Page 1

DIAMOND TECH

Innovations For Creativity

DL5000 INSTRUCTION MANUAL

DL 5000

DIAMOND LASER BAND SAW

OPERATIONS MANUAL

Page 2

DL5000 INSTRUCTION MANUAL

- PAGE 1

Before Y ou Begin

Read and follow all instructions carefully.

• After unpacking all components, assemble band saw on a firm level surface to prevent saw from tilting

and rocking.

• Be sure the power switch is in the OFF position before plugging in the band saw.

• Always disconnect band saw from electrical outlet before setting up or servicing.

• Wear proper apparel. Never wear loose fitting clothes, neckties, jewelry and gloves that may get caught in

moving parts.

• Remove all wrenches before using band saw. Leaving wrenches attached while operating this tool may

result in damage to the machine and/or operator.

• Always wear safety goggles. Everyday eyeglasses have only impact resistant lenses; they are not

safety glasses.

• Never turn on band saw while glass or working materials are touching the blade.

• Always hold material being cut firmly on cutting table.

• Feed materials at a slow easy pace into the blade. A void sudden twisting of the blade, which may cause

kinking or breaking.

• Keep out of reach of children.

• Never leave saw running unattended. Turn power OFF when not in use.

• Do not operate while under the influence of medication or alcohol.

• T o ensure top performance keep band saw properly maintained.

Contents

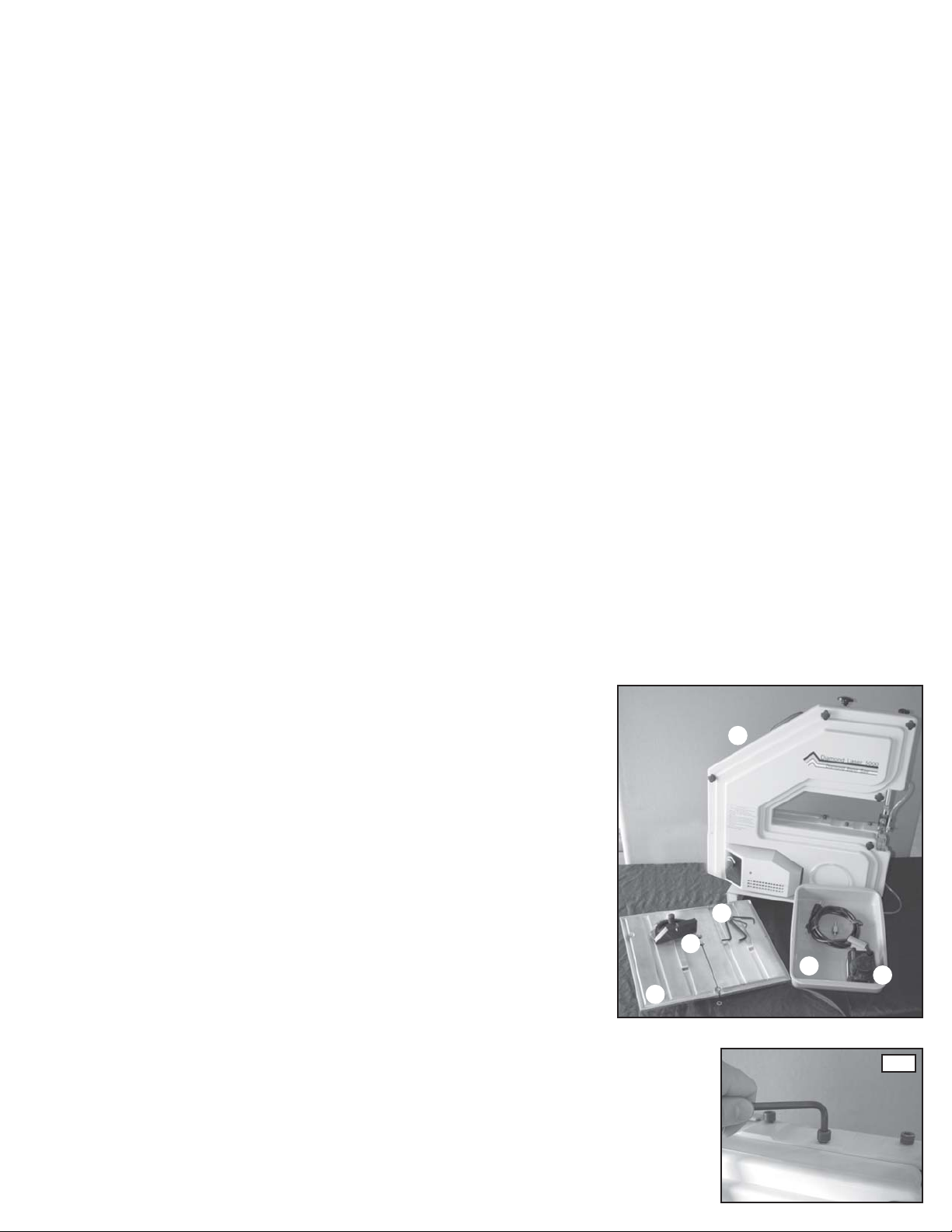

Y our Diamond Laser 5000™ has been shipped partially

assembled. Carefully remove saw and parts from the packaging.

1-Band Saw Body

2-Cutting T able

3-Recirculating Water Pump and Valve

4-Detachable Water Reservoir

5-Straight Edge/Angle Cutting Guide

6-Adjusting Wrenches

Assembly Instructions

A. Table Installation

1) Remove table mounting set screws and washers from

the table mounting block directly behind the blade (Fig.1).

Loosen and remove the table alignment screw and wingnut located on the

front of the cutting table blade slot (Fig.2).

2) While holding the table with the slot opening directly behind the blade,

carefully slide the diamond blade through the slot.

3) Secure cutting table to the mounting block with the table mounting set

screws. Return alignment screw to the front of the cutting table

and tighten in place with the wingnut positioned under table.

1.

6.

5.

4.

2.

3.

Fig.1

Page 3

PAGE 2 -

DL5000 INSTRUCTION MANUAL

B. Blade Installation

Blade comes preinstalled; however should it become loose in

shipment or need to be replaced, follow these instructions.

1) Turn power OFF and unplug from electrical outlet. Open the band

saw cover by loosening the knobs on the front of the saw and

removing front panel.

2) Remove table alignment screw and wing nut.

3) Loosen blade tensioning knob, located at the top of the band

saw (Fig.3) until blade has give.

4) Pull downward on the upper blade wheel (Fig.4) and remove worn

blade. Install the new blade by centering it on the lower blade wheel

(Fig.5), then on the center wheel and finally on the upper wheel.

5) Ensure blade is centered and fits between the blade guides

located on the upper guide block and the lower block under the table.

(refer to section D - Band Saw Use and Maintenance: Blade

Guide Adjustment).

6) Tighten blade by turning blade tensioning knob clockwise (Fig.3)

(refer to section C - Band Saw Use and Maintenance: Blade

Tensioning).

7) If necessary , adjust table position to recenter blade in the

table opening.

WARNING: If the diamond blade is too loose, it can slip from the

wheels. If stretched too tight, it could break.

Fig.2

Table Alignment Screw

Fig.3

Fig.4

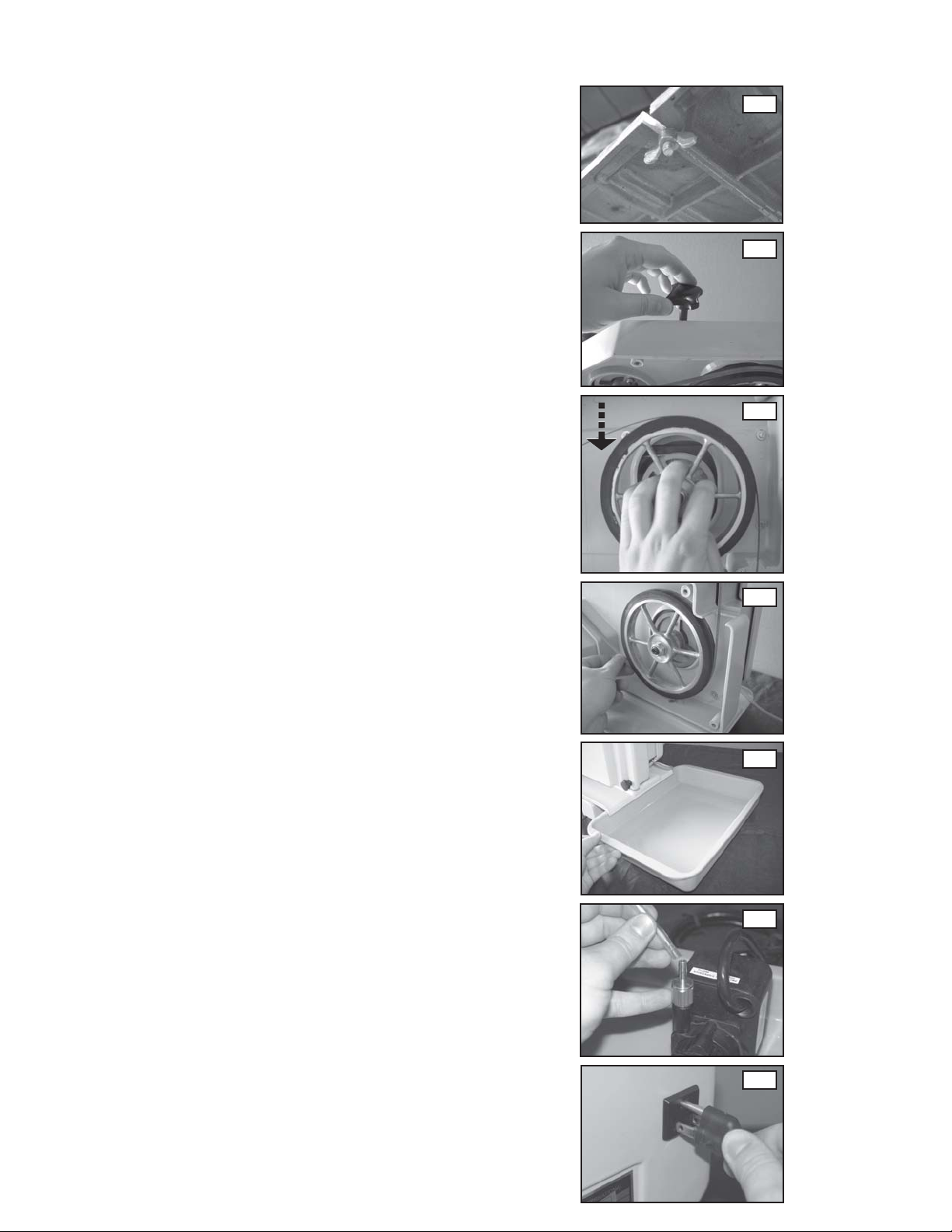

C. Water Systems

1) Place the water reservoir on a solid level work surface. Place

reservoir underneath the lip located on the right side of the saw

base (Fig.6).

2) Insert brass pump valve into the top of the recirculating water

pump. Place pump in the water reservoir (Fig.7).

3) Plug pump’s electrical connector into the outlet on the rear of the

saw (Fig.8).

5) Fill the reservoir with 2” of water before use

(Approximately 3 quarts).

6) To test pump, the saw must be turned ON. Be sure the blade has

been properly installed and there are no obstructions to interfere with

its operation and blade movement. DO NOT attempt to touch the

blade or blade wheels while the machine is turned ON.

7) T est pump and water flow by turning machine ON. The blade

should not be moving; be sure reostat is turned to “0”. Watch for

bubbles in the hose. Water should begin to flow freely from the water

nozzle mounted on the upper blade guide block assembly . To insure

water flow is directed at the front edge of the blade just below the

guide assembly , adjust position of water nozzle by loosening the set

screw (Fig.9).

8) If large pockets of air appear in the hose line, this may stop the

flow of water to the blade. If this occurs, prime the pump by tipping it

on its side and allow the intake to draw in air through the line. Then

return the intake grill into the water and watch for the water to fill the

line. Small air bubbles may persist in the line but these will not

interfere with sufficient flow to the blade.

WARNING: Never operate saw if there is insufficient water at the

point of cutting, as this will cause damage to the blade.

Fig.5

Fig.6

Fig.7

Fig.8

Page 4

DL5000 INSTRUCTION MANUAL

- PAGE 3

Band Saw Use and Maintenance

A. Drive Belt T ension Adjustment

A loose drive belt may result in a noticeable loss of power to the

blade wheels.

1) To tighten the drive belt, turn saw OFF and unplug the saw from the

electrical outlet.

2) Remove all screws securing rear panel encasing the motor (Fig.10).

3) Loosen both motor mount set screws using a large hex

wrench (Fig.1 1).

4) Press the motor downward to desired belt tension and secure into

position by retightening the motor mount set screws. There should be

moderate give in the belt tension (1/4” flex top and bottom).

WARNING: Do not overtighten belt. Overtightening the drive belt will

slow the motor down and damage the motor. A loose belt will not

turn the blade wheels properly.

B. Drive Belt Replacement

1) T o replace the drive belt, turn saw to OFF position and unplug from

the electrical outlet.

2) Remove all screws securing panel encasing the

motor (Fig. 1 1).

3) Remove left center screw holding the motor plate into position.

Loosen right motor mount screw slightly .

4) Pivot motor slightly to the right and drive belt will loosen (Fig.12).

Pull drive belt off the motor and pulley wheel.

5) Replace drive belt by first wrapping it around the motor pulley . Then

holding the belt over the pulley wheel, rotate it to the right, coaxing

the belt onto the pulley wheel from the bottom up (Fig.13).

6) Replace and tighten motor mount plate screws and adjust belt

tension as needed.

7) Replace the rear panel encasing the motor and fasten

with screws.

Fig.9

Fig.10

Fig.11

Fig.12

C. Blade Tension

A tension meter is located on the top back panel of the DL5000

(Fig.14). Proper tension is achieved when the gauge is just touching

the top of the “tight” red mark. You can check this by pushing on the

flat side of the blade between the upper wheel and upper guide and

you should get 1/4”-1/2” movement side to side. If you can not flex the

blade 1/4” - 1/2”, loosen until you can and use this meter reading as

the correct setting for this blade. Recheck with each new

blade replacement.

WARNING: If the diamond blade is too tight, breakage could occur.

During operation, the blade will begin to expand due to friction and

heat. If the blade begins to vibrate from side to side during operation,

tighten the tension knob again so the meter position remains the

same as it was originally set for this blade.

WARNING: When shutting off the machine after a day of operation,

loosen the blade tension. Before returning to operation again,

tighten the tension so the meter reads correctly for the blade in use.

D. Blade Guide Adjustment

The DL5000 comes with lower and upper blade guides. Proper

alignment of these guides are essential for proper cutting and

extending blade life.

Fig.13

Fig.14

Page 5

PAGE 4 -

DL5000 INSTRUCTION MANUAL

1) To adjust the rear roller bearings, use a small hex wrench and

loosen the set screw located on the top of the blade guide block.

Slide the blade guide block backward or forward to achieve proper

position (1/16” away from blade).

2) The blade should fit directly between the small square guides (Fig.15),

located on the front of the upper blade guide block no more than 1/16”

from the blade (Fig.16). Guides help stabilize the blade to prevent it

from twisting.

3) The blade should pass through the lower blade guide block the

same as the upper set. To adjust, loosen the set screws located on

the lower blade guide mounting block and slide blade guide arm back

or forward to adjust properly (Fig.17).

NOTE: Blade guides and blade tension should be checked and

adjusted if needed after 3 hours of use. Frequent replacement

of blade guides is recommended to maintain cutting accuracy

and extend blade life.

When pushing the material through the blade while cutting, make

sure the round support bearing behind the blade does not spin. If the

roller begins to spin, back off the pressure of feeding the material until

the spinning stops. Eventually you will begin to know the exact pressure

required to cut specific materials. NOTE: The support bearing should

not be used as a back stop for the blade to increase cutting time. This

constant contact will wear the blade down from the back side as well

as add pressure and friction to the blade until it snaps.

Fig.15

Fig.17

Set

Screw

Fig.16

Upper

blade

guide

E. Upper Blade Guide Height Adjustment

The position of the upper guide should be 1/4” from the top of the

material you are cutting.

T o adjust height of blade guide, loosen guide bar locking knob on

back of saw and raise or lower the guide assembly (Fig. 18).

F . Straight Edge / Angle Guide

The band saw is designed for intricate radius cuts, however the straight

edge guide will permit moderate straight edge or fixed angle cutting

when needed. Place work material against the straight edge guide and

feed the material

slowly . For easy installation, place guide in groove located on cutting

table. Adjust guide location by removing the adjusting screw and moving

guide to the various slots on the table top (Fig.19).

G. Blade Tracking - Upper Wheel Tracking Adjustment

The optimal position for the blade is to track in the center of all three

blade wheels but most importantly the top wheel. If the blade is not

centered, you can adjust the hub assembly screws behind the upper

wheel. This allows for the wheel to tilt, forcing a repositioning of the

blade. You will need to remove the rear cover of the machine to

expose the 6 adjusting bolts. Need photo here of hub assembly

with arrows to inner and outer bolts (Fig.20).

Locking

Knob

Inner Top

Fig.18

Fig.19

Outer Top

Fig.20

If the blade is coming off or riding towards the front of the top

wheel, loosen the Inner Top Hex Bolt and tighten the Outer Top

Hex Bolt, then retighten the Inner Top Hex Bolt.

If the blade is coming off or riding towards the back of the upper

wheel, loosen the Inner Bottom Hex Bolt and tighten the Outer

Inner Bottom Outer Bottom

Page 6

DL5000 INSTRUCTION MANUAL

- PAGE 5

Bottom Hex Bolt, then retighten the Inner Bottom Hex Bolt. After

adjusting, manually turn the wheels to ensure proper blade tracking.

Quick Tips

1) When cutting, the highest blade speed will usually result in efficient and

smooth cutting. Use a slower speed when working with delicate materials

or making very tight turning radius.

2) Do not force materials into the blade. Ease the materials into the blade,

turning as you go to create your pattern. Keep a constant forward

movement of the material through the blade as you make your curves.

Avoid twisting the blade on tight curves.

3) To back out of a cut, turn the saw off and ease the material away from

the blade.

4) Clean band saw after each use with water . Run clean water through

pump until it runs clear and the water tube appears clean. Frequent use of

WD40 or similar lubricant on all screws and moving parts is recommended.

5) When not in use, loosen blade wheel tension. When storing for

extended periods, remove blade and drive belt, then store.

6) Use a waterproof pen to mark your pattern on material. For added

protection, use Chap Stick™ or candle wax over line before cutting.

7) T wo or more pieces may be cut at the same time by stacking them

together and using “tacky wax”, rubber cement or double-sided tape to

hold material in place. If using glue or tape, clean blade after use by

running a clean piece of glass or tile through blade. It is not recommended

that you cut through thickness greater than 3/4”.

Page 7

DL5000 INSTRUCTION MANUALPAGE 6 -

Troubleshooting

Problem: Blade jammed in work material.

Cause: Twisted blade from forcing work materials into the blade.

Solution: Before freeing any jammed materials, immediately turn OFF power switch and wait until all moving

parts have stopped. Gently free work material, holding blade against the blade guides to prevent it from stretching

or badly twisting. Back out of the cut if needed. Inspect blade for kinks and ensure there is no remaining debris

in the blade path which may have caused the jam.

Problem: Saw runs slowly or stops while cutting

Cause: Drive belt slippage or broken.

Solution: See Band Saw Use and Maintenance Drive Belt T ension-Section A.

Additional Parts

Item Item Number

DL5000 TABLE P500

DL5000 MAIN FRAME P501

DL5000 VARIABLE SPEED CONTROL 1 10V/220V P502/P502A

DL5000 WHEEL SET P503

DL5000 DRIVE BEL T P540

DL5000 UPPER BLADE BLOCK P542

DL5000 LOWER BLADE BLOCK P543

DL5000 DRIVE HUB ASSEMBL Y P544D

DL5000 NON-DRIVE HUB ASSEMBL Y P544ND

DL5000 ST AINLESS STEEL BLADE - TILE 16

DL5000 ST AINLESS STEEL BLADE - GLASS 47

DL5000 BLADE GUIDE SET 34

Blade Repair Service

Diamond T ech of fers a blade repair service should a blade break with ample diamond remaining. Return

blade, indicating saw model and payment to Diamond T ech, Blade Repair Service, 5600 Airport Blvd.,

Suite C,T ampa, FL 33634. For International and special handling, please include extra postage and

shipping instructions

Blade Repair Fees (U.S. Dollars):

Speedster, DL1000, DL3000........................................................................ $25.00

DL5000......................................................................................................$45.00

DL7000......................................................................................................$78.00

Page 8

DL5000 INSTRUCTION MANUAL

Diamond Tech

Diamond Laser 5000 1 Year War ranty

All Diamond Laser 5000 Band Saw and accessories are manufactured to high quality standards

and are serviced by highly qualified technicians.

Diamond Laser 5000 Band Saw is warranted to the original purchaser for one full year from

the original purchase date. During the one year period, if you feel the Diamond Laser 5000

Band Saw is not performing properly and needs to be serviced, contact Diamond Tech at 800937-9593 or email info@dticrafts.com for a Return Authorization Number. Equipment will not

be accepted at Diamond Tech without a Return Authorization Number.

If returning the Band Saw for evaluation or repair, be sure to include your Name, Address,

Daytime Phone Number with Area Code and a letter explaining the specific problem you are

encountering. You will be contacted if any necessary parts or service are not covered under

the warranty .

Date of purchase ___ / ___ / ___

Mark the Return Authorization Number clearly on every package! Do not send this product back

without such prior authorization! Return postage and insurance are the responsibility of the

consumer. Diamond Tech will return your equipment postage paid and insured if it is under

warranty. Any Band Saw no longer under warranty will be returned at the owner ’s expense.

Diamond Tech reserves the right to repair or replace faulty equipment at its discretion. The

Diamond Laser 5000 Band Saw is warranted against defective materials or workmanship. If the

Diamond Laser 5000 Band Saw suffers damage due to customer modifications and/or is used

for any application other than that for which it was designed, this warranty is void. This warranty

does not include damage due to: (A) neglect (B) accident (C) unreasonable use (D) improper

maintenance (E) any other causes not attributed to defects in material or workmanship. This

warranty specifically excludes the Diamond Laser 5000 Band Saw blades and/or guides. Any

implied or otherwise explicit guarantees made through merchandiser of this product are not

covered in this warranty coverage agreement and are expressly disclaimed.

IMPORTANT NOTE: This machine was designed for certain applications only. Diamond Tech

strongly recommends that this machine NOT be modified and/or used for any application other

than that for which it was designed. If you have any questions relative to its application, please

contact us and we will advise as to it proper use.

Diamond Tech, USA

5600 Airport Blvd., Suite C, T ampa, Florida 33634

T ech Support: 800-937-9593 (U.S.A., Canada) 813-806-2923 (International)

Fax: 813-806-1988, Email: info@dticrafts.com

www. DiamondSaws.com

4/2007

Loading...

Loading...