Diamond MCV/12C User Manual

Mod:MCV/12C

Production code: DELTA 12

08/2009

Dear customer,

we congratulate you for choosing a high quality product

which will surely satisfy your expectations.

With our thanks for choosing us, we kindly invite you

to examine the present operating instructions manual

before operating your new machine.

SUMMARY

Z15.027 V01

3

1 IMPORT ANT SAFETY SUGGESTIONS AND

PRECAUTIONS ...................................................... 4

2 TECHNICAL DA TA.................................................. 5

2.1 Technical data plate and CE marking .............. 5

2.2 Acoustic pressure level ................................... 5

3 CARRYING AND UNP ACKING ............................... 5

4 INSTALLA TION...................................................... 6

4.1 Placing ........................................................... 6

4.2 Assembling..................................................... 6

4.3 Electrical connection....................................... 7

5 MACHINE’S OPERATION....................................... 7

5.1 Controls and indicators ................................... 8

5.2 Operating the machine.................................... 8

5.3 Setting of air-inlet valve.................................... 9

5.4 Using the TIMER function...............................10

5.5 Tub defrosting ................................................10

5.6 Accessories and their use..............................10

6 WASHING AND SANITISING................................11

6.1 Warnings and hints........................................ 11

6.2 Washing procedure ........................................12

6.3 Accurate washing of the accessories.............1 3

7 MAINTENANCE .....................................................14

7.1 Regular checks ..............................................14

7.2 Yearly maintenance .......................................14

7.3 Warnings for the service engineer...................15

8 PERIODS OF INACTIVITY ....................................15

9 MALFUNCTIONS ..................................................15

WARNING:

GENERAL/MECHANICAL DANGEROUS

DANGER VOLTAGE

A TEXT IN CAPITOL LETTERS, IDENTIFIED BY ONE OF THE SYMBOLS ABOVE, CONTAINS INSTRUCTIONS THAT, IF NOT FOLLOWED, MAY CAUSE HARM TO PEOPLE.

A text in lower-case, identified by this symbol, contains instructions that, if not followed, could

cause damages or malfunctions to the device, or falls in its quality.

4

Z15.027 V01

Automatic cream-whipper

English

1IMPORTANT SAFETY SUGGESTIONS AND PRECAUTIONS

PLEASE READ THESE INSTRUCTIONS BEFORE ATTEMPTING TO INSTALL AND OPERATE YOUR

MACHINE.

THIS MANUAL PROVIDES ALL INFORMATION REQUIRED TO INSTALL, OPERATE AND MAINTAIN

MACHINE

OUT

FEIT ANY MANUFACTURER'S GUARANTEE.

— All technical documentation supplied with the CREAM-WHIPPER (from now on defined as “MACHINE”) is to be

considered as an INTEGRAL PART of the machine and kept in a safe place for as long as the machine is in

existence. This documentation, in compliance with the law in force (EU directives on health and safety measures), is

made up by:

• OPERATING INSTRUCTIONS (this manual): it must be read by the USER as well as anyone authorized to

INSTALL it. It provides all information required to correctly install the machine, correctly operate it, for routine

maintenance and any possible malfunction of the machine;

• TECHNICAL HANDBOOK: it contains the machine's technical specifications (characteristics, diagrams, spare

parts etc.) It is to be referred to by the AUTHORIZED ASSISTANCE SERVICE personnel to whom any call for

assistance must be given.

UNDER SAFE CONDITIONS. FAILURE TO COMPLY WITH THE SAFETY MEASURES SET

IN THIS HANDBOOK MAY RESULT IN SERIOUS DAMAGE TO THE MACHINE AS WELL AS FOR-

• EU DECLARATION OF COMPLIANCE: in compliance with EU directives relevant to the machine;

• FORM of electric running tests.

— In case of sale or transfer of the machine to another person, the above documentation must be handed over to the

new owner in order to become acquainted with all safety norms, technical specifications as well as how to operate the

machine.

— Always unplug the machine before proceeding with any maintenance, that will have to be performed by profession-

ally qualified and certified personnel.

— Any modifying of the electrical supply plant must be exclusively performed by professionally qualified and certified

personnel.

— Any use of the machine that is not for the production of whipped cream, ice-cream cake or mousse, is to be consid-

ered improper.

— Do not connect and/or operate the machine when any part is missing.

— Do not introduce objects, tools or other in the machine’s loopholes.

— The machine is designed to be operated by adults: do not allow children to get close and untrained people to operate it.

— Modifying, or attempting to modify this machine, can be dangerous and would void any type of warranty.

— Always use original spare parts.

— As soon as the user discontinues operation of the machine, we recommend to rendering it inoperative by cutting its

supply cable (after having unplugged the machine). We also recommend to:

• avoid dispersing the freezing gas and the oil contained in the condenser;

• carry out the draining and/or recycling according to the local provisions of the law currently in force on this

matter.

English

Operating instructions

Z15.027 V01

2TECHNICAL DATA

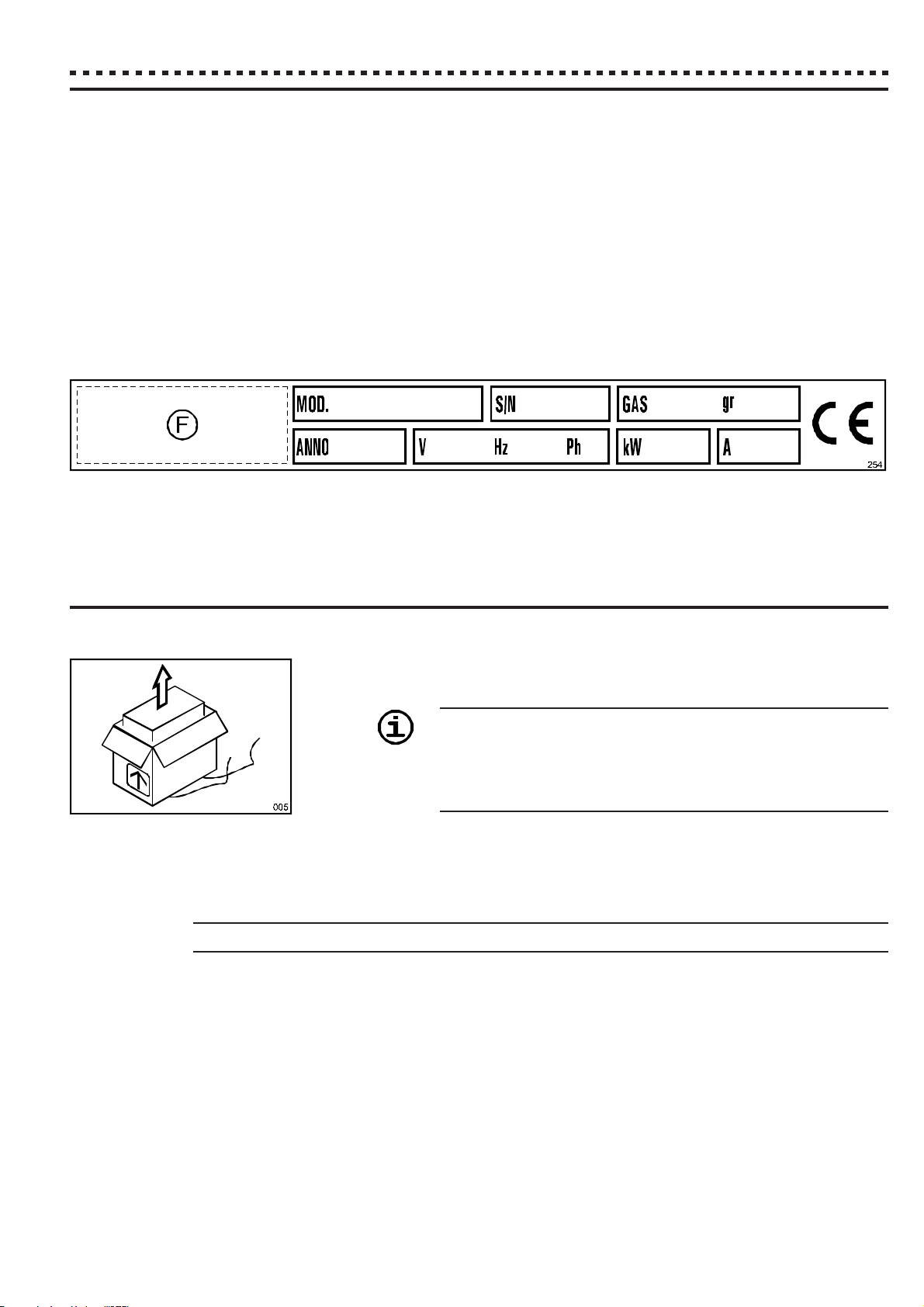

2.1 Technical data plate and CE marking

The technical data plate and CE marking must not be removed. It is located on the back part of the machine and identifies:

— the name and address of the manufacturer [F];

— the designation of the model [MOD.] and the relative series number [S/N];

— the type [GAS] and quantity [gr] of freezing gas contained;

— the year of construction [ANNO];

— voltage [V], frequency [Hz] and number of phases [Ph], electrical input power [kW] and current [A];

— the CE marking.

5

2.2 Acoustic pressure level

The average equivalent continuous acoustic pressure level of this machine is lower than 70 dB(A). This data has been

measured at 1 meter from the surface of the machine and at 1.60 meters from ground-level, during the machine’s

functioning.

3CARRYING AND UNPACKING

The weight of this machine, net and with packing, are stated both in the packing list

and on the packing itself.

To prevent the oil contained in the compressor to flow into

the refrigerating circuit, it is necessary to always keep the

machine in upright position, both during carrying and during

the installation and operation. Always follow the instructions

on the packing.

To unpack the machine, cut the strings, open up the pack from the top, pull away the

protecting cardboards and pull out the machine.

After unpacking the machine, make sure it has not visible damage. In case of doubt, don’t use it and ask for help directly

from your dealer.

Note: The packing is made out of recyclable materials (cardboard).

6

Z15.027 V01

4INSTALLATION

THE INSTALLATION MUST BE MADE IN COMPLIANCE WITH THE LAWS IN FORCE, ALWAYS

FOLLOWING INSTRUCTIONS OF THE MANUFACTURER.

4.1 Placing

English

Automatic cream-whipper

Place the machine on a flat and steady surface.

Install the machine away from any source of heat, avoiding direct exposure to sun

radiation and making sure that air can freely circulate around each side of the machine itself. In particular, the free space in front of the grid of the condenser must be

of at least 20 cm or more.

Make sure that the pump body [3] is complete with the air-inlet valve [11] of the knob

of the non return valve [24] of the fixing knobs [27] of the pump’s lid and the suction

tube [15], than check that the packing contains:

— supply faucet [6] (complete with labyrinth-tube), and inside [4] and outside [21] labyrinths;

— container [19];

— drip tray [8];

— tube-brushes [16] and [20] and plastic blade [17];

— spare parts outfit bag [18].

Also make sure that the Technical Handbook, the EC Conformity Certification and Electrical Tests Schedule are included.

4.2 Assembling

Proceed with the installation of the parts as follows:

— insert the inside labyrinth [4] in the outside labyrinth [21] and fit it into the pump [3] through the hole on front panel;

— place the faucet’s labyrinth-tube on the labyrinth, by pushing it until it inserts on the pump [3] pipe union by rotating

it counterclockwise (45°). Check that the outlet nozzle [7], is correctly facing the floor;

— insert coil [22] onto the electrovalve [32]; if available, place cover [48] and secure them with fastening knob [46];

Loading...

Loading...