Diamond DA435HA User Manual

DA435HA: 99901219 20100927

Model DA435HA

Air Compressor

(PART NO. 20013)

(Single Cooler - 10GPM)

(Replaces Model DA435HAR-10)

IOWA MOLD TOOLING CO., INC.

BOX 189, 500 HWY 18 WEST, GARNER, IA 50438

Iowa Mold Tooling Co., Inc. is an Oshkosh Truck Corporation company.

TEL: 641-923-3711

MANUAL PART NUMBER 99901219

DA435HA: 99901219: ii

--------

REVISIONS LIST

DATE LOCATION DESCRIPTION OF CHANGE

20000731 4-10 I2 70395091 WAS 73095091 ID DECAL

20010925 4-2 EN-1365 - CHANGED BLOCK TO 301996, SOLENOID TO 301997, VALVE TO 301998

20020328 Section 4 UPDATED, IMPROVED DRAWING QUALITY

20030715 4-10 ADDED DECAL KIT NUMBER TO DECAL PLACEMENT DRAWING

20040408 4-5 ADDED “M” TO ITEM #66, RUBBER CAP

20050630 4-9 through 4-14 ECN 9835 - UPDATE CONNECTIONS ON 99901281, ADD HARNESS 304710, ADD CONNECTOR

20061127 4-4,5 ADDED ITEM 67 - 70392665 - RUBBER COUPLING TO 20056-2 PARTS LIST, 20056-3 DRAWING

20070405 Throughout ECN 10421 - MANUAL TITLE CHANGED TO CAS435HA

20100927 4-3 ECN 11273 -

4-3 UPDATED ITEMS M6, M11, M24, M25

4-4 M46 WAS 90° F ELBOW, IS NOW ELBOW 3/4JIC X 3/4NPT

4- 5 UPDATED DRAWING

4-7 EN-1369 - CHANGED BOLTS TO SS STAR DRIVE 1/4-20x3/4, ADDED 1/4 SS WASHER

4-9 ADDED DRAWING NO. TO BOM

4-10 ADDED AIR, HYDRAULIC TANK, HYDRAULIC PRESSURE DECALS

4-11 NEW HYDRAULIC INSTALLATION KIT DRAWING, BOM

CHART, ADD 99903712

6-1 through 6-8 REMOVED RELAY BOARD SECTION - OUTDATED

20056-1 - ITEM M30, 301438, REPL WITH 70048241

DA435HA: 99901219: iii

N

19980930

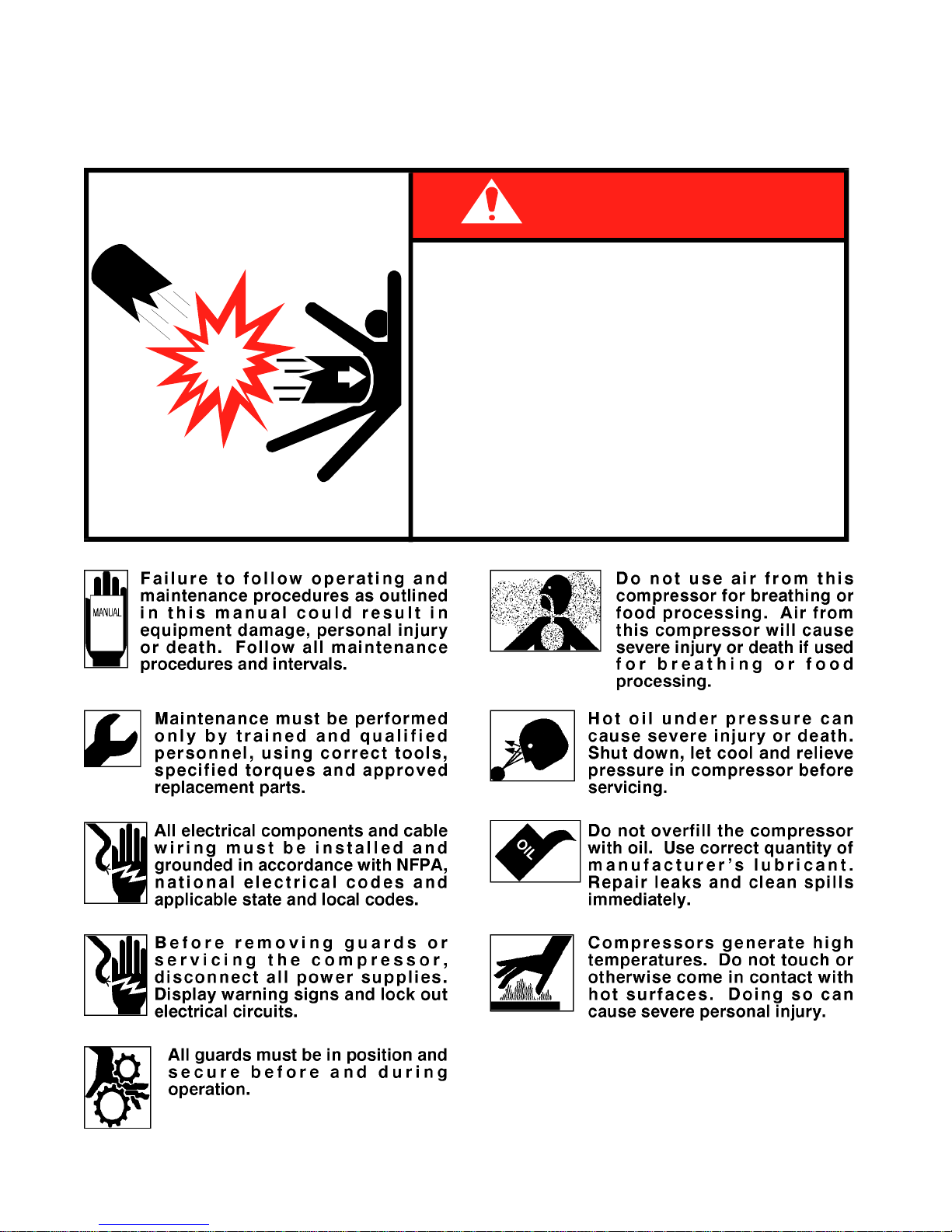

PRECAUTIONS

Read before operating your compressor!

EXPLODING T ANK WILL CAUSE

DEATH, SERIOUS INJURY

OR PROPERTY DAMAGE

●

Drain air tank after each use to prevent

moisture build-up and corrosion which

leads to tank failure.

Assure that tank and compressor relief

●

valves work properly, and are at correct

71393886

pressure settings.

DO NOT modify or repair air tank.

●

●

EVER drive vehicle with pressure in air

tank.

DANGER

DA435HA: 99901219: iv

19980930

TABLE OF CONTENTS

PARA TITLE PAGE

SECTION 1. INTRODUCTION AND SPECIFICATIONS

1-1. INTRODUCTION ................................................................................................................ 1-1

1-2 ORDERING REPAIR PARTS ............................................................................................. 1-1

1-3. GENERAL INFORMATION................................................................................................. 1-1

1-4. SPECIFICATIONS.............................................................................................................. 1-1

SECTION 2. INST ALLATION

2-1. GENERAL .......................................................................................................................... 2-1

2-2. PTO AND PUMP INSTALLATION....................................................................................... 2-1

2-2-1. PTO INSTALLATION .......................................................................................................... 2-1

2-2-2. DRIVELINE AND PUMP INST ALLA TION ........................................................................... 2-2

2-3. COMPRESSOR INSTALLATION........................................................................................ 2-2

2-4. DRIVELINE INSTALLATION TECHNIQUES ...................................................................... 2-3

2-4-1. U-JOINT OPERATING ANGLES ........................................................................................ 2-3

2-4-2. SINGLE PLANE AND COMPOUND U-JOINT OPERATING ANGLES............................... 2-3

2-4-3. ELIMINA TING COMPOUND ANGLE INDUCED VIBRATION............................................. 2-4

2-4-4. ANGLE SIZE ...................................................................................................................... 2-5

SECTION 3. OPERA TION

3-1. GENERAL .......................................................................................................................... 3-1

3-2. OPERATION ...................................................................................................................... 3-1

SECTION 4. MAINTENANCE & PARTS

4-1. GENERAL .......................................................................................................................... 4-1

ROUTINE MAINTENANCE CHECKLIST ........................................................................... 4-1

OIL COOLING SYSTEM............................................................... 200057......................... 4-2

COMPRESSOR MOUNTING SYSTEM .......................................200056-1 ..................... 4-3

COMPRESSOR ASSEMBLY........................................................200056-2 ..................... 4-4

COMPRESSOR ASSEMBLY........................................................200056-3 ..................... 4-5

COMPRESSOR ASSEMBLY........................................................200056-4 ..................... 4-6

CANOPY SYSTEM............................................................................................................. 4-7

COMPRESSOR WIRING DIAGRAM.................................................................................. 4-8

INSTALLA TION KIT......................................................................51712642..................... 4-9

DECAL PLACEMENT......................................................................................................... 4-10

HYDRAULIC INST ALLATION KIT ................................................91707052..................... 4-11

DRIVELINE MOUNTING OPTION ...............................................31701761..................... 4-12

REPAIR KITS ..................................................................................................................... 4-12

SECTION 5. REP AIR

5-1. GENERAL .......................................................................................................................... 5-1

5-2. PISTON RING REPLACEMENT ........................................................................................ 5-1

5-3. OIL PUMP REPLACEMENT............................................................................................... 5-2

5-4. CRANKSHAFT AND BEARING REPLACEMENT .............................................................. 5-2

5-5. TROUBLESHOOTING ....................................................................................................... 5-4

SECTION 6. RELAY BOARD OPERATION

6-1. INTRODUCTION ................................................................................................................ 6-1

6-2. OPERATION ...................................................................................................................... 6-1

6-2-1. IGNITION “ON”................................................................................................................... 6-1

6-2-2. REMOTE STARTING THE VEHICLE................................................................................. 6-1

6-2-3. REMOTE ENGINE STOP................................................................................................... 6-1

6-2-4. REMOTE ENGINE SPEED (FROM CRANE)..................................................................... 6-3

6-2-5. COMPRESSOR ENGINE SPEED CONTROL (COMPRESSOR ONLY) ........................... 6-3

6-2-6. ENGINE SPEED CONTROL (CRANE&COMPRESSOR USED SIMULTANEOUSLY) ...... 6-3

6-3. INSTALLATION .................................................................................................................. 6-7

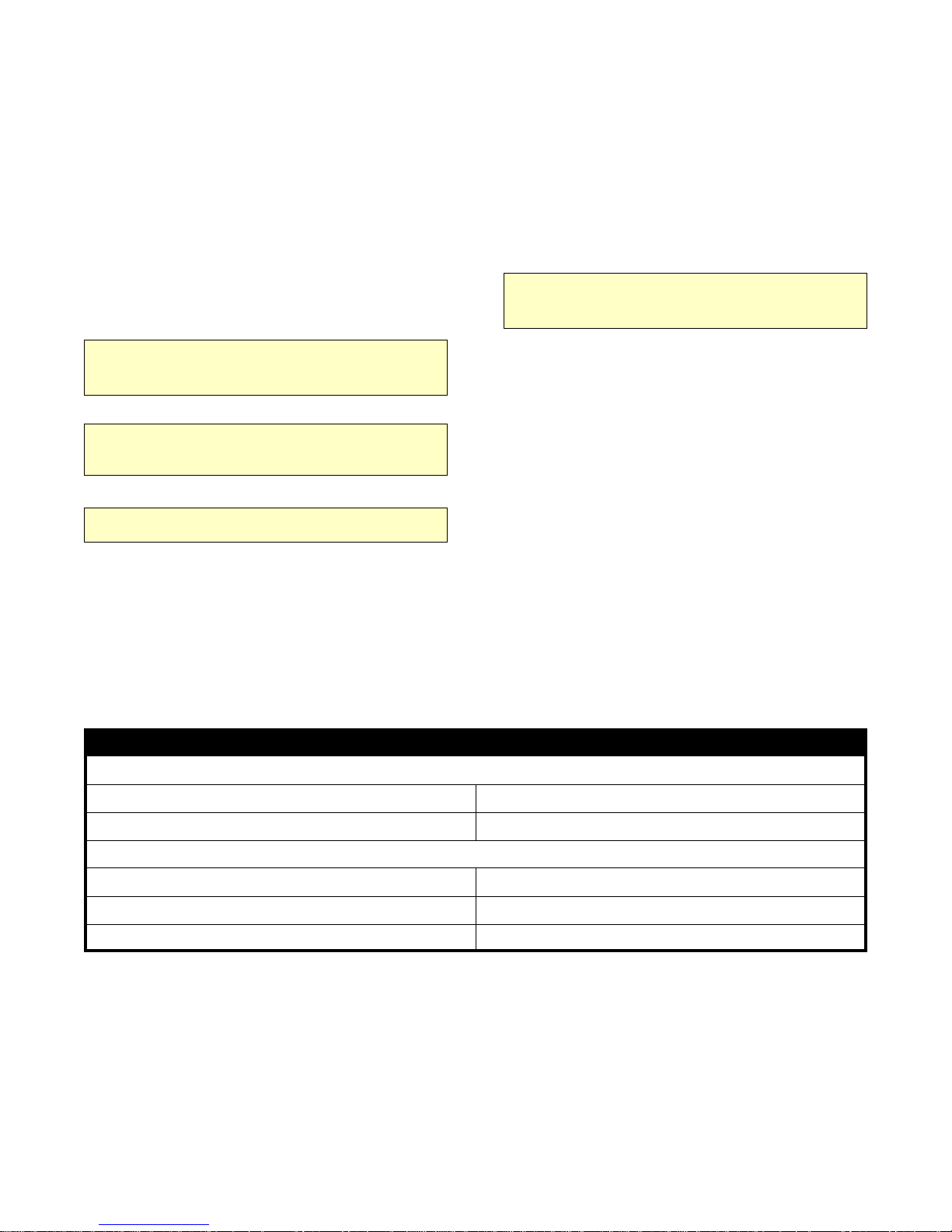

DA435HA: 99901219: 1-119980930

SECTION 1. INTRODUCTION AND SPECIFICATIONS

1-1. INTRODUCTION

This manual provides information on the

installation, operation and repair of the IMT Model

DA435HA Hydraulic Air Compressor.

Three means are used throughout this manual to gain

the attention of operating and service personnel.

They are NOTES, CAUTIONS and WARNINGS

and are defined as follows:

NOTE

A NOTE IS USED TO EITHER CONVEY ADDITIONAL

INFORMATION OR TO PROVIDE FURTHER EMPHASIS

FOR A PREVIOUS POINT.

CAUTION

A CAUTION IS USED WHEN THERE IS THE STRONG

POSSIBILITY OF DAMAGE TO THE EQUIPMENT OR

PREMA TURE EQUIPMENT FAILURE.

WARNING

A W ARNING IS USED WHEN THERE IS THE POTENTIAL

FOR PERSONAL INJURY OR DEATH.

Operate this equipment with respect and service it

regularly for a safer working environment and

longer equipment life.

1-2. ORDERING INFORMATION

When placing orders or requesting assistance, refer

to the information below:

1-3. GENERAL INFORMATION

The IMT DA435HA air compressor is a single

stage, air cooled, 4-cylinder, pressure lubricated,

hydraulically driven unit, with a delivery rate of

35 CFM at 100 PSI.

CAUTION

OPERATING THE COMPRESSOR AT PRESSURES

ABOVE 150 PSI WILL SHORTEN THE SERVICE LIFE

AND VOID THE WARRANTY.

1-4. SPECIFICATIONS

Power Source Hydraulic Motor

Bore 2-5/8"

Stroke 2-1/2"

Cylinder Configuration V4

Dimensions 26-1/2"L x 19-1/8"H* x 19-3/4"W

Displacement 44 CFM**

Delivery 35 CFM**

Cooling Air

Fan Diameter 14-1/8"

Operating Speed 1400 RPM maximum

Lubrication Oil Pump

Oil Capacity 1-1/3 qts

Weight 200 lbs.

Reservoir requirement 12 Gallon minimum

Normal GPM @1400rpm 9.3 GPM

Normal Operating PSI 1850 PSI

Maximum PSI 2400 PSI

* Add 2-5/8” to height for air filter cap.

** @ 1400 RPM - 100 PSI

TRANSMISSION MAKE:

PTO NUMBER:

COMPRESSOR MODEL:

PUMP MAKE:

RESERVOIR CAPACITY:

TO BE COMPLETED BY DEALER

CHASSIS INFORMA TION

MODEL:

PTO %:

COMPRESSOR AND HYDRAULIC PUMP INFORMATION

SERIAL NUMBER:

MODEL:

ENGINE RPM:

DA435HA: 99901219: 1-219980930

NOTES

DA435HA: 99901219: 2-1

19980930

SECTION 2. INSTALLATION

2-1. GENERAL

This section pertains to the installation of the IMT

DA435HA compressor, PTO and pump. The

instructions are intended as a guide to assist you

with your particular installation. These instructions

will provide only general information.

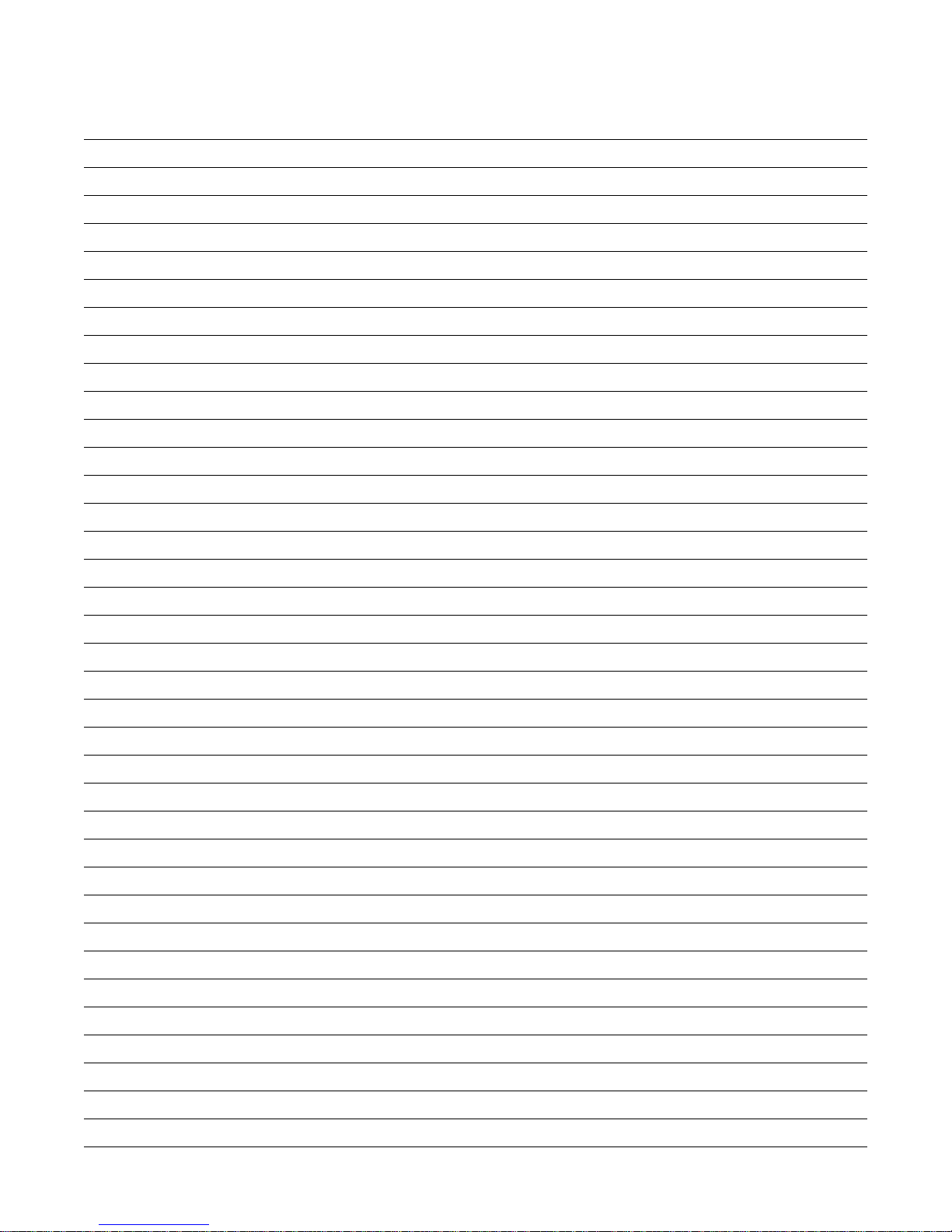

2-2. PTO AND PUMP INSTALLATION

The pump may either be installed directly on the

PTO (see Figure B-1) or, as an optional method, it

may be driven by a driveline (see Figure B-2).

2-2-1. PTO INSTALLATION

Power take-off manufacturers provide specific

installation instructions for their products. Those

instructions should be followed when installing a

PTO. Check with the PTO manufacturers

representative for specific instructions regarding

your particular make, model and year of vehicle.

The following instructions are a guide in this

application.

1. If the vehicle is new, drain the transmission oil

into a clean container for reuse. If the vehicle is

used, drain and dispose of the transmission oil

properly.

2. Temporarily install the PTO with the proper

gaskets and only two studs. Snug the PTO down

and check the backlash for maximum allowance of

.006" to .012". If the backlash is excessive, remove

gaskets and check backlash again until it is

corrected.

3. Remove the PTO and apply Permatex® to the

gaskets. If the holes for the studs are tapped through

the transmission housing, apply Permatex to the

studs and tighten them down. Make certain that the

studs do not interfere with the transmission gears.

CAUTION

AVOID CONTACT OF PERMATEX WITH

TRANSMISSION FLUID.

Registered Trademark of Permatex Co., Inc., Kansas City, Kansas

4. Install the PTO and gaskets. Torque the nuts to

30 - 35 ft-lbs (4.14 - 4.84 kg-m) for a 6-bolt PTO

and 45 - 50 ft-lbs (6.22 - 6.91 kg-m) for 8-bolt

PTOs. Recheck the backlash.

5. Install the shifter cable to suit conditions.

Always allow for a slight overshift on lever or knob

to ensure the PTO is fully disengaged.

CAUTION

IT IS IMPORTANT THAT ADEQUATE SPACE BE

ALLOWED FOR FULL ENGAGEMENT OF THE PTO.

MODIFY THE EXHAUST OR OTHER OBSTRUCTIONS

AS NEEDED.

FIGURE B-1. PTO INSTALLATION

CAUTION

AVOID SHARP BENDS IN THE SHIFTER CABLE. ALL

BENDS SHOULD HAVE AT LEAST A 6" RADIUS.

TIGHTER BENDS WILL CAUSE DIFFICUL T OPERA TION

OF THE SHIFTER KNOB.

6. Replace the transmission oil. If the PTO is

located below the transmission oil level, an

additional quantity of oil will be required.

7. Start the engine, engage the PTO and check for

proper PTO rotation. Allow it to run for 5 - 10

minutes. Check for leaks, unusual noise and proper

operation.

8. Retorque the mounting bolts.

DA435HA: 99901219: 2-2

19980930

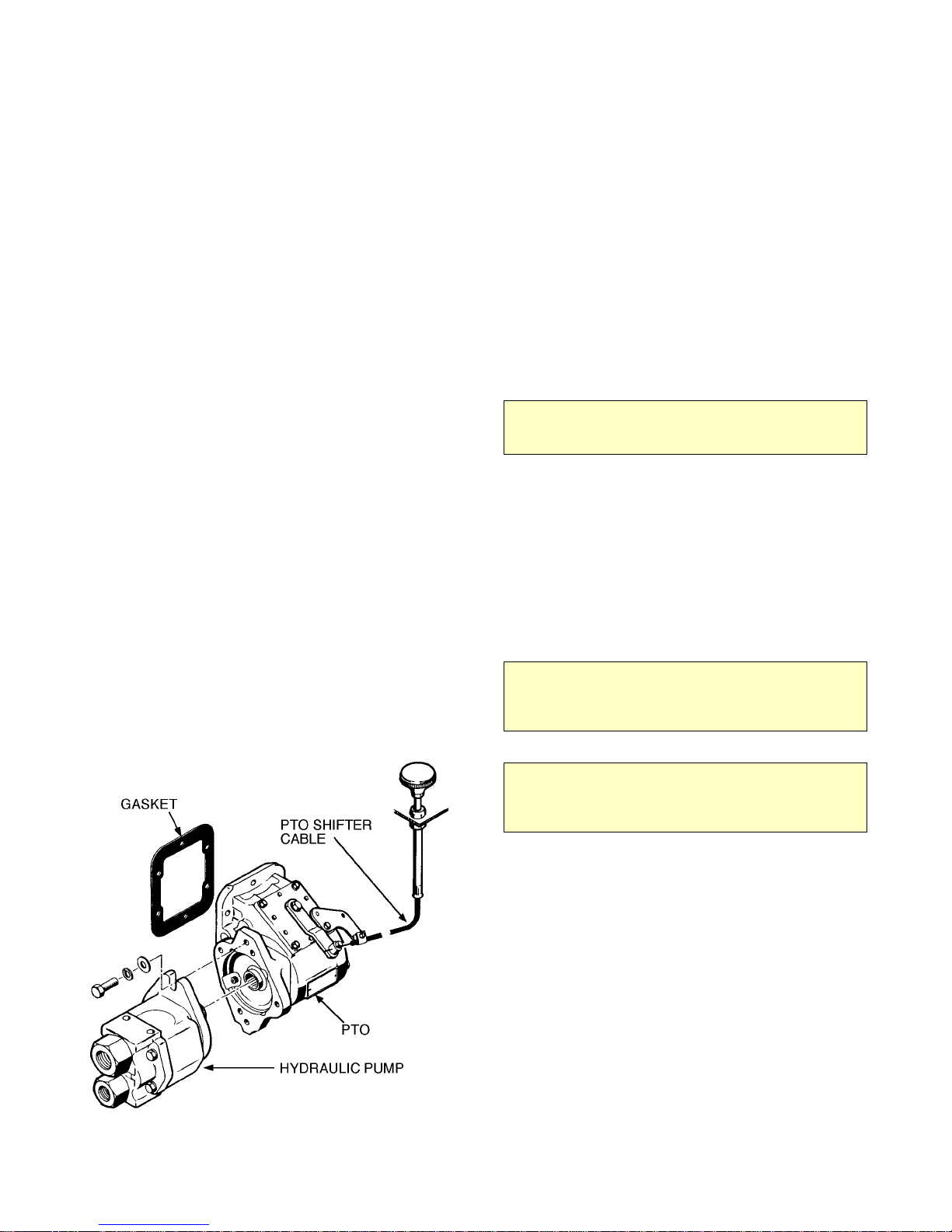

2-2-2. DRIVELINE AND PUMP

INSTALLATION

The pump may be driven as shown in Figure B-2 as

an optional method to the one shown in Figure B-1.

The following steps are a guide in this application.

NOTE

BEFORE INSTALLING DRIVELINE, REFER TO

PARAGRAPH 2-4 FOR PROPER DRIVELINE

INST ALLATION TECHNIQUES.

1. Install the PTO (refer to Paragraph 2-2-1).

2. Loosely bolt the pump mounting bracket (A) to

the adjustable bracket (B) in Figure B-2.

3. Bolt the adjustable bracket to the frame at a

point that will not exceed 48" (122cm) from the

PTO and will not cause a joint angle greater than 3°.

4. Check the pump rotation and install pump, pump

end yoke and PTO end yoke.

WARNING

THE INSTALLER OF THE DRIVELINE MUST INSPECT

THE FINAL POSITION OF THE DRIVELINE TO

DETERMINE WHETHER ITS LOCATION PROVIDES

SUFFICIENT PROTECTION TO AN OPERATOR, OR

OTHER PERSONNEL, FROM HAZARDS ASSOCIATED

WITH A ROTATING DRIVELINE. IF PROTECTION IS

INSUFFICIENT, THE INSTALLATION OF A GUARD IS

REQUIRED. IF YOU ARE UNSURE OF METHODS TO

GUARD A ROTATING DRIVELINE, CALL IOWA MOLD

TOOLING CO., INC. FOR INSTRUCTIONS. FAILURE

TO DO SO MAY RESULT IN SERIOUS INJURY OR

DEATH.

5. Size, cut and weld the driveline to the necessary

length. Ensure driveline balance and run out meet

specification. Allow 1" (2.54cm) extra for PTO end

yoke.

6. Install driveline in phase with proper operating

angle calculations, lock set screws and grease Ujoints and mating spline.

7. Ensure all mounting bolts are tight.

2-3. COMPRESSOR INSTALLATION

See Installation Kit Drawing in the Parts Section for

specific installation and parts information.

FIGURE B-2. DRIVELINE & PUMP INSTALLATION

DA435HA: 99901219: 2-319980930

2-4. DRIVELINE INSTALLATION

TECHNIQUES

2-4-1. U-JOINT OPERATING ANGLES

Every U-joint that operates at an angle creates

vibration.

U-joint operating angles are probably the most

common cause for driveline vibration in vehicles

that have been reworked or that have had auxiliary

equipment installed.

When reworking a chassis or installing a new

driveshaft in a vehicle, make sure that you follow

the basic rules that apply to u-joint operating angles,

as follows:

1. U-joint operating angles at each end of a shaft should

always be at least 1°.

2. U-joint operating angles on each end of a driveshaft

should always be equal within 1° of each other.

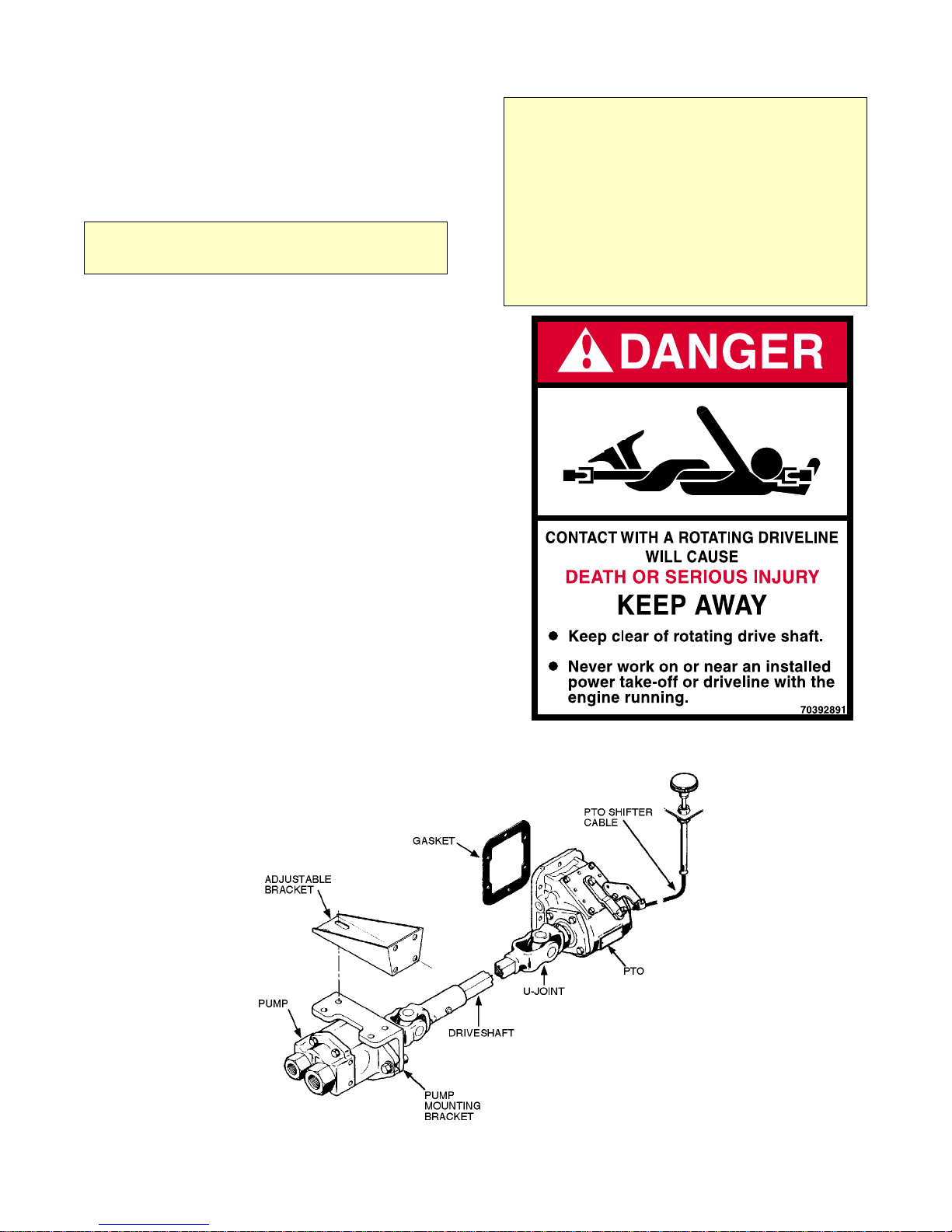

2-4-2. SINGLE PLANE AND COMPOUND

U-JOINT OPERATING ANGLES

There are two types of u-joint operating angles,

single plane and compound.

SINGLE PLANE

Single plane angles occur when the transmission and

pump components are in line when viewed from

either the top or side, but not both.

Determine the u-joint operating angle in an

application where the components are in line when

viewed from the top, but not in line when viewed

from the side, is as simple as measuring the slope of

the components in the side view, and adding or

subtracting those slopes to determine the angle. See

figure.

3. U-joint operating angles should not be larger than 3°. If

more than 3°, make sure they do not exceed the

maximum recommended angles for the RPM at which

they will be operating.

A u-joint operating angle is the angle that occurs at each

end of a driveshaft when the output shaft of the

transmission and the input shaft of the pump are not in

line. See figure.

The connecting driveshaft operates with an angle at

each u-joint. It is that angle that creates a vibration.

REDUCING AND CANCELING VIBRATION

A key point to remember about u-joint operating

angles: To reduce the amount of vibration, the

angles on each end of a driveshaft should always be

SMALL.

To cancel an angle vibration, the u-joint operating

angles need to be EQUAL within 1° at each end of a

shaft. See figure.

These angles should be SMALL and equal within 1°.

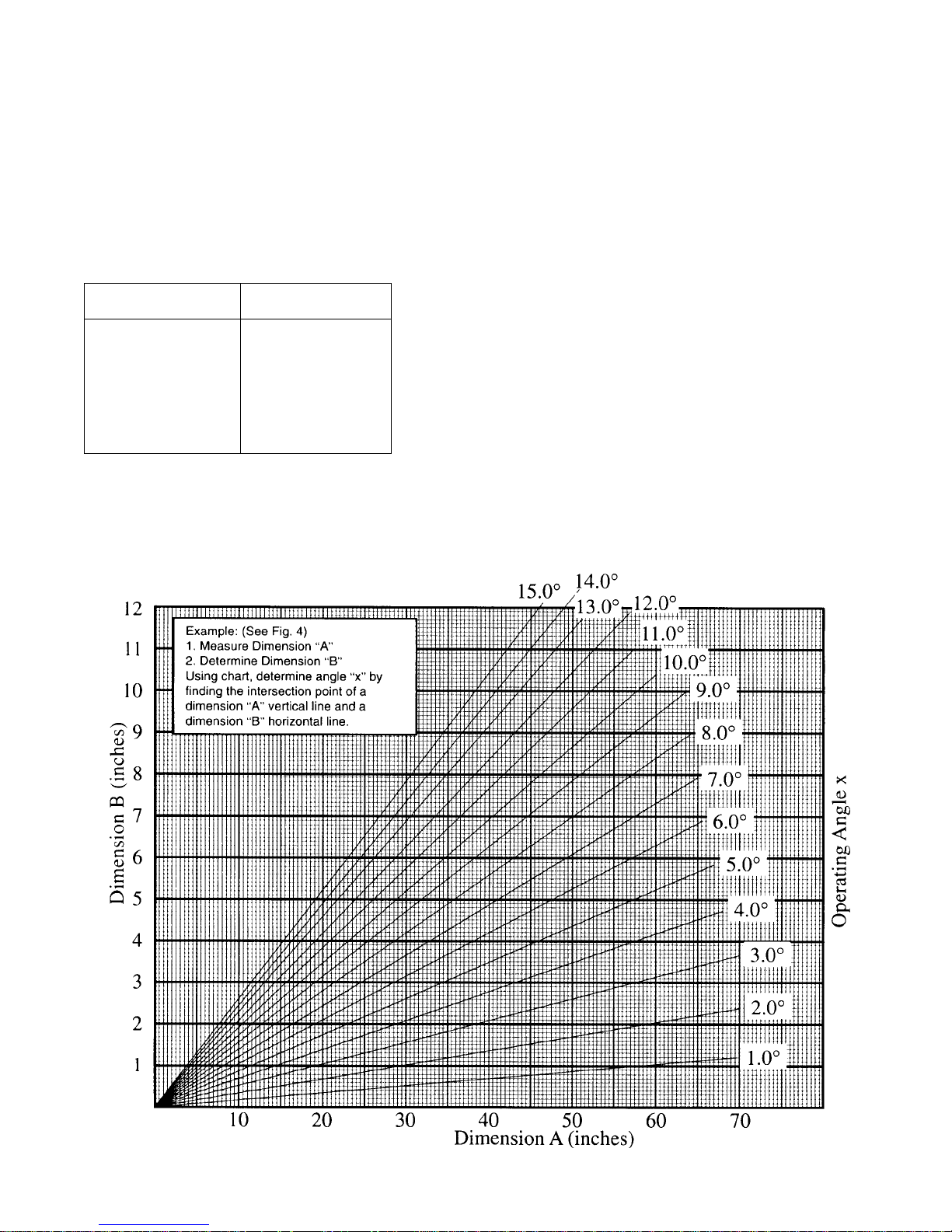

Determine the u-joint operating angles on a shaft

that is straight when viewed from the side and offset

when viewed from the top requires the use of a

special chart (See accompanying chart). In this type

of application, the centerlines of the connected

components must be parallel when viewed from the

top, as shown. These angles should also be SMALL

and equal within 1°. See figure.

Look at the angle chart and note that the smaller the

offset, the smaller the resultant angle.

To reduce the possibility of vibration, keep any

offset between connected points to a minimum.

DA435HA: 99901219: 2-419980930

There are two things which can be done to make

certain single plane angles are SMALL and

EQUAL:

Make sure that the transmission and pump are mounted

so that their centerlines are parallel when viewed from

both the side and the top.

Make sure the offset between them is mall in both views.

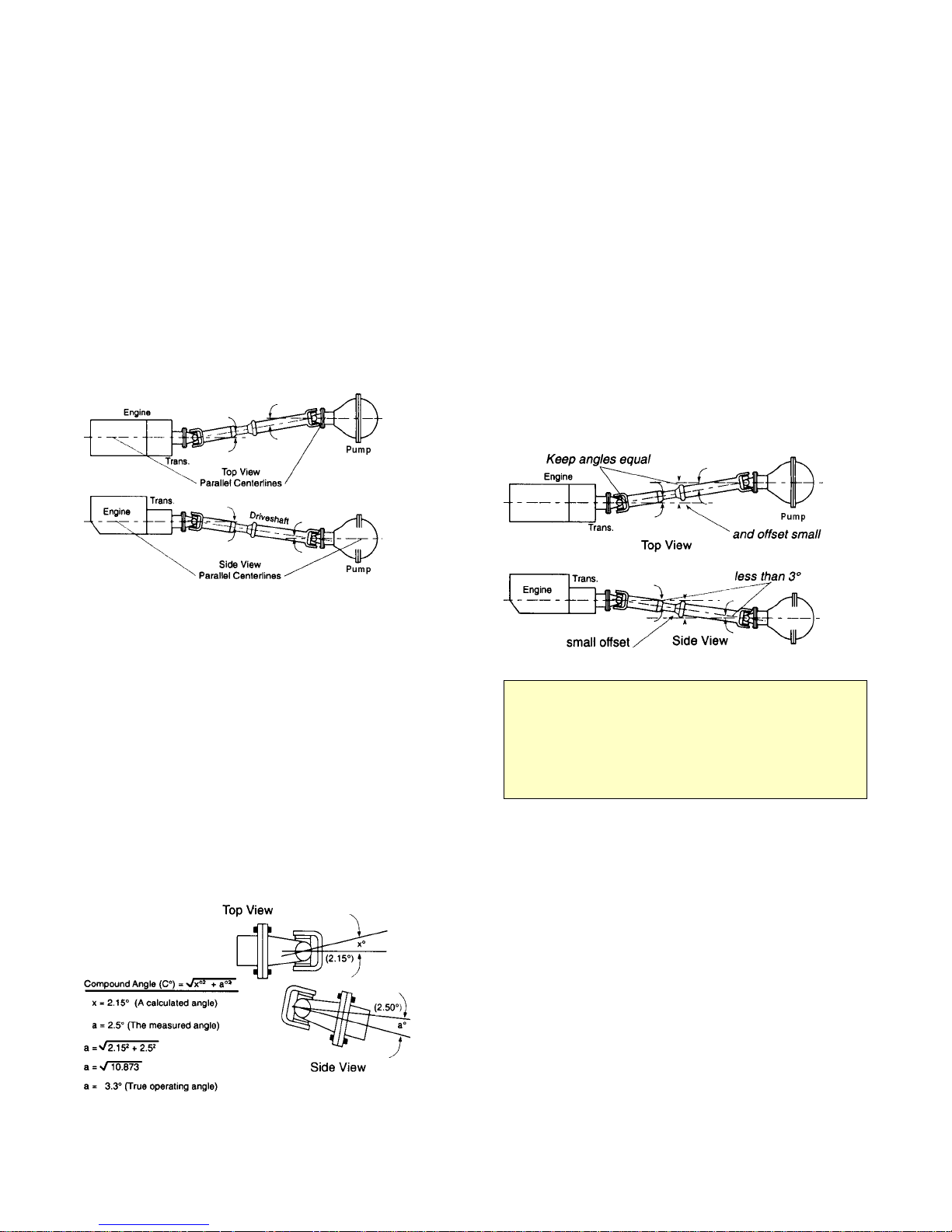

COMPOUND ANGLES

Compound u-joint operating angles occur when the

transmission and pump are not in line when viewed

from both, the top and side. Their centerlines,

however, are parallel in both views. See figure.

Do the same for the other end of the shaft. Compare

the resultant calculated u-joint operating angle for

each end. They should be EQUAL within 1°. If they

are not, the driveshaft will vibrate.

2-4-3. ELIMINATING COMPOUND

ANGLE INDUCED VIBRATIONS

Compound u-joint operating angles are one of the

most common causes for driveline vibration. To

avoid thease problems, remember these important

considerations:

When setting up an application that requires compound ujoint operating angles, always keep the centerlines of the

transmission and pump parallel in both views.

Always keep the offset between their horizontal and

vertical centerlines small.

TRUE U-JOINT OPERATING ANGLE

The true u-joint operating angle, which must be

calculated for each end of the shaft with compound

angles, is a combination of the u-joint operating

angle in the top view, as determined from the chart,

and the measured u-joint operating angle in the side

view.

To determine the true u-joint operating angle for one

end of a shaft, (compound angle C° in the formula

shown in figure below) insert the u-joint operating

angle measurement obtained in the side view and the

u-joint operating angle obtained from the chart into

the formula.

NOTE

CENTERLINES OF TRANSMISSION AND AXLE MUST

BE PARALLEL IN BOTH TOP AND SIDE VIEWS TO USE

THIS METHOD OF DETERMINING TRUE U-JOINT

OPERATING ANGLE. CONTACT IMT TECHNICAL

SUPPORT IF YOU HAVE AN APPLICATION WHICH

CANNOT BE INSTALLED WITH THEIR CENTERLINES

PARALLEL.

DA435HA: 99901219: 2-519980930

2-4-4. ANGLE SIZE

The magnitude of a vibration created by a u-joint

operating angle is proportional to the size of the ujoint operating angle. IMT recommends true u-joint

operating angles of 3° or less.

Obtain the true u-joint operating angle, as explained

above, and if it is greater than 3°, compare it to the

following chart.

The angles shown on the chart are the MAXIMUM

u-joint operating angles recommended by IMT and

are directly related to the speed of the driveshaft.

Any u-joint operating angle greater than 3° will

lower u-joint life and may cause vibration.

Remember to check maximum safe driveshaft RPM

as recommended by the driveshaft manufacturer.

DRIVESHAFT

RPM

5000 3.2°

4500 3.7°

4000 4.2°

3500 5.0°

3000 5.8°

2500 7.0°

2000 8.7°

1500 11.5°

OPERATING ANGLE

MAXIMUM

ANGLE CHART

FOR DRIVESHAFTS HAVING AN ANGLE IN THE TOP VIEW

DA435HA: 99901219: 2-619980930

Loading...

Loading...