Diamond SOFTGEL 320 P, SOFTGEL 112 P, SOFTGEL 336 P Operating Instructions Manual

Mod: DST/2-27AP

Production code: SOFTGEL 336 P AIR

05/2015

English

Soft ice-cream machine

2

Z15.069 V01

Z15.076

0113 V01 ING SOF

OPERATING INSTRUCTIONS

SOFTGEL 112 P

SOFTGEL 320 P

SOFTGEL 336 P

Soft ice-cream machine

English

Operating instructions

3

Z15.069 V01

Dear customer,

We congratulate you on your great choice, and we thank you and invite you to read this manual to use this

machine with no risks and hazards.

While reading this manual you will have the opportunity to get the hang of your new machine, and appreciate

all the production advantages. You will discover that this machine is very easy to use, and you will learn how

you can easily change the processing product, optimising your own production by making it even more profitable.

You will learn how applied technology can help you in your business. In fact, the machines manufactured by

TELME S.p.A. are the fruits of synthesis of years of experience in the designing and manufacturing of machines

for processing food products.

Quality is the hallmark of all our machines, and it renders them cost-effective, reliable, easy to use, noiseless,

safe and ergonomic, requiring reduced maintenance.

In order to maintain machines in perfect working order, it is imperative that the simple maintenance operations

described herein be carried out.

Cleaning the machines is essential and necessary to maintain their reliability.

The manufacturer – in order to provide manuals even more thorough and comprehensive – asks for the precious

collaboration of the users who can send their remarks or corrections stemming from their direct experience.

For the safety of operators and the integrity of the machine, it is strictly forbidden to change the use or change

any design parameter, device or protection system to avoid voidance and cancellation of warranty.

The manufacturer shall not be liable in case of change of use, in the event of replacement with non-original

parts, improper use, tempering, mistreatment, lack of maintenance, removal of safety devices and, in general,

of any changes made to the design parameters.

A highly qualified service system is always at your disposal for any technical request.

Do not try to solve any technical problems you may have on your own to avoid incurring severe dangers;

contact your seller.

TELME S.p.A. technical staff wishes you a continued success in using our machines!

This instruction manual belongs to the machine, therefore it must always be supplied with it, and in the event

that the machine is sold, delivered to the new buyer.

4

SUMMARY

1 TEST, WARRANTY AND LIABILITY......................... 5

1.1 Teechnical documentation............................... 5

1.2 Environmental conditions .................................. 5

1.3 Intervention request – technical assistance ........ 6

1.4 How to order spare parts ................................... 6

1.5 Marking.............................................................. 6

2 SAFETY ................................................................. 7

2.1 General safety notes .......................................... 7

2.2 Definition of safety terms .................................. 8

2.3 Safety symbols and labels ............................... 8

2.4 Correct use of the machine ............................ 8

2.5 Operator’s position (Workstation) ..................... 8

3 MACHINE TECHNICAL SPECIFICATION .............. 9

3.1 Data and dimensions of the machine .............. 9

3.2 General description of machine units ............... 10

4 MOVING AND UNPACKING ................................. 11

4.1 Moving machine in its packaging ................... 11

4.2 Unpacking ..................................................... 11

5 INSTALLING ........................................................ 12

5.1 Placing your machine ................................... 12

5.2 Assembling ................................................... 12

5.3 Connecting to power ..................................... 13

5.4 Connecting to water supply system

(water condensing machines) ....................... 14

5.5 Checking rotation.......................................... 15

6 HOW TO OPERATE YOUR MACHINE ................ 15

6.1 Controls and indicators ................................. 15

6.2 Preparing production .................................... 17

6.3 Programming ................................................ 18

6.4 Production .................................................... 18

6.5 Preservation (overnight)............................... 19

7 WASHING AND SANITATION .............................. 20

7.1 Rinse - preliminary wash .............................. 20

7.2 Washing the pumps ...................................... 20

7.3 Parts disassembling ...................................... 20

7.4 Washing of the parts..................................... 22

7.5 Disassembling and washing tubes and by-pass

valve periodically ........................................... 22

7.6 Re-assembling of the parts ........................... 23

7.7 Reassembling the tubes and by-pass valve ... 24

7.8 Sanitation ...................................................... 25

8 MAINTENANCE.................................................... 25

8.1 Standard maintenance (operator) ................. 25

8.2 Yearly maintenance ...................................... 25

9 PERIODS OF INACTIVITY ................................... 26

10 MALFUNCTIONS ................................................. 26

English

Operating instructions

5

Z15.069 V01

1 TEST, WARRANTY AND LIABILITY

PLEASE READ THESE INSTRUCTIONS BEFORE ATTEMPTING TO INSTALL AND OPERATE YOUR

MACHINE.

THIS MANUAL PROVIDES ALL INFORMATION REQUIRED TO INSTALL, OPERATE AND MAINTAIN

MACHINE

UNDER SAFE CONDITIONS. FAILURE TO COMPLY WITH THE SAFETY MEASURES

SET

OUT IN THIS HANDBOOK MAY RESULT IN SERIOUS DAMAGE TO THE MACHINE AS WELL

AS FORFEIT ANY MANUFACTURER'S GUARANTEE.

1.1 Teechnical documentation

Test

The whole machine is sent to the customer and prepared to be installed after having passed all the tests and inspections laid

down by the manufacturer in compliance with the regulations in force.

Warranty

TELME warrants sold machines for a time of 12 months from delivery date. During the time of warranty, TELME will replace,

free ex-factory, all parts damaged for evident defects of manufacturing or for a bad quality of the materials. Replaced parts

still belong to TELME and will have to be returned to the head office free of charge. Labour and eventual travelling expenses

will be at purchasers charge. Freon gas filling is excluded from the warranty. The warranty declines if the machine is used

not in conformity with the sales instructions; it they are damaged willingly or unintentionally; if the machine is modified,

repaired or disassembled by not authorized staff. The warranty also declines if the connections, power an water, for the

feeding of the machine (at purchasers charge) are uncorrect. Suspension of payment, agreed in the sales proposal and

accepted by TELME will cause the suspension of warranty.

Additional warranty

TELME warrants sold machines according to above mentioned conditions for a time of 12 months from delivery date. In

order to acquire the right of having the additional warranty of 1 year, so that the warranty is extended to a total time of 24

months, the buyer has to cut out, fill in, sign and send back, by registered letter, to TELME, within 15 days from date of

installation, the warranty card which is enclosed in the manual “OPERATING INSTRUCTIONS”. If TELME doesn’t receive

the warranty card, the additional warranty time will not be acknowledged.

Responsibility

TELME is free from every responsibility and obligation for any further accident to people and goods that could verify for

and/or during the use, for reasons or/in dependence on supplied machines, during eventual testing and even if accident is

due to defects of manufacturing or materials. Any further claims of reimbursement must be considered excluded.Products

cannot be used for intent different to that indicated.

1.2 Environmental conditions

The machine working environmental conditions must follow the indications reported below:

Temperature +2°C ÷ +35°C (35.6°F ÷ 95°F)

Humidity 10% ÷ 95% (not condensed)

THE MACHINE MUST BE PLACED IN A PLACE SHELTERED FROM RAIN.

Environmental conditions differing from the ones speci?ed herein may cause serious damages to the machine, in particular

to the electrical equipment and the refrigeration system.

PLACING THE MACHINE IN PLACES DIFFERENT FROM THE ONES DESCRIBED HEREIN

CANCELS AND VOIDS THE WARRANTY.

The storage of machine when not working allows temperature to range between +2°C (+35,6°F) and +60°C (140°F), it

being understood all the other precautions.

IT IS STRICTLY FORBIDDEN TO USE THE MACHINE IN PRESENCE OF EXPLOSIVE

ATMOSPHERE OR FIRE HAZARD.

English

Soft ice-cream machine

6

Z15.069 V01

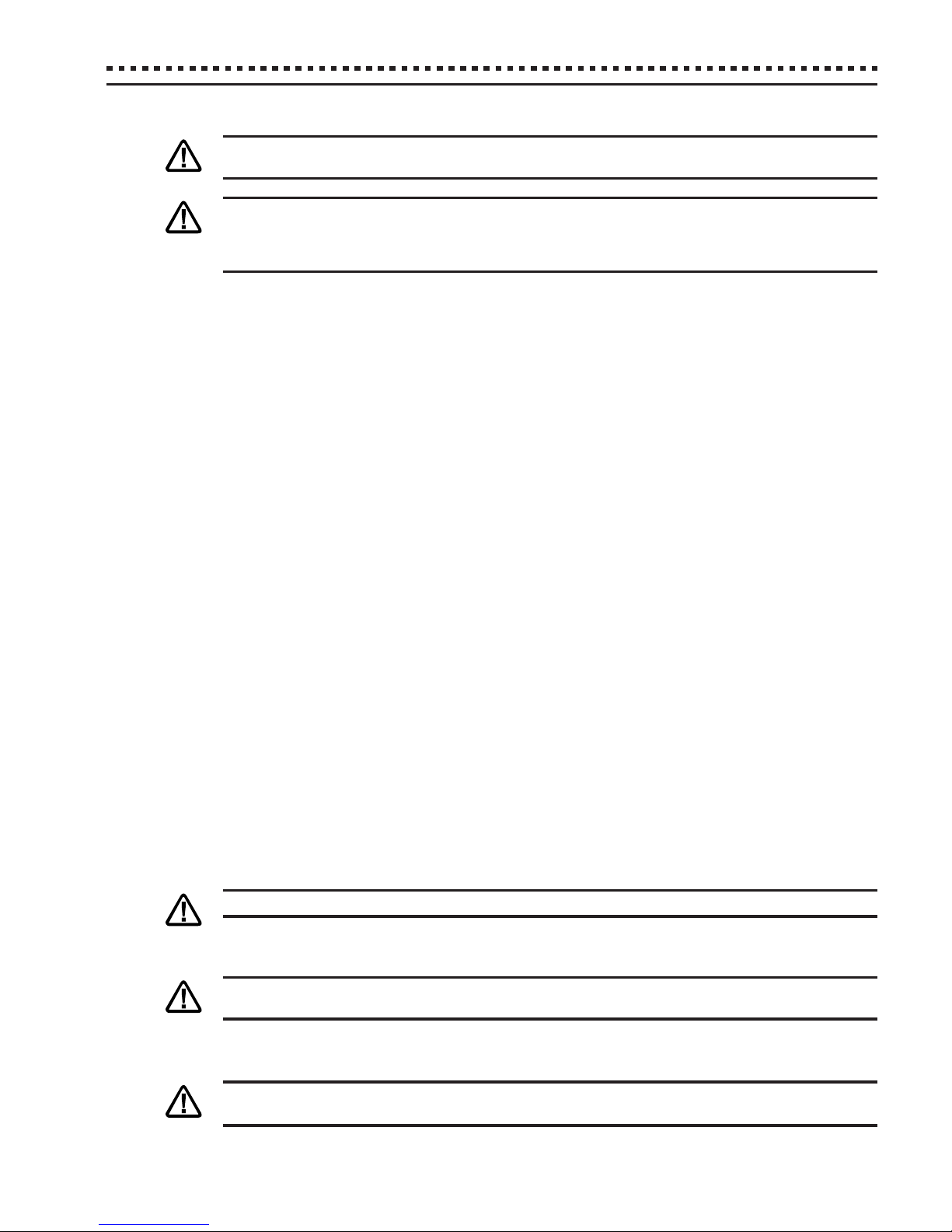

1.3 Intervention request – technical assistance

Every intervention request to the Customer Technical Service must be submitted via fax or email to the retailer where the

machine was purchased. The sell/assistance net of the manufacturer can be consulted on the internet site www.telme.it.

In the intervention request or technical assistance the following shall be specified:

1. type of machine, serial number and year of installation;

2. defects noticed;

3. retailer where the machine was purchased;

4. fiscal document bearing witness to the date of purchase by the user.

1.4 How to order spare parts

To request spare parts, please contact your local main dealer or consult the updated list of the authorized service centers

through TELME official website.

1. Press “TELME DEALERS” (A) key from the main website page.

2. The system displays the page where the updated list of dealers can be found and consulted.

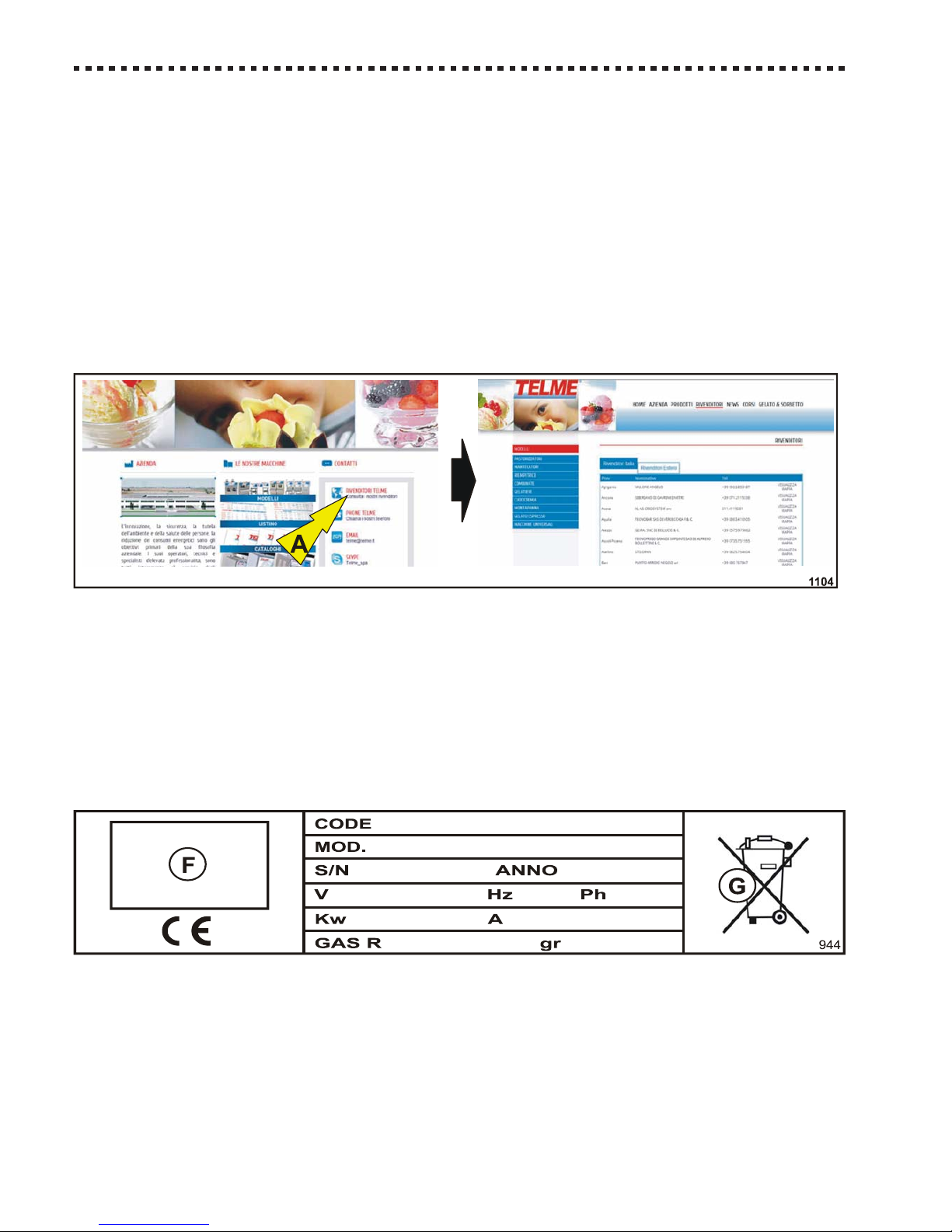

1.5 Marking

All identification data of the machine are engraved on its rating plate placed on the back of the machine. Such data shall

have to appear always on every document exchanged between the user and the manufacturer, e.g. upon every assistance

request or when requesting spare parts, etc…

The following ID plate is placed on the machines.

The technical data plate and CE marking must not be removed. It is located on the back part of the device and identifies:

- the name and address of the manufacturer [F];

- the machine code [CODE], the designation of the model [MOD] and the relative series number [S/N];

- the type and quantity of freezing gas contained [GAS];

- the year of construction [ANNO];

- the values of voltage and frequency [V], and the power [Hz] and current [Ph] consumption;

- the CE marking [9];

- dismantle symbol [G];

English

Operating instructions

7

Z15.069 V01

2 SAFETY

THE RULES LISTED BELOW MUST BE CAREFULLY READ TO BECOME AN ESSENTIAL

PART OF THE DAILY PRACTICE OF USING AND MAINTAINING THE MACHINERY, SO

THAT ANY ACCIDENT TO THE PEOPLE AND/OR DAMAGES TO THINGS SHALL BE

AVOIDED.

2.1 General safety notes

1. Do not try to start the machine until its operation has been clearly understood.

2. Should any doubt arise, even after having carefully and thoroughly read this manual, contact Technical Service.

3. Make sure that the whole staff using the machine is informed of all the instructions regarding safety.

4. Before starting the machine, the operator shall check the presence of any visible defects on the safety devices and

machine. In this case, immediately notify every apparent breakdown to the manufacturer or to the nearest Customer

Service Centre.

5. Daily check the correct operation of all the switches and safety devices.

6. Safety devices shall never be removed or made ineffective.

7. During the operations of maintenance, adjustment or repair it might be necessary to bypass some safety devices from

the service. This operation must be carried out by authorized personnel only.

8. It is imperative that all the plates and signs placed on the machine be promptly replaced, should they be damaged.

9. The operator must know the function and position of the STOP and START buttons.

10. Replace the broken parts with original spare parts, guaranteed by the manufacturer.

11. Never try anything too risky!

12. All interventions on live parts shall be carried out by authorized personnel only, who shall work only with the machine

unplugged.

13. Do not make any junctions in the electrical connections of electrical circuits.

14. Do not wear clothing, jewellery, accessories that may get caught in moving parts.

15. Keep the area surrounding the machine constantly free of any obstructions.

16. Always wear light gloves and caps and hair nets.

17. Pay utmost attention to all the caution, warning and hazards signs placed on the machine.

18. Enforce safety rules and make workers abide by them. Should any doubt arise, read this manual again before starting

to work.

19. The machine shall be solely used for the purposes associated with its design and according to what was contractually

laid down by the manufacturer.

20. It is strictly forbidden to open the protection panelling: the machine does not contain components that the user can

handle.

21. Do not lean against the machine while it is running.

22. Do not sit down on and/or lean against the machine components.

23. It is forbidden to apply any further device to the machine.

24. Clean the machine components, panels and controls, with soft cloths soaked in a food-grade solution.

25. Any use of solvent - such as alcohol or petrol or diluents - is forbidden for cleaning all the surfaces.

26. Do not start the machine nor the equipment, after drinking or while using drugs or psychotropic substances.

27. Disabled people are forbidden to operate this machinery.

28. Anyone under 18 years is strictly forbidden to operate this machinery.

The misuse of the machine may pose a hazard for the personnel working with it and damage the

machine.

For any problem which might arise during the machine service life and which was not included in this technical manual,

please contact our Customer Technical Service to solve the problem as soon as possible.

English

Soft ice-cream machine

8

Z15.069 V01

2.2 Definition of safety terms

The following terms shall be used thorough this manual in relation to safety:

Dangerous zone every zone inside and/or in the proximity of the machine where the presence of a person

poses a risk for the safety and health of the person.

Persona esposta: whoever finds themselves in a dangerous zone both completely and partially.

Operatore: person in charge of installing, operating, adjusting, servicing, cleaning, repairing,

transporting parts of the machine, and all other activities required for its running.

Safety devices component speci?cally designed by the manufacturer and put on the market separately

from the machine to perform safety functions. Safety component is that device whose

failure impairs the safety of exposed people.

2.3 Safety symbols and labels

The following signs are applied to the machine: prohibition signs, indication signs and warning signs.

This symbol indicates the electrocution risk.

When this sign is present, the operator shall move closer to the machine

only when disconnected from power supply. In this case always wear

dielectric gloves.

This symbol indicates there is a risk of burning.

In case this sign is present, the operator shall get close to the machine

only when all hot parts have cooled down. Before coming in contact,

make sure the surface has cooled down; in any case, always wear

thermal gloves.

2.4 Correct use of the machine

Softgel was designed and manufactured to produce Ice cream and Frozen yogurt. This process takes place inside the

cylinder where the product is continuously blended.

IT IS STRICTLY FORBIDDEN TO USE THE MACHINE FOR OTHER PURPOSES WITHOUT THE

PROPER AUTHORIZATION BY TELME S.p.A., WHICH SHALL NOT BE HELD LIABLE FOR ANY

DIRECT OR INDIRECT DAMAGE THAT MAY RESULT FROM AN IMPROPER USE OF THE MACHINE.

2.5 Operator’s position (Workstation)

The machine requires one operator in charge of loading the mix for Ice cream and Yogurt, starting the processing and

unloading the processed product. The operator shall stand in front of the machine.

English

Operating instructions

9

Z15.069 V01

3MACHINE TECHNICAL SPECIFICATION

The machine specifications are the following:

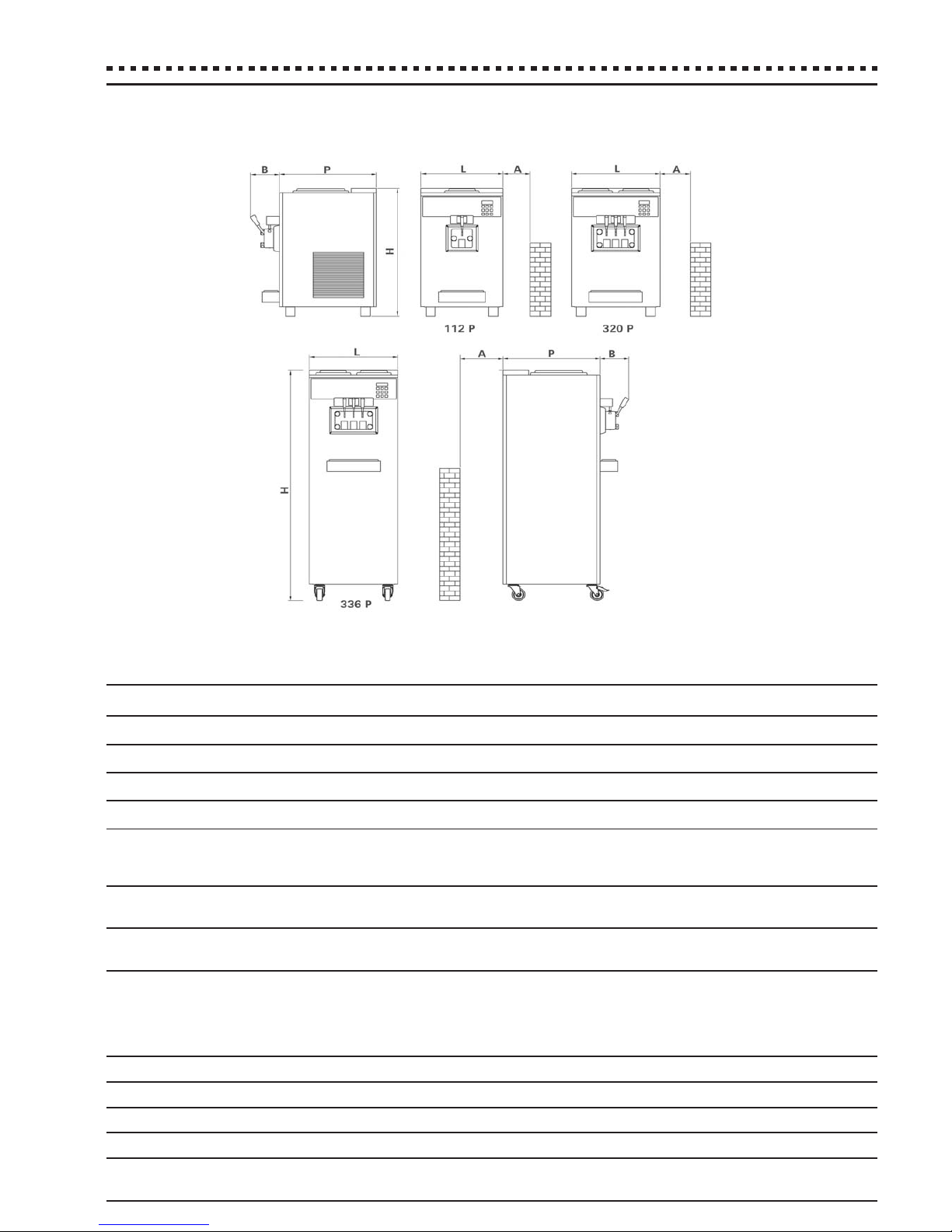

3.1 Data and dimensions of the machine

Name Soft ice-cream machine

Model Softgel 112 P Softgel 320 P Softgel 336P

Year of manufacture 2012 2012 2012

Net weig Kg 110 140 200

MAX ambient temperature °C +35 +35 +35

Air condensation

(room temp.26°C) (pressure) bar 18 18 18

(temperature) °C 42 42 42

Evaporation (pressure) bar 0,6/1 0,6/1 0,6/1

(temperature) °C 42 42 42

Coolant (type) R404 R404 R404

(quantity) gr. 900 1100 1800

Dimensions L (mm) 450 550 600

P (mm) 600 600 700

H (mm) 820 820 1500

A (mm) 500 500 500

B (mm) 180 180 180

Hourly production Kg 9 15 27

Hourly production cones 75g N° 120 200 360

Riserva miscela Lt. 7 2x7 2x14

Potenza Kw 2,1 2,9 4

Power supply voltage Volt/Hz/Phases 230/50/1 230/50/1 400/50/3 400/50/3

Amp. 11 15 12 11

English

Soft ice-cream machine

10

Z15.069 V01

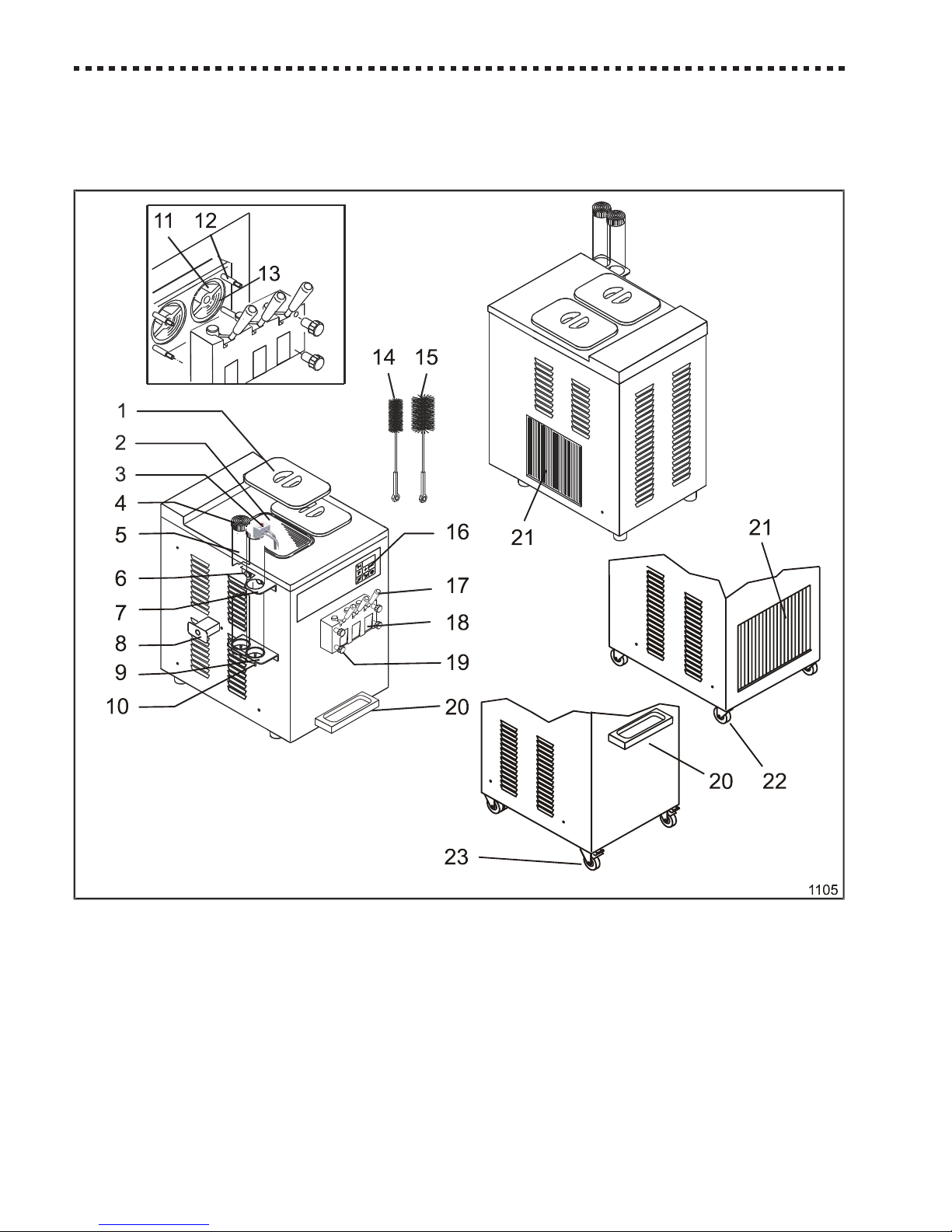

1 Tub lid

2 Spare mixture tub

3 Pump

4 Cones holder cap

5 Cones holder

6 Cones holder brackets' fixing

knob

7 Cones holder top bracket

8 Side collection box

9 Cones holder bottom bracket

10 Cones holder valve

11 Beater

12 Tap fixing rod

13 Cylinder

14 Small brush

15 Large brush

16 Control panel

17 Mixture level control

18 Tap

19 Tap fixing knob

20 Front drip tray cup

21 Air condenser grill

22 Rear wheel (no brake) (only

mod. softgel 336)

23 Front wheel (with brake) (only

mod. softgel 336)

3.2 General description of machine units

Loading...

Loading...