Page 1

250

DIAMOND-MM-48-AT

Autocalibrating 16-bit Analog I/O PC/104 Module

With Relays and Optocouplers

User Manual V1.01

Copyright 2004

Diamond Systems Corporation

8430-D Central Ave.

Newark, CA 94560

Tel (510) 456-7800

www.diamondsystems.com

Page 2

TABLE OF CONTENTS

DESCRIPTION.......................................................................................................................... 3

1.

2. DIAMOND-MM-48-AT BOARD DRAWING .............................................................................4

3. I/O HEADER PINOUT AND PIN DESCRIPTION..................................................................... 5

4. BOARD CONFIGURATION .....................................................................................................7

5. I/O MAP ....................................................................................................................................9

6. REGISTER DEFINITIONS......................................................................................................11

7. ANALOG INPUT RANGES AND RESOLUTION ..................................................................27

8. PERFORMING AN A/D CONVERSION.................................................................................28

9. A/D SCAN, FIFO, AND INTERRUPT OPERATION ..............................................................31

10. ANALOG OUTPUT OVERVIEW ............................................................................................ 34

11. GENERATING AN ANALOG OUTPUT ................................................................................. 35

12. AUTOCALIBRATION OPERATION ......................................................................................36

13. DIGITAL I/O OPERATION .....................................................................................................37

14. OPTOCOUPLER OPERATION.............................................................................................. 38

15. RELAY OPERATION .............................................................................................................40

16. COUNTER/TIMER OPERATION............................................................................................41

17. SPECIFICATIONS..................................................................................................................44

Diamond-MM-48-AT User Manual V1.01 Page 2

Page 3

DIAMOND-MM-48-AT Autocalibrating Analog I/O PC/104 Module

1. DESCRIPTION

Diamond-MM-48-AT (DMM-48-AT) is a PC/104 expansion board offering embedded systems

designers a full feature set of analog and digital I/O capabilities. It is designed to be used in

any PC-compatible embedded computer with a PC/104 (ISA-bus) expansion connector.

DMM-48-AT offers reduced embedded system size and weight, as well as lower cost, by

providing more functionality on one board than other data acquisition boards.

Key features include:

Analog Inputs

♦ 16 single-ended analog inputs

♦ 16-bit A/D resolution

♦ 200KHz maximum aggregate A/D sampling rate

♦ +/-10V and +/-5V input ranges standard; 0-5V input range optional

♦ 2048-sample FIFO for reliable high-speed sampling

♦ Autocalibrated input circuit

Analog Outputs

♦ 8 analog outputs

♦ 12-bit D/A resolution, 0-4.096V output range (1mV per LSB)

♦ Autocalibrated output circuit

Digital I/O

♦ 4 programmable direction digital I/O lines

♦ Edge detection capability with interrupt on change of state

Optocoupler Inputs

♦ 4 optocoupler inputs, 3-28VDC input range

♦ Configurable input polarity

♦ Edge detection capability with interrupt on change of state

Relay Outputs

♦ 8 SPDT (form C) relays

♦ 1A / 30VDC or 0.125A / 125VAC rating

Counter/Timers

♦ 1 24-bit counter/timer for A/D sampling rate control

♦ 1 16-bit counter/timer for user counting and timing functions

♦ Programmable clock source for user counter/timer

System Features

♦ +5V-only operation

♦ Latching I/O connectors

♦ Jumpers may be replaced with zero-ohm resistors for increased ruggedness

o

♦ Extended temperature operation (-40 to +85

C)

Diamond-MM-48-AT User Manual V1.01 Page 3

Page 4

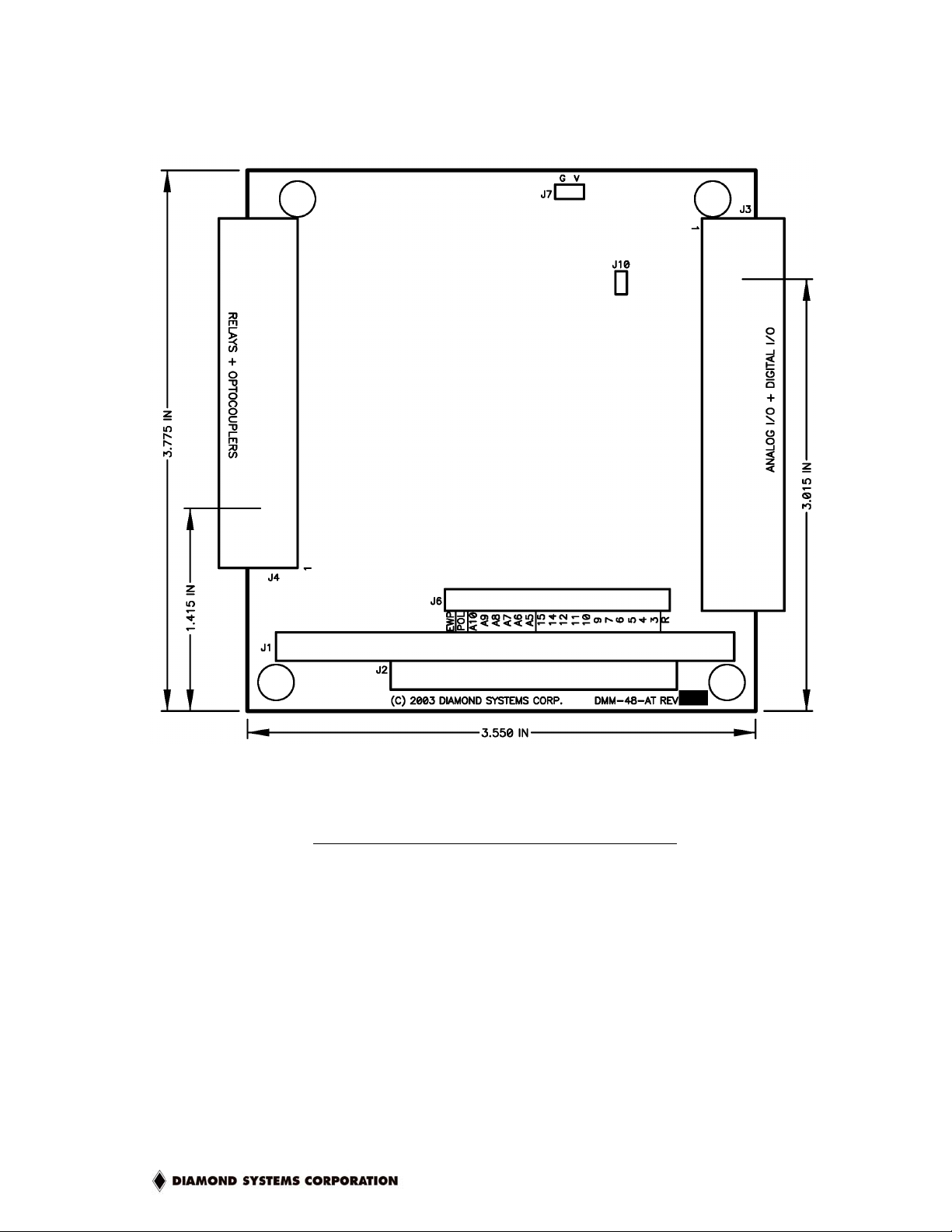

2. DIAMOND-MM-48-AT BOARD DRAWING

Feature descriptions

J1 PC/104 8-bit bus connector

J2 PC/104 16-bit bus connector

J3 Analog and digital I/O connector

J4 Relay and optocoupler I/O connector

J6 Configuration jumper block

J7 Factory use only (used in factory calibration process)

J10 +/-5 input range selection (bipolar model only)

Diamond-MM-48-AT User Manual V1.01 Page 4

Page 5

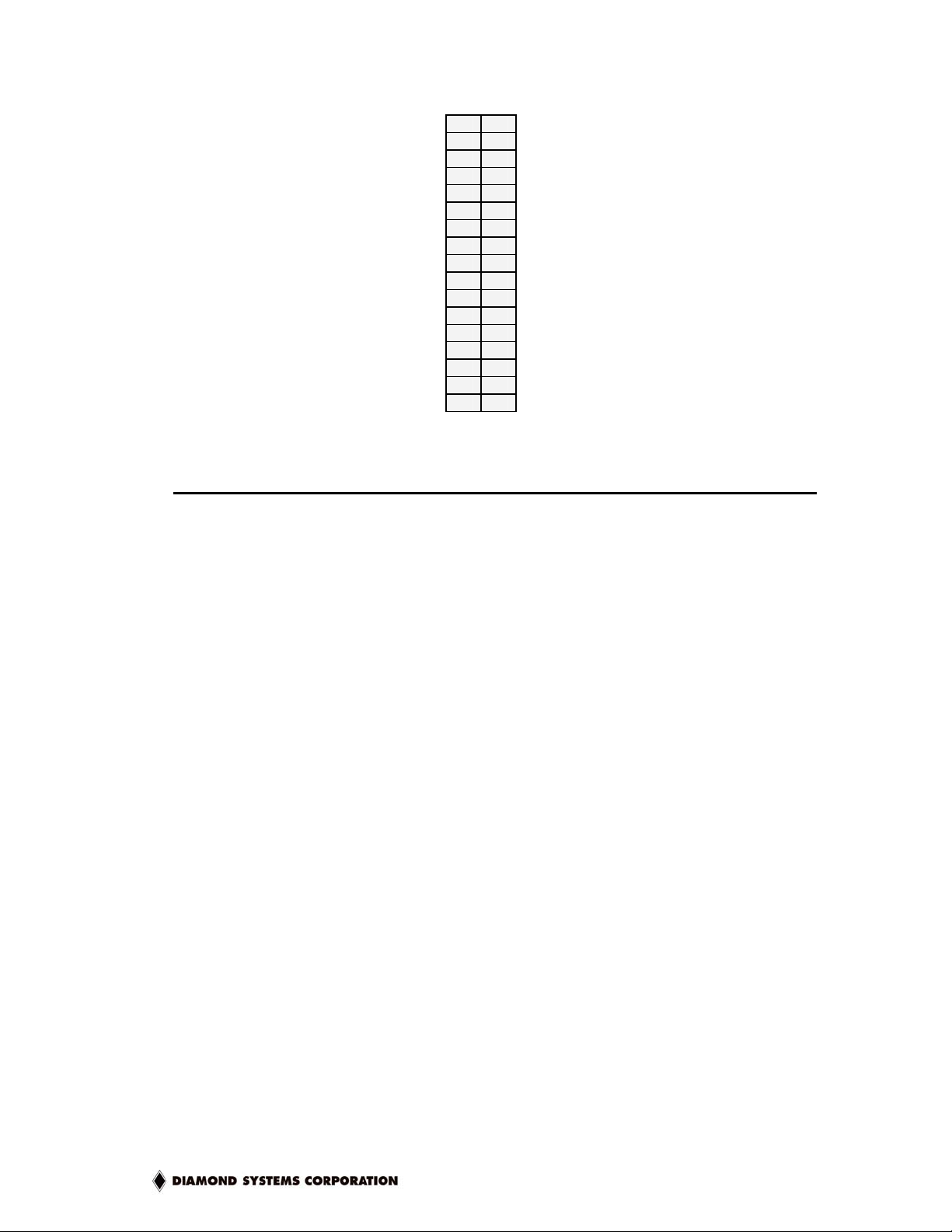

3. I/O HEADER PINOUT AND PIN DESCRIPTION

Diamond-MM-48-AT provides two I/O headers. J3, located on the right side of the board, is a

40-pin header that includes the analog in, analog out, and logic-level digital I/O features. Pin

1 is the upper left pin and is marked on the board. J4, located on the left side of the baord, is

a 34-pin header with the relay and optocoupler features.

J3: Analog and Digital I/O

Vin 0 1 2 Vin 1

Vin 2 3 4 Vin 3

Vin 4 5 6 Vin 5

Vin 6 7 8 Vin 7

Vin 8 9 10 Vin 9

Vin 10 11 12 Vin 11

Vin 12 13 14 Vin 13

Vin 14 15 16 Vin 15

A/D Gnd 17 18 A/D Gnd

Vout 0 19 20 Vout 1

Vout 2 21 22 Vout 3

Vout 4 23 24 Vout 5

Vout 6 25 26 Vout 7

D/A Gnd 27 28 Dgnd

Extclk 29 30 Gate 0

Out 0 31 32 Clk 1

Gate 1 33 34 Out 1

DIO 0 35 36 DIO 1

DIO 2 37 38 DIO 3

+5V 39 40 Dgnd

Signal Name Definition

Vin 0-15 Analog input channels 0 to 15; all inputs are single-ended

Vout 0-7 Analog output channels 0 – 7

DIO 0-3 Digital I/O port, TTL / CMOS compatible; programmable direction

Extclk External A/D trigger input

Gate 0 Counter 0 gate input

Out 0 Counter 0 output

Clk 1 Counter 1 clock input

Gate 1 Counter 1 gate input

Out 1 Counter 1 output

+5V Connected to PC/104 bus power supply

A/D Gnd Analog ground for analog inputs

D/A Gnd Analog ground for analog outputs

Dgnd Digital ground

Note: all grounds are electrically connected. The different pins are

intended to reduce noise by separating the current paths on the

board.

Diamond-MM-48-AT User Manual V1.01 Page 5

Page 6

J4: Relays and Optocouplers

Opto 0- 1 2 Opto 0+

Opto 1- 3 4 Opto 1+

Opto 2- 5 6 Opto 2+

Opto 3- 7 8 Opto 3+

No connection 9 10 No connection

Relay 0 NO 11 12 Relay 0 NC

Relay 0 C 13 14 Relay 1 NO

Relay 1 NC 15 16 Relay 1 C

Relay 2 NO 17 18 Relay 2 NC

Relay 2 C 19 20 Relay 3 NO

Relay 3 NC 21 22 Relay 3 C

Relay 4 NO 23 24 Relay 4 NC

Relay 4 C 25 26 Relay 5 NO

Relay 5 NC 27 28 Relay 5 C

Relay 6 NO 29 30 Relay 6 NC

Relay 6 C 31 32 Relay 7 NO

Relay 7 NC 33 34 Relay 7 C

Signal Name Definition

Relay output contacts:

Relay N C (N = 0 to 7) Relay output common contact; this contact is always

used with relay output connections.

Relay N NC Relay output normally connected contact; this contact is connected

to the Out N C contact when power is off or when a 0 is written to the

relay’s control bit in the relay control register, and it is disconnected

when power is on and a 1 is written to the relay’s control bit.

Relay N NO Relay output normally open contact; this contact is disconnected

when power is off or when a 0 is written to the relay’s control bit in

the relay control register, and it is connected to the Out N C contact

when power is on and a 1 is written to the relay’s control bit.

Optoisolated input contacts:

Opto N + (N = 0 to 3) Optoisolated input contact, high side

Opto N - Optoisolated input contact, low side; opto inputs are polarized

Diamond-MM-48-AT User Manual V1.01 Page 6

Page 7

4. BOARD CONFIGURATION

Refer to the Drawing of Diamond-MM-48-AT on page 4 for locations of the configuration

items mentioned here. All configuration except the A/D input range is done with jumper block

J6.

4.1 Base Address

Each board in your system must have a unique I/O address range. The first address in this

range is called the base address. Diamond-MM-48-AT uses an I/O range of 16 bytes. The

base address of this range is set with a portion of jumper block J6, located along the lower

portion of the board near the PC/104 bus connectors. Each of the six jumper locations

marked 10, 9, 8, 7, 6, 5 corresponds to the same-numbered address bit in the board’s 10-bit

I/O address. Bits 4-0 are always 0 for the base address, resulting in a 16-byte I/O address

block located on a 32-byte boundary. A jumper out is equal to a 1, and a jumper in is equal to

a 0. Although any address is selectable, certain locations are reserved or may cause conflicts

with other system resources. The table below lists recommended base address settings for

Diamond-MM-48-AT. The default setting is 300 Hex.

Base Address Jumper Position

Hex Decimal 10 9 8 7 6 5

200 512 In Out In In In In

240 512 In Out In In Out In

280 512 In Out In Out In In

2C0 512 In Out In Out Out In

300 768 (Default) In Out Out In In In

340 832 In Out Out In Out In

380 896 In Out Out Out In In

3C0 960 In Out Out Out Out In

4.2 Interrupt Level Selection

In addition to the base address described above, J6 is used to configure hardware interrupt

activity. Interrupts are used for several functions. They can be used to transfer A/D data from

the board to memory at a rate higher than can be achieved through software sampling. In

addition, they can be used to indicate to the application software when a change of state has

occurred on the optocoupler or digital inputs.

During interrupt operation, the board will periodically generate an interrupt request, or IRQ.

The processor will respond and run a user-supplied interrupt routine function, or the function

supplied with the board’s driver software. The interrupt routine reads the data from the board

and makes it available to the user application program.

DMM-48-AT allows you to select from levels 15, 14, 12, 11, 10, 9, 7, 6, 5, 4, and 3. Only one

IRQ level may be used. To select the desired IRQ level install a jumper in that number’s

location in the Interrupt area of jumper block J6.

On the PC/104 bus each IRQ level in use must have a 1KΩ pull-down resistor attached. To

enable the pull-down resistor for this board, install a jumper in the R location on J6.

Typically each board in the computer will use a different interrupt level, or IRQ level. However

in special circumstances multiple boards may share the same IRQ level. In this case only one

Diamond-MM-48-AT User Manual V1.01 Page 7

Page 8

board should have the pull-down resistor enabled with a jumper in the R location. The other

boards should have the R jumper removed to disable their pull-down resistors.

4.3 Optocoupler Polarity

The 4 optocouplers may be configured for either direct or inverted polarity with the POL

position on J6. For direct polarity, an open circuit / low voltage input reads back as a 0, and a

high voltage reads back as a 1. For inverted polarity, an open circuit / low voltage reads as 1,

and a high voltage reads as 0. For direct polarity, the POL jumper should be absent. For

inverted polarity, install a jumper in the POL location.

4.4 Reserved

The EWP position on J6 is reserved for a future option and currently has no function.

4.5 Analog Input Range

On the standard bipolar input range model, the input range can be selected with a jumper for

either +/-10V or +/-5V. For +/-10V operation, jumper block J10 should be open. For +/-5V

operation, install a jumper in J10.

On the unipolar input range model, the input range is fixed at 0-5V, and J10 does not serve

any purpose.

Diamond-MM-48-AT User Manual V1.01 Page 8

Page 9

5. I/O MAP

5.1 Overview

Diamond-MM-48-AT occupies 16 bytes in I/O memory space. A functional list of these

registers is provided below, and detailed register bit definitions are provided on the next page

and the following chapter. The information in chapters 5 and 6 is provided to assist in

understanding the board’s operation and for use by programmers writing their own driver

software. Diamond Systems’ Universal Driver software provides high-level control of the

board’s functionality and will isolate these underlying hardware details for most programmers.

Base + Write Function Read Function

0 D/A LSB A/D LSB

1 D/A MSB A/D MSB

2 A/D channel register A/D channel register

3 Relay control register Relay control readback

4 Digital I/O configuration Digital I/O config + status readback

5 Digital I/O output data Digital I/O input and edge data

6 Optocoupler configuration Optocoupler configuration readback

7 D/A channel and update control Optocoupler input and edge data

8 Command register Status register

9 Configuration register Configuration register readback

10 FIFO control register FIFO status register

11 Interrupt control register Interrupt status register

Addresses 12-15 form a window into 2 4-byte pages. The page is selected with a bit in

register 10.

Page 0: counter/timers

12 Ctr 0 and Ctr 1 LSB Ctr 0 and Ctr 1 MSB

13 Ctr 0 CSB (center byte) / Ctr 1 MSB Ctr 0 CSB / Ctr 1 MSB

14 Ctr 1 MSB Ctr 1 MSB

15 Counter/timer control register ---

Page 1: Calibration Control

12 EEPROM / TrimDAC data register EEPROM / TrimDAC data register

13 EEPROM / TrimDAC address register EEPROM / TrimDAC address register

14 Calibration control register Calibration status register

15 EEPROM access key FPGA code version

Diamond-MM-48-AT User Manual V1.01 Page 9

Page 10

5.2 Register Map Bit Assignments

A blank location in the Write registers has no function.

A blank location in the Read registers has no function and reads back as 0.

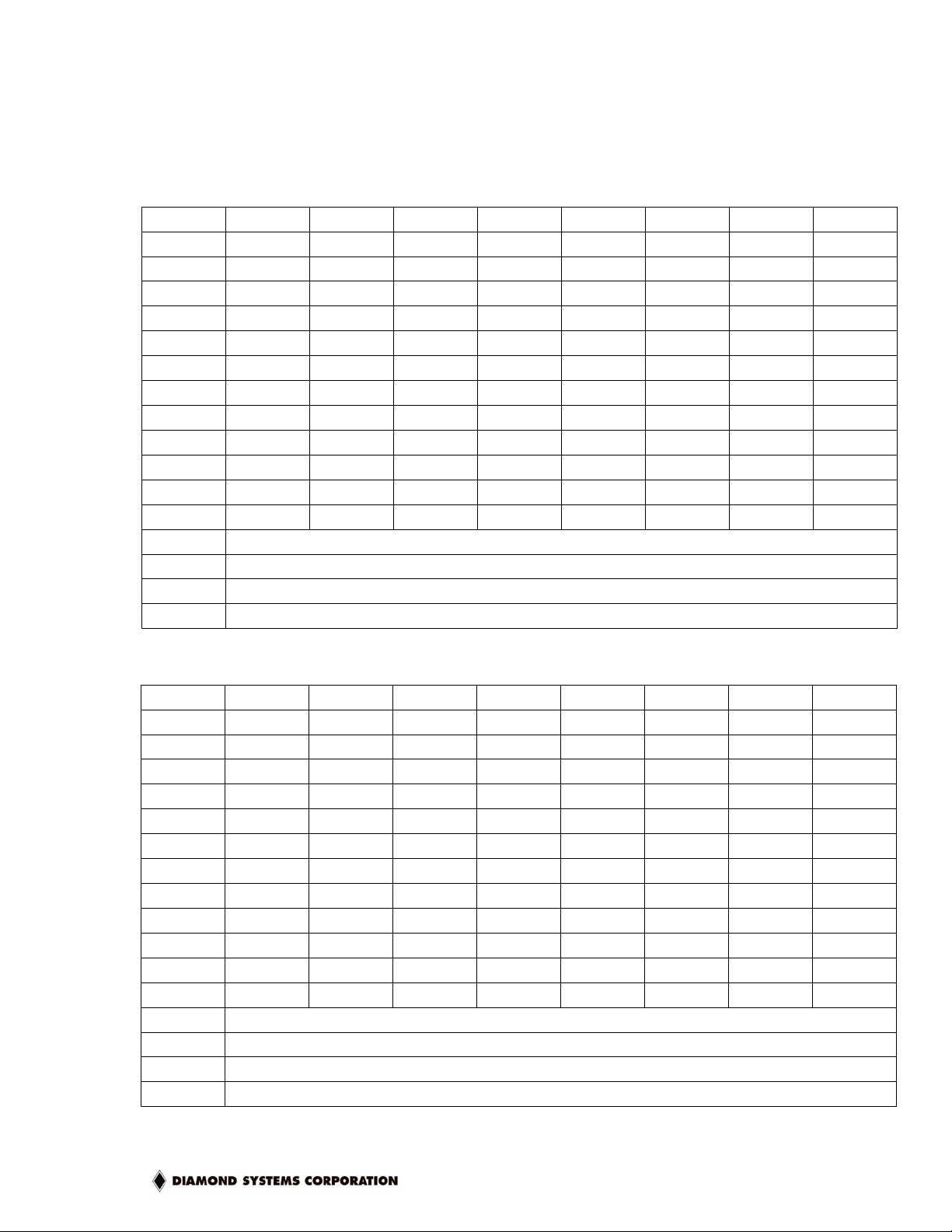

WRITE operations

7 6 5 4 3 2 1 0

0 DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

1 DA11 DA10 DA9 DA8

2 HIGH3 HIGH2 HIGH1 HIGH0 LOW3 LOW2 LOW1 LOW0

3 RELAY7 RELAY6 RELAY5 RELAY4 RELAY3 RELAY2 RELAY1 RELAY0

4 DIR3 DIR2 DIR1 DIR0

5 DIO3 DIO2 DIO1 DIO0

6 OEN3 OEN2 OEN1 OEN0 POL3 POL2 POL1 POL0

7 DAUPDT DACH2 DACH1 DACH0

8 DAPRE DAPRLD RESET FIFORST ADSTART

9 CKSEL1 CKFRQ1 CKFRQ0 SCNINT CLKEN CLKSEL

10 PAGE FIFOTH FIFOEN SCANEN

11 CLRT CLRD CLRO CLRA TINTE DINTE OINTE AINTE

12 Page 0: Counter data LSB Page 1: Calibration Data

13 Page 0: Counter data CSB Page 1: Calibration Address

14 Page 0: Counter data MSB Page 1: Calibration Control

15 Page 0: Counter Control Register Page 1: EEPROM Access Key Register

READ operations

7 6 5 4 3 2 1 0

0 AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0

1 AD15 AD14 AD13 AD12 AD11 AD10 AD9 AD8

2 HIGH3 HIGH2 HIGH1 HIGH0 LOW3 LOW2 LOW1 LOW0

3 RELAY7 RELAY6 RELAY5 RELAY4 RELAY3 RELAY2 RELAY1 RELAY0

4 DIR3 DIR2 DIR1 DIR0

5 DEDGE3 DEDGE2 DEDGE1 DEDGE0 DIO3 DIO2 DIO1 DIO0

6 OEN3 OEN2 OEN1 OEN0 POL3 POL2 POL1 POL0

7 OEDGE3 OEDGE2 OEDGE1 OEDGE0 OPTO3 OPTO2 OPTO1 OPTO0

8 POL ADCH3 ADCH2 ADCH1 ADCH0

9 ADBUSY DABUSY CKSEL1 CKFRQ1 CKFRQ0 SCNINT CLKEN CLKSEL

10 OVF HF 8F EF PAGE FIFOTH FIFOEN SCANEN

11 TINT DINT OINT AINT TINTE DINTE OINTE AINTE

12 Page 0: Counter data LSB Page 1: Calibration Data

13 Page 0: Counter data CSB Page 1: Calibration Address

14 Page 0: Counter data MSB Page 1: Calibration Control/Status

15 Page 0: --- Page 1: FPGA revision code

Diamond-MM-48-AT User Manual V1.01 Page 10

Page 11

6. REGISTER DEFINITIONS

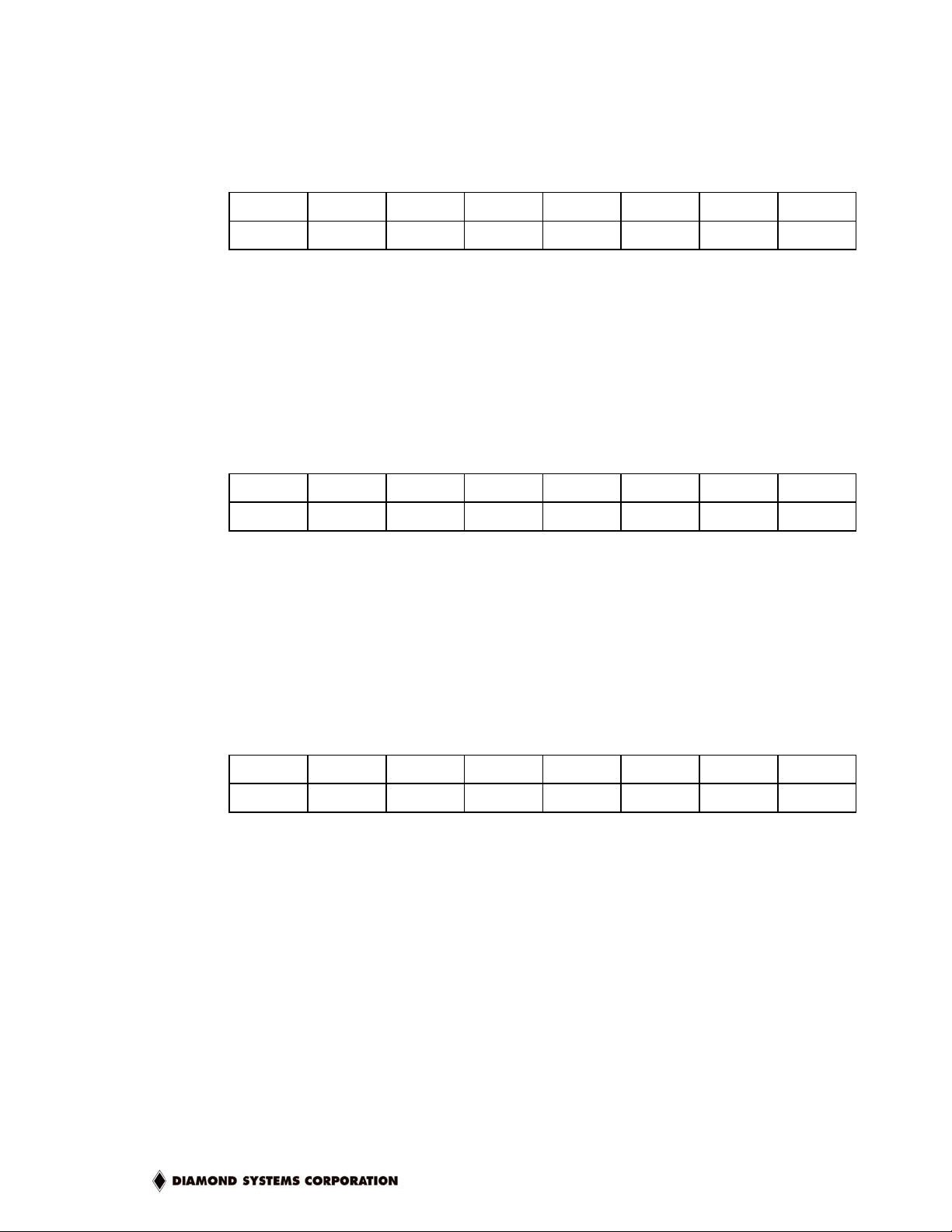

Base + 0 Write D/A LSB

Bit No. 7 6 5 4 3 2 1 0

Name DA7 DA6 DA5 DA4 DA3 DA2 DA1 DA0

Definitions:

DA7-0 D/A bits 7-0; DA0 is the LSB. D/A data is an unsigned 12-bit number ranging

from 0 to 4095.

Base + 0 Read A/D LSB

Bit No. 7 6 5 4 3 2 1 0

Name AD7 AD6 AD5 AD4 AD3 AD2 AD1 AD0

Definitions:

AD7 – 0 A/D LSB data (bits 7-0 of the 16-bit value). A/D data is a signed 16-bit value

ranging from -32768 to 32767.

Base + 1 Write DAC 0 – 3 MSB

Bit No. 7 6 5 4 3 2 1 0

Name DA11 DA10 DA9 DA8

Definitions:

DA11 – 8 D/A data bits 11-8 for the selected channel. DA11 is the MSB.

Diamond-MM-48-AT User Manual V1.01 Page 11

Page 12

Base + 1 Read A/D MSB

Bit No. 7 6 5 4 3 2 1 0

Name AD15 AD14 AD13 AD12 AD11 AD10 AD9 AD8

Definitions:

AD15 – 8 A/D MSB data (bits 15-8 of the 16-bit value). A/D data is a signed 16-bit value

ranging from -32768 to 32767.

Note: Reading from Base + 0 and Base + 1 result in the same physical operation, reading

from the FIFO. The FIFO is 8 bits wide x 2048 bytes deep, with A/D data stored and retrieved

in interleaved fashion. Data from the A/D is put into the FIFO in little-endian mode, with the

LSB inserted first, and the MSB inserted second. Thus the data comes out of the FIFO in the

same order. Each time a byte is read from either Base + 0 or Base + 1, the next byte will be

read from the FIFO and the FIFO counter will be decremented.

Because the FIFO decrements after each read operation, you cannot read out the same A/D

value more than once (unless the FIFO is empty, in which case the last byte may be read

indefinitely). It is the programmer’s responsibility to ensure that data is read out of the FIFO

properly so that appropriate LSB / MSB pairs are read out together.

Base + 2 Read/Write A/D Channel Register

Bit No. 7 6 5 4 3 2 1 0

Name HIGH3 HIGH2 HIGH1 HIGH0 LOW3 LOW2 LOW1 LOW0

Definitions:

HIGH3 – 0 High channel of channel scan range; ranges from LOW to 15

LOW3 – 0 Low channel of channel scan range; ranges from 0 to 15

The high channel must be greater than or equal to the low channel.

When this register is written, the current A/D channel is set to the low channel and ADBUSY

= 1 for 10 uS. A/D channels are automatically selected in sequence by the board. Each time

an A/D conversion starts, the board increments to the next channel in the range. When the

high channel is sampled, the board resets to the low channel.

Diamond-MM-48-AT User Manual V1.01 Page 12

Page 13

Base + 3 Read/Write Relay Control Port

Bit No. 7 6 5 4 3 2 1 0

Name RELAY7 RELAY6 RELAY5 RELAY4 RELAY3 RELAY2 RELAY1 RELAY0

These bits control the 8 relays. 0 = off (C connected to NC), 1 = on (C connected to NO). The

written value may be read back with true logic. The value on the corresponding output pin is

the inverse of the value in this register.

On power-up or reset, the output register is cleared to all zeroes and all relays reset to their

off condition (C connected to NC) by resetting all RELAY pins to 1. Relays are in the off

condition when power is off and remain in that condition when power is applied until a 1 is

written to their corresponding control register bit.

Base + 4 Read/Write Digital I/O Configuration Register

Bit No. 7 6 5 4 3 2 1 0

Name DIR3 DIR2 DIR1 DIR0

Definitions:

DIR3-0 Digital I/O direction settings for each bit: 1 = output, 0 = input

All digital I/O lines are in input mode on power-up.

Diamond-MM-48-AT User Manual V1.01 Page 13

Page 14

Base + 5 Write Digital I/O Data

Bit No. 7 6 5 4 3 2 1 0

Name DIO3 DIO2 DIO1 DIO0

Definitions:

DIO3 – 0 Digital I/O output data. Only bits in output mode are affected. Any bit in input

mode will ignore data written to this register.

Base + 5 Read Digital I/O Data and Edge Status

Bit No. 7 6 5 4 3 2 1 0

Name DEDGE3 DEDGE2 DEDGE1 DEDGE0 DIO3 DIO2 DIO1 DIO0

Definitions:

DEDGE3 – 0 Edge status for DIO lines: 1 = change occurred since last read, 0 = no

change occurred

DIO3 – 0 Digital I/O readback. If a bit is in output mode, the readback value is equal to the

programmed value.

Base + 6 Read/Write Optocoupler Edge Detection Configuration Register

Bit No. 7 6 5 4 3 2 1 0

Name OEN3 OEN2 OEN1 OEN0 POL3 POL2 POL1 POL0

OEN3-0 Enable edge detection on the selected digital input line: 0 = disabled, 1 =

enabled

POL3-0 Select active edge polarity for selected digital input line: 0 = falling, 1 = rising

An interrupt request will occur when OINTE = 1 and a digital input line enabled with OENn

exhibits an edge whose polarity matches POLn (a qualifying edge). If an interrupt request

occurs, and an additional qualifying edge occurs before the digital interrupt flip flop is reset,

no additional interrupt request will be generated. It is possible for more than one line’s

qualifying edge to be detected in a single interrupt (for example if 3 lines exhibit qualifying

edges at the same time), but not more than one edge per line (for example if a second

qualifying edge on the same line occurs before the interrupt is serviced).

It is possible for a qualifying edge to occur in the time between when the interrupt routine

reads the digital input status register and when it resets the interrupt flip flop. In this case the

qualifying edge will be lost, since resetting the flip flop also resets the edge detection status

bits.

Diamond-MM-48-AT User Manual V1.01 Page 14

Page 15

Base + 7 Write D/A Channel and Control Register

Bit No. 7 6 5 4 3 2 1 0

Name DAUPDT DACH2 DACH1 DACH0

DAUPDT Writing a 1 to this bit updates the D/A chip. All channels with new data written to

them since the previous update are updated simultaneously. When a 1 is written

to this bit the other bits in the register are ignored.

When DAUPDT = 0, the remaining bits in this register behave as described below:

DACH2-0 D/A channel number, valid range 0-7

Base + 7 Read Optocoupler Input Port and Edge Detection Register

Bit No. 7 6 5 4 3 2 1 0

Name OEDGE3 OEDGE2 OEDGE1 OEDGE0 OPTO3 OPTO2 OPTO1 OPTO0

OEDGE3-0 Indicates whether an edge has occurred on the indicated digital input line.

1 edge has occurred since last flip flop reset

0 edge has not occurred since last flip flop reset

These bits are reset when this register is read or when the digital input interrupt flip flop is

reset by writing to the CLRO bit in register 8.

OPTO3-0 These signals correspond to the logic state of the optocoupler inputs on J4.

Diamond-MM-48-AT User Manual V1.01 Page 15

Page 16

Base + 8 Write Command Register

Bit No. 7 6 5 4 3 2 1 0

Name DAPRE DAPRLD RESET FIFORST ADSTART

Writing a 1 to any bit in this register causes a command or operation to be executed. Only

one bit may be activated (set to 1) at a time. When a 1 is written to any bit, no other bit or

related operation is affected.

DAPRE All 8 D/A channels are set to the value in the D/A preset register. This value is

user-definable and can be used for any purpose. A typical purpose is to generate

a D/A reset to 0V by loading a preset value that corresponds to 0V for the

selected D/A mode. For example, for D/A in unipolar mode, the preset value

would be 0, and for D/A in bipolar mode, the preset value would be 2048.

DAPRLD The D/A preset register is loaded with the value contained in registers 0-1. After

the preset value is loaded into the D/A, a DAPRE command will update all 8 D/A

channels with this value.

RESET Reset the board to a known condition: All registers are cleared to 0, all DIO lines

are set to input mode, interrupts are disabled, and the FIFO is reset. D/A

channels are not reset or changed in any way.

FIFORST Reset FIFO. Writing a 1 to this bit causes the on-board FIFO to be reset to empty

in preparation for an interrupt-based A/D operation. After FIFORST, EF = 1 and

OVF, FF, and HF = 0.

ADSTART Start an A/D conversion.

Diamond-MM-48-AT User Manual V1.01 Page 16

Page 17

Base + 8 Read Status Register

Bit No. 7 6 5 4 3 2 1 0

Name POL ADCH3 ADCH2 ADCH1 ADCH0

POL Optocoupler polarity jumper setting; the value indicates the value of an open

circuit:

1 Open circuit reads as 1, “high” input reads as 0

0 Open circuit reads as 0, “high” input reads as 1

ADCH3 - 0 Current A/D channel; this is the channel currently selected on board and is the

channel that will be used for the next A/D conversion (unless a new value is

written to the channel register before then).

Diamond-MM-48-AT User Manual V1.01 Page 17

Page 18

Base + 9 Write Configuration Register

Bit No. 7 6 5 4 3 2 1 0

Name CKSEL1 CKFRQ1 CKFRQ0 SCNINT CLKEN CLKSEL

CKSEL1 Clock source select for counter/timer 1:

1 External signal Clk0 in I/O connector J3

0 On-board clock, frequency selected by CKFRQ1 below

CKFRQ1 Clock frequency select for counter/timer 1 when CKSEL1 = 0:

1 100KHz

0 10MHz

CKFRQ0 Clock frequency select for counter/timer 0:

1 1MHz

0 10MHz

SCNINT Scan interval. This is the time between A/D samples during an A/D scan. An A/D

scan occurs when SCANEN = 1 (Base + 10 bit 4) and an A/D conversion is

triggered.

1 5.0µS

0 9.3µS

CLKEN Enable hardware A/D clock:

1 Enable hardware A/D trigger (source is selected with CLKSEL bit); software

triggers are disabled

0 Disable hardware trigger; A/D is triggered by setting the ADSTART bit

CLKSEL A/D clock select, used only when CLKEN = 1:

1 Internal clock: counter/timer 0 generates A/D conversions

0 External clock: the EXTCLK pin on I/O connector J3, generates A/D

conversions

Diamond-MM-48-AT User Manual V1.01 Page 18

Page 19

Base + 9 Read Configuration & Status Register

Bit No. 7 6 5 4 3 2 1 0

Name ADBUSY DABUSY CKSEL1 CKFRQ1 CKFRQ0 SCNINT CLKEN CLKSEL

ADBUSY A/D chip status:

1 A/D conversion or scan is in progress or A/D input circuit in settling mode

0 A/D is idle

Do not attempt to start a new A/D conversion or scan when ADBUSY = 1.

DABUSY D/A chip status:

1 D/A conversion is in progress

0 D/A is idle

Do not attempt to start a new D/A conversion when DABUSY = 1.

CKSEL1 Clock source select for counter/timer 1:

1 External signal Clk0 in I/O connector J3

0 On-board clock, frequency selected by CKFRQ1 below

CKFRQ1 Clock frequency select for counter/timer 1 when CKSEL1 = 0:

1 100KHz

0 10MHz

CKFRQ0 Clock frequency select for counter/timer 0:

1 1MHz

0 10MHz

SCNINT Scan interval. This is the time between A/D samples during an A/D scan. An A/D

scan occurs when SCANEN = 1 (Base + 10 bit 4) and an A/D conversion is

triggered.

1 5.0µS

1 9.3µS

CLKEN Enable hardware A/D clock:

1 Enable hardware A/D trigger (source is selected with CLKSEL bit); software

triggers are disabled

0 Disable hardware trigger; A/D is triggered by setting the ADSTART bit

CLKSEL A/D clock select, used only when CLKEN = 1:

1 Internal clock: counter/timer 0 generates A/D conversions

0 External clock: the EXTCLK pin on I/O connector J3, generates A/D

conversions

Diamond-MM-48-AT User Manual V1.01 Page 19

Page 20

Base + 10 Write FIFO Control Register

Bit No. 7 6 5 4 3 2 1 0

Name

PAGE FIFOTH FIFOEN SCANEN

PAGE Page number for registers at Base + 12 through Base + 15

Page 0: 82C54 counter/timer access

Page 1: Calibration registers

FIFOTH FIFO threshold: 0 = 1024 samples (half full), 1 = 256 samples (1/8 full)

FIFOEN FIFO enable:

1 Enable FIFO operation; if interrupts are enabled, interrupt requests will occur

when the FIFO reaches or exceeds the threshold selected with FIFOTH.

0 Disable FIFO operation; if interrupts are enabled, interrupts will occur after

each A/D conversion or scan is completed.

SCANEN Scan enable:

1 A/D scan mode enabled; FIFO will fill up with data for a single scan, and

ADBUSY will stay high until an entire scan is complete. If interrupts are

enabled, interrupts will occur at the end of the scan. If FIFOEN = 1 and

SCANEN = 1, the interrupt will occur at the end of the scan that causes

the FIFO to reach or exceed its half-full point (256 samples).

0 Scan mode disabled; the ADBUSY bit will remain high for a single

conversion

Base + 10 Read FIFO Status Register

Bit No. 7 6 5 4 3 2 1 0

Name OVF HF 8F EF PAGE FIFOTH FIFOEN SCANEN

OVF FIFO overflow flag: 0 = no overflow, 1 = overflow

Overflow is defined as the state when the FIFO is full and another A/D

conversion occurs before any data is read out of the FIFO. In an overflow

condition the FIFO contents are preserved, and no new data will be written to the

FIFO. To clear an overflow condition, the FIFO must be reset with the FIFORST

bit in register 8.

8F FIFO 1/8 full flag:

0 FIFO is less than 1/8 full (256 samples)

1 FIFO is greater than or equal to 1/8 full

HF FIFO half full flag

0 FIFO is less than half full (1024 or less samples)

1 FIFO is greater than half full (1025 or more samples)

EF FIFO empty flag: 0 = FIFO is not empty, 1 = FIFO is empty

PAGE Readback of PAGE bit described above

FIFOTH Readback of FIFO threshold bit described above

FIFOEN Readback of FIFOEN bit described above

SCANEN Readback of SCANEN bit described above

Diamond-MM-48-AT User Manual V1.01 Page 20

Page 21

Base + 11 Write Interrupt Control Register

Bit No. 7 6 5 4 3 2 1 0

Name CLRT CLRD CLRO CLRA TINTE DINTE OINTE AINTE

CLRT Clear the timer interrupt flip flop.

CLRD Clear the digital input interrupt flip flop and reset their edge detect status bits.

CLRO Clear the optocoupler input interrupt flip flop and reset their edge detect status

bits.

CLRA Clear the analog input interrupt flip flop.

The interrupt flip flop for each circuit is set whenever an interrupt request is generated by that

circuit, and it must be cleared by software before another interrupt of that type can be

generated. An interrupt request from one or more circuits will generate an interrupt request

on the selected IRQ line. Writing a 1 to any CLRx bit clears the interrupt flip flop for that

circuit and leaves alone all other bits in this register. Writing a 0 to a CLRx bit has no effect

on that circuit. Each circuit’s interrupt flip flop can be reset individually. When all interrupt

circuits have been reset, either by clearing them individually or by disabling them with xINTE

= 0, the board’s interrupt request line will be tristated.

TINTE Timer interrupt enable:

1 Enable interrupts on falling edge of timer 1

0 Disable timer interrupts

DINTE Digital I/O interrupt enable:

1 Enable interrupts on any change of state of DIO3-0

0 Disable digital input interrupts

OINTE Optocoupler input interrupt enable:

1 Enable optocoupler interrupts on change of state determined by register 6; in

order for an interrupt to occur, OINTE must be set to 1, at least one of OEN30 must also be set to 1, and the edge indicated by the corresponding bit

POL3-0 must occur on the selected optocoupler.

0 Disable optocoupler interrupts

AINTE Analog input interrupt enable:

1 Enable A/D interrupts

0 Disable A/D interrupts

Diamond-MM-48-AT User Manual V1.01 Page 21

Page 22

Base + 11 Read Interrupt Status Register

Bit No. 7 6 5 4 3 2 1 0

Name TINT DINT OINT AINT TINTE DINTE OINTE AINTE

TINT Timer interrupt status:

1 Timer interrupt pending

0 Timer interrupt not pending

DINT Digital interrupt status:

1 Digital input interrupt pending

0 Digital input interrupt not pending

OINT Optocoupler input interrupt request status:

1 One or more qualifying edges have occurred on the optocouplers

0 No qualifying edges have occurred

AINT Analog input interrupt request status:

1 Interrupt request is pending from A/D circuit

0 No interrupt is pending from A/D circuit

TINTE Readback of TINTE bit described on previous page

DINTE Readback of DINTE bit described on previous page

OINTE Readback of OINTE bit described on previous page

AINTE Readback of AINTE bit described on previous page

Diamond-MM-48-AT User Manual V1.01 Page 22

Page 23

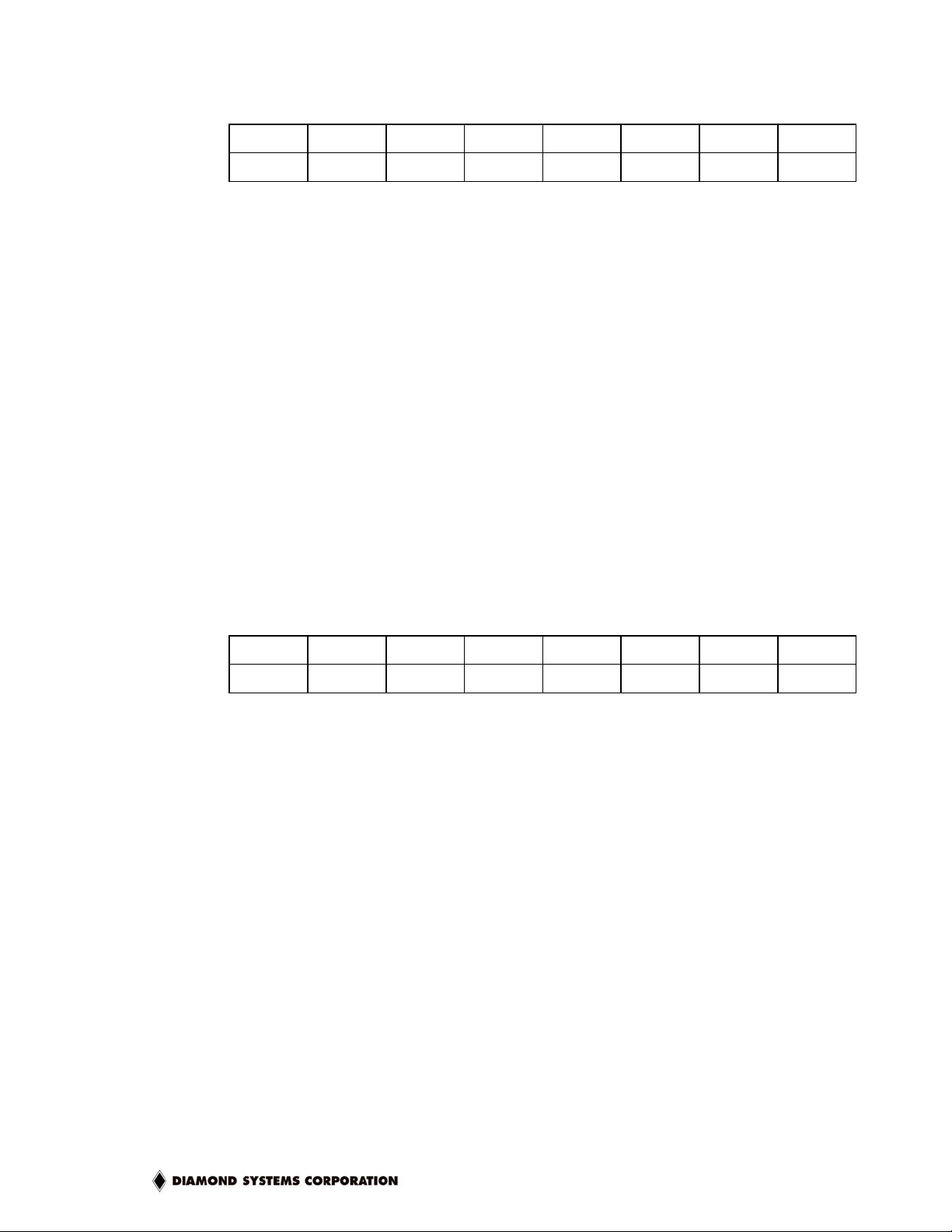

Page 0: Counter/Timer

Base + 12 Read/Write Counter/Timer D7 - 0

Bit No. 7 6 5 4 3 2 1 0

Name D7 D6 D5 D4 D3 D2 D1 D0

This register is used for both Counter 0 and Counter 1. It is the LSB for both counters.

When writing to this register, an internal load register is loaded. Upon issuing a Load

command through Base + 15, the selected counter’s LSB register will be loaded with this

value.

When reading from this register, the LSB value of the most recent Latch command will be

returned. The value returned is NOT the value written to this register.

Base + 13 Read/Write Counter/Timer D15 - 8

Bit No. 7 6 5 4 3 2 1 0

Name D15 D14 D13 D12 D11 D10 D9 D8

This register is used for both Counter 0 and Counter 1. It is the MSB for counter 1 and the

middle byte for counter 0.

When writing to this register, an internal load register is loaded. Upon issuing a Load

command through Base + 15, the selected counter’s associated register will be loaded with

this value. For counter 0, it is the middle byte. For counter 1, it is the MSB.

When reading from this register, the associated byte of the most recent Latch command will

be returned. The value returned is NOT the value written to this register.

Base + 14 Read/Write Counter/Timer D23 - 16

Bit No. 7 6 5 4 3 2 1 0

Name D23 D22 D21 D20 D19 D18 D17 D16

This register is used for Counter 0 only. Counter 0 is 24 bits wide, while Counter 1 is only 16

bits wide.

When writing to this register, an internal load register is loaded. Upon issuing a Load

command through Base + 15 for Counter 0, the counter’s MSB register will be loaded with

this value. When issuing a Load command for counter 1, this register is ignored.

When reading from this register, the MSB value of the most recent Latch command for

counter 0 will be returned. The value returned is NOT the value written to this register.

Diamond-MM-48-AT User Manual V1.01 Page 23

Page 24

Base + 15 Write Counter/Timer Control Register

Bit No. 7 6 5 4 3 2 1 0

Name CTRNO LATCH GTDIS GTEN CTDIS CTEN LOAD CLR

This register is used to control the counter/timers. A counter is selected with bit 7, and then a

1 is written to any ONE of bits 6 – 0 to select the desired operation for that counter. The other

bits and associated functions are not affected. Thus only one operation can be performed at

a time.

CTRNO Counter no., 0 or 1

LATCH Latch the selected counter so that its value may be read. The counter must be

latched before it is read. Reading from registers 12-14 returns the most recently

latched value. If you are reading Counter 1 data, read only Base + 12 and Base

+ 13. Any data in Base + 14 will be from the previous Counter 0 access.

GTDIS Disable external gating for the selected counter.

GTEN Enable external gating for the selected counter. If enabled, the associated gate

signal GATE0 or GATE1 controls counting on the counter. If the GATEn signal is

high, counting is enabled. If the GATEn signal is low, counting is disabled.

CTDIS Disable counting on the selected counter. The counter will ignore input pulses.

CTEN Enable counting on the selected counter. The counter will decrement on each

input pulse.

LOAD Load the selected counter with the data written to Base + 12 through Base + 14

or Base + 12 and Base + 13 (depending on which counter is being loaded).

CLR Clear the current counter (set its value to 0).

To load a counter: First write the load value to Base + 12 and Base + 13 (for Counter 1) or

Base + 12 through Base + 14 (for Counter 0). Then write a Load command to Base + 15. For

example, to load Counter 0 with the hex value 123456:

♦ Write 0x12 to Base + 14 (these three bytes can be written to in any order)

♦ Write 0x34 to Base + 13

♦ Write 0x56 to Base + 12

♦ Write 0x02 to Base + 15 to load counter 0

To enable counting: Write 0x04 (ctr 0) or 0x84 (ctr 1) to Base + 15.

To stop counting: Write 0x08 (ctr 0) or 0x88 (ctr 1) to Base + 15.

To read a counter: First latch it, then read the value:

♦ Write 0x40 to Base + 15 to latch counter 0 or 0xC0 to latch counter 1

♦ Read LSB from Base +12

♦ Read Middle Byte from Base + 13

♦ Read MSB from Base + 14

♦ Assemble 3 bytes into the current counter value

Diamond-MM-48-AT User Manual V1.01 Page 24

Page 25

Page 1: Autocalibration Control Registers

Base + 12 Read/Write EEPROM / TrimDAC Data Register

Bit No. 7 6 5 4 3 2 1 0

Name D7 D6 D5 D4 D3 D2 D1 D0

D7-0 Calibration data to be read or written to the EEPROM and/or TrimDAC.

During EEPROM or TrimDAC write operations, the data written to this register will be written

to the selected device.

During EEPROM read operations this register contains the data to be read from the

EEPROM and is valid after EEBUSY = 0 (Page 1, Base + 14).

The TrimDAC data cannot be read back.

Base + 13 Read/Write EEPROM / TrimDAC Address Register

Bit No. 7 6 5 4 3 2 1 0

Name A7 A6 A5 A4 A3 A2 A1 A0

A7-A0 EEPROM / TrimDAC address. The EEPROM recognizes address 0 – 127 using

address bits A6 – A0. The TrimDAC only recognizes addresses 0 – 7 using bits

A2 – A0. In each case remaining address bits will be ignored.

Diamond-MM-48-AT User Manual V1.01 Page 25

Page 26

Base + 14 Write Calibration Control Register

Bit No. 7 6 5 4 3 2 1 0

Name EE_EN EE_RW RUNCAL CMUXEN TDACEN

This register is used to initiate various commands related to autocalibration. More detailed

information on autocalibration may be found elsewhere in this manual.

EE_EN EEPROM Enable. Writing a 1 to this bit will initiate a transfer to/from the

EEPROM as indicated by the EE_RW bit.

EE_RW Selects read or write operation for the EEPROM: 0 = Write, 1 = Read.

RUNCAL Writing 1 to this bit causes the board to reload the calibration settings from

EEPROM.

CMUXEN Calibration multiplexor enable. The cal mux is used to read precision on-board

reference voltages that are used in the autocalibration process. It also can be

used to read back the value of analog output 0.

1 = enable cal mux and disable user analog input channels

0 = disable cal mux, enable user inputs

TDACEN TrimDAC Enable. Writing 1 to this bit will initiate a transfer to the TrimDAC (used

in the autocalibration process).

Base + 14 Read Calibration Status Register

Bit No. 7 6 5 4 3 2 1 0

Name 0 TDBUSY EEBUSY CMUXEN TDACEN 0 0 0

TDBUSY TrimDAC busy indicator

0 User may access TrimDAC

1 TrimDAC is being accessed; user must wait

EEBUSY EEPROM busy indicator

0 User may access EEPROM

1 EEPROM is being accessed; user must wait

Base + 15 Write EEPROM Access Key Register

The user must write the value 0xA5 (binary 10100101) to this register each time after setting the

PAGE bit in order to get access to the EEPROM. This helps prevent accidental corruption of the

EEPROM contents.

Base + 15 Read FPGA Revision Code

This register may be read back to indicate the revision level of the FPGA code. The FPGA

revision starts at 1 and increments up each time the code is revised.

Diamond-MM-48-AT User Manual V1.01 Page 26

Page 27

7. ANALOG INPUT RANGES AND RESOLUTION

7.1 Resolution

Diamond-MM-48-AT uses a 16-bit A/D converter. This means that the analog input voltage

can be measured to the precision of a 16-bit binary number. The maximum value of a 16-bit

binary number is 2

a Diamond-MM-48-AT analog input channel is 0 - 65535.

The smallest change in input voltage that can be detected is 1/(2

scale input range. This smallest change results in an increase or decrease of 1 in the A/D

code, and so this change is referred to as 1 LSB, or 1 least significant bit.

7.2 Input Ranges

Diamond-MM-48-AT is available in two models. The default model has bipolar inputs of +/10V and +/-5V, selectable with jumper block J10. An optional model with a slightly different

component configuration has unipolar inputs of 0-5V.

7.3 Single Ended and Differential Inputs

A single-ended input is a two-wire input (one input signal and ground) that is referenced to

analog ground on the board. This means that the input voltage will be measured with respect

to the board’s analog ground. A differential input is a three-wire input (input +, input -, and

ground), and the board will measure the difference between the voltages of the two inputs.

Diamond-MM-48-AT works only with single-ended inputs.

In some cases, a differential input can be simulated by connecting the high and low input

wires to two adjacent analog input channels, measuring both of them with and A/D scan

operation, and subtracting the low reading from the high reading. This will work only for very

slow changing (or DC) signals with very low noise. The problem with this technique is that the

two signals are sampled at different times, either 5µs or 9.3µs apart depending on the setting

of the SCANINT register bit. This time delay can lead to measurement errors due to the

change in the input signal during the delay. For example, an input signal consisting of a 1KHz

sine wave with 10V amplitude has a maximum slope of 10V x 2 x π x 1000Hz = 63,000

V/sec, or 63 mV/µs. This represents a change of 315mV during the 5µs delay between the

sampling of the high input and the low input. For a 16-bit A/D converter on a +/-10V input

range, this is an error of over 1,000 counts.

16

- 1, or 65535, so the full range of numerical values that you can get from

16

), or 1/65536, of the full-

Diamond-MM-48-AT User Manual V1.01 Page 27

Page 28

8. PERFORMING AN A/D CONVERSION

This chapter describes the steps involved in performing an A/D conversion on a selected

input channel using direct programming (not with the driver software). This describes the

basic operation of a single A/D conversion without interrupts. For a more complete

description including interrupts and all register control bits, see chapter 9.

There are five steps involved in performing an A/D conversion:

1. Select the input channel

2. Wait for analog input circuit to settle

3. Trigger an A/D conversion

4. Wait for the conversion to finish

5. Read the data from the board

6. Convert the numerical data to a meaningful value

8.1 Select the input channel

To select the input channel to read, write a low-channel/high-channel pair to the channel

register at base + 2. (See Chapter 6). The low 4 bits select the low channel, and the high 4

bits select the high channel. When you write any value to this register, the current A/D

channel is set to the low channel.

For example:

To set the board to channel 4 only, write 0x44 to Base + 2.

To set the board to read channels 0 through 15, write 0xF0 to Base + 2.

⇒ Note: When you perform an A/D conversion, the current channel is automatically

incremented to the next channel in the selected range. Therefore, to perform A/D

conversions on a group of consecutively-numbered channels, you do not need to write the

input channel prior to each conversion. For example, to read from channels 0 - 2, write Hex

20 to base + 2. The first conversion is on channel 0, the second will be on channel 1, and the

third will be on channel 2. Then the channel counter wraps around to the beginning again, so

the fourth conversion will be on channel 0 again, and so on.

If you are sampling the same channel repeatedly, then you set both high and low to the same

value as in the first example above. Then on subsequent conversions you do not need to set

the channel again.

8.2 Wait for analog input circuit to settle

After writing to the channel register (Base + 2), you must allow time for the analog input

circuit to settle before starting an A/D conversion. The board has a built-in 10µs timer to

assist with the wait period. Monitor the ADBUSY bit at Base + 9 bit 7. When it is 1 the circuit

is actively settling on the input signal, or else the board is currently performing and A/D

conversion or scan. When it is 0 the board is ready to perform A/D conversions.

Diamond-MM-48-AT User Manual V1.01 Page 28

Page 29

8.3 Trigger an A/D conversion on the current channel

After the above steps are completed, start the A/D conversion by writing a 1 to the ADSTART

bit in Base + 8. This write operation only triggers the A/D if the CLKEN bit is 0 to disable

hardware triggering and enable software triggering. Otherwise the A/D will only trigger when

the selected clock or trigger signal occurs. CLKEN should always be 0 when controlling A/D

conversions in software.

8.4 Wait for the conversion to finish

The A/D converter takes up to 5 microseconds to complete a conversion. Most processors

and software can operate fast enough so that if you try to read the A/D converter immediately

after writing to base + 0, you will beat the A/D converter and get invalid data. Therefore the

A/D converter provides a status signal ADBUSY to indicate whether it is busy or idle. This bit

can be read back as bit 7 in the status register at Base + 9. When the A/D converter is busy

(performing an A/D conversion), this bit is 1, and when the A/D converter is idle (conversion

is done and data is available), this bit is 0. Here is a pseudocode explanation:

Status = read(base+9) AND 128 // or Status = read(base+9) AND 80 Hex

If Status = 0 then conversion is complete, else A/D converter is busy

Keep repeating this procedure until Status = 0.

8.5 Read the data from the board

Once the conversion is complete, you can read the data back from the A/D converter. The

data is 16 bits wide and is read back in two 8-bit bytes. The following pseudocode illustrates

how to construct the 16-bit A/D value from these two bytes:

LSB = read(base)

MSB = read(base+1)

Data = MSB * 256 + LSB // combine the 2 bytes into a 16-bit value

The final data is interpreted as a signed value ranging from –32768 to +32767.

⇒ Note: The data range always includes both positive and negative values, even if the board

is set to a unipolar input range. The data must now be converted to volts or other engineering

units by using a conversion formula as shown on the next page.

Diamond-MM-48-AT User Manual V1.01 Page 29

Page 30

8.6 Convert the numerical data to a meaningful value

Once you have the A/D code, you need to convert it to a meaningful value. The first step is to

convert it back to the actual measured voltage. Afterwards you may need to convert the

voltage to some other engineering units (for example, the voltage may come from a

temperature sensor, and then you would need to convert the voltage to the corresponding

temperature according to the temperature sensor’s characteristics).

Since there are a large number of possible input devices, this secondary step is not included

here; only conversion to input voltage is described.

It is possible to combine both transformations into a single formula for computing efficiency.

To convert the A/D value to the corresponding input voltage, use the following formulas:

Conversion Formula for Bipolar Input Ranges

Input voltage = A/D value / 32768 * Full-scale voltage

Example: Input range is ±10V and A/D value is 17761:

Input voltage = 17761 / 32768 * 10V = 5.420V

For a bipolar input range, 1 LSB = 1/32768 * Full-scale voltage. For the +/-10V range, 1 LSB

= 305µV, and for the +/-5V range, 1 LSB = 153µV.

Here is an illustration of the relationship between A/D code and input voltage for a bipolar

input range (V

= Full scale input voltage, 10V or 5V):

FS

A/D Code Input voltage symbolic formula Input voltage for ±10V range

-32768 -V

-32767 -V

-10.0000V

FS

+ 1 LSB -9.9997V

FS

. . . . . . . . .

-1 -1 LSB -0.00032V

0 0 0.0000V

1 +1 LSB 0.00032V

. . . . . . . . .

32767 V

- 1 LSB 9.9997V

FS

Conversion Formula for Unipolar Input Range

Input voltage = (A/D value + 32768) / 65536 * Full-scale voltage

Example: Input range is 0-5V and A/D value is 17761:

Input voltage = (17761 + 32768) / 65536 * 5V = 3.855V

For a unipolar input range of 0-5V, 1 LSB = 1/65536 * 5V = 76µV.

Here is an illustration of the relationship between A/D code and input voltage for a unipolar

input range (V

= Full scale input voltage):

FS

A/D Code Input voltage symbolic formula Input voltage for 0-5V range

-32768 0V 0.0000V

-32767 1 LSB (V

/ 65536) 0.000076V

FS

. . . . . . . . .

-1 V

0 V

1 V

/ 2 - 1 LSB 2.4999V

FS

/ 2 2.5000V

FS

/ 2 + 1 LSB 2.5001V

FS

. . . . . . . . .

32767 V

- 1 LSB 4.9999V

FS

Diamond-MM-48-AT User Manual V1.01 Page 30

Page 31

9. A/D SCAN, FIFO, AND INTERRUPT OPERATION

This chapter describes in detail the interrupt performance of the A/D circuit under all

conditions.

The control bits FIFOEN (FIFO enable), FIFOTH (FIFO threshold), SCANEN (scan enable),

SCNINT (scan interval), and AINTE (A/D interrupt enable) determine the behavior of the

board during A/D conversions with interrupts. Control bits CLKEN and CLKSEL determine

the source of the A/D trigger, either software, on-board counter/timer, or external signal.

In all cases, at the end of an AD conversion A/D data is latched into the FIFO in an

interleaved fashion, first LSB, then MSB. A/D Data is read out of the FIFO with 2 read

operations, first Base + 0 (LSB) and then Base + 1 (MSB).

When SCANEN = 1, each time an A/D trigger occurs, the board will perform an A/D

conversion on all channels in the channel range. The time between A/D conversions is

determined by the setting of the SCNINT bit. When SCANEN = 0, each time an A/D trigger

occurs, the board will perform a single A/D conversion and then advance to the next channel

and wait for the next trigger.

During interrupt operation, if FIFOEN = 1, then the FIFO will fill up with data until it reaches or

exceeds half-full (half-full = 256 samples), and then the interrupt request will occur.

The basic sequence is as follows:

1. A/D trigger command occurs

2. A/D conversion or A/D scan occurs

3. A/D data is stored in the FIFO

4. Interrupt request occurs

5. Interrupt routine extracts data from the FIFO and resets the interrup request

A/D Trigger

The A/D trigger may come from one of three sources as determined by the control bits

CLKEN and CLKSEL:

CLKEN CLKSEL A/D trigger source

0 0 Software command: write a 1 to ADSTART bit in register 8

0 1 Same as above

1 0 External signal: rising edge on EXTCLK pin on I/O header J3

1 1 Internal; counter/timer 0 controls the A/D conversion timing

A/D Conversion or Scan

Once the A/D trigger occurs, either a single A/D conversion will occur on the current channel,

or an A/D scan will occur on a range of channels selected by the setting of register 2. The

selection is made with the control bit SCANEN:

SCANEN Function

0 Single conversion occurs on the current channel; The internal A/D channel

counter increments after each conversion, so each successive trigger samples

the next channel in the list. At the end of the list, the channel register resets to

the starting channel and the sequence repeats.

1 Scan occurs on all channels in the range programmed in the channel register

(base + 2). The delay between the start of each conversion is determined by the

setting of SCNINT in base + 9: SCNINT = 0 sets a delay of 5µs, and SCNINT = 1

sets a delay of 9.3µs.

Diamond-MM-48-AT User Manual V1.01 Page 31

Page 32

FIFO Operation

After each A/D conversion is completed, the A/D data is stored in the FIFO. The data is

inserted in LSB / MSB sequence. The FIFO holds 4096 bytes, or 2048 samples. It has

several flags that indicate its state:

EF Empty flag 1 when the FIFO is empty and 0 otherwise.

8F 1/8 full flag 1 when the FIFO has 256 or more samples, 0 otherwise

HF Half full 1 when the FIFO has 2048 or more bytes of data (1024 or more

samples), 0 otherwise

FF Full flag 1 when the FIFO has 4096 bytes (2048 samples), 0 otherwise

OVF Overflow flag 1 when the FIFO is full and the board attempts to store a new A/D

sample in the FIFO. This indicates an error condition. The new A/D

data will not be stored in the FIFO and will be lost. The current

contents of the FIFO will be preserved.

If OVF is set, the only way to clear it is to reset the FIFO by writing a 1 to the FIFORST bit in

register 8. Generally the data would be read out before resetting the FIFO.

Interrupt Operation

If AINTE is set, the board will generate an interrupt when the selected condition occurs, as

determined by the control bits FIFOEN, FIFOTH, and SCANEN. The table below describes

the timing of interrupts and the expected performance of the application software’s interrupt

routine (including Diamond Systems’ Universal Driver software). Note that in all cases, A/D

data is stored in and read from the FIFO, regardless of the FIFOEN setting. FIFOEN only

controls whether the FIFO flags are used to drive interrupt requests.

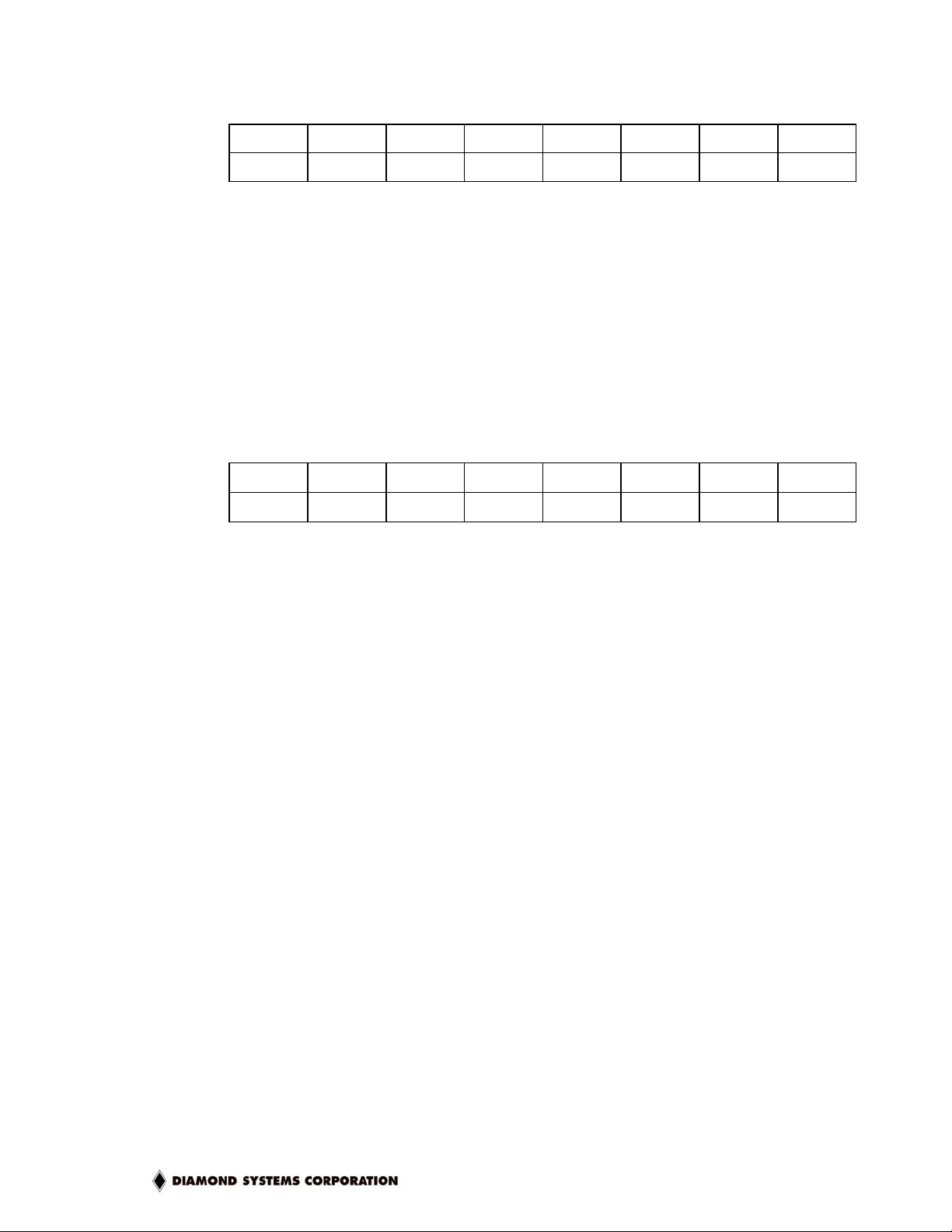

FIFOEN FIFOTH SCANEN Interrupt Operation

0 0 0 Interrupt occurs at the end of each individual A/D

conversion. Interrupt routine reads one A/D sample from

the board.

0 0 1 Interrupt occurs at the end of each A/D scan. Interrupt

routine reads one complete scan from the board.

0 1 0 Same as case 0 0 0 above. FIFOTH is ignored when

FIFOEN = 0.

0 1 1 Same as case 0 0 1 above. FIFOTH is ignored when

FIFOEN = 0.

1 0 0 Interrupt occurs when 1024 A/D conversions are

complete. Interrupt routine reads 1024 samples from the

FIFO.

1 0 1 Interrupt occurs when 1024 A/D conversions are

complete AND the current A/D scan is complete (total

no. of conversions may be greater than 1024). Interrupt

routine reads enough scans from the A/D FIFO to equal

or exceed 1024 samples.

1 1 0 Interrupt occurs when 256 A/D conversions are

complete. Interrupt routine reads 256 samples from the

FIFO.

1 1 1 Interrupt occurs when 256 A/D conversions are

complete AND the current A/D scan is complete (total

no. of conversions may be greater than 256). Interrupt

routine reads enough scans from the A/D FIFO to equal

or exceed 256 samples.

Diamond-MM-48-AT User Manual V1.01 Page 32

Page 33

Guidelines for Selecting FIFO Use (FIFOEN and FIFOTH)

The below data is a guideline for interrupt use that will work in typical applications and

systems. Each application’s optimum performance will be based on the processor speed,

operating system, sampling method, and need to obtain data as soon as possible.

Sample rate Suggested use

Rate < 500Hz FIFO not needed; one interrupt per sample or scan is acceptable.

This setting applies to both single A/D samples and A/D scans.

500 <= Rate < 50,000 FIFO should be used to reduce interrupt overhead. Set FIFOTH = 1

to select the lower threshold of 256 samples to allow the application

program to obtain A/D data as quickly as possible.

Rate >= 50,000Hz FIFO should be used. Set FIFOTH = 0 to select the higher threshold

of 1024 samples to reduce the interrupt rate and resulting overhead.

A/D Operation Table

The following table describes the behavior of the A/D circuit in the 8 major operating modes

based on scan, FIFO, and interrupt settings.

AINTE FIFOEN SCANEN Operation

0 0 0

Single A/D conversions are triggered by write to B+0.

STS stays high during the A/D conversion.

No interrupt occurs.

The user program monitors STS and reads A/D data when it goes low.

0 0 1

A/D scans are triggered by write to B+0. All channels between LOW and HIGH

will be sampled.

STS stays high during the entire scan (multiple A/D conversions).

No interrupt occurs.

The user program monitors STS and reads all A/D values when it goes low.

0 1 0

0 1 1

1 0 0

Same operation as case 000 above.

Same operation as case 001 above.

Single A/D conversions are triggered by the source selected with CLKSEL.

STS stays high during the A/D conversion.

A/D interrupt occurs after each conversion is done (when STS goes low).

The interrupt routine reads one A/D sample each time it runs.

1 0 1

A/D scans are triggered by the source selected with CLKSEL.

STS stays high during the entire scan (multiple A/D conversions).

A/D interrupt occurs after the entire scan is complete.

The interrupt routine reads out one entire A/D scan (multiple values) each time

it runs.

1 1 0

Single A/D conversions are triggered by the source selected with CLKSEL.

STS stays high during the A/D conversion.

A/D interrupt occurs when HF goes high (256 A/D conversions have occurred).

The interrupt routine reads out 256 samples (half the FIFO) each time it runs.

1 1 1

A/D scans are triggered by the source selected with CLKSEL.

STS stays high during the entire scan (multiple A/D conversions).

A/D interrupt occurs after the scan is complete AND HF is high (i.e. an integral

no. of scans has occurred and the FIFO is half full or more).

The interrupt routine reads out enough complete scans to equal 256 or more

samples each time it runs.

Diamond-MM-48-AT User Manual V1.01 Page 33

Page 34

10. ANALOG OUTPUT OVERVIEW

10.1 Description

Diamond-MM-48-AT uses an 8-channel 12-bit D/A converter (DAC) to provide 8 analog

voltage outputs. A 12-bit DAC can generate output voltages with the precision of a 12-bit

binary number. The maximum value of a 12-bit binary number is 2

range of numerical values that you can write to the analog outputs on Diamond-MM-48-AT is

0 - 4095. The value 0 always corresponds to the lowest voltage in the output range, and the

value 4095 always corresponds to the highest voltage.

⇒ Note: In this manual, the terms analog output, D/A, and DAC are all used interchangeably

to mean the same thing.

10.2 D/A Resolution

12

- 1, or 4095, so the full

The resolution is the smallest possible change in output voltage. For a 12-bit DAC the

resolution is 1/(2

12

), or 1/4096, of the full-scale output range. This smallest change results

from an increase or decrease of 1 in the D/A code, and so this change is referred to as 1

LSB, or 1 least significant bit. The value of this LSB is calculated based on the output range

of the circuit. On the Diamond-MM-48-AT, the output range is fixed at 0-4.096V, making the

formula simple:

1 D/A LSB = 4.096V / 4096 = 1mV

10.3 D/A Conversion Formulas and Tables

The formulas below explain how to convert between D/A codes and output voltages.

Conversion Formulas for Unipolar Output Ranges

Output voltage = D/A code x 1mV

D/A code = Desired output voltage in mV

Example: Desired output voltage = 1.234V = 1234mV; D/A code = 1234

Here is an illustration of the relationship between D/A code and output voltage for a unipolar

output range (V

D/A Code Output voltage for 0–4.096V range

= Reference voltage):

REF

0 0.000V

1 0.001V

2 0.001V

. . . . . .

4095 4.095V

10.4 D/A Output Current

The output current capability of the 4 analog outputs varies according to the output voltage.

Output current can be either sink or source, depending on the load characteristics. Normally

the output will drive a voltage to ground, in which case the output is sourcing current.

D/A voltage Sink current, max Source current, max

0-0.200V -0.5mA 4.0mA

0.201V-0.500V -1.0mA 4.0mA

0.501V-0.900V -2.0mA 4.0mA

0.901V-4.095V -4.0mA 4.0mA

Diamond-MM-48-AT User Manual V1.01 Page 34

Page 35

11. GENERATING AN ANALOG OUTPUT

This chapter describes the steps involved in generating an analog output (also called

performing a D/A conversion) on a selected output channel using direct programming (not

with the driver software).

There are three steps involved in performing a D/A conversion:

1. Compute the D/A code for the desired output voltage

2. Write the value to the selected output channel

3. Update the D/A

11.1 Compute the D/A code for the desired output voltage

D/A code = desired output voltage in mV

⇒ Note: The DAC cannot generate the actual full-scale reference voltage; to do so would

require an output code of 4096, which is not possible with a 12-bit number. The maximum

output value is 4095. Therefore the maximum possible output voltage is 4.095V, 1mV less

than the full-scale voltage of 4.096V.

11.2 Write the value to the selected output channel

First use the following formulas to compute the LSB and MSB values:

LSB = D/A Code AND 255 ;keep only the low 8 bits

MSB = int(D/A code / 256) ;strip off low 8 bits, keep 4 high bits

Example: Output code = 1776

LSB = 1776 AND 255 = 240 (F0 Hex); MSB = int(1776 / 256) = int(6.9375) = 6

(In other words, 1776 = 6 * 256 + 240)

Then write these values and the D/A channel no. to the board:

Write LSB to Base + 0

Write MSB to Base + 1

Write the channel no. to Base + 7

11.3 Update the D/A

Write a 1 to the DAUPD bit in Base + 7 to update the D/A.

To update several channels simultaneously, follow steps 1 and 2 for each channel. After all

channel data has been written, write a 1 to the DAUPD bit, and all channels with new data

will be updated simultaneously.

Diamond-MM-48-AT User Manual V1.01 Page 35

Page 36

12. AUTOCALIBRATION OPERATION

Diamond-MM-48-AT includes a sophisticated autocalibration circuit that manages the

calibration of both the A/D and the D/A circuitry. Operation is as follows.

12.1 Reference Voltages

The board contains a precision reference voltage chip that is selected for high stability over

time and temperature. The value of the voltage output from this chip is measured at the

factory. The board also contains some precision resistor divider ladders that produce

intermediate voltages derived from the original reference. All these voltages are measured at

the factory and their values are stored in an EEPROM on the board.

12.2 A/D calibration

When the A/D is calibrated, it measures the reference voltages using an extra input

multiplexor reserved for autocalibration. The calibration software compares the actual

measurements to the stored values and makes adjustments to the board to bring the

measurements into tolerance (less than 2 LSBs max, in most cases less than 1 LSB). The

adjustments are produced by controlling several 8-bit DACs that are inserted at various

points in the circuit. The data written to these DACs is then stored in the EEPROM.

12.3 D/A Calibration

When the D/A is calibrated, the board performs a similar operation. The output of DAC 0 is

routed through the calibration multiplexor. The offsets of the other DACs relative to DAC 0

are measured at the factory and stored in the EEPROM. During calibration the average offset

is added to the measured output of DAC 0, and this value is used as the comparison value to

minimize overall errors.

12.4 Universal Driver Software Support

Calibration is simple when using the Diamond Systems Universal Driver software. Several

functions are provided to manage the entire operation, and a demo program is included. For

application developers targeting an operating system not supported by Universal Driver, the

source code is included so you can incorporate it into your own program.

With the Universal Driver software, you have the option of recalling calibration values each

time you change the input range, or leaving the current ones in place. Leaving the current

ones in place will match the performance of other A/D boards which also use only a single

set of calibration values. Recalling the values specific to the new input range will improve

performance by a few LSBs but will result in a time delay since the data must be recalled

from the EEPROM and loaded into the DACs.

A/D and D/A maybe calibrated separately. Calibration takes a few seconds and may be

performed as often as desired, for example at system startup, once a day, etc.

NOTE: When calibrating the D/A channels, the output voltage of DAC0 will fluctuate between

– full scale and + full-scale as part of the procedure. Any circuitry connected to the DAC

during this time may be affected and produce unwanted results.

Diamond-MM-48-AT User Manual V1.01 Page 36

Page 37

13. DIGITAL I/O OPERATION

Diamond-MM-48-AT contains a 4-bit digital I/O port with programmable direction and edge

detection capability. The digital I/O lines are located at pins 35 through 38 on the I/O header

J3. They are CMOS / TTL compatible. Each line can drive up to -6mA in a logic high state or

sink up to 8mA in a logic low state. All digital input lines have 10KΩ pull-up resistors. The I/O

lines are written and read with 4 bits in the register at Base + 5.

To use the digital I/O lines for simple I/O, set the desired direction using the control register in

Base + 4. Each bit’s direction may be set independently with the control bits DIR3-0 in this

register. On power-up or system reset, all lines are set to input mode.

To enable edge detection, set the DINTE bit in Base + 11. When DINTE = 1, any change of

state on any input line will generate an interrupt and set the DINT bit in Base + 11. The

interrupt routine reads the data by reading from Base + 5, and then it clears the interrupt

request by writing a 1 to the CLRD bit in Base + 11. When DINTE = 0, any pending interrupt

request will be cleared, and further changes in state on the input lines will not generate

interrupts.

NOTE: Diamond-MM-48-AT has 4 distinct interrupt circuits that may request interrupt service

independently of each other. A PC/104 bus interrupt request will occur when any one of the

circuits requests service. As long as any circuit is still requesting service, the interrupt request

will stay active. This means that writing to the CLRD bit may not clear the bus interrupt

request even though it clears the specific digital input interrupt request. The interrupt service

routine is responsible for determining which of the three circuits is requesting service and

handling all of them as needed.

Diamond-MM-48-AT User Manual V1.01 Page 37

Page 38

14. OPTOCOUPLER OPERATION

Diamond-MM-48-AT contains 4 optocoupler inputs with programmable polarity,

programmable edge detection capability, and interrupt capability on edge detection. These

lines accept inputs up to 28VDC. The transition between logic 0 and 1 occurs at

approximately 1.5VDC and is guaranteed to be 1 at 3VDC or above.

The POL jumper on jumper block J6 selects the logic polarity of the 4 register bits OPTO3-0.

The POL jumper can be read with the POL bit in Base + 8. The POL register bit indicates the

value of an open circuit or logic 0 input signal:

OPTO3-0 readback value

POL jumper POL bit Vin < 1.5VDC Vin > 3VDC

Out 0 0 1

In 1 1 0

To enable edge detection on any optocoupler, set the corresponding OENn bit to 1, and then

select the desired edge polarity with POLn. POLn = 0 selects falling edge, and POLn = 1

selects rising edge. NOTE: The edge polarity is determined with respect to the polarity

selected with the POL jumper. If the POL jumper is in, an input voltage change from 0V to 3V

is considered a falling edge, not a rising edge.

Whenever you read the optocoupler logic level data OPTO3-0 in Base + 7, you also read the

edge status data in the upper 4 bits OEDGE3-0. Reading this register clears the OEDGE3-0

data, so successive reads will show a change in the value of these bits to 0. Note that if an

input toggles in both directions between reads, you will still see the change because the

OEDGEn bit will be 1 even though the logic level remains the same.

The board may also be programmed to generate interrupts when any selected edge occurs.

To enable interrupts on edge detection, set the OINTE bit in Base + 11. when OINTE = 1,

any edge programmed in the above manner will generate an interrupt and set the OINT bit in

Base + 11. The interrupt routine reads the data by reading from Base + 7, and then it clears

the interrupt request by writing a 1 to the CLRO bit in Base + 11.

NOTE: Diamond-MM-48-AT has 4 distinct interrupt circuits that may request interrupt service

independently of each other. A PC/104 bus interrupt request will occur when any one of the

circuits requests service. As long as any circuit is still requesting service, the interrupt request

will stay active. This means that writing to the CLRO bit may not clear the bus interrupt

request even though it clears the specific optocoupler input interrupt request. The interrupt

service routine is responsible for determining which of the three circuits is requesting service

and handling all of them as needed.

Procedure for enabling interrupts on selected edges

1. Select the desired input channel(s) by setting OENn = 1 for each one to be detected.

2. Select the desired edge polarity for each enabled channel by setting POLn appropriately.

NOTE: Steps 1 and 2 are done together with a single write operation to Base + 6.

3. Enable optocoupler interrupts by setting the OINTE bit in Base + 11.

4. When an interrupt occurs, read the edge and logic level data from Base + 7.

5. After reading the edge and logic data, write a 1 to the CLRO bit in Base + 11 to clear the

interrupt request.

6. When interrupt activity is no longer needed, write a 0 to the OINTE bit to disable

optocoupler interrupts.

Diamond-MM-48-AT User Manual V1.01 Page 38

Page 39

Tables describing behavior of POL jumper, opto inputs, and edge detection

The POL bit is the inverse of the POL pin. Non-inverted inputs means the opto bit is reported

as the inverse of the corresponding input pin, since the opto circuit has a built-in inversion.

Edge detection always operates with respect to the actual input voltage, not the logic. Rising

always means from 0V to 3V, and falling always means from 3V to 0V.

1. Polarity and logic readback

POL jumper POL pin POL bit Opto state Opto input pin Opto databit

Case 1: Non-inverted inputs

Out 1 0 0-1.5VDC 1 0

Out 1 0 3-28VDC 0 1

Case 2: Inverted inputs

In 0 1 0-1.5VDC 0 1

In 0 1 3-28VDC 1 0

2. Edge detection (assumes OENn = 1 to enable edge detection)

The POL pin and POL bit operate in the same manner as above. Note that the behavior of

the edge detection circuit does not depend on the POL jumper. The POL jumper only affects

the meaning of 0 and 1 in the reported opto data bits.

POL jumper POLn bit Opto change Pin change Opto data bit EDGEn

Case 1: Non-inverted inputs

Out 0 0V -> 3V 1 -> 0 0 -> 1 No change

Out 0 3V -> 0V 0 -> 1 1 -> 0 1

Out 1 0V -> 3V 1 -> 0 0 -> 1 1

Out 1 3V -> 0V 0 -> 1 1 -> 0 No change

Case 2: Inverted inputs

In 0 0V -> 3V 1 -> 0 1 -> 0 No change

In 0 3V -> 0V 0 -> 1 0 -> 1 1

In 1 0V -> 3V 1 -> 0 1 -> 0 1

In 1 3V -> 0V 0 -> 1 0 -> 1 No change

Diamond-MM-48-AT User Manual V1.01 Page 39

Page 40

15. RELAY OPERATION

Diamond-MM-48-AT contains 8 relays with SPDT (form C) configuration. The relays are

Omron type G6K or equivalent. Note that these relays are actually DPDT (double pole)

relays. The two poles are connected in parallel for lower on resistance and greater current

carrying capacity. The relays have the following operating characteristics:

Rated load 0.3A / 125VAC, 1A / 30VDC

Contact material Gold plating over silver

Max operating voltage 125VAC, 60VDC

Max switching capacity 37.5VA, 30W

Min permissible load 10

Initial contact resistance 100mΩ max

Operate time 3ms max

Release time 3ms max

Bounce time 3ms max

Mechanical life 50,000,000 operations min (at 36,000 operations / hr)

Electrical life 100,000 operations min at rated load (at 1,800 operations / hr)

The relay signals are on connector J4 on the left side of the board. Each relay has 3

contacts: C, NC, and NO. The functions of these contacts are as follows:

Relay N C (N = 0 to 7) Relay output common contact. This contact is always

µA at 10mVDC

used with relay output connections.

Relay N NC Relay output normally connected contact. This contact is

connected to the Relay N C contact when power is off or when a 0 is

written to the relay’s control bit in the relay control register. It is

disconnected when power is on and a 1 is written to the relay’s

control bit.

The relay is called “off” when the NC contact is connected to the C

contact (because this represents the power-off state).

Relay N NO Relay output normally open contact. This contact is disconnected

when power is off or when a 0 is written to the relay’s control bit in

the relay control register. It is connected to the Relay N C contact

when power is on and a 1 is written to the relay’s control bit.

The relay is called “on” when the NO contact is connected to the C

contact.

The relays are controlled with a register at Base + 3. Writing a 1 to a relay’s control bit turns

that relay “on”, and writing a 0 to a bit turns the relay “off”. Any combination of relays may be

“on” or “off” at any time under software control. On power-up or system reset, all relays are in

the off position.

The board stores the value written to the relays, and this value may also be read back at

Base + 3. A 1 indicates a relay “on”, and a 0 indicates a relay “off”. This readback value is

only accurate as long as power is maintained to the board.

Diamond-MM-48-AT User Manual V1.01 Page 40

Page 41

16. COUNTER/TIMER OPERATION

Diamond-MM-48-AT contains two counter/timers that provide various timing functions,

including A/D timing and user functions. These counters are integrated into the system

controller FPGA.

The user interface consists of a 24-bit data register in Base + 12 through Base + 14, an 8-bit

command register in Base + 15, and control bits in several other registers. Using the

command register, the counter can be loaded, cleared, enabled, and disabled, the optional

gate can be enabled and disabled, and the counter value can be latched for reading. Detailed

information on the counter/timer control register bits is provided beginning on page 23.

16.1 Counter 0 – A/D Sample Control

Counter 0 is a 24-bit “divide-by-n” counter used for controlling A/D sampling. The counter has

a clock input, a gate input, and an output. The input is a 10MHz or 1MHz clock provided on

the board and selected with bit CKFRQ0 in Base + 9 bit 3. The gate is an optional signal that

can be input on pin 30 of the I/O header J3. If this signal is not used then the counter runs

freely. The output is a positive pulse whose frequency is equal to the input clock divided by

the 24-bit divisor programmed into the counter. The output appears on pin 31 of the I/O

header.

The counter operates by counting down from the programmed divisor value. When it reaches

zero, it outputs a positive-going pulse equal to one input clock period (100ns or 1µs,