Diamond CHEF, TVA-38, CHEF 300 MN, CHEF 300 TR, CHEF 400 MN Series Manual

...

Mod: TVA-38

Production code: CHEF 300

03/2010

PAGE

1. INFORMATION ON SAFETIES

GENERAL PRECAUTIONS

1.1

MECHANICAL SAFETIES

1.2

ELECTRICAL SAFETIES

1.3

2. TECHNICAL FEATURES

TABLE OF WEIGHTS AND MEASURES - NOISE

2.1

SUPPLY CONDITIONS AND DISPOSAL OF PACKINGS

2.2

3. INSTALLATION

SETTING THE MACHINE

3.1

ELECTRIC CONNECTIONS

3.2

SAFETY MEASURES AND TRAINING THE FINAL USER

3.3

4. USE OF THE EQUIPMENT

CONTROLS

4.1

SETTING THE DISCS ON THE MACHINE

4.2

SETTING THE FOOD FOR CUTTING

4.3

REMOVAL AND REPLACEMENT OF DISCS

4.4

5. CLEANING AND MAINTENANCE

GENERALITIES AND PRODUCTS FOR CLEANING

5.1

OPERATIONS IN THE CASE OF FAILURES

5.2

MACHINE IDLE FOR A LONG TIME

5.3

6. ACCESSORIES UPON REQUEST

"D" SERIES DICE CUTTING DISCS

6.1

"B" SERIES STICK CUTTING DISCS

6.2

"E" SERIES SLICING DISCS

6.3

"H" SERIES MATCH-LIKE CUTTING DISCS

6.4

"Z-V" SERIES SLITTER DISCS AND GRATING DISCS

6.5

ALLEGATI

FIGURE

ELECTRIC DIAGRAM

DESIGN AND TECHNICAL DETAILS CAN BE CHANGED ALSO WITHOUT NOTI

INDEX

16

16

16

17

17

17

17

18

18

18

18

19

19

19

19

20

20

20

20

20

35-36-37

38-39-40

CE.

15

1) INFORMATION ON SAFETIES

1.1 GENERAL PRECAUTIONS

• THE VEGETABLES CUTTING MACHINE MUST BE MANAGED BY SKILLED PERSONNEL, FAMILIAR

WITH THE INSTRUCTIONS FOR USE AND SAFETY CONTAINED IN THIS MANUAL.

• IN THE CASE OF ROTATION OF THE PERSONNEL, VOCATIONAL TRAINING IS NECESSARY.

• EVEN IF THE MACHINE COMES WITH SEVERAL SAFETY SYSTEMS, AVOID SETTING THE HANDS

NEAR THE CUTTING DISCS AND MOVING PARTS.

• BEFORE ANY CLEANING AND MAINTENANCE OPERATIONS, CHECK TO MAKE SURE THE

MACHINE IS DISCONNECTED FROM THE MAINS.

• PERIODICALY CHECK CABLES AND ELECTRIC ELEMENTS CONDITIONS.

• NEVER USE THE CUTTING MACHINE WITH FREEZED FOOD.

• NEVER REPLACE PARTS OF THE MACHINE BY YOURSELF, BUT APPLY TO THE ASSISTANCE

SERVICE.

1.2 MECHANICAL SAFETIES

THE VEGETABLES CUTTING MACHINES WE PRODUCE AND WHICH ARE DESCRIBED IN THIS

MANUAL MEET, AS FAR AS SAFETIES ARE CONCERNED, THE PRESCRIPTIONS ON THE RISKS

OF MECHANICAL 2006/42/CEE FOR THE SANITARY REGULATIONS THEY COMPLY WITH THE RULE

1935/2004/CEE. AND ROHS 2002/95/CEE AND RAEE 2002/96/CEE.

1.3 ELECTRICAL SAFETIES

THE SAFETIES AGAINST ELECTRICAL RISKS COMPLY WITH THE REGULATIONS 2006/95/CEE

CENELEC EN 60335-2-64.

A SECURITY MICROSWITCH IS MOUNTED ON THESE MACHINES TO STOP THE MACHINE

OPERATION WHEN THE COVER IS OPENED TO GAIN ACCESS TO THE CUTTING DISCS, AND

ANOTHER MICROSWITCH ON THE INLET OF THE MATERIAL. (Fig.1)

A RELAY REQUIRING REQUIRES THE VOLUNTARY RESTART (ACTIVATION) OF THE MACHINE

WHEN THE CURRENT IS LACKING HAS BEEN SET ON THE LOW VOLTAGE CONTROL CIRCUIT.

FOR THE PERFECT INSULATION OF ALL THE ELECTRIC ELEMENTS AND THE REMARKABLE

RESISTANCE OF THE ALUMINIUM TREATMENT, COUPLED WITH THE MATERIAL USED, OUR

MACHINES CAN BE INSTALLED TO WORK INSIDE MOIST PREMISES. IN FACT, THEY HAVE BEEN

CREATED TO WITHSTAND CLEANING THROUGH A FINE WATER SPRINKLE AS PRESCRIBED BY

THE REGULATIONS CEI 70-1 FOR THE DEGREE OF PROTECTION IP23.

WARNING: IN CONFORMITY WITH POINT 1.7.2. FOR "INSTRUCTIONS ON FURTHER RISKS"

CONTAINED IN THE E.E.C. 2006/42/CEE, THESE PROTECTIONS AND SAFETIES STRICTLY COMPLY

WITH THESE REGULATIONS.

WE POINT OUT HOWEVER THAT THE ABOVE MENTIONED PROTECTIONS, EVEN IF THEY

SENSIBLY REDUCE BOTH THE POSSIBILITY AND EXTENT OF THE DAMAGE, DO NOT ELIMINATE

FULLY THE RISK OF CUTTING.

2) TECHNICAL FEATURES

TECHNICAL FEATURES OF VEGETABLES CUTTING MACHINES SERIES "CHEF":

• POSSIBILITY OF CONTINUOUS WORK (MODEL 400), OR INTERMITTENT WORK (MODELS 200-

400)

• THEIR USE, CLEANING AND MAINTENANCE IS QUITE SAFE

THANKS TO THEIR DESIGN AND TO THE REALIZATION OF ALL PARTS IN STAINLESS STEEL

WITHOUT EDGES FOR EASY CLEANING OPERATIONS

16

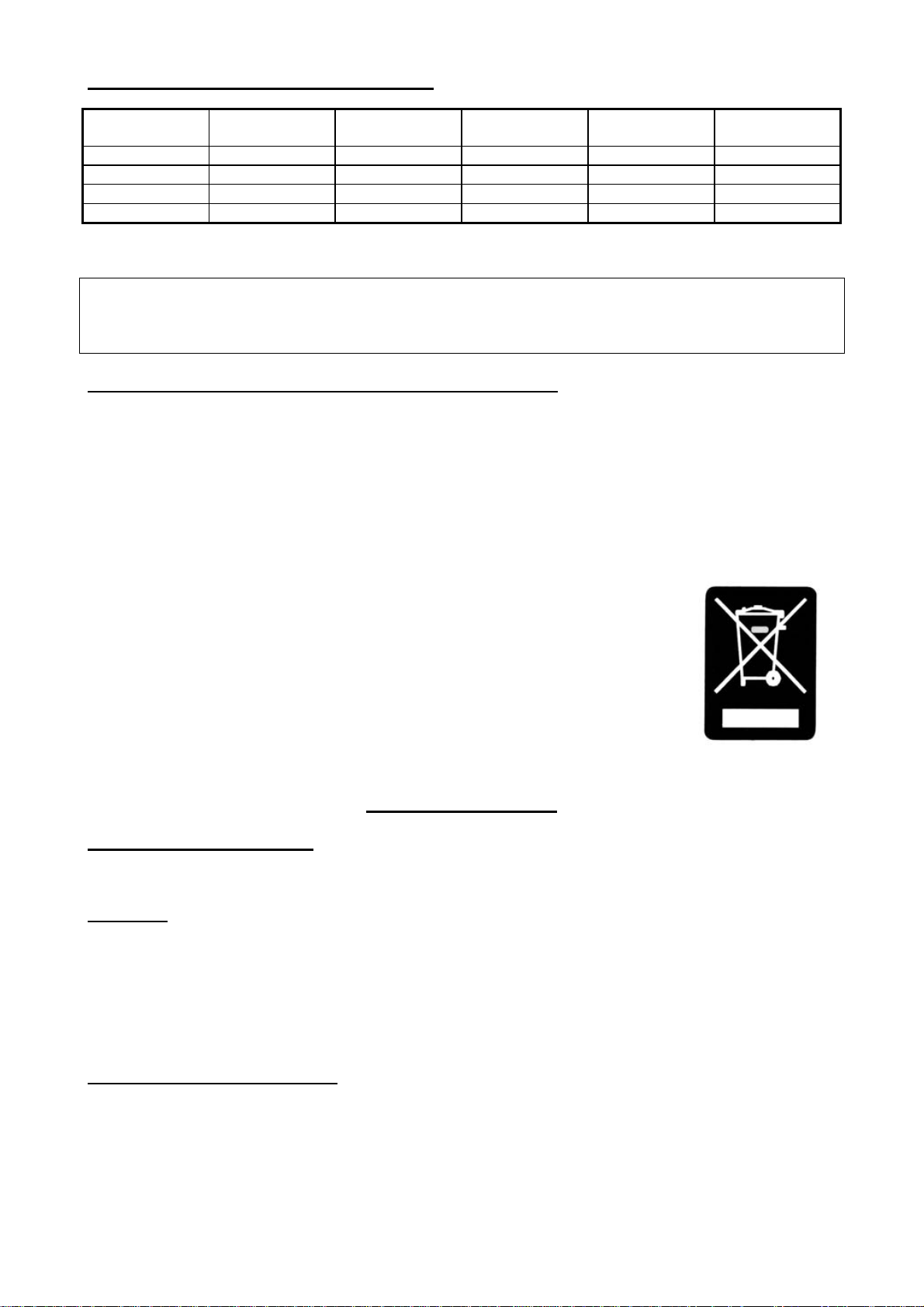

2.1 TABLE OF WEIGHTS AND MEASURES

MODEL

DIMENSIONS

CM.

WEIGHT

KG.

POWER

WATT

ELECTRICAL

CONNECTION

REVS

DISC

CHEF 300 MN 57x24x47 18 380 230/1/50 270

CHEF 300 TR 57x24x47 18 400 400/3/50 270

CHEF 400 MN 57x24x47 17,5 550 230/1/50 270

CHEF 400 TR 57x24x47 17,5 600 400/3/50 270

NOISE "CHEF 300" N. 67 DB - "CHEF 400" N. 68 DB

WARNING: THE ELECTRICAL FEATURES OF EACH EQUIPMENT ARE PRINTED ON THE MOTOR

DATA PLATE. A CHECK OF THE ELECTRIC CONNECTION IS NECESSARY BEFORE INSTALLING

THE EQUIPMENT.

2.2 SUPPLY CONDITIONS AND DISPOSAL OF PACKINGS

ALL THE CUTTING MACHINES ARE PACKED IN A STURDY CARDBOARD BOX WITH INTERNAL

SHAPED EDGES WHICH GUARANTEE THE PERFECT INTEGRITY OF THE MACHINE DURING

TRANSPORT.

EACH EQUIPMENT INCLUDE:

• DECLARATION OF CONFORMITY E.E.C.

• INSTRUCTIONS FOR USE AND MAINTENANCE

• HIGH EJECTING DISC AND LOW EJECTING DISC

ALL THE PACKING COMPONENTS (CARTON, FOAM, STRAPS, AND SO ON)

CAN EASILY BE DISPOSED OF AS HOUSEHOLD RUBBISH.

WHENEVER THE MACHINE IS INSTALLED IN COUNTRIES HAVING SPECIAL

REGULATIONS ON PACKING DISPOSAL, THE FINAL USER MUST COMPLY

WITH THE REGULATIONS IN FORCE.

THE USE OF THE WEEE SYMBOL INDICATES THAT THIS PRODUCT MAY

NOT BE TREATED AS HOUSEHOLD WASTE. BY ENSURING THIS PRODUCT

IS DISPOSED OF CORRECTLY, YOU WILL HELP PROTECT THE

ENVIRONMENT. FOR MORE DETAILED INFORMATION ABOUT THE

RECYCLING OF THIS PRODUCT, PLEASE CONTACT YOUR LOCAL

AUTHORITY, YOUR HOUSEHOLD WASTE DISPOSAL SERVICE PROVIDER

OR THE SHOP WHERE YOU PURCHASED THE PRODUCT.

3) INSTALLATION

3.1 SETTING THE MACHINE

THE MACHINE CONNECTION AND THE SETTING AT WORK MUST BE MADE BY SKILLED

PERSONNEL.

WARNING: BOTH THE SYSTEM AND LOCATION WHERE THE EQUIPMENT HAS TO BE SET MUST

COMPLY WITH THE REGULATIONS FOR THE ACCIDENT PREVENTION AND ELECTRICAL

REGULATIONS CEI IN FORCE.

THE MANUFACTURER DECLINES ANY AND ALL RESPONSIBILITY FOR DIRECT OR INDIRECT

DAMAGES WHICH MAY ENSUE FOR NON-COMPLIANCE WITH THE ABOVE MENTIONED

REGULATIONS.

SET THE EQUIPMENT ON A WIDE, LEVELLED, DRY AND FIXED FACE, FAR FROM HEAT SOURCES

AND WATER SPRAYS.

3.2 ELECTRIC CONNECTIONS

THE EQUIPMENT IS SUPPLIED WITH AN ELECTRIC CABLE TO BE CONNECTED TO A MAGNETOTHERMIC MAIN SWITCH WHICH STOPS THE MACHINE WHEN THE OPERATOR COMES IN

FORTUITOUS CONTACT WITH THE ROTATING ELEMENTS.

17

Loading...

Loading...