Page 1

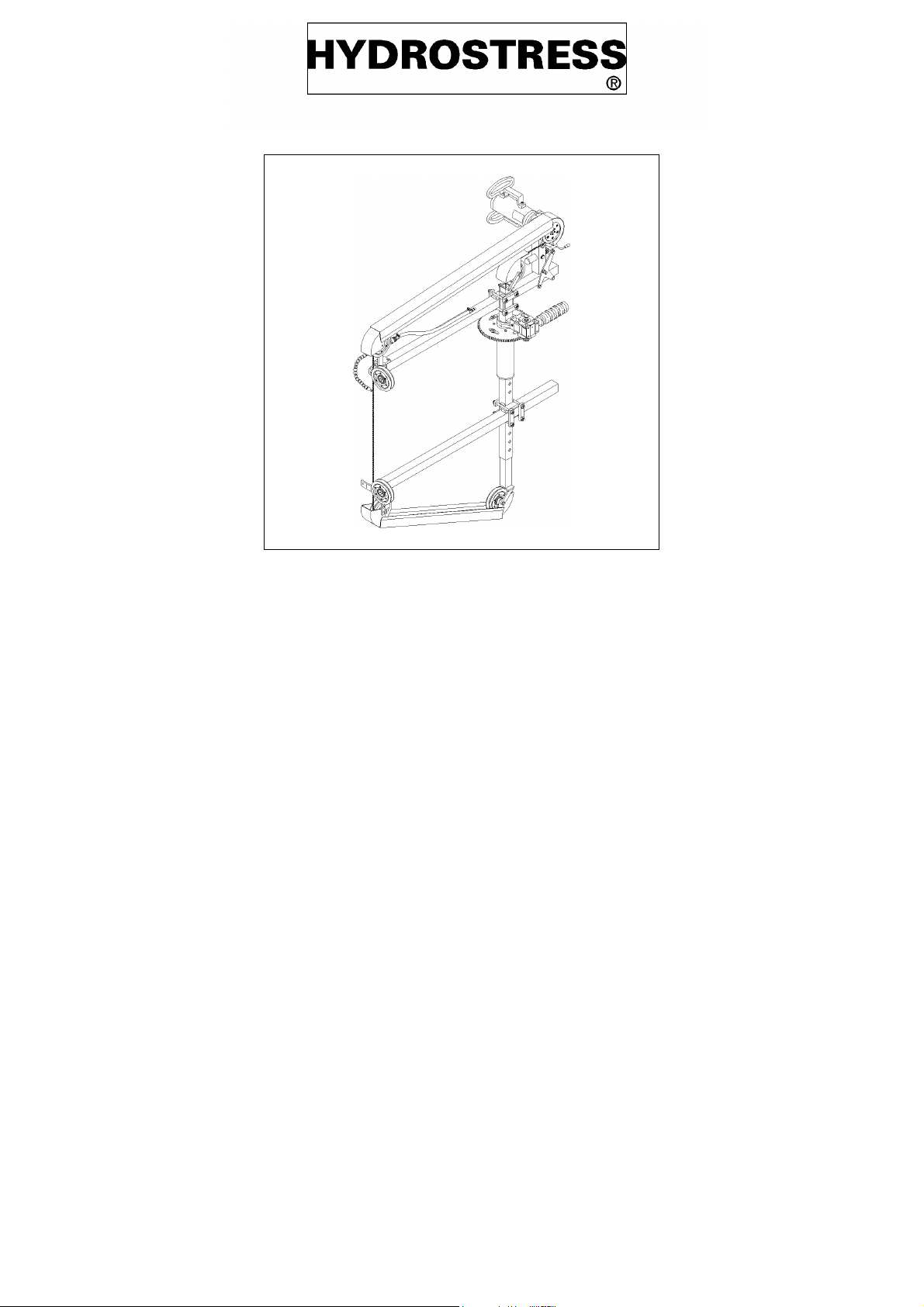

Circular wire saw system SL

Operating instructions

Spare parts list

Page 2

SL

0.1 Introduction

Dear customer,

you have decided in favor of a progressive, proven

HYDROSTRESS equipment, hence for a stand-

ard of technological leadership.

Due to our efforts in the field of quality assurance the

Circular Rope Saw Type SL represents a Swiss top

performance product:

• High sawing performance

• Reliable operation

• High mobility

• Convenient handling

• Low maintenance cost

Only original HYDROSTRESS spare parts assure

quality and compatibility.

If proper maintenance work is neglected or done

incompetently we can not fulfill the guarantee obliga-

tions set forward in our terms of delivery.

All repair work is to be made by professionally trained

persons only.

0.2 Validity of this Operation

Instruction

This Operating Instruction is exclusively valid for

the following equipment:

Circular Rope Saw Type SL Index 000

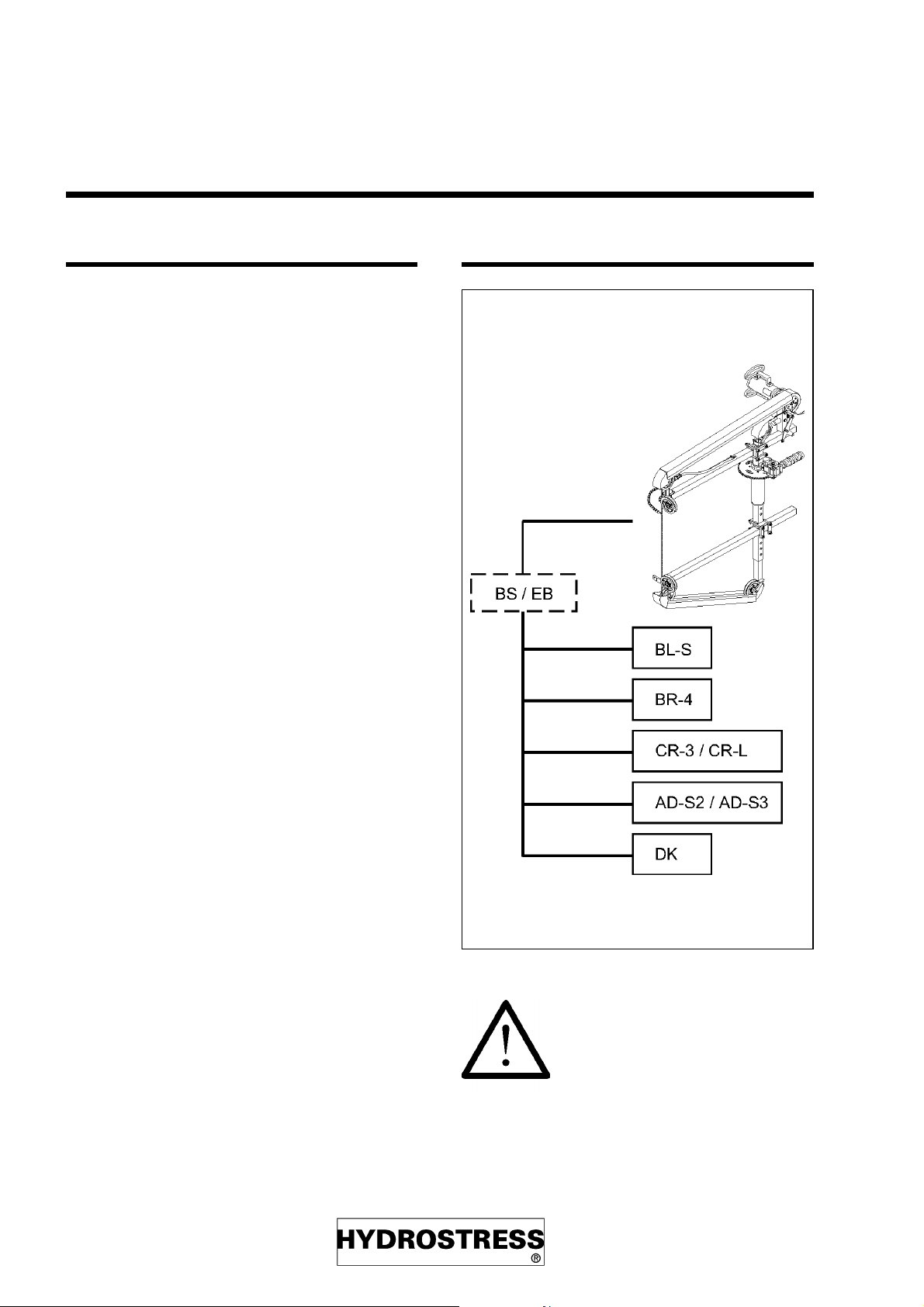

0.3 System range definition

This Operation Instruction describes the use of

the Circular Rope Saw Type S including the

matching electric drive motor type EM and the

hydraulic drive motors.

The Circular Rope Saw Type SL must only be

operated after the respective Operating Manual

has been paid attention to.

Spare parts and maintenance instructions for

the drive unit engaged in the individual case can

be found in the respective Operating Manual.

Our customer service is at your disposal to maintain

your equipment in perfect condition.

We wish you trouble-free and unproblematic wor-

king with your HYDROSTRESS equipment.

HYDROSTRESS AG

The Management

Copyright © HYDROSTRESS AG, 1998

HYDROSTRESS AG

Witzbergstrasse 18

CH-8330 Pfäffikon

Switzerland

Telefon 0041 1 950 10 74

Telefax 0041 1 950 10 18

Hotline 079 / 608 19 07

0.3.1 Operating Manuals of drive units

Indications for the use of drive units are meant

to increase the safety of operators. However for

safe operation of drive units the respective Operating Manual consulting the respective Operating Manual is indispensable!

page 2 sl9806e

Page 3

SL

0.4 Table of contents

0.1 Introduction 2

0.2 Validity of this Operation Instruction 2

0.3 System range definition 2

0.4 Table of contents 3

1 Safety instructions 4

1.1 Basic provisions 4

1.2 Designated usage 6

1.3 Before starting work 6

1.4 During sawing 7

1.5 After finishing work 7

2 Technical Data 8

2.1 Dimensions 8

2.2 Attachable equipment, hydraulic 8

2.3 Attachable electric motor, electric 9

2.4 Design 10

2.5 Function with hydraulic drive 11

2.6 Funktion electric drive 12

2.7 Protection material 13

3 Preparation for work 14

3.1 Procedure 14

3.2 Select drive unit and sawing

motor (hydraulic) 15

3.3 Calculation of rope length 16

3.4 Secure construction site 17

3.5 Secure part to be sawn out 17

4.5 Mount protection hoods 23

4.6 Water cooling 23

4.7 Connection of water in case of using a

hydraulic unit 23

4.8 Connection of water in case of using

electric motor "EM" 24

5 Sawing 25

5.1 Before sawing 25

5.2 Sawing, hydraulic 25

5.3 Sawing, electric 26

5.4 Trouble shooting 27

5.5 After sawing 27

6 Maintenance 28

6.1 Maintenance table 28

7 Repair 29

7.1 Connection and repair of rope 29

7.2 Connecting the rope by joint lock 29

7.3 Connecting the rope by repair sleeve 30

7.4 Connecting the rope by threaded lock 31

8 Transportation, shut-down , storage,

disposal 32

8.1 Transportation 32

8.2 Shut-down, storage 32

8.3 Disposal 32

8.4 Accessories 32

4Set-up 18

4.1 Fastening of system 18

4.2 Connecting the drive unit 20

4.3 Connecting the electric module 21

4.4 Mounting of rope 22

9 Spare parts list 33

sl9806e page 3

Page 4

Safety instructions SL

1 Safety instructions

1.1 Basic provisions

1.1.1 Dangers at work on construction

sites

The equipment is built in accordance with state-

of-the-art and generally accepted rules of safety

techniques. Nevertheless its operation may ef-

fect hazards to life and limb of the user or third

persons resp. damage to the equipment or to

other objects of value. Pay attention to the

special working conditions at a construction site.

Protect yourself and others within your area of

responsibility extensively against the multiple

dangers!

1.1.2 Qualification of operating personnel

The operators need to be introduced and

trained for work by experienced experts.

For maintenance and repair specifically trained

personnel has to be engaged.

HYDROSTRESS can assist you for training.

1.1.3 Read the Operating Manual and

inform your co-workers!

This Operating Manual contains important indications for

operating the equipment both

safely and economically.

The owner of the equipment needs to make sure

that the instructions of the Operating Manual are

paid attention by each and every person who

will in any possible way be dealing with the

equipment or the connected auxiliary and ope-

rating materials.

The Operating Manual has to be made available

at the working site at all times

Noise impact (sound level)

The noise level during work lies

above 90 dB(A). This noise

strain may permanently damage your hearing. Therefore during operation always wear ear

protection devices.

page 4 sl9806e

Page 5

SL Safety instructions

1.1.4 Recognize the Safety Alerts!

Danger: Pay attention to the following phrases,

their symbols (characteristics, displays, mar-

kings) and their meaning:

Danger:

Specific information for prevention of bodily injuries

Attention:

Specific information for prevention of da-

mage to the equipment

1.1.5 Personal protective clothing

During drilling, sawing, biting, and pressing of

concrete and stone

wearing protective clothing is necessary to give

protection against the following dangers:

Source of danger protective clothing:

falling pieces: helmet, steel

reinforced footwear

moving, sharp-

gloves

edged pieces:

flying stone pieces,

goggles

flying sparks:

slipping: footwear with non-slip

soles

Advice:

Specific information for economic use

of the equipment

.

noise: earmuffs

contamination of

breathing mask

respiratory tract:

sl9806e page 5

Page 6

Safety instructions SL

1.2 Designated usage

The system is designated for sawing with dia-

mond ropes of Ø11mm into the materials

quoted below.

Any different usage may create risks which are

not described in this Operating Manual and will

void any warrantee by HYDROSTRESS.

Process with this equipment exclusively:

• Concrete, rock, masonry, asphalt

Other materials are not allowed for proces-

sing, especially:

– Wood, plastics and glass

1.2.1 Sawed-off pieces

These pieces may weigh heavily. Example: A

cube of concrete of 1m edge dimension (~33")

weighs about 2.5 tons (~5600 lb.). Secure such

pieces against dropping or tipping over and

close off that area of the construction site!

1.2.2 Drive units and accessories

1.3 Before starting work

1.3.1 Static of the edifice

The sawing of large openings can impair the

static of an edifice. Therefore the sawing of large

openings must be planned in coordination with

construction static experts.

1.3.2 Tension reinforced concrete

Inform yourself if any tension rods are situated

within the range of your planned cuts. Sever

these only after explicit authorization.

1.3.3 Emergency Stop

Make sure that you can promptly stop the

machine in case of emergency (see “Emergen-

cy Stop” in this Operation Instruction)!

1.3.4 First Aid in accidents

Find out how to organize help fastest possible

in case of accident!

Use the machine or equipment exclusively with

the recommended drive units or equipment and

1.3.5 Water-, Gas and Power-lines

accessories (see “Attachable units” or “Attacha-

ble equipment” and “Accessories” in this Ope-

ration Instruction)

Make sure that such lines within your cutting or

drilling range are out of operation! Obtain infor-

mation whether such lines may be cut through!

1.2.3 Accident prevention regulations in

your country

Observe the general and particular accident

prevention regulations of trade associations and

federations in your country!

1.3.6 Reinforcement rods

Obtain information whether you may sever pos-

sibly present reinforcement rods in the course

of the cut or bore.

page 6 sl9806e

Page 7

SL Safety instructions

1.3.7 Organize your working place

Organize your working place properly! Thereby

you will considerably reduce accident hazard!

1.3.8 Lighting of working place

Provide for sufficient lighting of working place.

1.3.9 Protection gear

Never start sawing before all protection gear is

attached and in place.

1.3.10 Flushing water

Ascertain that flushing water can not spill over

into electric installations. Avoid material dama-

ges by flushing water by exercising good con-

trol of the water’s draining flow.

1.4.3 Rotating and moving parts

Keep away from the rope and the pulleys. In

order to avoid being caught by rotating or mo-

ving parts wear tight clothes, and if having long

hear, wear a hair net!

1.5 After finishing work

After work pull out the power plug of the drive

unit to prevent unintentional switching on!

1.5.1 Removal of concrete and rock

pieces

Utilize suitable lifting equipment for the removal

of those pieces, in order to avoid injuries!

1.4 During sawing

1.4.1 Rope ruptures

A rope rupture must be taken into account at any

time.

Observe the measures for avoiding rope ruptu-

res (see “Malfunction remedy”).

1.4.2 Motorized forward feed

Equipment with motorized forward feed are not

automates. During operation they must be su-

pervised at all times. A emergency shut-off must

be possible at any time.

sl9806e page 7

Page 8

Technical Data SL

2 Technical Data

2.1 Dimensions

2.1.1 Sawing diameters

min. 50 cm

max. 200 cm

2.1.2 Thickness

max. 60 cm

2.1.3 Weights

Weight 122 kg (~276 lbs.)

separable into subassemblies of max. 20 kg ea. (~43

lbs.)

2.1.4 Drive wheel

effective diameter

2.2 Attachable equipment, hydraulic

for rope grip Ø 180mm(~7-1/8”)

2.1.5 Diamond ropes

Diameter Ø 11mm (~7/8”)

Length 621 cm max. (~20’4-11/16”)

351 cm min. (~11-1/2’)

2.1.6 Cutting speed with electric motor

V = 26m/s

2.1.7 Cutting speed with hydraulic motor

See chapter 3.2

Fig.sl_conn.tif

Do not use any other

equipment!

page 8 sl9806e

Page 9

SL Technical Data

2.2.1 Particular characteristics of the

various drive units

The power output differs from drive unit to drive

unit. Therefore:

– choose correct sawing motor

– choose correct level at the drive unit

(see "Selecting drive unit and sawing motor",

Chapter 3.2.)

2.3 Attachable electric motor, electric

2.3.1 Which extension arm for what

diameter?

Fig. sl_conn2.tif

Do not use any different

electric motor or control unit!

Fig.auslzent.tif

Extension arm Ø

750 mm (~2-1/2’) 500 - 700 mm (~1’7-

1/2” – 2’3-1/2”)

1500 mm (~5’) 700 - 2500 mm (~2-

1/2’ – 8’2-1/2”)

2.3.2 The center tube

Center tube thickness "D" max.

1000 mm (~3’3-3/8”) 0.6 m (~2’)

sl9806e page 9

Page 10

Technical Data SL

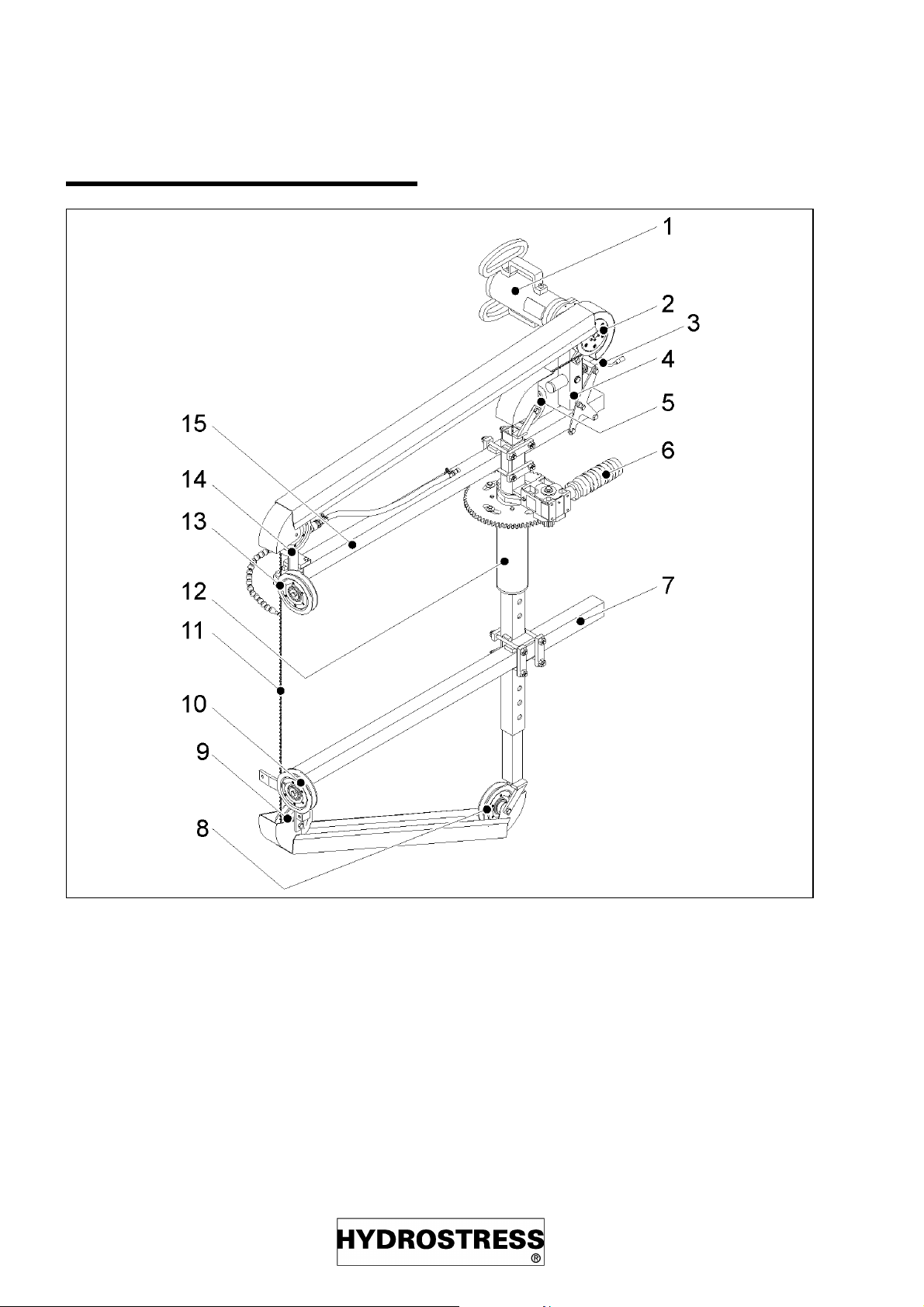

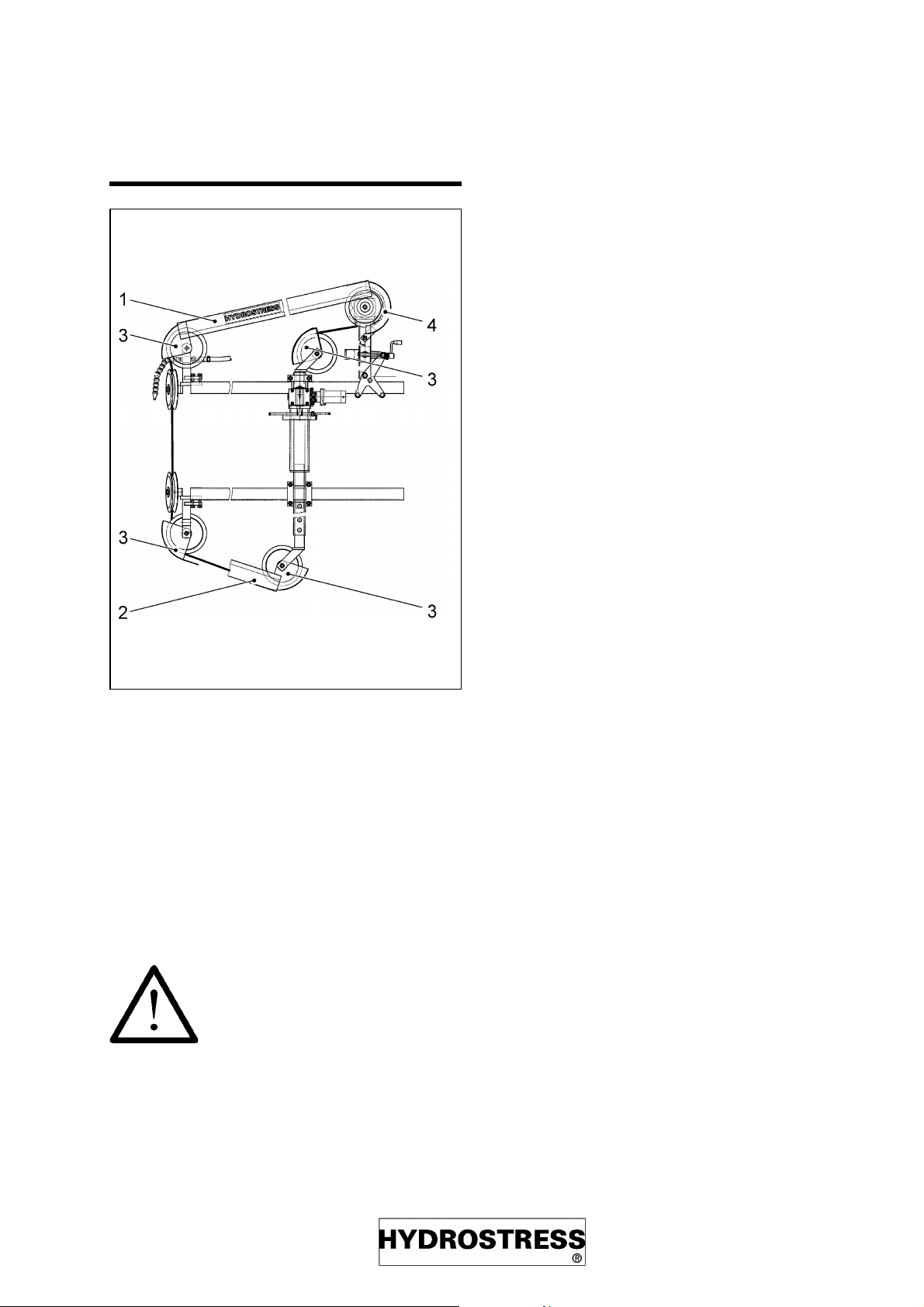

2.4 Design

Fig.aufbau.tif

1) Electric motor or hydraulic motor

2) Drive wheel

3) Crank for rope tension

4) Swivel rack

5) Central reversal pulley, top

6) Forward feed motor electric or hydraulic

7) Extension arm, bottom

8) Central reversal pulley, bottom

9) Deflection pulley, bottom

10) Guiding pulley, bottom

11) Diamond rope

12) Center tube

13) Guiding pulley, top

14) Deflection pulley, top

15) Extension arm, top

page 10 sl9806e

Page 11

SL Technical Data

2.5 Function with hydraulic drive

Hydraulic drive

2.5.1 Guiding and tightening of rope

The rope is being guided by ...

– the drive wheel (2)

– two central deflection pulleys - top and

bottom (5 and 8),

– two deflection pulleys top and bottom

(9 and 14),

– and by the guiding reels top and bot-

tom (10 and 13).

> which engages with the gearwheel circumfe-

rence at the support.

2.5.3 Rope drive, hydraulic

> When the Main circuit of the drive unit is

opened,

> the sawing motor (1) will turn and will drive

> the drive wheel (2) and thereby

> will drive the rope.

The speed of the rope is determined by...

1) ... the oil flow from the drive unit

2) ...flow intake of the sawing motor

(controllable)

2.5.4 Emergency Stop

The rope is being tightened by ...

> turning the tension spindle (3) clockwise,

> by which the swivel rack (4) tilts outward

> and the diamond sawing rope is being

tightened across the drive wheel (2)

2.5.2 Circular motion /Forward feed,

hydraulic

The movable portion of the system turns around

the center tube (12), when...

> the connected forward feed circuit at the dri-

ve unit is being opened,

> the hydraulic forward feed motor (6) will turn

> and through the transmission gear in front of

the feed motor

The system can only be stopped at the drive unit. Observe

also the Operating Manual of

the drive unit.

> will drive the cogwheel (on the feed transmis-

sion gear)

sl9806e page 11

Page 12

Technical Data SL

2.6 Funktion electric drive

Electric drive

2.6.1 Guiding and tightening of rope

The rope is being guided by ...

– the drive wheel (2)

– two central deflection pulleys - top and

bottom (5 and 8),

– two deflection pulleys top and bottom

(9 and 14),

– and by the guiding reels top and bot-

tom (10 and 13).

> which engages with the gearwheel circumfe-

rence at the support

2.6.3 Rope drive, electric

> When the main drive unit is switched on at

the electric control,

> the electric sawing motor (1) will run

> and drive the drive wheel (2)

> and thereby the rope.

The speed of the rope is determined by...

1) ...the number of revolutions of the

electric drive motor (not controllable)

2) ...the diameter of the drive wheel

(not controllable)

The rope is being tightened by ...

> turning the tension spindle (3) clockwise,

> by which the swivel rack (4) tilts outward

>and the diamond sawing rope is being

tightened across the drive wheel (2)

2.6.2 Circular motion/Forward feed,

electric

The movable portion of the system turns around

the center tube (12), when...

> the connected forward feed is switched on

at the electric control,

> the electric feed motor (6) runs

> and through the transmission gear (in front

of the feed motor)

2.6.4 Emergency Stop

The system can only be stopped at the electric control unit.

Observe also the Operating Manual of the electric control unit.

> drives the cogwheel (at the feed transmissi-

on gear)

page 12 sl9806e

Page 13

SL Technical Data

2.7 Protection material

Fig.schutz.tif

1) Splash channel long/short, top (2

pcs. ea.)

2) Splash channel long/short, bottom (2

pcs. ea.)

3) Splash shielding, deflection pulleys

(4pcs.)

4) Splash shielding, tension reel (1 pc.)

2.7.1 Protective provisions

Never start sawing before having all protective devices in

place

sl9806e page 13

Page 14

Preparation for work SL

3 Preparation for work

3.1 Procedure

Always proceed as follows:

1) Select drive unit and sawing motors

(hydraulic only)

2) Calculate length of rope

3) Secure construction site

4) Secure parts designated for sawing

out

5) Fix system solidly fast

6) Connect drive unit or electric motor

including control unit

7) Put on rope

8) Put on safeguard hood

9) Connect water

10) Start sawing

11) Conduct maintenance work

page 14 sl9806e

Page 15

SL Preparation for work

3.2 Select drive unit and sawing

motor (hydraulic)

Hydraulic drive

Through correct selection of drive unit, power

level (in case of multi-level drive units) and

Sawing motor the correct cutting speed will be

obtained, hence:

– optimum sawing performance

– best endurance of rope

– few rope ruptures

• Set the mark Ø 180 onto

the range SK-SD (1:1) and ...

• ... depending on output rate of drive unit

read out the correct sawing motor.

3.2.2 Drive units

Multi-level drive units: Use Level II or higher.

When hitting upon reinforcement steel rods one

can then switch down.

BR-3

26 l/min 30 l/min 33 l/min 40 l/min 42 l/min 45 l/min 47 l/min 50 l/min

11 ccm

22

16 ccm

18 ccm

3.2.1 Specifics for the use of the "profi

DK

(I)

m/s26 m/s

- - - 24

-- -21

CR-3

(I)

BR-4

28

CR-3

m/s

(I)

(II)

DK

(II)

34 m/s- ---

m/s 24 m/s 26 m/s 28 m/s 29 m/s

m/s 22 m/s 24 m/s 25 m/s 26 m/s

BR-3

Fig.drehztab.tif

disk"

The effective diameter of the drive wheel measures 180mm (~7-5/64”). Therefore:

CR-3

AD-S3

(III)

(II)

(II)

AD-S2

AD-S3

DK

(III)

(I)

BL-S

CR-L

Work only with the designated drive units

and only on the recommended levels

(base: v = 20...30 m/s (~22...33 yards/second))

sl9806e page 15

Page 16

Preparation for work SL

3.3 Calculation of rope length

The minimum length of the rope results from:

– Invariant = 331 cm

– two times thickness "D" of building

– "A" according to saw-Ø

from table (see bottom)

ØA

0.5 m 0.0

1.0 m 55 cm

1.5 m 115 cm

2.0 m 140 cm

2.5 m 170 cm

L

= 331 + 2 x D + A

total

Fig. dicke.tif

Example:

Thickness D = 45 cm

Ø = 1.5 m, therefore A = 115 cm

L

= 331 + (2 x 45) + 115 = 536 cm

total

3.3.1 Length of extension arm and center

tube

Depending on diameter 2 different extension

arms are available.

See "Which extension arm for what application

" and "The center tube " (Chapter 2.3.1. and

2.3.2.) and "Spare parts list".

page 16 sl9806e

Page 17

SL Preparation for work

3.4 Secure construction site

Secure danger zone and make sure that nobody

enters that zone during active work.

3.5 Secure part to be sawn out

Secure the parts to be sawed

out in their initial position, such

that...

1) ... the rope will not be jam

2) ... nobody will be endangered by uncontrollable motion of the parts

being sawed out. Depending on situation utilize these auxiliary means

or a combination thereof:

– Wedges

Example:

Securing with prop-jacks in three steps

(Cut into the ceiling, view from below!)

– Connecting straps

– Supporting it

– Suspending it by crane or from building

Secure the parts being sawed out according to

their weight (approx. 2.5 to per m

3

)

(~200 lbs. per cu.ft) and position.

Fig. sichern.tif

sl9806e page 17

Page 18

Set-up SL

4 Set-up

4.0.1 Set-up for first operation

The system is supplied ready for use. The pro-

cedures described under ”Set-up” apply also to

the first operation run of a new machine.

4.1 Fastening of system

4.1.1 procedure

Fig.mont5.tif

Fig.mont4.tif

• Drill Ø 100 mm for center tube (6)

• Drill Ø 15 mm for rope at a distance of the

sawing radius (1/2D!)

Fasten center tube assembly (6) with two

hammer plugs M12 (5)

Fig. mont3.tif

• Insert central deflection reel (3) into top of

central tube unit (6)

• and tie fast with bracket (7) (Central de-

flection reel at bottom analogous)

• Insert upper extension arm (2) into the

receptacle and tighten up (lower extension

arm analogous)

page 18 sl9806e

Page 19

SL Set-up

• Mount top reel pair (1) in accordance with

sawing direction (bottom reels analogous)

• Mount drive tightening pulley assembly (5)

onto the upper extension arm (2)

• Put on upper shielding (4) (lower shielding

analogous)

• Mount rope (see chapter 4.3)

Fig. mont1.tif

The pairs of reels (6 and 8) must be mounted anti-symmetrically into the extension arm (2), in order to be able to cut in

the cutting direction designated by the

arrows (S). (See also chapter 4.1.2.

"Change of sawing direction ")

sl9806e page 19

Page 20

Set-up SL

Change of sawing direction

Fig. mont6.tif

4.2 Connecting the drive unit

Hydraulic drive

Fig. mont7.tif

The reels (16) can be mounted in two different

positions depending on direction of sawing.

Fig. anschl.tif

H: Sawing motor to the main circuit

V1: Hydraulic motor for forwardb feed motion

to the feed circuit 1

V2: Forward feed 2 remains disconncted

W: Connect water ALWAYS first to the drive

unit (see also chapter 4.7. "Connecting

water for use with hydraulic drive unit ")

Never connect or decouple hoses while the drive unit is running. Set control valves to

position "0".

To observe:

– First clean couplings thoroughly.

– Connect angular shape hose cou-

plings with the sawing motor.

page 20 sl9806e

Page 21

SL Set-up

– Connect straight hose couplings with

the drive unit.

– Slide hose coupling onto the counter-

part until snapping in with an audible

click.

– Turn securing ring of the coupling.

– Hoses not engaged in operation

should be coupled among themselves

for couplings’ protection.

– Never engage couplings by force.

– If hoses appear to require force to con-

nect they are likely to be under pressure (see below).

Relieve pressure of hose.

1) Repeatedly actuate m ain or feed valve at drive unit.

2) Connec t the supplied pr ess ure relief

unit to the hose and screw in.

4.3 Connecting the electric module

Electric drive

Fig. anschdma.tif

1: Control handle

2: Electric connection

3: Electric connection for the main motor

4: Electric connection for the forward feed mo-

tor

5: Water

sl9806e page 21

Page 22

Set-up SL

4.4 Mounting of rope

Running direction of rope

Correct running direction of the rope is important

for satisfactory endurance.

A used rope must be run always in the same

direction as initially used.

The running direction of the rope can be recognized by the following attributes:

– Arrow on new rope

– Wear of the used rope: thin portion of

conical bead points forward

Rotational direction of the rope

sawing system

Twisting of rope

In order to avoid eccentric wear of the diamond

beads the rope needs to be twisted at the point

of connection. A new rope of Ø 11mm needs to

be twist by one turn per 1 meter of length. In the

course of increasing wear more twisting will

become necessary. The following table is valid

for a rope of a length of 10 m.

Ø of rope total

Turns

11 10

10.5 13

10 17

9.5 22

928

With threaded connectors additionally 5 turns in

order to compensate for the threading.

Fig.drehr.tif

Inserting the rope into the

equipment, connecting and

tightening

Insert the rope into the equipment in the correct

running direction, connect it (see “Connecting

and repairing of the rope”, chapter 7) and tighten

it reasonably with the crank (14).

page 22 sl9806e

Page 23

SL Set-up

4.5 Mount protection hoods

• Put on protection hood on top and bottom,

and never remove during sawing

Never keep sawing without all

the correctly mounted protection hoods!

(see spare parts list)

4.6 Water cooling

Why is water needed?

– Flushing out sawdust from the cut

– Flushing the rope of sawdust

• Open water cock

Pressure: min. 1, max. 10 bar /

5

min. 1x10

Make sure that the water supply is not

interrupted during operation.

Pa, max. 10x105Pa

– Cooling the rope

– Cooling of electric motor, in case of

using EM (Water feeder connected directly to the motor)

– Cooling of the electric motor and the

oil cooler, in case of using a hydraulic

drive unit (Water feeder connected to

the equipment)

4.7 Connection of water in case of

using a hydraulic unit

Hydraulic drive

1) Connec t water feeder with coupling

to the water nipple of the hydraulic

unit

2) Connect water hose of the hose

package between the drive unit and

the nipple of the upper reel pair

3) Dir ect water spout onto the r ope be-

fore switching on

Fig.wasser.tif

4) W ater input to the unit (1)

5) Ex tend water hos e of the hose

package by the supplied water hose

and connect to SL unit (2).

6) Dir ect water spout onto the r ope be-

fore switching on

sl9806e page 23

Page 24

Set-up SL

4.8 Connection of water in case of

using electric motor "EM"

Electric drive

1) Connec t water feeder with coupling

to the water nipple of the electric motor

2) Connect supplied water hose between the electric motor and the

nipple of the upper reel pair

3) Pos i tion water spout befor e switching on

• Open water cock

Pressure: min. 1, max. 10 bar /

5

min. 1x10

Pa, max. 10x105Pa

Fig.waansdma.tif

Make sure that the water supply is not

interrupted during operation.

page 24 sl9806e

Page 25

SL Sawing

5 Sawing

5.1 Before sawing

• check if all screws are fastened tightly

• control rope tension and if necessary

readjust (A) with the crank (3)

5.2 Sawing, hydraulic

Hydraulic drive

Switching water on

• Open water cock at drive unit

Switch on drive unit

• Set all valves to position "0"

• Start drive unit (see Operating Manual of

drive unit)

Select level

Fig. vors1.tif

• With multi-level drive units, select the pro-

per level

(see "Selecting drive unit and sawing motor ”, chapter 3.2.)

Switch on rope drive

• Set main valve at the drive unit to position

"I"

The rope will now be moving (C)

Switch on forward feed (B)

Increase forward feed pressure up to...

... main pressure: 100...150 bar

sl9806e page 25

Page 26

Sawing SL

When hitting upon reinforcement steel structu-

When hitting upon reinforcement steel

structures reduce main pressure to 100

bar by reducing forward feed pressure.

Stopping the rope

res the load of the rope will in all cases be

adjusted for optimum relation by the automatic

feed unit through reducing the forward feed

pressure.

• Switch off forward feed

• Let the rope run freely for a few seconds

• Switch off rope drive

5.3 Sawing, electric

Electric drive

Switch on water

• Open water cock at the electric motor

Optimum forward feed pressur e

Fig. vordruck.tif

Switch on electric motor/rope drive

• Push button at electric control unit DM-A

• Wait for the electric motor to start (centrifu-

gal force coupling)

The rope will now be moving. (C)

Switch on forward feed (B)

The forward feed speed is load dependent always regulated for the optimum range by the

automatic feed control unit.

• The forward feed pressure is to be set in

such a way as to have the rope enter into

the building object under an angle of approx. 45°.

1) W ith less slanted rope entry the cut

will become less accurate

2) W ith steeper rope entry the cutting

performance will be low

Stopping the rope

• Switch off forward feed

• Let the rope run freely for a few seconds

• Switch off rope drive

page 26 sl9806e

Page 27

SL Sawing

5.4 Trouble shooting

• Observe also the Operating Manual of the

drive unit

In case of rope rupture

• excessive forward feed pressure

• to narrow radii > forward feed too fast and

rope tension too low

• Reinforcement elements being sawed with

a too narrow wrap-around radius > forward

feed too fast and rope tension too low

• rope connecting joint too long (=to stiff) >

use shorter pressed sleeve joint

In case of asymmetric rope wear

Diamond beads getting pushed

together

• Plastic gets soft because rope is being coo-

led insufficiently

Rope getting pulled out of joint

sleeve

• Squeezed portion of rope in joint sleeve

too short

If the rope does not run despite the

electric motor is running

• Replace centrifugal weights of the electric

motor

5.5 After sawing

• too high forward feed pressure

• rope not properly twisted (see "Rope twi-

sting " chapter 4.4.3.)

In case of insufficient cutting

performance

• Cutting speed too low

(see "Selecting drive unit and sawing motor ")

If rope slips on drive wheel

• Rope tension too low

• Drive wheel cover band worn too much

Excessive rope wear

• too little water

• Switch off drive unit or electric motor

• Close water cock

• Pull out power plug

• Remove protection hoods

• Wash off Circular Rope Saw Type SL with

water

• Dismantle and remove rope

• Conduct daily maintenance work

(see "Maintenance", chapter 6)

• Cutting speed too low

• Running direction of rope inverted

sl9806e page 27

Page 28

Maintenance SL

6 Maintenance

6.1 Maintenance table

Disconnect power plug before

any maintenance work

Conduct the following maintenance work within

the designated periods in order to warrant:

– Safety for the user

– Optimum performance

– Ready to use at any time

interval activity remarks

GDLO\ FKHFNUROOHUOLQLQJIRUZHDU UHSODFHOLQLQJEHIRUHLWLVFRPSOHWHO\

ZRUQRII

FOHDQV\VWHP

FKHFNGHIOHFWLRQUROOHUVIRUZHDU

\HDUO\ PDMRUVHUYLFLQJ PD\EHFDUULHGRXWE\

+<'52675(66RUDQDXWKRUL]HG

+<'52675(66UHSUHVHQWDWLRQRQO\

Fig. wart_d.vpo

page 28 sl9806e

Page 29

SL Repair

7 Repair

7.1 Connection and repair of rope

Do not join ropes with different degrees

of wear:

Difference of the two Ø: max. 0.2mm

(~8 mil)

The rope can be joined or repaired by the following locking devices:

– Joint lock

– Repair sleeve

– Threadlock

Needed are:

– Pressing tongs, sleeve, knife

– Angular grinder/shearing cutter

additionally for joint lock

7.2 Connecting the rope by joint lock

Fig.sk2_glvs.tif

– Mounting kit for joint lock

Pressing the lock on

1) Cut r ope at both ends at 11 mm distance from the first bead (Attenti-

on: take care to make a straight cut).

2) Rem ov e rubber sleev ing cleanly by

pulling reinforcement spring off with

pliers, and shorten free rope ends to

max. 8 mm.

3) Slide loos e fork head part of the joint

lock onto the rope end (blank portion

of rope must extend to the bore

dead end)

4) Pr ess with TYROLIT-Original pressing tongs.

5) Slide the pr eassembled lock part

onto the other rope end (similar to

pt. 3)

6) Pr ess as described under pt. 4

sl9806e page 29

Page 30

Repair SL

Closing the lock

1) Twist rope according to instruction

(see application guide supplied with

the rope)

2) Connect the two pressed on lock

parts with the bolt supplied with the

lock kit, by a few hammer strokes.

Opening the lock

1) Dr ive out bolt by a few ham mer st rokes.

2) The rope can be reconnected using

a new replacement bolt which is

supplied with the lock kit resp. can

be ordered separately.

7.3 Connecting the rope by repair

sleeve

Pressing on of lock

1) Cut r ope at both ends ac cor ding to

drawing at 12 mm resp. 9 mm distance from bead (Attention: take

care to make a straight cut). Never

mount the locks directly behind the

rope beads as rigid portions will lead

to untimely rope rupturing.

2) Rem ov e rubber sleev ing with reinforcement spring by pulling off with

pliers.

3) Slide the r ubber rings s upplied with

the lock kit onto the blank rope ends

(important for maintaining flexibility

of the rope within the lock range)

4) Slide joint loc k par t onto the rope

end (blank portion of rope must extend to the bore dead end) and take

care that the threaded stud points always to the forward running direction. (pay attention to the direction

arrow on the rope)

5) Press lock part with T YROLIT-Original pressing tongs and pressing inlay. The pressed

Fig.seilrep.tif

The range available for pressing is separated by

a ring groove from the threaded portion on the

lock

6) Side the 2. loc k par t onto the other

rope end ( similar to pts.3 + 4) and

press as under (Pt. 5).

page 30 sl9806e

Page 31

SL Repair

7.4 Connecting the rope by threaded

lock

Pressing on of lock

• Procedure similar to pt. 7.3.

Closure of lock

• Twist rope according to instruction (see

application guide supplied with the rope)

• The rope needs to twisted by additional 5

turns in order to compensate for the

thread turns of the lock.

• Screw the two lock parts together –coun-

ter clock thread.

Opening of lock

1) Open the loc k by turning cl ock wise

with the help of a waterpipe pliers.

2) Befor e repeated closing the loc k

should be inspected for wear and if

need be replaced by a new lock.

sl9806e page 31

Page 32

Transportation, shut-d own , storage, disposal SL

8 Transportation, shut-down , storage, disposal

8.1 Transportation

The system is a high value technical system.

Protect it against damage in transportation:

– Dismantle rope

– Do not deposit any parts onto or side-

wise to the sawing system

The rope sawing system

weighs approx. 122 kg (~270

lbs.). Disassemble it for transportation and carry the individual parts (max. 20 kg, ~45 lbs.)

with caution, and if possible

twosome, to avoid back damage and accidents.

8.2 Shut-down, storage

The system consists to some extent of material

which may corrode. If out of use for ext periods

proceed as follows:

– Oil and store in a dry place

8.3 Disposal

The system consists of the following materials:

– Aluminum

– Steel

– Rubber

– Rubber/nylon fabric

– Synthetic grease

– Plastics

Obtain information on the regulations on disposal in your country.

8.4 Accessories

#TVKENG 1TFGT0Q

4XLFNH[FKDQJHNLW$=)=IRUIDVWHUPRXQWLQJDQG

H[FKDQJLQJ

RIK\GUDXOLFPRWRUV +6$=

5RSHFXWWLQJVKHDUVFRPSOHWHZLWKWKUHDGHGVOHHYHDQG

UHSDLUVOHHYH =8+7

page 32 sl9806e

Page 33

SL Spare parts list

9 Spare parts list

Ordering information

For orders of spare parts we need the following

information:

– Equipment type according to type pla-

te (e.g. L Index 000)

– Serial number according to type plate

(e.g. 12136)

– Spare part number according to spare

parts list (e.g. 08W7-75648-02)

For orders, questions and information please

contact the allotted branch office (see below).

Fig.typ.tif

Unsere Vertretung our branch office notre f iliale la nostra rappresentanza

sl9806e page 33

Page 34

Fig.sl_expl2.tif

Page 34

SL9910

Page 35

99MS-60114-50 3401019 Drive Wheel Comp.

SL9910

1 99MS-60139-06 3401943 IdlerPulley Ø 200 mm standard 6

2 0000-60114-01 3400182 Central tube 1

3 0000-60114-02 3401266 Cross Pipe pc. 2

4 0000-60114-03 n/a Cutting pulley support short 2

5 0000-60114-05 341267 Cross clamp 8

6 0000-60114-06 3400936 Extension tube 2

7 0000-60114-35 3400937 Extension tube short 2

8 0000-60114-07 3401200 Pulley support

9 0000-60114-08 n/a

10 0000-60114-09 n/a Plate 2

11 0000-60114-38 n/a Plate for gear 1

12 0000-60114-12 n/a Support 1

13 0000-60114-13 n/a Bushing sleeve 4

14 0000-60114-14 n/a Threaded pivot block with bushing 1

15 0000-60114-15 n/a Spacer 1

16 0000-60114-16 n/a Pivot block handle 1

17 0000-60114-17 n/a Shaft carriage 1

18 0000-60114-18 n/a Worm gear 1

19 0000-60114-22 n/a Central tube 1

20 0000-60114-25 3401256 Spur-toothed wheel 1

Pulley support long 1

short 1

21 0000-60114-26 n/a Support 1

22 0000-60114-28 n/a Pan head screw 3

23 0000-60059-32 n/a Flange 1

24 0000-60059-33 n/a Ring 1

25 0000-60072-26 n/a Flange plate 1

26 0000-60086-51 n/a Snap ring 2

27 0000-60086-52 n/a Spacer 1

28 0000-60086-53 3401050 Driven shaft 1

Page 35

29 0000-60086-54 n/a Flange 1

30 0000-60086-68 3401951 Lining 1

Page 36

Fig.sl_expl2.tif

Page 36

SL9910

Page 37

99MS-60114-50 3401019 Drive Wheel Comp.

SL9910

31 0000-60114-39 n/a Pinion 1

32 0001-52747-01 n/a Lever 1

33 0000-60114-31 n/a Splash Flap 6

34 0000-60114-32 n/a Splash Flap 1

35 0000-60114-33 n/a Splash drain 2

36 0000-60114-34 n/a Splash drain short 2

37 0002-52047-04 3400339 Coupling Danfoss 1

38 0000-60087-31 Coupling shaft 1

39 0000-60087-29 n/a Danfoss flange 1

40 13K1-01924-00 3400338 Star coupling plate 1

41 13V7-03220-20 n/a Lamellar plug 20 1

42 13V7-03250-50 n/a Lamellar plug 50 1

43 13P1-09059-05 n/a Bellow 1

44 02S1-03015-50 3400594 Circlip arbor 2

45 01S1-08016-00 n/a Hexagonal screw 4

46 01S1-08045-00 n/a Hexagonal screw 1

47 01S1-12040-00 3402151 Hex screw 2

48 01S1-12025-00 n/a Hex head cap screw 3

49 01S1-12030-00 n/a Hexagonal screw 4

50 01S1-12055-00 n/a Hex head cap screw 4

51 01S1-12070-00 3401165 Hex head cap screw 1

52 01S1-12100-00 n/a Hex head cap screw 3

53 01S1-06025-00 n/a Hex head cap screw 4

54 01U2-12028-50 n/a Washer 6

55 01U2-12037-50 3403024 Washer 4

56 01U6-08035-50 n/a Washer 1

57 01M1-12000-00 3402015 Hex nut 3

58 01M3-12000-60 3401921 Stop nut

Page 37

59 04W2-00007-00 n/a Nut 1

60 05L1-00040-50 3401116 V-Seal 2

Page 38

Fig.sl_expl2.tif

Page 38

SL9910

Page 39

99MS-60114-50 3401019 Drive Wheel Comp.

SL9910

61 01I1-06020-00 n/a Allen head screw 6

62 04Z3-03207-00 3401945 Angular ball bearing 1

63 01I1-06050-00 n/a Allen head screw 6

64 01M1-06000-00 3402059 Hex Nut 6

65 01I1-06030-00 3400085 Allen head screw 6

66 01I1-10040-00 n/a Allen head screw 2

67 01I1-08016-00 3402017 Allen head screw 4

68 01I1-06010-00 n/a Allen head screw 1

69 01I1-06016-00 3400693 Allen screw 2

70 07S2-07013-13 3400683 Hose nipple 1

71 12Z2-38639-24 n/a ABA Hose Clip 15-24 2

72 12W1-00525 n/a Hose no. 525 1

73 07S2-07013-00 3400359 Water coupling female 1

74 07S2-17217-38 3400427 Plug in nipple 3/8" 1

75 12Q2-51804-00 3403016 Loc-Line threaded nipple 1

76 12Q2-51800-00 3401175 Loc-Line joint sleeve lrg 20

77 12Q2-51806-00 3400769 Loc-Line nozzle 6mm 1/2" 1

78 02L1-06012-00 n/a Grooved pin 6x12 2

79 02W1-00807-32 n/a Shaft key 10x8x70 1

80 XXKL-00000-02 n/a HS-Logo sticker 4

81 0002-54457-02 3402010 Type plate small

82 02L2-00040-08 n/a Grooved drive stud

Page 39

Page 40

Page 40

SL9910

Fig.200_9907.tif

Page 41

Pos Stk 964254 99MS-60139-06 Umlenkrolle Dm 200 Umlenkrolle Dm 200

SL9910

1 1 977529 0000-60086-68 3401951 Lining 200mm

2 2 964209 0000-60139-01 3401059 8"Wheel Hub

3 8 971711 01I1-06025-00 3400865 Allen head screw

4 8 971677 01I1-04008-00 2900761 Inbus-S

chraube M 4x

5 1 964218 0000-601396 1 964210 0000-60139-02 3400856 Bushing

7 1 972000 02S1-03515-50 3400857 CIRCLIP

8 2 972149 04R3-06007-00 3402057 Ball Bearing 6007

9 2 964355 05O1-00620-15 2702791 O-Ring Dm 62x1.5

10 8 979307 01M1-06000-00 3402059 Hex Nut

11 1 964213 0000-60139-05 3401186 Pulley Hub

12 1 964212 0000-60139-04 3402157 Rear Cover

13 1 969143 05D1-45524-00 3401866 Seal

14 1 971916 01S1-12030-00 n/a Hex screw M12x30

14 1 979338 01S1-12055-00 n/a 6kt-Schraube M12x55

14 1 971922 01S1-12070-00 3401165 Hex Screw

03 3402156 Front Cover

Page 41

Loading...

Loading...