Dialog Semiconductor DA852 Series, DA8521-00-BC-1, DA8522-00-BD-1, DA8523-00-BE-1, DA8524-00-BF-1 User Manual

Display Controllers

© Dialog Semiconductor 2008. All rights reserved.

User Guide Release 2.0

DA852X E Ink Evaluation Kit

1 Summary

This document describes the hardware and software produced by Dialog Semiconductor to allow users to evaluate E Ink

segmented displays along with the DA852X family of driver ICs from Dialog Semiconductor. The system is designed with

the following objectives:

• To assess the suitability of the E Ink technology for a given product concept,

• To quickly evaluate the performance of the display (for example, in terms of its contrast ratio, look

and feel, and transition speed),

• To design the display (particularly its size, segmentation, and other parameters),

• To evaluate different driving waveforms, and

• To start the design of the software for the microcontroller being used in the system.

The software uses a PC operating Windows 2000/XP with a USB1.1 or USB2 interface. The software has not been

extensively tested on Windows Vista, but has been shown to function. See Section 3.1.2

1.1 Product Lineup

The DA852X E Ink Evaluation Kit series has been produced to allow evaluation of the DA852X series drivers

These currently comprise:

Product Lineup

Device P/N Description Package Evaluation Kit

P/N

DA8521-00-BC-1 64 segments 80-pin 5x5mm VTLGA DA8521-eval

DA8522-00-BD-1 96 segments 112-pin 6x6mm VTLGA DA8522-eval

DA8523-00-BE-1 192 segments 208-pin 12x7mm VTLGA DA8523-eval

DA8524-00-BF-1 256 segments 272-pin 20x10mm VTLGA DA8524-eval

All kits include a CD ROM containing documentation and driver files. The driver software uses a simple graphical

interface, allowing the DA852X series board to be controlled via a USB port of a PC. The software is the same for all the

different kits.

1.2 Feedback/Contact Details

We welcome feedback of all types in order to make this kit and User Guide accelerate your project development. Please

direct any comments, questions, support issues or general remarks, to the Display Driver Applications Department at

Dialog Semiconductor, contact details below:

Contact: Display Driver Applications Department

Company: Dialog Semiconductor

Address: Windmill Hill,

Whitehill Way,

Swindon. SN5 6PJ.

UK

Telephone: +44 1793 875327

Fax: +44 1793 875328

E-mail: EPDsupport@diasemi.com

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 1 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

1 SUMMARY...........................................................................................................1

1.1 Product Lineup.....................................................................................................1

1.2 Feedback/Contact Details....................................................................................1

2 HARDWARE.........................................................................................................5

2.1 DA852X Evaluation Board....................................................................................5

2.1.1 USB Connector...................................................................................................5

2.1.2 Power Supplies...................................................................................................5

2.1.3 Jumpers..............................................................................................................5

2.1.4 Expansion Input..................................................................................................6

2.1.5 Expansion Output...............................................................................................6

2.1.6 Flex Connection..................................................................................................7

2.1.7 Output Connectors..............................................................................................7

3 SOFTWARE.........................................................................................................9

3.1.1 Release Notes....................................................................................................9

3.1.2 Installation..........................................................................................................9

3.1.3 Control Panel....................................................................................................11

3.1.4 Interface Description.........................................................................................12

3.2 Common Controls..............................................................................................12

3.2.1 Device Type......................................................................................................12

3.2.2 Top Plane Connection(s)..................................................................................12

3.2.3 Field Connection(s)...........................................................................................12

3.2.4 Status Message................................................................................................12

3.2.5 USB OK? Indicator...........................................................................................12

3.3 DA852X Panel.....................................................................................................12

3.3.1 Direct Control....................................................................................................13

3.4 Parameter Control Panel....................................................................................13

3.4.1 Waveform Selection..........................................................................................15

3.4.2 File Menu..........................................................................................................16

3.4.3 Toolbar.............................................................................................................17

3.4.4 Image Controls.................................................................................................18

3.4.5 Image Information.............................................................................................20

3.5 File Formats........................................................................................................21

3.5.1 The Configuration Files.....................................................................................21

3.5.2 The Image File..................................................................................................22

3.5.3 The Map File.....................................................................................................23

3.5.4 The Slide File...................................................................................................24

3.5.5 Slide file names for numbers and alphanumerics..............................................25

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 2 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

3.5.6 Number Entry...................................................................................................25

3.5.7 Alphanumeric Entry..........................................................................................26

3.6 Programming Information..................................................................................28

3.6.1 Decode states to provide drive waveform.........................................................29

3.6.2 Creating a Hex string from state outputs...........................................................30

3.6.3 Decode a hex string to state array....................................................................30

DA852X E Ink Evaluation Kit

4 TUTORIAL – A MEMORY GAUGE EXAMPLE..................................................31

4.1 Connecting the Display Hardware.....................................................................31

4.2 Creating a New Project.......................................................................................33

4.3 Top Plane Connection........................................................................................34

4.4 Load Image of Display........................................................................................34

4.5 Mapping the Segments......................................................................................35

4.6 Creating the Map File.........................................................................................36

4.7 Creating a Slide Show........................................................................................39

5 WAVEFORM PHASE TABLE............................................................................40

6 CASCADE CONNECTION.................................................................................43

7 FLEX CONNECTION..........................................................................................44

8 TROUBLESHOOTING.......................................................................................45

8.1 Software issues..................................................................................................45

8.2 Hardware Issues.................................................................................................45

9 RELEASE NOTES FOR VERSION 2.0..............................................................46

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 3 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

Notices

Dialog Semiconductor provides this evaluation kit (the “product”) for engineering evaluation purposes only. It is not

considered suitable for use in end products.

This product contains static sensitive devices and care should be taken that it is handled appropriately to avoid damage

from electrostatic discharge. Dialog Semiconductor does not assume responsibility for the safe handling of the product

after it has been delivered and subsequent disposal.

As a prototype the product has not been subject to any regulatory approval (CE, FCC, etc.) and may not meet the

technical requirements from such bodies for electromagnetic compatibility. Dialog Semiconductor does assume

responsibility for such compliance.

Whilst care has been taken in the design of the product, Dialog Semiconductor assumes no liability from the user for any

indirect, incidental or consequential damages resulting from use of the product or from applications assistance given in

support of the product.

Dialog Semiconductor reserves the right to alter without notice the specification, design, price or condition of sale of this

product.

Before using the product we recommend that the user reads both the guide and the product datasheet to familiarise

themselves with the operation of the product.

Maximum supply voltages for this product are defined within this guide; operation outside these voltages may result in

permanent damage to the product. Applying loads outside the range specified in this guide or the product datasheet may

also result in permanent damage. It is possible that during operation with high load currents or voltages being applied,

some components may operate at an elevated temperature. Care should be exercised when touching components on

the board in such circumstances.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 4 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

2 Hardware

2.1 DA852X Evaluation Board

The DA852X Evaluation Board comprises the DA852X device, a USB bridge for PC communication with the device, and

a few external active components to reduce the requirement for external equipment. The device U3 is a level shifter,

used to move the digital control signals from the 3.3v domain to the chip supply domain.

The board can be used flexibly with external hardware, and can accept connections from an external microcontroller.

The board is designed to be cascadable with other DA852X boards, to allow connection of large displays with more than

256 segments.

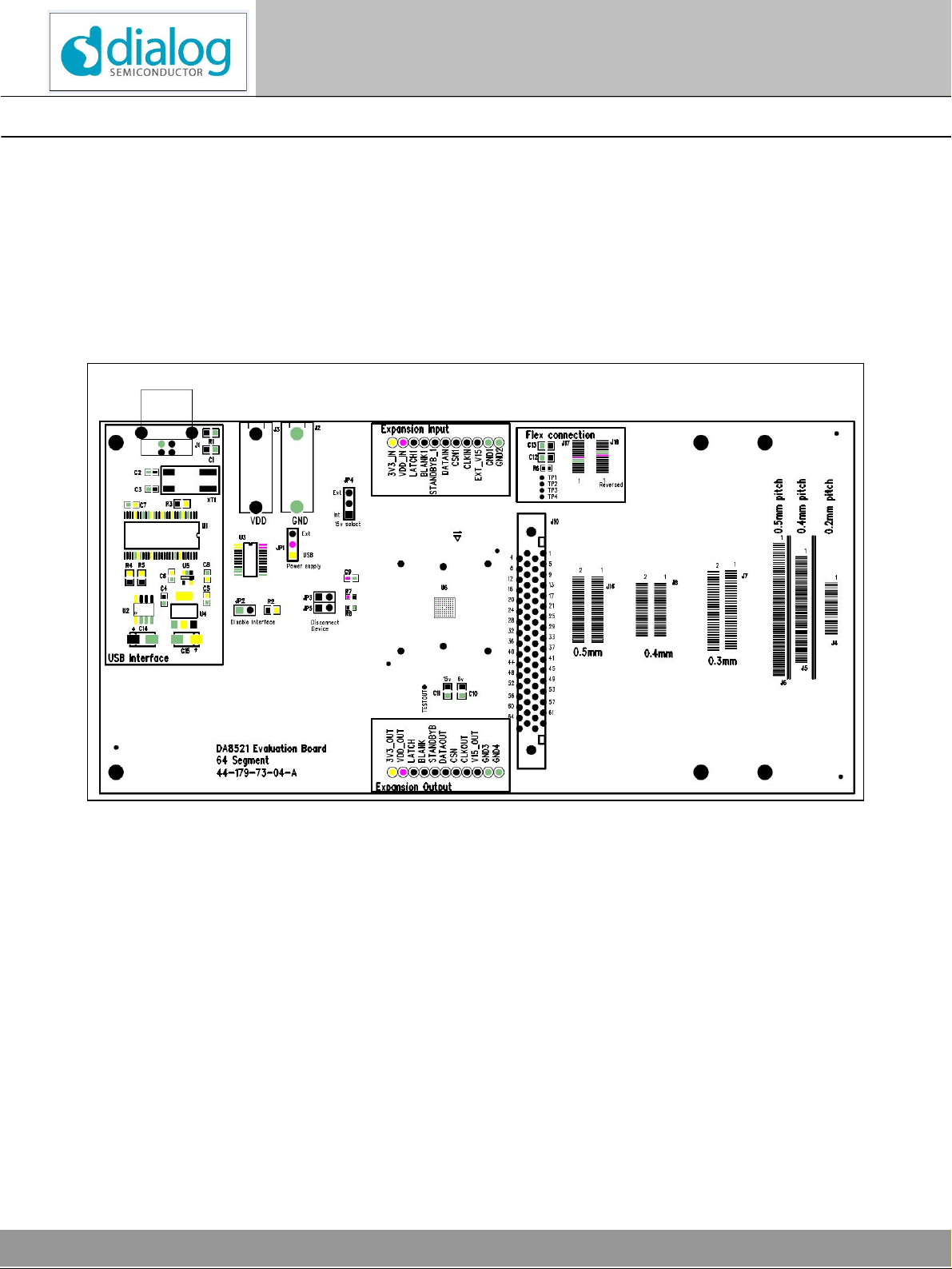

Figure 1. DA8521 PCB layout

The hardware solution is based upon PCBs numbered 44-179-73-04/05/06/07-A for the 64, 96, 192 and 256 segment

driver devices respectively.

2.1.1 USB Connector

The USB interface is used to control the board from the PC. The USB interface may also be used to power the board.

The USB interface consumes approximately 50ma in the standby state.

2.1.2 Power Supplies

The board is intended to be supplied by a single 1.8v-3.3v supply attached to the two 4mm banana sockets marked

VDD and GND.

It may also be powered with 3.3v directly from the USB interface by setting jumper JP1 to the USB position. Note: If JP1

is set to the External position, VDD should be powered before, or as soon as possible after the USB lead is plugged in.

2.1.3 Jumpers

JP1 This will connect VDD to the 3.3v supply generated by the USB module.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 5 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

JP2 Removing this disables the digital I/O signals from the level shifter to the DA852X. This allows direct access and

control of the chip from an external controller via the expansion input pins

JP3 Removal of this disables the Chip Select signal to the DA852X device. This would only be done if using the

external Flex connection.

JP5 Removal of this disables the StandbyB signal to the DA852X device. This would be done if the device is using

an external 15v supply, or is being operated as a slave cascaded device.

JP4 Selects the 15volt supply either from the internal charge pump, or from the EXT_V15 pin.

The normal positions of the jumpers are as shown below in red:

DA852X E Ink Evaluation Kit

Figure 2. Normal Position of Jumpers

2.1.4 Expansion Input

This series of test points can be used to

• Monitor the control signals from the USB interface

• Transmit the signals to external hardware (e.g. the DA852X device mounted onto a flexible PCB).

• Allow an external microcontroller to provide the control signals to the DA852X device. (Remove JP2)

• Accept the signals from the Expansion Output port of another DA852X board. (Remove JP2)

• Note that CSN1 is Active High, labelling on the PCB is incorrect

2.1.5 Expansion Output

This series of test points can be used to

• Monitor the control signals from the USB interface

• Send the control signals to the Expansion Input port of another DA852X board.

• Note that CSN is an Active High output, labelling on the PCB is incorrect.

Note that the signals DATAOUT and CLKOUT are different from the Expansion Input port. These are passed from the

DATAOUT and CLKOUT pins of the DA852X device and allow cascade connection of devices

The 3V3_OUT power supply is intended to supply the USB interface components of the second board, which will not be

plugged into the USB port.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 6 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

2.1.6 Flex Connection

The connectors J17 and J18 have 16 connections on a 0.5mm pitch. This is intended to connect via a suitable FPC

socket or direct connection to an assembly which contains both the display surface and the driver device mounted on a

flex PCB.

2.1.7 Output Connectors

The segment outputs from the DA852X device are routed to a series of parallel-connected interfaces. Note that ALL

connectors are numbered from 1 upwards, whereas segment outputs are numbered from 0 upwards. That is connector

pin 1 is driven by DA852X signal DD0 and connector pin 20 is driven by DA852X signal DD19.

It is anticipated that the E Ink Display has a flexible tail of at least 4mm, with a pitch down to 0.2mm. Some will be

intended for direct-to-board bonding using ACF material, others will be intended to connect via an inline or low profile

FPC socket. It is not possible for us to predict all the possible variations, so we have allowed for the following:

0.2mm pitch FPC connection direct-to-board

0.4mm and 0.5mm FPC connection direct-to-board or socket (64,96 output versions only).

0.3mm narrow pitch connector with staggered pins. This gives 0.6mm pitch on solder pins

0.4mm and 0.5mm narrow pitch connector with in-line pins (64,96 output versions only).

1.27mm IDC sockets for connection via ribbon cable.

Typically, inline FPC sockets, for direct insertion of the FPC tail, are available for up to about 70 ways. Low profile

sockets, using complementary mating halves on PCB and flexible tail, are available for up to about 160ways. Typical

manufacturers are JAE, Panasonic, Hirose, Molex etc.

DA852X E Ink Evaluation Kit

These connections are present on both sides of the PCB, allowing for top-side and bottom side connections. However, if

the display in use has the connections on the same side as the visible surface, it should be appreciated that part of the

display may be masked by the PCB if the flexible tail is short, as it is not possible for all the connector positions to be at

the edge of the PCB.

For such a display, there are several solutions:

a) Connect the display to the top side connectors and bend the display to make the display surface visible. The

user should take care to avoid cracking of the flexible tail.

b) Add an extender PCB (flexible or rigid) to extend the tail

c) Use an FPC socket (if available) with top side contacts.

d) Make or purchase an interface PCB to convert from FPC to wired or Insulation Displacement connector, and

use the IDC connections on the board.

Device type DA8521 DA8522

Outputs 64 96 192 256

Board no 44-179-73-04-A 44-179-73-05-A 44-179-73-07-A 44-179-73-07-A

Connectors 0.2mm FPC 0.2mm FPC 0.2mm FPC 0.2mm FPC

0.4mm FPC 0.4mm FPC

0.5mm FPC 0.5mm FPC

0.3mm skt 0.3mm skt 0.3mm skt 0.3mm skt

0.4mm skt 0.4mm skt 0.4mm skt

0.5mm skt 0.5mm skt

68 way 1.27mm 100 way

1.27mm

DA8523 DA8524

3x68 way

1.27mm

4x68way

1.27mm

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 7 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

The 1.27mm pitch IDC sockets we have chosen are the TX3 pin header series from JAE, which use the TX2 series IDC

sockets for flat ribbon cable. These are available from several suppliers. Other connectors compatible with the PCB

footprint are available (e.g. www.gtk.co.uk, www.hirose.co.jp).

Device type DA8521 DA8522

Outputs 64 96 192 256

Board no 44-179-73-04-A 44-179-73-05-A 44-179-73-07-A 44-179-73-07-A

Connector 68 way 1.27mm 100 way

1.27mm

Part number TX3-68P-D2ST-

LN1E

Distributor Farnell 996-4940 Farnell 996 RS 509-9077 RS 509-9099 RS 509-9077 RS 509-9077

Mating IDC TX2-68S-D2P1-

1CE

RS 509-8939 Farnell 996-

TX3-100PD2ST-LN1E

4967

TX2-100SD2P1-1CE

4860

DA8523 DA8524

3x68 way

1.27mm

TX3-68PD2ST-LN1E

Farnell 9964940

TX2-68SD2P1-1CE

RS 509-8939 RS 509-8939

DA852X E Ink Evaluation Kit

4x68way

1.27mm

TX3-68P-D2STLN1E

Farnell 9964940

TX2-68S-D2P11CE

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 8 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

3 Software

The E Ink Evaluation Kit software allows you to activate and deactivate the segments of the target display using a user

friendly graphical user interface. This section describes version 2.0 of the software.

3.1.1 Release Notes

Version 2.0 has been upgraded extensively from earlier versions, with a new image interface. Several new features have

been added, such as Inverse mode, and Waveform definitions to control the look and operation of the display transitions.

Alphanumeric and numeric entry have been simplified, and the ability to modify recorded sequences included.

Compatibility of sequence and initialisation files is retained, except for embedded special codes which have changed

slightly. See details below in Section 9.

3.1.2 Installation

Insert the CD containing the software. If the installation does not start automatically, run the program ‘setup.exe’ from the

CD containing the software. (This will be found in the directory ‘Software’ on the CD). An automated script will install the

program on your PC. By default, the directory C:\ Dialog Semiconductor\Display Controllers\DA852X will be used to

(hopefully) be more compatible with Windows Vista.

Plug in the USB cable, and Windows will detect the USB device. It will prompt for the drivers, which should be

automatically located on the root directory of the CD. The setup file is Dlgezusb.inf.

The following images show the procedure step by step.

First step - Select “No, not this time” then “Next” Second step – Select “Install automatically”

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 9 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Third step – Select Dialog USB Driver Fourth step – “Continue Anyway”

DA852X E Ink Evaluation Kit

Fifth step – (not always produced) If prompted, select Sixth Step – Select “Finish”.

D: (or your CDROM drive letter)

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 10 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

If installed correctly, Dialog USB Driver (EZUSB) should be listed on Device Manager as shown above.

If you are using Windows XP, you may get a message saying that a USB2 device is attached to a USB1.1 port. This can

safely be ignored.

To uninstall the software please use the Windows ‘Add/Remove Programs’ function that can be found under ‘Start’-

>’Settings’->’Control Panel’.

Note: This procedure may need to be repeated if the USB Interface is plugged into a different USB Port. This is a

“feature” of Windows, which identifies a USB driver as “belonging” to the port on which it was installed.

The software has not been tested extensively on Windows Vista, but no problems have been identified with the software

or device driver installation. If the software is installed into the “Program Files” directory, it may not be possible to edit

text files, since these are “virtualised” into the Users home folder. The software will (probably) require an administrator

privelige to install.

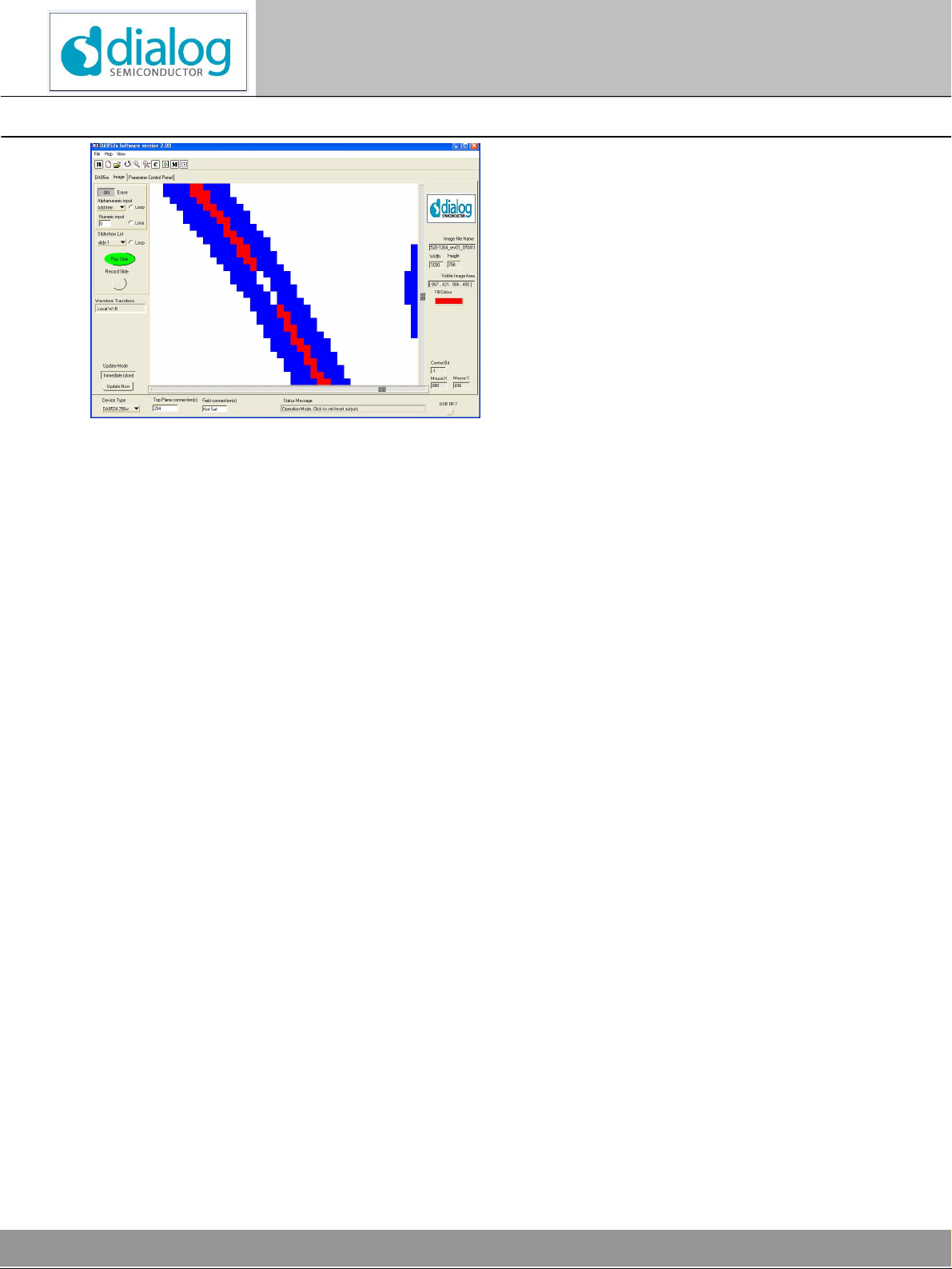

3.1.3 Control Panel

Run the “DA852X” program by clicking the shortcut in the Start menu Start>Programs>Dialog Semiconductor>Display

Controllers>DA852X_nnn.exe (where nnn is the latest version number). The best setting for the PC display size is

1024x768 pixels.. It is important to note that a display size other than the recommended setting may affect the way in

which the panels appear. It will operate with both normal and large fonts.

DA852X E Ink Evaluation Kit

Figure 3. Initial Interface

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 11 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

3.1.4 Interface Description

The interface comprises three tabbed panels, DA852X, Image, Parameter Control Panel and some common controls

Device Type, Top Plane Connection(s), Field Connection(s), Status Message, and USB indicator.

The interface has file menu items, toolbar icons and keyboard shortcuts for many of the common functions.

Hovering the mouse over controls on the selected panel produces floating “tooltip” text with helpful descriptions of the

controls.

DA852X E Ink Evaluation Kit

3.2 Common Controls

3.2.1 Device Type

This pulldown menu selects a current Project, or allows the creation of a new User Project. We have pre-defined the first

4 and included data appropriate to those device sizes.

The user will normally select “Add Item”, (or alternatively select “New Project” on the File Menu, or “Start a New Project”

on the toolbar ), provide a meaningful project name, and provide the number of output segments in use for that project.

This number can be more (implying a cascade connection) or less that the outputs available on the chip.

A subdirectory under the Data directory is created to hold all the information relevant to this project.

Once a project has been created, it is added to the pulldown menu, and will be reloaded whenever the software is

started.

3.2.2 Top Plane Connection(s)

The user must manually enter the output connected to the top plane connection. Usually this is easily available from the

documentation provided with the display panel and by inspection of the display panel to PCB interface. If not, it can be

deduced, see Tutorial.

Where the physical display has multiple connection tabs, it is possible that each tab has a connection to the top plane

and field (background). If each tab were connected to an Evaluation board, two outputs with opposite phase could be

shorted out. Therefore the software allows multiple top planes to be entered, e.g. “63,127,191”. All these outputs will then

switch in synchronism.

3.2.3 Field Connection(s)

Entering information here is optional, but if multiple top plane connections above are being used, this allows mutiple field

connection to be entered also. The connections entered will switch together always.

3.2.4 Status Message

This message box will display the current mode of the software. This is especially useful to communicate Map entry and

zoom modes.

3.2.5 USB OK? Indicator

A green light here shows that the USB interface is functioning correctly.

If offline mode is in use (offline=1 in [Setup] section of DA852X.ini) then the system will temporarily go online and operate

the hardware if available. The offline mode is not cancelled, however, so a restart of the software will return to offline

mode.

3.3 DA852X Panel

This is the simplest interface to the attached panel, showing the current state of the segments. The number of segments

shown reflects the size of the device selected. For large numbers of segments, scroll bars appear to allow access to the

higher numbers.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 12 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

The software operates by keeping track of the state of the panel, i.e. which segments are black and which are white.

Operation of the segment controls, image interface and sequences results in a change from an old_state to a

new_state, under control of a wavefrom selection, which affects how the transition looks. Upon completion of the

transition, new_state is copied to the old_state. The state of a segment does not indicate whether its physical output

connection is high or low.

3.3.1 Direct Control

Clicking on any control will turn that segment dark or light. If the display has been mapped, the appropriate segment will

be shown in the small thumbnail image alongside the controls.

Please note that these states do not necessarily indicate the output voltage of the segment outputs.

The segment designated as the top plane connection, or connections, are greyed out and cannot be activated

separately. It will, however, be controlled by the software.

If you have not used the software before, the device type selected will be DA8521 (a 64 segment device). An image of a

suitable E Ink display appears alongside.

3.3.1.1 Direct Input

The Direct Input box allows entry of a string of hex digits representing the individual states. The length of this string

should be number of states/4 . If the length of the string entered is less than this, the characters entered will affect the

lowest numbered states. The length of the string that can be entered is limited automatically to number of states/4 .

This box has a few practical uses, such as providing a fast way of filling all or part of the image (e.g. enter FFFFFF…

until the entry limit is reached), or entering a string that is cut-and-pasted from the user’s own software to verify correct

operation during system development.

DA852X E Ink Evaluation Kit

3.3.1.2 Hex equivalent

The Hex equivalent box shows the current output state expressed in hexadecimal. It can be useful during software

development to cut-and-paste this string into external software.

3.4 Parameter Control Panel

This is used to adjust settings which affect the appearance of the panel between state changes , to change slideshow

and signal timings and to access test features.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 13 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

Figure 4. Parameter Control Panel

The user is able to adjust display control timings, and activate the charge pump for a longer period to make

measurements etc.

Clock Period This adjusts the timing of the serial interface. A clock period of 5 will result in each bit being transmitted

at a rate of 1.14Mb/s (250ns+5x125ns). The maximum rate using this software is 4Mb/s. The value

should should be adjusted to the minimum value consistent with correct transfer across the hardware.

Standby Delay This adjusts the amount of time that the 15volt generator is allowed to charge to its final value before

data is sent and the display is enabled. A typical figure is 20ms for VDD=3.3v. It is only required that

the output voltage has reached its working voltage before the display is enabled. This can be verified

on an oscilloscope by monitoring pins BLANK and V15_OUT.

Standby Extend This adjusts the amount of time that the 15v generator is enabled after the transition is complete. This

should be small, and can usually be zero to conserve power.

Sequence Update Rate This sets the rate at which new sequences are displayed when in “Loop” mode. This control

can be updated from within sequence files (see Section “The Slide File “).

StandbyB Switching this to the “Always On” position allows the charge pump to be enabled for the period shown

in the box below. It will revert back at the end of the period. This is for protection of any attached

display, to avoid power being applied for a prolonged period. This control is only used during

development, investigating parameters such as the level of 15v ripple.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 14 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Output Enable This will override the programmed Enable Period to enable the output drive permanently. This allows

measurment and inspection of the output drives during development.

Dialog Test Allows access to internal test modes and automated test for Dialog Semiconductor use. Requires

password which will not normally be provided.

Export Current Phase Table This will generate a text file containing the current phase table.

See Section 5 Waveform Phase Table

3.4.1 Waveform Selection

Each tab contains the parameters necessary to control 6 different predefined types of transition appearance, and one

type which can be defined by the user, see 5 Waveform Phase Table. Selecting a tab changes the state transition to that

mode. The mode selection is stored in the project configuration file.

The waveform can be changed temporarily (i.e. not stored in the configuration file) under control of sequence events, see

section 3.5.4 “The Slide File”.

Detailed selection of the parameters will not be covered in this section.

The user should ensure that the parameters T0, T1 and P0 are long enough to allow complete switching of the segment.

If the values are too short, a grey level will be produced. The default is 280ms.

The types are:

DA852X E Ink Evaluation Kit

Local White then Black This is a local update waveform. Only the pixels that have a different ending state from their

starting state switch.

The black-to-white (B->W) transition happens before the white-to-black (W->B) transition. This waveform is useful for

non-flashy updates; however, repeated updates or long dwell times in between updates may cause image artifacts.

Local Black then White This is a local update waveform. Only the pixels that have a different ending state from their

starting state switch. This is better used for inverse mode operation.

The black-to-white (B->W) transition happens before the black-to-white (B->W) transition. This waveform is useful for

non-flashy updates; however, repeated updates or long dwell times in between updates may cause image artifacts.

Slideshow White

This is a slide show waveform. Every transition travels through white.

This waveform gives a clean transition appearance when switching characters. This is useful to use when updating

alphanumeric displays since it completely erases the old information before the new information is displayed. This is

recommended for use with white backgrounds.

Slideshow Black This is a slide show waveform. Every transition travels through black.

This waveform gives a clean transition appearance when switching characters. This is useful to use when updating

alphanumeric displays since it completely erases the old information before the new information is

displayed. This is recommended for use with inverse mode operation.

Global White then Black This is a global update waveform. All pixels switch during a transition.

The display will switch to white then to black, before displaying the final image. This waveform is useful to clear image

artifacts from the display. With optimal settings, it provides the best image performance.

Global Black then White This is a global update waveform. All pixels switch during a transition.

The display will switch to black then to white, before displaying the final image. This waveform is useful to clear image

artifacts from the display. With optimal settings, it provides the best image performance for inverse mode operation.

User Defined This allows the user to import his own phase table (see 5 Waveform Phase Table). The transition will be

shown as a waveform or bi-level view. This is obviously an advanced function, but can be useful during system

development.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 15 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

The waveforms are shown in two possible modes:

Wave Mode shows the drive waveform in differential mode. This is the voltage difference between the segment and the

top plane connections. A positive value drives the segment towards black, and a negative value drives the segment

towards white. The assumption here is that the top plane is always zero.

This visualisation of the transition can be the easiest to see the effect of parameter changes.

Note that the device drivers does not use negative voltages, so these waveforms are conceptual.

Bilevel Mode shows the waveform as logic values, and includes control over the top plane. This mode is closest to what

is actually ocurring at the device driver pins. This mode is useful to create and visualise custom phase tables (see

Appendix 2) as the order of the state changes (W-B, B-W, W-W, B-B, TP) are the same as those in the phase table.

3.4.2 File Menu

File>New Project Keyboard shortcut Ctrl+N . Prompts the user for a project name and number of outputs.

Creates directory for project name, and .ini configuration file to store changes.

File>Open Project Keyboard shortcut Ctrl+O. Displays a list of current projects, allowing selection of new

project.

File>Import Project Allows an existing directory to be added to the Project list. This might be a project previously

deleted, or a directory manually copied from another location. The directory must contain an

.ini file with the same name as the directory.

DA852X E Ink Evaluation Kit

File>Copy Project Allows the creation of a copy of the existing selected project with a new name. This is

especially useful to allow a different set of slide files to be selected, or a different map file to

link to different hardware.

File>Delete Project Displays a list of current projects. Select to the left of a project to delete that project from the

list.

A prompt box allows cancelling of the selection if performed in error, with a final confirmation

afterward.

File>Load Image Keyboard shortcut Ctrl+I. Opens a dialog box to select an existing Windows Bitmap (.bmp)

image, which should reside in the project directory. Right-clicking here allows various

navigation and copy-paste activities.

File>Load Map Keyboard shortcut Ctrl+P. Opens a dialog box to select an existing map file (.map). For a new

project this would not exist, but it could be a copy of an existing file for a similar project. Rightclicking here allows various navigation and copy-paste activities.

File>Export Phase Table This writes the current phase table to a selected file. This phase table may be modified to

achieve a new transition appearance or to remove display artifacts. See Section 5.

File>Reset Display This resets the display by ignoring its current state, and setting the display to all-white, all-

black, then all-white again. This is performed if development and testing has resulted in grey

or partially on segments which cannot be cleared by a View>Clear command.

The Reset command will usually result in a white display again. Repeat if necessary.

If the Invert Mode has been set, the display will finish in the black state.

File>Exit Keyboard shortcut Alt+F4. Shuts down the software, leaving the display intact.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 16 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Map>Load Number Offset File This specifies the number offset file to be used to facilitate simple entry of numbers on

the display

Map>Load Alpha Offset File This specifies the alphanumeric offset file to be used to facilitate simple entry of

alphanumeric strings on the display

Map>Undo Last Map Entry Keyboard shortcut Ctrl+Z. In map entry mode, this highlights the last box to be entered and

allows it to be deleted.

Edit>Map Entry Mode Keyboard shortcut Ctrl+L. Toggles Map Entry Mode

View>Refresh Keyboard shortcut F5. Refresh the PC display with no change to status.

View>Invert Toggles Invert mode. This will invert the current display and all slides.

View>Zoom Zoom in to image area.

View>Zoom Full Show entire image area

View>Map Keyboard shortcut Ctrl+M. Toggles viewing of map boxes on the image

View>Fill This toggles Fill mode. Normal mode is enabled, which allows the PC screen to reflect the

physical display. The fill colour is selectable.

View>Clear Keyboard shortcut Ctrl+Y. Clears the image area and display.

DA852X E Ink Evaluation Kit

3.4.3 Toolbar

Reset Display identical to File>Reset Display

Start New Project identical to File>New Project and Add Item in Device Type pulldown

Open Project identical to File>Open Project and selecting Item in Device Type pulldown

Undo identical to Edit>Undo Last Map Entry

Zoom identical to View>Zoom

Zoom Full identical to View>Zoom Full

Clear identical to View>Clear

Refresh identical to View>Refresh

Show Map identical to View>Map

Map Entry mode identical to Map>Map Entry Mode

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 17 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

3.4.4 Image Controls

DA852X E Ink Evaluation Kit

Figure 5. Image panel showing loaded bitmap and filled symbols

Alphanumeric Input Selecting “Add item” allows entry of an alphanumeric string, which will be decoded into a

series of slides. If the “Erase “ button is off, the alphanumeric string is added to the existing

display, else the screen is cleared before display.

Selecting an existing item in the list displays that item. Right-clicking on the control brings up

a control panel , which allows reordering and deletion of alphanumeric items.

Click on the text to highlight the item, then Move Item Up or Down to reorder it in the list.

Clicking on the check mark beside any alphanumeric will toggle the selection. Any unchecked

items will be removed after pressing the “Delete Unchecked” button which closes the panel.

Figure 6. Alphanumeric Control panel

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 18 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Alphanumeric loop Checking this item causes all the alphanumeric items in the list to be displayed endlessly until

it is unchecked

Numeric Input Allows entry of a single number, which will be decoded into a series of slides. If the “Erase “

button is off, the number is displayed on top of the existing display, else the screen is cleared

before display.

Numeric Loop Checking this item cycles all numbers up to 999 endlessly until it is unchecked.

Slideshow List Selecting “Add item” allows selection of multiple, previously recorded sequences which will

be added to the list. The control panel Figure 7 is then active to allow reordering or further

selection. Selecting an existing item in the list displays that item.

Alternatively, right-clicking on the control brings up the control panel, Figure 7, to allow

addition, reordering, temporary selection and deletion of sequence items.

Click on the text to highlight the item, then Move Item Up or Down to reorder it in the list.

Clicking on the check mark beside any alphanumeric will toggle the selection.

Further files may be added to the list by pressing the “Add Files” button.

Any unchecked items will be temporarily disabled after pressing the “Disable Unchecked” or

“OK” button which closes the panel.

Any unchecked items will be removed after pressing the “Delete Unchecked” button which

closes the panel.

DA852X E Ink Evaluation Kit

Selecting “Cancel” closes the panel with no changes made.

All changes are reflected into the sequence list box, and also stored in the configuration file.

Figure 7. Sequence Control Panel

Erase Causes Alphanumeric and numeric inputs to be preceded by a Clear command. Use erase if

the alphanumerics or numerics are simply being looped independently, but turn it off if

alphanumeric or number input are being used as part of a slide creation.

Slideshow Loop Checking this item causes all the slideshow items in the list to be displayed endlessly until it

is unchecked. The time between sequences is controlled by the Sequence Update Rate in the

Configuration panel.

Play Slide Opens a Dialog box to choose single sequence to display.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 19 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Record Slide Clicking this starts recording of all mouse clicks which toggle segment outputs. The control

turns red to indicate recording mode. Clicking Record Slide again causes the recording mode

to finish, opening a dialog box to prompt a filename for the slide. It is not necessary to add the

.txt suffix, this will be done automatically. If an existing file is selected, the option to Replace

or Cancel is provided.

Waveform Transitions Indicates the type of transitions in use. See Section 3.4.1

Update Mode If Update Mode is Synchronous, mouse clicks are not transmitted immediately to display. If

mode is Immediate, mouse clicks are transmitted immediately, but this could result in fairly

slow response due to the Enable time of the display. The default mode is Immediate.

Update Now Updates the display with stored mouse clicks if mode is Synchronous.

3.4.5 Image Information

Image File Name Displays Image file name

Width, Height Displays Image file width and height in pixels.

Visible Image Area Displays top left and bottom right coordinates of viewed area of image. This is updated during

zoom operations.

DA852X E Ink Evaluation Kit

Control Bit Displays segment output associated with clicked area of the image. If area is not associated

with a segment in the map file, displays -1

MouseX, MouseY Displays position of mouse click on the panel in Bitmap units. 0,0 is in the top left of the

image.

Scroll Bars These can be used when the image is zoomed in to pan the image vertically or horizontally.

The scroll bars will not allow the image to be scrolled past the limits of the bitmap.

Fill Colour This allows modification of the colour which will be used to infill the symbols on the PC

display. This should not be the same colour as the outline of the symbols.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 20 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

3.5 File Formats

3.5.1 The Configuration Files

Plain text configuration files (.ini) are used to store all settings that will be restored when the program is started.

DA852X.ini, stored in the Data subdirectory, contains some basic setups such as the device index selected, and the list

of user-added projects. This ini file is editable if the program is not running.

[Setup]

offline=0

Device_index = 3

[User Projects]

User project8 = "cascade,128"

User project12 = "numerics,30"

User project13 = "memory,32"

If the line “offline=0” is changed to “offline=1”, this flags to the software that hardware is not attached.

Filename.ini, stored in the subdirectory filename in the Data directory is used to store settings specific to that project.

This includes the number of outputs, the location of the Map and Image files, timing parameters, and lists of sequences

and alphanumerics.

The file allows the project to be reopened with all parameters and settings intact from previous sessions.

[Setup]

Device = 64

ImageFile = " 520-1264_rev01_070410.BMP"

Clock Period = 5

Blank Period = 350

Standby Delay = 20

Standby Period = 420

Backplane = 63

Sequence Update Rate = 0.1

FillColour = 16711680

Fill = 1

Waveform Select = 7

MapFile = " 520-1264_rev01_070410.map"

Invert = 0

Number Offset File = Number_defs.txt"

[Alphanumerics]

Alpha1 = "a"

Alpha2 = "b"

Alpha3 = "c"

[Waveform 3]

T0 = 280

T1 = 280

T2 = 280

P0 = 280

P1 = 280

P2 = 280

P3 = 280

P4 = 280

P5 = 280

[Waveform 2]

P0 = 280

[Waveform 4]

T0 = 280

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 21 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

T1 = 280

T2 = 280

P0 = 240

P1 = 280

P2 = 200

P3 = 160

P4 = 280

P5 = 130

[Waveform 6]

T0 = 280

T1 = 280

P0 = 170

P1 = 140

[Waveform 1]

P0 = 280

[Waveform 7]

Configuration File = " phase.txt"

[Waveform 5]

T0 = 280

P0 = 220

P1 = 170

[Sequences]

Sequence1 = " slide 1.txt"

Sequence2 = " slide 2.txt"

Sequence3 = " slide 3.txt"

Sequence4 = " slide 4.txt"

Sequence5 = " slide 5.txt"

Sequence7 = " slide 6.txt"

DA852X E Ink Evaluation Kit

3.5.2 The Image File

The Image File is a representation of the E Ink display to be used. It will normally be generated from the CAD database

used to define the Display for the manufacturer.

The Image file is a standard Windows Bitmap file (.bmp) in any colour depth, size or resolution. The software will fit this

file into the available display area.

The image should have clean feature lines, do not convert from a JPEG file if this can be avoided. The feature lines can

be any suitable colour. The background of the image must be white. In order for the fill routines to work correctly, there

should be no breaks in the symbol outlines, and all parts of the symbol interior should be connected by white pixels in the

vertical or horizontal directions. The Windows program Paint uses the same method for its own PaintFill routine, so this

can be used to test the requirements.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 22 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Figure 8. Detail of image, showing area that fill routine cannot reach

3.5.3 The Map File

The Map file is usually created by the software interactively, but can be generated by other means if this should be more

efficient, particularly for large displays.

DA852X E Ink Evaluation Kit

The file (.map) is a simple text file, editable with Notepad or similar, containing the mapping of bitmap rectangles to

segment control outputs.

The format is Left, Top, Right, Bottom coordinate of a bounding rectangle, followed by the Channel number which

controls that segment. All the coordinates refer to the Image bitmap, where 0,0 is in the top left corner. For example,

//X1 Y1 X2 Y2 Channel

648 608 712 694 61

718 667 732 689 60

738 653 754 689 59

Comment lines are supported with // at the beginning or within a line.

Note that multiple lines in the file may refer to the same control channel. Overlapping rectangles which contain the

same channel number are allowed as the map file will be searched in line order.

When the “Undo” function is performed in the software, the last line of this file is deleted.

It is possible to edit the file manually, but this is best performed while the file is not being used, to avoid conflict with the

internal copy of the data. This can be done by stopping the software, or by switching the project to another temporarily.

For large displays which have a number of identical complex symbols, as in the example below, it can be more efficient

to create the map interactively for one symbol only, then to import this information into a spreadsheet.

The map data for the remaining symbols can be created by adding position (X,Y) offsets and channel number offsets,

assuming that the connection assignments to the display are regular and predictable. The spreadsheet data can then be

re-exported to the text file.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 23 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Figure 9. Example of part of a large display with many segments

.

3.5.4 The Slide File

This is a simple text file (.txt) file that can be created or edited using Notepad or similar. The most usual way to create

these files is from within the software, as a recorded series of mouse clicks.

DA852X E Ink Evaluation Kit

The sequence file will be a copy of the state of the display when the recording is finished. Only segments which are

“black” are recorded in the file, as there is a “clear” function performed before the display of each slide.

Slide files are the key to producing effective “slideshows” using the display. Slide file names can be any alphanumeric

characters to show meaning of the contents, but certain naming conventions are used to decode numbers and

alphanumeric strings on the display. See the next section.

The slide consists of a series of BitmapX,Y coordinates that lie within mapped areas, along with the desired state of the

segment (black=1, white=-1). This data is a recording of the mouse activity in recording mode. Coordinates are relative

to the Image Bitmap, with 0,0 at the top left of the image.

The program computes the hex equivalent of the state of all the output segments at the end of the recording and

presents this as a comment, which can be useful during software development.

Comment lines are supported with // at the beginning or within a line.

Five “special” codes are supported in the file that can be entered manually:

-1 00 forces a “clear display” to be performed before any other processing.

It is especially useful to create a file “Erase.txt” containing only these codes, and being able to insert

this anywhere in the sequence list.

-1 -1 0 or 1 Changes the Invert mode (0=Black on White, 1=White on Black). This persists until changed again.

-1 -2 nnnn Changes the Sequence Update Rate to a new value (0-9999) milliseconds. This value will persist until

changed again.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 24 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

It is especially useful to create a file “Delaynn.txt” containing only these codes, and being able to insert

this anywhere in the sequence list. This allows the sequence to run at variable speeds.

-1 -3 no Changes the Waveform Transition type (valid numbers 1-7). . This value will persist until changed

again.

-1 -4 Performs Reset Display to remove any greying of the display or ghosting of the segments.

The best method to use these codes is to create a suitably named slide file with just a single code.

Example file

//BitmapX BitmapY State

-1 -2 10 //delay

680 651

725 678 -1

746 671 1

769 664 -1

790 655 1

814 648 -1

//Hex data = 3f00000000000000

When the slide file is loaded, all lines are processed to derive a new state from the existing old state.

DA852X E Ink Evaluation Kit

3.5.5 Slide file names for numbers and alphanumerics

To allow simple entry of numbers and other alphanumerics from the Image panel, a special naming of the slide files is

required so that the number and alphanumeric entries can be broken down into individual characters. This is simply an

aid to performing common functions, the same can be achieved by using specific sequences files if required.

3.5.6 Number Entry

A numeric such as 12345678 must be broken down into its constituent parts to be displayed as in Figure 10 below

Figure 10. A typical Numeric display

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 25 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Figure 11. Segments making up each numeric

The number 1 must appear in the leftmost segment display position (10 in the figure above), number 2 in the next

position etc. As the software cannot know where these segments are located, a sequence file is required for each

number 0-9.

The procedure is as follows:

1. Capture a sequence which represents the number 0 in any segment position. This would involve clicking

on segments A-F. Save this as filename 0.txt . Clear the display and repeat for numbers 1 thru 9.

2. Test the numbers 0-9 using the Numeric Loop button.

3. Create a file (default name is number_defs.txt). This should contain the following:

DA852X E Ink Evaluation Kit

0 X0 Y0

1 X1 Y1

2 X2 Y2

Etc for all numbers…

X0,Y0 is a reference position of the character location used to generate the numerics 0-9. It can be any identifiable point

of the symbol, such as the centre point, or lower left. The only requirement is that the same identifiable point is present

on all copies of the character.

X1,Y1 is the identified position of the units location. (This is probably the same as X0,Y0).

X2, Y2 is the identified position of the tens location.

X3,Y3 thru Xn,Yn will be the identified position for the hundreds position and upwards.

Test the number decode at any point using the Numeric Input box.

This file will be used to shift the numeric slide files into the correct locations to make up a number on the screen (up to

2,000,000,000).

3.5.7 Alphanumeric Entry

To enter the word “TEST” using the alphanumeric entry box, to appear on the display shown in Figure 9 must be

involves some breaking down of the entry string.

The letter T must appear in the leftmost position, then E followed by S and T in the last position. The DA852X software

contains some routines to allow this to happen if slide files are generated with the correct naming convention.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 26 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

The procedure is as follows:

1. Capture a slide which represents the letter A in any segment position. This would involve clicking on

segments A-N. Save this as filename A.txt . Clear the display and repeat for letters B through Z and 0

through 9.

2. Test the letters A-Z 0-9 using the Alphanumeric input control.

3. Create a file (default name is alpha_defs.txt). This should contain the following:

0 X0 Y0

DA852X E Ink Evaluation Kit

Figure 12. Example Alphanumeric display

1 X1 Y1

2 X2 Y2

Etc for all alphanumeric character locations

X0,Y0 is a reference position of the character location used to generate the alphanumerics A-Z, 0-9. It can be any

identifiable point of the symbol, such as the centre point, or lower left. The only requirement is that the same identifiable

point is present on all copies of the character.

X1,Y1 is the identified position of the leftmost location. (This may be the same as X0,Y0).

X2, Y2 is the identified position of the next location to the right.

X3,Y3 through Xn,Yn will be the identified position for the next positions to the right.

It is always possible to construct a slide for a defined word that does not use this mechanism, e.g. create a sequence

“TEST.txt” which places the word TEST on the above display. You are free to choose whichever method is most

convenient to you.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 27 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

3.6 Programming Information

This section provides information useful to the software developer in programming an application using the DA852X

device.

The DA852X EPD driver is a very simple device with an SPI interface. Serial data is streamed into the device and

latched by the LATCH signal if the CS signal is high. The last data bit sent will appear at output DD0. Databits in the

bitstream will cause the appropriate outputs to switch to 15volts for a period determined by the BLANK signal.

The E-Paper process requires a differential voltage across each segment, such that +15v will switch the segment to

black, -15v will switch to white. The DA852X driver achieves this using only a single +15v supply by switching the TopPlane connection as one of its outputs to achieve the differential voltage. This does, however, cause slightly more

complication in the software since the connection designated as the Top Plane must be managed.

Consider two adjacent segments S1 and S0. The connected outputs are D1 and D0 with TOP as the top plane

connection

S0 S1 TOP D0 D1 Comment

White White 0v 0v 0v Initial state

Black White 0v +15v 0v

Black Black 0v 0v +15v

White Black +15v 0v +15v

White White +15v +15v 0v

S0 switches on,

S1 remains off

S1 switches on,

S0 remains on

S0 switches off,

S1 remains on

S1 switches off,

S0 remains off

As you can see, the outputs D0 and D1 depend upon previous state as well as the desired state. The term state is used

here to denote the desired display condition of a segment, black or white.

For transition between each state, we can express the following relationships.

1. If any segment switches from a Black state to a White state, the Top-Plane shall be high, else it is low.

2. For each segment that must switch from Black to White, its Data output shall be zero.

3. If any segment remains constant while the Top-Plane is high, its Data output shall be one.

4. For each segment that must switch from White to Black, while Top-Plane is zero, its Data output shall be one.

In simple terms this means that Data outputs will be the same state as the Top-Plane if they are not to change,

and opposite to the Top-plane if they are to change. It will be understood from this if some segments change

from White to Black, and others from Black to White, then two separate operations are required.

The reason behind this “complication” is to retain charge balancing in the display. It is required that only one packet of

charge switches the display elements in a positive or negative direction. Successive packets in the same direction will

cause overdriving, resulting in a partially stuck segment, which appears as a “ghost”. Another way to view this to say that

DC balance must be maintained at zero.

The following code snippets are provided as an aid to the developer. They are written in ANSI C, so should be

transportable to most development environments with minimal change. They are provided as is.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 28 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

3.6.1 Decode states to provide drive waveform

These two functions Decode_Transitions, and senddata are the principal means by which changes of state are converted

into bit outputs.

They both use the following global variables, although these could obviously be modified to pass the data as parameters.

device=number of outputs in use (Global variable)

state[]=desired state of segment outputs (Global variable)

old_state[]=current state of segment outputs (Global variable)

/*-----------------------------------------------------------------------------*/

int Decode_Transitions (short int *change_state)

//Take state[] and old_state[] to decide transitions for each bit.

//return array change_state, which is in same format as phase table.

// new old

// W>W is 4 0 0

// B>W is 2 0 1

// W>B is 1 1 0

// B>B is 8 1 1

// TP is 16 - Top Plane is not used here.

{ short i,a,b;

for (i=0;i<device;i++){

a=state[i]&0x01;b=old_state[i]&0x01;

change_state[i]=((a&&b)<<3)|((!a&&!b)<<2)|((!a&&b)<<1)|((a&&!b));

}

return 0;

}

/*---------------------------------------------------------------------------*/

void senddata(void)

//Uses array Phase_table[], and phase_count to drive outputs. These are global

variables.

//Phase table contains details of transitions and delays

//Bits 0 to 3 are WB,BW,WW,BB in that order, Bit 4 is TP

//Next byte is delay in ms/10

//phase length is number of transitions

{

int i,j;

short change_state[MAX_OUTPUTS];

Decode_Transitions (&change_state[0]);

//set Standby off

setbit(ONOFFB,1);

Delay(standby_delay/1000);

for (j=0;j<phase_length;j++){

for (i=0;i<device;i++) {

d[i]=(change_state[i]&(phase_table[j*2]&0x0F))?1:0; //bitwise AND

}

d[topplane]=((phase_table[j*2]&TP)&TP)?1:0; //bitwise AND

LoadVector(); //Construct serial bitstream with d[] and clocks.

Output(); //Output bitstream

Delay((double)phase_table[j*2+1] *0.01); //Delay in 10ms increments

setbit(BLANK,1);

}

//Blank is high while transmitting data.

DA852X E Ink Evaluation Kit

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 29 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Delay((standby_extend)/1000);

setbit(ONOFFB,0);

//now update old_state[] with current values

for (i=0;i<device;i++) {

old_state[i]=state[i];

}

return;

}

3.6.2 Creating a Hex string from state outputs

It may be convenient to treat long arrays as hex strings, for import and export purposes.

This function will convert between hex string and state array.

Input: state[] array as global variable

Output: OutputString as global variable

Globals: topplane, device

void Create_String(void)

{

int i,val;

char string[MAX_OUTPUTS]="";

state[topplane]=0;

for (i=device-1;i>=3;i=i-4) {

val=state[i]*8+state[i-1]*4+state[i-2]*2+state[i-3];

sprintf(string,"%s%x",string,val);

}

strcpy (OutputString,string);

return ;

}

DA852X E Ink Evaluation Kit

3.6.3 Decode a hex string to state array

It may be convenient to treat long arrays as hex strings, for import and export purposes.

This function will convert between hex string and state array.

Input: pointer to data string

Output: state[] array as global variable

Globals: topplane, device

Int String_to_Array ( char *data)

{ int i,j,val,length;

int index;

char *poi=NULL;

for (i=0;i<(length);i++){

poi=&data[length-1-i]; //rightmost character

sscanf (poi, "%1x", &val); //convert one character

//decode variable into its constituent 4 bits

for (j=0;j<=3;j++){

index=4*i+j;

if ((index<=device-1)&(index>=0)&(index!=topplane))

state[index]=(val>>j)&0x01;

}

}

return 0;

}

length=strlen(data);

// to decimal equivalent.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 30 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

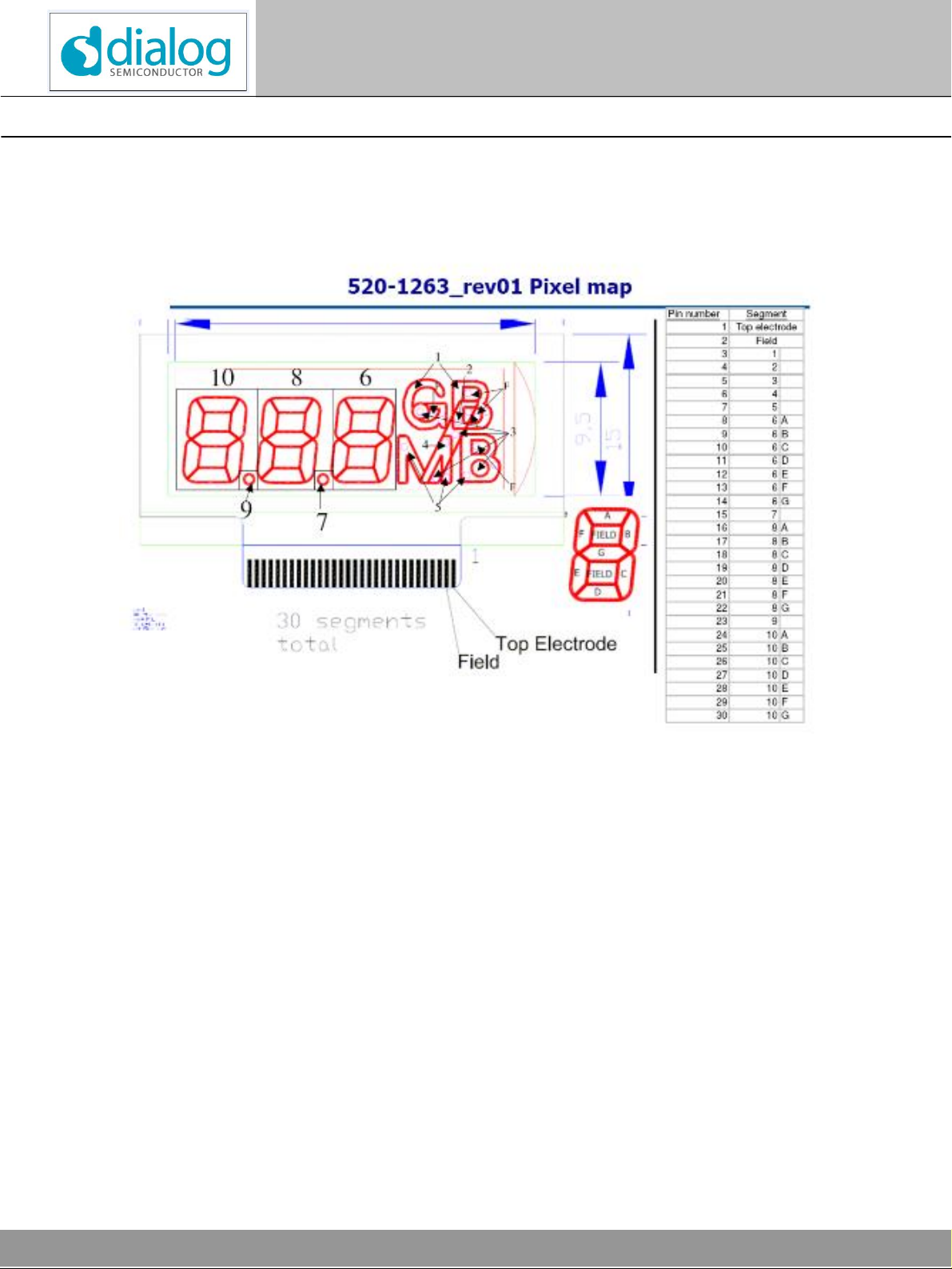

4 Tutorial – A Memory Gauge Example

This section of the guide takes you step-by-step through the process of connecting and setting up a new display. We’ll use a fairly

simple numeric “Memory Gauge” display as an example, as shown in Figure 13.

Figure 13. Details of Memory Display

The display is 33mm x 15mm overall size, with 30 active segments. The connector is 32 ways 0.5mm pitch contacts on

the bottom of the display, with pins 31 and 32 uncommitted.

We are going to connect this display to the DA8521 Evaluation 64 Segment Board. We’ll assume that the display is to

be connected to the board directly, and that FPC connectors will not be used.

This information has been provided by E-ink, which should allow simple connection and allocation of the segments.

It is possible that you do not have this information to hand, (i.e. the person who has it is on holiday!), or the information

might be out of date, in which case I will lead you through the steps to sort this out later in this tutorial.

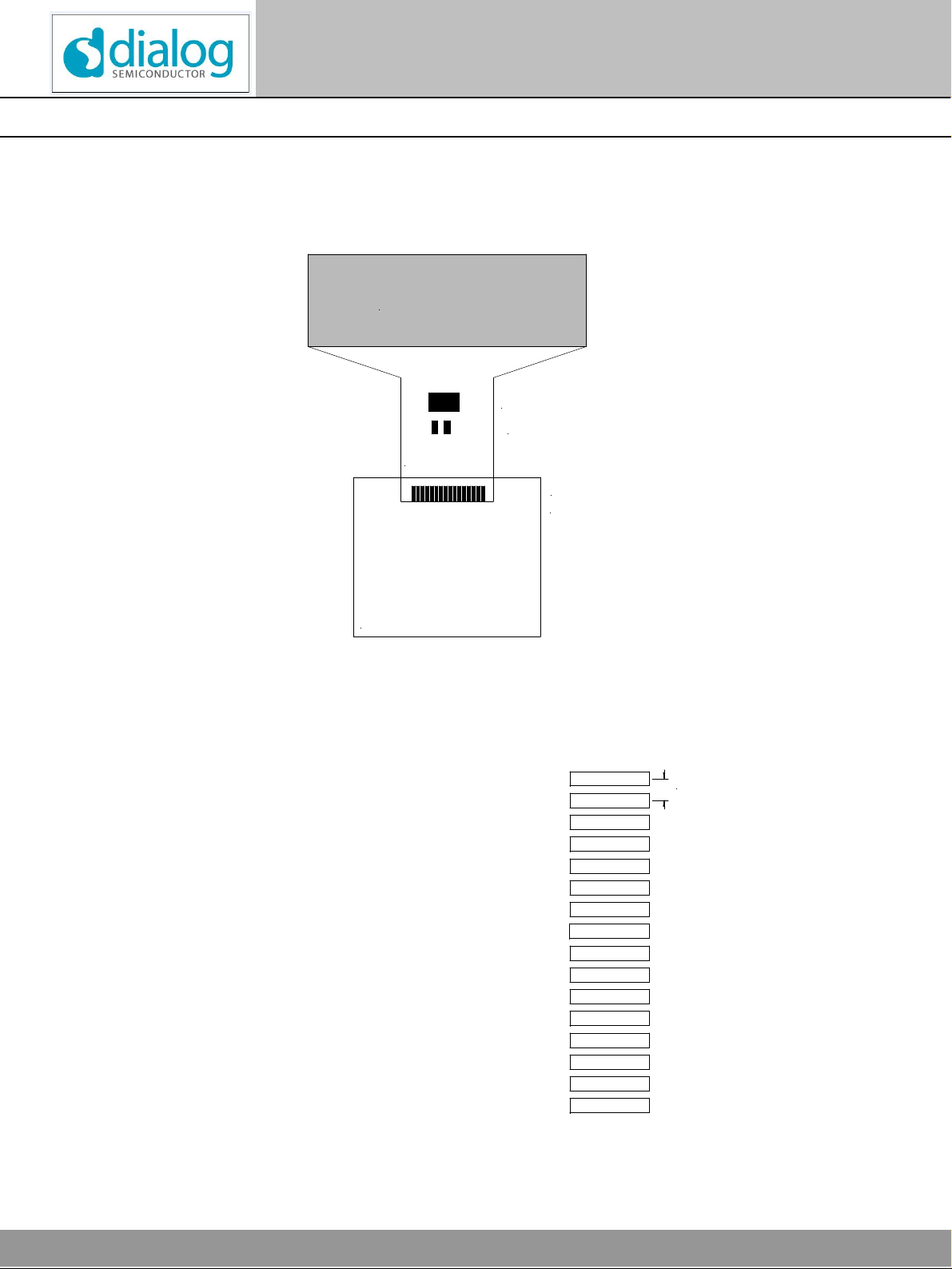

4.1 Connecting the Display Hardware

First, connect the display to the PCB. This is achieved by positioning the display contacts on the 0.5mm pitch connector

J6 on the top side of the PCB (see Figure 14), securing the contact with a piece of matt adhesive tape. Use a type with

low stickiness to avoid leaving residue on the PCB. For the 0.5mm pitch the connector of this display, it is just possible to

align the connector correctly with the naked eye. For smaller pitch connectors, some magnification is required.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 31 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

DA852X E Ink Evaluation Kit

Figure 14. Evaluation board with display connected

You are free to choose where to position the display contacts relative to the connector. Here I have chosen to align

the leftmost contact (pin 32 on the display) with pin 1 of the connector. Therefore the Top Electrode will be at pin 32

of J6 (or segment output 31). We will need this information later.

Figure 15. Close up of connections

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 32 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Use the clamp provided to ensure a good connection with an even pressure. Don’t tighten the clamp too much, it

can flex and give a less effective pressure.

DA852X E Ink Evaluation Kit

Figure 16. Clamp fitted to ensure good connections

That is job done, we move on now to working with the software.

For troubleshooting, see Section 8.2.

4.2 Creating a New Project

We’ll assume that you have followed the instruction on page 9 onwards, and have successfully installed the software and

USB driver. If not, do it now.

Start the software by selecting Start>Programs>Dialog Semiconductor>Display Controllers>DA852X.

You will be greeted by the image in Figure 17.

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 33 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Figure 17. Initial screen

You will now want to create a new project to match the fitted display. We’ll call it „memory“.

Press the „New Project“ icon and enter „memory“ into the popup box. Enter „32“ for the number of outputs, as the

display has 32 connections, even though 2 of them are not used. The number of outputs tells the software what is the

maximum output used.

DA852X E Ink Evaluation Kit

4.3 Top Plane Connection

Next, enter the output number for the top plane connection into the box at the bottom of the screen. In our example case

this is easy, the information tells us that it is the rightmost connection, which is attached to pin 32. This is output segment

31 in the software. Watch out for this- pins of connectors are always numbered from 1, but outputs from many chips

including this one, number from 0. Enter 31 into the box.

What happens if you don’t know the pin number of the top plane connection? It will usually be the last used pin on the left

or right of the display, there may be dummy connections outside. The top plane connection is visible on the right or left of

the display by a large rectangular „blob“ , so the position of this will tell you which end of the connector is used for the top

plane.

4.4 Load Image of Display

Next we need to load in a bitmap image of the display to be used.

With any luck, you have a CAD database with a clean artwork for the display. You can export a bitmap from this in

Windows .bmp format. Size and bit depth is irrelevant.

If not, the information may be present in a Adobe Acrobat .pdf document as in Figure 17 of this document. You can

select an appropriate area, copy it, and paste into Windows Paint program or any other graphical editor. Some

retouching can be carried out to remove arrows, text etc if you wish.

Save this file into the newly created directory

c:\Dialog Semiconductor\Display Controllers\DA852X\Data\Memory

Press the tab „Image“ to change to the image view:

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852x-UG02-608 Page 34 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

Select File>Load Image (or Ctrl I if you prefer) and select the image you have just saved.

You will now see Figure 18 Error! Reference source not found. on the screen. The bitmap may look a little different

depending on how much cleaning up you have done.

DA852X E Ink Evaluation Kit

Figure 18. Image Screen with bitmap loaded

4.5 Mapping the Segments

Now is the fun part, we need to map the segments of the display to the connected segment outputs.

There are two ways to do this: calculation from the supplied information, or interactively on the display.

From the information in Figure 13, and by inspection of the connections that we previously made, segment G of location

10 (pin 30) would be assigned to output 2 (3rd connection on display), segment F would be output 3 etc. The field

connection is output 330, and the top plane output 31.

We could therefore add the list of outputs to a paper copy of figure 11.

The second method, if the information is not readily available, is to activate individual segment outputs by using the

controls on the DA852X tab. Clicking the round numbered controls will switch the outputs individually. The change in

state of the segment on the display can be observed, and the number written onto a paper copy of the display inside the

segment. Repeat until finished!

All brand and product names are trademarks or service marks of their respective owners. Printed in Europe.

DA852X-UG02-608 Page 35 of 47

© Dialog Semiconductor 2008. All rights reserved.

Display Controllers

User Guide Release 2.0

4.6 Creating the Map File

Select Edit>Map Entry Mode (or Ctrl L).

This enters Map Entry mode (signified by the cursor changing to a rectangle) where it is expected that you will click on a