Page 1

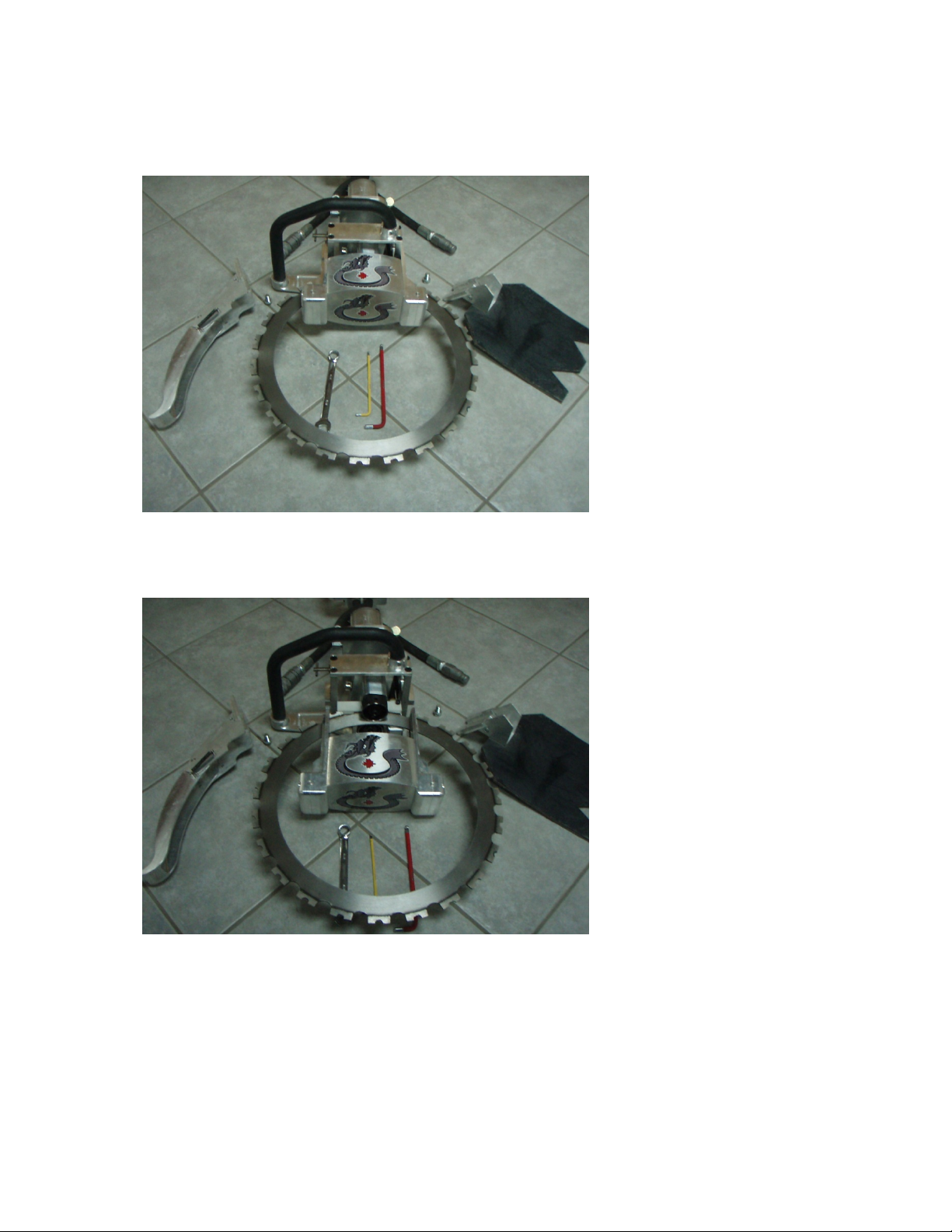

Blade removal and installation

Step 1: Remove blade guard and splash flap using 9/16” wrench provided (figure

1).

Figure 1

Step 2: Remove adjustable arm assembly (figure 2).

Figure 2

Page 2

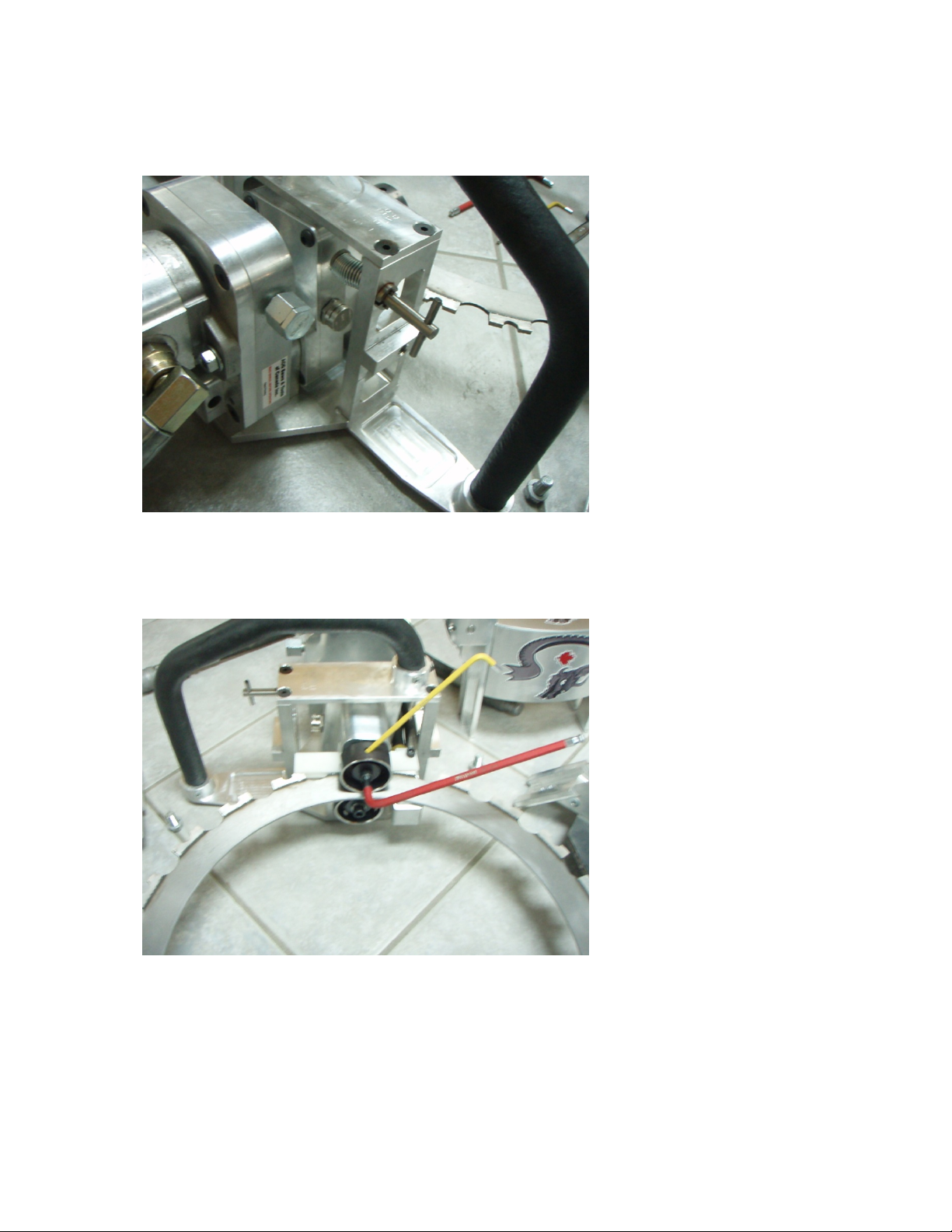

Blade removal and installation

Step 3: Relieve transmission assembly tension by pulling t-handle out and

turning 90 degrees (figure 3)

Figure 3

Step 4: Disassemble upper drive roller by locking roller and removing allen screw

with the ¼” allen wrench provided (figure 4).

Figure 4

Page 3

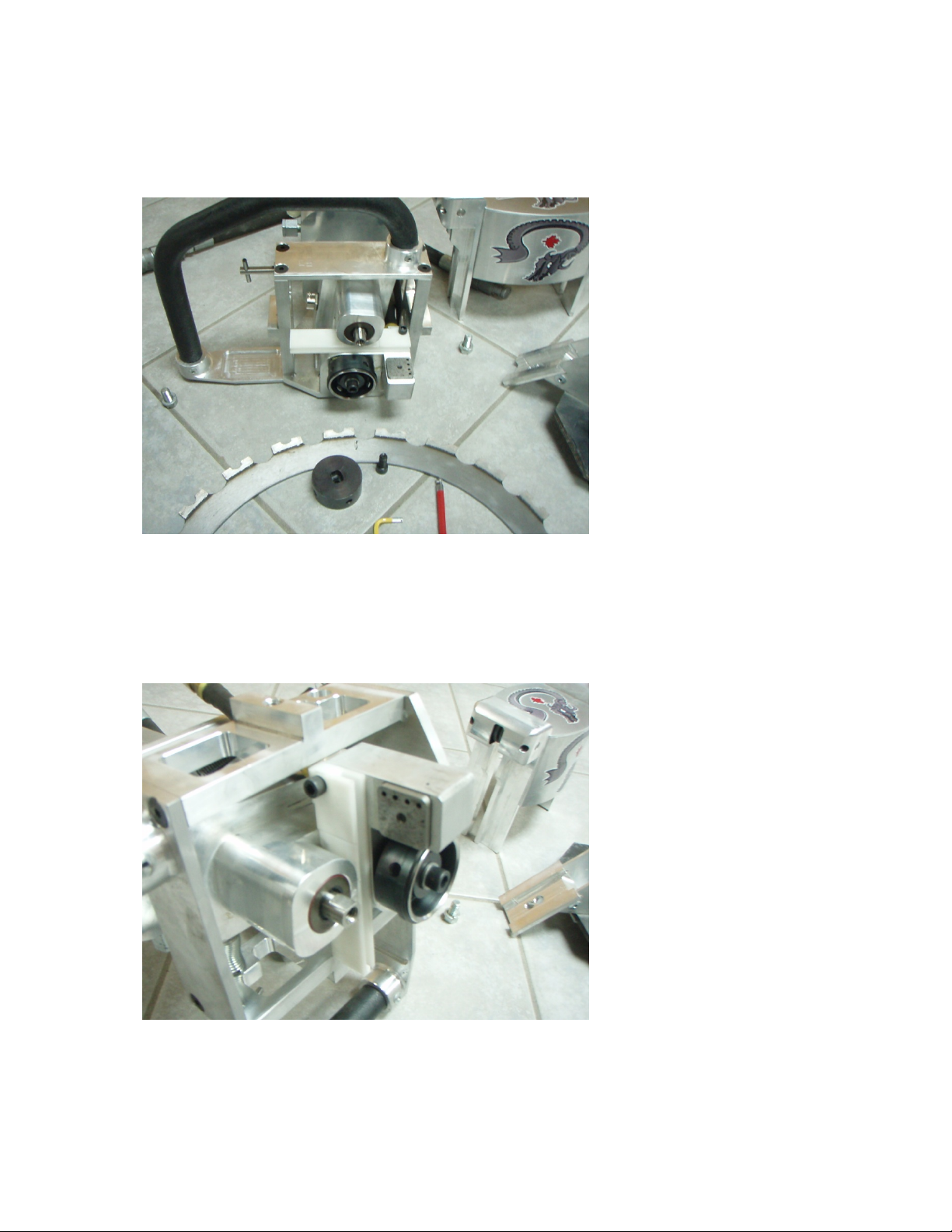

Blade removal and installation

Step 5: Hold transmission in neutral position and remove upper drive wheel and

blade

(figure 5).

Figure 5

Step 6: Remove water injection plate with the 5/32” allen wrench provided. Note

location of water injection holes prior to removing plate. Install new plate with

water injection holes matching previous mounted location (outer right side

opposite from drive wheel)(figure 6).

Figure 6

Page 4

Blade removal and installation

Step 7: Inspect lower drive roller for wear on lip. Replace if lip is worn to half the

original width (.200”)(figure 7).

Figure 7

Step 8: Install new blade, matching groove in blade to lip on the lower drive

roller. (figure 8)

Figure 8

Page 5

Blade removal and installation

Step 9: With the transmission assembly in neutral position, reinstall upper drive

roller using the ¼” allen wrench provided. Tighten securely by locking drive

wheel in position (figure 9).

Figure 9

Step 10: Using 5/32” allen wrench provided, remove guide roller cover and

inspect both guide rollers for wear or damage. Guide rollers should spin freely.

Replace if necessary (figure 10).

Figure 10

Page 6

Blade removal and installation

Step 11: Reinstall adjustable arm assembly, blade guard and splash flap on saw.

Hand tighten bolts. Place ring saw on flat surface (figure 11) so that the

adjustable arm assembly is sitting with the weight of the saw on it. Tighten bolts

using the 9/16” wrench provided. Guide rollers should be firmly in contact with

the blade. Move t-handle to original location by pulling up and rotating 90

degrees, returning transmission assembly to the tensioned position.

Figure 11

Step 12: Lay saw flat on table and reinspect blade for play at the guide rollers.

Repeat step 11 if blade is not in firm contact with guide rollers.

Loading...

Loading...