Page 1

Mod: ICE32A

Production code: CB316A

11/2007

Page 2

It is strictly forb

idden to reproduce this instruction manual or any part thereof.

AUTOMATIC ICE-CUBE MAKER

INSTRUCTIONS AND WARNINGS

24478 ed. 11-2007

Page 3

Page 4

Page 5

Page 6

Page 7

Dear Customer, Congratulations on having chosen a quality product which will certainly fully

meet your expectations. Thank you for having purchased one of our products. Please read

this instructi on manual carefully before using your new automatic ice-cube maker.

TABLE OF CONTENTS

1 IMPORTANT ADVI

CE AND RECOMMENDATIONS

2 TECHNICAL SPECIFICATIONS

3 ADVICE ABOUT TRANSPORTATION

4 UNPACKING

5 INSTALLATION

5.1

CONNECTION DIAGRAM

5.2 POSITIONING

5.2.a POSITIONING FOR FLUSH-MOUNTING MODELS

5.3 CONNECTION TO WATER MAINS

5.3.a WATER SUPPLY

5.3.b DRAIN

5.4 CONNECTION TO THE ELECTRICITY MAINS

6 START-UP

6.

1 CLEANING INTERNAL P A R TS

6.2 START-UP

6.2.a STARTING-UP MODELS WITH CONTINUOUS DELIVERY

7 MAIN CAUSES OF OPERATING FAILURE

8 OPERATION

8.

1 MODEL WITH CONTINUOUS DELIVER Y

8.1.a ADJUSTING DISPENSED QUANTITY

8.2 MODEL WITH COLD WATER DISPENS ER

9 MAINTENANCE

9.

1 CLEANING THE FILTE R OF WATER SUPPLY SOLENOID VALVE

9.2 AIR-COOLED MODELS

9.3 CLEANING AND SANITIZING OPERATIONS

10 PERIODS AT A STANDSTILL

T

h

e figures in this manual are of a general nature. Some details may therefore differ

depending on the specific model.

The Manufacturer declines all liability for an y inaccuracies in this instruction manual due to

printing or transcription errors. The Manufacturer also reserves the right to make any

modifications to the products that may be necessary or useful, also in the interests of the

user, without impairing the products’ essential features of functional ity and safety.

Page 8

1 IMPORTANT ADVICE AND RECOMMENDATIONS

This instruction manual forms an integral part of the automatic ice-cube maker (also more

simply called “appliance” in the text) and must be kept for possible future consultation.

In the event of the appliance being sold or transferred to another person, this manual must be handed

over to the new user, in order to enable him to become familiar with the operation of the equipment and

the corresponding advice and recommendations.

‼ Before installing and using the appliance, read the advice and recommendations contained

in this instruction manual very carefully. They are given in order to ensure safe installation, use

and maintenance of the appliance.

• always remove the plug from the power socket before proceeding with any cleaning or maintenance

operations

• to ensure the appliance operates efficiently and correctly, it is essential to comply with th

e

Ma

nufacturer’s instructions and to make sure that maintenance is performed by specially q

ualified

personnel

• do not remove any of the panels or grilles

• do not rest objects on the appliance or in front of the ventilation grilles

• always lift the appliance to move it, even slightly. Do not push or pull it

• any use of the appliance other than for the production of ice cubes using cold drinking water is to be

considered as improper use

• do not obstruct the ventilation and heat-dissipation grilles, since poor aeration - in ad

dition to

reducing efficiency and causing poor operation - may also cause serious damage to the appliance

• if the appliance breaks down and/or operates in a faulty way, switch it off by means of the main

switch fitted during the installation phase, remove the plug from the socket (if any), and turn off the

water tap. Do not make any attempt to repair the appliance yourself. Contact only professionally

qualified and authorized personnel

• in addition to rendering any form of warranty null and void, modifying (or attempting to modify) this

appliance is extremely dangerous

• open and close the door carefully without slamming it

• do not use the ice-cube container to cool or preserve food or drinks, as these operations could cause

the drain system to become clogged, thus leading to the container filling up and water leaking out

• in the event of a failure, contact the dealer who sold you the appliance; he will be able to give y

ou

the address of your nearest Authorized Technical Service Centre. Always insist on having original

spare parts mounted

• any specific information or diagrams regarding particular models will be attached to this instruction

manual

‼ Use of this electrical appliance requires compliance with certain fundamental rules; in particular:

• do not touch the appliance with wet or damp hands or feet

• do not use the appliance when you are barefoot

•

do not use extensions in premises such as bathrooms or shower rooms

• do not tug on the power supply cable to disconnect it from the mains

• do not allow the appliance to be used by children, incapable or inexperienced persons, unless they are

supervised or instructions have been issued about the use of the appliance by a person responsible

for their safety

• supervise children to ensure that they do not play with the appliance

Should you decide to scrap appliance, first disconnect the power cable from the mains, and then cut the

cable off.

In addition, proceed as follows:

• break off and remove the door in order to prevent the possible danger of a child getting trapped inside

• do not allow the coolant gas and oil in the compressor to disperse into the environment

• dispose of or recover the various materials according to the provisions established by the current laws

in force in your Country

Page 9

This appliance does not contain coolant that damages the ozone layer.

‼ The Manufacturer shall not be liable for any damage to the environment, animals, persons

or objects caused by incorrect installation.

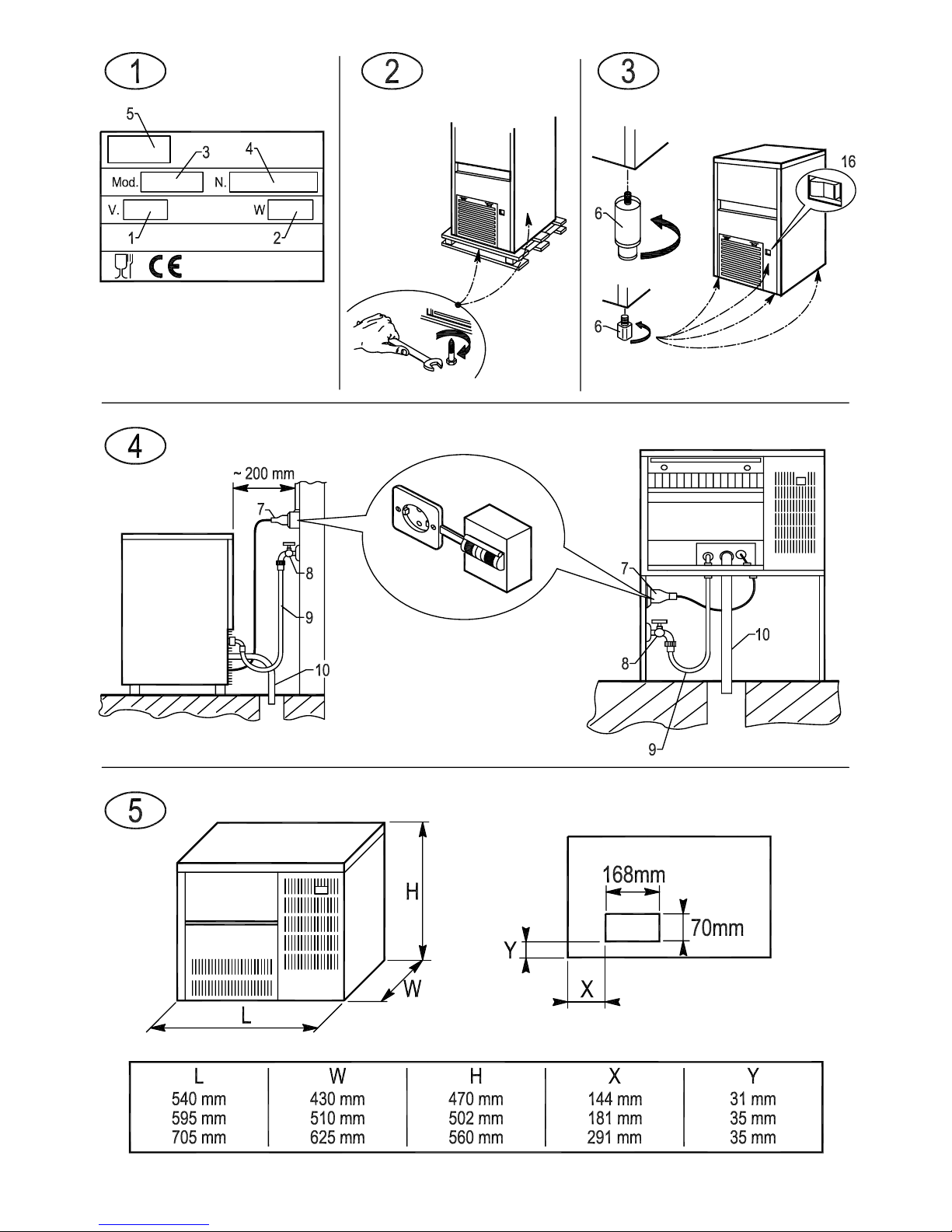

2 TECHNICAL DATA (Fig. 1)

The voltage and frequency are given on the data plate on the appliance. Refer to this data plate to

check compliance.

Voltage (1), power (2), model (3 ), serial No. (4), Manufacturer (5).

The weighted equivalent continuous sound level A of this appliance is less than 70 dB(A). The

measurements were made over an entire production cycle, at a distance of 1 m from the surface of the

appliance and at a height of 1.60 m from the floor.

The wiring diagram is stuck on the front counterpanel of the appliance.

In order to gain access thereto, unplug the appliance from the power source, loosen screws holding the

front panel, and slide it away after first opening the door.

3 ADVICE ABOUT TRANSPORTATION

The net weight and the weight including packaging of the appliance are given on the cover of this

instruction manual. Please refer to the instructions on the packaging in order to correctly transport and

lift the appliance.

To prevent the oil in the compressor from flowing back into the coolant circuit, always make sure that

the appliance is kept upright during transport, storage, and handling. Follow the instructions given on

the packaging.

4 UNPACKING

The appliance must be installed by authorized personnel, in compliance with the current laws in

force and the Manufacturer’s instructions.

Once you have removed the packaging according to the instructions on the box, MAKE SURE THAT

THE APPLIANCE IS IN A PERFECTLY GOOD CONDITION. IF IN DOUBT, DO NOT USE IT AND

IMMEDIATELY CONTACT THE DEAL E R who sold it to you.

All the packaging items (plastic bags, cardboard, polystyrene foam, nails, etc.) must be removed

and put out of the reach of children, as they are potential sources of danger.

Rest the wooden pallet on the floor and, using a hex socket wrench, loosen and remove the bolts (Fig. 2)

that fix the appliance to the pallet.

Lift the appliance using equipment fit to bear its weight. Separate the appliance from the wooden pallet

and fit the supplied legs into the housings on the base plate provided for the purpose (6 in Fig. 3).

Use a spirit level to ensure that the appliance is standing perfectly level. If necessary, adjust the legs.

5 INSTALLATION

5.1 CONNECTION DIAGRAM (Fig. 4)

7. electrical connection controlled by omnipolar circuit-breaker with residual current device

8. water tap

9. water supply pipe

10. water drainag

e pipe

Page 10

5.2 POSITIONING

‼ The appliance must be installed in a hygienically clean location; it is advisable to avoid

rooms like cellars and store-rooms, because failure to meet hygiene requirements is likely to

lead to the formation and prolif er ation of bacteria in the applia nc e .

The appliance can operate at an ambient temperature of between 10°C and 43°C.

The best performance will be obtained by installing the appliance in a place with an ambient

temperature of between 10°C and 35°C and a water temperature of between 3°C and 25°C.

Avoid direct exposure to sunlight and do not install near heat sources.

‼ This appliance:

• must be installed in a place where it can be supervised by skilled personnel

• must not be used outdoors

•

must not be installed in damp places or where it is liable to be sprayed with water

• must not be cleaned with jets of water

• must be positioned at a distance of at least 5 cm from the side walls (this does not apply to the

flush-mounting models)

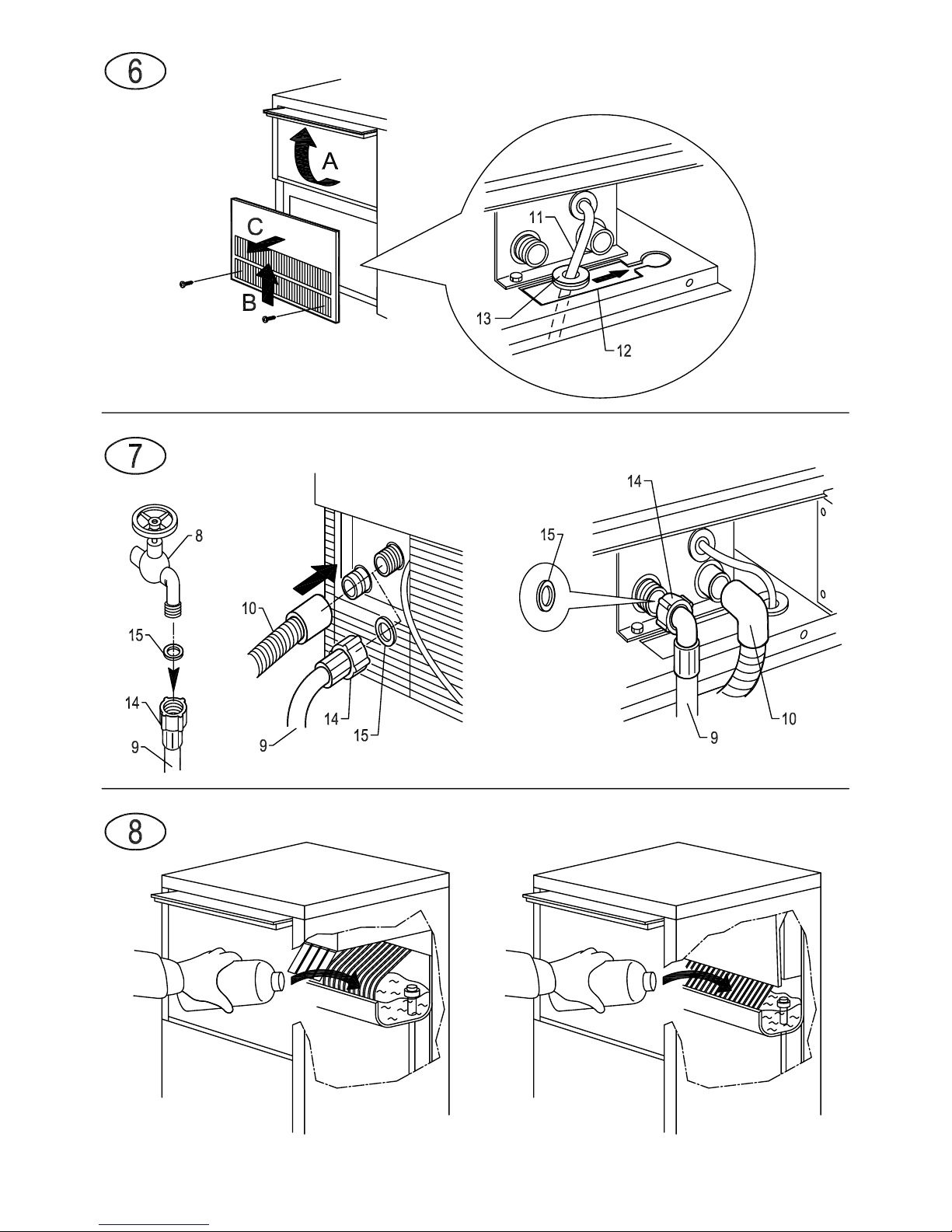

5.

2.a POSITIONING FOR FLUSH-MOUNTING MODELS

Ventilation is ensured by the grille on the front panel; it is therefore not necessary to leave any gap,

except to facilitate installation.

A hole must be made in the surface where the appliance is to be located so that the power cable,

water supply pipe and the w a ter drain pipe can be passe d through as shown in Fig. 5.

The plug and water supply and drain connections are accessible from the front panel.

To access these, disconnect the appliance from the power supply, unscrew the screws that hold the

front panel in place and after opening the door, pull out the panel from above (Fig. 6).

Before fitting the appliance in place, the power cable must be fixed to the base plate as shown in

the diagram in Fig. 6:

• pass the plug and cable (11) through the hole (12) in the plate

• position the cable clamp (13) in its housing

Fit the front panel back in place after making these connections.

5.3 CONNECTION TO THE WATER MAINS

‼ IMPORTANT:

• the appliance must be connected to the water mains by professionally qualified personnel in

accordance with the Manufacturer’s instructions

• this appliance must be only be supplied with cold water for human consumption (drinking water)

• the operating pressure must be between 0.1 and 0.6 MPa

• a tap must be installed between the water mains and the feed pipe of the appliance, so that the

water supply may be shut off if necessary

• where the feed water is particularly hard, you are advised to install a softener. Any solid particles

(e.g. sand) may be eliminated by installing a mechanical filter, which must be periodically inspecte

d

and cleaned. These devices must comply with the standards in force in the Country of use

• never turn the water supply tap off when the appliance is working

5.3.a FILLING WITH WATER ( Fig. 7)

Inse

rt the special seals provided (15) in the two threaded ring nuts (14) of the water supply pipe (9)

supplied with the appliance.

Without exerting excessive force (otherwise the unions could crack), firmly tighten one of the

threaded ring nuts on the outlet of the solenoid valve located in the rear of the appliance (front for

t

he flush-mounting models). The other threaded ring nut must be screwed to the water tap (8);

this too must be provided with a thread.

Page 11

5.3.b DRAIN (Fig. 7)

Fix the water drain pipe ( 10) in the housing provided on the rear of the appliance (front for the

flush-mounting models). Make sure that:

• the pipe is a hose

•

the internal diameter is 22 mm, as required

• the water drain hose is not throttled at any point throughout its length

• the drain hose slopes downwards by at least 15%

It is advisable to drain the water straight into an open drain trap.

5.4 CONNECTION TO THE ELECTRICITY MAINS

‼ IMPORTANT:

• the appliance must be connected to the electricity mains by professionally qualified personnel in

accordance with the Manufacturer’s instructions

• before connecting the appliance to the electricity mains, make sure that the mains voltage ra

ting

corresponds to the value indicated on the rating plate

• make sure that the appliance is connected to an efficient earthing system

• make sure that the capacity of the power supply system suits the maximum power value indicated

on the rating plate of the appliance

• if the appliance comes supplied with a plug, prepare a socket controlled by an omnipolar circuitbreaker (7 in Fig. 4), with a contact-opening gap of not less than 3 mm, in accordance with national

safety standards currently in force. This switch must be equipped with fuses, with the associated

residual current device positioned in such a way as to be readily accessible. Insert the plug into the

socket controlled by the switch (7 in Fig. 4)

• the plug must only be replaced by professionally qualified and authorized personnel, and the new

plug must comply with current national safety standards

• if the appliance comes supplied without a plug and you wish to connect it permanently to the power

supply, prepare an omnipolar circuit-breaker (7 in Fig. 4), with a contact-opening gap of not less

than 3 mm, in accordance with national safety standards currently in force. This switch must be

equipped with fuses, with the associated residual current device positioned in such a way as to be

readily accessible. This operation must be carried out by a specialized technician

• make sure that you fully uncoil the power supply cable and check that it is not crushed in any way

• should the supply cable be damaged, it must be replaced by a specialized technician usin

g a

special cable available from the Manufacturer or from the Technical Service Centres

6 START-UP

6.1 CLEANING INTERNAL PARTS

The appliance will have already been cleaned in the factory. However, you are advised to wash the

internal parts again before using the appliance. Make sure that the power supply cable is unplugged

before carrying out the above cleaning operation.

See cleaning and sanitizing manual for information regarding cleaning operations.

For cleaning operations in general, use an ordinary detergent for washing dishes or a solution of water

and vinegar. Rinse thoroughly with plenty of cold water and remove any ice that may have been

produced during the first 5 cycles after cleaning, together with any ice present in the bin.

It is advisable to avoid using abrasive detergents or powders, since these might damage the finish.

6.2 START-UP

When you start up the appliance the first time, or when you start it up again after a long period at

a standstill, fill the basin manually with water (Fig. 8).

This filling operation must be carried out by opening the door, raising the flaps (if any) and pouring the

water directly into the internal basin.

In the cycles subsequent to the initial one, the appliance will be filled with water in a fully automatic way.

Page 12

Once the appliance has been correctly connected to the electricity mains, water mains and water drain

system, it can be started up as follows:

a) turn on the water supply tap (8 in Fig. 4)

b) insert the plug (if any) in the socket and switch on the power supply by means of the relative switch

fitted during the installation phase (7 in Fig.

4)

Switch on appliance by pressing the luminous switch (16 in Fig. 3).

For appliances that are connected permanently to the electricity mains, turn on by means of the switch

on the outside of the appliance, fitted during the installation phase.

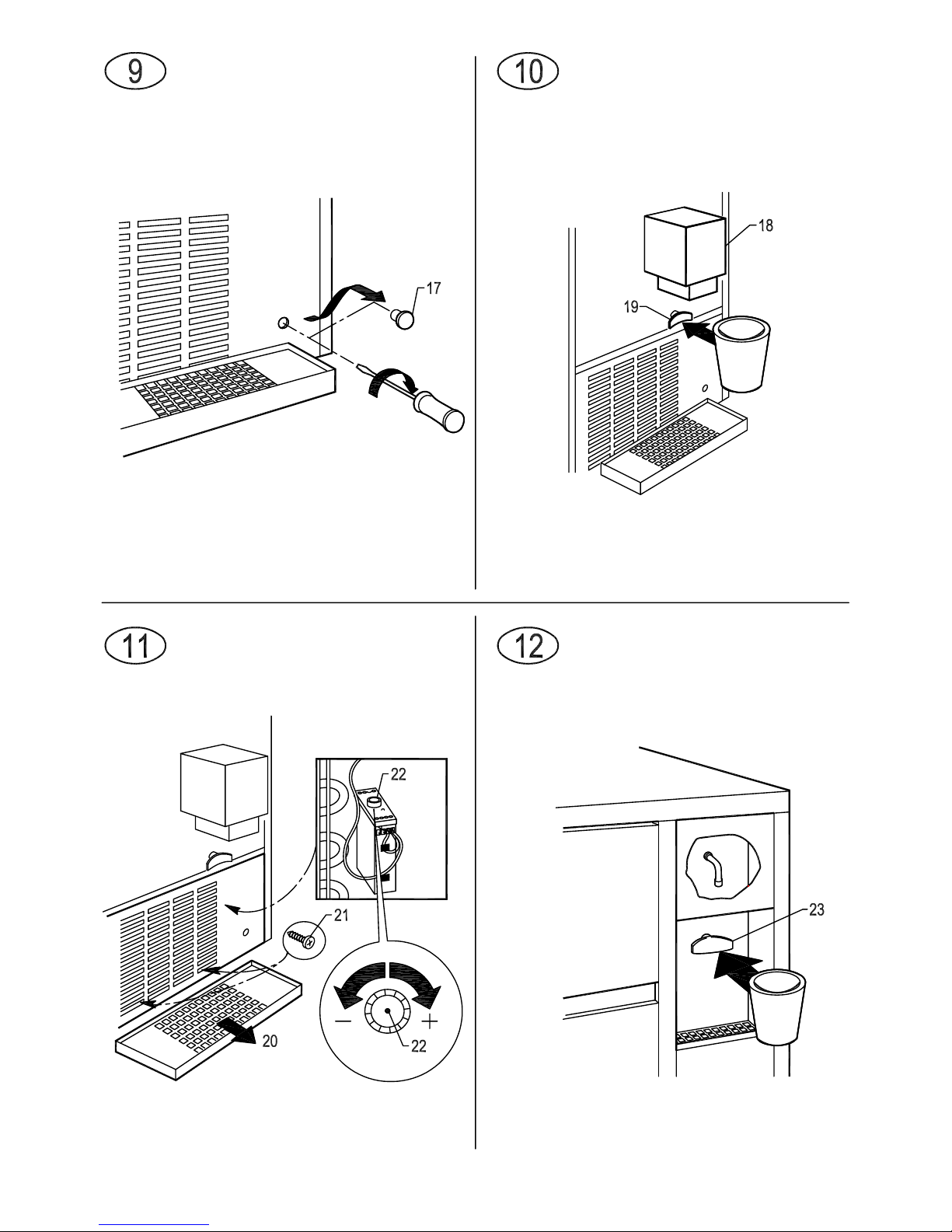

6.2.a STARTING UP MODELS WITH CONTINUOUS DELIVERY (Fig. 9)

Carry out operations a) and b) described above; then:

•

remove the plug (17) on the front grille pan

el

•

using a screwdriver turn the adjusting screw of the timer clockwise until you hear a click and the

water pump stops

• repeat the previous operation three times consecutively at intervals of one minute each

• when this operation has terminated, fit the plug (17) back on the front grille; the appliance will

automatically start producing ice

7 MAIN CAUSES OF OPERATING FAILURE

Should the appliance fail to produce ice, before calling on the Authorized Technical Service Centre, first

check carefull y t hat:

• the water supply tap (8 in Fig. 4), fitted during the installation phase, has been turned on

• electric power is reaching the appliance; the plug (if any) is properly inserted in the socket, the switch

(7 in Fig. 4) is in the “ON” position, and the push button (16 in Fig. 3) is lighted up

Furthermore:

• if there is excessive noise, make sure that the appliance is not touching furniture or sheet metal which

can give rise to noise or vibrations

• should any trace of water appear, check the drain hole of the container to ensure that it is not clogged,

that the water fill and drain pipes are correctly connected and are not throttled or damaged

• make sure that the temperature of the air or water does not exceed the installation limit values

(see paragraph 5.2)

• make sure that the water inlet filter is not clogged (see paragraph 9.1)

• make sure that the spray nozzles are not clogged with scaly deposits

If the fault still persists after the above inspections have been made, turn off the electric power source

by means of the switch fitted during the installation phase, pull out the plug from its socket, turn off the

tap connecting the appliance to the water mains, and contact the nearest Authorized Technical Service

Centre.

To obtain a faster and more efficient reply when you call the Centre, state the model of the appliance

precisely, together with its serial number or manufacturing number. This information is given on the

serial N° plate (Fig. 1) affixed to the rear of the appliance and on the cover of this instruction manual.

8 OPERATION

The appliance has a thermostat probe in the ice bin, which stops ice production when the ice

accumulated in the bin reaches the probe connected to the thermostat.

When ice is taken from the bin, the thermostat will automatically rea ctivate ice-cube production, thus

creating a new supply of ice.

8.1 MODEL WITH CONTINUOUS DELIVERY (Fig. 10)

The appliance is equipped with an ice-cube dispenser (18) on the front.

To take the required quantity of ice, place a glass or a suitable container under the dispenser and press

the button (19) to turn on the supply.

Page 13

8.1.a ADJUSTING DISPENSED QUANTITY (Fig. 11)

‼ IMPORTANT:

• the operations described below must be performed by a specialized technician, and only after

disconnecting the appliance from the electricity mains

• all operations that require handling of parts made of metal plate must be carried out wearing

suitable gloves to prevent cuts

The appliance is provided with an electronic device for adjusting the quantity of ice dispensed each

time.

To increase or decrease the dispensing time and the proportionate quantity of ice dispensed,

proceed as follows:

• remove the basin (20)

• slacken off the screws (21) on the front panel using a Phillips screwdriver

• pull out the front panel from above

•

turn the knob (22) on the electronic device clockwise to increase the quantity of ice dispensed

whenever the button is pressed, and anti-clockwise to reduce the quantity

8.2 MODEL WITH COLD WATER DISPENSER (Fig. 12)

The appliance is provided with a cold water dispenser located beside the ice bin.

To obtain cold water, place a glass under the outlet and gently press the button (23) to turn on the water

tap. Release the button to stop the flow of cold water.

If the appliance is already provided with a filter located on the cold water supply circuit, read the

instructions on the filter label carefully and follow the manufacturer’s recommendations regarding the

replacement schedules.

9 MAINTENANCE

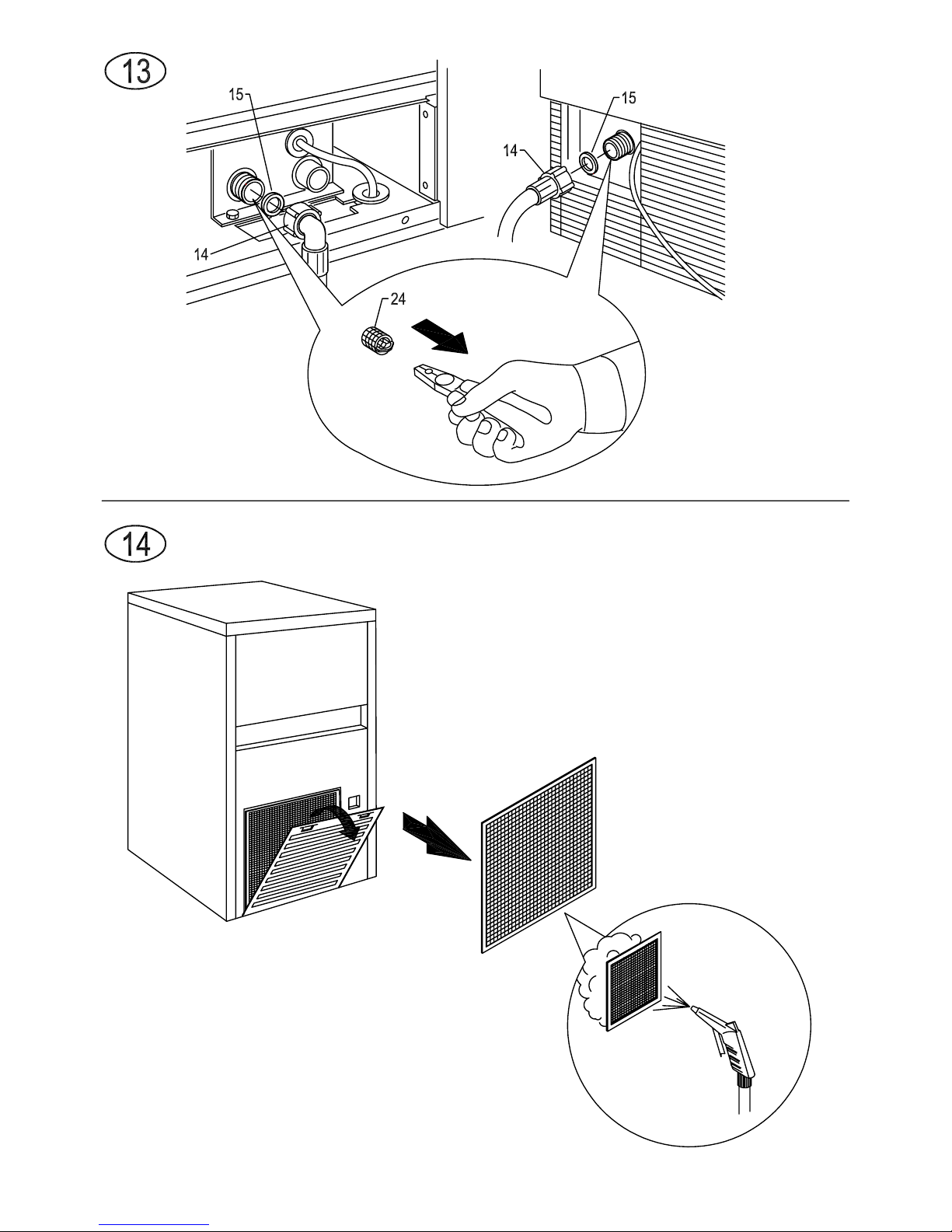

9.1 CLEANING THE FILTER OF WATER SUPPLY SOLENOID VALVE (Fig. 13)

!! At least every two months, clean the filter (24) located on the water inlet solenoid valve, proceeding

as follows:

• switch off the electric power supply by means of the switch (7 in Fig. 4), fit ted during installati on,

and disconnect the plug of the appliance from its socket (if any)

• shut off the water supply by turning the tap (8 in Fig. 4) fitted during installation

• unscrew the threaded ring nut (14) of the water feed hose, located at the outlet of the solenoid valve at

the rear of the appliance (front for the flush-mounting mode ls). For the built-in model, first remove

the panel as indicated at point 5.2.a

•

using a pair of pliers, remove the filter (24) from its seat without damaging the water feed pipe

connector

• place the filter under a strong jet of water to remove residue, but replace the filter if it is excessively

dirty

After having carried out the cleaning operations, refit the filter and hose pipe taking the necessary

precautions described earlier in the instruction manual.

When the operations have terminated, turn on both the electricity supply and wate r supply.

9.2 AIR-COOLED MODELS (Fig. 14)

For air-cooled models, it is very important to keep the finned condenser and its external filter (if any) clean.

Have the finned condenser cleaned at least once every two months by an Authorized Technical Service

Centre, which can include this operation in the scheduled maintenance programme.

The external filter (if any) must be cleaned at least once a month, as follows:

• switch of f app l ian ce an d cut off power supply with the switch (7 in Fig. 4) fitted at the installation stage

• open plastic grille

• remove filter and keep it at a distance form the appliance

•

remove dust from filter by blowing with compressed air

• replace filter in its seat and close plastic grille

Page 14

9.3 CLEANING AND SANITIZING OPERATIONS

A cleaning and sanitizing kit specifically designed for this appliance is available from your

dealer.

‼ Do not use corrosive substances to remove limescale from the appliance, because this will

invalidate the warranty, and may cause serious damage to the materials and components of the

appliance.

Do not use jets of water to clean the appliance.

‼ All cleaning operations must be carried out only after the electric power and water supplies

have been disconnected, as described previously, by professionally qualified and authorized

personnel.

Follow the instructions given in the cleaning and sanitizing manual supplied with the appliance.

‼ IMPORTANT:

All the ice produced during the first 5 cycles after cleaning and sanitizing operations, and any

ice already in the container, must be eliminated.

Complete sanitizing can only be carried out only by the Authorized Technical Service Centres, and must

be done regularly depending on the conditions of use of the appliance, the chemical and physical

features of the water, and after every period in which the appliance has remained at a standstill for any

length of time.

You are advised to ask your dealer to draw up a scheduled maintenance contract that will cover the

following:

• cleaning the condenser

• cleaning the filter located on the water supply solenoid valve

• cleaning the ice-tray

• checking the cha rge of coolant gas

•

checking the operating cycle

• sanitizing the appliance

10 PERIODS AT A STANDSTILL

If you do not intend to use the appliance for a certain period of time, proceed as follows:

• switch off the electric power source by means of the switch (7 in Fig. 4), and remove the plug of the

appliance from its socket (if any)

• shut off the water supply by turning off the water supply tap (8 in Fig. 4)

•

carry out all the operations envisaged for scheduled maintenance of the appliance (see chapter 9)

• empty the internal basin by raising the flaps (if any) and removing the overflow pipe

• empty out the pump body by blowing compressed air into the pipe that supplies water to the sprayer bank

• clean filter of water supply solenoid valve as described in chapter 9.1

•

clean filter of air condenser (if any) as described in chapter 9.2

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Check out Procedure for Service for CB

Anomaly THE ICE MAKER DOESN’T WORK

Cause Remedy

There is no supply mains voltage Check the user’s electrical system

Bin thermostat out of order Replace the bin thermostat

Safety thermostat of the water condenser out of

order

Replace the safety thermostat

Contactor out of order Replace the contactor

Anomaly THE ICE MAKER WORKS BUT THE ICE DOESN’T FORM

Cause Remedy

Overflow-tube in the bin not correctly positioned Check the right position

Ice maker without refrigerant Find the leak, repair it, make vacuum and charge

Refrigerant blow-by through the hot gas valve Clean the hot gas valve or replace it

Water blow-by through the evaporator water inlet

valve

Replace the valve

The compressor doesn’t compress Replace the compressor

For air-cooled models:

The fan is out of order

• Check the fan motor. If necessary, replace

it.

• Check the correct working of the pressure

switch

Anomaly THE ICE MAKER REMAINS WITHOUT WATER IN THE BASIN

Cause Remedy

No water supply to the ice maker Check the water supply

Overflow-tube in the bin not correctly positioned Check the right position

Water leakage from the pump Check and clamp the clips or replace the pump

Dirty spray nozzles Clean the spray nozzles

Faulty water inlet valve, it doesn’t open or is

clogged

Replace the water inlet valve

The timer doesn’t open the water inlet valve Replace the timer

Page 30

Anomaly

THE ICE MAKER REMAINS WITHOUT WATER IN THE MIDDLE OR AT

THE END OF THE CYCLE

Cause Remedy

Dirty spray nozzles Clean or replace the spray nozzles

Water leakage from the basin Check possible breakings

Filter of the water inlet valve clogged Clean the filter

Anomaly THE ICE MAKER DOESN’T SPRAY WATER

Cause Remedy

The pump is out of order

Check the electric and mechanical pump efficiency

or replace it

Filter of the pump suction clogged Clean the filter

Limestone inside the pump pipes Clean the pipes from the limestone

Spray nozzles clogged Clean the spray nozzles

Anomaly THE ICE MAKER DOESN’T STOP WHEN THE BIN IS FULL

Cause Remedy

Bin thermostat

Replace the thermostat or adjust it or check the

probe position

Anomaly

THE ICE MAKER STOPS BY INTERVENTION OF THE WATER

CONDENSER SAFETY THERMOSTAT / PRESSURE-SWITCH

(Water Leakage in the Condenser)

Cause Remedy

No water supply to the ice maker Check the water supply

The water inlet valve doesn’t open

• Check the correct working of the

thermostat / pressure-switch

• Check if the correct rated voltage reaches

the water inlet valve

• Replace the valve

Condenser clogged by limestone Remove the limestone from the condenser

Page 31

Anomaly THE ICE MAKER REMAINS IN THE DEFROSTING PHASE

Cause Remedy

Faulty evaporator thermostat Replace the evaporator thermostat

The hot gas valve doesn’t open

• Check the electric feeding

• Replace the valve coil

• Replace the valve

Timer locked Replace the timer

Anomaly NOT REGULAR OR INCOMPLETE DEFROSTING

Cause Remedy

Lack of water Check the right water flow to the evaporator

Lacking refrigerant charge Find the leak, repair it, make vacuum and charge

Evaporator encrusted by limestone

Remove the limestone from the whole evaporator,

but without roughening its surfaces

The water inlet valve of the water condenser

doesn’t close

• Replace the anti interference condenser

placed parallel to the pressure switch

• Replace the valve

Anomaly SHEET OF ICE UNDER THE EVAPORATOR

Cause Remedy

Faulty or not adjusted evaporator thermostat Replace the evaporator thermostat or adjust it

Refrigerant blow-by through the hot gas valve Clean or replace the valve

Timer locked Replace the timer

Ice maker without refrigerant Find the leak, repair it, make vacuum and charge

Page 32

Anomaly WATER LEAKAGES

Cause Remedy

Inlet or outlet pipe not connected Check connections

The pump is leaking Replace the pump

Slack pipe clips Check the clamp of the clips

The bin water-outlet joint is slack or badly

connected

Check or fasten

Anomaly IRREGULAR OR OPAQUE ICE CUBE

Cause Remedy

Water supply too calcareous

Spray nozzles badly lined up or dirty

Clean or direct the water jet toward the middle of

the ice cubes

Anomaly

COMPRESSOR: PROTECTION INTERVENTION

(Intermittent Working)

Cause Remedy

Faulty power supply

Check:

• continuity,

• the current carrying in Amp.,

• voltage of the electrical circuit.

Difficult condensation

Check:

• cleaning of the condenser and of the filter,

• the fan working,

• aeration in and out of the ice maker.

Starting capacitor out of order Replace the capacitor

Compressor starting relay out of order Replace the relay

Compressor winding discontinued Replace the compressor

Seizing Replace the compressor

Page 33

Anomaly NOISY COMPRESSOR

Cause Remedy

Extreme mechanical wear Replace the compressor

Anomaly NOISY PUMP

Cause Remedy

Worn bearings Replace the pump

Plate fixing Fasten the screws

Anomaly THE PUMP LEAKS WATER

Cause Remedy

Slack pipe-clips Check and clamp the clips

Worn ceramic seal Replace the pump

External gasket broken Replace the pump

Anomaly THE PUMP DOESN’T RUN

Cause Remedy

Lack of power supply Check the contacts of the timer micro-switch

Lack of power Replace the run capacitor

Mechanical locking Replace the pump

Interrupted winding Replace the pump

Page 34

Anomaly INTERVENTION OF THE USER’S MAIN SWITCH

Cause Remedy

Compressor: short circuit and/or low dielectric

strength

Replace the component

Pump: short circuit and/or low dielectric strength Replace the component

Hot gas valve: short circuit and/or low dielectric

strength

Replace the component

Thermostat: low dielectric strength Replace the component

Other electrical components: short circuit and/or

low dielectric strength

Replace the component

Anomaly ICE PRODUCTION DECREASE

Cause Remedy

Condenser or air filter clogged Clean the filter and the condenser

Bin flooded Check the water outlet pipes

Ice maker without refrigerant Find the leak, repair it, make vacuum and charge

Refrigerant blow-by through the hot gas valve Clean the valve or replace it

Water blow-by through the evaporator water inlet

valve

Replace the valve

The compressor doesn’t compress Replace the compressor

Page 35

ICE CUBE MAKERS “SPRAYERS” SYSTEM

Last Update: 04/04/2011

C

C

C

B

B

B

L

L

L

i

i

i

n

n

n

e

e

e

The following diagram shows the main concepts of the ice cube

makers working (‘sprayers’ system).

Compressor

Condenser

Air

Water

Evaporator

Each ice maker uses the properties of compression and

expansion of the liquefiable gases; its main principle is that each

change of bodies state is got by producing or absorbing heat.

The compressor sucks up the gases, generated by the

evaporation, and compresses them, increasing their

temperature and pressure.

A condenser, made up of a series of tubes (refrigerated by

cold water or ventilated air), carries away the heat, comprised in

the gas from the compressor and helps, in this way, the gas

liquefaction.

The refrigerating fluid, now in liquid state, circulates, then, in an

evaporator that permits an optimal heat exchange with the outroom, by taking away calories and producing ice, which is got by

means of the freezing of the water sprayed in the cubes forms

by the spray-bar.

The working of this machine is cyclical: ice cubes are produced

during the first phase and fall in the built-in bin during the

second phase.

Page 36

R

R

R

e

e

e

f

f

f

r

r

r

i

i

i

g

g

g

e

e

e

r

r

r

a

a

a

t

t

t

i

i

i

n

n

n

g

g

g

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

The working of this machine is cyclical. Each cycle is divided into

two phases: ice cubes are produced during the first phase and fall

in the built-in bin during the second phase.

The following diagram shows the main concepts of the

refrigerating circuit:

Hot gas

valve

Suction line

Capillar Tube

Condenser

(Water)

Condenser

(Air)

Refrigerating

filter

Compressor

Evaporator

Cubes basin

Production Phase of the Ice Cubes

The hot gas valve is closed; the refrigerating fluid

, after

having been cooled by the condenser, circulates through the

evaporator coil (welded to the cubes basin), and cools each

small copper cup.

Water is sprayed on the evaporator cubes-basin through the

spray-bar nozzles. An ice layer, due to the refrigerating fluid,

begins to form in the cups, till these are completely full (after

some minutes).

Ice Falling Phase (Defrosting)

Once the ice-production time is finished, the spray-

bar stops

spraying water on the cubes-basin and the hot gas valve,

assembled on the compressor delivery side, opens.

This opening permits to pipe the refrigerating fluid (now

overheated, after the compression) directly to the evaporator,

without letting it pass through the condenser.

Due to such overheated fluid, the evaporator warms up and

the ice cubes formed in the cups, fall in the bin below.

At the end of the defrosting phase, the cycle starts again.

The compressor is always working: during both the production

and the defrosting phase.

Page 37

R

R

R

e

e

e

f

f

f

r

r

r

i

i

i

g

g

g

e

e

e

r

r

r

a

a

a

t

t

t

i

i

i

n

n

n

g

g

g

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

(

(

(

C

C

C

o

o

o

m

m

m

p

p

p

o

o

o

n

n

n

e

e

e

n

n

n

t

t

t

s

s

s

)

)

)

Compressor

It sucks up the gases, generated by the evaporator by means of

a suction line and compresses them, increasing their

temperature and pressure.

Hot Gas Valve

It controls a circuit that starts from the compresso

r and arrives to

the evaporator, bypassing the condenser.

The opening of the valve permits to pipe the refrigerating fluid

(overheated after the compression) directly to the evaporator,

without letting it pass through the condenser thus warming up

the evaporator.

Condenser (Air/Water)

If ‘Water’, it is made up of a series of tubes, ref

rigerated by cold

water.

If ‘Air’, it is made up of a radiator, that exchanges heat with the

out-room, and is refrigerated by air, coming from a fan, run by

an electric motor.

Both of them carry away the heat, comprised in the gas that

comes out from the compressor, helping, in this way, the gas

liquefaction.

Refrigerating Filter + Capillar Tube

The refrigerant filter stops possible impurities and

the circuit

humidity.

The gas, in liquid status, goes to the evaporator through this

filter and the capillar tube.

Evaporator

It permits an optimal heat exchange with the water s

prayed on it

and produces ice by means of the water freezing.

It is made by a series of small tin plated cups, plunged into a

plastics support and welded to a copper coil, where the

refrigerating gas circulates.

Suction line

It permits the refrigerating gas circulation from th

e evaporator to

the compressor.

The suction line also controls and keeps constant the circulation

of the gas, coming out from the evaporator.

The liquid gas is trapped in a specific expansion boiler, that

prevents its arrival to the compressor.

Page 38

R

R

R

e

e

e

f

f

f

r

r

r

i

i

i

g

g

g

e

e

e

r

r

r

a

a

a

t

t

t

i

i

i

n

n

n

g

g

g

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

(

(

(

P

P

P

r

r

r

o

o

o

d

d

d

u

u

u

c

c

c

t

t

t

i

i

i

o

o

o

n

n

n

C

C

C

y

y

y

c

c

c

l

l

l

e

e

e

)

)

)

Ice cubes production

The hot gas valve is closed; the compressed gas from the

compressor, is piped to the condenser in order to get cool.

Hot gas

valve

Closed

Suction line

Capillar Tube

Condenser

(Water)

Condenser

(Air)

Refrigerating

filter

Compressor

Evaporator

Cubes basin

Defrosting

The hot gas valve is open; the compressed gas from t

he

compressor, is piped to the evaporator, bypassing the

condenser.

Hot gas

valve

Open

Suction line

Capillar Tube

Condenser

(Water)

Condenser

(Air)

Refrigerating

filter

Compressor

Evaporator

Cubes basin

Page 39

H

H

H

y

y

y

d

d

d

r

r

r

a

a

a

u

u

u

l

l

l

i

i

i

c

c

c

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

The following diagram shows the main concepts of the hydraulic

circuit:

Evaporator

Water-inlet

valve

Water

Supply

Water-inlet

valve

Water

Drain

Water

Condenser

Spray-bar

Pump

Overflow tube

Water Basin

CB1565 ONLY

Pressostatic

Valve

The water supply circuit of the basin, the water-inlet valve, the

pump and the evaporator are on all machines of the ‘CB’-line;

the water condenser circuit, on the contrary, is on water-cooled

versions only.

Water-inlet valve

It works during the defrosting phase and allows the

water to flow

on the evaporator, having two goals: 1st. one is to warm the

evaporator help, in this way, the ice cubes detaching; 2nd. one,

the water falls into the basin, restores the ideal level to start a

new production cycle.

The second water-inlet valve allows the water flow of the

through the water condenser.

Water basin

It gets water from the water mains. It feeds the pum

p by a

specific pipe provided with a filter.

Pump

It draws out water from the water basin and pipes it

, under

pressure, to the spray-bar.

Spray-bar

It gets water from the pump and, by means of its nozzles,

sprays it towards the cubes basin of the evaporator. The water

that does not freeze, by contacting the cups (refrigerated by the

evaporator coil), falls in the inside bin and is drawn by the pump

once again.

Overflow tube

It is a floodway. All the surplus water, entering in

to the water

basin, comes out from it.

Pressostatic valve (CB1565 only)

It is assembled only on water cooled machines.

I

t controls and keeps constant the condensing pressure, by

changing the quantity of water that flows in the condenser.

Page 40

E

E

E

l

l

l

e

e

e

c

c

c

t

t

t

r

r

r

i

i

i

c

c

c

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

The following diagram shows the main concepts of the electric

circuit:

Compressor

Condenser

Pressure switch

Bin

thermostat

Evaporator

thermostat

Hot gas

valve

Water-inlet

valve

(Evaporator)

Pump

Fan

Water-inlet

valve

(Condenser)

Safety

thermostat

no on CB1565W

Timer

Contactor - ONLY CB1565

H.P. Pressure switch - Only CB1565

The ice maker is energized by the bin thermostat, that stops

machine when the bin is full.

The timer is designed in such a way that it is connected

upstream the bin thermostat during the ice production phase, so

that the ice maker will stop only when the ice production phase

is over.

The following scheme shows this working system:

Timer

Utilizer

Unit

Bin thermostat

Only in the ice

production phase

NB: some components of the electrical circuit (called Utilizer

Units) are always energized and do not depend on the timer

status. See the following table:

““WWaatteerr”” mmaacchhiinneess

Condenser

pressure-switch

Compressor

Water-inlet

valve

(Condenser)

LINE

CCBB 224466 ÷÷ 442255 ““AAiirr””

Compressor

LINE

CCBB 664400 ÷÷ 11226655 ““WWaatteerr””

Condenser

pressure-switch

Compressor

Refrigerating

fan

LINE

For CB1565 the contactor energized the compressor.

Page 41

E

E

E

l

l

l

e

e

e

c

c

c

t

t

t

r

r

r

i

i

i

c

c

c

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

(

(

(

T

T

T

i

i

i

m

m

m

e

e

e

r

r

r

S

S

S

t

t

t

a

a

a

t

t

t

u

u

u

s

s

s

)

)

)

Ice cubes production

The timer, in the first phase, starts up the pump and the utilizer

units, as described in the scheme of the previous page.

Timer

Evaporator

thermostat

Pump

Utilizer

Unit

Some minutes after the beginning of the ice production phase,

due to the refrigerant in expansion in the coil, an ice layer starts

to form inside the cups; the evaporator thermostat, perceiving a

drop in temperature of the evaporator, starts the timer, in order

to complete the ice production phase.

Defrosting

The timer, once reached the set up time, simultaneou

sly

commutes three contacts, letting the defrosting phase begin.

Evaporator

thermostat

Timer

Hot gas

valve

Water-inlet

valve

(Evaporator)

The pump is stopped and also the spray noozles stop; on the

contrary, the hot gas valve is started in order to pipe the

refrigerating fluid (overheated) directly to the evaporator.

The water inlet valve opens and allows the water to flow from

water mains into the basin.

The evaporator thermostat, perceiving a temperature rise (due

to the circulation of hot fluid), starts up the timer again, so to

complete the defrosting phase.

Page 42

E

E

E

l

l

l

e

e

e

c

c

c

t

t

t

r

r

r

i

i

i

c

c

c

C

C

C

i

i

i

r

r

r

c

c

c

u

u

u

i

i

i

t

t

t

(

(

(

C

C

C

o

o

o

m

m

m

p

p

p

o

o

o

n

n

n

e

e

e

n

n

n

t

t

t

s

s

s

)

)

)

Controls systems

Hot gas valve – The opening of the valve permits to pipe the

refrigerating fluid (overheated after the compression) directly to

the evaporator, without letting it pass through the condenser

thus warming up the evaporator.

Evaporator thermostat – It feels the evaporator temperature

and drives the timer, as previuosly described.

Condenser pressure-switch – It controls and keeps constant

the condensing pressure; it drives the refrigerating fan, it drives

the condenser water inlet valve.

Timer – See next page.

Water-inlet valve (evaporator) – It is open during the

defrosting phase, allowing the water to flow on the evaporator

and, then, into the water basin, to restore the ideal water level to

start a new cycle of ice cubes production.

Water-inlet valve (condenser) – This second water-inlet valve

allows the water to flow through the water condenser.

Contactor – Energized the compressor.

Safety systems

Safety thermostat – Placed on the condenser of the water

models.

It stops the machine working, when the temperature of the water

condenser exceeds a preset threshold value.

Bin thermostat - The bin thermostat stops the ice machine

when it perceives a drop in temperature due to the ice cubes

accumulation in the bin.

The machine only stops during the defrosting phase, as the

timer keeps a second power source active during the production

phase till the phase commutation.

H. P. Safety Presssure switch – It stops the machine working,

when the condensation pressure exceeds the preset threshold

value.

Page 43

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

2

2

2

4

4

4

6

6

6

÷

÷

÷

4

4

4

2

2

2

5

5

5

(

(

(

A

A

A

i

i

i

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

Hydraulic Circuit

Refrigerating Circuit

Electric Circuit

LINE

CAMME 4

CAMME 3

CAMME 2 CAMME 1

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

TIMER

MOTOR

CONDENSER

CAPILLAR

TUBE

COMPRESSOR

HOT

GAS

VALVE

SUCTION

LINE

NEUTRAL

WATER

INLET

VALVE

WATER

SUPPLY

PUMP

EVAPORATOR

+ SPRAY BAR

OVERFLOW

TUBE

GREEN LIGHT SWITCH

(on-off)

GREEN LIGHT SWITCH

(on-off)

Page 44

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

2

2

2

4

4

4

6

6

6

÷

÷

÷

4

4

4

2

2

2

5

5

5

(

(

(

W

W

W

a

a

a

t

t

t

e

e

e

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

Hydraulic Circuit

Refrigerating Circuit

Electric Circuit

LINE

SAFETY

THERMOSTAT

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

CAMME 4 CAMME 3

CAMME 2

CONDENSER

PRESSURE-SWITCH

CONDENSER

WATER

DRAIN

WATER

INLET

VALVE

WATER

SUPPLY

SUCTION

LINE

NEUTRAL

COMPRESSOR

CAMME 1

TIMER

MOTOR

CAPILLAR

TUBE

WATER

SUPPLY

WATER

INLET

VALVE

PUMP

HOT GAS

VALVE

EVAPORATOR

+ SPRAY BAR

OVERFLOW

TUBE

GREEN LIGHT SWITCH

(ON-OFF)

GREEN LIGHT SWITCH

(ON-OFF)

Page 45

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

6

6

6

4

4

4

0

0

0

÷

÷

÷

1

1

1

2

2

2

6

6

6

5

5

5

(

(

(

A

A

A

i

i

i

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

Hydraulic Circuit

Refrigerating Circuit

Elctric Circuit

LINE

CAMME 4

CAMME 3

CAMME 2

CAPILLAR

TUBE

CONDENSER

CONDENSER

PRESSURE-SWITCH

COMPRESSOR

HOT GAS

VALVE

SUCTION LINE

NEUTRAL

FAN

CAMME 1

TIMER

MOTOR

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

WATER

INLET

VALVE

WATER

SUPPLY

PUMP

EVAPORATOR

+ SPRAY BAR

OVERFLOW

TUBE

GREEN LIGHT SWITCH

ON-OFF

GREEN LIGHT SWITCH

ON-OFF

Page 46

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

6

6

6

4

4

4

0

0

0

÷

÷

÷

1

1

1

2

2

2

6

6

6

5

5

5

(

(

(

W

W

W

a

a

a

t

t

t

e

e

e

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

Hydraulic Circuit

Refrigerating Circuit

Electric Circuit

LINE

SAFETY

THERMOSTAT

CONDENSER

PRESSURE-SWITCH

CONDENSER

CAMME 4 CAMME 3

CAMME 2 CAMME 1

TIMER

MOTOR

WATER

DRAIN

WATER

INLET

VALVE

WATER

SUPPLY

NEUTRAL

SUCTION

LINE

COMPRESSOR

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

CAPILLAR

TUBE

WATER

SUPPLY

WATER

INLET

VALVE

PUMP

HOT GAS

VALVE

EVAPORATOR

+ SPRAY BAR

OVERFLOW

TUBE

GREEN LIGHT SWITCH

ON-OFF

GREEN LIGHT SWITCH

ON-OFF

Page 47

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

1

1

1

5

5

5

6

6

6

5

5

5

(

(

(

A

A

A

i

i

i

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

Hydraulic Circuit

Refrigerant Circuit

Electric Circuit

LINE

CAMME 4

CAMME 3

CAMME 2

CAPILLARY

TUBE

CONDENSER

PRESSURE SWITCH

CONDENSER

COMPRESSOR

HOT GAS

VALVE

SUCTION

LINE

NEUTRAL

FAN

CAMME 1

TIMER

MOTOR

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

WATER

INLET

VALVE

WATER

SUPPLY

PUMP

EVAPORATOR

+ SPRAYERS

BAR

OVERFLOW

PIPE

GREEN LIGHT

SWITCH ON-OFF

CONTACTOR

CONTACTOR

COIL

CONTACTOR

HP SAFETY PRESSURE SWITCH

GREEN LIGHT

SWITCH ON-OFF

Page 48

W

W

W

o

o

o

r

r

r

k

k

k

i

i

i

n

n

n

g

g

g

S

S

S

c

c

c

h

h

h

e

e

e

m

m

m

e

e

e

C

C

C

B

B

B

1

1

1

5

5

5

6

6

6

5

5

5

(

(

(

W

W

W

a

a

a

t

t

t

e

e

e

r

r

r

V

V

V

e

e

e

r

r

r

s

s

s

i

i

i

o

o

o

n

n

n

)

)

)

LINE

HP SAFETY

PRESSURE SWITCH

CONDENSER

CAMME 4 CAMME 3

CAMME 2 CAMME 1

TIMER

MOTOR

WATER

OUTLET

PRESSOSTATIC

VALVE

WATER

INLET

NEUTRAL

SUCTION

LINE

COMPRESSOR

EVAPORATOR

THERMOSTAT

BIN

THERMOSTAT

CAPILLARY

TUBE

WATER

INLET

WATER

INLET

VALVE

PUMP

HOT GAS

VALVE

EVAPORATOR

+ SPRAYER

BAR

OVERFLOW

PIPE

CONTACTOR

CONTACTOR

COIL

CONTACTOR

Hydraulic Circuit

Refrigerant Circuit

Electric Circuit

GREEN LIGHT

SWITCH ON-OFF

GREEN LIGHT

SWITCH ON-OFF

Loading...

Loading...