Page 1

Mod: PSB-130/2

Production code: ZZIS1304053F

06/2012

Page 2

DOUGH MIXER

IRIS

OPERATING AND

MAINTENANCE

MANUAL

Rev.001 01-06-2012

Read the

instruction

manual

carefully

before

beginning

to work

with the

machine

Page 3

INDEX

SECTION 1: Description and Main

specifications

1.1 Presentation ....................................................3

1.2 Warranty ............................................................ 3

1.2.1 Warranty exclusions ..............................3

1.3 Description of the machine and use ................3

1.3.1 Use .........................................................5

1.3.2 Description ............................................5

1.3.3 Safety devices ........................................5

1.4 Identification ....................................................6

1.5 Noise level .......................................................6

1.6 Technical specifications ..................................6

SECTION 2: General safety rules

2.1 Safety ..........................................................8

2.1.1 Terminology used ..................................8

2.2 Safety decals ...................................................8

2.3 Clothing ..........................................................9

2.4 Ecology and pollution ....................................10

2.5 Safe use of the machine ................................10

2.6 Safe maintenance ..........................................10

SECTION 3: Transport and installation

3.1 Transport ............................................................ 11

3.2 Installation ......................................................11

3.2.1 Positioning ...........................................12

3.2.2 Electrical connection ............................12

3.3 General inspection .........................................12

SECTION 4: Instructions for use

4.1 Prior to use ....................................................13

4.1.1 Control panel (80-250) ........................13

4.1.2 Control panel (30-40) ..........................13

4.2 Use .........................................................13

4.2.1 How to start the dough mixer ..............14

4.2.2 How to take product from the bowl ......14

4.3 Emergency stop .............................................15

4.4 Cleaning after use ..........................................15

SECTION 5: Maintenance

5.1 Routine maintenance .....................................16

5.2 Belt transmission ...........................................16

5.2.1 Dough tool transmission ......................17

5.2.2 Bowl transmission ................................17

5.3 Storage .........................................................18

5.4 Troubleshooting .............................................19

SECTION 6: Spare parts

6.1 How to order spare parts …………………… ......21

6.2 Spare parts tables ..............................................21

Dati riportati nella targhetta di identificazione della macchina

Model

Year of manufacture

Serial number

Delivery date of machine

Manifacturer

Page 4

_______________________________

DOUGH

MIXER IRIS

_______________________________

3

SECTION 1

Description and main specifications

1.1 PRESENTATION

This manual contains the instructions and every

indication considered necessary for correctly

using and servicing the mod. «IRIS» dough

mixer, also called machine in the following text,

manufactured by

………………………………………………………

………….., also called Manufacturer in the text.

The information given in the manual does not

constitute a complete description of the various

components nor a detailed illustration of the way

they operate. However, the user will find

everything he normally needs to know for safe

use and correct care of the machine. Regular,

long-lasting operation and economic running of

the machine depend on compliance with the

instructions given in this manual as does careful,

regular maintenance.

WARNING

Failure to comply with the instructions given

in this manual will oblige the Manufacturer to

void the warranty provided with the machine.

If repairs or overhauls involving fairly complex

operations are required, contact the

Manufacturer where there are technicians able to

provide prompt and accurate technical

assistance.

1.2 WARRANTY

The Manufacturer guarantees its brand-new

products for a period of 24 (twenty-four) months

from the date of purchase. As soon as you

receive the machine, check to make sure that it

is in a perfect condition and complete.

Complaints must be presented in writing within 8

(eight) days from the date on which the actual

machine is received. The warranty solely covers

the repair or replacement, free of charge, of

those parts which, after having been carefully

examined by the manufacturer’s technical

department, are recognized as being defective

(excluding the electrical parts).

Repairs or replacement of parts under guarantee

will in no case extend the warranty terms.

However, the purchaser is only entitled to repairs

or replacements under guarantee if he has

complied with any other conditions concerning

warranty performance indicated in the contract of

supply.

1.2.1 WARRANTI EXCLUSIONS

The warranty also becomes void (besides in

the cases indicated in the contract of supply):

- When there have been incorrect

manoeuvres ascribable to the operator;

- When the damage has been due to

insufficient maintenance;

- When, following repairs carried out by

the user without the Manufacturer’s consent

or owing to the use of spurious spare parts,

the machine has been modified and the

damage is ascribable to these modifications;

- If the instructions in this manual have

not been complied with;

Damages caused by negligence,

carelessness, bad use and incorrect use of

the machine are also not covered by the

warranty.

Removal of the safety devices with which the

machine is equipped will automatically void

the warranty and relieve the Manufacturer

from all deriving liability.

If the machine or parts of it are returned, they

must be shipped CARRIAGE PAID even when

the Manufacturer’s warranty is still valid.

1.3 DESCRIPTION OF THE MACHINE

AND USE

The mod. «IRIS» dough mixer is a machine that

bears «CE» marking, in compliance with

Annexes «I» and «IV» of directive 2006/42CE

and directive 2006/95/CE - 93/68/CEE

concerning the electrical components, as

specified in the declaration of conformity with

which every machine is supplied.

Page 5

_______________________________

DOUGH

MIXER IRIS

_______________________________

4

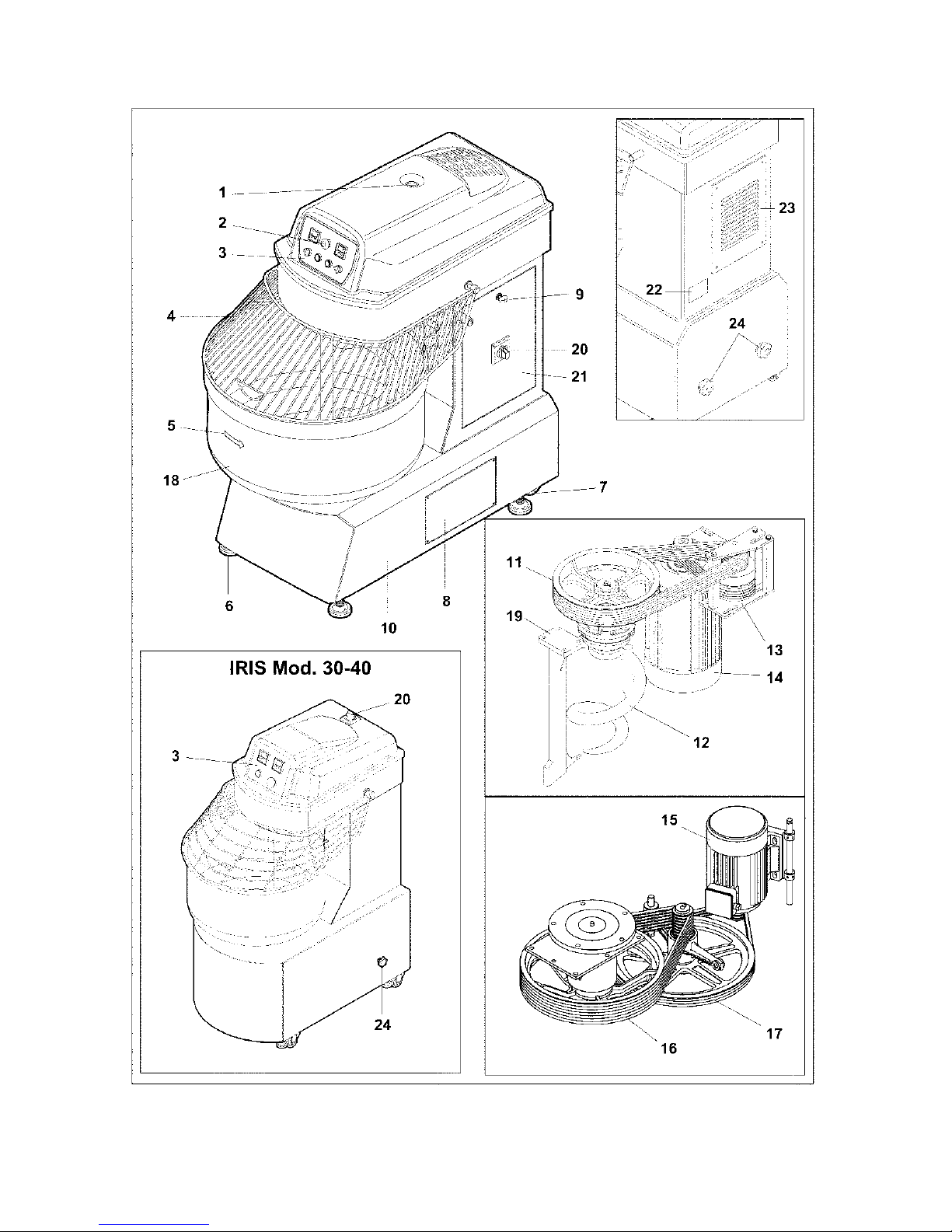

Fig. 1 - Overall view of the machine and main components

KEY Fig. 1 1) Upper cover fixing screw;

Page 6

_______________________________

DOUGH

MIXER IRIS

_______________________________

5

2) Emergency stop button;

3) Control panel (consult «4.1.1 Control

panel» for the relative description);

4) Protective grille;

5) Bowl;

6) Adjustable feet (4) to allow the machine

to stand in a stable way on the floor;

7) Wheels for moving the machine;

8) Side inspection panel;

9) Lock with key;

10) Bearing structure of the machine;

11) Upper pulley to control dough tool;

12) Dough tool;

13) Dough tool transmission unit;

14) Upper electric motor for controlling

dough tool;

15) Lower electric motor for controlling bowl

rotation;

16) Lower pulley for controlling bowl;

17) Bowl transmission unit;

18) Arrow indicating bowl rotation direction;

19) Shaft.

20) Main switch with door lock;

21) Door for accessing the electric panel;

22) Position of identification plate.

23) Rear inspection panel;

24) Lower belt tensioning knobs.

1.3.1 USE

The mod. «IRIS» dough mixer has been

exclusively designed for the use of mixtures of

various types of flour available on all the

international markets, in authorized work

environments and small industries such as:

bakeries, pizza restaurants and confectioners’

shops.

1.3.2 DESCRIPTION

(The numbers between brackets refer to Fig.1).

The machine mainly consists of a robust metal

bearing structure (10) equipped with two drive

units: an upper one (14), which turns the dough

tool. and a lower one (15), which drives the

bowl (18). The rotational movement of the IRIS

30-40 dough mixer is controlled by a single

motor. The electric panel is situated under the

upper cover, which also closes and protects

the machine. In both the drive units, the actual

drive is transmitted by V-belts, the tension of

which is regulated by belt stretchers. The

dough mixer’s functions are controlled by a

control panel (3), which is described in section:

«4.1.1 Control panel».

The work cycle can be programmed by means

of two timers, which allow the dough mixer to

automatically switch from the first to the second

speed. The bowl can be turned at first speed by

means of a selector, i.e.: NORMAL (anticlockwise direction), REVERSE (clockwise

direction), or bowl at a standstill. Drive reversal is

not available for version 30-40, thus the relative

selector is not installed. During the first phase,

the ingredients are mixed together so as to obtain

a homogeneous dough. As the consistency of the

mixture and the speed of the dough tool increase,

the dough is finished and fully blended in the

second phase. At the end of the process, the

operator can switch the selector to the reverse

rotation position (opposite to the direction of the

normal cycle, i.e. clockwise) to detach the dough

from the dough tool while bringing it to the center

of the bowl so that it can be easily cut and

removed.

WARNING

The Manufacturer declines all liability for

direct and indirect damages to persons,

animals or property caused by the machine

having been used for purposes other than

those described in this manual (see 1.3.2

Use).

1.3.3 SAFETY DEVICES

WARNING

The electrical system of this machine has

been built in compliance with the current

standards, particularly standard EN 60204-01.

The electrical system is equipped with a device

that protects against overloads and includes a

thermic relay and protective fuses (consult the

wiring diagram supplied separately).

To safeguard the operator, the grille (4) prevents

the limbs from accidentally accessing the bowl

interior when the dough tool is turning. The bowl

and dough tool will immediately stop if this grille is

raised when the machine is running. The electric

panel is also protected by a key-operated lock. In

versions 80-250, the access door has a keyoperated lock (9) and a main switch (20) with

Page 7

_______________________________

DOUGH

MIXER IRIS

_______________________________

6

door lock, i.e. it cannot be opened when the

machine is powered.

Protection is guaranteed for the 30-40 version

by the closing system of the upper cover with

main switch and the nut that closes the actual

cover itself. Lastly, the entire machine cycle will

immediately stop if the red stop button (2) on

the control panel is pressed.

1.4 IDENTIFICATION

Each machine has an identification plate (Fig.

2) positioned at the rear (22 Fig. 1), that

provides the following information:

- Manufacturer’s name and address;

- «CE» marking;

A) Model of the machine;

B) Serial number;

C) Year of manufacture;

The data plate also indicates:

Volts : Voltage

Hz : Frequency

kW : Kilowatts

A : Amperes

The information on the machine’s identification

plate must be copied into page 2 of this

manual and must always be stated when

spare parts and/or assistance are required.

The «IRIS» dough mixer is equipped with

the following items as part of the standard

supply:

- Operation and maintenance manual of the

machine with a list of spare parts;

- Wiring diagram;

- «CE» Declaration of conformity.

CARATTERISTICHE ELETTRICHE / ELECTRICAL CHARACTERISTICS

CARACTERISTIQUES ELECTRIQUES / CARACTERISTCAS ELECTRICA

Fig. 2 - Identification plate

1.5 NOISE LEVEL

When the dough mixer is operating, the noise

level at the operator’s station is less than 70 dB.

1.6 TECHNICAL SPECIFICATIONS

- Stainless steel bowl;

- Dough tool in highly resistant stainless steel;

- Moving parts assembled on bearings;

- Safety device with lock and immediate brake

that stops the motor as soon as the protective

grille is raised;

- Stove enamelled finish;

- V-belt transmission;

- Two mixing speeds;

- 24 Volt low voltage control panel;

- Two timers.

The timers stop when the protective grille is

raised during the work cycle, in both the first and

second speed mode. The cycle will continue

when the «START» key is pressed and the timers

will start from the same point in which they

stopped.

Page 8

_______________________________

DOUGH

MIXER IRIS

_______________________________

7

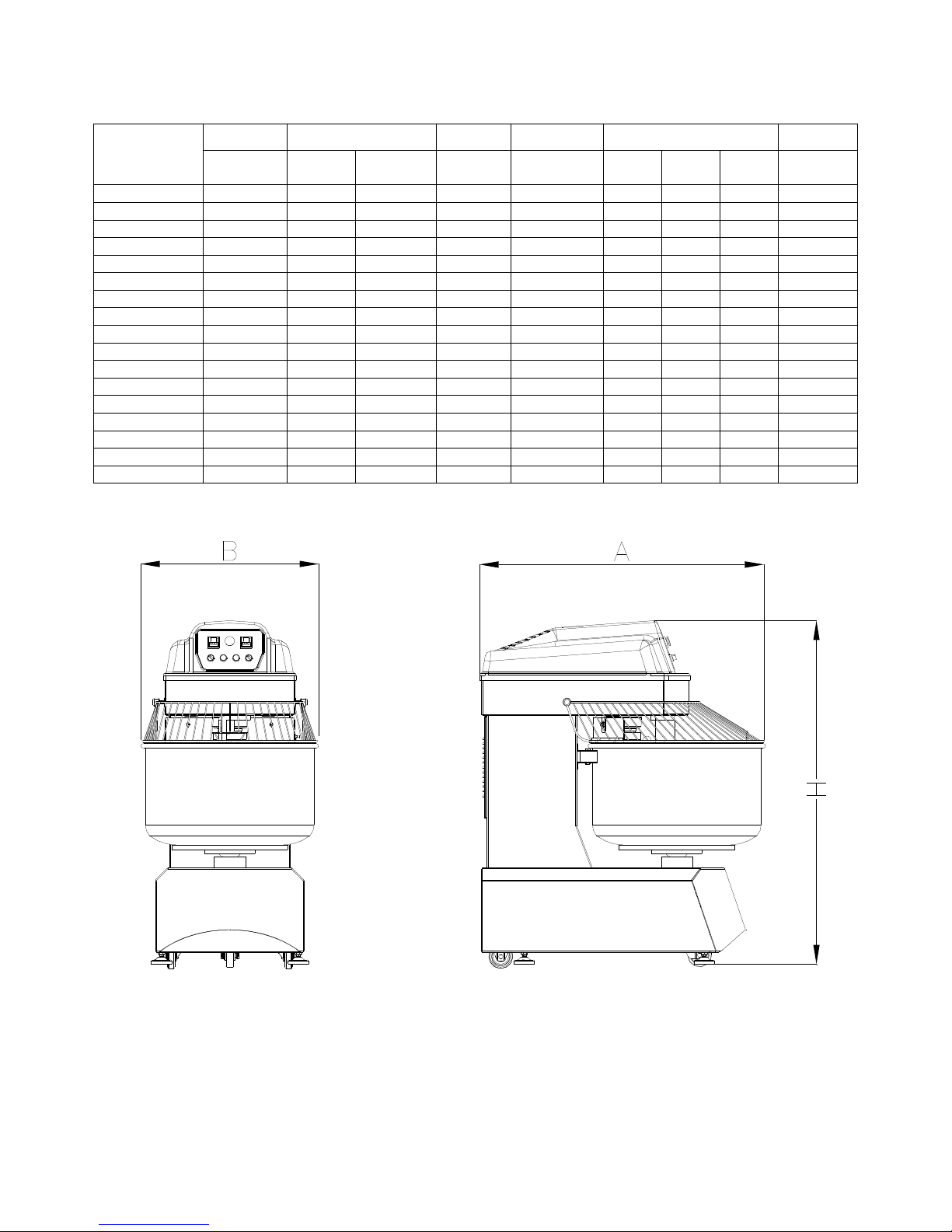

POWER DOUGH FLOUR BOWL DIMENSIONS WEIGHT

MIXER

MODEL

KW

Kg.

minimo

Kg.

massimo

Kg. Lt.

A

cm. B cm. C cm.

Kg.

IRIS 30

1,9 2 30 20 54 57 89 119 200

IRIS 40

1,9 4 40 27 63 57 89 119 200

IRIS 60

4,6 5 60 36 95 64 101 139 330

IRIS 80

4,6 6 80 50 127 75 119 145 410

IRIS 80-D

5,7 6 80 50 127 75 119 145 410

IRIS 100

5,7 8 100 65 145 75 119 145 410

IRIS 100-D

6,4 8 100 65 145 75 119 145 410

IRIS 130

6,9 12 130 80 193 85 140 150 580

IRIS 130-D

9,5 12 130 80 193 85 140 150 580

IRIS 160

8,5 15 160 100 250 95 156 160 740

IRIS 160-D

12,5 15 160 100 250 95 156 160 740

IRIS 200

8,5 17 200 125 275 95 156 160 740

IRIS 200-D

12,5 17 200 125 275 95 156 160 740

IRIS 250

9,7 22 250 150 320 105 163 160 790

IRIS 250-D

17,2 22 250 150 320 105 163 160 790

IRIS 300

12,5 27 300 180 420 113 173 166 840

IRIS 300-D

17,2 27 300 180 420 113 173 166 840

Fig. 3 - Dimensions of the machine

Page 9

_______________________________

DOUGH

MIXER IRIS

_______________________________

8

SECTION 2

General safety rules

2.1 SAFETY

WARNING

The user must train the personnel about the

risk of injuries, about the safety devices

installed in order to safeguard the operator

and about the general accident-prevention

rules established by the laws in force in the

country where the machine is installed.

Operator safety is of prime importance for

machine manufacturers. When creating a

new machine, manufacturers do all in their

power to foresee all the potentially dangerous

situations and naturally install all the

necessary protections. However, the number

of accidents caused by careless and inexpert

use of machines remains high. A distracted,

thoughtless and over-confident attitude often

leads to accidents, as can tiredness and

drowsiness.

It is therefore obligatory to read this manual

carefully, particularly the safety rules, and to

take great care when carrying out operations

that are particularly dangerous. This manual

must accompany the machine if it is moved to

another site or resold, until the time it is

completely dismantled.

The Manufacturer declines all liability for

failure to comply with the safety and

accident-prevention regulations.

WARNING

Pay attention to this symbol when it

appears in the manual. It highlights a

possible danger.

THERE ARE THREE HAZARD LEVELS:

- The word «DANGER» signals the

maximum danger level and warns that

unless the described operations are carried

out correctly, they will cause serious

injuries, death or long-term health risks.

- The word «WARNING» warns that unless

the described operations are carried out

correctly, they could cause serious

injuries, death or long-term health risks.

- The word «CAUTION» warns that unless

the described operations are carried out

correctly, they could cause damage to

the machine and/or the person.

2.1.1 TERMINOLOGY USED

• USER: The user is the person, body or

company who/that has purchased or rented

the machine and who/that intends to use it for

the purposes for which it has been designed.

• DANGER ZONE: Any zone inside and/or

near a machine where the presence of an

exposed person could put the safety and

health of that person at risk.

• EXPOSED PERSON: Any person who is

wholly or partly in a danger zone.

• OPERATOR: The person or persons

charged with installing, setting at work,

adjusting, servicing, cleaning, repairing and

transporting a machine.

• SPECIALIZED PERSONNEL: These are

those persons who have been specially

trained and authorized to carry out

maintenance work or repairs requiring

particular knowledge of the machine, the way

it works, the safety devices, the way of acting,

who are able to recognize the dangers

deriving from using the machine and are

therefore able to avoid them.

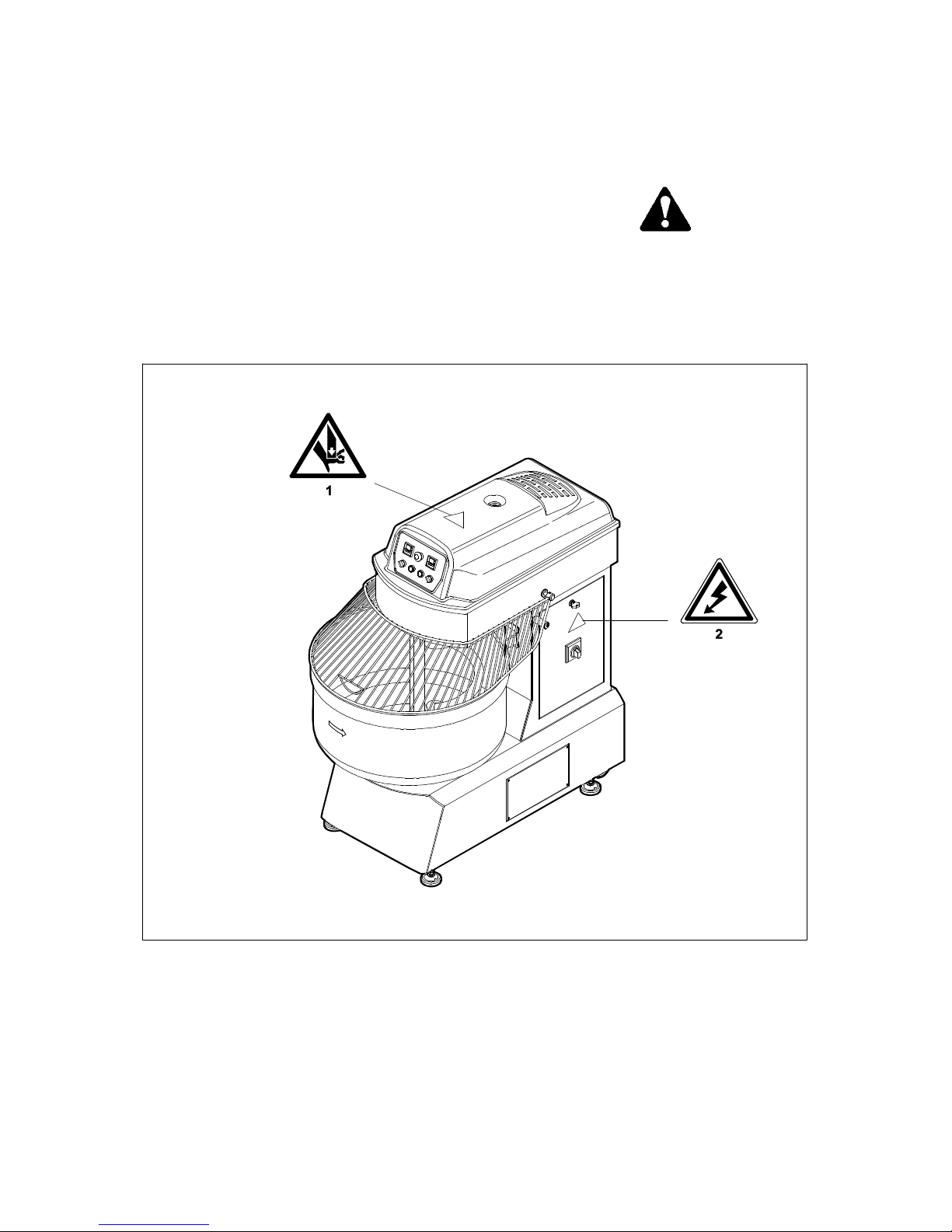

2.2 SAFETY DECALS

All possible measures were taken when the

machine was built in order to safeguard the

operators. Despite all this, there may still be

further residual risks that are indicated on the

machine my means of decals. This decals

(pictograms), illustrated in Fig. 4, are affixed

to the machine and point out the various

potentially unsafe and dangerous situations in

a schematic form.

Page 10

_______________________________

DOUGH

MIXER IRIS

_______________________________

9

Keep the decals clean and replace them

immediately if they detach or become

damaged.

With reference to Fig. 4, read the following

explanations carefully and memorize them.

1) Risk of injuries to the limbs. Take care

of the moving transmission belts when the

cover is raised.

2) Danger of high voltage. Do not work on

the electrical equipment unless the

machine has been disconnected from the

electric power source.

2.3 CLOTHING

WARNING

- Wear appropriate clothing. Do not wear

wide or loose clothing, necklaces, scarves,

ties, etc., which could become caught up in

moving parts. Long hair must be tied back.

Fig. 4 - Positions of the safety decals

Page 11

_______________________________

DOUGH

MIXER IRIS

_______________________________

10

2.4 ECOLOGY AND POLLUTION

WARNING

- Products used for cleaning purposes must be

disposed of in compliance with the laws in

force in the country where the machine is

used.

- Have packaging materials and processing

waste disposed of by specialized companies

authorized to collect and dispose of

differentiated waste.

- If the machine is dismantled, comply with the

anti-pollution laws in force in the country of

use.

2.5 SAFE USE OF THE MACHINE

DANGER

- It is absolutely forbidden to operate the

machine or have it operated by persons who

have not read and understood the instructions

in this manual, or by incompetent persons or

those who are not in good conditions of health.

- Make sure that all the safety devices are in

perfect conditions before starting up the

machine.

- Become familiar with the controls and their

functions before beginning work.

- It is absolutely forbidden to remove or tamper

with the safety devices.

- The area in which the machine is used must

be considered a «danger zone», especially for

persons who have not been trained to use the

machine.

- Before starting the machine, make sure that

there are no persons or animals in the

surrounding area.

- When a person is in a «danger zone», the

operator must act immediately, stop the

machine and possibly have the person in

question move out of the zone.

- It is absolutely forbidden to leave the machine

unattended when it is operating.

- It is absolutely forbidden to touch moving

parts or get between them.

- Before proceeding with any of the servicing

operations, disconnect the machine from the

power source and wait until all the moving parts

have come to a complete stop.

2.6 SAFE MAINTENANCE

WARNING

- Periodically check to make sure that the

overall machine and the safety devices are in

perfect conditions.

- It is obligatory to wear protective clothing,

work gloves to safeguard against cuts and

non-slip footwear with hard toe-tips when

servicing and repairing the machine.

- Spare parts must conform to the

specifications defined by the Manufacturer.

Only use genuine spares.

- Do not proceed with any servicing or cleaning

work unless the machine has been

disconnected from the electric power source.

- Strictly comply with the maintenance

instructions described in this manual. Have any

damaged or worn parts replaced by specialized

personnel.

- This instruction manual must be read,

memorized and kept throughout the entire

life of the machine.

Page 12

_______________________________

DOUGH

MIXER IRIS

_______________________________

11

SECTION 3

Transport and installation

3.1 TRANSPORT

If the machine must be transported for a long

distance, it can be easily loaded on to a truck

or other means of transport.

The dough mixer is usually supplied packed,

strapped, palletized and in a vertical position.

This means that the machine can be easily

moved, loaded or unloaded with a normal lift

truck. If the machine is moved without pallets, it

must be harnessed as illustrated in figure 5 and

lifted with a crane.

DANGER

Before proceeding with the lifting

operations, make sure that any mobile parts

of the machine are securely locked in place.

The lifting and transporting operations can

be very dangerous unless they are carried

out with the utmost care. Have anyone who

is not directly involved in the work move

well away; clear and delimit the area where

the operations will take place; make sure

that the lifting and handling means used are

in perfect conditions and fit for the job; do

not touch hanging loads and keep at a

safety distance away; the loads must not be

raised more than 20 centimeters from the

ground when they are transported. Make

sure that the work area is clear and that

there is an «escape route», i.e. a safe, free

area that can be rapidly accessed to the

operators should the load drop. To prevent

the load from shifting, the surface on to

which the machine is loaded must be

perfectly horizontal.

Once the machine has been transferred to the

means of transport, make sure that it remains

well locked in position and is unable to move.

Fix it firmly to the surface on which it has been

placed using taut ropes to prevent it from

shifting in any way.

3.2 INSTALLATION

After having made sure that the machine is in a

perfect condition, it can be positioned.

Bear the following details in mind when

choosing the definitive position for the

machine:

- choose a place that is free from damp and

sheltered from the weather conditions;

- the surface on which the machine is placed

must be perfectly flat, non-slip and with a load

capacity fit to bear the weight of the machine;

- allow for a clear, uncluttered work area around

the machine;

Fig. 5 - Lifting the dough mixer.

- the place in which the machine is positioned

must be supervised or closed, to prevent it from

being accessed by children or persons who have

not been trained to use it;

- the installation site must possess good lighting

that complies with the relative standards;

Page 13

_______________________________

DOUGH

MIXER IRIS

_______________________________

12

- the position must be near an electric panel

with a magnetothermic circuit-breaker;

- the voltage rating of the electricity main must

correspond to the value given on the

identification plate (Fig. 2);

- the electricity main must be equipped with a

grounding circuit that complies with the relative

standards;

- the ambient temperature must be between

+10° and +40°C;

- the machine must not be installed in a work

environment where there is an explosive

atmosphere.

3.2.1 POSITIONING

After the machine has been positioned and

bearing in mind the indications given in section

«3.2 Installation», proceed by ensuring that the

machine stands in a firm and stable way.

The mod. IRIS dough mixer has three wheels,

of which the front one is a castor (7 Fig. 1),

allowing it to be easily moved. After having

complied with the instructions given in the

previous section, lock the machine in the

required position and level it by means of its

adjustable feet (6 Fig. 1).

Fig. 6 – Plug

3.2.2 ELECTRICAL CONNECTION

DANGER

The machine must only be connected to the

electricity main by specialized and authorized

persons.

It is advisable to consult the wiring diagram of

the machine before proceeding.

Check the voltage rating of the electricity main in

the room and make sure that it corresponds to

the operating voltage of the machine’s electrical

system.

After having made the correct connection, start

the machine and make sure that the bowl turns in

the direction indicated by the arrow (18 Fig.1). If

this is not the case, invert two of the phases in

the plug (R and S - Fig. 6).

DANGER

If you are doubtful about the machine’s safety

systems, stop the machine and check them.

You may contact your nearest authorized

assistance service, the importer or the

Manufacturer if necessary.

3.3 GENERAL INSPECTION

WARNING

Carefully check to make sure that the machine

is efficient and that safety devices are

perfectly functional before setting the dough

mixer at work. Make sure that there are no

damaged components, that all the parts have

been installed correctly and that they function

perfectly.

Unsafe safety devices or damaged parts must

be repaired or replaced by specialized

personnel or by an Assistance center

authorized by the Manufacturer.

SECTION 4

Instructions for use

Page 14

_______________________________

DOUGH

MIXER IRIS

_______________________________

13

4.1 PRIOR TO USE

ATTENZIONE

It is advisable to remind the operator that

he is obliged to read and understand the

instructions in this manual, particularly

the ones in «Section 2» dedicated to

safety, before proceeding with normal use

of the machine. The operator must also

check to make sure that the machine is in

order and that any parts liable to wear and

deterioration are perfectly efficient.

DANGER

ALL THE ASSEMBLY, DISASSEMBLY

OPERATIONS AND ADJUSTMENTS MUST

ONLY BE CARRIED OUT AFTER THE

MACHINE HAS BEEN SWITCHED OFF

(MAIN SWITCH IN THE OFF POSITION)

AND AFTER IT HAS BEEN

DISCONNECTED FROM THE

ELECTRICITY MAIN.

4.1.1 CONTROL PANEL

(version 80-250)

The entire operating cycle of the dough mixer

is controlled by means of the control panel,

the voltage of which is reduced to 24 Volts

(Fig.7).

1) «First speed» timer. Used to select the

required time setting (in minutes).

2) Emergency button. Press this button to

disconnect the power source and stop all

the functions of the machine. The cycle

can be reset by turning the button and

then pressing the START button.

3) «Second speed» timer. Used to select

the time required (in minutes) to complete

the work cycle and obtain a homogeneous

dough that corresponds to the

specifications required by the operator.

4) Bowl rotation reversal selector.

Selector with two positions, plus neutral.

Reverses the rotation direction at the slow

speed only.

5) START button with indicator light.

Press this button to begin the work cycle.

When on, the indicator light shows that

the machine is powered.

6) Bowl rotation button. This button stops

the dough tool from turning and can

operate in both the continuous and

intermittent mode. By keeping the button

depressed, the bowl will turn. If it is

pressed intermittently, the bowl will turn to

a sufficient extent to allow the operator to

empty it.

7) Second speed cut-out switch. Allows

dough to be made using the slow speed

only. Turn the switch towards the right to

inhibit the second speed.

4.1.2 CONTROL PANEL

(version 30-40)

Consult the instructions in the previous

paragraph (4.1.1) in relation to points 1), 2)

and 3).

Points 4), 5), 6) and 7) are not pertinent to

this model of the machine.

8) Start button to start the machine.

4.2 USE

WARNING

The operator must supervise the area in

which the dough mixer is installed so as

to prevent unauthorized persons from

accessing the so-called danger zones

whilst the machine is working. He must

also keep the area constantly clean and

free from obstacles.

Page 15

_______________________________

DOUGH

MIXER IRIS

_______________________________

14

Fig. 7 - Control panel

4.2.1 HOW TO START THE DOUGH

MIXER

DANGER

IT IS ABSOLUTELY FORBIDDEN TO

USE THE MACHINE WITHOUT ITS

GRILLE AND PROTECTIVE CASING.

After having made all the adjustments, start

the machine and begin work.

1) Place the required quantities of flour,

water and any other ingredient required,

into the bowl.

2) Plug the machine into the electricity main,

then turn the main switch (Fig. 8) to the

ON position.

3) Now select the mixing times (if these have

not yet been memorized) by means of the

two timers (1 and 3 Fig. 7).

4) Press the START button - (5 Fig. 7) in

models 80-250, or (8 Fig. 7) in models 3040 - in order to start the operating cycle. If

the operator has selected the dough

mixing time settings in timer (1 Fig. 7) and

timer (3 Fig. 7), the machine will terminate

the work cycle during which it will

automatically switch from the first to the

second speed.

After the automatic stop, the mains voltage

is not disconnected and the machine is

ready for another batch of dough.

4.2.2 HOW TO TAKE PRODUCT FROM

THE BOWL

Proceed in the following way to take product

from the bowl:

1) Turn the selector (4 Fig. 7) in the opposite

direction to that of operation and then press

the START button.

The dough tool will turn in the opposite

direction, thus bringing most of the dough

towards the center of the bowl.

Page 16

_______________________________

DOUGH

MIXER IRIS

_______________________________

15

Fig. 8 - Machine’s main switch with two

positions (Fig.8), ON - OFF. The door that

accesses the electric panel remains locked in

the ON position

2) Lift the protective grille (4 Fig. 1) to

immediately stop the motors.

3) Now start to remove the dough.

The button (6 Fig. 7) allows the operator to

turn the bowl continuously or intermittently

and to access the part with the dough in

an easier way.

After this and if there are no other operations

to carry out, stop the machine in the

following way:

- press the red stop button (2 Fig. 7);

- turn the switch on the machine (Fig. 8) to

the OFF position;

- disconnect the machine from the electric

power source by means of the main switch

on the electricity main, prior to the

machine itself.

4.3 EMERGENCY STOP

Whenever the operator decides that the

machine must be blocked and prevented from

operating, he can raise the protective grille or

press the EMERGENCY button (red) on the

control panel. This latter action deactivates

the electric power supply.

4.4 CLEANING AFTER USE

WARNING

Disconnect the machine from the electric

power source before beginning to clean

the machine.

Remove any wet or dry residues and flour

dust with a slightly damp cloth.

WARNING

Never use continuous jets of water and

avoid splashing water indirectly in order

to clean the floor around and under the

machine. Once a month, remove the cover

and clean off the dust and residues from

the transmission with a vacuum cleaner.

Once the dough making and cleaning

operations have terminated, always make

sure that the electric power source has

been disconnected.

Page 17

_______________________________

DOUGH

MIXER IRIS

_______________________________

16

SECTION 5

Maintenance

5.1 ROUTINE MAINTENANCE

This range of dough mixers with fixed bowls

does not require any particular maintenance

work. However, tip-top performance and a

perfectly efficient machine are only obtained by

methodic and regular compliance with the

following regulations.

WARNING

The servicing, adjusting and preparation

jobs must always be carried out when

the machine is off and disconnected

from the electric power source.

- Maintenance work and adjustments may

only be carried out after the electric

power source has been disconnected by

turning off both the mains circuit-breaker

and the machine’s main switch (Fig. 8).

The routine maintenance operations can

be carried out by the operator, while

more complex jobs must be done by

specialized and authorized personnel.

- The general condition of the machine

must be inspected and the machine itself

cleaned daily, or as frequently as

possible.

- Excessively worn or broken parts must

be replaced immediately.

- The wiring diagram, which is supplied

together with the machine, must be kept

with care and consulted whenever

necessary. As soon as the machine is

received, it is advisable to make a copy

of the diagram and keep it with the other

documents.

5.2 BELT TRANSMISSION

The belts normally wear in an almost uniform

way, even though this wear may take place at

different times in one transmission as regards

the other and is bound to the consistency of the

dough as well as the number of hours that the

machine is used each day.

Every so often, the operator must therefore

check the degree of wear on all the belts in the

machine. Remember that if replacements are

required, the Manufacturer recommends

replacing all the belts at the same time

(complete replacement of each set of belts).

Fig. 9 - Dough tool belt tensioning

1) Belt stretcher fixing screws (4). - 2) Motor belt tension adjuster screw. - 3) Motor fixing screws (4).

- 4) Dough tool belt tension adjuster screw.

Page 18

_______________________________

DOUGH

MIXER IRIS

_______________________________

17

5.2.1 DOUGH TOOL TRANSMISSION

If the dough tool seems slow to turn, the

transmission belts may have loosened or be

broken. Proceed in the following way to

adjust and/or replace the belts:

1) Using a pipe wrench, unscrew the central

nut that fixes the cover to the machine (2 Fig. 1).

Raise the cover, paying particular

attention to the electric cables of the control

panel, which cannot be detached.

2) Loosen the four screws (1 Fig. 9) at the

base of the belt stretcher. Use the screw of

the belt stretcher (4 Fig. 9) to adjust the

tension of the transmission pulley/dough tool

belts.

Fig. 10 - Electric panel of IRIS 80-250

1) Thermic relay reset button. - 2)

Magnetothermic switches and fuses

Fig. 11 - Components of the electrical system

of IRIS 30-40

1) Thermic relay reset button. - 2)

Magnetothermic switches and fuses

3) Retighten the four screws (1 Fig. 9).

4) Loosen the four screws (3 Fig. 9) on

the motor bearing plate. Use the screw of the

belt stretcher (4 Fig. 9) to adjust the tension

of the motor pulley/transmission belts.

5) Retighten the four screws (3 Fig. 9).

6) Fit the upper cover back in place and

fix it with the relative nut (2 Fig. 1).

To replace any broken belts, remove the

cover and loosen the four screws that fix the

belt stretcher, as described previously, then

replace the broken belts. Always refer to the

spare parts tables which show the location of

the various different components. At the end

of the operation, tighten the belts in the

correct way and fit the upper cover back in

place.

5.2.2 BOWL TRANSMISSION

If the bowl seems slow to turn, the

transmission belts may have loosened or

be broken. Proceed in the following way to

adjust and/or replace the belts:

1) Turn the belt tightening knobs (24 Fig. 1)

positioned at the base of the machine (2

knobs in models 80-250, 1 knob in models

30-40).

Page 19

_______________________________

DOUGH

MIXER IRIS

_______________________________

18

Screw clockwise to tighten the belts,

unscrew to loosen or completely annul the

belt tension.

To replace any broken belts, first loosen them

with the two knobs (24 Fig. 1), remove the

side inspection panel (8 Fig. 1), then

replace the broken belts. Always refer to

the spare parts tables which show the

location of the various different

components. At the end of the operation,

tighten the belts in the correct way and fit

the side inspection panel back in place

with the relative four screws.

5.3 STORAGE

If the machine is to remain idle for a long

period of time, it must first be thoroughly

cleaned, the parts liable to wear must be

lubricated and the entire machine covered

with a plastic cloth.

If these operations are carried out with care, it

will be all to the advantage of the user, who

will find the machine in an excellent condition

when it is required for use once more.

Comply with the laws in force in the country

where the machine is used when it comes to

the way the products used for cleaning and

servicing the machine are used and disposed

of. Also comply with the recommendations of

the manufacturers of such products.

WARNING

If the machine is dismantled, comply with

the anti-pollution laws in force in the

country of use.

Page 20

_______________________________

DOUGH

MIXER IRIS

_______________________________

19

5.4 TROUBLESHOOTING

The following tables list the main faults, along with the relative causes and suggested remedies, to

which the machine may be subjected as it operates (NOTE: some of the indications are not

applicable to models 30-40).

Any operations required must be carried out by expert and authorized technicians and only after

having examined this manual.

FAULTS PROBABLE CAUSES POSSIBLE REMEDIES

The machine stops during

the work cycle but the green

starter indicator light

remains on.

The bowl is too full or the

voltage supply from the

electricity main is irregular.

Open the electric panel door (21

Fig. 1) and make sure that the

thermic relays and fuses function

correctly. If necessary, re-activate

the thermic relay by pressing the

button (1 Fig. 10). If the machine still

fails to operate, contact the Retail

Outlet’s Assistance Service.

The dough tool slows down

while the dough is being

mixed.

The dough tool’s transmission

belts have slackened or are

broken.

Tighten or replace the belts as

described in paragraph «5.1.1

Transmission belts».

The bowl slows down while

the dough is being mixed.

The bowl’s transmission belts

have slackened or are broken.

Tighten or replace the belts as

described in paragraph «5.1.1

Transmission belts».

When the START button is

pressed (5 Fig. 7 ), the

machine starts operating

but stops as soon as the

button is released.

The timer (1 Fig. 7) or the

relays of the electric panel

(Fig. 10) are dirtied with flour

or out of service.

Direct a jet of air (not too strong) on

to the timer and relays so as to

clean the contacts. If the machine

still fails to start, replace the

defective component.

When the START button is

pressed (5 Fig. 7), the

dough tool turns while the

bowl remains at a standstill.

Make sure that the bowl’s

mode selector (4 Fig. 7)

functions correctly. It could be

out of service.

Replace the selector if it is

defective.

The machine fails to

automatically switch from

the first to the second

speed.

The speed selector (7 Fig. 7)

is in the second speed

inhibited position.

The selector is defective.

Not enough power from the

electricity main.

Check the position of the second

speed inhibiting selector (7 Fig.7).

Replace the selector.

Check the power installed in the

bakery. Boost the power if

necessary.

Page 21

_______________________________

DOUGH

MIXER IRIS

_______________________________

20

FAULTS PROBABLE CAUSES POSSIBLE REMEDIES

The machine fails to

automatically switch from

the first to the second

speed.

The mains voltage is different

from that of the machine.

The second speed timer (3

Fig.7) is in the neutral position.

Check the mains voltage.

Make sure that the timer is in the

correct position (3 Fig. 7).

The machine is very noisy

and the protecting thermic

relays often stop it from

operating.

The machine may be powered

by two phases instead of

three.

Check the positions of the

magnetothermic switches (Fig. 10)

and the power cable connections.

When the main switch is

turned on (20 Fig. 1), the

indicator light (5 Fig. 1) fails

to come on and the

machine is not powered.

The wires in the mains plug

have detached.

The mains circuit-breaker is

broken.

Check the mains connections.

Replace the main circuit-breaker.

The machine fails to

operate when the START

button is pressed.

The button is broken.

The timers (1 and 3 Fig. 7) are

in the zero position.

The protective grille (4 Fig. 1)

is open.

The protective grille limit

switch is not positioned

correctly or is defective.

The protective

magnetothernmic switches

(Fig. 10) have tripped or are

faulty.

The stop button (2 Fig. 7) is in

the blocked position or is

defective.

Replace the START button.

Enter the operating values in the

timers.

Close the protective grille.

Check the grille limit switches.

Consult the relative spare parts

table for its position.

Position the magnetothermic

switches correctly or replace them if

necessary. Replace the protective

fuses.

Release the emergency button or

replace the contacts.

Page 22

_______________________________

DOUGH

MIXER IRIS

_______________________________

21

SECTION 6

Spare parts

6.1 HOW TO ORDER SPARE PARTS

The various components of the machine can

be ordered from:

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

-------------------------------------------------

specifying:

• The model of the machine.

• The serial number of the machine.

• Year of manufacture.

• Order number of the part.

• Description of the part and quantity required.

• Means of transport. If this item is not specified

and although particular care is taken with this

service, the Manufacturer shall not be liable for

any delays in shipment due to unforeseen

circumstances. The shipment expenses are

always at the consignee’s charge. The goods

travel at the principal’s risk and peril even if sold

ex destination.

Lastly, remember that the Manufacturer is

always at your disposal for any assistance

and/or spare parts required.

6.2 SPARE PARTS TABLES

Tab. 1 Dough mixer IRIS 30-40

Tab. 2 Dough mixer IRIS 80-250

– Structure and panels

Tab. 3 Dough mixer IRIS 80-250

- Upper drive unit

Tab. 4 Dough mixer IRIS 80-250

- Bowl and protections

Tab. 5 Dough mixer IRIS 80-250

- Lower drive unit

Page 23

_______________________________

DOUGH

MIXER IRIS

_______________________________

22

TAV. 01 Dough mixer IRIS 30-40 rev.00

Page 24

_______________________________

DOUGH

MIXER IRIS

_______________________________

23

TAV. 01 Dough mixer IRIS 30-40 rev.00

Pos. Mod. 30 Mod. 40 Descrizione

1 306200270 306200270 * PLASTIC LID IRIS 30-40

2 463200007 463200007 ELECTRONIC TIMER 1ST SPEED 48x48

3 464102002 464102002 COMPLETE GREEN START BUTTON - MIXER IRIS

4 464102005 464102005 COMPLETE RED EMERGENCY BUTTON - MIXER IRIS

5 463200007 463200007 ELECTRONIC TIMER 2ST SPEED 48x48

6 553110010 553110010 CONTROL PANEL MIXER 30-40 IRIS

7 554110041 554110041 ELECTRIC PANEL MIXER 30-40/IRIS IN 220/50

7 554110043 554110043 ELECTRIC PANEL MIXER 30-40/IRIS IN 400/50

7 554110042 554110042 ELECTRIC PANEL MIXER 30-40/IRIS IN 220/60

7 554110044 554110044 ELECTRIC PANEL MIXER 30-40/IRIS IN 400/60

8 423240041 423240041 TRAPEZOIDAL BELT

9 321400370 321400370 PIRAL PULLEY

10 321400510 321400510 MIXER SPIRAL MOTIVE PULLEY

11 462660002 462660002 ON-OFF MAIN ROTATING SWITCH

12 429202207 429202207 MOBILE FLANGE SUPPORT d.35

13 421025001 421025001 OBLIQUE BEARING

14 420812010 420812010 RADIAL BEARING

15 422600003 422600003 OIL BLOCK

16 369000010 369000010 * SMALL PLASTIC CUP

17 315000290 315000290 SPIRAL MIXER TRANSMISSION SHAFT

18 429202207 429202207 MOBILE FLANGE SUPPORT d.35

19 308600290 308600290 * BACK AIRING PANEL

20 490202015 490202015 DRAWN ROD D. 15

21 301100260 301100260 * MIXER BODY IRIS 30-40

22 352600030 352600030 MIXTURE BLOCK FIXING BRACKET

23 356000180 356000180 WHITE PROFILE IN Pe500 DESIGNED FOR PA

24 362400516 362400515 MIXTURE BLOCK PROTECTION

25 315000040 315000040 MIXER SPIRAL HOLDER SHAFT

26 372700040 372700040 MIXER SPIRAL

27 362500130 362500120 METAL BOWL PROTECTION

28 331700060 331700040 MIXER COLUMN

29 420812010 420812010 RADIAL BEARING

30 361900012 361900022 BOWL WITH BURR

31 315100030 315100030 BOWL-HOLDER SHAFT - MIXER 40

32 483010005 483010005 PLASTIC FOOT ARTICULATED STEM Fe

33 429321002 429321002 TWINNED RUBBER WHEEL GIR. SUPPORT

34 421025001 421025001 OBLIQUE BEARING

35 423210038 423210038 TRAPEZOIDAL BELT

36 321400390 321400390 BOWL PULLEY

37 315400050 315400050 TRANSMISSION CLUTCH PIN

38 321400450 321400450 BOWL TRANSMISSION MOTIVE PULLEY

39 345500010 345500010 WELDED NUT ANTI-ROTATION MIXER BELT REG.

40 420812001 420812001 TRANSMISSION BEARING

41 303900310 303900310 BOWL TRANSMISSION SUPPORT

42 415010122 415010122 BOWL TRANSMISSION SHAFT KEY

43 315000280 315000280 BOWL TRANSMISSION SHAFT

44 415010151 415010151 BOWL SUPPORT SHAFT KEY

Page 25

_______________________________

DOUGH

MIXER IRIS

_______________________________

24

TAV. 01 Dough mixer IRIS 30-40 rev.00

45 410192010 410192010 THREADED BAR

46 482550003 482550003 WHEEL 6 LOBE PASSING HOLE

47 423240032 423240032 TRAPEZOIDAL BELT

48 321400380 321400380 BOWL TRANSMISSION DRIVEN PULLEY

49 321400400 321400400 SPIRAL TRANSMISSION DRIVEN PULLEY

50 423240017 423240017 TRAPEZOIDAL BELT

51 321400490 321400490 MIXER MOTOR PULLEY

52 467341200 467341200 MOTOR 2°V IRIS 30-40 IN 220/50

52 467341400 467341400 MOTOR 2°V IRIS 30-40 IN 400/50

52 467341300 467341300 MOTOR 2°V IRIS 30-40 IN 220/60

52 467341500 467341500 MOTOR 2°V IRIS 30-40 IN 400/60

53 321400500 321400500 BOWL TRANSMISSION MOTIVE PULLEY

54 315400070 315400070 PIN MOTOR SUPPORT CLUTCH

55 303900071 303900071 BOWL MOTOR MOBILE SUPPORT

56 410192010 410192010 THREADED BAR

COLOURS

* WHEN ORDERING PLEASE SPECIFY MIXER COLOUR

WHEN ORDERING PARTS PLEASE SPECIFY REGISTRATION NUMBER

CODE COLOUR

BASE CODE -01 WHITE

BASE CODE -02 CREAM

BASE CODE -03 METAL GREY

BASE CODE -04 LIGHT BLUE

BASE CODE -05 YELLOW

Page 26

_______________________________

DOUGH

MIXER IRIS

_______________________________

25

Page 27

_______________________________

DOUGH

MIXER IRIS

_______________________________

26

TAV. 02 Dough mixer IRIS 60-300 - Structure and panels Rev.001

01-06-2012

Page 28

_______________________________ DOUGH MIXER IRIS _______________________________

27

TAV. 02 Dough mixer IRIS 60-300 - Structure and panels Rev.001 01-06-2012

Pos. Mod. 60 Mod. 80 Mod. 100 130 Mod. Mod. 16 Mod. 200 Mod. 250 Mod. 300

Descrizione

1*

306200520 306200120 306200120 306200210 306200140 306200140 306200140 306200140

* PLASTIC MIXER LID

2

410347010 410347010 410347010 410347010 410347010 410347010 410347010 410347010

BLIND INOX NUT

3

411015010 411015010 411015010 411015010 411015010 411015010 411015010 411015010

PLANE INOX WASHER

4

362600020 362600020 362600020 362600020 362600020 362600020 362600020 362600020

MIXER CONTROL PANEL COVER

5

463200007 463200007 463200007 463200007 463200007 463200007 463200007 463200007

ELETRIC TIMER 1ST SPEED 48x48

6*

464102001 464102001 464102001 464102001 464102001 464102001 464102001 463402001

COMP. SWITCH SIEMENS INV. BOWL MIXER IRIS

7*

464102002 464102002 464102002 464102002 464102002 464102002 464102002 463402002

* COMPLETE GREEN BUTTON SIEMENS STA RT MIXER IRIS

8*

464102003 464102003 464102003 464102003 464102003 464102003 464102003 463402003

* COMPLETE BLACK BU

TTON TELEMECANIQUE BOWL ROTAT ION

9*

464102004 464102004 464102004 464102004 464102004 464102004 464102004 463402004

* COMPL. BLACK SWITCH SIEMENS LOW /HIGH SPEED IRIS

10

463200007 463200007 463200007 463200007 463200007 463200007 463200007 463200007

ELETRIC TIMER 2ST SPEED 48x48

11*

460201002 460201002 460201002 460201002 460201002 460201002 460201002 460201002

* SCREEN-PRINTED PANEL FOR MIXER IRIS

12*

464102005 464102005 464102005 464102005 464102005 464102005 464102005 463402005

* COMPLETE RED BUTTON SIEMENS EMERG. IRIS

13*

553120020 553120020 553120020 553120020 553120020 553120020 553120020 553120020

* CONTROL PANEL MIXER 60-300 IRIS DIGITAL E LETTROMEC. SIEMENS

13*

553120010 553120010 553120010 553120010 553120010 553120010 553120010 553120010

* CONTROL PANEL MIXER 60-

300 IRIS ELETTROMEC. TELEMECANIQUE

14

356300040 356300040 356300040 356300040 356300040 356300040 356300040 356300040

THREADED BAR

15

410320010 410320010 410320010 410320010 410320010 410320010 410320010 410320010

HEXAGONAL NUT

16*

308600290 308600290 308600290 308600290 308600290 308600290 308600290 308600290

* BACK MIXER AIRING PANEL

17

482520002 482520002 482520002 482520002 482520002 482520002 482520002 482520002

LOCK WITH KEY WITH FINS

18

462660007 462660007 462660007 462660007 462660007 462660007 462660007 462660007

ON-OFF MAIN ROTATING SWITCH

19*

307600011 307600010 307600010 307600040 307600020 307600020 307600020 307600020

* MIXER CONTROL PANEL DOOR

20

483010001 483010001 483010001 483010001 483010001 483010001 483010001 483010001

PLASTIC FOOT ARTICULATED STEM Fe

21

429320002 429320002 429320002 429320002 429320002 429320002 429320002 429320002

WHEEL WITH TURNING SUPPORT HEAVY CAST IRON + POLES

22

429330001 429330001 429330001 429330001 429330001 429330001 429330001 429330001

WHEEL WITH FIXED SUPPORT D100 SUPP ORT PE

23*

301100270 301100070 301100070 301100190 301100100 301100100 301100100 301100510

* MIXER BODY IRIS

24*

308600280 308600280 308600280 308600280 308600280 308600280 308600280 308600280

* LOWER INSPECTION HATCH. IRIS

* WHEN ORDERING PLEASE SPECIFY MIXER COLOUR WHEN ORDERING PARTS PLEASE SPECIFY REGISTRATION NUMBER

CODE COLOUR CODE COLOUR

BASE CODE -01 WHITE BASE CODE -04 BASE CODE -04

BASE CODE -02 PANNA BASE CODE -05 YELLOW

BASE CODE -03 METAL GREY

Page 29

_______________________________

DOUGH

MIXER IRIS

_______________________________

28

TAV. 03 Dough mixer IRIS 60-300 - Upper drive unit Rev.001

01-06-2012

Page 30

_______________________________ DOUGH MIXER IRIS _______________________________

29

TAV. 03 Dough mixer IRIS 60-300 - Upper drive unit Rev.001 01-06-2012

Pos.

Mod. 60 Mod. 80 Mod. 100 130 Mod. Mod. 160 Mod. 200 Mod. 250 Mod. 300 Descrizione

1

429005002 429005002 429005002 429000001 429000001 429000001 429000001 429000001 CONE BUSH / KEYER

2

423240074 423240085 423240085 423240093 423240096 423240096 423240096 423240096 TRAPEZODAL BELT

3

423010525* 423010525* 423010525* 321400424* 321400424* 321400424* 321400424* 321400424 *

SPIRAL DRIVEN PULLEY MIXER IRIS

4

420812008 420812011 420812011 421005007 421005007 421005007 421005007 421005007 UPPER BEARING MIXER SPIRAL IRIS

5

303800310 303800220 303800220 303800220 303800220 303800220 303800220 303800220 SPIRAL BEARING SUPPORT

6

421025003 421005004 421005004 421005007 421005007 421005007 421005007 421005007 BEARING

7

422600005 422600007 422600007 422600010 422600010 422600010 422600010 422600010 OIL BLOCK

8

315000300 315000140 315000140 315000120 315000120 315000120 315000120 315000120 MIXER SPIRAL HOLDER SHAFT

9

369000020 369000020 369000020 369000030 369000030 369000030 369000030 369000030

PLASTIC CUP

10

372700080 372700010 372700010 372700060 372700020 372700020 372700030 372700090

MIXER SPIRAL- IRIS

11

467253400 * 467263401 * 467263400 * 467263402 * 467273400 * 467273400 * 467273401 * 467273402

* SPIRAL MOTOR

12

317500050-53 317500010-53 317500010-53 317500010-53 317500020-53 317500020-53 317500020-53 317500020-53

SPIRAL MOTOR SLIDE

13

321400261 321400260 321400260 321400171 321400170 321400170 321400170 321400170

SPIRAL MOTIVE PULLEY

14

346600020 346600020 346600020 346600020 346600020 346600020 346600020 346600020

PLAIN WASHER

15

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - -

16

303900131-53 303900131-53 303900131-53 303900261 303900261 303900261 303900261 303900261

SPIRAL TRANSMISSION SUPPORT MIXER

17

315000160 315000160 315000160 315000250 315000250 315000250 315000250 315000250

ALBERO PULEGGIA RINVIO

18

420812009 420812009 420812009 420812020 420812020 420812020 420812020 420812020

BEARING

19

423240014 * 423240021 * 423240021 * 423240021 * 423240031 * 423240031 * 423240031 * 423240031

* TRAPEZODAL BELT

20

321400250 * 321400250 * 321400250 * 321400430 * 321400430 * 321400430 * 321400430 * 321400430

*PULEGGIA DOPPIA

21

420812009 420812009 420812009 420812020 420812020 420812020 420812020 420812020

BEARING

22

351400080 351400080 351400080 351400080 351400080 351400080 351400080 351400080

DISTANZIALE

23

Vedi pos. 16 Vedi pos. 16 Vedi pos. 16 Vedi pos. 16 Vedi pos. 16 Vedi pos. 16 Vedi pos. 16 Vedi pos. 16

SUPPORTO RINVIO SPIRALE

* WHEN ORDERING PLEASE SPECIFY MIXER COLOUR

WHEN ORDERING PARTS PLEASE SPECIFY REGISTRATION NUMBER

Page 31

_______________________________

DOUGH

MIXER IRIS

_______________________________

30

TAV. 04 Dough mixer IRIS 60-300 - Bowl and protections Rev.001

01-06-2012

Page 32

_______________________________ DOUGH MIXER IRIS _______________________________

31

TAV. 04 Dough mixer IRIS 60-300 - Bowl and protections Rev.001 01-06-2012

Pos.

Mod. 60 Mod. 80 Mod. 100 130 Mod. Mod. 160 Mod. 200 Mod. 250 Mod. 300 Descrizione

1

362500380 362500100 362500110 362500070 362500050 362500060 362500210 362500320

METAL BOWL PROTECTION IRIS

1

362400810 362400090 362400090 362400180 362400110 362400110 362400960 362400950

* PLASTIC PROTECTION IRIS

2

464805001 464805001 464805001 464805001 464805001 464805001 464805001 464805001

BOWL PROTECTION LIMIT SWITCH

3

332800010 332800010 332800010 332800010 332800010 332800010 332800010 332800010

GRID LIMIT SWITCH STARTER RANGE

4 *

490202015 490202015 490202015 490202015 490202015 490202015 490202015 490202015

DRAWN ROD D. 15

5

334000051 334000051 334000051 334000051 334000051 334000051 334000051 334000051

GRID STOP IRIS L=35

6

334000050 334000050 334000050 334000050 334000050 334000050 334000050 334000050

GRID STOP IRIS L=70

7

511600040 511600040 511600040 511600040 511600041 511600041 511600041 511600041

ROLLER GROUP WULKOLAN WITH BEARINGS

8

315400090 315400090 315400090 315400090 315400100 315400100 315400100 315400100 THREAD PINS FOR THRUST BEARING ROLLER

9

303800400_50 303800260_50 303800260_50 303800260_50 303800360_50 303800360_50 303800360_50 303800360_50

THRUST BEARING ROLLER SUPPORT

10

352600030 352600030 352600030 352600030 352600030 352600030 352600030 352600030 MIXTURE BLOCK FIXING BRACKET

11 *

331700090 331700010 331700010 331700050 331700030 331700030 M253-93 331700070 MIXER COLUMN

12

361900031 361900041 361900051 361900061 361900071 361900081 361900091 361900100 MIXER BURR BOWL

13 *

356000180 356000180 356000180 356000180 356000180 356000180 356000180 356000180 WHITE PROFILE FOR MIXTURE STOP

14

362400511 362400510 362400511 362400512 362400513 362400514 362400517 362400760 MIXTURE BLOCK PROTECTION IRIS

15

511100190 511100050 511100050 511100050 511100060 511100060 511100060 511100060

BOWL THRUST BEARING SUPPORT GROUP

* WHEN ORDERING PLEASE SPECIFY MIXER COLOUR

WHEN ORDERING PARTS PLEASE SPECIFY REGISTRATION NUMBER

Page 33

_______________________________

DOUGH

MIXER IRIS

_______________________________

32

TAV. 05 Dough mixer IRIS 60-300 - Lower drive unit Rev.001

01-06-2012

Page 34

_______________________________ DOUGH MIXER IRIS _______________________________

33

TAV. 05 Dough mixer IRIS 60-300 - Lower drive unit Rev.001 01-06-2012

Pos.

Mod. 60 Mod. 80 Mod. 100 130 Mod. Mod. 160 Mod. 200 Mod. 250 Mod. 300 Descrizione

1

315100050 315100020 315100020 315100010 315100010 315100010 315100010 315100010 MIXER BOWL-HOLDER SHAFT

2

422600005 422600007 422600007 422600010 422600010 422600010 422600010 422600010 OIL BLOCK

3

421025003 421005004 421005004 420812012 420812012 420812012 420812012 420812012

UPPER BEARING MIXER SPIRAL IRIS

4 *

303800310 303800220 303800220 303800160 303900040 303900040 303900220 303800160 SPIRAL BEARING SUPPORT

5

420812008 420812011 420812011 421005007 421005007 421005007 421005007 421005007 LOWER SPIRAL BEARING

6

321400051 321400051 321400051 321400020 321400020 321400020 321400020 321400020 PULLEY

7

423240066 423240074 423240074 423240089 423240090 423240090 423240092 423240093 TRAPEZOIDAL BELT

8

346600030

410112091

346600030

410112091

346600030

410112091

429000004 429000004 429000004 429000004 429000004 TONGUE/KEYER

9

315400050 315400050 315400050 315400050 315400050 315400050 315400050 315400050

TRANSMISSION CLUTCH PIN

10

420812007 420812007 420812007 420812007 420812007 420812007 420812007 420812007

RADIAL BEARING

11

315000070 315000070 315000070 315000070 315000070 315000070 315000070 315000070

ALBERO PER RINVIO VASCA

12

303800250 303800250 303800250 303800250 303800250 303800250 303800250 303800250

SUPPORTO RINVIO VASCA

13

321400090 321400090 321400090 321400210 321400210 321400210 321400210 321400210

PULLEY

14

POS.22 o POS. 27 POS.22 o POS . 27 POS.22 o POS. 27 POS.22 o POS. 27 POS.22 o POS . 27 POS.22 o POS. 27 POS.22 o POS. 27 POS.22 o POS . 27

15

415010142 415010142 415010142 415010142 415010142 415010142 415010142 415010142

TONGUE

16

423240085 423240088 423240088

423240091 *

423240091 423240091 423240091 423240091

TRAPEZOIDAL BELT

17

415010175 415010175 415010175 415010175 415010175 415010175 415010175 415010175

TONGUE

18

410112132 + 410123048 + 411061006 + 346600020 + 410156038 + 411080016

TWO HOLE WASHER FOR SHAFT

19 *

467221400 467221400 467221400 467231400 467241400 467241400 467241400 467241400

SPIRAL MOTOR

20

414501040 414501040 414501040 414501040 414501040 414501040 414501040 414501040

EXTERNAL STOP RING

21

321400060 321400060 321400060 321400520 321400200 321400200 321400200 321400200

PULLEY

22

309100020-53 309100020-53 309100020-53 309100020-53 309100020-53 309100020-53 309100020-53 309100020-53

THREADED BAR

23

411008010 411008010 411008010 411008010 411008010 411008010 411008010 411008010

PLAIN WASHER

24

482550003 482550003 482550003 482550003 482550003 482550003 482550003 482550003

6 LOBE WHEEL PASSING HOLE

25

346600030 346600030 346600030 346600030 346600030 346600030 346600030 346600030

TWO HOLE WASHER FOR SHAFT

26

321400110 321400110 321400110 321400150 321400150 321400150 321400150 321400150

PULLEY

27

309100030-53 309100030-53 309100030-53 309100030-53 309100030-53 309100030-53 309100030-53 309100030-53

THREADED BAR

28

303900070-53 303900070-53 303900070-53 303900070-53 303900070-53 303900070-53 303900070-53 303900070-53

BOWL MOTOR MOBILE SUPPORT

29

315400070 315400070 315400070 315400070 315400070 315400070 315400070 315400070

PIN MOTOR SUPPORT CLUTCH

30

482550003 482550003 482550003 482550003 482550003 482550003 482550003 482550003

6 LOBE WHEEL PASSING HOLE

* WHEN ORDERING PLEASE SPECIFY MIXER COLOUR

WHEN ORDERING PARTS PLEASE SPECIFY REGISTRATION NUMBER

Page 35

_______________________________

DOUGH

MIXER IRIS

_______________________________

34

Loading...

Loading...