Page 1

Operating Instructions

Control unit WSE2226 USA

Index 000

Original operating instructions

10993031 en USA / 09.07.2012

Page 2

Congratulations!

With a Hydrostress unit from TYROLIT, you have chosen a tried and tested piece of equipment

which has been designed and built to leading technical standards. Only genuine TYROLIT Hy-

drostress replacement parts can guarantee quality and interchangeability. If maintenance work

is neglected or carried out inexpertly we will be unable to honour our warranty obligations. Any

repair work must be carried out by trained personnel only.

Our after sales service is available to help ensure that your TYROLIT Hydrostress units remain in

perfect working order.

We hope that working with your TYROLIT unit will be a satisfying and fault-free experience.

TYROLIT Hydrostress

Copyright © TYROLIT Hydrostress

TYROLIT Hydrostress AG

Witzbergstrasse 18

CH-8330 Pfäkon

Switzerland

Tel. 0041 (1) 952 18 18

Fax 0041 (1) 952 18 00

Page 2

Page 3

TYROLIT Hydrostress AG

Safety

1

DANGER

Failure to comply with the safety instructions in the «Safety Manuals / System Manuals» may result in serious injuries or even death.

X Make sure that the «Safety Manuals / System Descriptions» for the relevant type of saw have

been fully read and understood.

DANGER

Death or serious injury can be caused by sudden start-up of the machine.

X Before switching on the system, ensure that no other persons are present in the danger ar-

eas.

X Switch the system o before connecting or disconnecting cables.

X On leaving the system switch o and make safe so that it cannot be switched on again.

Death or serious injury as a result of the sawing machine continuing to run after an accident.

X Ensure that the EMERGENCY STOP button can be reached quickly.

1.1

Electric shock from live cables and connectors.

X Switch o the control unit WSE2226 before connecting or disconnecting cables.

X Ensure that the power supply is earthed and tted with a residual current operated protec-

tive device (FI) with a maximum residual current of 30mA.

Risk of re due to incorrect mains voltage.

X Make sure that the mains voltage and mains frequency correspond with the mains settings

of control unit WSE2226.

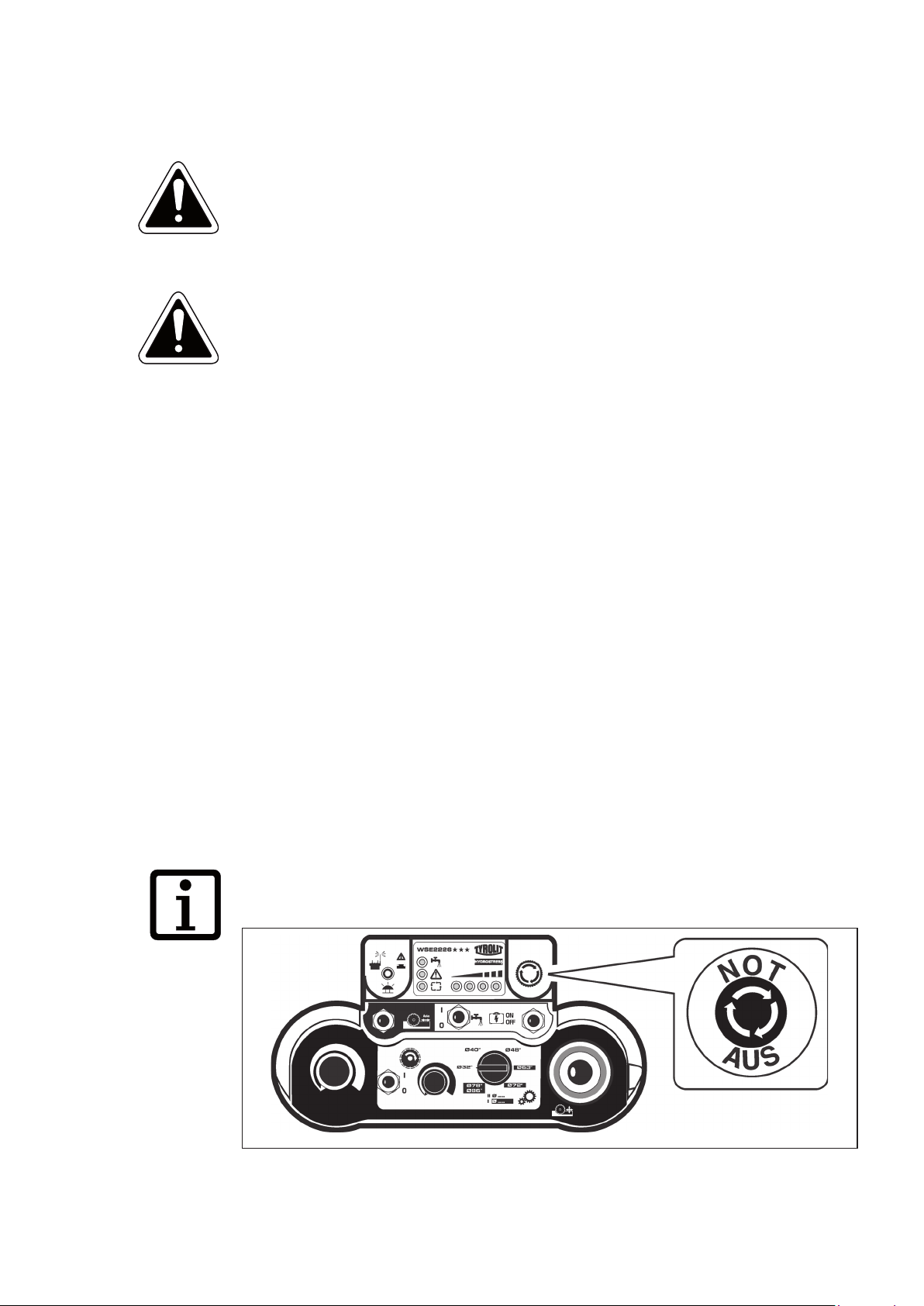

Action in an emergency

X Press the EMERGENCY STOP button on the remote controller.

If the EMERGENCY STOP has been activated on the radio remote controller, the LED pilot lamp

ashes quickly.

In an emergency the sawing machine can be also switched o using the main switch of control

unit WSE2226.

Emergency Stop

Page 3

Page 4

TYROLIT Hydrostress AG

Description

2

2.1

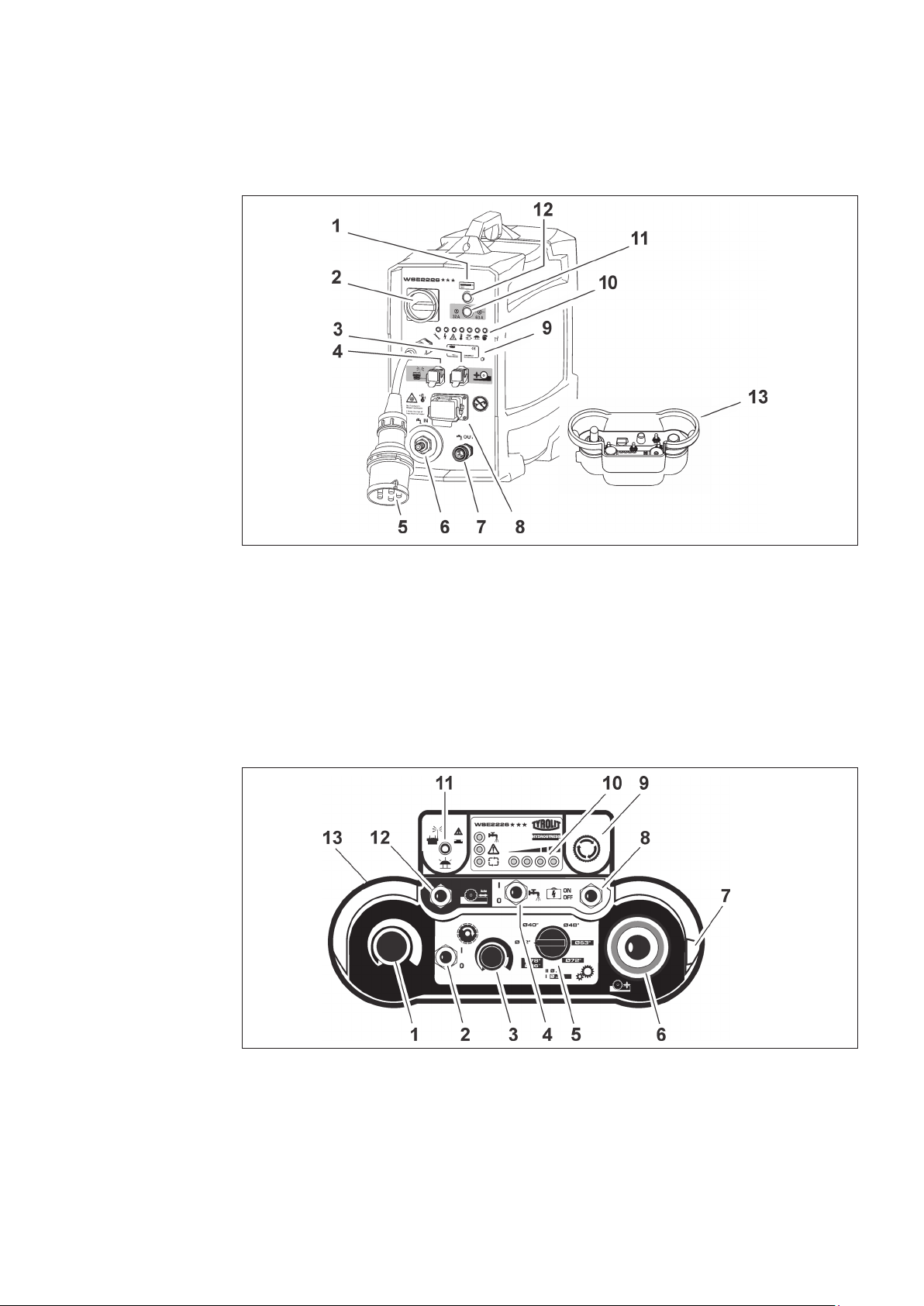

Main components Control unit

Main components Control unit

1 Operating hours counter 8 Main motor connection

2 Main switch 9 Name plate

3 Feed motor connection 10 Indicator lights

4 Remote controller connection 11 Mains system selection button

5 Mains connector 12 Reset button

6 Water nipple / water inlet 13 Radio remote controller

7 Water connection / water outlet

2.2

Main components of radio remote controller

Main components of remote controller

1 Feed potentiometer 8 Pulse switch Control unit

2 On / O Main motor 9 EMERGENCY STOP

3 Main motor potentiometer 10 Indicator lights

4 Water On / O 11 Warning light (radio & battery)

5 Diameter selector switch 12 Position lock switch (Traverse feed)

6 Traverse feed joystick 13 Casing

7 Starter switch

Page 4

Page 5

TYROLIT Hydrostress AG

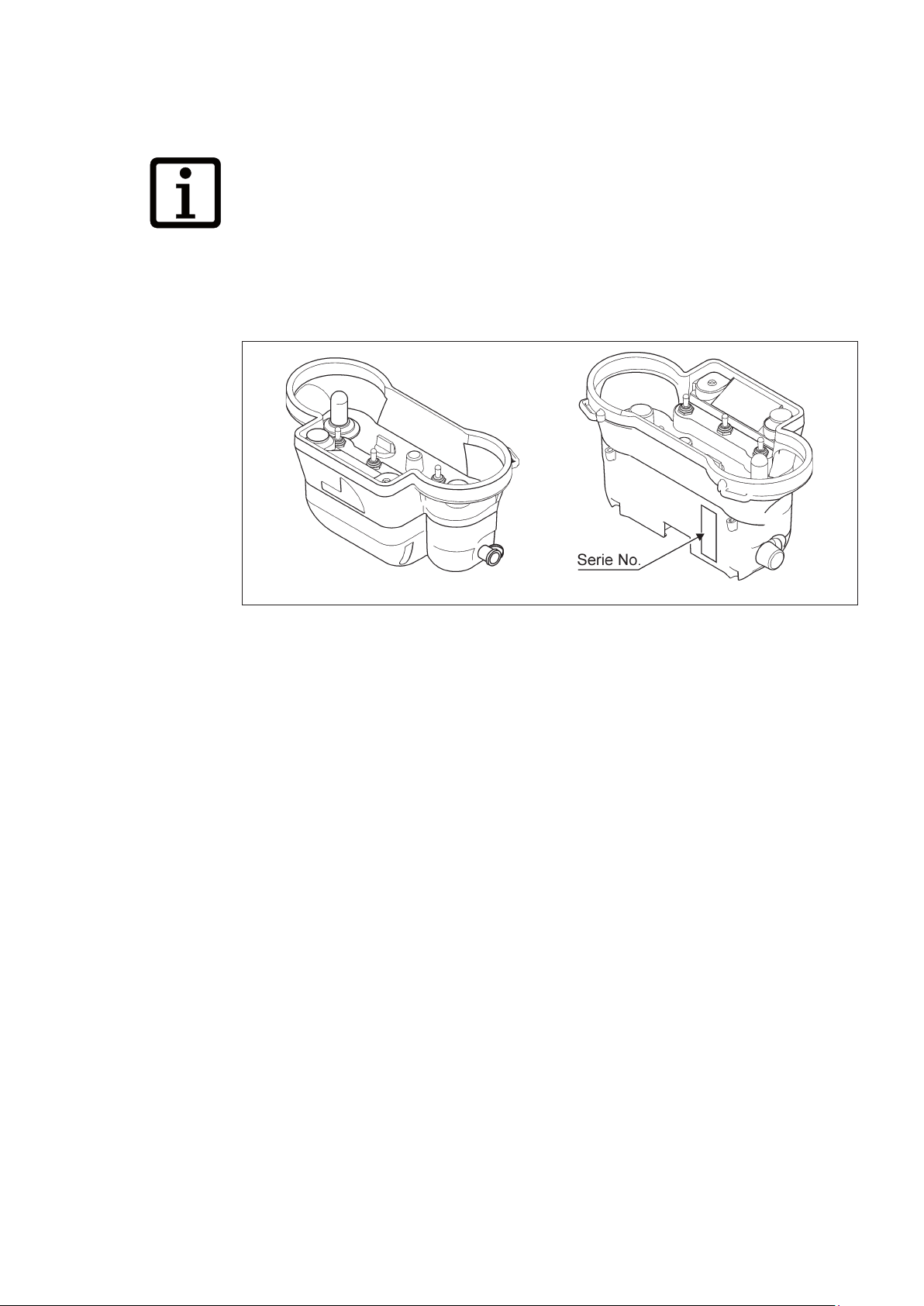

2.3

Remote controller

The remote controller can be replaced by an accumulator or a battery operated radio remote

controller. The remote controller can also be operated using a cable.

Radio remote controller

The transmitter and receiver are a pair of matched units. They cannot be used with other devices.

Transmitter = radio remote controller

Receiver = control unit

2.4

Remote controller

Operating modes

Rechargeable battery operation:

The interchangeable rechargeable battery is inserted in the base of the casing. The operating

period with a fully charged battery is approximately 12 hours. A shorter operating period can

be expected at low temperatures. The reception distance is 27 yards.

Battery operation:

The battery holder is included in the scope of supply and allows operation with three 1.5 V AA

batteries. The reception distance is 27 yards.

Cable operation:

The cable insert is included in the scope of supply and allows connection of the remote controller to the control unit WSE2226. The cable length is 11 yards. Cable operation makes it

possible to work in areas where radio operation is not allowed (e.g. hospitals).

With cable operation all control signals are transmitted via the power cable.

The rechargeable/ordinary battery holders may not be inserted in the base of the casing during

cable operation.

Page 5

Page 6

TYROLIT Hydrostress AG

2.5

Accessories for remote controller

The battery charger is exclusively for recharging the interchangeable rechargeable battery. The

battery holder must not be inserted.

Accessories

1 2x Interchangeable rechargeable batteries No. 10984306

2 Rechargeable battery charger No. 10984305

Rechargeable battery charger with

10-30 VDC connection

3 Remote control cable No. 10991362

4 Battery holder

5 Key

6 Adapter

No. 10984840

No. 10984307

No. 10984309

No. 10993019

During cable operation no interchangeable rechargeable battery or battery holder must be inserted into the remote controller.

Page 6

Page 7

Connections

3

TYROLIT Hydrostress AG

3.1

Connecting remote controller and motor connections

9 The control unit is isolated from the power supply

9 Connectors/plugs are clean

9 Cables are undamaged

X

3.2

Connecting the mains and water supply

9 The power supply is earthed and tted with a residual current operated protective device

(max. residual current 30mA)

9 Cable cross-section is sucient: for up to 27 yards long 5 x AWG 9, more than 27 yards long

5 x AWG7

Page 7

Page 8

TYROLIT Hydrostress AG

Operation

4

4.1

Overview of operating elements

Controls

1 Position lock switch (Traverse feed) 8 Main motor potentiometer

2 Water On / O 9 Diameter selector switch

3 EMERGENCY STOP 10 Feed joystick

4 Pulse switch control unit 11 Main switch Control unit

5 Starter switch 12 Reset button

6 Feed potentiometer 13 Mains system selection button

7 On / O, main motor

Page 8

Page 9

TYROLIT Hydrostress AG

4.2

Starting the control unit WSE2226

CAUTION

The control unit WSE2226 can be damaged if it slips or overturns!

X Make sure that the control unit WSE2226 stands horizontally (handle at top).

9 Control unit WSE2226 is connected to the mains and the water supply.

9 The sawing machine is connected to the control unit WSE2226.

9 The remote controller EMERGENCY STOP has been deactivated.

9 The control unit WSE2226 is not exposed to direct sunlight.

Starting the control unit WSE2226

X Move the controls shown below on the remote controller to the 0 position.

Feed potentiometer (6)

Starter switch (5)

Feed joy stick (10)

Main motor On/O (7)

X Switch on the control unit WSE2226 using the main switch (11).

X Switch on the radio remote controller using the starter switch (5).

– Warning lights (radio and battery) at rst show red

– An audible signal sounds simultaneously

– Indicators ash coloured

– Second audible signal sounds

– Indicators show coloured

– Warning light ashes green

X Press the pulse switch (4) on the radio remote controller briey to the ON-position.

All indicator lights except the warning light and the group alarm on the radio remote controller go o.

X Press the reset button (12) on the control unit.

X Press the remote control pulse switch (4) briey in the ON-position.

The the control unit 'ready' lights show green.

X Open the water valve on the system supply line.

X Press the Water On/O switch (2) on the remote control unit to I.

– Water ows from the cutting tool

X Press the main motor On/O switch (7) on the remote controller to position I.

– The electric motor starts when the main motor potentiometer is in the max. position.

X The control unit WSE2226 has started up and is ready for operation.

Page 9

Page 10

TYROLIT Hydrostress AG

4.3

4.4

4.5

Selecting mains network

The control unit WSE2226 is preset for a 63A power supply network (63A button lights

up). It is possible to switch over to a 32A power supply network. The system automatically

returns to the 63A settings when it is restarted.

X To set the power supply network to 32A press the power network selector (13), the button

light goes out.

Resetting must take place directly after switching on the control unit WSE2226.

Tool soft start

The control unit WSE2226 provides a facility for a tool soft start.

Proceed as follows:

X Starting the control unit WSE2226, see 4.2.

X Turn the main motor (8) potentiometer to the 0 position.

X Press the switch main motor (7) to I.

X Select the desired output level, see 4.5.

X Turn the main motor (8) potentiometer slowly to 100% power.

Selecting tool station

After the control unit WSE2226 has been started correctly the tool station can be selected.

Page 10

Selecting the power level

Proceed as follows:

X Set the diameter selector switch to the desired tool and turn the main motor potentiometer

from 0 to 100%.

X Check gear at gearbox of drive motor.

The tool stations may not be changed during operation.

The tool stations are set with reference to the tool diameter for the optimum rotational speed

and cutting performance.

The rotational speed can be reduced using the main motor potentiometer but at the same time

the power is reduced.

Page 11

TYROLIT Hydrostress AG

4.6

4.7

Power control

The main motor and the feed motor power are controlled via the potentiometers.

Power control

Feed motor potentiometer (6)

Main motor potentiometer (8)

Adjusting the feed

The feed movements are selected with the joystick.

Adjusting the feed

During the cutting process the feed speed is automatically assisted by a feed facility.

Page 11

Page 12

TYROLIT Hydrostress AG

4.7.1

4.7.2

4.8

Manually adjusting the feed speed

9 Control unit WSE2226 has started

X Select the required feed speed via the feed potentiometer (6).

Feed stop

So that the joystick does not have to be held in position during the travel feed motion the travel

feed can be locked.

Proceed as follows:

X Push the joystick in the desired travel direction and at the same time press the locking

switch (1).

X When the joystick and the locking switch are released the feed is locked.

In order to release the feed lock, move the joystick slightly in any desired direction.

Switching o the control unit WSE2226

4.9

Proceed as follows:

X Switch o electric motor (7) On / O main motor.

X Turn o cooling water, switch (2) Water On / O.

X Close water valve on control unit WSE2226.

X Turn the start switch (5) on the remote controller to the 0 position.

X Switch o the control unit WSE2226 using the main switch (11).

Only stop the wall saw WSE2226 using the EMERGENCY STOP function in an emergency.

CAUTION

Frost damage to control unit WSE2226!

Heat damage to control unit WSE2226!

X Blow out any water if there is a risk of frost (see chapter 4.9, Blowing out water).

X Direct sunlight on the WSE2226 control unit must be avoided.

Blowing out the water

9 Main switch is set to OFF

X Disconnect the mains plug.

X Disconnect all water lines.

X Connect blow out pump to the water nipple.

X Blow out water until all of the cooling water has been removed.

X Remove the pump.

Page 12

Page 13

TYROLIT Hydrostress AG

4.10

Deactivating EMERGENCY STOP

If the EMERGENCY STOP is activated on the radio remote controller, the radio and battery light

(8) ashes.

Deactivating EMERGENCY STOP

The following controls must be moved the 0 position:

4.11

Feed potentiometer (6).

Feed joy stick (10).

Main motor On/O (7).

Turn the EMERGENCY STOP button (3) clockwise.

Press pulse switch control unit (4) to the ON position.

After termination of work

Proceed as follows:

X Turn the main switch on the control unit WSE2226 to the 0-position.

X Withdraw the mains plug (Control unit WSE2226).

X Disconnect the water hoses from control unit WSE2226.

X Blow out the water from all the lines (blow out pump).

X Disconnect electric cable.

X Clean the control unit WSE2226, the remote controller and the cable with a damp

cloth.

Cleaning using high pressure cleaning equipment is not permitted.

Products containing cleaning agent can damage parts of the control unit WSE2226, the

radio remote controller and the cable.

Page 13

Page 14

TYROLIT Hydrostress AG

Reacting to displays

5

Symbols on the control unit / remote controller

Symbols on the control unit Symbols on the remote controller

1 Service 8 Radio and battery remote control

2 Control unit external fault 9 Cooling water

3 Fault within the control unit 10 Group alarm

4 Temperature 11 Ready for operation lights

5 Mains connector

6 EMERGENCY STOP

7 Potentiometers

Page 14

Page 15

Power and error displays on the control unit

Symbol Response Possible cause Action

TYROLIT Hydrostress AG

Lights up red After the rst 100 operating

hours, then after every 200 operating hours.

Lights up red Fault:

- current overload

- short circuit

- earth fault Main motor

- defective feed motor

Lights up red Defective

- main contactor

- brake resistance

- over current Motor

- CAN fault

- group fault

Lights up red Over heated

- cooling element

- control unit

- main motor

Lights up red Phase missing The drive unit will not start or switches o during operation.

Carried out only by TYROLIT Hydrostress AG

or an authorised representative

The control unit will not start.

X Check network connection.

X Check cable.

X Replace feed motors.

X Contact TYROLIT Hydrostress AG customer service.

The control unit will not start.

X Contact TYROLIT Hydrostress AG customer service.

X Check network connection.

The control unit will not start.

X Check cooling. Wait until it can be restarted. Before starting

press the reset button.

(Water cooling see page 20)

X Avoid direct contact with sun light.

Lights up red The EMERGENCY STOP has been

activated

- CAN fault

Lights up red Feed potentiometer not in zero

position

X Check the mains fuse in the distribution box and switch it on

if necessary.

X Have the site power supply checked.

X Have the extension cables, plugs and sockets

checked for faults.

X Deactivate the EMERGENCY STOP.

X Contact TYROLIT Hydrostress AG customer service.

The control unit will not start.

X Set the feed potentiometer to 0.

Page 15

Page 16

TYROLIT Hydrostress AG

Power and error displays on the remote controller

Symbol Response Possible cause Action

Flashes red Rechargeable battery voltage

too low

Flashes rapidly

green

No light shows No water ow The control unit will not start, motor does not run.

Lights up red

or ashes

Lights up green

No light shows Contactor not ready X Operate control unit pulse switch.

No radio connection

The EMERGENCY STOP has been

activated

• Group alarm on the control

unit

• When the pulse switch control

unit is operated, the main motor On/O switch is in the position On

The motor is ready to start

Shows the current power range

Ideally: At the third, orange coloured diode (In iron fourth, red diode).

X Recharge rechargeable battery.

X Switch on the control unit.

X Defective receiver.

X No receiver matched connection, see page 5.

X Press the cooling water button. (LED shows blue).

X Observe control unit fault indicators.

X Press the control unit reset button.

Page 16

Page 17

Servicing and maintenance

6

Maintenance and servicing table

Before starting

up

On nishing

work

TYROLIT Hydrostress AG

Weekly

Annually

After faults

After damage

Electrical system X Check the condition and cleanliness

of electric cables, plugs/connectors

and switches.

X Check the condition and cleanliness

of connections.

Water economy X Check water lines for cleanliness and

leaks.

X Blow out the water if there is a risk of

frost.

Entire WSE2226

control unit

Service X To be performed by TYROLIT Hydros-

X Clean with damp cloth

no high pressure cleaner

tress AG or an authorised workshop.

Cleaning using high pressure cleaning equipment is not permitted.

Cleaning using high pressure cleaning equipment can damage the control unit and the remote

controller.

X X X X

X X X X

X X X X

X X X

X

First service after 100 operating hours

Further services after every further 200 operating hours

Products containing cleaning agent can damage parts of the control unit WSE2226, the

radio remote controller and the cable.

Page 17

Page 18

TYROLIT Hydrostress AG

Faults

7

Faults

Faults Possible cause Solution

Control unit

does not run although the

mains cable is connected

The control unit starts and

then cuts out again

No power, even though

the control unit

is running

The control unit

suddenly cuts out

Main motor is not running • Main motor potentiometer is in

Control unit is switched o X Switch control unit on, see Chapter 4.

Mains cable is defective X Replace the mains cable.

No voltage at the power supply (building site)

Power supply phases incorrectly

connected

Phase missing See the chapter 5 entitled «Reacting to displays».

Building site power supply cut-o unit

trips

Incorrect voltage

Defective main motor

Over or under voltage X Check the power supply. Refer to fault indicator.

Cross section of power supply cable too

small

Defective plug connection X Check the plug connection.

Group alarm X Refer to fault indicator

0-position

• Defective main motor On / O switch

on remote controller

The remote controller 'ready to operate'

light does not come on.

X Check the power supply.

X Check the power supply.

X Check and if necessary adapt the cut-o protection.

X If necessary change the power supply.

X See chapter entitled «Reacting to displays».

X Make sure that the control unit voltage and frequency

match the mains supply specications.

X Contact TYROLIT Hydrostress AG customer service.

X Check the power supply.

X Check the power supply.

X Contact TYROLIT Hydrostress AG customer service.

X Do not start control unit, see Chapter 4.2

Remote controller

not working

Feed potentiometer indicates no function

Feed motor fails to

build up power

EMERGENCY STOP activated X Deactivate EMERGENCY STOP, see Chapter 4.10.

Overheating X Check the water circuit and the plug-in couplings.

X Refer to fault indicator.

No water X Switch on the water supply.

X Refer to fault indicator.

Rechargeable battery or battery have

too little

charge

• Defective potentiometer in the remote

controller

• Feed motors not connected

• Defective feed motor

• Joystick is in the zero position

Remote controller potentiometer is defective or in the 0-position

Defective cable X Contact TYROLIT Hydrostress AG customer service.

Motor fault X Contact TYROLIT Hydrostress AG customer service.

X Replace rechargeable battery and recharge or install

cable operation.

X Replace batteries.

X Contact TYROLIT Hydrostress AG customer service.

X See Chapter 3.1 / 4.6 / 4.7

X Contact TYROLIT Hydrostress AG customer service.

X See Chapter 4.7.1

Page 18

Page 19

Faults

Faults Possible cause Solution

No water emerging Water line blocked X Clean the water line.

TYROLIT Hydrostress AG

Water valve on the supply or water hose

are closed

Insucient water pressure X Make sure that the water pressure is at least 2 bar.

Water lter is blocked X Remove lter and clean

Switch for the radio remote controller

defective

Uncontrolled water leak • Water valve on the control unit is

defective

• Switch for the radio remote controller

defective

Group alarm on the remote controller X See chapter entitled «Reacting to displays».

X Open the water valve.

X Contact TYROLIT Hydrostress AG customer service.

X Contact TYROLIT Hydrostress AG customer service.

X Stop water leaks using the hose water valve.

X Contact TYROLIT Hydrostress AG customer service.

Page 19

Page 20

TYROLIT Hydrostress AG

Technical data

8

Dimensions in inch

Technical data

Parameter Value

Weight

Protection class IP 65 (4.4X NEMA rating)

Connection values 380 to 420 VAC / 50 Hz / 60 Hz

Max. current consumption 38 A

Power With 32 A power supply net-

Internal control voltages Controller / remote controller 24 VDC / 3.6 VDC

Control unit WSE2226

incl. remote controller

Remote controller separate 4.4 Ibs

work

With 63 A power supply network

Feed drives 48 VDC

Main drive unit 400 VAC, 0...400 Hz

57.3 Ibs

17 kW

26 kW

Page 20

Water Cooling the control unit Water cooling the power semi-

conductors

Cooling water ow rate min. 1.05 gmp at max 77 °F

Water connection min. 29psi / max. 87psi

Usage temperature

Control unit WSE2226

incl. remote controller

+14°F to +104°F

Page 21

Spare parts

9

TYROLIT Hydrostress AG

Page 21

Loading...

Loading...