Page 1

06/2016

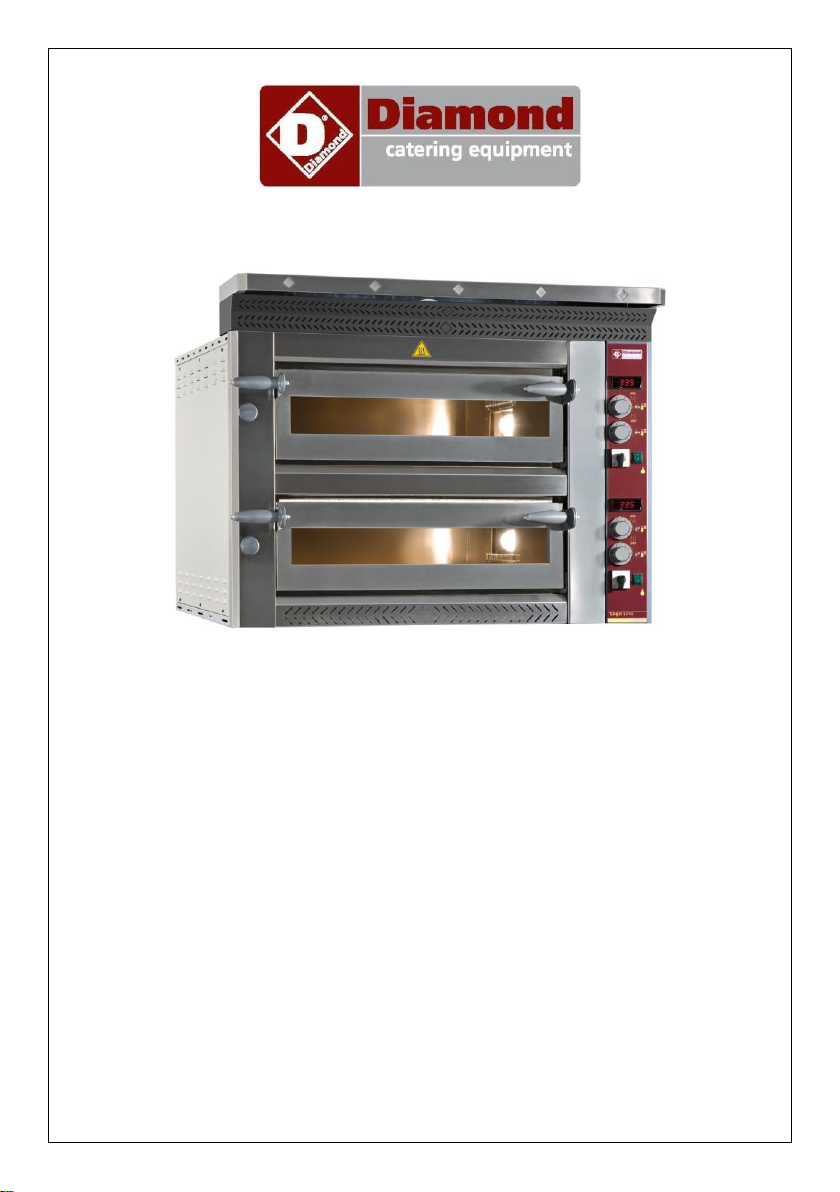

Mod: LD12/35-N

Production code: P08LG06006

Page 2

LOGIC LINE PLUS OVENS

LD4/35-N÷ LD6/35-N÷ LD6/35XL-N÷ LD9/35-N

LD8/35-N÷ LD12/35-N÷ LD12/35XL-N÷ LD18/35-N

Instruction manual

Page 3

- 25 -

DECLARATION OF CONFORMITY

In agreement with the Low Voltage Directive 2014/35 UE, with the directive 2014/30 UE (EMC9),with the

directive 2006/42 EEC (machines), integrated by the CE mark.

In agreement with Regulation (EC) No. 1935/2004 of the European Parliament and of the Council of 27

October 2004 on materials and articles intended to come into contact with food.

Type of appliance / Machine

ELECTRIC OVEN

Trademark

DIAMOND

Model

LD4/35-N÷ LD6/35-N÷ LD6/35XL-N÷

LD9/35-N

LD8/35-N÷ LD12/35-N÷ LD12/35XL-N÷

LD18/35-N

Manufacturer

PIZZA GROUP SRL

The harmonised standards or technical specifications (designations) that have been applied in

agreement with the highest professional standards on safety in force in the EEC are:

Standards or other normative documents

EN 60335-1 EN 60335-2-64

EN 55014

Other information:

In my capacity as manufacturer and/or authorised representative of the company inside the EEC, I

hereby declare, under my own responsibility that the appliances conform to the essential

requirements of the aforementioned Directives.

ENGLISH

Page 4

- 26 -

INDEX

1 SAFETY RECOMMENDATIONS

2 INSTALLATION

3 OVEN START UP AND USE

4 MAINTENANCE AND CLEANING

5 ALLARM AND POSIBLE FAULTS

6 INFORMATION FOR DEMOLITION AND DISPOSAL

WARNINGS FOR THE INSTALLER

WARNINGS FOR THE USER

WARNINGS FOR THE MAINTENANCE TECHNICIAN

OVEN POSITIONING

EQUIPMENT HOOK-UP

ELECTRICAL CONNECTION

GROUND CONNECTION

COMMAND PANNEL DESCRIPTION

FIRST LIGHTING OF THE OVEN

START UP FASE

GENERAL INDICATIONS FOR A GOOD COOKING

OUR PIZZA CHEF’ S SUGGESTION

WORKING PHASE

USE OF EXAUSTER VALVE

SHUT DOWN PHASE

SAFETY PRECAUTIONS

ORDINARY MAINTENANCE FOR THE USER

CLEANING OF REFRACTORY PLAN

EXTERNAL CLEANING OF THE OVEN

Page 5

- 27 -

1 SAFETY RECOMMENDATIONS

WARNINGS FOR THE INSTALLER

Check that the location of the oven is in compliance with local, national and European regulations.

Adhere to the instructions in this manual.

Do not execute electrical connections using temporary or uninsulated cables.

Check that the ground connection of the electrical system is functioning properly.

Always use individual safety devices and other means of protection in compliance with the law.

WARNING FOR THE USER

The conditions in the surrounding area where the machine will be installed must have the following

characteristics:

the area must be dry;

the area must have water and heat sources at an adequate distance;

ventilation and lighting must be suitable and comply with the hygiene and safety standards foreseen

by current laws;

the floor must be flat and compact to facilitate thorough cleaning;

there must be no obstacles of any kind in the immediate vicinity of the machine that could effect the

machine's normal ventilation.

In addition, the user must:

make certain to keep children away from the machine when it is operating;

adhere to the instructions in this manual.

not remove or tamper with the safety devices on the machine;

always pay careful attention to the work at hand and not use the machine when in a distracted state;

perform all operations with maximum safety and calm;

respect the instructions and warnings displayed on the machine labels.

The labels are accident prevention devices, and therefore must always be perfectly legible. If these should

be damaged and illegible, it is mandatory to replace them by requesting replacements from the

Manufacturer.

At the end of each working shift, before cleaning, maintenance or transfer operations, disconnect

electrical power.

WARNINGS FOR THE MAINTENANCE OPERATOR

Observe the instructions indicated in this manual.

Always use individual safety devices and other protection means.

Before starting any maintenance operations, make sure that the oven, it was used, is cooled down .

If any of the safety devices is worn or faulty, the oven is also considered faulty and not to be used.

Disconnect electrical power before intervening on electrical or electronic parts and connectors.

Page 6

- 28 -

2 INSTALLATION

Installation must be executed by qualified personnel in compliance with local, national and European

regulations.

OVEN POSITIONING

Ensure that the oven is put on a stand with the suitable carrying capacity and that is flat.

After unpacking the oven from its packing, position it in prepared location, taking into account the minimum

distances.

Remove possible protections in polystyrene and take off the protecting film (F) avoiding to use tools

which can damage the surfaces.

EQUIPMENT HOOK-UP

Electrical connection

The oven is not provided with power supply cable. When connecting the appliance electrically, an

automatic RCD must be interposed with an opening distance between contacts of at least 3 mm. To

connect the appliance electrically it is essential to procede in the following way:

remove the right side panel;

connect to the terminal block the power cable.

The power supply cable must be of H07-RNF type, with approved minimum cross section as prescribed by

the specific directive.

The electrical outlet must be easy to access, no moving should be necessary.

! The electrical connection (plug) must be easily accessible, also following oven installation.

The distance between the machine and the socket must be adequate to not cause tension in the power

supply cable. In addition, the cable must not be located beneath the machine support base.

Page 7

- 29 -

! If the electrical power supply cable is damaged, it must be replaced by the technical

assistance service or by a qualified technician to prevent any risks.

GROUND CONNECTION

It is mandatory that the electrical system is equipped with a ground connection.

The appliance must be part of an equipotential system. The connection is done on terminal marked with

symbol which you will find near the cable clamp. The section of the equipotential wire must be at least

10mm2

The equipotential symbol is showed in the following figure.

Page 8

- 30 -

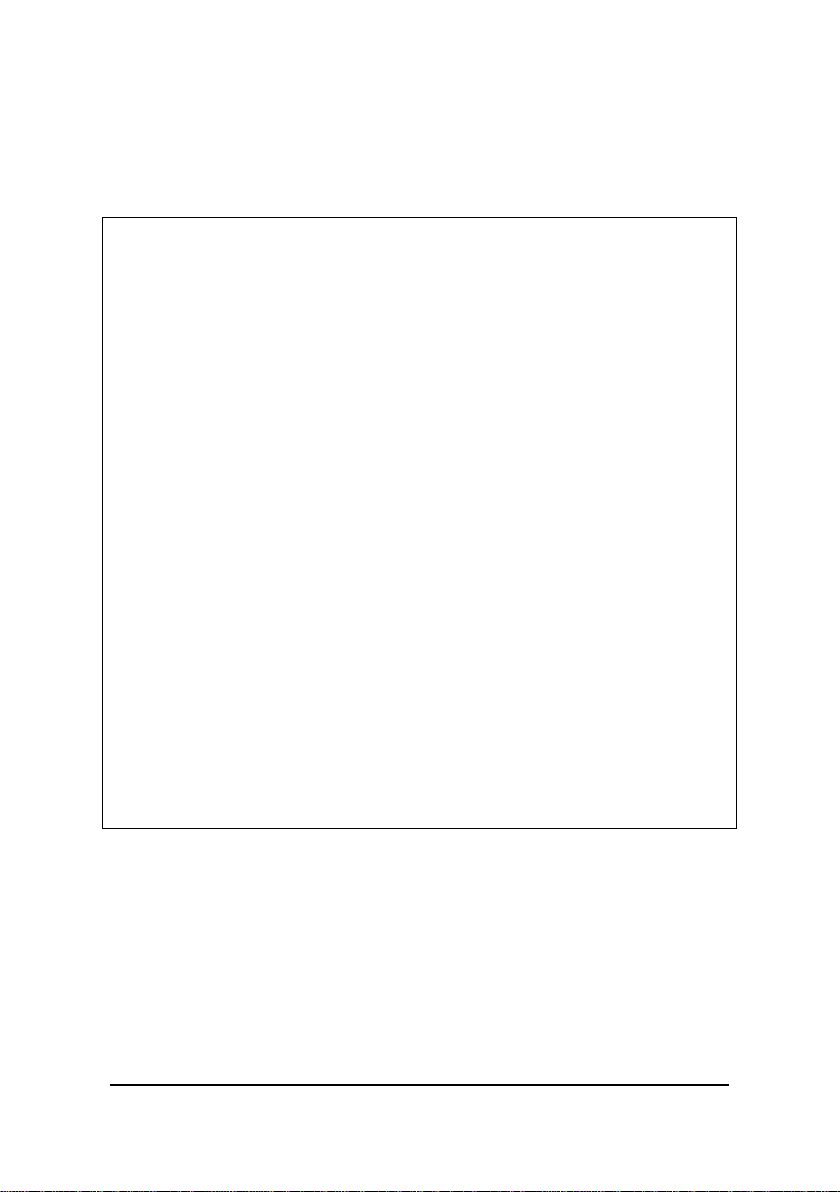

(A)

(E)

(B)

(C)

(D)

(G)

(F)

3 MECHANICAL OVEN START UP AND USE

COMMAND PANEL DESCRIPTION

The command pannel consists of:

Main switch (A)

Cooking chamber light switch (B)

Digital control thermometer (C)

Thermostat for the regulation of top temperatures (D)

Thermostat for the regulation of bottom temperatures (E)

Top heatin elements function pilot light (F)

Bottom heatin elements function pilot light (G)

FIRST LIGHTING OF THE OVEN

At the first use of the appliance it is advisable to heat the empty oven to eliminate bad smells caused by the

refractory stones evaporation and the inner metallic parts.

Procedure:

- fully open the exhauster valve

- set the main switch in the position “1” after checking that the oven is connected with the power supply

- leave the oven working (empty) for at least 8 hours at the temperature of 300° before proceeding to the

first baking

Page 9

- 31 -

START UP PHASE

After connecting the oven to the electric net rotate the main switch (A) in position “1”. The digital

thermometer display shows the actual average temperature of the baking chamber. Rotate the thermostat

knobs (D) and (E) until the expected temperature. In this way top and bottom heating elements are under

working and the relevant light signals switch on.

GENERAL INDICATIONS FOR A GOOD COOKING

Generally for the food products it is not advisable to give precise temperature and baking time, because of

their different characteristics.

Particularly, regarding pizza and similar products, time and temperatures depend on the shape and

thickness of the dough, as well as on the quantity and typology of the additional ingredients.

For those reasons it is always advisable to carry out previously some baking tests, (particularly when it is an

absolute new oven), with the aim of understanding as much as possible the characteristics and the

functioning of the oven.

Ideal Time and temperature choice is determinant for a right pizza baking; mostly they depend on the

operator’s experience.

OUR PIZZA CHEF’s SUGGESTIONS

In this chapter we report ideas and advices coming from a skilled Pizzaioli working team who

continuosly cooperates for the development of our products.

For an optimal result, and then a good pizza, baking must be carried out at an average temperature of

310°C for 3 minutes.

For an easier use and care of the oven, for the best result, we strongly advise to operate as follows:

1) The oven must be switched on (heating phase) at least one hour before the use; in this phase the

below mentioned temperatures must be set:

TOP → MARK 7

BOTTOM → MARK 4

2) At this stage proceed with the first baking keeping these settings

3) After baking the first pizzas (first baking), set on the oven:

TOP → MARK 8

BOTTOM → MARK 6

Proceeding with the second and step by step with the subsequent baking keeping these settings.

4) Once several baking done, or in any case while the oven must simply remain in temperature, without

any baking, reset the oven according to the setting under point 1

5) When wishing to resume the pizza baking, undertake again the same steps starting from point 1

For an optimal result, it is necessary that 20% of the baking surface (refractory stones) remains free. This

solution allows the best elimination of the water steams coming from the pizzas under baking.

When that solution is not applied, and the entire baking area is full (this is not ideal), the exhauster valve

must be fully opened for an easier water steam expulsion.

For an optimal result it is better to change always the area from one to another baking. This solution

enables the refractory stone to dry up in the right way an even temperature on the whole area.

Page 10

- 32 -

EXAUSTER

VALVE

WORKING PHASE

While working, at any time the oven can be modified in its temperature parameters; in addition, pizza

baking operation can be verified by inner chamber light (B).

Once the oven has reached the set temperature (visible on the display), it is possible to put in the pizza/s

for baking, proceeding as follows:

Open the door of the oven by the suitable handles

To light the inner chamber, set the lighting button (B) in the position “1”

Put in the oven the pizza/s to bake with suitable instruments for said use .

Close the door again by the suitable handles and check the baking through the door glass.

At baking over, open the door by the suitable handles and take out the pizza/s by suitable

instruments for said use.

When opening the door while the oven is on, it is important to stay at the right distance, to avoid being

invested by the heat coming out from the chamber.

Use suitable instruments to bake in and displace the pizzas in the baking chamber, to avoid burns.

When opening the door to bake the pizza/s, do not leave it opened for long time, to avoid heat dispersion

and consequently chambre temperature drop.

Avoid oil and fats to drop on bottom; if brought at high temperature can burn

USE OF EXAUSTER VALVE

While baking regulate the valve according to the exingencies.

oven is under heating; so, the set temperature is reached in shortest possible time.

By the exhauster valve the operator can regulate the baking steams and fumes flow out from the baking

chamber, while in the same the heat is kept.

It is advisable to keep the valve fully closed when the

SHUT DOWN PHASE

To shut down the oven turn the main switch (A) to the position “0”.

Page 11

- 33 -

4 MAINTENANCE AND CLEANING SAFETY PRECAUTIONS

! Before performing any maintenance operations, including cleaning, take the following precautions:

ensure that the oven is not working end completely cold

ensure that the electrical power is not present

make certain that the electrical power cannot be accidentally reinserted. Disconnect the plug from the

electrical power socket;

use individual protection devices in compliance with the directive 89/391/CEE;

always operate using appropriate maintenance tools;

once maintenance and repairs are finished, before starting up the oven, reinstall all of the protection

devices and reactivate all of the safety devices.

ORDINARY MAINTENANCE FOR THE USER

As any equipment also our ovens requires simple, frequent and careful cleaning to ensure efficient, regular

functioning,

! It is recommended to never use chemical products which are not specific for food preparation areas,

abrasives or corrosives for any reason. Avoid by all means using water jets, tools, rough or abrasive

instruments, such as steel wool, brillo sponges or any other item which could damage the surface of the

machine, and especially those that could compromise health safety.

CLEANING OF REFRACTORY PLAN

The oven must be cleaned at the end of each use, in compliance with the hygiene regulations and to

safeguard machine operation.

Before proceeding the oven temperature must be at 350° C for roughly 60 minutes (setting 350° on the top

and on the bottom as well), for an easy baking scoriae carbonization. Once reached the temperature,

switch off the oven and wait until the temperature drops until roughly 100°C (the best temperature for

cleaning). At this stage disconnect the electric power supply. After dressing in gloves and suitable dresses

as protection from burns, open the door and by a brush in natural fiber with a long handle, proceed to a first

removal of baking fragments from the refractory stones, then take them out by a suitable vacuum cleaner.

At the end, clean the refractory stone with an humid cloth.

EXTERNAL CLEANING OF THE OVEN

Oven external areas cleaning, external parts in stainless steel, door glass, and switch panel, must be

carried out at cold oven and at disconnected electric power supply.

Use a sponge or a soft cloth, not abrasive , slightly humidified with water or possibly with a neutral

detergent not corrosive. In any case, do not use

water jets which can penetrate through the electric parts and heavely damage them, as well as bring a

possible danger for people.

Page 12

- 34 -

WORKING ANOMALIES

Anomalies

Possibile Causes

Solutions

The oven does not

switch on

No electric Energy in the

net

Check the geneal contactor,

the socie, the plug, and the

supplì cable.

The oven does not

switch on

Main switch off

(poasitioned on "0")

Rotate the main switch to

position "1"

The display is off in spite

of the main switch being

on position 1 and the

electric supply is in

order

Digital thermostat

dfefected

Replace the digital thermostat

“PF” on the display

Probe failure

Replace probe

Inner light bulb does not

switch on

Burned inner light bulb

Replace inner light bulb

Inner light bulb does not

switch on

Inner light bulb switch

defected

Replace light bulb switch

Inner light bulb does not

switch on

No electric supplì power

on the light bulb

Check electric connection with

the light bulb

The door is closed, but

fume comes out

Exhauster butterfly valve

closed

Open more the valve and

check the right functioning.

The baking chamber

does not heat suitably

The set temperature are

too low

Set the right temperature

The baking chamber

does not heat suitably in

spite of the temperature

being set rightly

One or more heating

elements are defected

Replace the defecate heating

elements

The temperature

continues going up over

the set by thermo/timer

Power card contactors

contacts blocked (heating

elements always

supplied))

Check and, if necessary,

replace coctators card

The temperature

continues going up over

the set by thermostat

Thermostat conctas

defected

Check and if necessary

replace the thermostat

5 ALARM AND POSSIBLE FAULTS

Page 13

- 35 -

6 INFORMATION FOR DEMOLITION AND DISPOSAL

Demolition and disposal of the machine is the sole responsibility of the owner, who must perform these

tasks in compliance of currently enforced laws pertaining to safety and environmental protection in the

country where the machine is installed.

Disassembly and disposal can also be performed by a third party, as long as an authorized entity for

recovery and demolition of the materials in question.

INSTRUCTION: always adhere to the currently enforced laws pertaining to disposal of materials and

in the country where the machine is installed , and any possible necessity for registration of demolition.

! WARNING: All disassembly operations for demolition must take place with the machine shut-down

and disconnected from the electrical power supply.

remove all electrical apparatus;

separate the accumulators on the electronic cards;

dispose of the machine structure through authorized entities;

! WARNING: Abandoning the machine in accessible areas constitutes grave danger for persons and

animals.

Responsibility for possible damages to persons and animals is falls exclusively on the owner.

.

USER INFORMATION

The equipment falls under application of the European Directives 2002/95/CE,

2002/96/CE, 2003/108/CE which states to never dispose of this product together with

normal domestic waste. To prevent any possible damage to the environment or to

human health, please keep this product separately from other waste so it can be

recycled safely from an environmental point of view.

For more information about collection centers please contact the town office or the dealer you bought the

product from.

Loading...

Loading...