from the alpha screen.

– Press the Backspace key, as prompted on the bottom of the

screen, causes the bottom prompt to disappear and the large

flashing block to change to a cursor (flashing line).

– When the cursor appears, the alpha screen may be accessed by

selecting the Next Page key. If numeric entries are desired, those

values are made directly with the number keys.

4. Use the alpha screen to enter a grain name (up to 16 characters).

– Select the Enter key after each character selection to place the

character on the text line.

– Press the Previous Page key to return to the Enter/Change

Calibration screen. Note that the new grain title is now in place.

5. Press the Enter key to accept the new grain title. The cursor advances

to the next position (Issue Date).

6. Enter the Calibration Issue Date (up to 8 characters) and select the

Enter key . The cursor returns to a flashing blo ck in the ISSUE position.

The block signifies the date may include alpha characters (i.e.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

Enter Key

Backspace Key

Print Key

15NOV98) but normally is entered as numbers in a format such as

YYMMDD (i.e. 981115).

– Pressing the Backspace key will cause the flashing block to

disappear allowing the Next Page key to be used for selecting the

alpha screen.

7. Press the Enter key to accept the date. The cursor appears as a line

(flashing) under the first digit of K1 (const ant). The flashing cursor

(line) signifies this entry accepts only numbers.

8. Enter the K1 constant. Notice when entering the first digit the

remaining spaces are blank. All four digits of the constant must be

entered when making a change. If more than four digits ar e enter ed, a

long beep indicates an illegal entry.

9. When finished, press the Enter key to accept the constant and to

advance to the next position. If the screen is accidentally advanced

before finishing, press the Enter key as many times as necessary to

cycle through all menu items.

10. Enter K2 through K9 constants in the same manner as K1.

11. Press the Enter key after entering each constant (4 digits).

12. Press the Print key to print the calibration . The pr esent screen values

print.

13. Press the Next Page key to enter the Auto Range calibration

selection. The Auto Range screen allows entry for grains using higher

or lower moisture levels than the current calibration. These values are

automatically selected if the grain moisture is outside the standard

setting.

14. Press the Backspace key and choose a grain calibration if the sample

moisture is above the upper limit. After selecting a grain, the display

will return to the Auto Range screen. Repeat this procedure again for

the lower limit grain calibration.

15. Press the 0 (zero) key to delete either auto range calibration.

16. Press the Previous Page key to return to the Grain Calibration

screen.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

PRINT CALIBRATION GRAIN LIST (3 KEY)

Grain calibrations stored in memory can be printed by selecting the Print

key (Figure 23).

To Print a Calibration List:

1. Press the 3 key from the Calibration menu. The Print Calibration

List screen appears.

2. Select the Print key. The list of all grain calibrations will print.

CALIBRATE PROCEDURES 31

OPERATOR’S MANUAL

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

PRINT CALIBRATION LIST

Press PRINT to LIST CALIBRATIONS

Blue model

Figure 23

Printing Calibration Lists

OBTAIN BASIC CALIBRATION DATA (4 KEY)

This mode allows the user to generate data for developing grain

calibrations. The samples used for calibration should span the desired

moisture range.

Next Page key

Enter Key

Load Key

IMPORTANT : To obtain good calibration data, the samples must be as

evenly distributed throughout the moisture range as

possible. The grain samples should extend at least 2%

past each end of the desired moisture range, should

contain no spoilage or condensation, and be free of

broken pieces or foreign matter. The GAC 2100 readings

obtained can be sent to DlCKEY-john to derive the

calibration constants for the new grain.

To Obtain Accurate Calibration Constants:

1. Turn the power switch ON and allow approximately thirty minutes to

warm up before taking sample readings.

2. Turn the printer ON.

3. Verify the instrument is set up and functioning properly.

4. From the Main menu, choose the Calibration menu by pressing the 3

key.

5. Press the 4 key and select OBTAIN CALIBRATION DATA.

6. Enter a sample identification number so the sample is properly

identified. Key in a sample ID number (use the Next Page key if an

alpha ID is desired).

7. Press the Enter key.

8. Pour the sample into the hopper and press the Load key.

9. After the measurement cycle is complete, the screen displays four D

values (Figure 24). If using a printer, a printout automatically results. If

a printer is not used, record the D-values and sam p le ID.

32 CALIBRATE PROCEDURE S

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

PERFORMING SELF CHECKS

PLEASE WAIT

OBTAIN CALIBRATION DATA

ID:

ENTER SAMPLE ID

OBTAIN CALIBRATION DATA

ID: 22

FILL SAMPLE HOPPER AND

PRESS LOAD TO BEGIN

OBTAIN CALIBRATION DATA

ID: 22

MEASURING

PLEASE WAIT

OBTAIN CALIBRATION DATA

ID: 22

D1: 8

D2: 674

D3: 2467

D4: 272

OBTAIN CALIBRATION DATA

DATE: 09/15/13 TIME: 20:10:19

ID: 22

Blue model

Figure 24

Obtaining Calibration Data

NOTE: The facility name and location,

date/time, GAC 2100 serial

number and calibration data

print when the first sample is

run in this mode (Figure 25).

Unload Key

10. Write the grain type under the CALIBRATION DATA. Write the actual

moisture percentage of each sample (obtained by an accurate

approved means) next to STD. MOIST.

11. Run additional samples and record the actual moisture percentage for

each sample.

12. After runnin g each sam ple , pr es s the Unload key.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

CALIBRATE PROCEDURES 33

OPERATOR’S MANUAL

DICKEY-JOHN

CORP_GAC 2100

09/29/16 10:32:28

S/N: 1737-90909

CALIBRATION DATA

===============

ID: 1.1

STD. MOIST:

D1: 0

D2: 672

D3: 2412

D4: 233

===============

Figure 25

Calibration Data Printout

Print Key

PRINT AUDIT MEMORY DATA (5 KEY)

(Blue model)

The audit memory records data changes made to parameters affecting

moisture measurement or the display of the measurement data. The audit

memory stores the following types of data:

• Grain calibration settings

• Output option settings

• Date and time settings

• Moisture bias and slope adjustment settings

Memory contents can be printed at any time. Printing audit memory can be

initiated from either the unit or the computer site (Figure 27). For additional

information concerning printing from the computer, refer to the

Communications Software manual included with the Communication

software.

To Print the Audit Memory Contents:

1. From the Main menu, access the Calibration menu by selecting the 3

key.

– Access PRINT AUDIT MEMORY DATA by selecting the 5 key. A

screen appears displaying PRESS PRINT TO BEGIN.

2. Press the Print key to obtain a printout of the audit memory

(Figure 26). Multiple copies can be produced by selecting the Print key

again when the printer finishes. If only the header, current date, current

time, and GAC 2100 serial number print during this process, the audit

memory is empty.

34 CALIBRATE PROCEDURE S

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

DICKEY-JOHN

40554

CURRENT DATE/TIME

29/09/16 10:32:28

S/N: 1716-40554

EVENT COUNTER: 1

DATE OF CHANGE:

09/29/16 MM/DD/YY

TIME OF CHANGE:

10.33.25 HH.MM.SS

LOG ON TIME:

00.00.00 HH.MM.SS

CHGCD:

000000

PID: TIME

10.34.00 HH.MM.SS

===============

CALIBRATION MENU

1: VIEW CALIBRATION

2: ENTER/CHANGE CALIBRATION

3: PRINT CALIBRATION LIST

4: OBTAIN CALIBRATION DATA

5: PRINT AUDIT MEMORY DATA

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

PRINT AUDIT MEMORY DATA

Press PRINT to begin

Blue model

Figure 26

Audit Memory Data

Previous Page Key

Figure 27

Printing Audit Memory Data (Blue Model)

3. After printing , press the Previous Page key to return to the

Calibration menu.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

CALIBRATE PROCEDURES 35

OPERATOR’S MANUAL

PID: Denition of Terms

CB* Calibration

USRCD User Code

OO - D&OTW Output Option - Display & Output Test Wright

OO - D & OT Output Option - Display & Output Temperature

OO - DOOLR Output Option - Display & Out-Of-Limits Results

OO - OOOLR Output Option - Output Out- Of-Limits Results

OO - OROAE Output Option - Output Report Of All Errors

OO - MPR Output Option - Moisture Printout Resolution

OO - RP Output Option - Radix Point

OO - TF Output Option - Temperature Format

OO - WF Output Option - Weight Format

TIME Time

DATE Date

DATE FORMAT Date Format

Table 1: Audit Memory Parameter Identication (PID) Codes

AUDIT MEMORY FULL!

OPERATION CANNOT BE PERFORMED

Each event lists the following items:

1. Date of change

2. Time of change

3. Log on time

4. User code (Figure 26).

The user code prints asterisks to maintain user code security. The event (or

change) is identified with a PID (Parameter Identification), a colon and then

a code to indicate the specific type of change (refer to Table 1). The printout

begins with the most recent event and progresses in reverse order to the

oldest event.

MEMORY FULL

(Blue Model)

When the instrument reaches 1000 event s, a memory full message displays

and no additional events can be recorded until a udit memory is cleared. The

unit will not respond to keypad input and must be turned off and on to regain

control and to resume normal grain measurement routines. If any attempt is

made to modify an auditable parameter , the warning reap pears and must be

cleared again. This limitation persists until the memory is cleared.

Figure 28

Audit Memory Full Screen

36 CALIBRATE PROCEDURE S

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

PRINTING AUDIT MEMORY COMPLETE

1: CLEAR AUDIT MEMORY

2: DO NOT CLEAR AUDIT MEMORY

TO PROCEED

Unseal Access Port on Rear Panel

and Depress White Push Button

Previous Page Key

After Printing Audit Memory:

1. Press the Previous Page key.

2. After printing, select (1 key) to clear audit memory or (2 key) to retain

audit memory.

Figure 29

Printing Complete Screen (Blue Model)

To Clear Audit Memory:

Clearing Audit Memory should only be performed by an authorized user.

1. Press the (1 key) Clear Audit Memory on the display.

2. Locate the access port door located on the back of the instrument and

remove seal, if necessary, from the door.

3. Remove screw to open access port door.

4. Press the white security button located on the bottom of the circuit

board to advance to the next screen.

5. When the white push button is pressed, audit memory is cleared and

the unit returns to the Calibration menu.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

CALIBRATE PROCEDURES 37

OPERATOR’S MANUAL

38 CALIBRATE PROCEDURE S

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

MAIN MENU

1: MEASURE MOISTURE 3: CALIBRATION MENU

2: SELECT GRAIN 4: SETUP MENU

5: TESTS MENU

SELECT ITEM NUMBER (NEXT PAGE: STATUS)

SETUP MENU

1: CLEAR COUNTER

2: ID OPTIONS

3: OUTPUT OPTIONS

4: EDIT ACCESS CODE

SELECT ITEM NUMBER

<more>

5: DATE/TIME MENU

6: LABELS MENU

7: COM MENU

8: SERVICE MENU

SETUP MENU

1: QUICK KEYS MENU

2: TEST WEIGHT BIAS ADJUSTMENT

3: TEST WEIGHT SLOPE ADJUSTMENT

4: MOISTURE BIAS ADJUSTMENT

5: MOISTURE SLOPE ADJUSTMENT

SELECT ITEM NUMBER

(NEXT PAGE: STATUS)

Resets the accumulated

sample count since

last reset.

Sets Method

of identifying

grain samples.

Congures information

appearing on display

and printout.

Allows changing

the Access Code.

Sets the date, time,

and date format.

Allows for a Bias and

Slope oset value adjustment

to test weight and moisture

values to enhance agreements

Establishes output

parameters for

communications with

printer and computer.

Contains constants

aecting unit accuracy

(used by technical

personnel)

Label setup

for printout.

Blue model-Sets a key

for quick grain selection

when testing moisture

INSTRUMENT SETUP

The Setup menu establishes basic operating parameters for the unit.

These parameters include:

• Resetting the cycle counter

• ID options

• Output options

• Setting the access code

• Setting date and time

• Entering labels

• Configuring communication ports

From the Main menu, the Setup menu is accessed by selecting the 4 key.

From the Setup menu, eight sub-menus will appear. Most functions require

the access code before changes can occur . If the access code has not been

changed, the factory installed temporary code is set for 0 (zero).

Figure 30

Setup Menu Choices

Enter Key

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

CLEAR CYCLE COUNTER (1 KEY)

The CYCLE COUNTER increments once each time a moisture

measurement or data collection sequence is successful. The screen

displays the total counts accumulated since the last reset.

To Reset the Cycle Counter:

1. From the Setup menu, press the 1 key (NOTE:). A screen displays

ENTER ACCESS CODE.

2. Enter the current personal access code (or 0) and press the Enter key .

Enter 0 if the code has not been changed from factory settings.

INSTRUMENT SETUP 39

OPERATOR’S MANUAL

SETUP MENU

1: CLEAR COUNTER

2: ID OPTIONS

3: OUTPUT OPTIONS

4: EDIT ACCESS CODE

SELECT ITEM NUMBER

<more>

5: DATE/TIME MENU

6: LABELS MENU

7: COM MENU

8: SERVICE MENU

CYCLE COUNTERS

ENTER ACCESS CODE: __

CYCLE COUNTER: 4358

THIS COUNTRER INCREMENTS AFTER EACH

SAMPLE MEASUREMENT OR DATA COLLECTION

SEQUENCE IS SUCCESSFULLY COMPLETED

PRESS TO CLEAR CYCLE COUNTER

3. Press the Enter key again to reset the number (count) to zero. The

counter returns to zero.

NOTE: The date, time, and cycle

counter values are

automatically sent to the COM1

and COM2 ports each time the

counter is cleared resulting in a

printout of the most recently

cleared counter contents. The

printout should be retained for

records. Com 2 Baud Rate is

115,200, 8 data bits, no parity,

and 1 stop bit.

Figure 31

Clearing The Cycle Counter

Enter Key

40 INSTRUMENT SETUP

ID OPTIONS (2 KEY)

ID OPTIONS determines how each moisture measurement sample is

identified on the output data. ID numbers appear in the lower left corner of

each test result screen. All sample ID numbers can contain up to 16

alphanumeric characters. Three methods of sample identification are

available for display:

• Automatic Sequential ID – Automatically increments once for each

measurement cycle, but resets each time the unit is turned OFF.

• Enter Required for ID – With each measurement, a screen displays

ENTER SAMPLE ID before the grain sample is measured. This option

ensures a grain sample identification number/label is assigned for

each test printout.

• Optional Entry ID – If both of the selections have been checked NO,

the ID number can be added to each measureme nt m an ua lly or not

at all. Manually added ID numbers do not require any specific format

or sequencing.

To Configure the ID Options:

1. From the Setup menu, select the 2 key to access the ID Options

screen (Figure 32). A screen displays ENTER ACCESS CODE.

2. Enter the access code (or 0) and select the Enter key. The ID Option

screen displays only two lines but allows three choices – the

AUTOMATIC SEQUENTIAL ID and ENTER REQUIRED FOR ID

functions cannot both be enabled (YES) at the same time.

GAC® 2100 Grain Analysis Computer (Blue, Gray, Agri Models)

11001-1688-201609

OPERATOR’S MANUAL

5

0

&

1

3

&

SETUP MENU

1: CLEAR COUNTER

2: ID OPTIONS

3: OUTPUT OPTIONS

4: EDIT ACCESS CODE

SELECT ITEM NUMBER

<more>

5: DATE/TIME MENU

6: LABELS MENU

7: COM MENU

8: SERVICE MENU

ID OPTIONS

ENTER ACCESS CODE: __

ID OPTIONS

AUTOMATIC SEQUENTIAL ID: YES

ENTER REQUIRED FOR ID : NO

TO SELECT,

TO CHANGE

Up/Down Arrow Keys

Left/Right Arrow Keys