Page 1

Auxiliary Power Unit Installation Guide

MODEL No. DPS6500

Page 2

DP

READ BEFORE STARTING INSTALLATION

Each truck chassis is built differently and will require a different installation method.

Review the placement of ALL parts and components

before beginning the installation process.

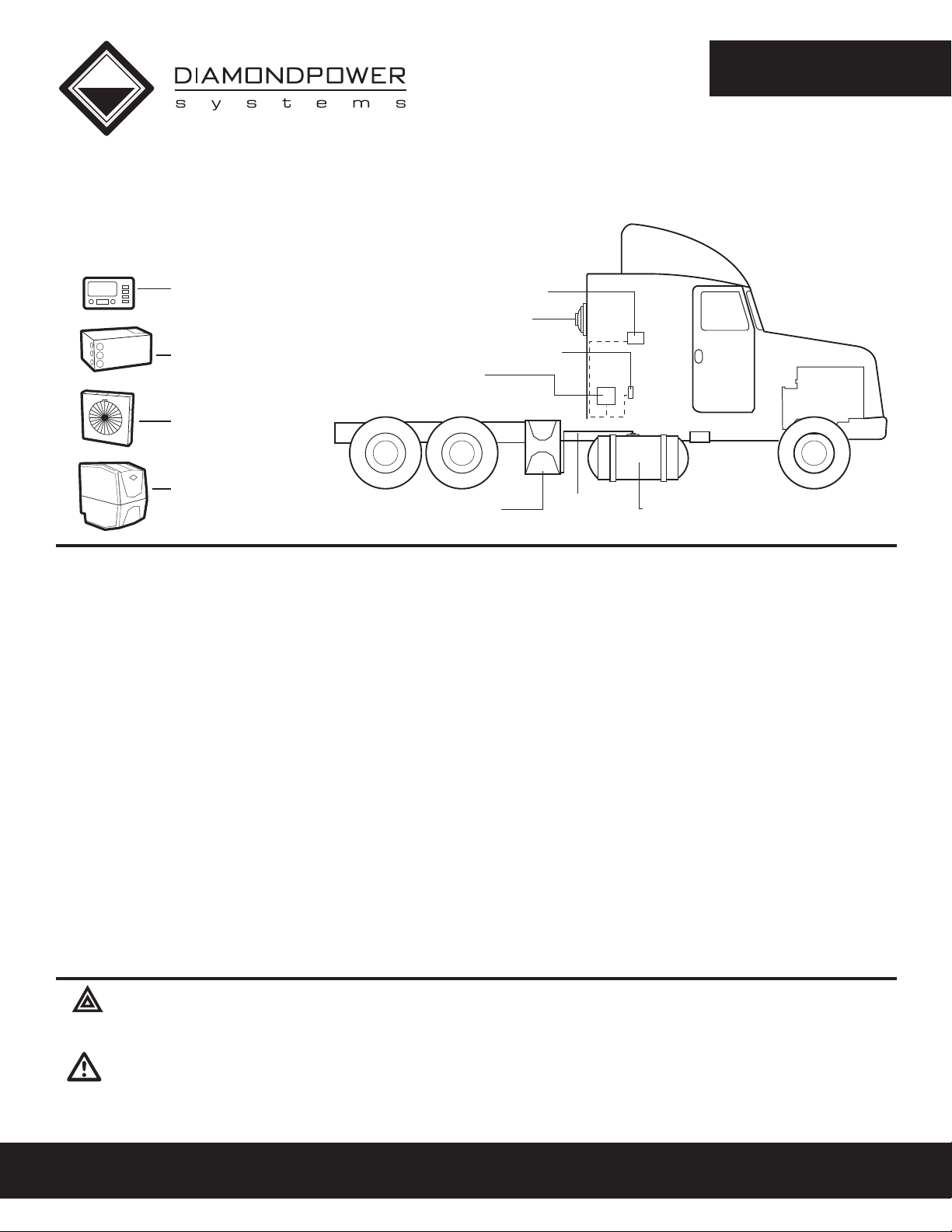

Step One

DCP (Driver Control Panel)

HVAC

CONDENSER

APU

APU Parts and Components

Parts List:

APU 1

APU Installation Kit 1

Frame locks 4

_” x 6 _” Bolts 4

_” Split Lock Washers 8

_” lock nuts 4

Frame Washers 2

Fuel Pick-up Kit 1

Pick-up 1

Clamps 2

Exhaust Extension Kit 1

90 Degree exhaust pipe 1

Support bracket 1

Exhaust clamps 2

5/16” NC bolt 1

5/16” Washers 2

5/16” Lock Nuts 2

Driver Control Panel

Condenser

120 VAC Receptacle Panel

HVAC

APU

Fuel Supply

And Return

Battery Terminal Kit 1

Red heat shrink 1

Black heat shrink 1

Ring terminals 2

Cable ties 75

Condenser 1

Hoses 2

Mounting hardware 1

Harness 1

HVAC 1

Driver Control Panel 1

Power Outlet 1

Vehicle Fuel Tank

Parts and Tools Required

• Radiator hose – 3/4”

• Radiator shut off valves

• Radiator hose clamps

• An assortment of nuts, bolts, and

washers as required

• An assortment of electrical connectors

and protective conduit as required

• Heat shrink, pipe sealant, never seize,

electrical tape, expanding foam

• Torque wrench (100ft/lb)

• Hole saw kit (1”,1 _”, 3”, 3 _”, 4 _”)

• Portable lighting

• Hand forklift/lifting device

• Step drill

• Angle drill

• Reciprocating saw

• Nutsert ® installation tool

• Scale (refrigerant) accurate to ounces

• Gauges (refrigerant) 134A compatible

• Diamond Test Switch Module PG1008

• Flow Meter TK 9002

NOTE: The APU requires periodic maintenance. Ensure you have access to internal components (i.e. oil filter, air filter,

fuel filter and oil filter). The Diamond comes filled with long life coolant. Consult the truck owner prior to altering the vehicle in any way.

CAUTION: Trucks with longer chassis should have the APU mounted closer to the sleeper unit to avoid obstacles such as

railway crossings, speed bumps, curbs, etc. Before beginning installation of the Diamond system, disconnect the vehicle’s batteries.

If truck is equipped with a coolant valve, valve must be fully opened before starting APU.

Page1

Page 3

DP

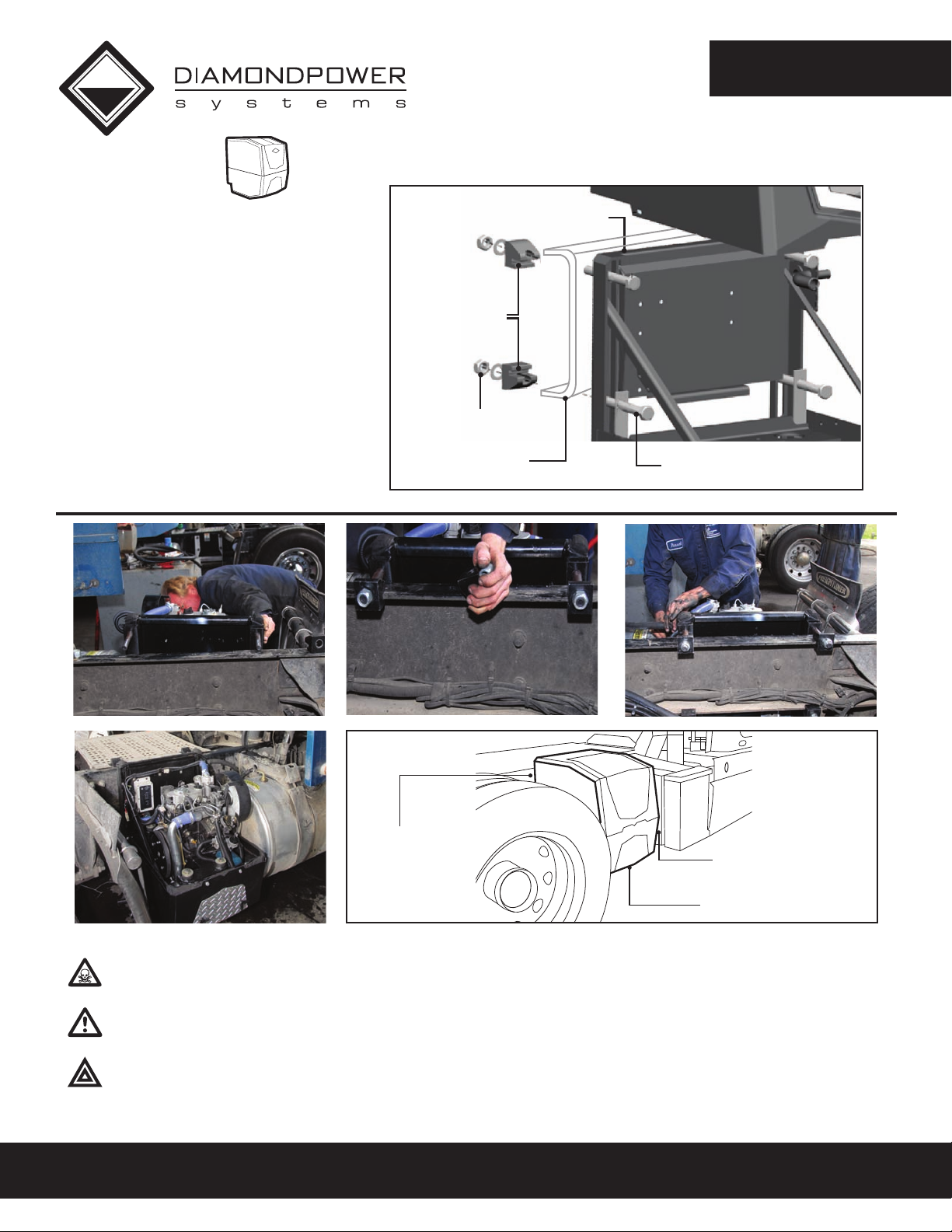

MOUNTING THE APU

Installing

1. Use existing holes at back of APU. Do not

drill new holes in the APU.

2. Torque mounting bolts to 100 ft/lbs.

3. Install exhaust pipe extension to APU; direct

exhaust away from vehicle.

Consider the Following:

• Free space around existing covers.

• Brackets for attaching covers, dryers,

fuel tanks, fasteners, existing plumbing

for air, fuel and water lines.

• Battery tray.

• Any hardware found in the mounting

location: move or modify if necessary.

Back Plate OF APU Enclosure

Frame Gripper

Torque 100 ft/lb

Frame Rail

Step Two

Frame Gripper Bolts

2 5/8” Minimum

Side Clearance

WARNING: The APU is weighty. Do not drop it! Use a lifting device.

CAUTION: Do not mount the Diamond APU to bottom pan. Unit is designed to hang from chassis rails.

NOTE: Consult OEM frame drilling requirements if you are bolting APU directly to the trucks frame rail.

Page2

2 5/8” Minimum Side Clearance

11” Minimum Ground Clearance

Page 4

DP

MOUNTING THE CONDENSER

Step Three

Condenser Installation

1. Select the site for the condenser on the rear or the vehicle sleeper.

2. Hold condenser in the preferred location and mark the holes clearly.

3. Drill holes 17/32” for Nutserts®.

4. Install the condenser assembly in the preferred location.

Mounting Considerations

• The condenser must be installed on the back wall of the sleeper (outside).

Airflow around the condenser must not be blocked by headache racks, for

example.

• Install condenser within 8’ of the HVAC.

• The condenser must be installed vertically with the blue-marked side on the

bottom right (where the liquid refrigerant collects).

• Hose connection side of the condenser requires 5” free space to the nearest

obstruction to allow for hose connection.

• Keep the condenser out of the path of road spray.

• Refrigerant hoses must be clamped firmly.

• Do not allow Refrigerant hoses to touch each other; heat transfer will occur

and change the performance of the HVAC. Insulate or keep the hoses together.

Nutserts®

Blue Marking

3/8” NC Bolts

3 Per Side

Min 5” Clearance To

Allow For Hose

Connection

WARNING: If you are installing the

condenser to the back wall of the sleeper, use

large fender washers or a backing plate for extra

support.

Page3

NOTE: All hoses, cables, and

electrical wiring should be kept safe and

secured using split loom and cable ties

to prevent abrasion. Stay clear of exhaust

pipe and muffler.

Condenser

Refrigerant

Hoses - Clamp

Securely

Condenser 12V

Power Harness

HVAC

Page 5

DP

Step Four

PLUMB THE APU TO THE MAIN ENGINE

Note: This APU Systems comes with a built in radiator. The connection below is optional.

Plumbing Procedure

1. Remove the truck radiator cap to free pressure from coolant system. Do not open when hot.

2. Deplete the truck coolant system (if necessary).

3. The APU is shipped with extensive life anti-freeze. Ensure this is compatible with truck coolant.

4. Ensure that the coolant will flow in the right direction (same direction whether the Diamond or main engine is running). The Diamond flow indicator

can be used to verify the flow.

5. Replenish the engine coolant in the system according to the specific engine manufacturer’s recommendations (additional coolant will be required).

Plumbing Considerations

• Silicon hose is satisfactory to use as coolant hose, but requires the use of silicon hose clamps.

• Ensure radiator coolant can always flow between truck engine and APU.

3/4” Fitting Return From APU

3/4” ID Hose

Loom All

Hoses

3/4” Fitting

Supply To APU

No Sharp Bends

High Pressure

Port

Truck EngineBack View Of APU

1/2” Or Larger

NPT Fittings

Choose Ports That Are Far

Apart For Max Crossflow

Low Pressure

Port (Suction)

Install ShutOff Valves

Use A Flow Indicator To Comfirm

Flow Direction And Speed

WARNING: To avoid serious injury, permit the engine to cool before opening the radiator cap.

CAUTION: Plumbing through the dash or sleeper heater will null and void your warranty.

CAUTION: Take care not to spill coolant.

Page4

Page 6

DP

INSTALLING THE FUEL LINES

Installing The Stand Pipe

1. Locate hole in an area where the fuel pickup is kept safe (the center of the tank is recommended).

2. Tighten hose clamps.

3. Secure the fuel lines to reduce movement.

Step Five

Drill 1” Hole Using Unibit or Hole Saw

Fuel Line

Tighten Until

Secure

Cut Tube

Bottom 45°

12” Min Between

Supply And Return

Gas Tank

Nut

Washer

Gasket

Tank

Flange

Supply 5/16” ID

Return 3/16” ID

Back View Of APU

No Kinks Or

Abrasion Points

Allow 1” To 2” Min.

Space To Bottom Of Tank

WARNING: Exercise safety measures when working

near flammable fuel.

CAUTION: Keep fuel lines safe from wear points.

Page5

CAUTION: Keep fuel lines away from exhaust pipes and heated moving parts.

CAUTION: The standpipe must enter the tank from the top and not the side.

Page 7

DP

ARRANGE BATTERY CABLES

Connecting To The Truck’s Battery

Step Six

Strip 3/8”

Red Or Black Heat

Shrink Tubing

Copper Lug

Using The Correct Crimping Tool Crimp

And Solder Copper Lug To Battery Cables

Ensure That the battery terminals are clean and free

of corrosion.

If not, remove and clean them.

Apply an dielectric grease to prevent corrosion.

Apply anti-corrosion paint over cable ends.

Apply Heat To Shrink

Positive Or Negative

Battery Cable

Truck Batteries

12 VDC Power

Supply Harness

Back View Of APU

APU-HVAC

Control Harness

Negative (-Black)

Ground Cable

Teck Cable

Positive (+Red)

12 VDC Battery Cable

WARNING: Do not join the APU battery connections until the installation is complete and the APU is ready to test-start.

WARNING: Make sure the 120 VAC cable is connected to the installed CCU (if applicable). Terminate cable ends if no CCU is installed.

WARNING: Make sure that the polarity is correct before attaching battery leads. (The APU connects to 12VDC systems only).

Page6

Page 8

DP

SYSTEM CHECK

Important: Perform these steps only after the HVAC and all other components have been installed.

System Check

• Oil level in the APU engine, add oil if necessary.

• Electrical and plumbing connections are secure.

• Radiator coolant valves (if any) fully open.

APU First Time Start Up

Before first time starting use the priming pump to clear the air in the fuel line.

WARNING: Do not start or run the APU prior to purging the entire cooling system of air.

Failure to do so will result in APU engine failure.

WARNING: Do not operate the engine without the enclosure cover in place. Failure to do so may result in injury.

Priming Pump

Step Seven

Completing the Installation

• Test all the functions of the APU and the HVAC.

• Replace vehicle access panels, fairings, interior components and hardware that was removed to facilitate the installation.

• Seal all holes made through the floor or walls of the truck bunk with suitable sealant such as expanding foam.

• Vacuum the interior of the cab/sleeper.

• Review the installation with the owner and instruct them on the proper operation of the Diamond Power Systems. Give the owner the Operator’s Manual.

• Complete all warranty cards and return to Diamond Power Systems.

Page7

Loading...

Loading...