Page 1

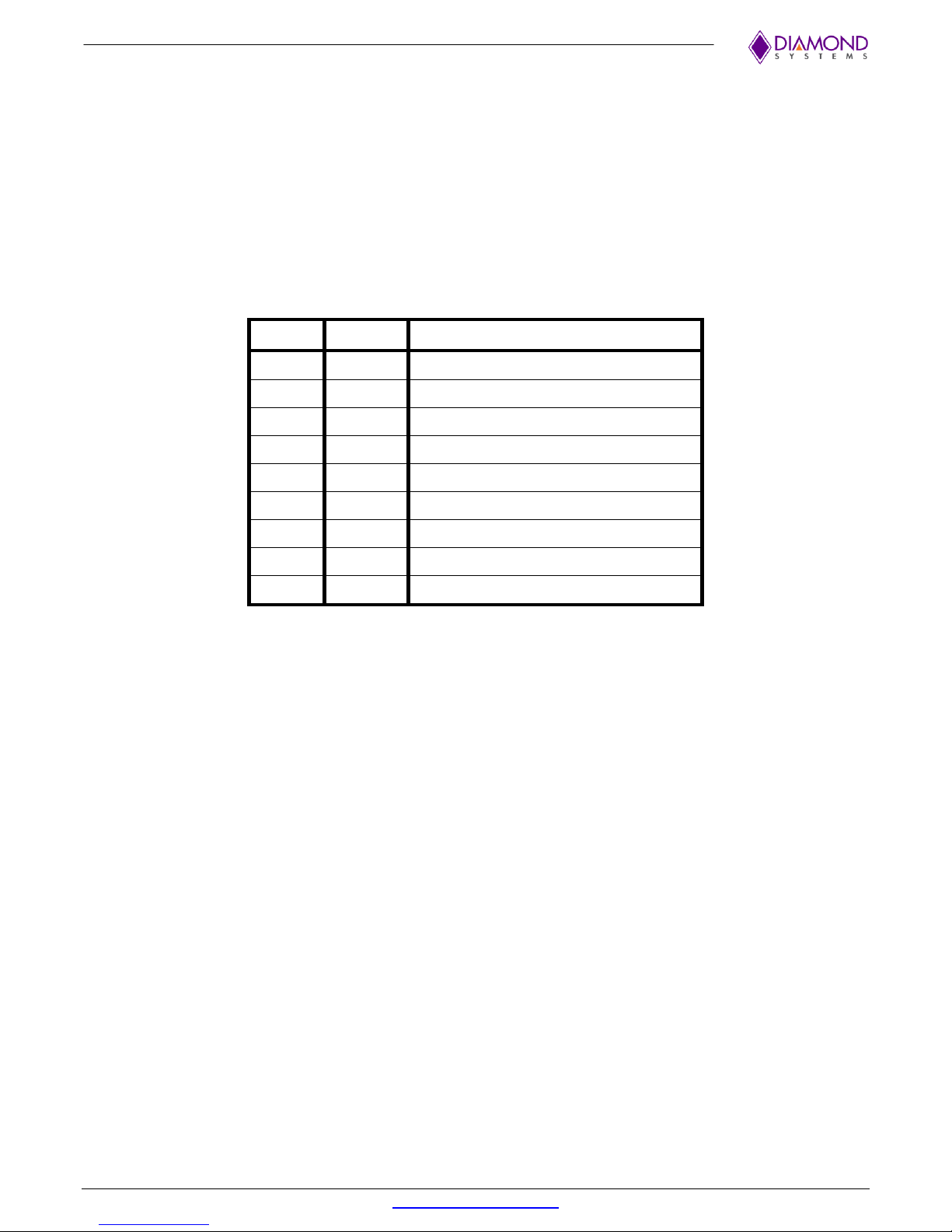

Revision

Date

Comment

A.00

3/26/2015

Initial Release

A.01

8/26/2015

JP4 update and minor changes

A.02

11/3/2015

Section 8.5 removed

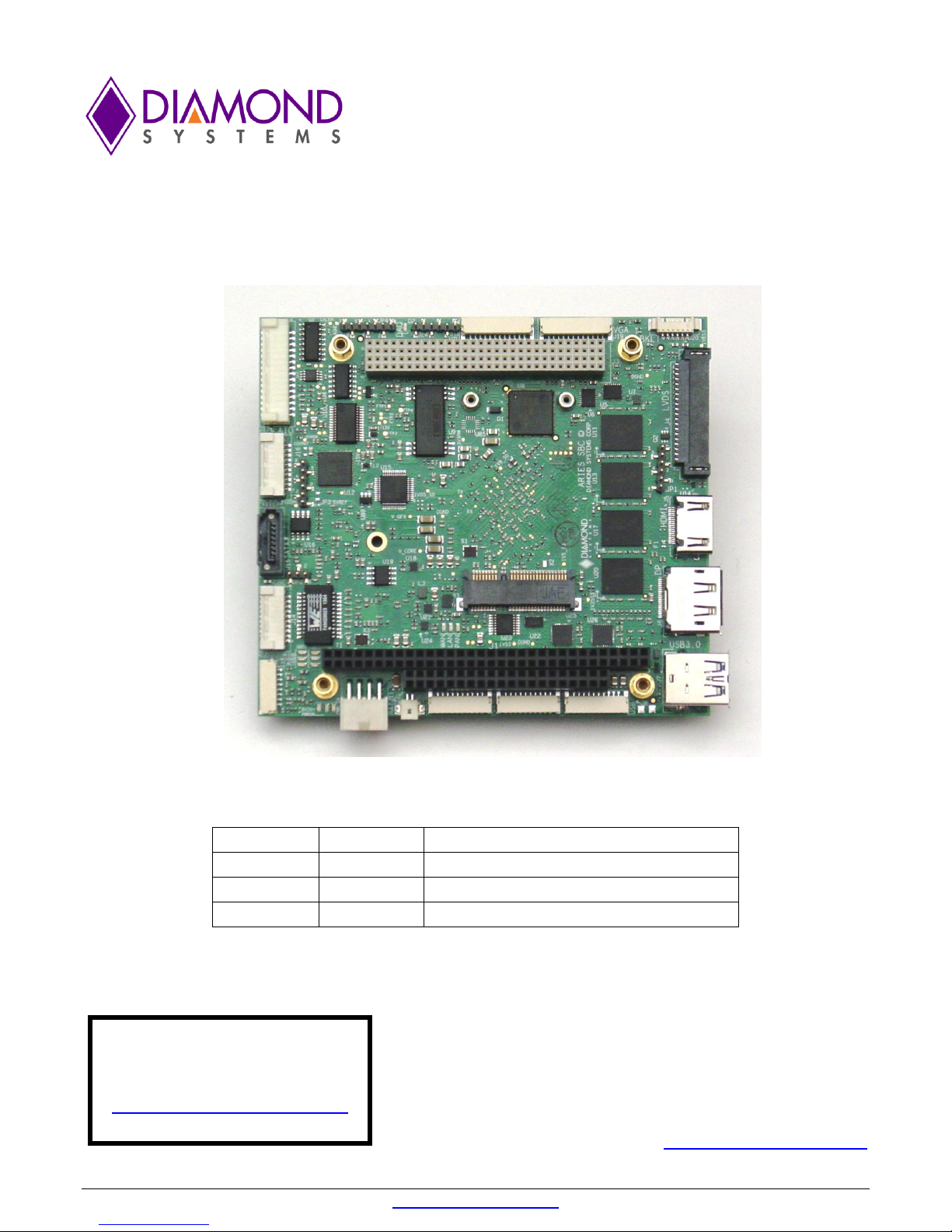

Aries Single Board Computer

PC/104-Plus SBC with Intel E3800 “Bay Trail” Processor

Copyright 2015

FOR TECHNICAL SUPPORT Diamond Systems Corporation

PLEASE CONTACT: 555 Ellis Street

Mountain View, CA 94043 USA

support@diamondsystems.com Tel 1-650-810-2500

Fax 1-650-810-2525

www.diamondsystems.com

Aries User Manual Rev A.02 www.diamondsystems.com Page 1

Page 2

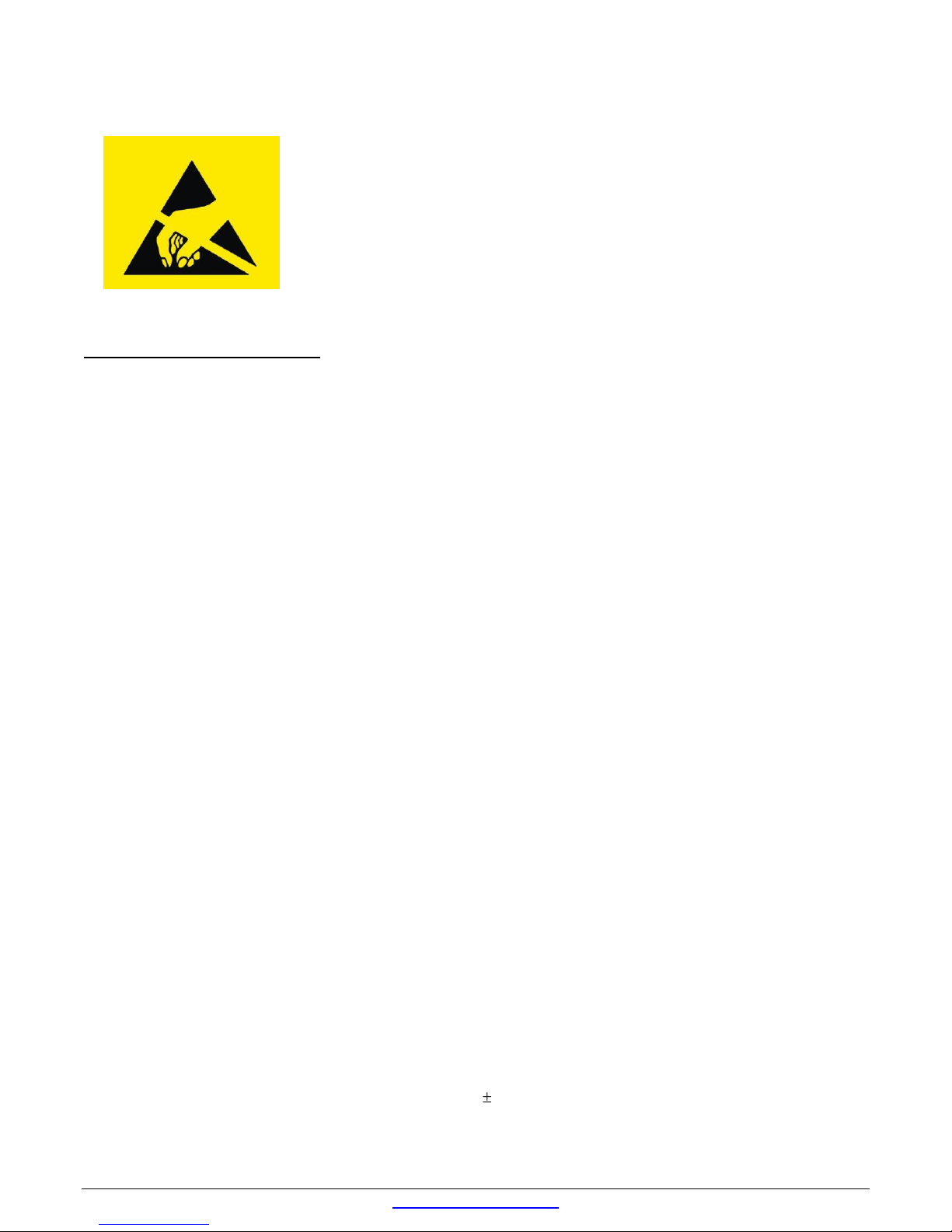

CONTENTS

1. Important Safe Handling Information .............................................................................................................4

2. Introduction .......................................................................................................................................................6

2.1 Models ...........................................................................................................................................................6

2.2 Features .........................................................................................................................................................6

2.3 Operating System Support ............................................................................................................................7

2.4 Mechanical, Electrical, Environmental ...........................................................................................................7

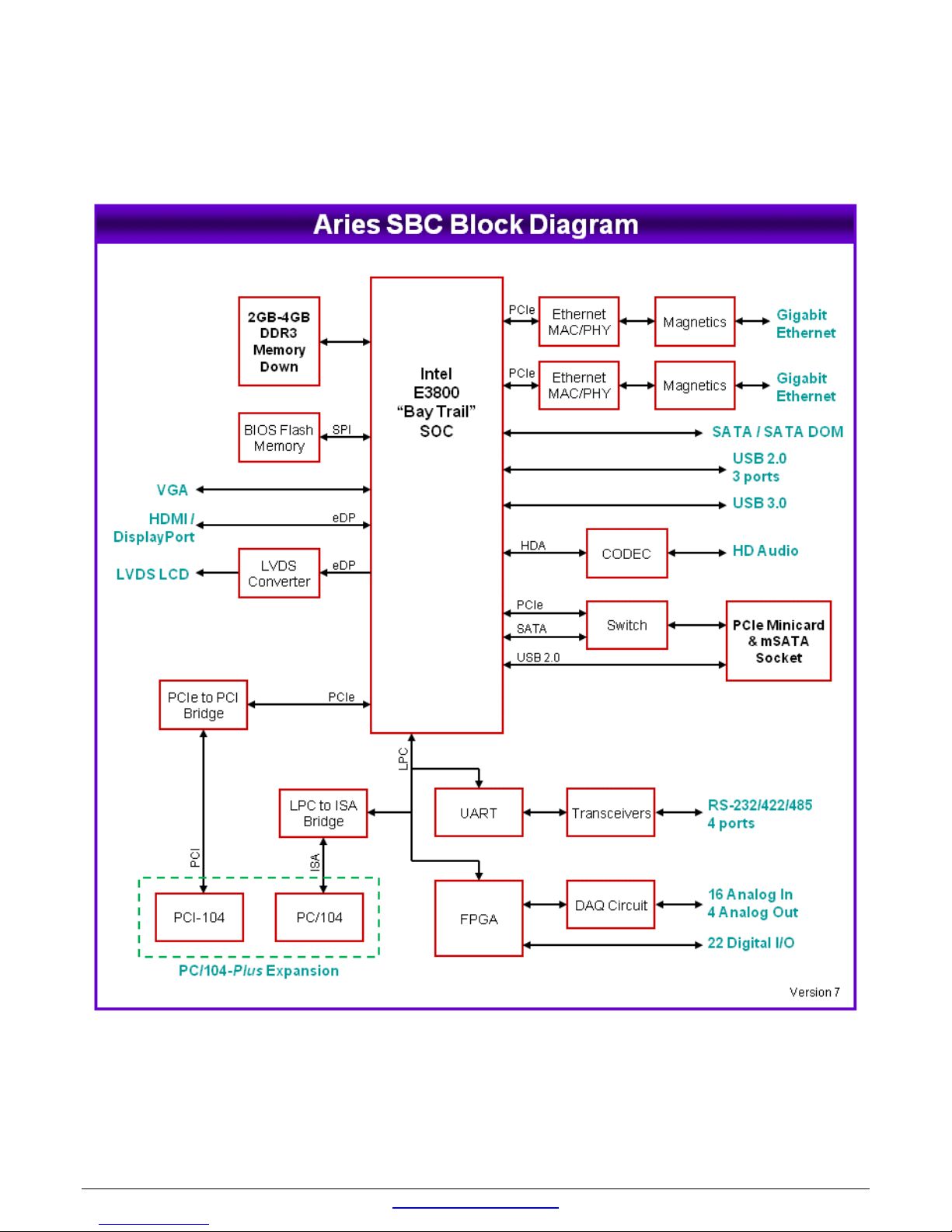

3. Functional Overview .........................................................................................................................................8

3.1 Block Diagram ...............................................................................................................................................8

3.2 Feature Descriptions .....................................................................................................................................9

3.2.1 Processor and Memory .........................................................................................................................9

3.2.2 Ethernet.................................................................................................................................................9

3.2.3 Video .....................................................................................................................................................9

3.2.4 SATA .....................................................................................................................................................9

3.2.5 USB .......................................................................................................................................................9

3.2.6 Serial Ports ...........................................................................................................................................9

3.2.7 Audio .....................................................................................................................................................9

3.2.8 Data Acquisition ................................................................................................................................. 10

3.2.9 Backup Battery ................................................................................................................................... 10

3.2.10 PCIe MiniCard Socket ........................................................................................................................ 10

3.2.11 PC/104-Plus Expansion ..................................................................................................................... 10

3.2.12 PCIe link routing ................................................................................................................................. 10

3.2.13 Watchdog Timer ................................................................................................................................. 10

3.2.14 LED Indicators ................................................................................................................................... 11

3.2.15 BIOS Features ................................................................................................................................... 11

4. Mechanical Board Drawing ........................................................................................................................... 13

5. Board Layout .................................................................................................................................................. 14

5.1 I/O Connectors, Jumpers and LED Summary ............................................................................................ 15

6. I/O Connectors ............................................................................................................................................... 16

6.1 Connector Pin-out and Signal Description ................................................................................................. 16

6.1.1 PC/104 (J1, J2) .................................................................................................................................. 16

6.1.2 PC-104 (J3) ........................................................................................................................................ 17

6.1.3 LVDS LCD (J4) .................................................................................................................................. 18

6.1.4 HDMI (J5) ........................................................................................................................................... 19

6.1.5 Display Port (J6) ................................................................................................................................ 19

6.1.6 USB 3.0 Ports (J7) ............................................................................................................................. 20

6.1.7 USB 2.0 Ports (J8) ............................................................................................................................. 20

6.1.8 Serial ports (J9, J10) .......................................................................................................................... 21

6.1.9 External Battery (J11) ........................................................................................................................ 21

6.1.10 Input Power (J12) ............................................................................................................................... 21

6.1.11 Audio (J13) ......................................................................................................................................... 22

6.1.12 Ethernet (J14) .................................................................................................................................... 22

6.1.13 SATA (J15) ........................................................................................................................................ 22

6.1.14 Digital I/O (J16) .................................................................................................................................. 23

6.1.15 Analog I/O (J17) ................................................................................................................................. 23

6.1.16 Utility Connector (J18) ....................................................................................................................... 24

6.1.17 VGA (J19) .......................................................................................................................................... 25

6.1.18 LCD Backlight (J20) ........................................................................................................................... 25

6.1.19 mSATA / PCIe MiniCard Socket (J21) ............................................................................................... 26

6.2 List of Connectors ....................................................................................................................................... 27

7. Jumper Description ....................................................................................................................................... 28

7.1 LVDS Backlight and LVDS VDD (JP1) ....................................................................................................... 29

7.2 SATA (JP2) ................................................................................................................................................. 29

7.3 Digital IO (JP3) ........................................................................................................................................... 30

7.4 Miscellaneous (JP4) ................................................................................................................................... 31

8. BIOS Key Features......................................................................................................................................... 32

8.1 Entering the BIOS ....................................................................................................................................... 32

8.2 Restoring Default BIOS Settings ................................................................................................................ 32

8.3 Setting the Date and Time .......................................................................................................................... 32

8.4 Boot Priority ................................................................................................................................................ 32

8.5 LED ............................................................................................................................................................. 32

Aries User Manual Rev A.02 www.diamondsystems.com Page 2

Page 3

8.6 Quiet / Quick Boot / Splash Screen ............................................................................................................ 32

8.7 Selecting the Displays ................................................................................................................................ 33

8.8 Serial Port Configuration ............................................................................................................................ 33

9. Getting Started ............................................................................................................................................... 33

9.1 Development Kit ......................................................................................................................................... 33

9.2 Quick Setup ................................................................................................................................................ 34

9.3 Boot Device Options ................................................................................................................................... 34

10. Data Acquisition Circuit ................................................................................................................................ 35

10.1 Overview ..................................................................................................................................................... 35

10.2 FPGA .......................................................................................................................................................... 36

10.3 Bus Interface ............................................................................................................................................... 36

10.4 Interrupts ..................................................................................................................................................... 36

11. A/D Circuit ...................................................................................................................................................... 38

11.1 A/D Input Ranges and Resolution .............................................................................................................. 38

11.2 Unipolar and Bipolar Inputs ........................................................................................................................ 38

11.3 Ranges and Resolutions ............................................................................................................................ 38

11.3.1 Conversion Formulas ......................................................................................................................... 39

11.4 A/D Sampling Methods ............................................................................................................................... 40

11.4.1 FIFO Description ................................................................................................................................ 40

11.4.2 Scan Sampling ................................................................................................................................... 41

11.4.3 Sequential Sampling .......................................................................................................................... 41

11.4.4 Sampling Methods ............................................................................................................................. 41

12. D/A Circuit ...................................................................................................................................................... 42

12.1 Ranges and Resolutions ............................................................................................................................ 42

12.1.1 Ranges ............................................................................................................................................... 42

12.1.2 Resolution .......................................................................................................................................... 43

12.2 D/A Conversion Formulas and Tables........................................................................................................ 43

12.2.1 D/A Conversion Formulas for Unipolar Output Ranges ..................................................................... 43

12.2.2 D/A Conversion Formulas for Bipolar Output Ranges ....................................................................... 44

12.3 Calibration ................................................................................................................................................... 45

12.4 Waveform Generator .................................................................................................................................. 45

13. Digital I/O ........................................................................................................................................................ 46

14. Counters and Timers ..................................................................................................................................... 47

15. Pulse Width Modulation ................................................................................................................................ 48

16. Watchdog Timer ............................................................................................................................................. 49

17. Thermal Solutions.......................................................................................................................................... 50

17.1 Heat Spreader Drawing .............................................................................................................................. 50

17.2 Bottom view of Heat Spreader .................................................................................................................... 51

17.3 Heat Spreader Installed on the Board ........................................................................................................ 52

17.4 Thermal Pad ............................................................................................................................................... 53

17.5 Heat Sink Accessory .................................................................................................................................. 54

18. Specifications ................................................................................................................................................. 55

19. Appendix ......................................................................................................................................................... 57

Aries User Manual Rev A.02 www.diamondsystems.com Page 3

Page 4

1. IMPORTANT SAFE HANDLING INFORMATION

WARNING!

ESD-Sensitive Electronic Equipment

Observe ESD-safe handling procedures when working with this product.

Always use this product in a properly grounded work area and wear appropriate

ESD-preventive clothing and/or accessories.

Always store this product in ESD-protective packaging when not in use.

Safe Handling Precautions

The Aries SBC contains a high number of I/O connectors with connection to sensitive electronic components. This

creates many opportunities for accidental damage during handling, installation and connection to other

equipment. The list here describes common causes of failure found on boards returned to Diamond Systems for

repair. This information is provided as a source of advice to help you prevent damaging your Diamond (or any

vendor’s) embedded computer boards.

ESD damage – This type of damage is usually almost impossible to detect, because there is no visual sign of

failure or damage. The symptom is that the board eventually simply stops working, because some component

becomes defective. Usually the failure can be identified and the chip can be replaced.

To prevent ESD damage, always follow proper ESD-prevention practices when handling computer boards.

Damage during handling or storage – On some boards we have noticed physical damage from mishandling. A

common observation is that a screwdriver slipped while installing the board, causing a gouge in the PCB surface

and cutting signal traces or damaging components.

Another common observation is damaged board corners, indicating the board was dropped. This may or may not

cause damage to the circuitry, depending on what is near the corner. Most of our boards are designed with at

least 25 mils clearance between the board edge and any component pad, and ground / power planes are at least

20 mils from the edge to avoid possible shorting from this type of damage. However these design rules are not

sufficient to prevent damage in all situations.

A third cause of failure is when a metal screwdriver tip slips, or a screw drops onto the board while it is powered

on, causing a short between a power pin and a signal pin on a component. This can cause overvoltage / power

supply problems described below. To avoid this type of failure, only perform assembly operations when the

system is powered off.

Sometimes boards are stored in racks with slots that grip the edge of the board. This is a common practice for

board manufacturers. However our boards are generally very dense, and if the board has components very close

to the board edge, they can be damaged or even knocked off the board when the board tilts back in the rack.

Diamond recommends that all our boards be stored only in individual ESD-safe packaging. If multiple boards are

stored together, they should be contained in bins with dividers between boards. Do not pile boards on top of each

other or cram too many boards into a small location. This can cause damage to connector pins or fragile

components.

Power supply wired backwards – Our power supplies and boards are not designed to withstand a reverse

power supply connection. This will destroy each IC that is connected to the power supply (i.e. almost all ICs). In

this case the board will most likely will be unrepairable and must be replaced. A chip destroyed by reverse power

or by excessive power will often have a visible hole on the top or show some deformation on the top surface due

to vaporization inside the package. Check twice before applying power!

Board not installed properly in PC/104 stack – A common error is to install a PC/104 board accidentally shifted

by 1 row or 1 column. If the board is installed incorrectly, it is possible for power and ground signals on the bus to

make contact with the wrong pins on the board, which can damage the board. For example, this can damage

components attached to the data bus, because it puts the 12V power supply lines directly on data bus lines.

Aries User Manual Rev A.02 www.diamondsystems.com Page 4

Page 5

Overvoltage on analog input – If a voltage applied to an analog input exceeds the design specification of the

board, the input multiplexor and/or parts behind it can be damaged. Most of our boards will withstand an

erroneous connection of up to 35V on the analog inputs, even when the board is powered off, but not all boards,

and not in all conditions.

Overvoltage on analog output – If an analog output is accidentally connected to another output signal or a

power supply voltage, the output can be damaged. On most of our boards, a short circuit to ground on an analog

output will not cause trouble.

Overvoltage on digital I/O line – If a digital I/O signal is connected to a voltage above the maximum specified

voltage, the digital circuitry can be damaged. On most of our boards the acceptable range of voltages connected

to digital I/O signals is 0-5V, and they can withstand about 0.5V beyond that (-0.5 to 5.5V) before being damaged.

However logic signals at 12V and even 24V are common, and if one of these is connected to a 5V logic chip, the

chip will be damaged, and the damage could even extend past that chip to others in the circuit.

Bent connector pins – This type of problem is often only a cosmetic issue and is easily fixed by bending the pins

back to their proper shape one at a time with needle-nose pliers. The most common cause of bent connector pins

is when a PC/104 board is pulled off the stack by rocking it back and forth left to right, from one end of the

connector to the other. As the board is rocked back and forth it pulls out suddenly, and the pins at the end get

bent significantly. The same situation can occur when pulling a ribbon cable off of a pin header. If the pins are

bent too severely, bending them back can cause them to weaken unacceptably or even break, and the connector

must be replaced.

Aries User Manual Rev A.02 www.diamondsystems.com Page 5

Page 6

2. INTRODUCTION

Model

Processor/

Speed

Memory

Analog

I/O

Digital

I/O

ARS3845-4GA

E3845/1.91GHz

4GB DDR3

Yes

Yes

ARS3845-4GN

E3845/1.91GHz

4GB DDR3

No

Yes

ARS3826-2GA

E3826/1.46GHz

2GB DDR3

Yes

Yes

ARS3826-2GN

E3826/1.46GHz

2GB DDR3

No

Yes

Aries is an embedded single board computer (SBC) in the PC/104 form factor. Aries integrates on-board memory,

PC/104-Plus expansion, one PCIe Mini card socket, dual Gigabit Ethernet and optional data acquisition circuit

with analog and digital I/O.

The Aries SBC is based on Intel “Bay Trail” E3800 series processors. The form factor is similar to PC/104 with left

and right side extensions that extend the full length of the two sides without providing the corners traditionally

seen in PC/104 boards with “wings”.

2.1 Models

2.2 Features

1.91GHz Intel quad core E3845 or 1.46GHz dual core E3826 Bay Trail CPU

2GB or 4GB 64-bit DDR3 SDRAM soldered on board

I/O Support:

3 USB 2.0 ports, 1 USB 3.0 port

4 RS-232/422/485 ports with programmable protocol and line termination

2 10/100/1000Mbps Ethernet ports

1 SATA port for disk-on-module or external drive

24-bit LVDS LCD display and VGA CRT

DP and HDMI sharing on single channel

HD audio

Shared expansion socket auto-selects for either PCIe MiniCard or mSATA flash disk modules

Programmable watchdog timer

Data Acquisition:

16 16-bit analog inputs with 250KHz maximum sample rate

4 16-bit analog outputs with waveform generator

22 digital I/O lines with programmable direction

8 32-bit counter/timers

4 24-bit PWMs

PC/104-Plus and PCIe MiniCard expansion capability

Aries User Manual Rev A.02 www.diamondsystems.com Page 6

Page 7

2.3 Operating System Support

Windows 7, 8, Linux

Driver packages and/or BSPs available for each OS

2.4 Mechanical, Electrical, Environmental

PC/104 form factor 4.5” x 4.0” (not including I/O connector overhang).

-40°C to +85°C ambient operating temperature

Power input: +5VDC +/- 5%

Aries User Manual Rev A.02 www.diamondsystems.com Page 7

Page 8

3. FUNCTIONAL OVERVIEW

3.1 Block Diagram

Aries User Manual Rev A.02 www.diamondsystems.com Page 8

Figure 1: Functional Block Diagram

Page 9

3.2 Feature Descriptions

This section describes the key subsystems of the Aries SBC.

3.2.1 Processor and Memory

Aries core embedded computer circuit is based on Intel’s Bay Trail. Depending on the model chosen the

processors speed and its memory will differ. The two different cores available are 1.91GHz quad core Intel E3845

with 4GB DDR3 and 1.46GHz dual core Intel E3826 with 2GB DDR3 memory.

3.2.2 Ethernet

Aries provides two Gigabit Ethernet Ports derived from Intel I210IT PCIe Gigabit Ethernet Controllers (MAC +

PHY). The board has been provided with necessary magnetics for the ports. Instead of a standard RJ-45 jack a

pin header has been used.

On-board LEDs are provided for Link, Activity, and Speed. The LEDs are located along the board edge near the

Ethernet connector. The Ethernet connector does not provide access to the LED signals. However, the LED’s can

be accessed from the Utility Connector J18.

3.2.3 Video

The processor offers three video output options: 2 DDI and one dedicated VGA. The DDI ports are configurable

for either HDMI 1.4, DP 1.1a, or eDP. Any two outputs can be active at any time.

The second DDI port can be configured for either HDMI or DP, and the board’s circuit and I/O connector are

configured accordingly. Maximum resolution of DP is 2560 x 1600 x 60Hz x 24bpp. Maximum resolution of HDMI

is 1920 x 1080 x 60Hz x 24bpp.

The first DDI port can be used in eDP mode and an eDP to LVDS converter provides a dual-channel LVDS LCD

output.

Maximum LVDS and VGA resolution is 2560 x 1600 x 60Hz x 24bpp.

The LCD backlight control is provided by a PWM circuit. LCD backlight power and control are on a separate

latching connector.

3.2.4 SATA

Aries offers two SATA ports derived from the processor. One port is connected to an industry-standard vertical

SATA connector that accepts cables with latching connectors or an on-board SATA-DOM. The second port is

dedicated to the combination mSATA / PCIe Mini Card socket.

3.2.5 USB

Aries provides 3 user accessible USB 2.0 ports and one USB 3.0 port coming directly from the processor. Three

come directly from the processor. The fourth USB 2.0 port from the processor is connected to the PCIe Mini card

socket. All ports have minimum 500mA per port drive capability with short circuit / over current and ESD

protection on each port. USB port connected to mini PCIE does not have ESD protection.

The USB 3.0 port uses an industry standard right-angle USB 3.0 connector. The USB 2.0 ports use miniature

1.25mm pitch latching connectors.

3.2.6 Serial Ports

Aries provides four serial ports with varying protocols and signal availability using the Exar XR28V384 LPC

UART. RS-232/422/485 protocols are supported with Exar SP335 multiprotocol transceivers, one per port. In RS232 mode, only signals TX, RX, RTS, and CTS are provided. Protocol selection and TX / RX 121 ohm line

termination resistors for RS-422/485 are controlled using GPIO pins from the FPGA and are configurable via

BIOS configuration screens as well as via application software. The GPIO pins are controlled from a page in the

FPGA register map dedicated for board configuration. Console redirection is available on COM1.

3.2.7 Audio

The design provides HD audio support from ALC892. Audio I/O signals include stereo line in, stereo line out and

mono mic in. The audio signals are made available on a latching connector.

Aries User Manual Rev A.02 www.diamondsystems.com Page 9

Page 10

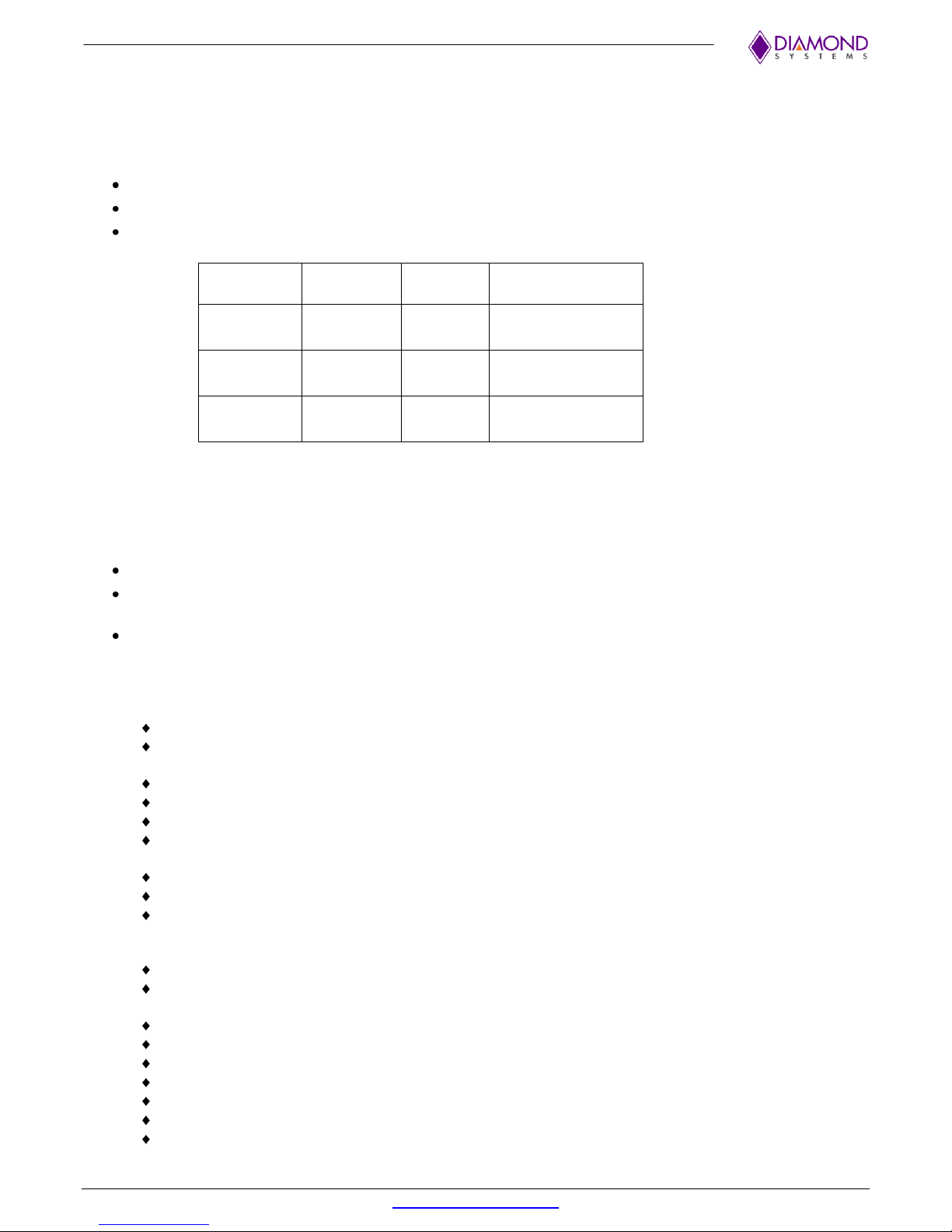

Type of I/O

Characteristics

Analog Input

16 single-ended/8 differential inputs, 16-bit resolution

250KHz maximum aggregate A/D sampling rate

Programmable input ranges/gains:

+/-10V, +/-5V, +/-2.5V, +/-1.25V, 0-10V, 0-5V, 0-2.5V

2048 sample A/D FIFO for reliable high-speed sampling

Analog Output

4 analog outputs, 16-bit resolution

±10V, ±5V, ±2.5V, 0-5V and 0-10V output ranges

Indefinite short circuit protection on outputs

Digital I/O

22 programmable digital I/O, 3.3V and 5V logic compatible

Counter/Timers

Eight 32-bit counter/timer for A/D sampling rate control

3.2.8 Data Acquisition

Aries provides an optional data acquisition sub-circuit containing analog input, analog output, and digital I/O

features. This circuit is controlled by an FPGA attached to the processor via the LPC bus. A pin header on the

board provides access to JTAG signals for reprogramming the FPGA on the board and in the field.

Apart from the characteristics mentioned in the above table DAQ also offers selectable pull up/down resistors,

programmable directions, buffered I/O and capability to use a counter/timer and PWM circuits.

3.2.9 Backup Battery

The board does not contain an on-board RTC backup battery. A connector is provided to enable the use of an

external battery. A jumper is also provided for clearing the CMOS NVRAM

3.2.10 PCIe MiniCard Socket

The board has one full size (51mm length) PCIe MiniCard socket. The socket supports both PCIe MiniCards and

mSATA modules. It has a PCIe/mSATA switch controlled by a pin on the socket to select which interface is active.

Additionally, a USB port is also available in PCIe MiniCard socket.

3.2.11 PC/104-Plus Expansion

The board offers a full PC/104-Plus expansion socket with both PCI and ISA expansion connectors on the top

side of the board. The PCI bus is provided by a PCIe to PCI Bridge. It supports both 5V and 3.3V logic levels

configurable with a jumper. The ISA bus is provided by the Fintek F85226AF LPC to ISA Bridge.

3.2.12 PCIe link routing

Lane 1: Ethernet #1

Lane 2: Ethernet #2

Lane 3: PCIe Mini card

Lane 4: PCIe to PCI bridge for PCI-104 connector

3.2.13 Watchdog Timer

The board contains a watchdog timer (WDT) circuit with programmable delay time derived from the LPC UART.

The WDT can be enabled, disabled, and retriggered in software. If the WDT times out before it is retriggered, it

will cause a system reset. The watchdog timer circuit timeout period is programmable from 0 to 255 seconds with

1 second or better resolution.

Aries User Manual Rev A.02 www.diamondsystems.com Page 10

Page 11

Activity

LED

LINK 100

LED

LINK

1000 LED

Description

On

Off

Off

Port is active

Speed is 10MBps

On

On

Off

Port is active

Speed is 100MBps

On

On

On

Port is active

Speed is 1GBps

3.2.14 LED Indicators

The board provides the following LED indicators. All LEDs are located near to a board edge or their respective

features. The blue LED is located along the lower edge of the board. All LEDs are labeled in silkscreen with their

function.

Power input: Green LED when 5VDC is applied

Power on: Green LED when board is powered on

Ethernet: Green LED for Link, activity, and speed for each port

The Activity LED when Blinking: Activity on the port.

Solid: Link

LED locations of all the Ethernet LED’s on the board are shown in the Board Layout section.

Digital I/O: Blue, driven with reverse logic from +5V, controlled by data acquisition FPGA

Programmable LED: Green, connected to a GPIO line on the processor; this LED is off during power-

up and is turned on in the BIOS to indicate a successful system BIOS startup.

PCIe Mini Card socket: 3 green LEDs to support WWAN, WPAN, WLAN signals from the connector

3.2.15 BIOS Features

The BIOS provides the following key features:

Boot from LAN (PXE) as well as USB, SATA, and mSATA ports

Free boot sequence configuration to allow different boot sequences as first, second and third boot

devices

Support for various LCD configurations supported by the video chipset (default should be 1024x768)

LCD brightness control adjustment

Console (display and keyboard) redirection to COM1 port.

DSC-configurable default settings in battery-less configurations; the necessary BIOS customization is

provided

Customizable splash screen

Quiet boot option

POST message will display “Diamond Systems Corporation” and also display the board name and

BIOS version. The BIOS version will be displayed as “Major.Minor-rev – Date Built” format. For

example “Version 1.01 – 12-Oct-2012”.

Enable/disable for individual COM ports.

Protocol selection for each of the COM ports to select serial port protocol on SP330 using DIO lines.

Default for all ports is RS-232.

121 ohm line termination for serial ports in RS-422/485 protocol.

IRQ sharing for COM ports

IRQs can be reserved in BIOS for use on ISA bus; a minimum of 2 IRQs can be reserved.

Watchdog timer enable/disable and timeout period selection

Ethernet MAC address readback on boot-up and in BIOS screens

Wake on LAN for on-board Ethernet and mini card socket

Field upgradeable via a DOS utility.

Aries User Manual Rev A.02 www.diamondsystems.com Page 11

Page 12

5V

3.3V

Features

2.0A

2.0A

PC/104 and PC/104-Plus add-on modules

1.5A

PCIe Mini card add-on modules

0.25A SATA disk module

1.4A

0.7A

LCD power

0.9A

LCD backlight

0.05A

DAQ connector

0.05A

Utility connector

1.0A

USB 2.0 ports

0.9A

USB 3.0 port

3.2.15.1 POWER SUPPLY

The board requires only +5VDC input voltage as per the PC/104 Specification. It supports ACPI pushbutton on/off

control. It supports Standby mode. In standby mode the board may be powered on via Wake on LAN feature on at

least one Ethernet port.

The 5V supply on the PC-104 and PC/104-Plus connectors is routed directly to the input power connector, so that

the board may obtain its input power from either the input power connector or either of these bus connectors.

Maximum allowable reflected ripple, measured at the voltage input connector is 50mV p-p.

All required supply voltages for the board, other than the +12V, are derived from the 5V input. These power

supplies are sized to support the highest power E3800 family processor with the highest capacity on-board

memory plus have enough reserve capacity to support the below add-on features:

The PC/104 and PC/104-Plus connectors obtain 5V power from the input connector. The PC/104-Plus connector

obtains 3.3V power from the on-board power supply. The +12 pin on the input power connector is routed to the

+12V pins on the PC/104 and PC/104-Plus connectors as well as the +12V source for the LCD backlight.

Aries User Manual Rev A.02 www.diamondsystems.com Page 12

Page 13

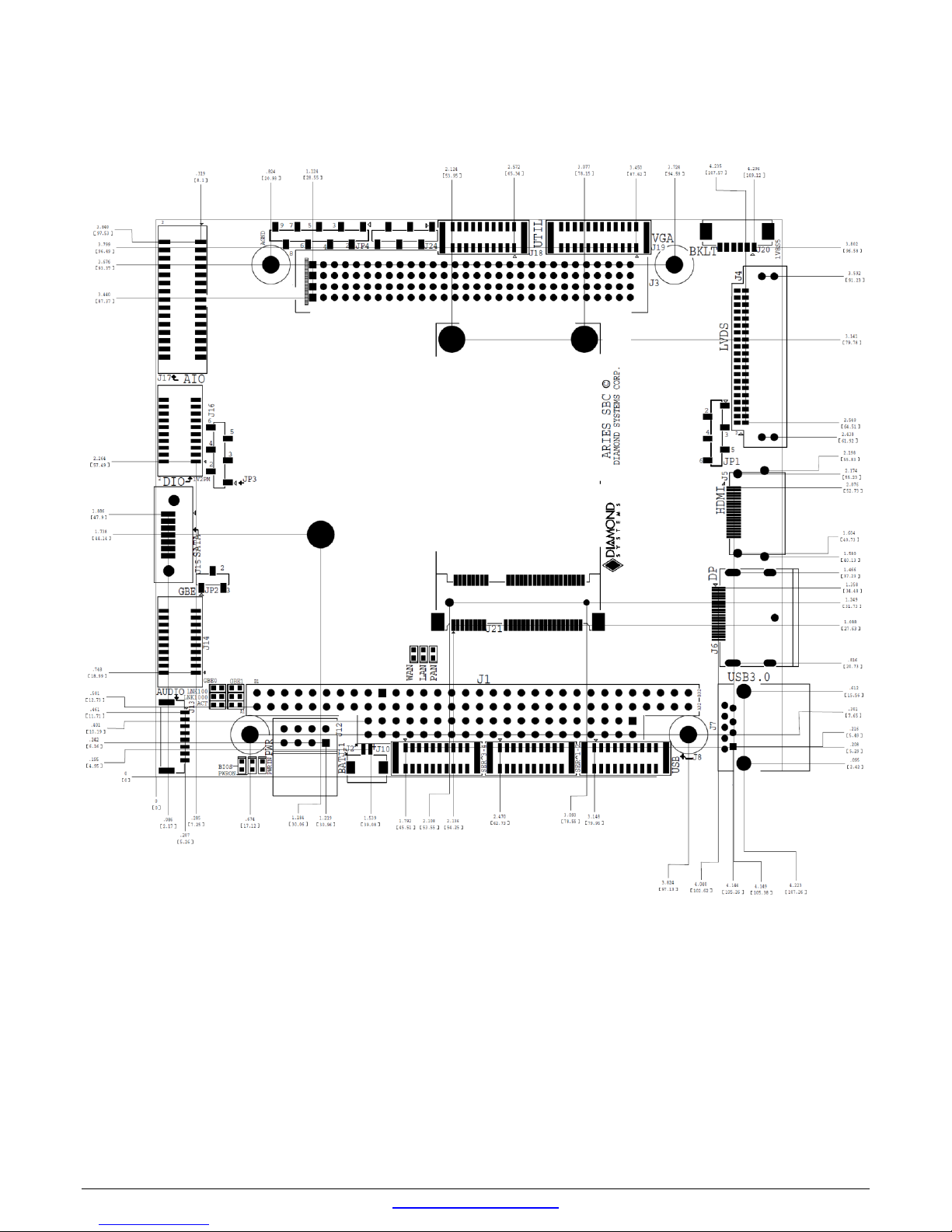

4. MECHANICAL BOARD DRAWING

Aries User Manual Rev A.02 www.diamondsystems.com Page 13

Figure 2: Mechanical Board Drawing

Page 14

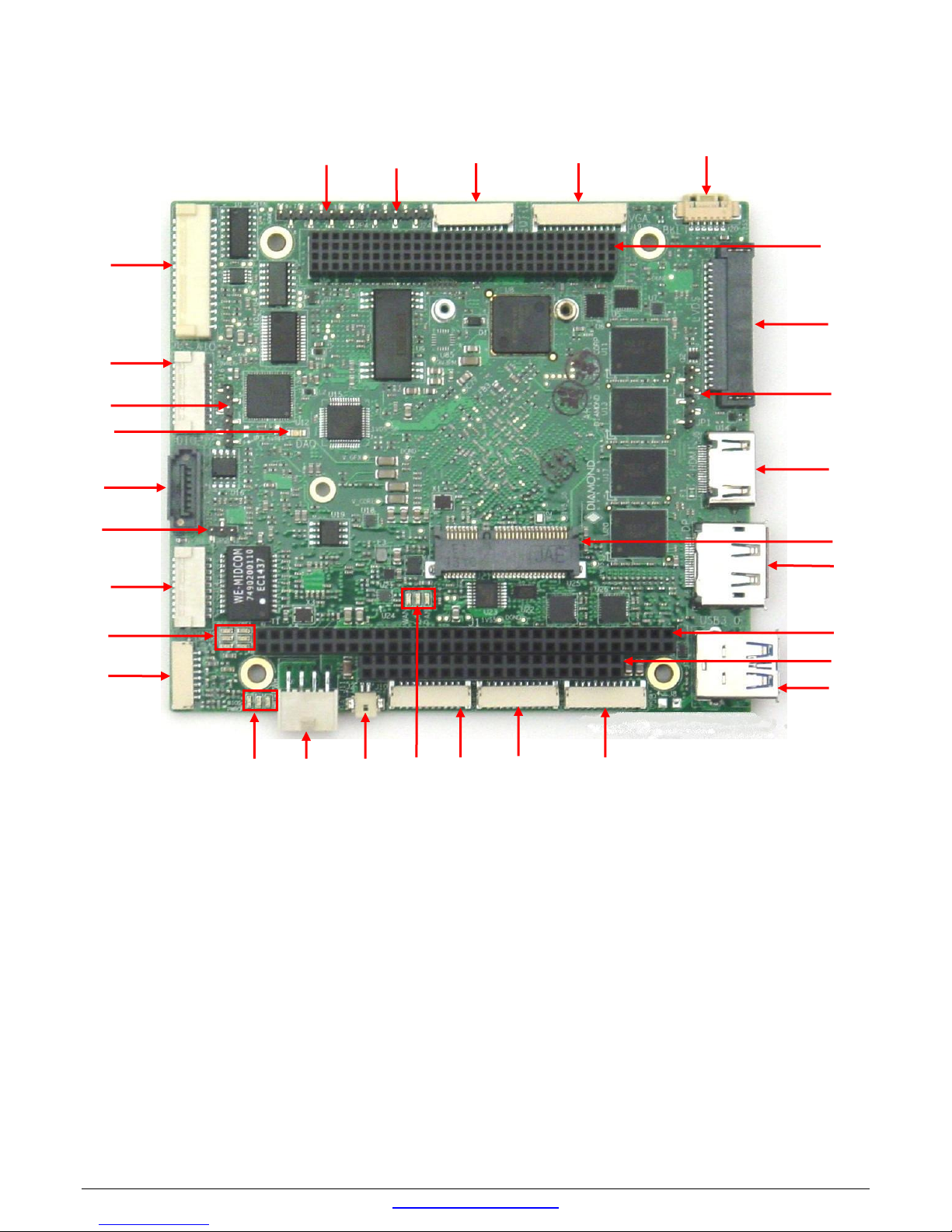

5. BOARD LAYOUT

J3

J1

J2

J4

JP1

J5

J6

J7

J8

J9

J10

J11

J12

J13

J14

J15

JP2

JP3

J16

J17

JP4

J24

J18

J19

J20

J21

LED

Block 1

LED

Block 2

LED

Block 3

LED

Block 4

Figure 3: Board Layout

Aries User Manual Rev A.02 www.diamondsystems.com Page 14

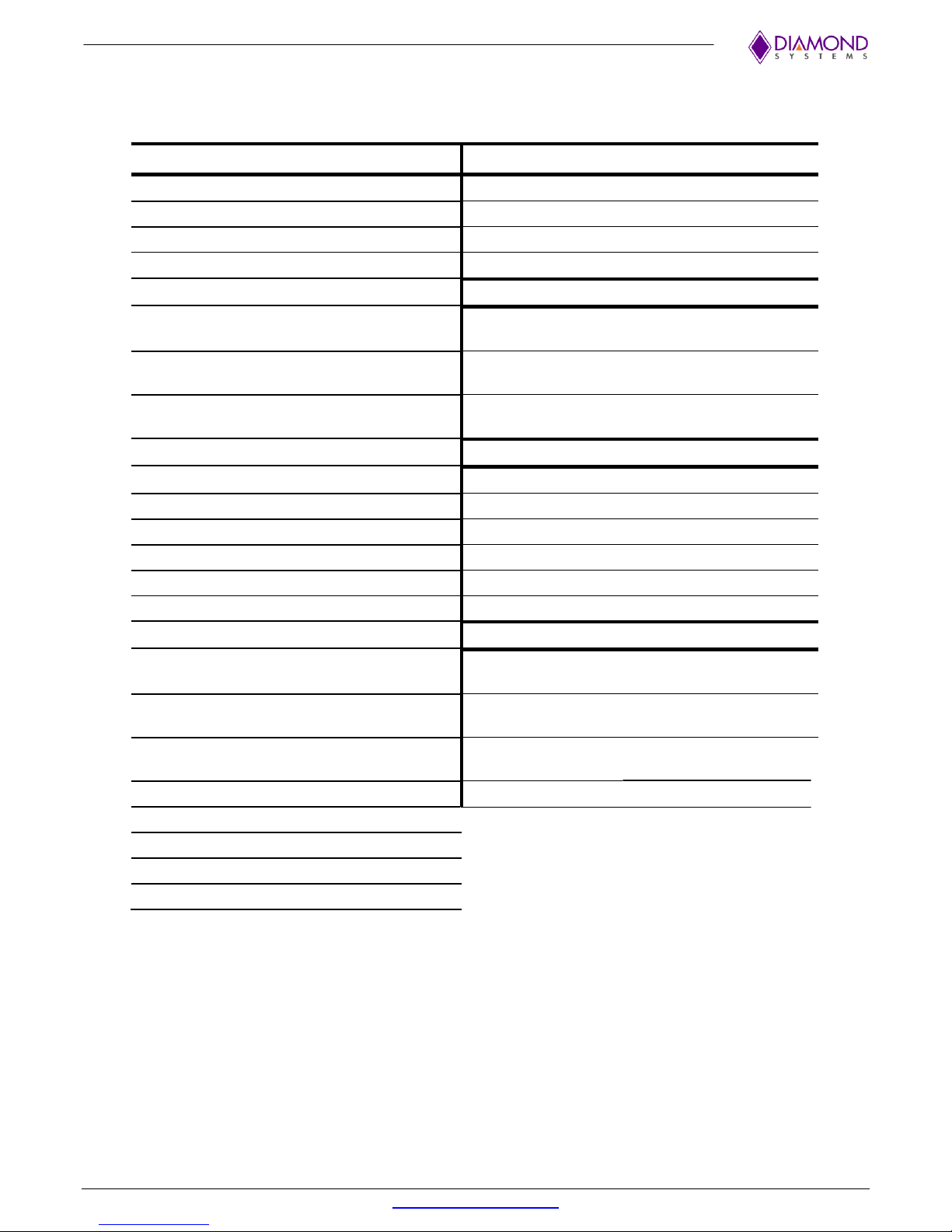

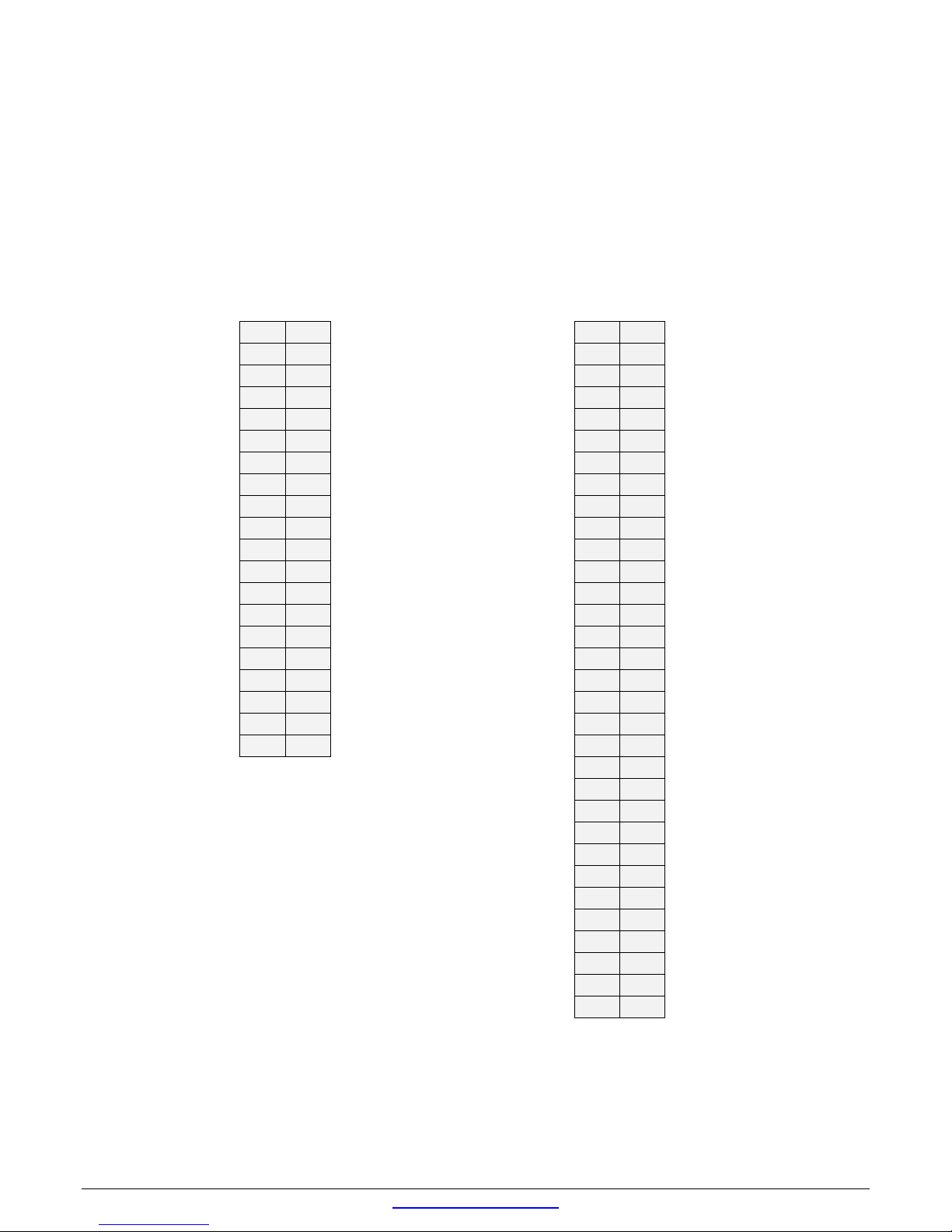

Page 15

Connector

Function

Jumper

Function

J1

PC/104 - ISA A/B

JP1

LVDS VCC & Backlight

J2

PC/104 - ISA C/D

JP2

SATA DOM

J3

PC/104-Plus - PCI

JP3

Digital VIO

J4

LCD

JP4

Miscellaneous

J5

HDMI

LED Block 1

J6

DP

1st LED (Leftmost

in the block)

BIOS

J7

USB-3.0

2nd LED (Middle

one in the block)

PWRON

J8

USB-2.0

3rd LED (Rightmost

in the block)

PWRIN

J9

Serial ports 1,2

LED Block 2

J10

Serial ports 3,4

1st row 1st LED

GBE 0 LINK100

J11

External Battery

1st row 2st LED

GBE 1 LINK100

J12

Power In

2nd row 1st LED

GBE 0 LINK1000

J13

Audio

2

nd

row 2nd LED

GBE 1 LINK1000

J14

Ethernet

3rd row 1st LED

GBE 0 ACT

J15

SATA

3rd row 2nd LED

GBE 1 ACT

J16

DAQ Digital I/O

LED Block 3

J17

DAQ Analog I/O

1st LED (Leftmost

in the block)

WAN

J18

Utility

2nd LED (Middle

one in the block)

LAN

J19

VGA

3rd LED (Rightmost

in the block)

PAN

J20

LCD Backlight

LED Block 4

DAQ LED

J21

PCIe Mini-Card

J22

XTP Connector

J23

SPI socket for BIOS

J24

JTAG for FPGA

5.1 I/O Connectors, Jumpers and LED Summary

Aries User Manual Rev A.02 www.diamondsystems.com Page 15

Page 16

6. I/O CONNECTORS

Ground

D0

C0

Ground

IOCHCHK-

A1

B1

Ground

MEMCS16-

D1

C1

SBHE- SD7

A2

B2

RESET

IOCS16-

D2

C2

LA23 SD6

A3

B3

+5V

IRQ10

D3

C3

LA22 SD5

A4

B4

IRQ9

IRQ11

D4

C4

LA21 SD4

A5

B5

-5V

IRQ12

D5

C5

LA20 SD3

A6

B6

DRQ2

IRQ15

D6

C6

LA19 SD2

A7

B7

-12V

IRQ14

D7

C7

LA18 SD1

A8

B8

0WS-

DACK0-

D8

C8

LA17 SD0

A9

B9

+12V

DRQ0

D9

C9

MEMR-

IOCHRDY

A10

B10

Key

DACK5-

D10

C10

MEMW- AEN

A11

B11

SMEMW-

DRQ5

D11

C11

SD8 SA19

A12

B12

SMEMR-

DACK6-

D12

C12

SD9 SA18

A13

B13

IOW-

DRQ6

D13

C13

SD10 SA17

A14

B14

IOR-

DACK7-

D14

C14

SD11 SA16

A15

B15

DACK3-

DRQ7

D15

C15

SD12 SA15

A16

B16

DRQ3

+5V

D16

C16

SD13 SA14

A17

B17

DACK1-

MASTER-

D17

C17

SD14 SA13

A18

B18

DRQ1

Ground

D18

C18

SD15 SA12

A19

B19

Refresh-

Ground

D19

C19

Key SA11

A20

B20

SYSCLK

SA10

A21

B21

IRQ7

SA9

A22

B22

IRQ6

SA8

A23

B23

IRQ5

SA7

A24

B24

IRQ4

SA6

A25

B25

IRQ3

SA5

A26

B26

DACK2-

SA4

A27

B27

TC

SA3

A28

B28

BALE

SA2

A29

B29

+5V

SA1

A30

B30

OSC

SA0

A31

B31

Ground

Ground

A32

B32

Ground

6.1 Connector Pin-out and Signal Description

6.1.1 PC/104 (J1, J2)

The Aries SBC contains the non-stack-through / short pin 8-bit and 16-bit PC/104 connectors on the top side in

the standard position as described by the PC/104-Plus specification. Press fit PC/104 connectors have been

used.

J2: PC/104 16-bit bus connector J1: PC/104 8-bit bus connector

Connector Type: J1 - 64 pins .435” high solder tails

J2 - 40 pins .435” high solder tails

Aries User Manual Rev A.02 www.diamondsystems.com Page 16

Page 17

J3

Pin A B C D

1

GND/5.0V KEY2

Reserved

+5

AD00

2

VI/O

AD02

AD01

+5V

3

AD05

GND

AD04

AD03

4

C/BE0*

AD07

GND

AD06

5

GND

AD09

AD08

GND

6

AD11

VI/O

AD10

M66EN

7

AD14

AD13

GND

AD12

8

+3.3V

C/BE1*

AD15

+3.3V

9

SERR*

GND

SB0*

PAR

10

GND

PERR*

+3.3V

SDONE

11

STOP*

+3.3V

LOCK*

GND

12

+3.3V

TRDY*

GND

DEVSEL*

13

FRAME*

GND

IRDY*

+3.3V

14

GND

AD16

+3.3V

C/BE2*

15

AD18

+3.3V

AD17

GND

16

AD21

AD20

GND

AD19

17

+3.3V

AD23

AD22

+3.3V

18

IDSEL0

GND

IDSEL1

IDSEL2

19

AD24

C/BE3*

VI/O

IDSEL3

20

GND

AD26

AD25

GND

21

AD29

+5V

AD28

AD27

22

+5V

AD30

GND

AD31

23

REQ0*

GND

REQ1*

VI/O

24

GND

REQ2*

+5V

GNT0*

25

GNT1*

VI/O

GNT2*

GND

26

+5V

CLK0

GND

CLK1

27

CLK2

+5V

CLK3

GND

28

GND

INTD*

+5V

RST*

29

+12V

INTA*

INTB*

INTC*

30

-12V

Reserved

Reserved

GND/3.3V KEY2

6.1.2 PC-104 (J3)

The board contains a non-stack through / short pin PC-104 connector on the top side in the standard position as

described by the PC/104-Plus specification.

Connector Type: 30 x 4 pin 2mm pitch with solder tails

Aries User Manual Rev A.02 www.diamondsystems.com Page 17

Page 18

Ground

1

2

Ground

Power

3

4

Power

Power

5

6

Power

Power

7

8

NC

DID Clk

9

10

DID Data

D0- odd

11

12

D0- Even

D0+ Odd

13

14

D0+ Even

Ground

15

16

Ground

D1- Odd

17

18

D1- Even

D1+ Odd

19

20

D1+ Even

Ground

21

22

Ground

D2- Odd

23

24

D2- Even

D2+ Odd

25

26

D2+ Even

Ground

27

28

Ground

Clk- Odd

29

30

Clk- Even

Clk+ Odd

31

32

Clk+ Even

Ground

33

34

Ground

D3- Odd

35

36

D3- Even

D3+ Odd

37

38

D3+ Even

Ground

39

40

Ground

Signal

Definition

D0-3 +/- Even

Primary Data Channel, bits 0-2 (LVDS Differential signaling)

D0-3+/- Odd

Primary Data Channel, Clock (LVDS Differential signaling)

CLK+/- Even

Secondary Data Channel, bits 0-2 (LVDS Differential signaling)

CLK+/- ODD

Secondary Data Channel, Clock (LVDS Differential signaling)

Power

+3.3V Switched Power Supply for LCD display

(only powered up when LCD display is active)

Ground

Power Ground, 0V

6.1.3 LVDS LCD (J4)

J4 can be used to connect the LCD. Connector J4 provides access to the internal LVDS LCD display drivers.

Note that the connector J20 can be used for LCD backlight properties. The LCD panel power is jumper-selectable

for 3.3V (default) or 5V.

J4

Connector Type: 40 position .050” pitch dual row right angle latching

Aries User Manual Rev A.02 www.diamondsystems.com Page 18

Page 19

Data 2+

1

2

Ground

Data 2-

3

4

Data 1+

Ground

5

6

Data 1-

Data 0+

7

8

Ground

Data 0-

9

10

Clock+

Ground

11

12

Clock-

CEC (NC)

13

14

Reserved

DDC Clock

15

16

DDC Data

Ground

17

18

+5V

Hot Plug Detect

19

20

NC

Lane 0+

1

2

Ground

Lane 0-

3

4

Lane 1+

Ground

5

6

Lane 1-

Lane 2+

7

8

Ground

Lane 2-

9

10

Lane 3+

Ground

11

12

Lane 3-

Ground

13

14

Ground

Aux+

15

16

Ground

Aux-

17

18

Hot Plug Detect

Power return

19

20

3.3V (fused)

6.1.4 HDMI (J5)

Standard HDMI connector Type A right angle has been mounted on the board.

Note: If HDMI is used, Display Port will not be available and vice versa. Selection between HDMI and DP can be

done from BIOS GUI.

J5

Connector Type: Standard HDMI type A connector, right angle

6.1.5 Display Port (J6)

A standard Display port connector with the following pin-out has been used on the board.

Note: If HDMI is used, Display Port will not be available and vice versa. Selection between HDMI and DP can be

done from BIOS GUI.

J6

Connector Type: Standard DisplayPort connector, right angle

Aries User Manual Rev A.02 www.diamondsystems.com Page 19

Page 20

1

USB Power

2

USB 2.0 Data-

USB 2.0 signals

3

USB 2.0 Data+

4

Ground

5

SSRX-

USB 3.0 signals

6

SSRX+

7

Ground

8

SSTX-

9

SSTX+

1

USB1 Power

2

USB1 Data-

3

USB1 Data+

4

Ground

5

Shield

6

USB2 Power

7

USB2 Data-

8

USB2 Data+

9

Ground

10

Shield

6.1.6 USB 3.0 Ports (J7)

Connector J7 provides both USB 3.0 and USB 2.0 connections.

J7

Connector Type: USB 3.0 type A receptacle, right angle

6.1.7 USB 2.0 Ports (J8)

Aries provides four USB 2.0 ports. Two of which are connected to the USB 2.0 header, whose pin-out has been

provided below. Access to one of the remaining two is provided by a USB3.0 connector and the other through the

PCIe MiniCard connector.

J8

Connector Type: 10 position 1.25mm pitch right angle latching

Aries User Manual Rev A.02 www.diamondsystems.com Page 20

Page 21

1

TX1

1

TX1-

1

TX/RX 1-

NC

NC

NC

2

RX1

2

RX1+

2

NC

RXD

RX+

3 RTS1

3

TX1+

3

TX1/RX 1+

TXD

TX-

D-

4

CTS1

4

RX1-

4

NC

NC

NC

NC

5

Ground

5

Ground

5

Ground

GND

GND

GND

6

TX2

6

TX2-

6

TX/RX 2-

NC

NC

NC

7

RX2

7

RX2+

7

NC

RTS

TX+

D+

8

RTS2

8

TX2+

8

TX/RX 2+

CTS

RX-

9 CTS2

9

RX2-

9

NC

NC

NC

NC

10

Ground

10

Ground

10

Ground

GND

GND

GND

1

Battery In

2

Ground

Ground

1

2

+12V

Ground

3

4

+5V

Ground

5

6

+5V

Ground

7

8

+5V

6.1.8 Serial ports (J9, J10)

Connector J9 and J10 provide 4 serial ports for RS-232/422/485 protocols, two ports per connector. Pin-out of

both connectors is the same.

The following tables list the signal assignments on the pin header for each serial protocol.

DB15 pin equivalent

RS-232 RS-422 RS-485 RS-232 RS-422 RS-485

Connector Type: 10 position 1.25mm pitch right angle latching

6.1.9 External Battery (J11)

Connector J11 should be used to enable the use of an external battery.

J11

Connector Type: 2 position 1.25mm pitch right angle

6.1.10 Input Power (J12)

Input power may be supplied through the connector J12 or through PC-104 and PC/104-Plus connectors, as the

5V supply is routed directly to the input power connector. All the required supply voltages for the board except

+12V are derived from the 5V input.

J12

Connector Type: 2x4 box header T/H right angle .1” pitch

Aries User Manual Rev A.02 www.diamondsystems.com Page 21

Page 22

1

LineOut – L

2

LineOut – R

3

GND_Audio

4

LineIn – L

5

LineIn – R

6

GND_Audio

7

MIC IN

8

GND_Audio

Port 1 DA+

1

2

Port 2 DA+

Port 1 DA-

3

4

Port 2 DA-

Port 1 DB+

5

6

Port 2 DB+

Port 1 DB-

7

8

Port 2 DB-

Port 1 DC+

9

10

Port 2 DC+

Port 1 DC-

11

12

Port 2 DC-

Port 1 DD+

13

14

Port 2 DD+

Port 1 DD-

15

16

Port 2 DD-

Port 1 Shield

17

18

Port 2 Shield

N/C

19

20

N/C

1

Ground

2

SATA 1 TX+

3

SATA 1 TX-

4

Ground

5

SATA 1 RX-

6

SATA 1 RX+

7

Ground / 5V

6.1.11 Audio (J13)

Audio signals are made available on a latching connector J13.

J13

Connector Type: 8 position 1.25mm pitch right angle latching

6.1.12 Ethernet (J14)

Ethernet ports 1 and 2 are made available on the header J14 connected by two magnetics one per port.

J14

Connector Type: 20 position 1.25mm pitch right angle latching

6.1.13 SATA (J15)

J15 can be used to connect and external SATA hard drive or an on-board SATA-DOM. Pin 7 is connected to a

jumper that selects either ground or 5VDC system voltage rail. Ground is used for external storage device, and 5V

is used for a board-mounted SATA flash-disk module.

J15

Connector Type: 7-pin SATA connector, vertical

Aries User Manual Rev A.02 www.diamondsystems.com Page 22

Page 23

VIO (fused)

1

2

DIO A0

DIO A1

3

4

DIO A2

DIO A3

5

6

DIO A4

DIO A5

7

8

DIO A6

DIO A7

9

10

DIO B0

DIO B1

11

12

DIO B2

DIO B3

13

14

DIO B4

DIO B5

15

16

DIO B6

DIO B7

17

18

DIO C5

Ground

19

20

Ground

Ain 0

1

2

Ain 8

Ain 1

3

4

Ain 9

Ain 2

5

6

Ain 10

Ain 3

7

8

Ain 11

Ain 4

9

10

Ain 12

Ain 5

11

12

Ain 13

Ain 6

13

14

Ain 14

Ain 7

15

16

Ain 15

Analog Ground

17

18

Analog Ground

Aout 0

19

20

Aout 1

Aout 2

21

22

Aout 3

Analog Ground

23

24

DIO C0

DIO C1

25

26

DIO C2

DIO C3

27

28

DIO C4

VIO (fused)

29

30

Digital Ground

6.1.14 Digital I/O (J16)

Aries provides three digital I/O ports with 8 lines on port A and B, and 6 lines on port C. Port A and B are provided

on connector J16. Port C is on connector J17 and pin 18 of connector J16.

J16

Connector Type: 20 position 1.25mm pitch right angle latching

6.1.15 Analog I/O (J17)

The VIO pins on the analog and digital I/O connectors are tied together on the board and provide access to

jumper-selectable 3.3V / 5V system voltage rail through a poly-switch resettable fuse. The fuse is rated for

~100mA maximum sustained current.

J17

Connector Type: 2x15 position 1.5mm pitch right angle latching

Aries User Manual Rev A.02 www.diamondsystems.com Page 23

Page 24

1

I2C Clock

2

I2C Data

3

Ground

4

Reset

5

Power Switch

6

Eth 1 Activity

7

Eth 1 Link 100

8

Eth 1 Link 1000

9

Eth 2 Activity

10

Eth 2 Link 100

11

Eth 2 Link 1000

12

+3.3V

Signal

Definition

Eth1/2 ACT

Activity LED

Eth1/2 Link 100

Link 100 LED

Eth1/2 Link 1000

Link 1000 LED

Power Switch

Power switch button

Reset

System reset button

6.1.16 Utility Connector (J18)

Status LED’s of Ethernet ports are accessible from the utility connector J18. The 3.3V pin is connected to the

system 3.3V rail through a poly-switch resettable fuse.

J18

The Aries SBC can be powered on by pressing the power switch when the board has been shut down. Also, the

reset button can be used for a system reset. All the LEDs are active LOW.

Connector Type: 12 position 1.25mm pitch right angle latching

Aries User Manual Rev A.02 www.diamondsystems.com Page 24

Page 25

1

Red

1

2

Gnd-Red

6

3

Green

2 4 Gnd-Green

7

5

Blue

3

6

Gnd-Blue

8 7 HSync

13

8

VSync

14

9

Gnd-Sync

10

10

DDC-Data

12

11

DDC-Clock

15

12

Ground

5

Signal

Definition

Ground

Ground return

Red

RED signal

Green

GREEN signal

Blue

BLUE signal

DDC clock/data

Digital serial I/O signals used for monitor detection (DDC1 specification)

HSYNC

Horizontal sync

VSYNC

Vertical sync

1

Power, +5V/+12V, jumper selectable

2

Power, +5V/+12V, jumper selectable

3

Ground

4

Ground

5

Backlight Enable (GPIO output), 0 = off, open circuit = on

6

Brightness control

6.1.17 VGA (J19)

Connector J19 is used for connecting a VGA monitor.

Pin Signal DB15 pin equivalent

Connector Type: 12 position 1.25mm pitch right angle latching

6.1.18 LCD Backlight (J20)

Connector J20 can be used for the LCD backlight. Input power source is user selectable using jumpers to 5V or

12V.

J20

Brightness may be controlled over pin 6 on this connector.

Connector Type: 6 position 1.25mm pitch right angle

Aries User Manual Rev A.02 www.diamondsystems.com Page 25

Page 26

1

2

+3.3V

3

4

Gnd

5

6

+1.5V

Clkreq-

7

8

Gnd

Gnd

9

10 PCIe 1 Clk-

PCIe 1 Clk- *

11

12

PCIe 1 Clk+

PCIe 1 Clk+ *

13

14

Gnd

Gnd

15

16

KEY

17

18

Gnd

19

20

Disable-

Gnd

Gnd

21

22

PCIe Reset-

PCIe 1 RX-

SATA 0 TX+

23

24

+3.3V

PCIe 1 RX+

SATA 0 TX-

25

26

Gnd

Gnd

Gnd

27

28

+1.5V

Gnd

Gnd

29

30

SMB Clk

PCIe 1 TX-

SATA 0 RX-

31

32

SMB Data

PCIe 1 TX+

SATA 0 RX+

33

34

Gnd

Gnd

Gnd

35

36 Gnd

Gnd

37

38

+3.3V

+3.3V

39

40

Gnd

+3.3V

+3.3V

41

42

WWAN LED-

Ground

Ground

43

44

WLAN LED-

45

46

WPAN LED-

47

48

+1.5V

Pull-up to +3.3V

Pull-up to +3.3V

49

50

Gnd

51

52

+3.3V

6.1.19 mSATA / PCIe MiniCard Socket (J21)

This socket can be used for both PCIe MiniCard and mSATA disk module use. The configuration is selected with

a switch that is controlled by pin 7. A PCIe MiniCard will tie pin 7 to ground, while an mSATA module will leave pin

7 open. Pin 7 has a pull-up resistor on the board. All TX/RX signals are with respect to the host. TX on the socket

drives RX on the installed module, and RX on the socket is driven by TX on the installed module.

The two mounting standoffs at the far end of the module installation site are not connected to ground.

PCIe Mini Card mSATA J21 mSATA / PCIe MiniCard

* For mSATA mode, the PCIe clock signal is not active because CLKREQ- pin is not driven low by the module.

Connector Type: 52-pin MiniCard, full size, with PCB mount threaded spacers

Aries User Manual Rev A.02 www.diamondsystems.com Page 26

Page 27

Ref

Designator

Function

Manufacturer

Part Number

Description

Cable

part

numbers

J1

PC/104

Harwin*

M20-6113245*

64 pins .435” high solder tails

J2

PC/104

Harwin*

M20-6112045*

40 pins .435” high solder tails

J3

PC/104-Plus

Aptos*

PQE-C0-VB-094/023-FG*

30 x 4 pin 2mm pitch with

solder tails

J4

LCD

Samtec

TFM-120-02-L-DH-WT

40 pos .050” pitch dual row right

angle latching

J5

HDMI

Generic

Generic

Standard HDMI type A

connector, right angle

J6

DisplayPort

Generic

Generic

Standard Display Port

connector, right angle

J7

USB 3.0 / 2.0

FCI*

10117835-002LF

USB 3.0 type A receptacle, right

angle

J8

USB 2.0

JST

SM10B-GHS-TBT

10 pos. 1.25mm pitch right

angle latching

6980503

J9, J10

Serial ports

(qty 2)

JST

SM10B-GHS-TBT

10 pos. 1.25mm pitch right

angle latching

6980500

J11

External battery

Hirose

DF13A-2P-1.25H

2 pos. 1.25mm pitch right angle

6980511

J12

Power in

Samtec

IPL1-104-01-L-D-RA-K

2x4 box header T/H right angle

.1” pitch

6980512

J13

Audio

JST

SM08B-GHS-TBT

8 pos. 1.25mm pitch right angle

latching

6980508

J14

Ethernet

JST

SM20B-GHDS-GAN-TF

20 pos. 1.25mm pitch right

angle latching

6980513

J15

SATA

Generic

Generic

7-pin SATA connector, vertical

6989101

J16

DAQ digital I/O

JST

SM20B-GHDS-GAN-TF

20 pos. 1.25mm pitch right

angle latching

6980501

J17

DAQ analog I/O

JST

SM30B-ZPDSS-TF

2x15 pos. 1.5mm pitch right

angle latching

6981504

J18

Utility

JST

SM10B-GHS-TBT

10 pos. 1.25mm pitch right

angle latching

6980514

J19

VGA

JST

SM12B-GHS-TBT

12 pos. 1.25mm pitch right

angle latching

6980507

J20

LCD backlight

Molex

053261-0671

6 pos. 1.25mm pitch right angle

J21

PCIe Mini Card

JAE

MM60-52B1-E1-R650 +

NT4R1600 spacer

52-pin MiniCard, full size, with

PCB mount threaded spacers

6.2 List of Connectors

The following table provides a summary of all I/O connectors on the board and their corresponding Diamond

Systems cables where appropriate. Connectors on the top side are mostly vertical, and connectors on the bottom

side are always right-angle

* Representative part; other manufacturers / part numbers are also acceptable.

Aries User Manual Rev A.02 www.diamondsystems.com Page 27

Page 28

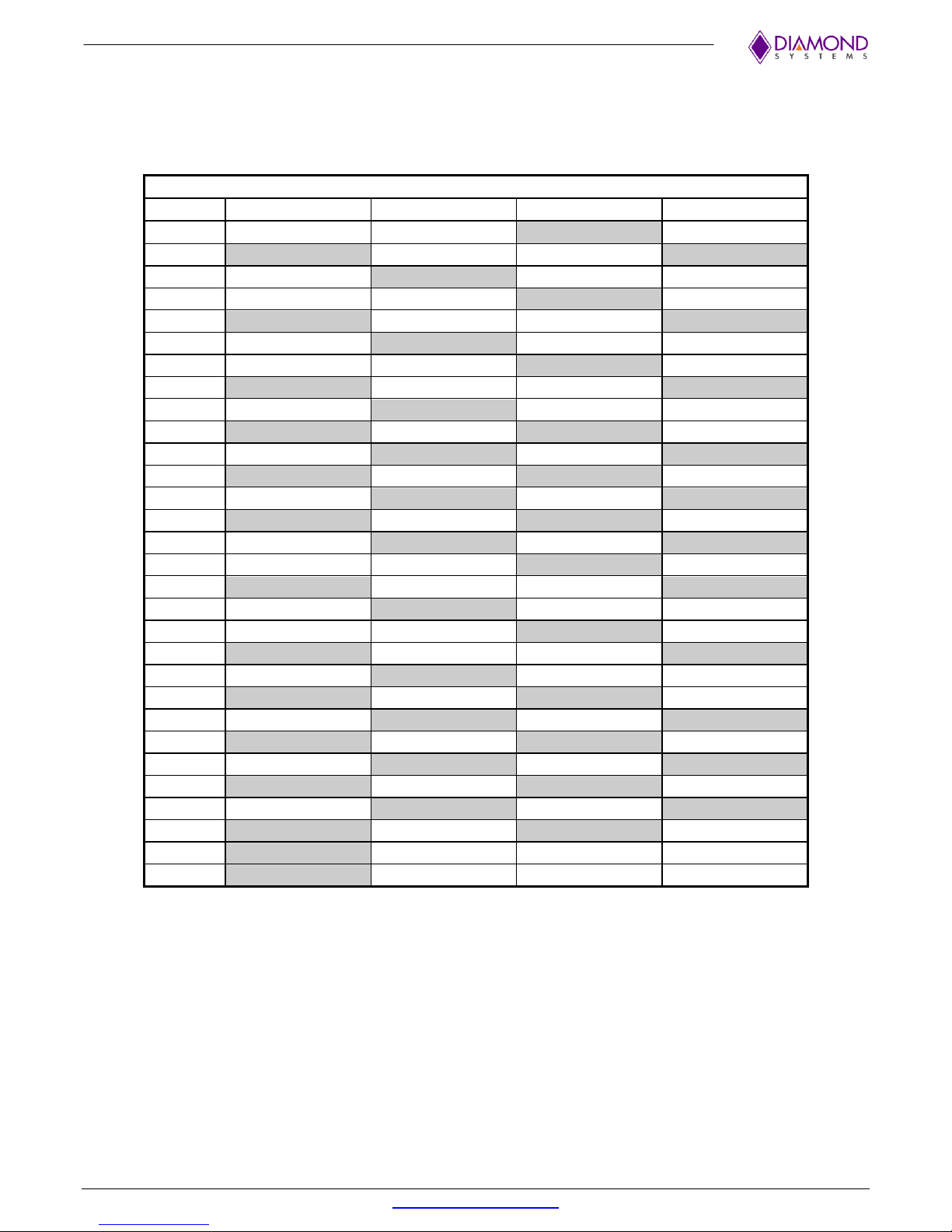

7. JUMPER DESCRIPTION

Jumper

Description

JP1

LVDS VDD & Backlight

JP2

SATA DOM

JP3

Digital VIO

JP4

PCI voltage selection and FPGA base address

Following drawing shows only the connectors and jumper blocks on the board. The default jumpers of the jumper

blocks are shown in red.

Aries User Manual Rev A.02 www.diamondsystems.com Page 28

Figure 4: Default Jumper locations

Page 29

1-2

2-3

4-5

5-6

LVDS

Backlight

LVDS

VDD

In

Out

In

Out

12V

5V

In

Out

Out

In

12V

3.3V

Out

In

In

Out

5V

5V

Out

In

Out

In

5V

3.3V

7.1 LVDS Backlight and LVDS VDD (JP1)

Jumper block JP1 configures the voltage supply for the LCD backlight and for LVDS VDD as well. The orientation

of the block in the diagrams matches the orientation of the jumper block when the board is rotated so that the

PC/104 connector is on the lower edge.

Available options are +5V and +12V from the main power supply input. +12V is not used by any circuit on the

Aries. +12V is needed for the LCD backlight, and the backlight is to be powered via the backlight power connector

J9, hence +12V is supplied on the main power input connector along with +5V.

By default LVDS backlight is provided with +12V and the LVDS VDD is provided with 3.3V. Figure 5 shows the

default jumper locations.

Figure 5: Jumper Block JP1

The following table shows different combinations of jumper locations on JP1.

Note:

1. Voltage supply on LVDS backlight will not depend on or affect the voltage input of LVDS.

2. Do not install a jumper on 3-4 positions.

7.2 SATA (JP2)

The 7th pin of the SATA connector J15 can be configured for SATA DOM or for SATA cable. By default 7th pin of

J15 is connected to ground for the SATA cable. The default jumper location is shown in Figure 6.

The following table shows the combination of jumper block JP2. The row in bold and italics shows the default

configuration.

Aries User Manual Rev A.02 www.diamondsystems.com Page 29

Figure 6: Jumper Block JP2

Page 30

1-2

2-3

Description

Out

In

SATA_PIN7 = GND

(SATA CABLE)

In

Out

SATA_PIN7 = 5.0V

(SATA DOM)

1-2

2-3

4-5

5-6

DIO pull

high/low

DIO

Voltage

In

Out

In

Out

Low

3.3V

In

Out

Out

In

Low

5V

Out

In

In

Out

High

3.3V

Out

In

Out

In

High

5V

7.3 Digital IO (JP3)

The digital I/O can be pulled up to 5V/3.3V or pulled down to GND by configuring jumper block JP3. The jumper

locations of this jumper block will also determine the input voltage to the DAQ circuit.

By default the DIO’s are pulled high to 3.3V. Figure 7 shows the default jumper locations of JP3.

Figure 7: Jumper Block JP3

The following table shows the different combinations of jumper block JP3. The row in bold and italics shows the

default configuration of jumper block JP3.

Note:

1. Jumpers should be installed in either positions 4-5 or 5-6 even if the jumper in position 1-2 is Out (DIO

are pulled Low to GND) as this voltage is tied to the input voltage to the DAQ circuits.

Aries User Manual Rev A.02 www.diamondsystems.com Page 30

Page 31

JP4

1 2 3 O O O

JP4

4 5 O

O

7.4 Miscellaneous (JP4)

Jumper block JP4 can be used to select the PCI voltage and configure the FPGA base address. The following

information describes how to set these various options.

PCI Voltage Selection

The PCI voltage can be set for either 3.3V or 5V with pins 1, 2 and 3 of JP4 as follows:

Jumper on Pins PCI voltage

1 & 2 3.3V (default)

2 & 3 5V

FPGA Base Address Selection

The base address of Aries’ FPGA can be set for either 0x280 or 0x240 with pins 4 and 5 of JP4 as

follows:

Pins 4 & 5 FPGA Base Address

No jumper 0x280 (default)

Jumper 0x240

Note: Jumper block JP4 pins 6/7 and 8/9 are for factory use only. A jumper should never be applied to these

pins.

Aries User Manual Rev A.02 www.diamondsystems.com Page 31

Page 32

8. BIOS KEY FEATURES

The BIOS on Aries provides access to many valuable features. These instructions show how to enter the BIOS

and set up features.

8.1 Entering the BIOS

The BIOS may be entered during startup by pressing the DEL key on an attached keyboard or pressing ESC.

Press the key repeatedly right after power-on or reset until the BIOS screen appears.

After a certain amount of time during startup, the BIOS will ignore the DEL or ESC key. If the user waits too long

and the system does not respond, then the user can simply reset the board (or power down) and try again.

8.2 Restoring Default BIOS Settings

When the user makes changes to the BIOS settings, the new settings are stored in SPI flash. If the user wants to

restore the BIOS settings to their defaults, it can be done by using the following procedure.

1. Connect a keyboard to the USB keyboard port and connect a monitor.

2. Reboot the CPU (reset or power-down and power-up).

3. Hold down the HOME/END key while the CPU is booting.

4. The board will boot up normally. The BIOS settings will be reset to their defaults.

8.3 Setting the Date and Time

The date and time are set in the BIOS. Select Main menu, then enter the date and time at the bottom of the

screen. This screen also displays the CPU speed and memory capacity of the board.

8.4 Boot Priority

To select Boot devices and priority, go to the Boot menu and select Boot Device Priority. Only devices which

are connected to the board will appear in the list of options. Therefore if the user wants to select a hard drive or

USB device as the boot device, CPU should be connected first, then boot up and enter the BIOS, then select it as

a boot device. If this menu option does not appear on the screen, it means that the on-board flash drive is not

enabled, and either no boot devices are attached or the CPU does not recognize any attached boot devices.

8.5 LED

A green BIOS LED has been provided to indicate that the board has been booted to BIOS GUI. The location of

the BIOS LED is been shown in the Board Layout Section.

8.6 Quiet / Quick Boot / Splash Screen

Quiet boot replaces the system status and configuration screen that appears during startup with a blank screen or

custom splash screen (if available). Quick boot turns off memory test during startup to save time. To enable these

features, go to the Boot menu, then select Boot Settings Configuration. Diamond can provide custom splash

screens upon request from an image file.

Aries User Manual Rev A.02 www.diamondsystems.com Page 32

Page 33

Model Number

Description

ARS3845-4GA

Aries SBC, 1.91GHz E3845 CPU, 4GB DRAM, data acquisition

CK-ARS-01

Aries Cable Kit

PS-5V-04

5V AC Power Adapter

32GB MLC SATA-DOM flash-disk with bootable Linux image

Aries Development Kit manual

8.7 Selecting the Displays

Aries SBC supports two independent displays at a given time. Any two of the following displays can be selected

from BIOS GUI:

VGA

LVDS

DP or HDMI

8.8 Serial Port Configuration

Aries SBC provides four serial ports. Each of these ports can be individually configured as RS-232/422/485 from

the BIOS GUI. To configure the serial ports, the user must first specify the target operating system as follows:

In BIOS Setup

go to Advanced

then Miscellaneous Control

select the target operating system under OS Selection

Once this selection is done, the serial port configuration can be made.

9. GETTING STARTED

This section describes the steps needed to get Aries SBC up and running, and assumes that user also has a

Aries Development Kit or Aries Cable Kit. The Cable Kit includes all cables needed for the I/O, except the LCD

and backlight. The Development Kit includes the Cable Kit, an AC adapter to power the board, an SATA hard

drive, and the hard drive programmer board.

9.1 Development Kit

Aries User Manual Rev A.02 www.diamondsystems.com Page 33

Page 34

9.2 Quick Setup

1. Attach VGA cable 6980507, USB keyboard / mouse cable and USB cables 6980503 as needed.

2. Attach display, keyboard, and mouse (if needed) to the cables.

3. Connect the jumpers as mentioned in Section 7 for a default settings or can be changed as desired by the

user.

4. Attach the hard disk with cable or install hard drive with bootable OS or DSC provided BSP

5. Connect power to power input connector J12 using AC adapter or personal power supply with power

cable 6980512. The input connector and cable are keyed to prevent incorrect connection.

The input voltage for Aries is 5V. The current drawn by the board for this configuration would be

approximately. 1A.

WARNING: Attaching the power connector may damage the Aries SBC!

5. On powering up and continuously pressing the DEL/ESC key will lead the board to boot the BIOS GUI.

9.3 Boot Device Options

Aries can boot from SATA, mSATA, any of the four USB ports or PXE. Either a board powered SATA DOM or an

externally powered SATA HDD can be connected to the SATA port. DSC will provide a flash-disk (SATA DOM or

mSATA) with pre-loaded OS.

Aries can boot to an SATA device or a USB device. SATA supports mSATA and SATA DOM. Aries can be booted

from the flash-disk provided by DSC or from an external blank drive.

WARNING: It is possible to destroy the Aries SBC by connecting a SATA cable incorrectly (reverse

orientation or offset from correct position). Always use keyed cables to avoid connection errors.

The Boot device selection and priority are configured in the BIOS Boot menu. Only devices which are connected

to the SBC will appear in the list of options. Therefore if user wants to select a hard drive or USB device as the

boot device, the SBC should be connected first, then boot up and enter the BIOS, then select it as a boot device.

The following are a few example boot scenarios.

Install an externally powered SATA hard drive directly on the SATA connector.

Attach a SATA DOM on the SATA connector (the Aries SBC will provide power to the SATA DOM over

Jumper JP2 1-2)

Attach an mSATA device on the Mini PCIe socket

Attach a bootable USB device to one of the USB ports.

PXE boot

If no bootable device is attached to the Aries SBC, the system will boot to EFI shell.

Aries User Manual Rev A.02 www.diamondsystems.com Page 34

Page 35

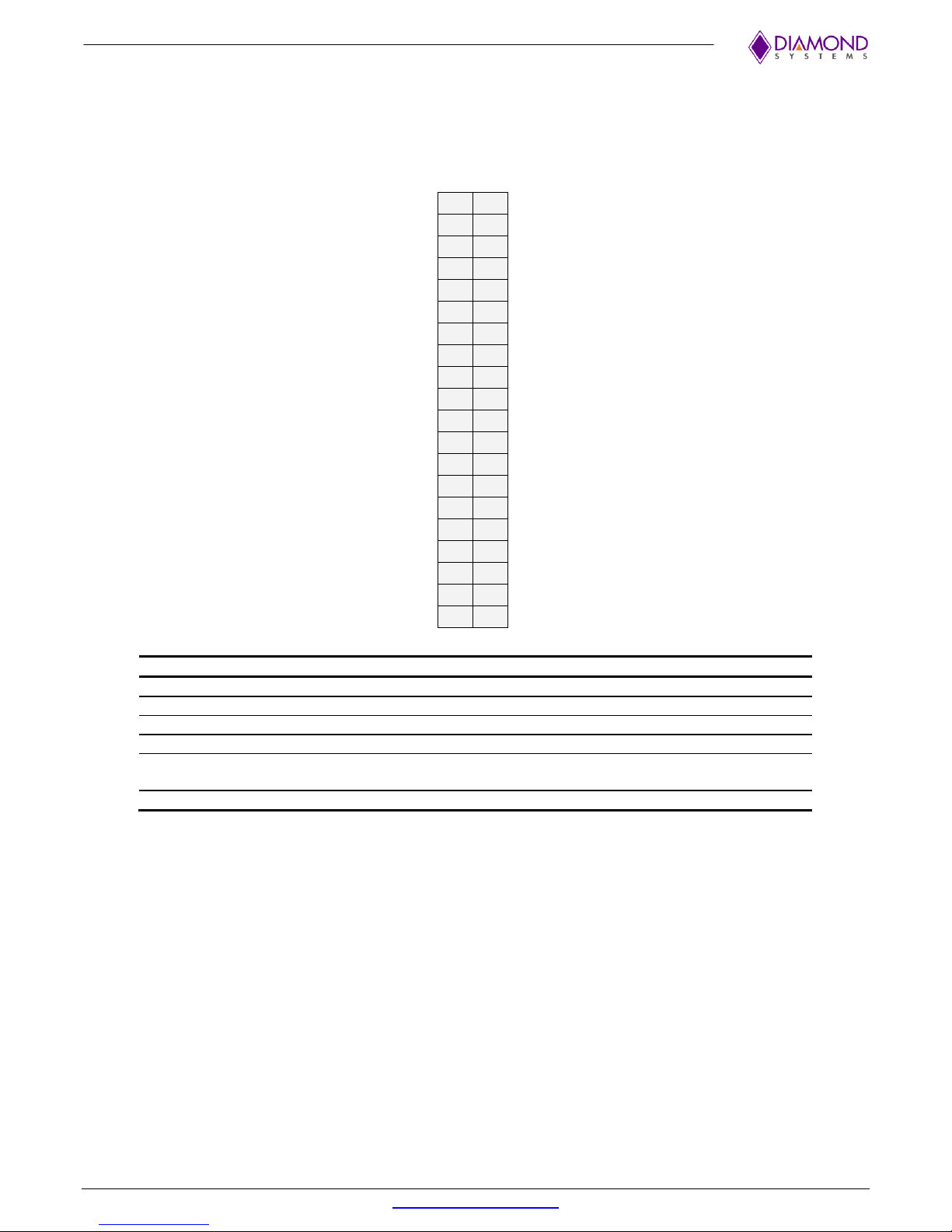

10. DATA ACQUISITION CIRCUIT

10.1 Overview

Aries contains a Data Acquisition subsystem consisting of A/D, D/A, digital I/O, and counter/timer features.

The A/D section includes a 16-bit A/D converter, 16 analog input channels and a 2048-sample FIFO. Input ranges

are programmable, and the maximum sampling rate is 250 KHz. The D/A section include 4 16-bit D/A channels.

The digital I/O section includes up to 22 lines with programmable direction. The counter/timer section includes 32bit counter/timer to control A/D and a 32-bit counter/timer for user applications.

High-speed A/D sampling is supported with interrupts and a FIFO. The FIFO is used to store up to 2048 A/D

samples. An interrupt occurs when the FIFO reaches a user-selected threshold. Once the interrupt occurs, an

interrupt routine runs and reads the data out of the FIFO. In this way the interrupt rate is reduced by a factor equal

to the size of the FIFO threshold, enabling a faster A/D sampling rate and lower software overhead.

The A/D circuit uses the default settings of I/O address range 0x240 – 0x280 (base address 0x240). These

settings can be changed if needed. The I/O address range is changed in the BIOS.

The figure below shows the overview of the data acquisition circuit.

Figure 9: Data Acquisition Circuit Block Diagram

Aries User Manual Rev A.02 www.diamondsystems.com Page 35

Page 36

Feature

Description

A/D channels

16 16-bit Analog inputs

D/A channels

4 16-bit analog outputs

DIO Lines

22 lines: 1 8-bit port, 14

1-bit ports

Counter/Timers

8 32-bit

PWM

4 24-bit

Watchdog timer

2 Down counters

Counter A - 16-bits

Counter B - 8-bits

10.2 FPGA

FPGA provides all logic functions of the Aries baseboard data acquisition as well as a watchdog timer and a

power sequencing circuit. The chip also interfaces to a Renesas encryption chip for future security features.

The following table shows a list of all the features offered by Aries FPGA.

10.3 Bus Interface

Aries uses LPC for bus interface. LPC lines LAD[3:0] communicate address, control, and data information over

the LPC between a host a peripheral. The information communicated is start, stop (abort a cycle), transfer type

(memory I/O), transfer direction (Read/Write), address, data, wait states and bus master grant. Not all cycle types

use the LAD bus in the same fashion.

Following are the different LPC pins used in the FPGA for communicating between a host and the peripheral.

LPC_FRAME# - Indicates start of a new cycle, termination of broken cycle.

LPC_RESET# - Same as PCI Reset on the host.

LPC_CLK - Buffered 33MHz clock from the host. Input to the FPGA.

LPC_SERIRQ - Serialized IRQ signal

10.4 Interrupts

The FPGA supports LPC interrupts from the analog input circuit, D/A fault indicator, digital I/O, and two

counter/timers. Register bits ADINTEN, FINTEN, DINTEN, T2INTEN, and T3INTEN enable/disable interrupts.

When an INTEN bit is 1, interrupts for that circuit are enabled. However, 0 disables the interrupt feature. The LPC

bus interrupt level is selected with register bits IRQ3-0.

When a circuit is requesting interrupt service, its corresponding status bit DINT, ADINT, T2INT, or T3INT is high.

Command bits DINTCLR, ADINTCLR, T2INTCLR, and T3INTCLR reset the associated interrupt request and

status bit. In contrast to other command registers in this design, any or all of these command bits may be set

simultaneously to clear multiple interrupt requests simultaneously.

Aries User Manual Rev A.02 www.diamondsystems.com Page 36

Page 37

FIFOEN

SCANEN

Action

0

0

Interrupt occurs after each A/D conversion completes (ADBUSY goes low).

0

1

Interrupt occurs after each A/D scan completes (ADBUSY goes low).

1

0

Interrupt occurs when A/D conversion completes and FIFO threshold is

reached or exceeded.

1

1

Interrupt occurs when A/D scan completes and FIFO threshold is reached or

exceeded.

ADINT=1 and an interrupt occurs when ADINTEN=1 and one of the following occurs:

T2INT=1 and an interrupt occurs when T2INTEN=1 and counter/timer 2 counts down to 0. There is no terminal

count and therefore no interrupt source when counter/timer 2 is counting up.

T3INT=1 and an interrupt occurs when T3INTEN=1 and counter/timer 3 counts down to 0. There is no terminal

count and therefore no interrupt source when counter/timer 3 is counting up.