User Manual

DA14531 Development Kit Pro

Hardware User Manual

UM-B-114

Abstract

Dialog Semiconductor’s DA14531 development kit PRO consists of one DA145xx DEVKT-P PROMotherboard, FCGQNFN daughterboard and a WLCSP daughterboard (the WLCSP daughterboard

must be purchased separately). This user manual describes the system functions of the hardware as

well as the guidelines of how to enable or disable features of the DA14531 development kit PRO.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

2 of 80

© 2019 Dialog Semiconductor

Contents

Abstract ................................................................................................................................................ 1

Contents ............................................................................................................................................... 2

Figures .................................................................................................................................................. 4

Tables ................................................................................................................................................... 5

1 Terms and Definitions ................................................................................................................... 7

2 References ..................................................................................................................................... 7

3 Introduction .................................................................................................................................... 8

3.1 System Overview ................................................................................................................ 10

3.1.1 Features of DA14531 PRO-DB ........................................................................... 10

3.1.2 Features of DA14531 PRO-MB ........................................................................... 10

4 Getting to Know DA14531 DK PRO ........................................................................................... 11

4.1 DA14531 PRO-DB .............................................................................................................. 11

4.1.1 Power Section ...................................................................................................... 13

4.1.2 RF Section ........................................................................................................... 15

4.2 PRO-MB (376-18-B) ............................................................................................................ 16

4.2.1 USB HUB (U11) ................................................................................................... 18

4.2.2 USB to UART (U12) ............................................................................................. 18

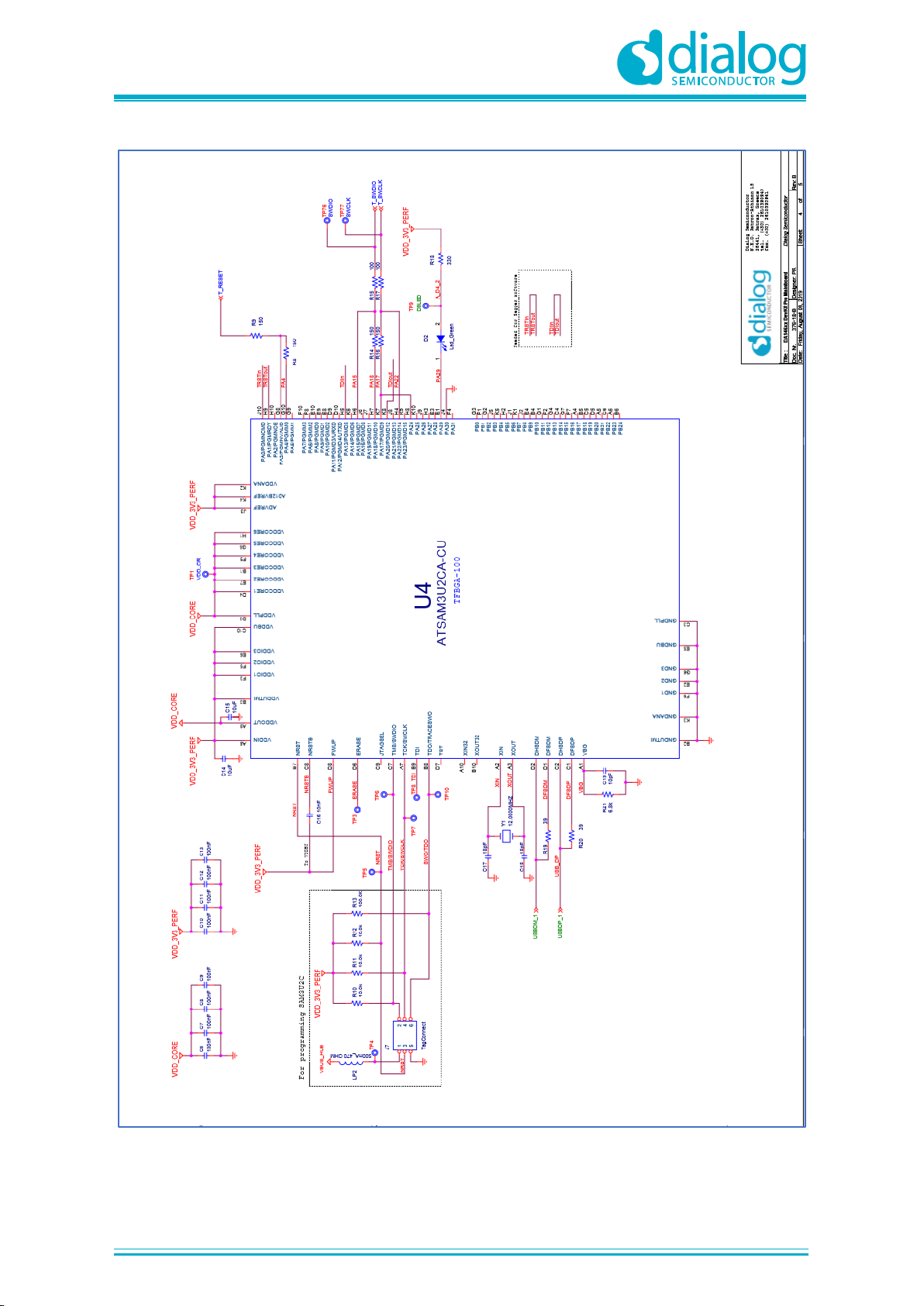

4.2.3 USB to JTAG (U4) ............................................................................................... 19

4.2.4 Voltage Translator ............................................................................................... 20

4.2.5 Power Section ...................................................................................................... 21

5 GPIOs and Pin Assignment and Functions of DA14531 DK PRO .......................................... 22

5.1 DA14531 WLCSP17 PRO-DB, Default Setup .................................................................... 24

5.2 DA14531 FCGQFN24 PRO-DB, Default Setup .................................................................. 25

5.3 PRO-MB Setup ................................................................................................................... 27

5.3.1 Reset.................................................................................................................... 27

5.3.2 JTAG .................................................................................................................... 28

5.3.3 SPI Data Flash (U2) ............................................................................................. 28

5.3.4 UART ................................................................................................................... 29

Single-wire UART ................................................................................................ 30

5.3.4.1 2-wire UART Configuration .............................................................. 30

5.3.4.2 Full UART (4-wire) Configuration .................................................... 31

5.3.5 Push Buttons ....................................................................................................... 32

5.3.6 User LED (D5) and C-Trig (Software Cursor) ..................................................... 33

5.3.7 mikroBUS 2 Interface ........................................................................................... 34

5.3.8 Arduino Interface ................................................................................................. 35

6 How to Configure Power of DA14531 DK PRO ......................................................................... 36

6.1 Battery Operation ................................................................................................................ 37

6.1.1 Enabling Coin Cell Battery on DA14531 PRO-DB .............................................. 38

6.1.2 Enabling Coin Cell Battery on PRO-MB .............................................................. 38

7 First Steps with DA14531 DK PRO ............................................................................................ 40

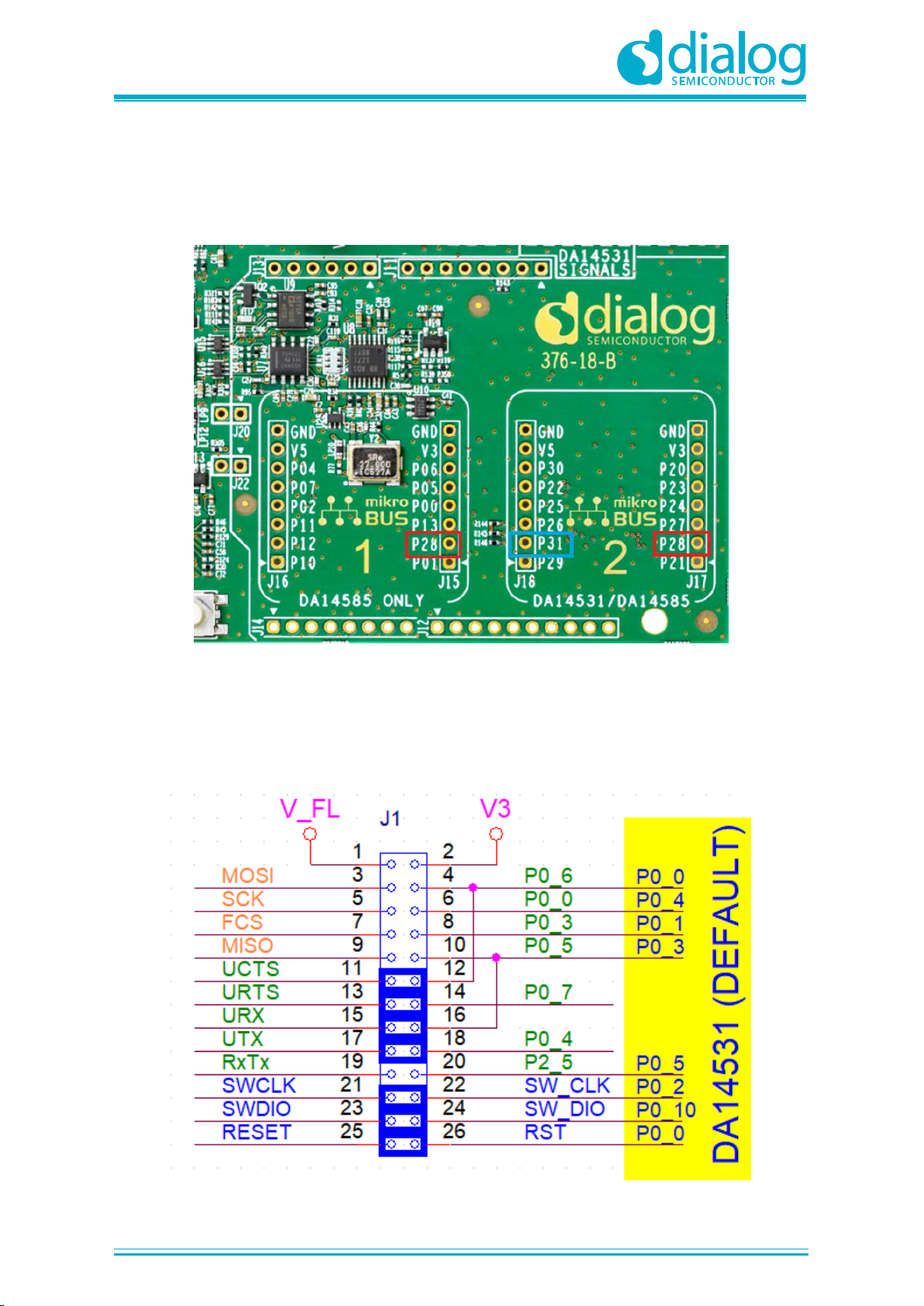

7.1 Configuration of DA14531 DK PRO with a DA14531 FCGQFN24 PRO-DB ...................... 40

7.2 Configuration of DA14531 DK PRO with a DA14531 WLCSP17 PRO-DB ........................ 42

8 Current Measurements ............................................................................................................... 43

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

3 of 80

© 2019 Dialog Semiconductor

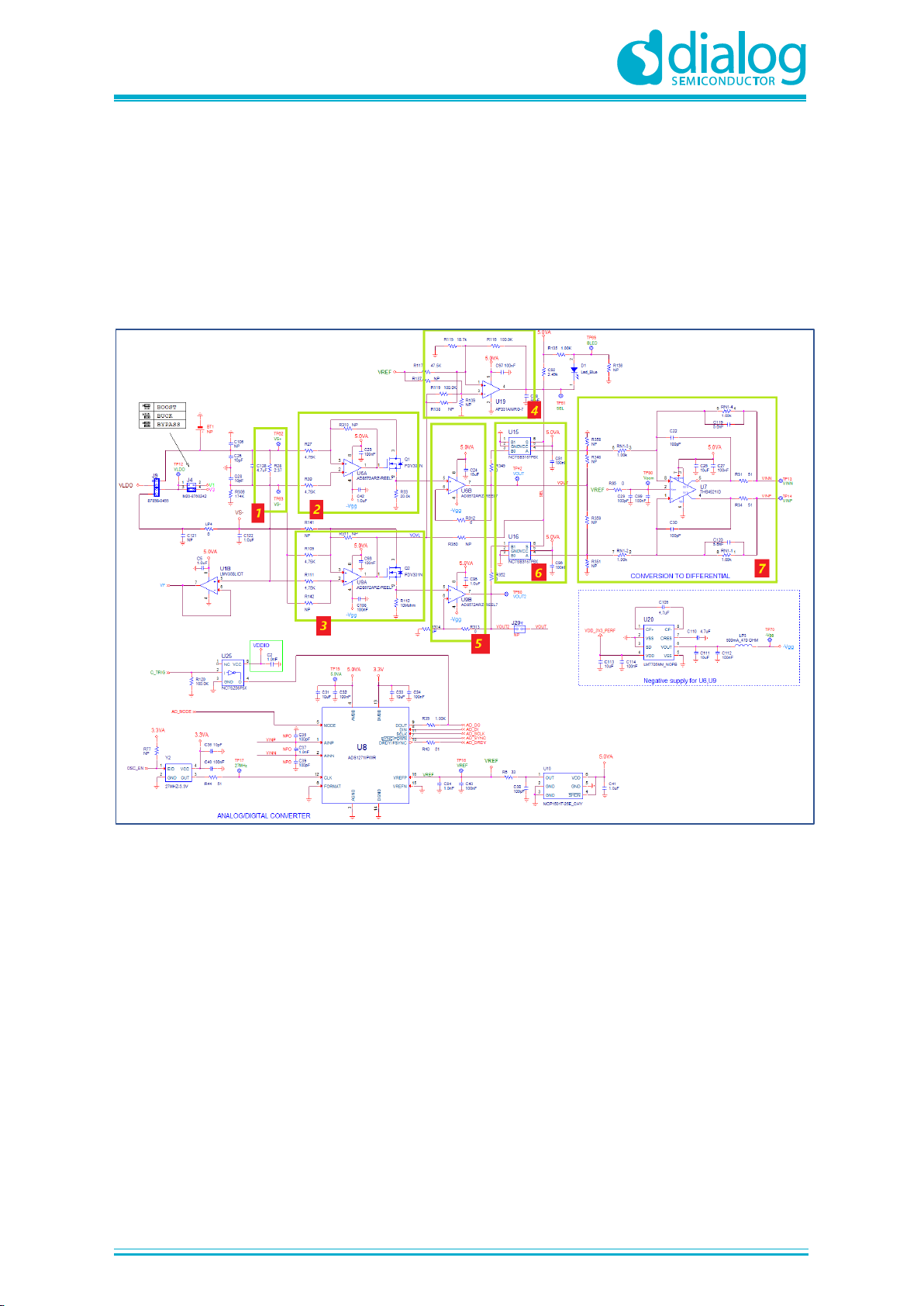

8.1 Current Measurement Circuit of PRO-MB .......................................................................... 43

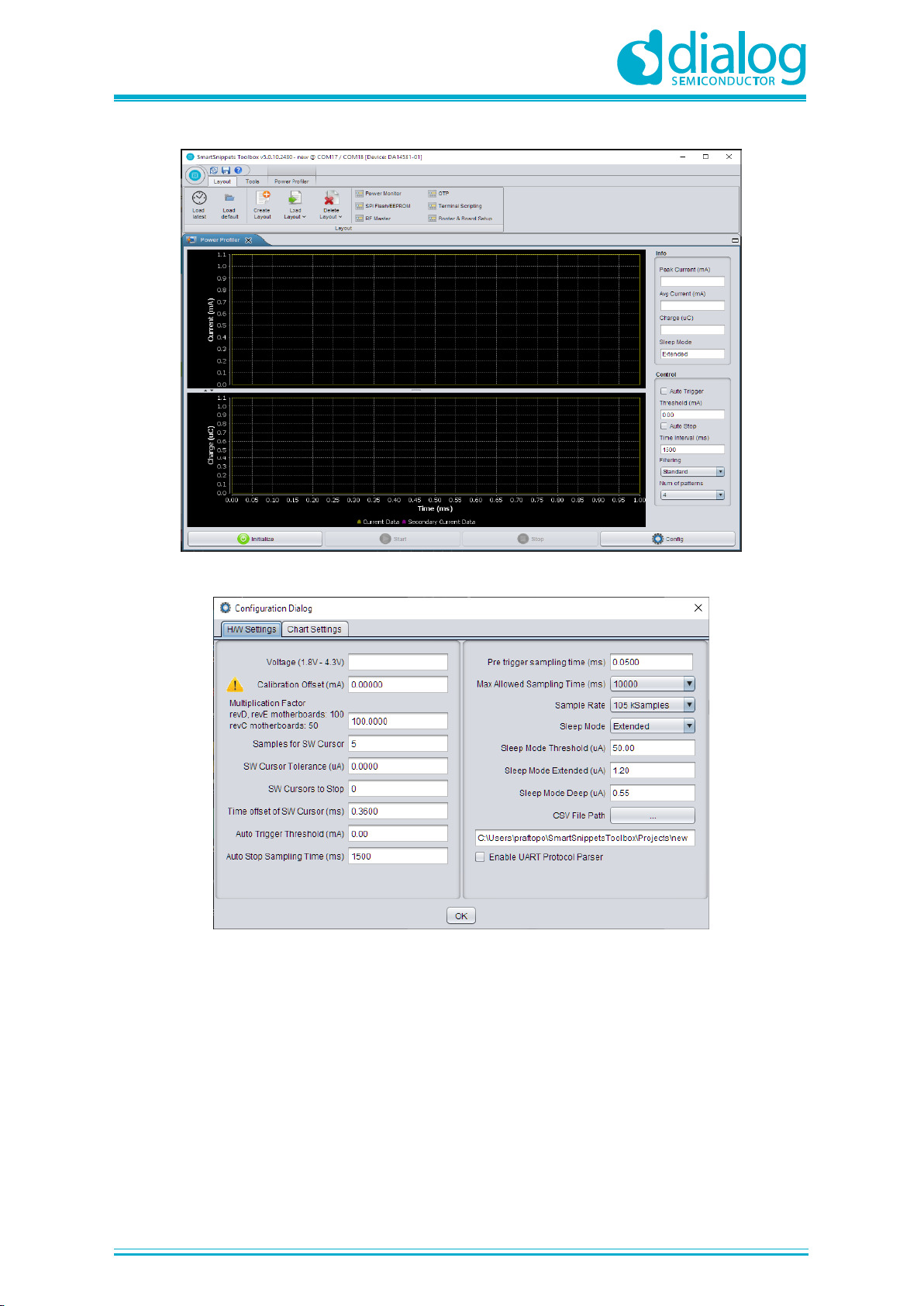

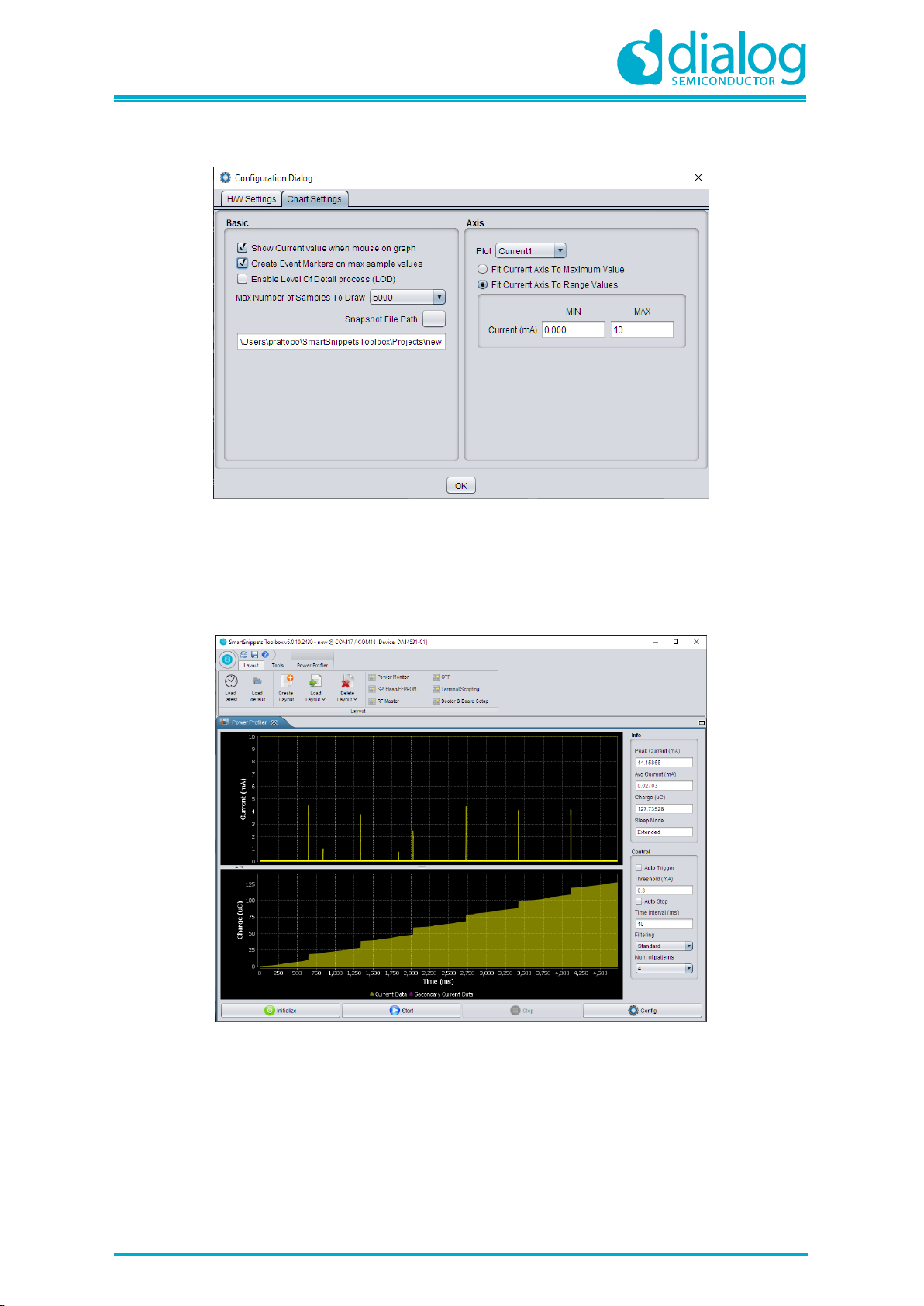

8.2 Power Profiler of Smartsnippet Toolbox ............................................................................. 44

8.3 Power Profiler Setup ........................................................................................................... 45

8.4 Measurements .................................................................................................................... 47

8.5 Power Profiler Software Cursors ......................................................................................... 49

8.6 Manual Calibration .............................................................................................................. 49

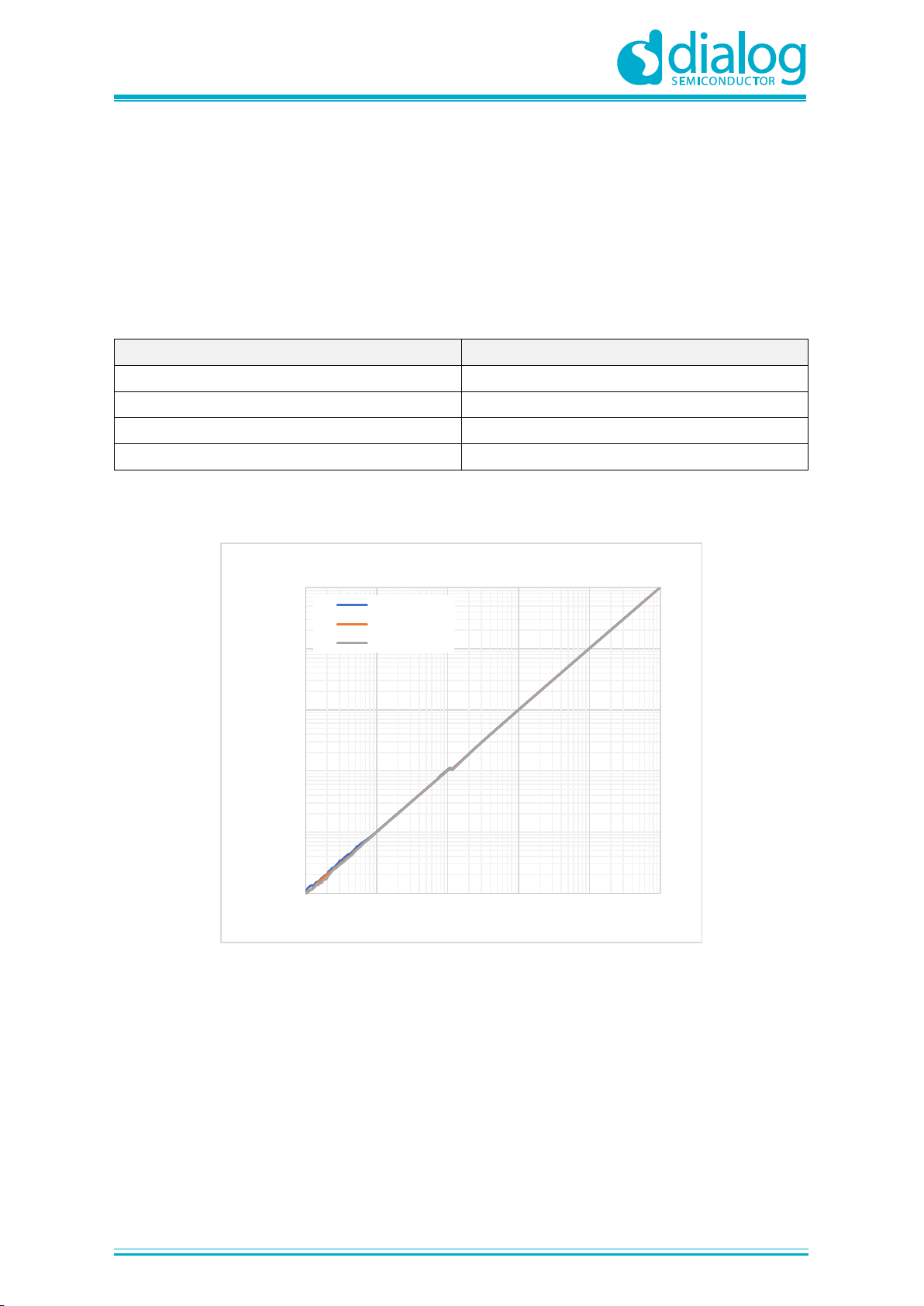

8.7 Accuracy of Current Measurement Circuit .......................................................................... 51

9 Known Issues .............................................................................................................................. 53

9.1 Switching Transient Artifacts of Current Measurement Circuit ........................................... 53

9.2 Push Button SW3 ................................................................................................................ 53

9.3 mikroBUS Wrong Label ....................................................................................................... 54

9.4 4-Wire UART Special Considerations ................................................................................. 54

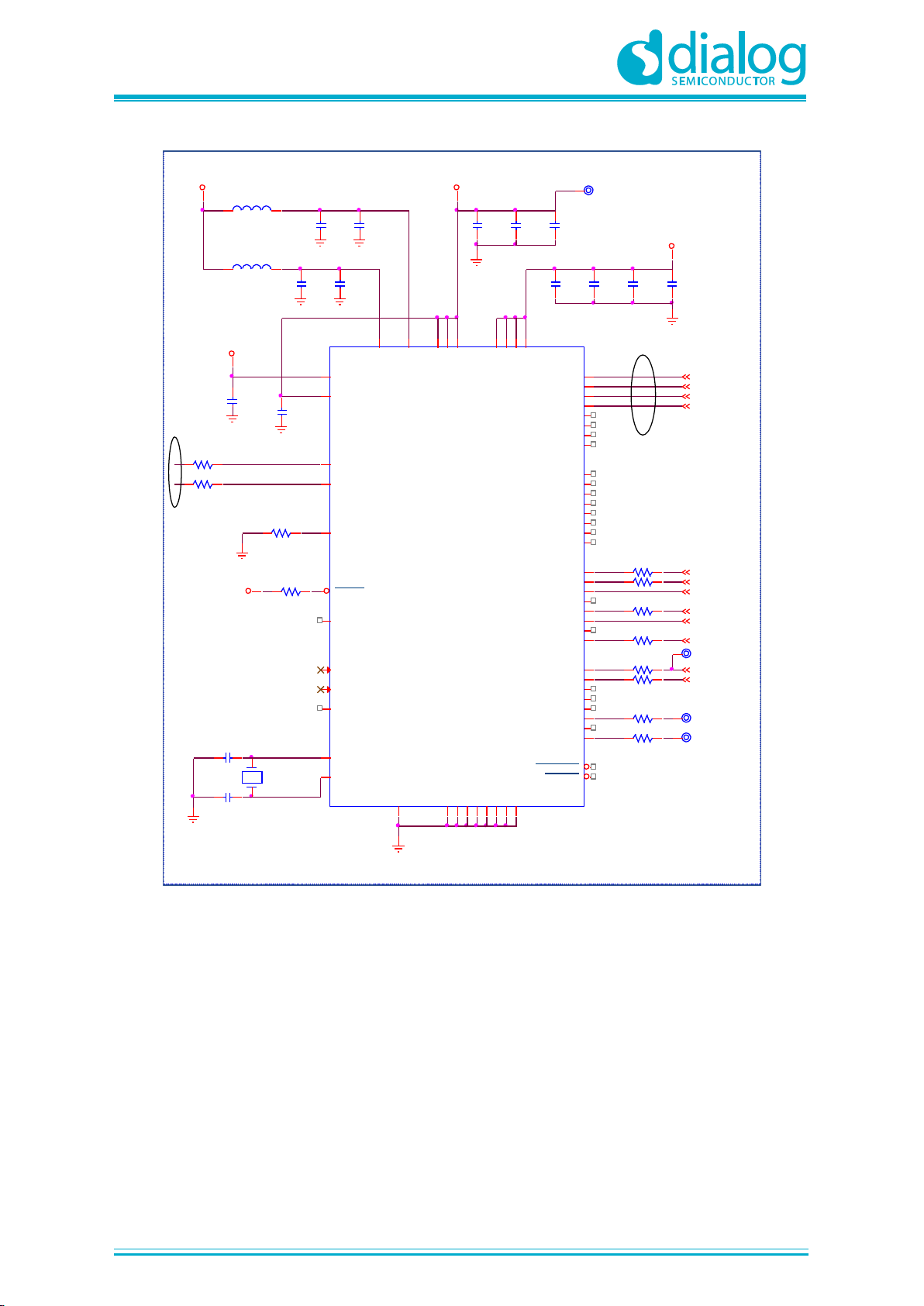

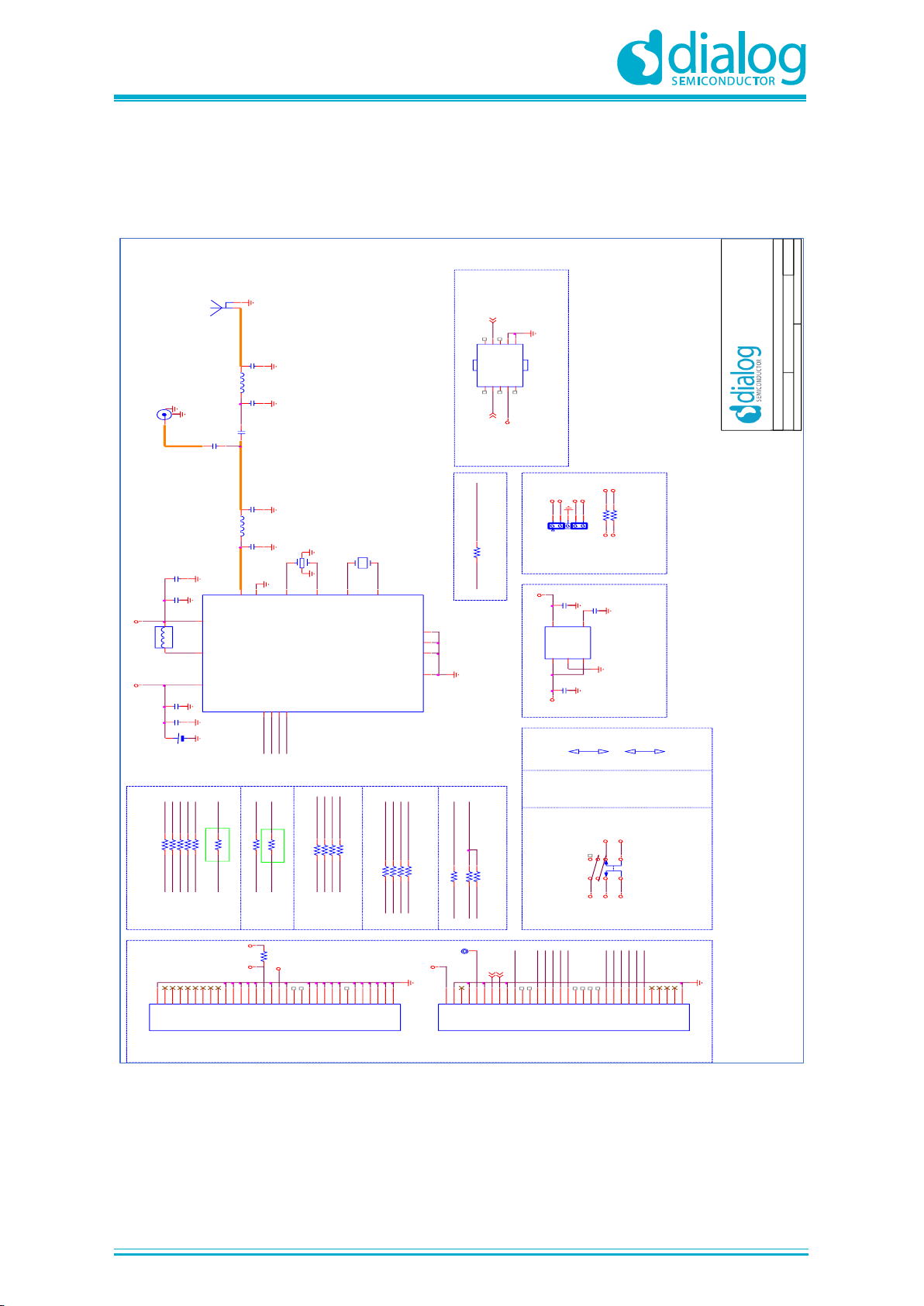

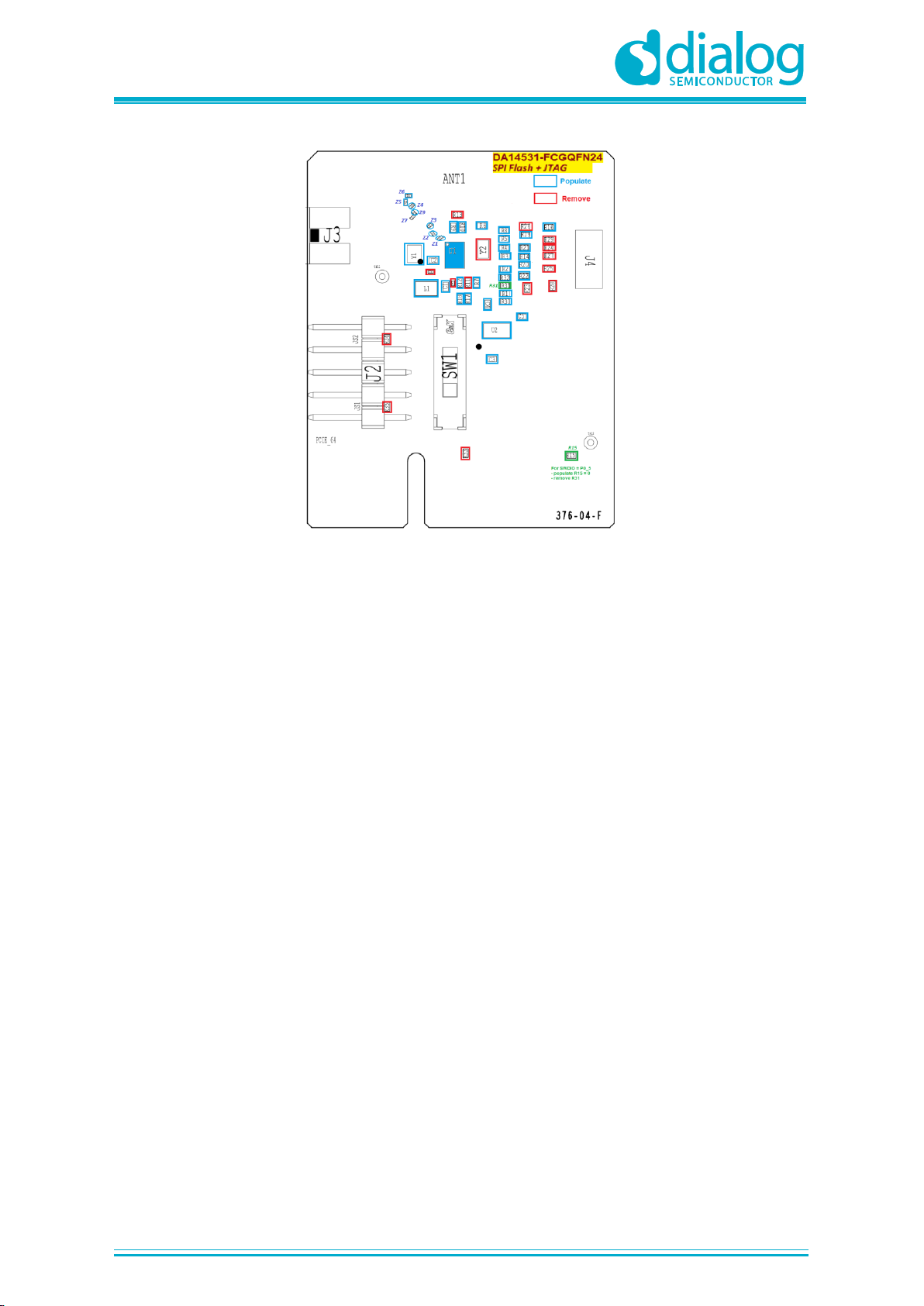

Appendix A FCGQFN24 PRO-DB: DA14531-00FXDB-P_(376-04-F2) ............................................ 56

A.1 Schematic ........................................................................................................................... 56

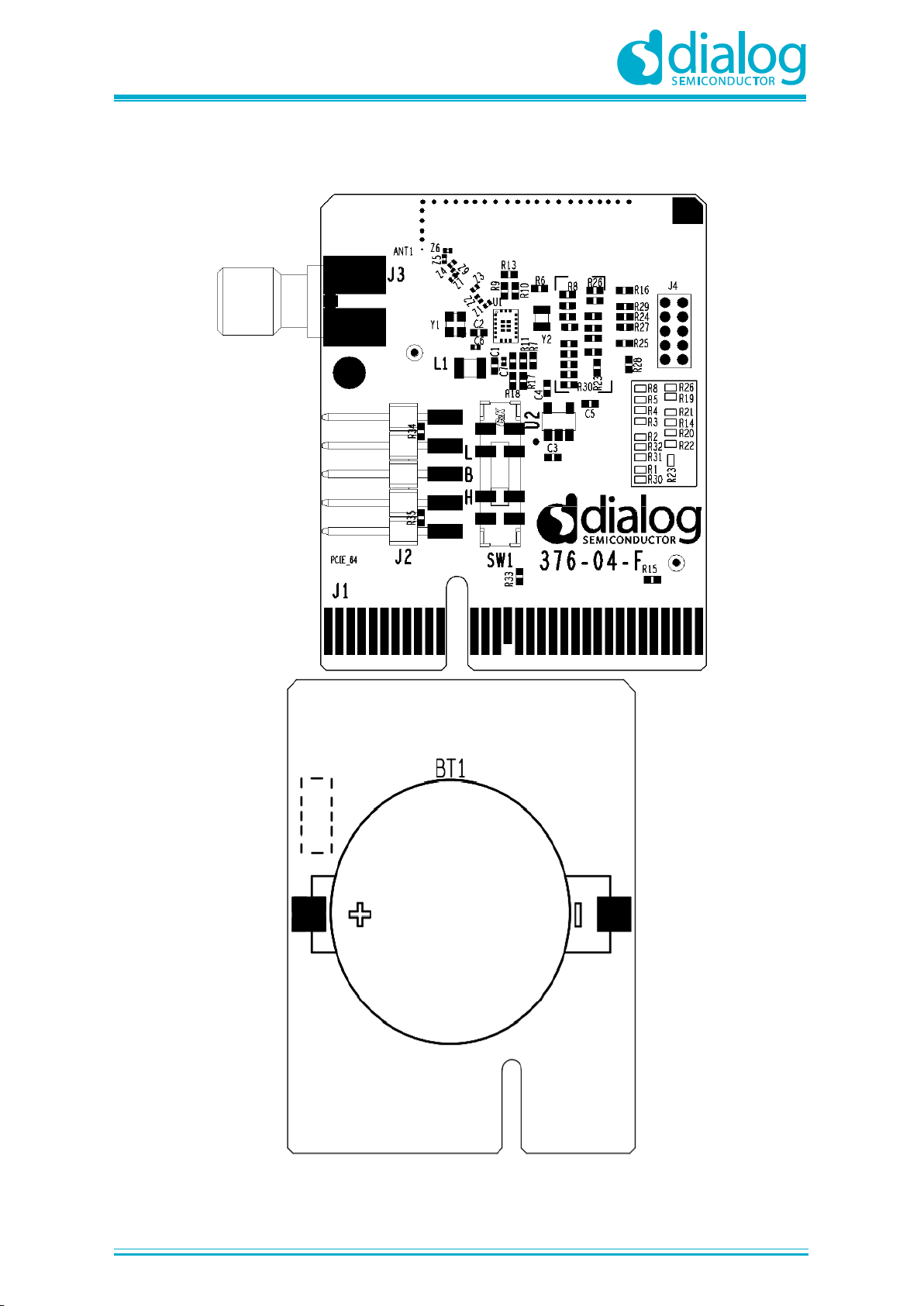

A.2 Components Placement ...................................................................................................... 57

Appendix B WLCSP17 PRO-DB: DA14531-00OGDB-P_(376-05-E) ............................................... 58

B.1 Schematic ........................................................................................................................... 58

B.2 Components Placement ...................................................................................................... 59

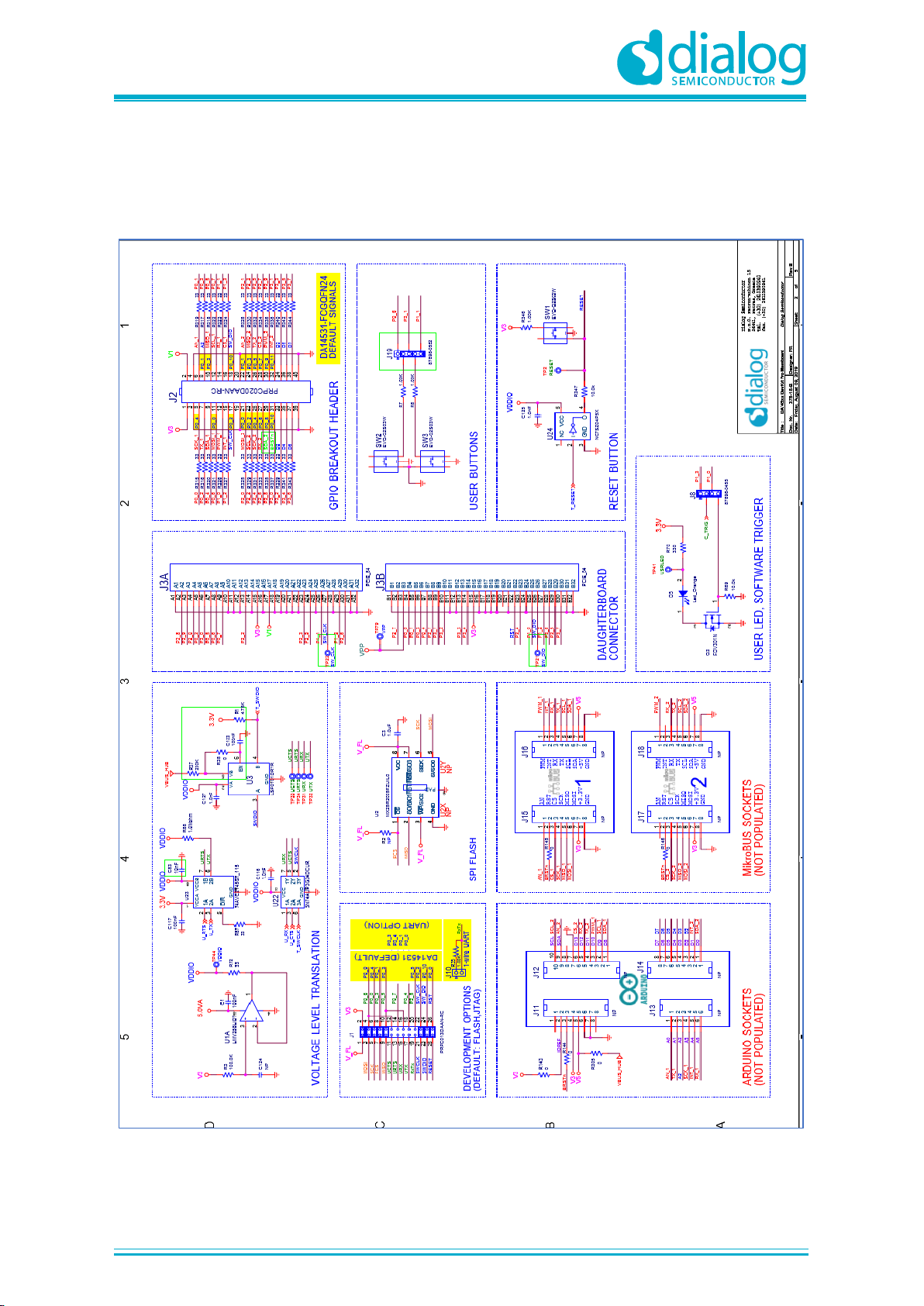

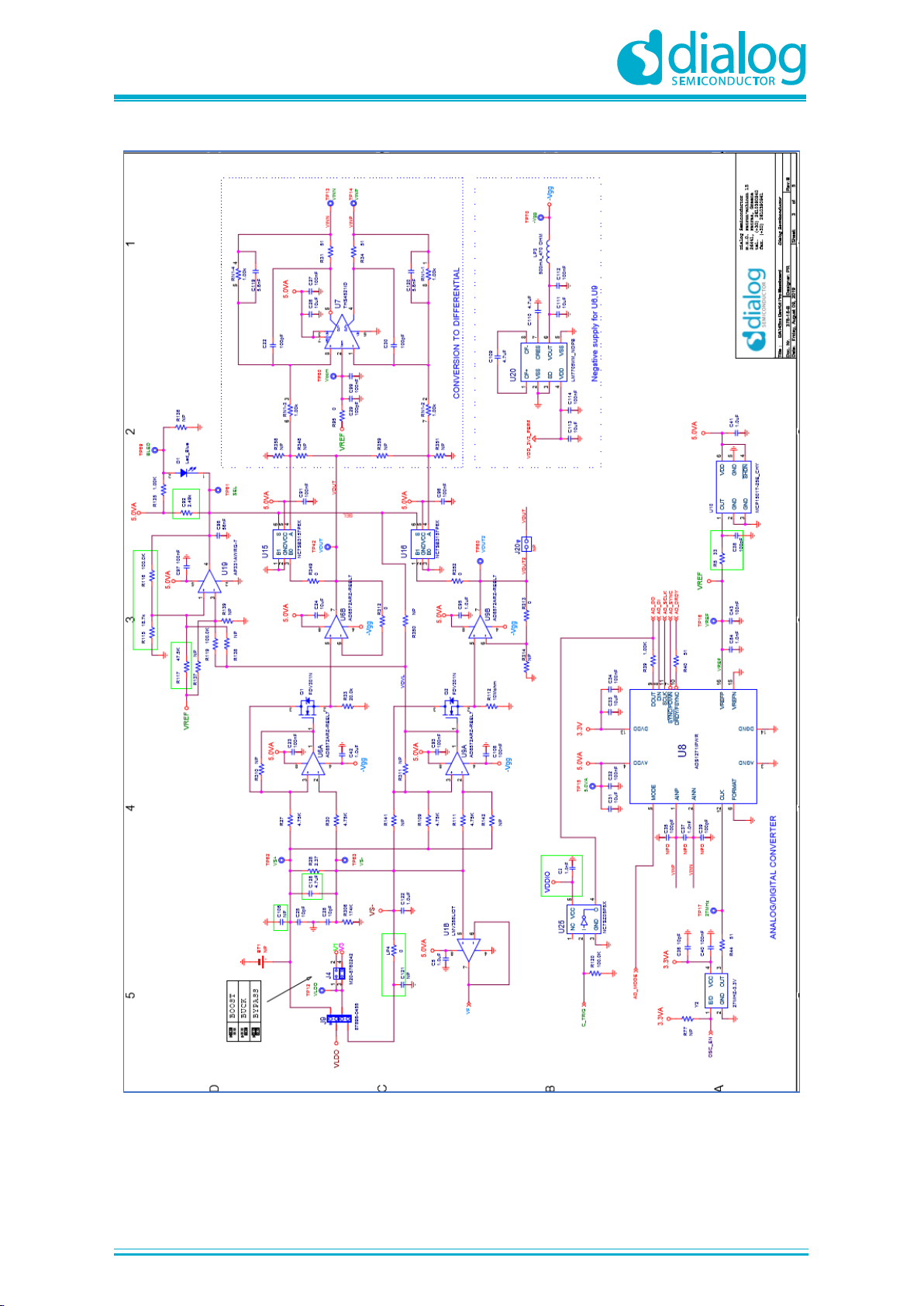

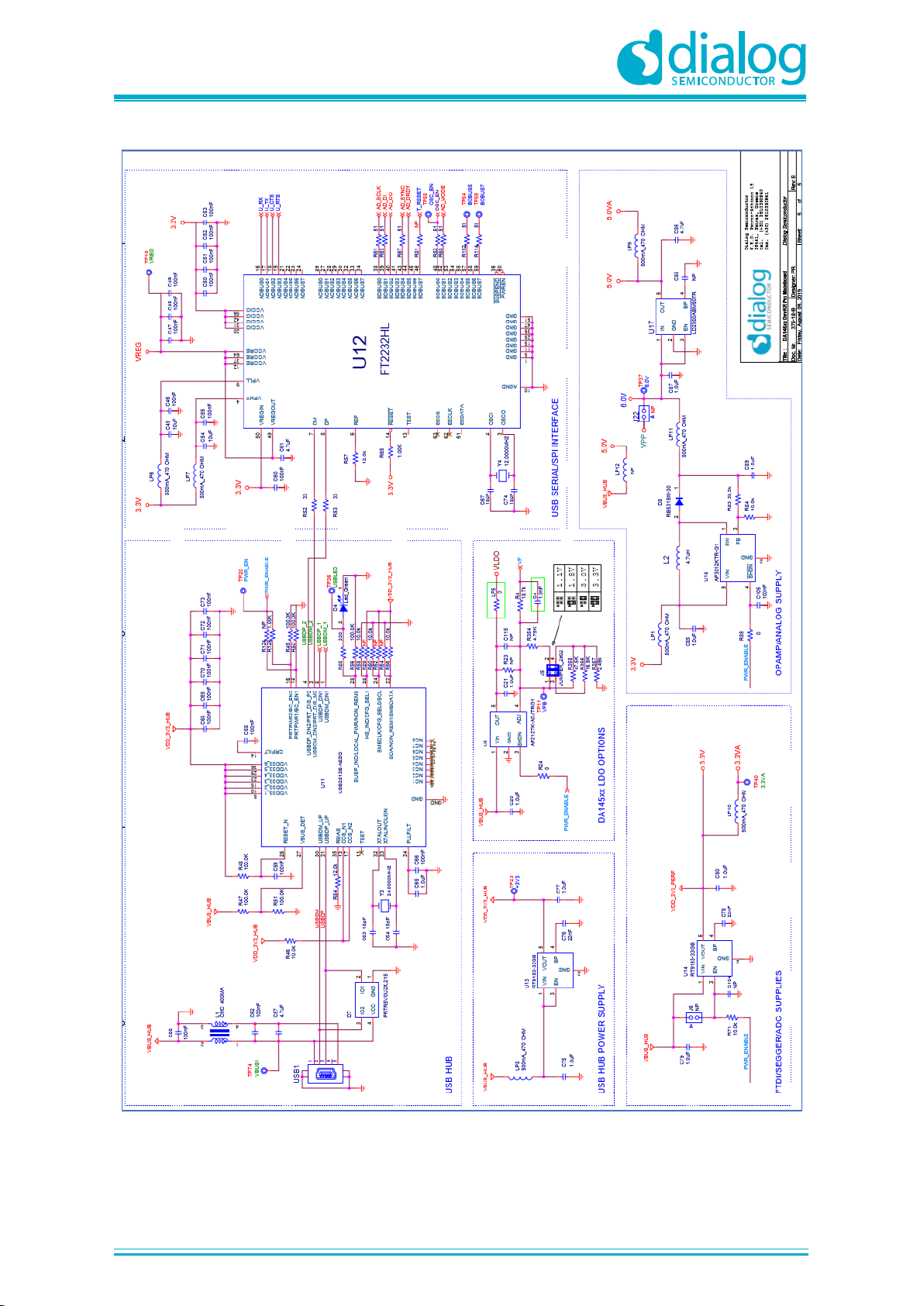

Appendix C PRO-MB ......................................................................................................................... 60

C.1 Schematic ........................................................................................................................... 60

C.2 Components Placement ...................................................................................................... 64

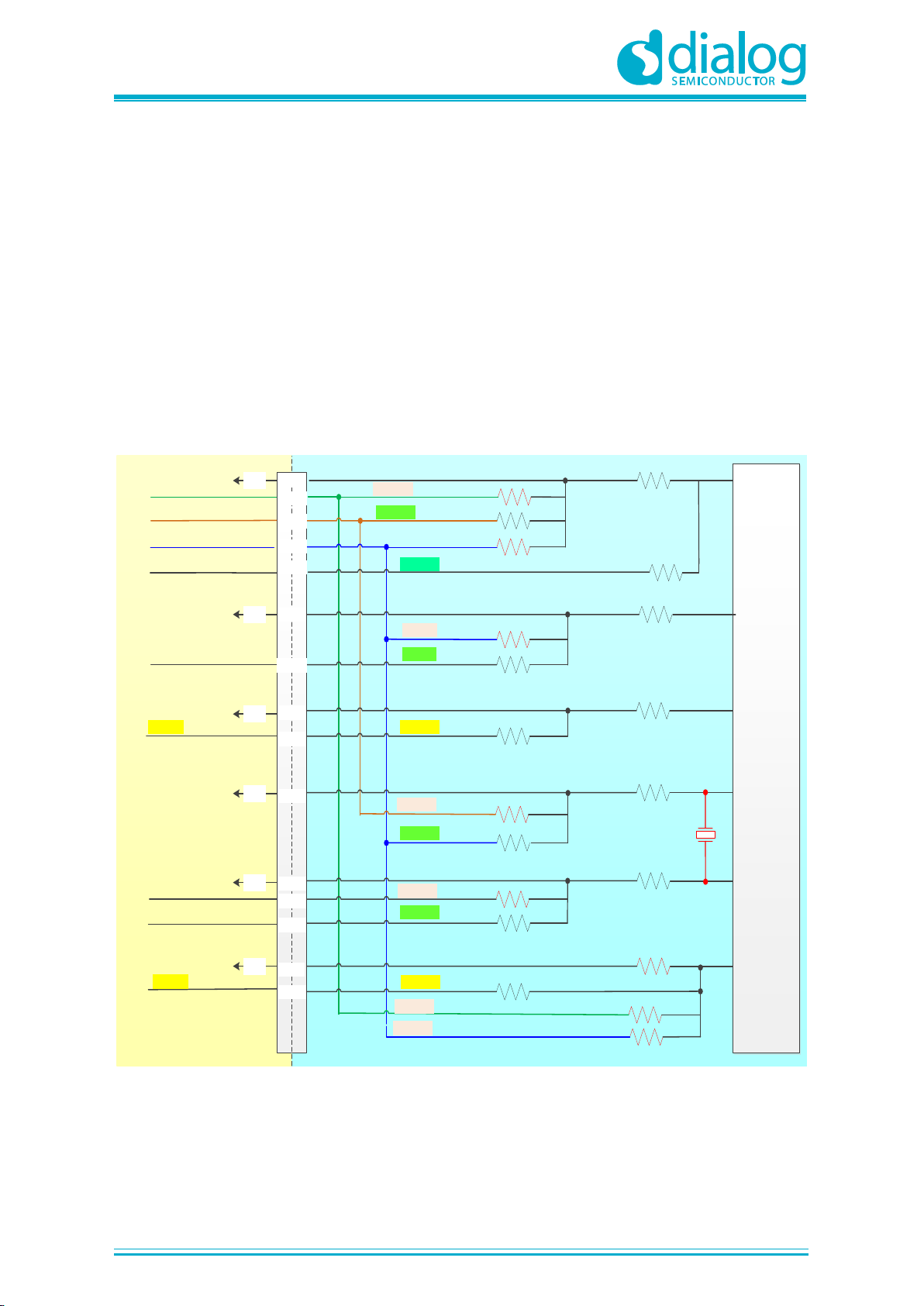

Appendix D Detailed Description of Hardware Setup .................................................................... 65

D.1 DA14531 WLCSP17 PRO-DB, GPIOs Configuration, and R-matrix .................................. 65

D.2 DA14531 FCGQFN24 PRO-DB, GPIOs Configuration, and R-matrix ................................ 66

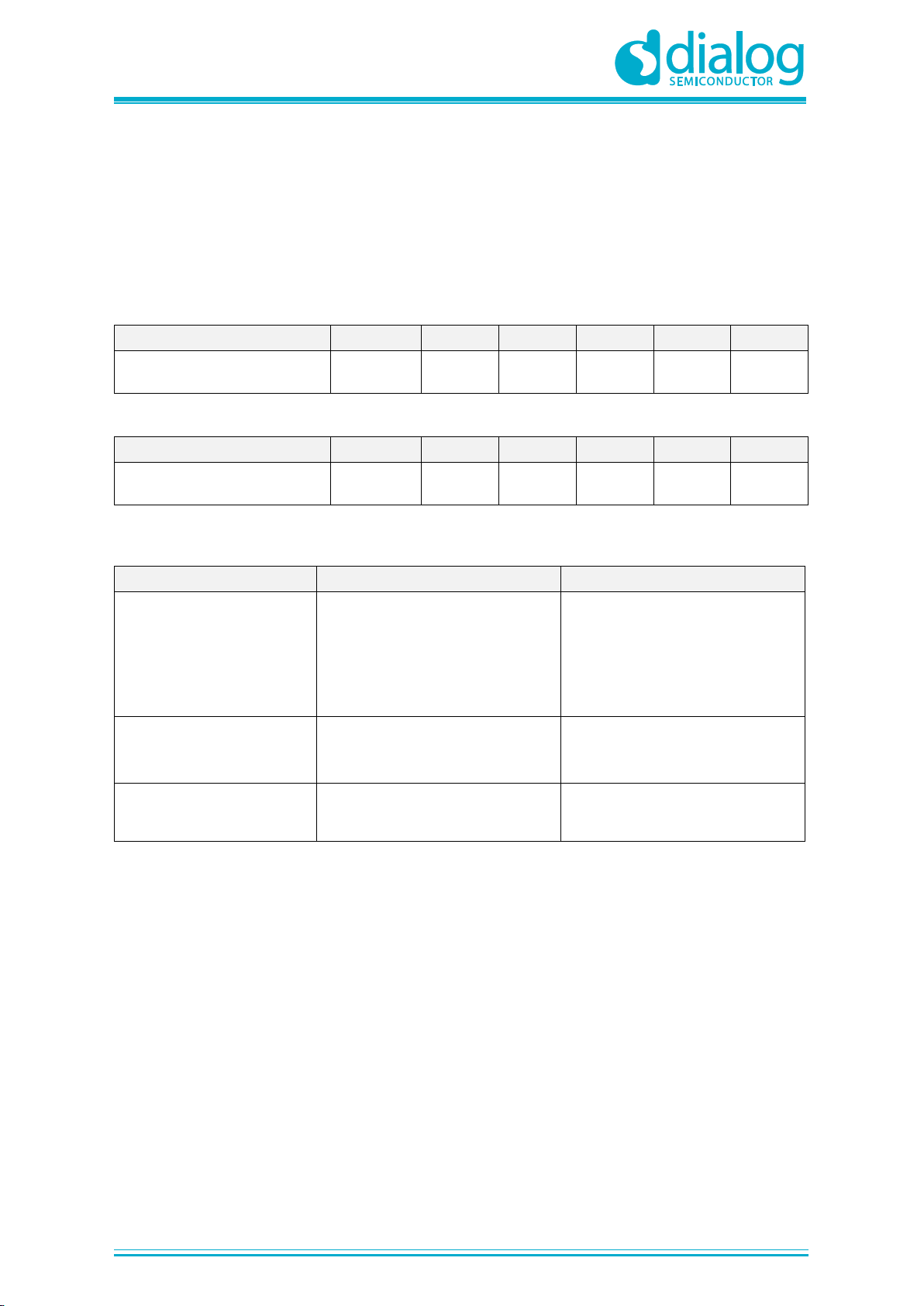

Appendix E SPI Data Flash, JTAG, and Single-Wire UART (Default) ........................................... 69

E.1 DA14531 WLCSP17 PRO-DB and PRO-MB Settings ........................................................ 69

E.2 DA14531 FCGQFN24 PRO-DB and PRO-MB Settings ..................................................... 71

Appendix F Enabling UART, JTAG and 32.768 kHz Crystal .......................................................... 75

F.1 UART (2-wire), JTAG, and 32.768 kHz Crystal .................................................................. 75

F.2 Full UART and JTAG .......................................................................................................... 77

Revision History ................................................................................................................................ 79

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

4 of 80

© 2019 Dialog Semiconductor

Figures

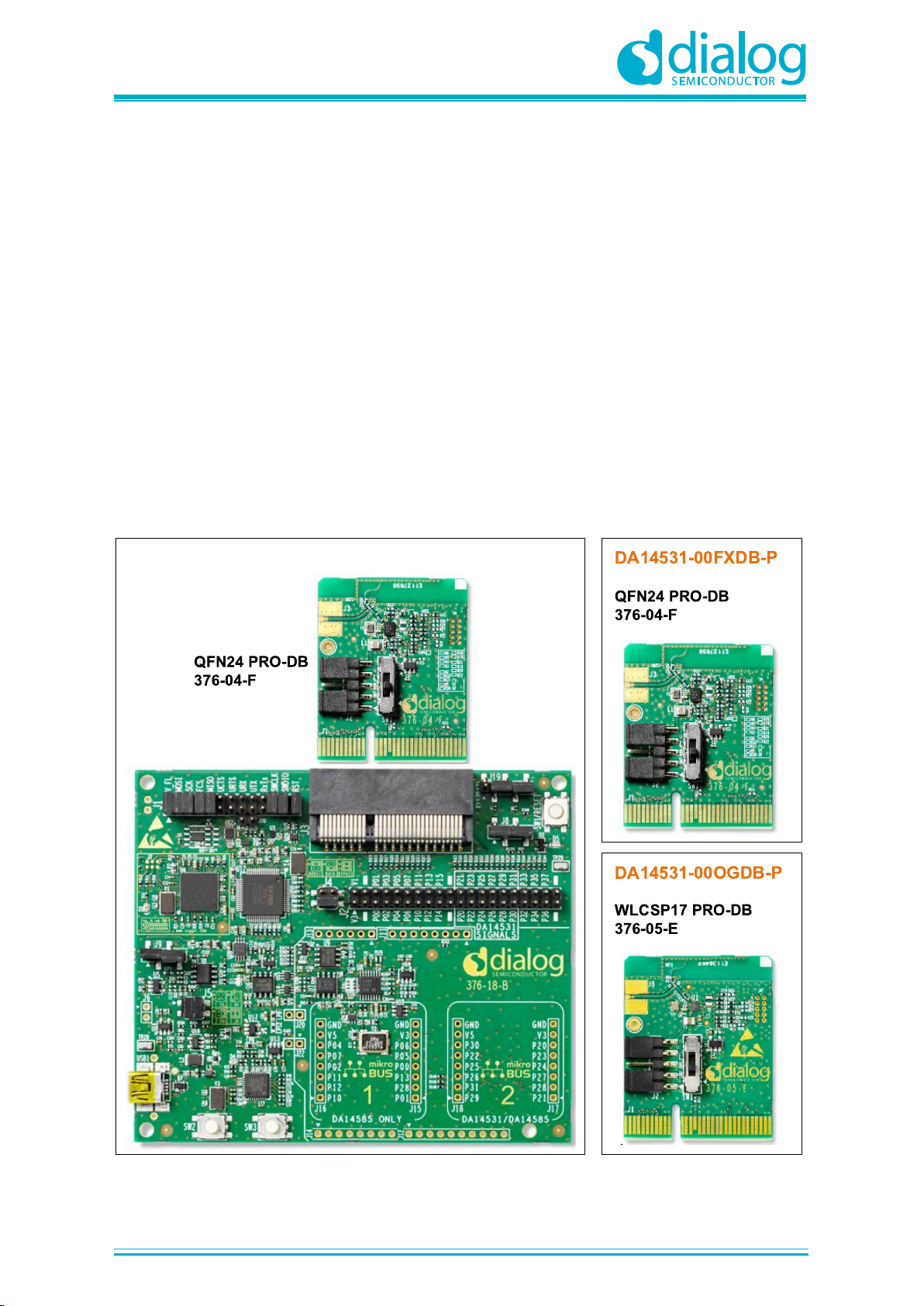

Figure 1:DK PRO, DA14531-00FXDEVKT-P DK with PRO-MB and the PRO-DBs ............................. 8

Figure 2: Block Diagram of the DA14531 DK PRO Hardware Platform .............................................. 10

Figure 3: System Block Diagram of DA14531 PRO-DB ...................................................................... 11

Figure 4: DA14531-00FXDB-P, FCGQFN24 PRO-DB_[376-04-F] ..................................................... 11

Figure 5: DA14531-00OGDB-P, WLCSP17 PRO-DB_[376-05-E] ...................................................... 12

Figure 6: DA14531 PRO-DB Power Section ....................................................................................... 13

Figure 7: Power Section of DA14531 PRO-DB ................................................................................... 14

Figure 8: RF Section of DA14531 PRO-DB ........................................................................................ 15

Figure 9: Modifications Required for Performing RF Measurements .................................................. 15

Figure 10: DA145xx DEVKT-P PRO-MB Block Diagram .................................................................... 16

Figure 11: PRO-MB (376-18-x) ........................................................................................................... 16

Figure 12: USB HUB Circuitry of DA14531 PRO-MB ......................................................................... 18

Figure 13: USB to UART (U12) ........................................................................................................... 19

Figure 14: USB to JTAG (U4) .............................................................................................................. 20

Figure 15: Voltage Translator Circuitry of DA14531 PRO-MB ............................................................ 20

Figure 16: Power Topology for DA14531 PRO-MB and PRO-DB ...................................................... 21

Figure 17: Power Circuit for DA14531 PRO-MB ................................................................................. 21

Figure 18: J2, Breakout Header of DA14531 PRO-MB ....................................................................... 22

Figure 19: J1, Configuration Header on DA14531 PRO-MB ............................................................... 23

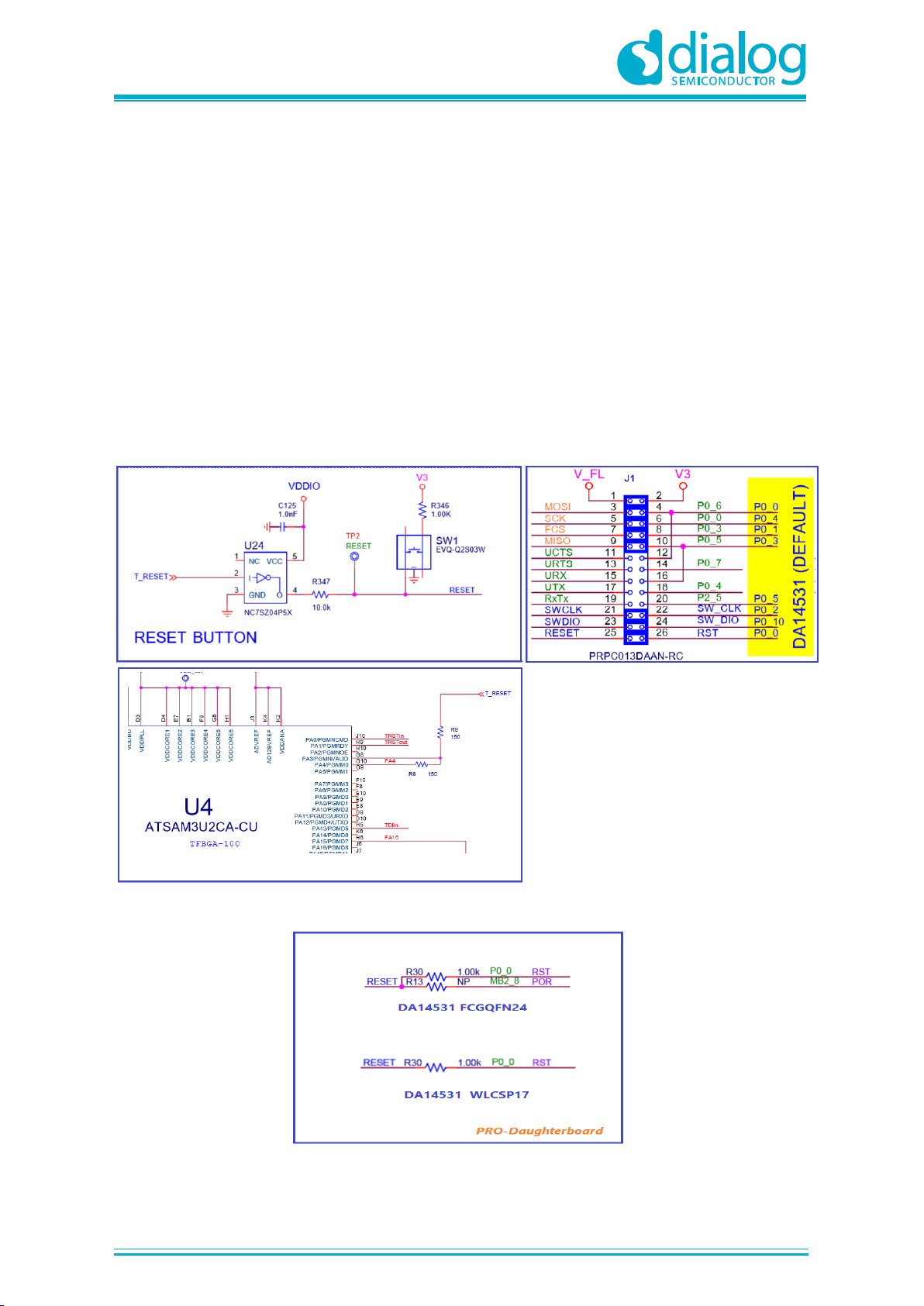

Figure 20: RESET Circuit on DA14531 PRO-MB ............................................................................... 27

Figure 21: Reset Pin Assignment on PRO-DBs for FCGQFN24 and WLCSP17 ............................... 27

Figure 22: Optional Debug Port ........................................................................................................... 28

Figure 23: SPI Data Flash Circuit in DA14531 DK Pro ....................................................................... 29

Figure 24: Single-wire UART for DA14531 WLCSP17 PRO-DB ........................................................ 30

Figure 25: 2-wire UART Connectivity .................................................................................................. 31

Figure 26: Full UART (4-wire) Connectivity ......................................................................................... 32

Figure 27: Miscellaneous Peripherals ................................................................................................. 32

Figure 28: User LED and Software Trigger Circuit and Jumpers ........................................................ 33

Figure 29: MikroBus 2 Circuit .............................................................................................................. 34

Figure 30: DA14531 PRO-DB Configuration and DA14531 PRO-MB Jumpers ................................. 36

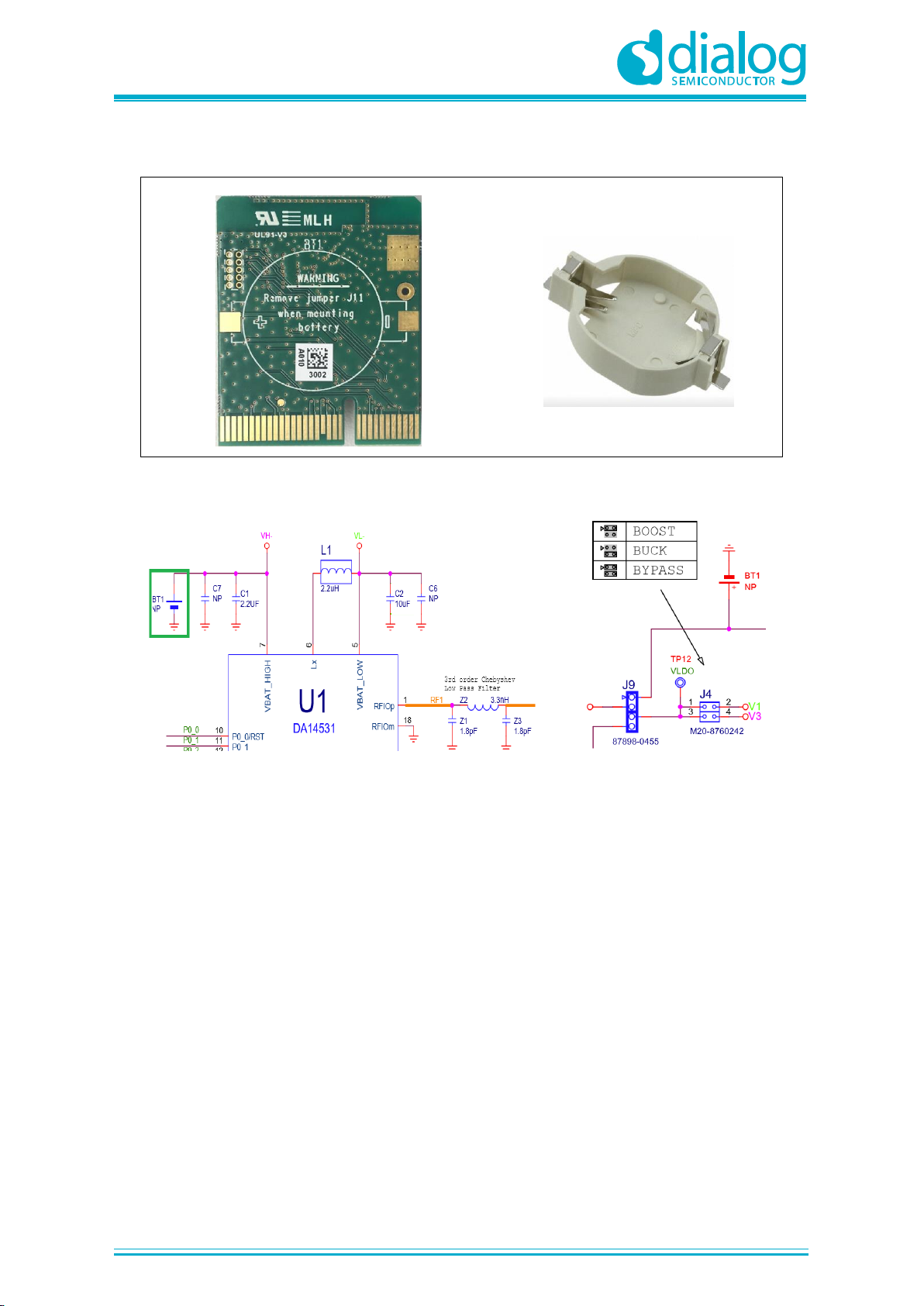

Figure 31: BT1 Position (Left). Battery Holder, BC2032-F1, to Be Soldered (Right) .......................... 38

Figure 32: DA14531 PRO-DB Schematic (Left). DA14531 PRO-MB, Header J4 Settings (Right) ..... 38

Figure 33: BT1 Position on PRO-MB (Left). Battery Holder, BU2032SM-BT-GTR, to Be Soldered

(Right) .................................................................................................................................................. 39

Figure 34: Default Setup of the DA14531 DK PRO with DA14531 FCGQFN24 PRO-DB ................. 40

Figure 35: Default Setup of the DA14531 DK PRO with a DA14531 WLCSP17 PRO-DB ................. 42

Figure 36: Current Measurement Circuit of DA14531 PRO-MB ......................................................... 43

Figure 37: Current Measurement Presented in Power Profiler of SmartSnippets Toolbox ................ 44

Figure 38: SmartSnippets Toolbox Configuration ............................................................................... 45

Figure 39: Hybrid Configuration .......................................................................................................... 45

Figure 40: Power Profiler of SmartSnippets Toolbox Main Window ................................................... 46

Figure 41: Power Profiler Configuration .............................................................................................. 46

Figure 42: Power Profiler Chart Settings ............................................................................................. 47

Figure 43: Free Running Capture ........................................................................................................ 47

Figure 44: Triggered Capture .............................................................................................................. 48

Figure 45: Oscilloscope Option ........................................................................................................... 48

Figure 46: Power Profiler Software Cursors ........................................................................................ 49

Figure 47: Setting Offset to Zero ......................................................................................................... 49

Figure 48: Measuring Offset ................................................................................................................ 50

Figure 49: Setting Calibration Offset ................................................................................................... 50

Figure 50: Current Measurement Circuit Response, Indicative Graph ............................................... 51

Figure 51: Current Measurement Circuit Inaccuracy, Indicative Graph .............................................. 52

Figure 52: A/D Converter Distortions .................................................................................................. 53

Figure 53: Disable SW3. Remove Jumper from J19:4-5 ..................................................................... 53

Figure 54: mikroBUS Wrong Label ...................................................................................................... 54

Figure 55: Full UART Configuration - CTS Issue ................................................................................ 54

Figure 56: Schematic, FCGQFN24, DA14531-00FXDB-P_(376-04-F2) ............................................ 56

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

5 of 80

© 2019 Dialog Semiconductor

Figure 57: Components on Top and Bottom Sides for FCGQFN24, DA14531-00FXDB-P_(376-04-F2)

............................................................................................................................................................. 57

Figure 58: Schematic, WLCSP17, DA14531-00OGDB-P_(376-05-E) ................................................ 58

Figure 59: Components on Top and Bottom Sides for WLCSP17, DA14531-00OGDB-P_(376-05-E)

............................................................................................................................................................. 59

Figure 60: DA14531 PRO-MB, headers and connectors .................................................................... 60

Figure 61: DA14531 PRO-MB, Current Measurement Circuit ............................................................ 61

Figure 62: DA14531 PRO-MB, JTAG MCU ........................................................................................ 62

Figure 63: DA14531 PRO-MB, USB Hub, USB to UART IC, and Power Section .............................. 63

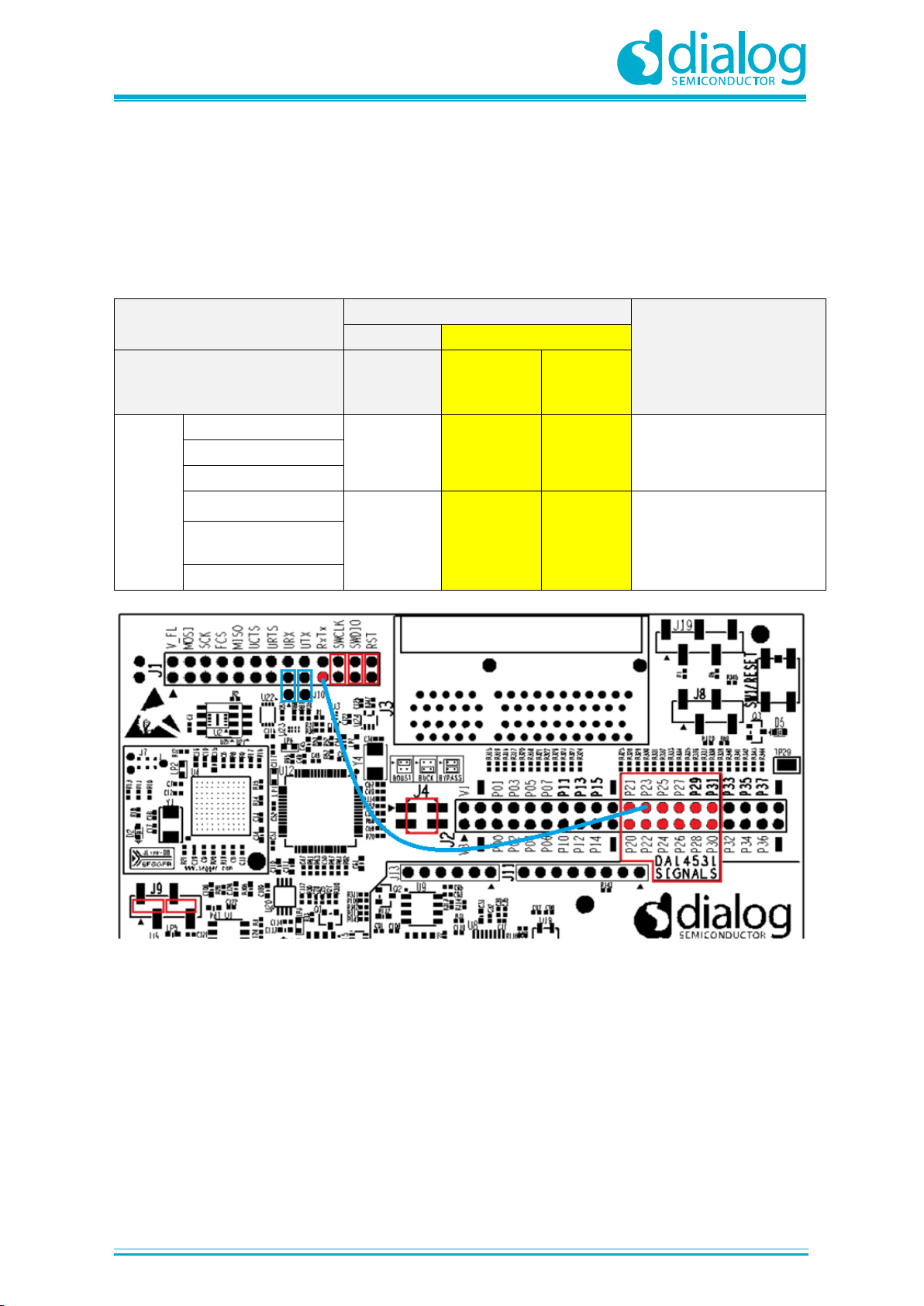

Figure 64: Components on Top Side of DA14531 PRO-MB ............................................................... 64

Figure 65: System Configuration for DA14531 DK PRO with a DA14531 WLCSP17 PRO-DB

(Default) ............................................................................................................................................... 65

Figure 66: System Configuration for DA14531 DK PRO with a DA14531 FCGQFN24 PRO-DB

(Default) ............................................................................................................................................... 67

Figure 67: System Configuration for DA14531 DK PRO with a DA14531 WLCSP17 PRO-DB

(Default) ............................................................................................................................................... 69

Figure 68: Jumper Settings for PRO-MB (Marked in Red) .................................................................. 70

Figure 69: Resistor and Jumper Settings for DA14531 WLCSP17 PRO-DB ...................................... 71

Figure 70: System Configuration for DA14531 DK PRO with a DA14531 FCGQFN24 PRO-DB

(Default) ............................................................................................................................................... 72

Figure 71: Jumper Settings for PRO-MB ............................................................................................. 73

Figure 72: Resistor and Jumper Settings for DA14531 FCGQFN24 PRO-DB ................................... 74

Figure 73: Resistor and Jumper Setting for PRO-MB (Top) and DA14531 PRO-DBs (Bottom) to

Support 2-Wire UART, JTAG, and 32.768 kHz Crystal ....................................................................... 76

Figure 74: Resistor and Jumper Setting for PRO-MB (Top) and DA14531 PRO-DBs (Bottom) to

Support Full UART AND JTAG ........................................................................................................... 78

Tables

Table 1: DK PRO part numbers and description ................................................................................... 9

Table 2: PRO-MB to DA14531 Signal Correspondence and Function Multiplexing ........................... 23

Table 3: DA14531 WLCSP Signals Assignment ................................................................................. 25

Table 4: DA14531 FCGQFN24 PRO-DB and PRO-MB Signals Assignment (Default) ...................... 26

Table 5: Configuration Settings for JTAG In DA14531 DK Pro ........................................................... 28

Table 6: Configuration Settings for SPI Data Flash in DA14531 DK Pro ............................................ 28

Table 7: UART Signals Assignment in DA14531 DK PRO ................................................................. 29

Table 8: Single-wire UART Pin Assignment ........................................................................................ 30

Table 9: 2-wire UART Pin Assignment ................................................................................................ 31

Table 10: Full UART Pin Assignment .................................................................................................. 31

Table 11: Configuration settings for push buttons ............................................................................... 33

Table 12: Configuration settings for miscellaneous peripherals.......................................................... 33

Table 13: mikroBUS 2 Signals ............................................................................................................ 34

Table 14: Arduino Signals ................................................................................................................... 35

Table 15: DA14531 DCDC Configuration and Input Voltage .............................................................. 37

Table 16: Jumper Settings for J9 ........................................................................................................ 37

Table 17: Accuracy of the Current Measurement Circuit .................................................................... 51

Table 18: DA4531 WLCSP17 PRO-DB Default Setup ........................................................................ 66

Table 19: DA4531 FCGQFN24 PRO-DB Default Setup ..................................................................... 68

Table 20: Pin Assignment for DA14531 WLCSP17 PRO-DB ............................................................. 69

Table 21: Pin Assignment for DA14531 FCGQFN24 PRO-DB ........................................................... 69

Table 22: The Components for DA14531 DK PRO in WLCSP17 Package ........................................ 70

Table 23: The Components for DA14531 DK PRO in FCGQFN24 Package ..................................... 73

Table 24: Pin Assignment for DA14531 WLCSP17 PRO-DB ............................................................. 75

Table 25: Pin assignment for DA14531 FCGQFN24 PRO-DB ........................................................... 75

Table 26: The Components for the Two Packages to Support 2-Wire UART, JTAG, and 32.768 kHz

Crystal .................................................................................................................................................. 75

Table 27: Pin Assignment for DA14531 WLCSP17 PRO-DB ............................................................. 77

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

6 of 80

© 2019 Dialog Semiconductor

Table 28: Pin Assignment for DA14531 FCGQFN24 PRO-DB ........................................................... 77

Table 29: The Components for the Two Packages to Support Full UART and JTAG ........................ 77

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

7 of 80

© 2019 Dialog Semiconductor

1 Terms and Definitions

UART Universal Asynchronous Receiver Transmitter

GPIO General Purpose Input Output (pin)

JTAG Joint Test Action Group

RF Radio Frequency

IC Integrated Circuit

PCB Printed Circuit Board

PCBA Printed Circuit Board Assembly

SoC System on Chip

SWD Serial Wire Debug

DK Development Kit

PRO-DB PRO daughterboard

PRO-MB PRO Motherboard

FCGQFN24 PRO-DB PRO daughterboard with DA14531 - FCGQFN24

WLCSP17 PRO-DB PRO daughterboard with DA14531 - WLCSP17

OTP One-Time Programmable Memory

2 References

[1] DA14531, Datasheet, Dialog Semiconductor.

[2] UM-B-083, SmartSnippets Toolbox User Manual, User Manual, Dialog Semiconductor.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

8 of 80

© 2019 Dialog Semiconductor

3 Introduction

This document describes the hardware of DA14531 development kit (DK) PRO. It supersedes the

older DA14580/5 DK PRO, providing a richer feature set and an improved performance. The

DA14531 DK PRO motherboard fully supports DA14585/6 daughterboards, and the DA14531 DK

PRO daughterboards are backwards compatible with the older DA1458x DK PRO motherboard.

However, for a better development experience and a full feature support, it is recommended to use

the newer DA14531 DK PRO motherboard.

In this document we focus on the DA14531 DK PRO which consists of the following two parts:

● PRO-Motherboard

○ PRO-MB: PCBA reference number 376-18-B

● PRO-daughterboard (PRO-DB) (two options, interchangeable)

○ FCGQFN24 PRO-DB: it uses DA14531-FCGQFN24. PCBA reference number 376-04-F,

○ WLCSP17 PRO-DB: it uses DA14531-WLCSP17. PCBA reference number 376-05-E.

Figure 1 and Table 1 present the part numbers (also ordering code) for the DK PRO

DA14531-00FXDEVKT-P

PRO-MB

376-18-B

DK PRO

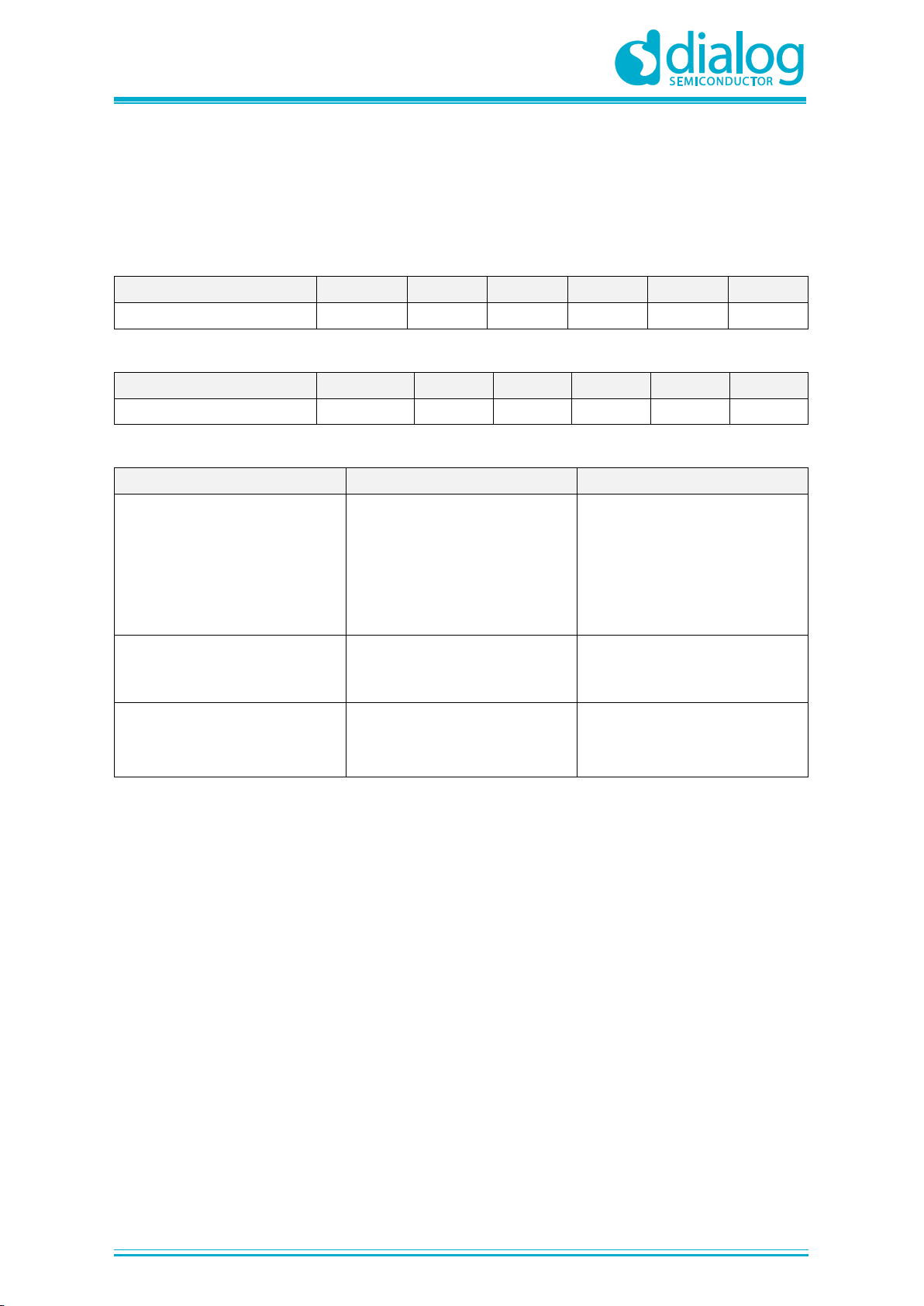

Figure 1:DK PRO, DA14531-00FXDEVKT-P DK with PRO-MB and the PRO-DBs

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

9 of 80

© 2019 Dialog Semiconductor

Table 1: DK PRO part numbers and description

Part number

Description

DA14531-00OGDB-P

WLCSP17 PRO-DB.

Bluetooth Low Energy DA14531 WLCSP17 PRO-daughterboard

DA14531-00FXDB-P

FCGQFN24 PRO-DB

Bluetooth Low Energy DA14531 FCGQFN24 PRO-daughterboard

DA14531-00FXDEVKT-P

DK-PRO

Bluetooth Low Energy Development Kit Pro for DA14531, including PRO-MB

and PRO-DB.

NOTE

When DA14531-00FXDEVKT-P is ordered, the user gets a set of PRO-MB and a FCGQFN24 PRO-DB.

Daughterboard WLCSP17 PRO-DB must be ordered separately.

A single PRO-MB cannot be ordered.

The following sections guide users to understand the system setup, the different available

configuration options, as well as the tools provided to debug, develop, and evaluate the system

performance.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

10 of 80

© 2019 Dialog Semiconductor

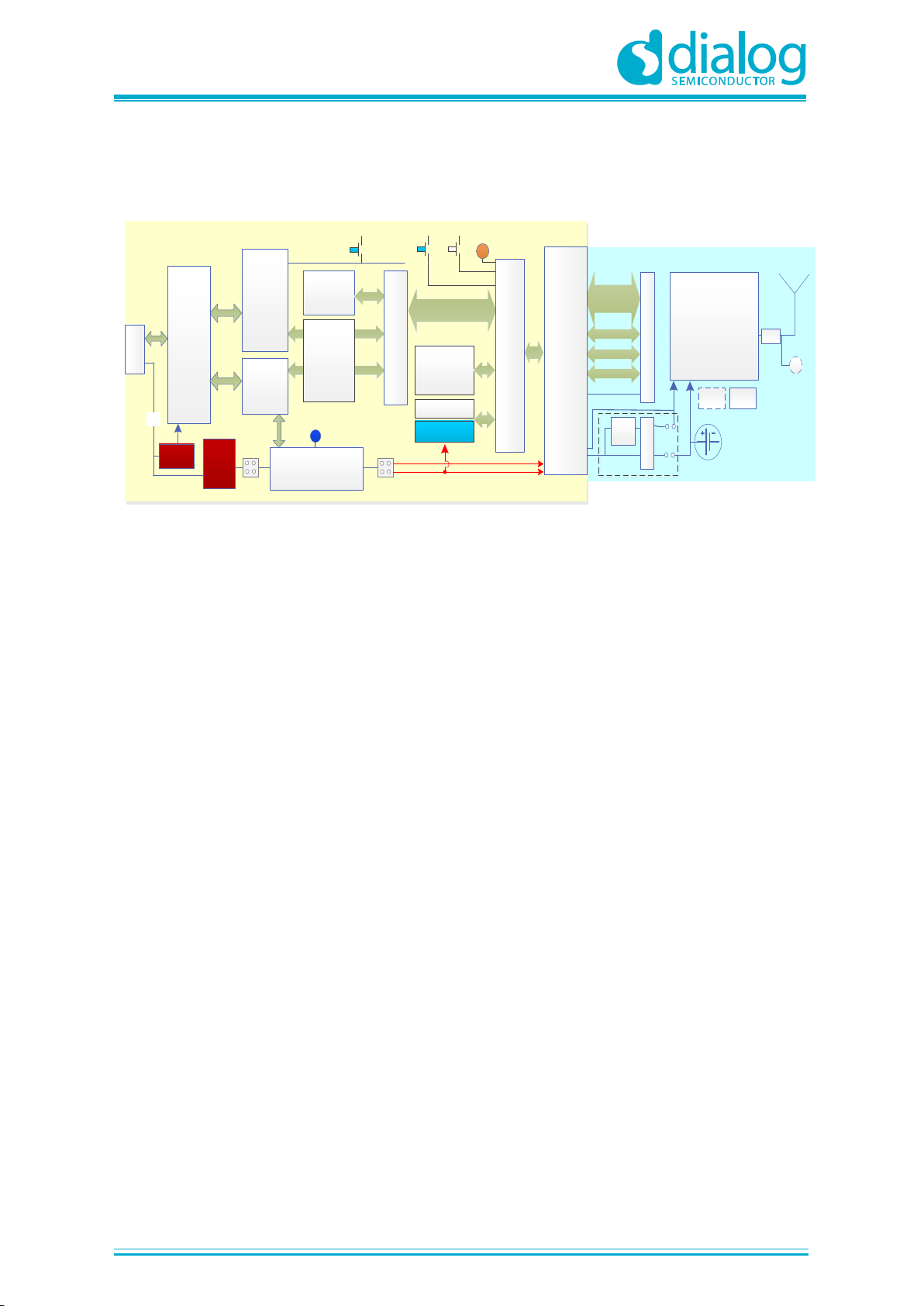

3.1 System Overview

PRO-MB

PRO-DB

UART

bridge

DA14531

BUCK

BOOST

Bypass

Flash

memory

(2Mbit)

32M

3V3

UART

JTAG

RST

VLDO

1.1/1.8/

3.0/3.3V

SMA

JTAG

(SWD)

interface

USB

HUB

Current Sense

circuitry

5V

PRO-MB

LDO

1.1V

R-Multiplexer

Pwr Sw

32K

DA14531

PRO-DB

Level

Translate

J5

J4

SW2 SW3

Mikrobus 1

Mikrobus 2

Arduino

socket

SPI

SW1

D5

UART

JTAG

P2_x

P3_0,1

SPI

MINI B

USB

USB1

V3

V1

SW1

LPF

Config. Header (

J1)

Breakout Header (

J2)

PCI-e connector (J3)

Figure 2: Block Diagram of the DA14531 DK PRO Hardware Platform

3.1.1 Features of DA14531 PRO-DB

● Embedded printed antenna

● RF port output (connector not included)

● DA14531 power mode configuration switch (only for backwards compatibility with DA1458x DK

PRO motherboard)

● Current measurement port to connect external measurement equipment

● Onboard JTAG connector

● Support for coin cell battery (battery holder not included)

3.1.2 Features of DA14531 PRO-MB

● A slot to connect a DA14531 PRO-DB which hosts either the DA14531-FCGQFN24 or the

DA14531-WLCSP17 SoC

● All the power wiring configurations to allow DA14531 PRO-MB to operate in either Buck, Boost,

or Bypass mode

● Dedicated hardware for current measurement that enables Dialog’s SmartSnippets Toolbox

power profiler software as well as any externally connected power measurement device to profile

the power consumption of the system

● Single USB port to provide power and data interfacing to a PC (USB1)

● Onboard JTAG debugger

● Virtual 4-wire UART port

● The DA14531 RESET line is controlled over JTAG by using an onboard push button

● Onboard 2-Mbit SPI data Flash (MX25R2035)

● Multiple voltage options (1.1 V, 1.8 V, 3.0 V, and 3.3V) to supply the DA14531 SoC on the

DA14531 PRO-DB

● Support for coin cell battery (battery holder not included)

● User LEDs and push buttons (to be used with a DA14531 FCGQFN24 PRO-DB)

● Voltage translation for the JTAG and UART signals that allows the current leakage during system

operation to be eliminated

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

11 of 80

© 2019 Dialog Semiconductor

4 Getting to Know DA14531 DK PRO

4.1 DA14531 PRO-DB

The system on DA14531 PRO-DB consists of the DA14531 SoC, crystals, power section, and radio

section. The system block diagram and the actual components location are presented in Figure 3,

Figure 4, and Figure 5.

U1

DA14531

BUCK

BOOST

Bypass

32M

J3

SMA

U2

LDO

1.1V

R-Multiplexer

Pwr Sw

32K

rst

SW1

Y2

Y1

V3

J2

ANT1

V1

LPF

UART

JTAG

P2_x, P3_0,1

spi

VBAT_Hi

VBAT_Lo

J1-mating connector on PCB

R33

2.2uH

10u

2.2u

For DA145xxDEVKT-P

PRO-MB, set SW1 on

BUCK position

Not Mounted

Figure 3: System Block Diagram of DA14531 PRO-DB

ANT1

PCB ANTENNA

R-Multiplexer

J4

Debug

U1

QFN24

Y2

Y1

32MHz

L1, 2.2μF

CLC

Matching

J3

SMA

J2 – Power

Measurements

SW1

U2

LDO

1.1V

J1 – Mating Connector

Figure 4: DA14531-00FXDB-P, FCGQFN24 PRO-DB_[376-04-F]

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

12 of 80

© 2019 Dialog Semiconductor

ANT1

PCB ANTENNA

R-Multiplexer

J4

Debug

U1

Y2

Y1

32MHz

L1,

2.2μF

CLC

Matching

J3

SMA

J2 – Power

Measurements

SW1

U2

LDO

1.1V

J1 – Mating Connector

Figure 5: DA14531-00OGDB-P, WLCSP17 PRO-DB_[376-05-E]

● BLE SoC (U1): DA14531 is an ultra-low power SoC integrating a 2.4 GHz transceiver and an

ARM CortexM0+TM microcontroller with 48 kB of RAM and 32 kB of One-Time Programmable

memory (OTP).

● 32 MHz XTAL (Y1): The main clock of the system is generated from a 32 MHz XTAL which is

connected to the internal clock oscillator. The selected crystal for this reference is the

XRCGB32M000F1H00R0 of Murata.

● 32.768 kHz XTAL (Y2, not assembled by default): A crystal of 32.768 kHz can be placed on

the pins P0_3 and P0_4 of DA14531. A crystal that can be used is the SC20S-7PF20PPM of

SEIKO Instruments.

In most applications the DA14531 can run with good accuracy with its internal RC oscillator

(RCX) and therefore the XTAL32k is not needed. For applications with more demanding

accuracy/drift characteristics, such as timekeeping, using the XTAL32k is considered as a

suitable solution.

By default, Y2 is not assembled on PRO-DB. Internal RC clock is used. P0_3 and P0_4 are

assigned to other SPI data flash (mounted on PRO-MB).

For assembling and utilizing Y2, refer to Appendix F.

● RF section: see section 4.1.2.

● R-Multiplexer: A group of 16 resistors of 0 Ω can be placed/removed as needed in order to

hardwire various peripherals to the DA14531 pins as desired (Appendix D).

To complete a configuration, it is necessary to set/remove jumpers on the DA14531 PRO-MB

accordingly. The default settings are presented in section 5.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

13 of 80

© 2019 Dialog Semiconductor

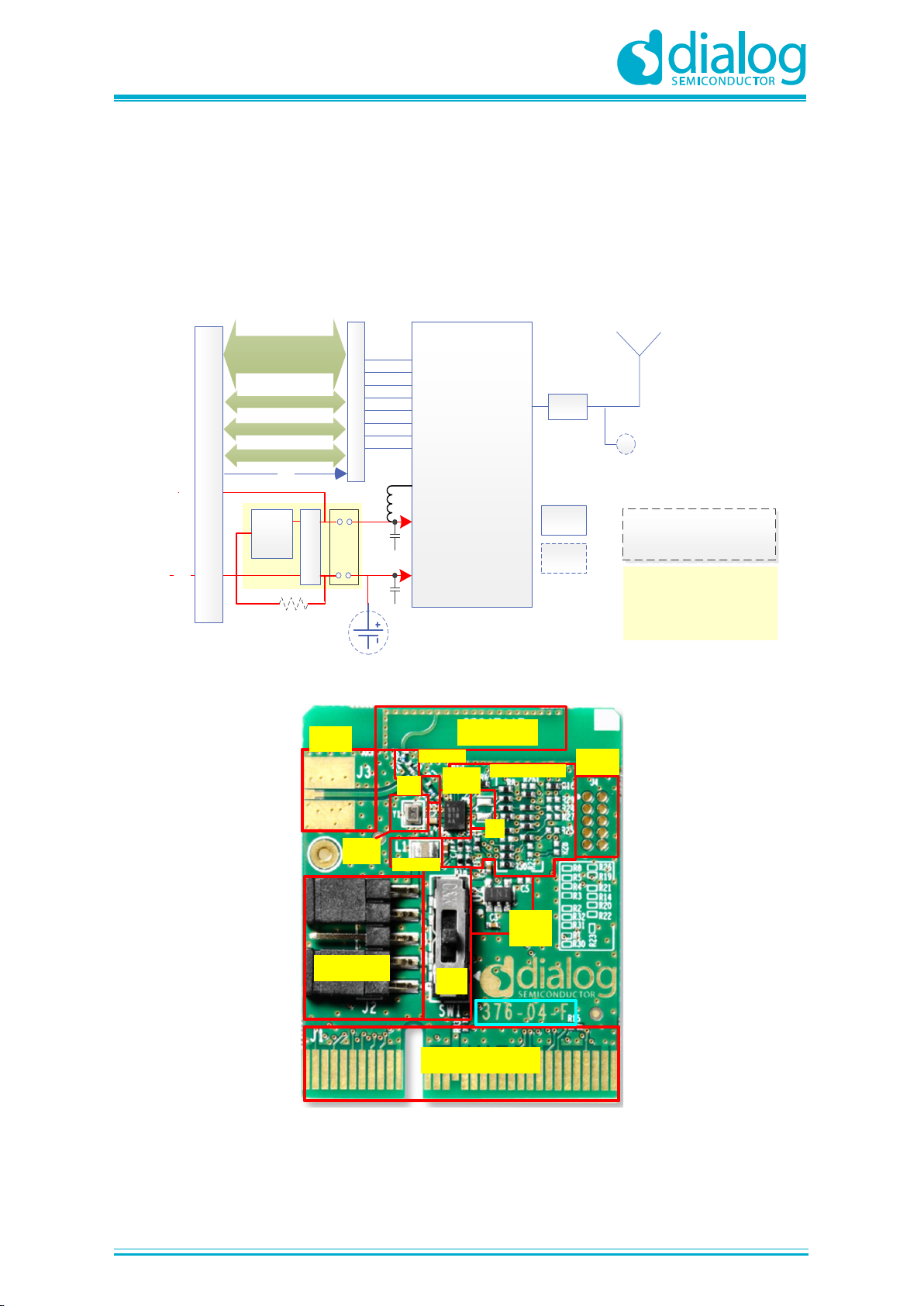

4.1.1 Power Section

The power circuit of DA14531 PRO-DB is designed to support two generations of PRO-MBs:

● PRO-MB: there is no need for the additional circuit. The DCDC power configuration and the

voltage applied to DA14531 SoC are arranged on the PRO-MB (see section 6). In this case, SW1

must be always set to BUCK position.

● In this document the operation with DA14531-00FXDEVKT-P is presented.

U1

DA14531

BUCK

BOOST

Bypass

U2

LDO

1.1V

Pwr Sw

SW1

J2

VBAT_Hi

VBAT_Lo

R33

2.2uH

2.2u

10u

SW1 set to

BUCK Mode

Not

Mounted

V3

V1

NP

PRO-DB

376-04-x

376-05-x

J1-mating connector on PCB

C1

C2

L1

VBAT

Vin

VH-

VL-

Figure 6: DA14531 PRO-DB Power Section

Components:

● U2: it is an LDO which generates V

LDO

= 1.1 V. U2 is supplied from Vin voltage rail and it is

enabled only when SW1 is set for Boost mode. Please notice that the quiescent current of U2 is

measured from the power measurement of PRO-MB. It is disabled for the use with PRO-MB.

● J2: it is used for connecting external power measurement equipment. For current measurements

of sub-μΑ range, users can insert an external equipment. When no external equipment is applied,

jumpers must be applied between 1 and 2 as well as between 4 and 5.

● L1: inductor for the DA14531 DCDC converter in Buck or Boost mode of operation.

● C1: input capacitor for buck mode and output capacitor for boost mode. As input capacitor this

must be equal to 2.2 µF. As an output capacitor, the effective capacitance must be at least 1 μF.

● C2: for the PRO-daughterboard, this capacitor is set to 10 μF.

● SW1: it is a power switch of three positions. Settings:

○ Setting SW1 to position H (Buck) connects the V

BAT_High

and V

BAT_Low

pins of DA14531 to the

voltage rails V1 and V3 of the PRO-MB

○ Setting SW1 to position B (Bypass) connects both V

BAT_High

and V

BAT_Low

pins of DA14531 to

the voltage rail V3 of the PRO-MB

○ Setting SW1 to position L (Boost) connects the V

BAT_Low

pin of DA14531 to the voltage rail

generated from U2 on the PRO-DB

○ For DA14531-00FXDEVKT-P, SW1 must be set to H position (Buck)

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

14 of 80

© 2019 Dialog Semiconductor

U1

L1

U2

C2

C1

VBAT

VL

VH

GND

Figure 7: Power Section of DA14531 PRO-DB

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

15 of 80

© 2019 Dialog Semiconductor

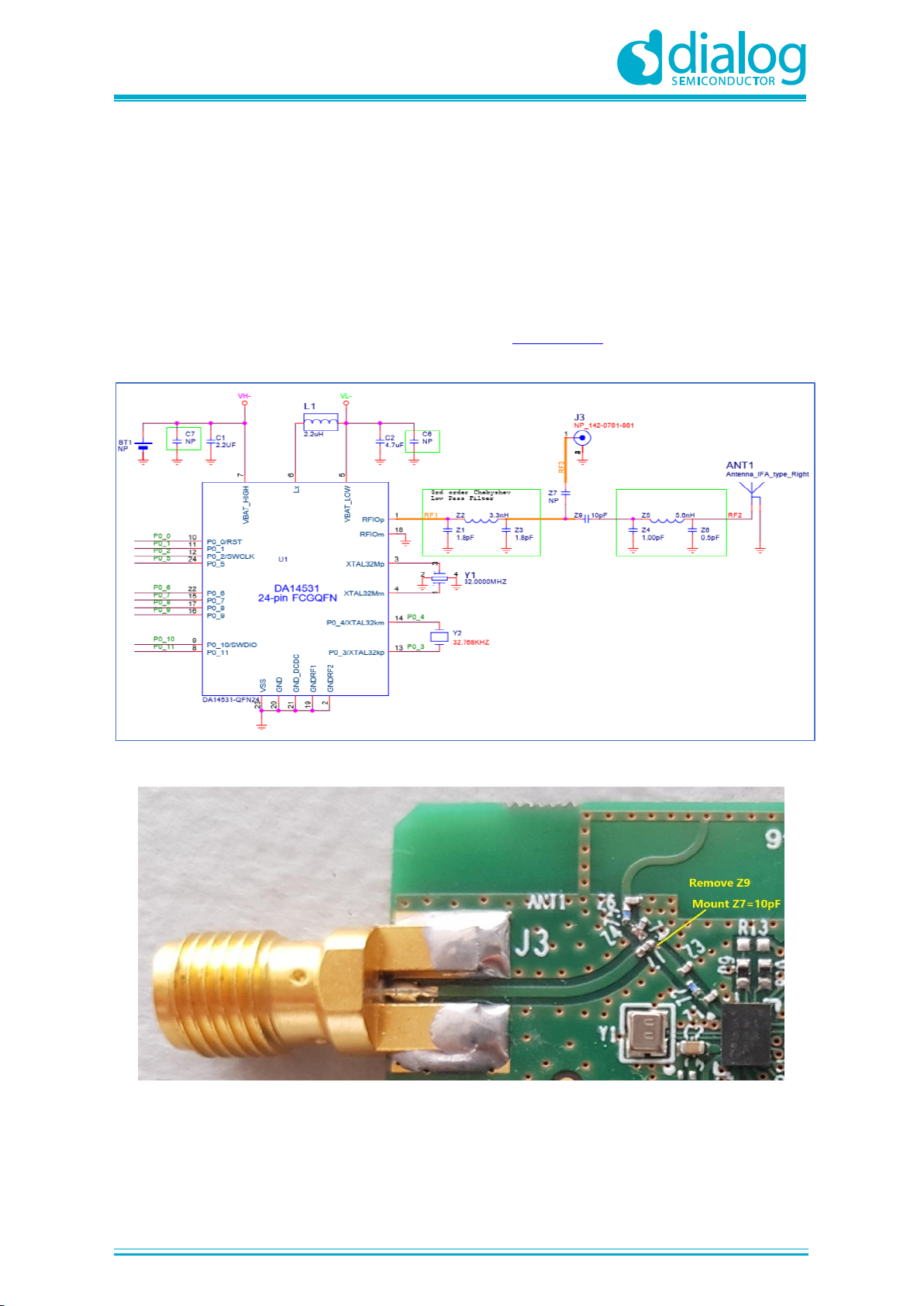

4.1.2 RF Section

A printed F-antenna (ANT1) is used as the radiating element for the DA14531 PRO-DB.

The DA14531 RFIO pin is connected to the printed antenna through a RF stripline and a matching

circuit.

To conduct RF measurements, please proceed with the following hardware modifications (Figure 9):

● Remove Z9

● Assemble Z7 = 10 pF

● Assemble J3, SMA Female Socket 50 Ω Board Edge (142-0761-861 of Cinch Connectivity

Solutions Johnson)

Figure 8: RF Section of DA14531 PRO-DB

Figure 9: Modifications Required for Performing RF Measurements

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

16 of 80

© 2019 Dialog Semiconductor

4.2 PRO-MB (376-18-B)

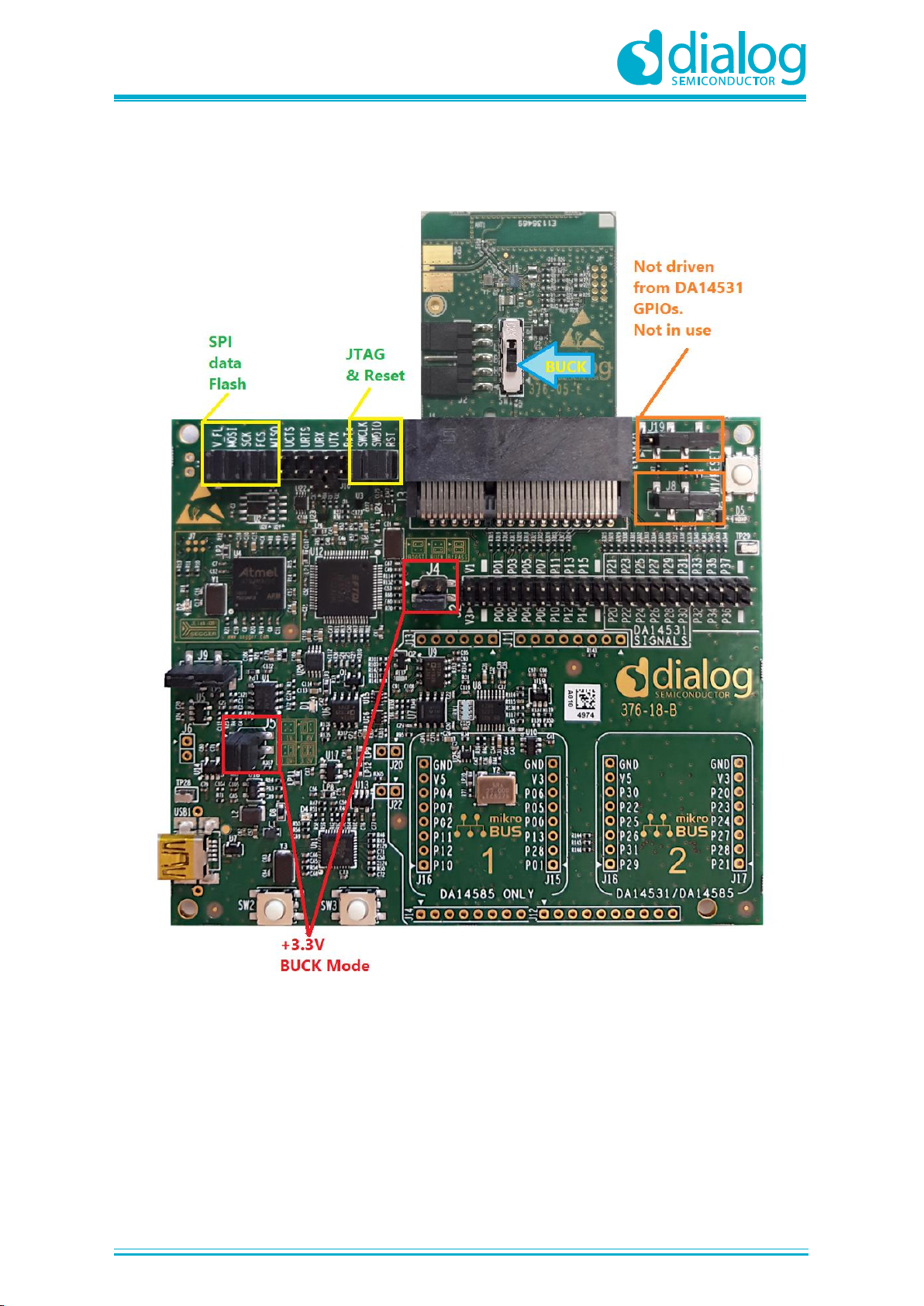

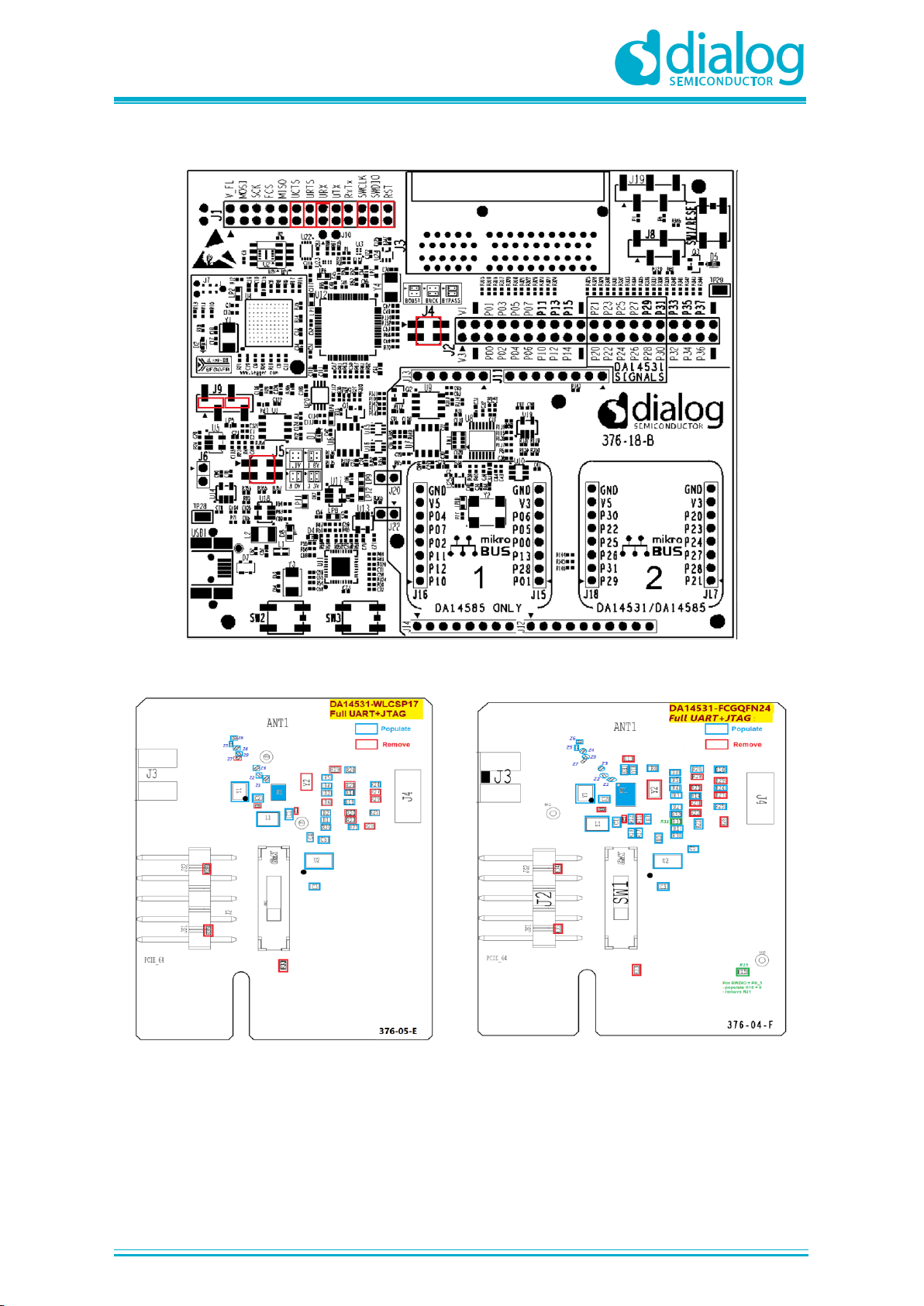

The block diagram and the actual component locations of the PRO-MB of DA14531-00FXDEVKT-P

DK PRO are presented on Figure 10 and Figure 11, respectively.

Figure 10: DA145xx DEVKT-P PRO-MB Block Diagram

PRO-DB

Mating header

(J3)

Push Button

Selection header

(J19)

Configuration Header

(J1)

Current

Sense

(J9)

JTAG MCU

(U4)

UART

MCU

(U12)

Voltage

Translator

FLASH

(U2)

VLDO (U5)

VLDO

Selection

(J5)

USB

Connector

(USB1)

GND

GND

GND

User LED &

SW Trigger

(J8)

RESET

Push Button

(SW1)

DA145xx GPIO

Monitoring Header

(J2)

Dialog

Semiconductor

PCB Number

MIKROBUS 2

(J17, J18)

MIKROBUS 1

(J15, J16)

ARDUINO

(J11, J12, J13,

J14)

KEYS

(SW2 & SW3)

DA14531 DCDC

config selection

(J4)

USB HUB

(U11)

Current

Sense Circuit

Figure 11: PRO-MB (376-18-x)

U12

FTDI

UART

U2

Flash

MX25R2 035

3V3

24M

UART

JTAG

RST

VLDO

U4

MCU

with

Segger

JTAG

U11

USB

HUB

Current Sense

circuitry

12M

24M

5V

27M

DA145xxDEVKT-P PRO-MB

J1

Level

Translation

J5

J4

SW2 SW3

Mikrobus 1

Mikrobus 2

Arduino

socket

J3

J2

SPI

SW1 D5

MINI B

USB

USB1

V3

V1

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

17 of 80

© 2019 Dialog Semiconductor

● USB Hub (U11): connects JTAG and UART interfaces to the PC.

● USB to UART (U12): provides communication between DA14531 UART port and PC. It also

transfers the current measurement samples to PC.

● USB to JTAG (U4): provides communication between DA14531 JTAG and PC.

● USB Connector (USB1): mini-USB connector for power supply and data interfacing to the PC.

● Configuration Header (J1): wiring of the available peripherals to the DA14531 pins is done with

the help of jumpers on J1 (for default configurations) or with jumper wires from J1 to J2 when

custom pin assignments of the peripherals to DA14531 pins are desired.

● DCDC Configuration (J4): selects either Boost, Buck, or Bypass mode for DA14531.

● PRO-DB Mating Header (J3): a connector that accepts the DA145xx PRO-DB board.

● Push Button Selection Header (J19): configures the assignment of onboard push buttons to

certain DA14531 pins.

● Reset Push Button (SW1): push button used to reset DA14531.

● User LED and C-Trig (J8): enables use of the onboard LED (D5) and the software cursor, see

section 5.3.6

● GPIO Monitoring Header (J2): exposes all the pins of the PRO-DB to allow wiring for custom

configurations as well as monitoring of the hardware signals.

● ARDUINO: socket for plugging in an Arduino board. It consists of J11, J12, J13, and J14. It is

multiplexed with mikroBUS (to be used with DA14531-FCGQFN24).

● MikroBUS1 (J15 and J16): the first socket for plugging a mikroBUS click.

● MikroBUS2 (J17 and J18): the second socket for plugging a mikroBUS click.

● Push Buttons (SW2 and SW3): general use push buttons.

● VLDO Selection (J5): selects the output voltage generated for the PRO-DB board (1.1 V, 1.8 V,

3.0 V, or 3.3 V)

● Current Sense Circuit: monitors the current of PRO-DB. It is described in section 8.1.

● Current Sense (J9): enables the current sense circuit (jumpers mounted by default). Also, it

allows the simultaneous connection of an external current measurement instrument in order to

measure and profile the current consumption of D14531.

● RxTx Single Wire UART (J10): Generates RxTx single wire UART by shorting UTX and URX

through a 1 KΩ resistor. Jumpers must be applied to from J10.1 to J1.15 and to from J10.2 to

J15.17.

● J6: manual enable of USB hub voltage regulator. Not in use by default.

● J20: monitoring current sense circuit. Not mounted. No functional use.

● J22: it can provide 6.0 V to PRO-DB. Not mounted. No functional use.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

18 of 80

© 2019 Dialog Semiconductor

4.2.1 USB HUB (U11)

The USB HUB of DA14531 PRO-MB is implemented by U11, USB2512B. This chip is supplied with

3.3 V from U13.

The signal PWR_ENABLE is generated from U11 and it is an active high signal. It enables the power

components (LDOs and DCDC converter) for UART, JTAG, and the current sensing circuit. The

system will power up only after the USB HUB has enumerated properly.

Its operation is indicated via the green LED D4 on DA14531 PRO-MB. A 24 MHz crystal (Y3) is

required for the chip operation.

Figure 12: USB HUB Circuitry of DA14531 PRO-MB

4.2.2 USB to UART (U12)

The USB to UART function is implemented by U12, FT2232HL. This chip is supplied with 3.3 V from

U14. A 12 MHz crystal (Y4) is required for the chip operation.

Functions served by U12 are the following:

● Connecting a PC to the UART port of DA14531 SoC

● Connecting a PC to the current sensing circuitry:

○ SPI connection with ADC (U8)

○ Software cursor triggering (C_TRIG)

● Reset capability of the DA14531 SoC through the T_RESET signal (not enabled)

R55 330

TP74

VBUS1

USBDP

R49 100.0K

R50 100.0K

TP20

PWR_EN

R56 100.0K

C59

100nF

C63 18pF

R60 10.0k

C66

100nF

R66 10.0k

USB2512B-AEZG

U11

USBDM_DN1

1

USBDP_DN1

2

USBDM_DN2/PRT_DIS_M2

3

USBDP_DN2/PRT_DIS_P2

4

VDD33_1

5

NC16NC27NC38NC4

9

VDD33_2

10

TEST

11

PRTPWR1/BC_EN1

12

OCS_N1

13

CRFILT

14

VDD33_3

15

PRTPWR2/BC_EN2

16

OCS_N2

17

NC518NC619NC720NC8

21

SDA/NON_REM1/SMBDATA

22

VDD33_4

23

SMBCLK/CFG_SEL0/ SCL

24

HS_IND/CFG_SEL1

25

RESET_N

26

VBUS_DET

27

SUSP_IND /LOCAL_PWR/NON_REM0

28

VDD33_5

29

USBDM_UP

30

USBDP_UP

31

XTALOUT

32

XTALIN/CLKIN

33

PLLFILT

34

RBIAS

35

VDD33_6

36

GND

GND

Y3

24.0000MHZ

C62

100nF

R46

10.0k

D4

Led_Green

2 1

R59 NP

R64 NP

R48

100.0K

L1

CMC 400MA

1

4

2

3

R47

100.0K

C56

100nF

C64 18pF

R58 10.0k

C65

1.0uF

R51

100.0K

R62 NP

VDD_3V3_HU B

VBUS_HUB

VDD_3V3_HU B

VBUS_HUB

R124 NP

USBDM

USBDM_2

USBDP_2

USB HUB

R129 1.00K

C58

100nF

1

2

3

4

5

USB1

USBDP_1

USBDM_1

D7

PRTR5V0U2X,215

GND

1

IO1

2

IO2

3

VCC

4

TP36

USBLED

C73

100nF

C69

100nF

C72

100nF

C68

100nF

C70

100nF

C71

100nF

VDD_3V3_HU B

R54 12.0k

PWR_ENABLE

C57

4.7uF

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

19 of 80

© 2019 Dialog Semiconductor

Figure 13: USB to UART (U12)

4.2.3 USB to JTAG (U4)

The USB to JTAG function is implemented by U4, SAM3U2CA. On the ROM of U4, software from

SEGGER is loaded. Its operation is indicated via the green LED D2 on the DA14531 PRO-MB. This

chip is supplied with 3.3 V from U14. U14 is enabled by the PWR_ENABLE signal.

Functions served by U4 include:

● Connecting a PC to the JTAG port of DA14531 SoC

● Reset capability of the DA14531 SoC through the T_RESET signal

OSC_EN

TP58

OSC_EN

R152 51 TP64

BCBUS5

TP59

BCBUS7

R114 51

R61 51

AD_SCLK

R63 51

AD_DI

AD_MODE

AD_DO

R68 51

AD_SYNC

R67 51

Y4

12.0000MHZ

R81 NP

C74

18pF

C67

18pF

C55

100nF

C54

10uF

T_RESET

C46

100nF

C45

10uF

3.3V

3.3V

LP6

500mA_470 OHM

C48

100nF

C47

100nF

C49

100nF

VREG

C50

100nF

C51

100nF

C52

100nF

C53

100nF

R65

1.00K

AD_DRDY

3.3V

R82 51

3.3V

C61

4.7uF

C60

100nF

R52 33

R53 33

TP18

VREG

R57

12.0k

LP7

500mA_470 OHM

U12

FT2232HL

VPHY

4

OSCO

3

OSCI

2

AGND

10

DM

7

DP

8

TEST

13

VPLL

9

VCORE12VCORE37VCORE

64

VCCIO20VCCIO31VCCIO56VCCIO

42

GND1GND5GND11GND15GND25GND35GND47GND

51

ADBUS0

16

ADBUS1

17

ADBUS2

18

ADBUS3

19

ADBUS4

21

ADBUS5

22

ADBUS6

23

ADBUS7

24

ACBUS0

26

ACBUS1

27

ACBUS2

28

ACBUS3

29

ACBUS4

30

ACBUS5

32

ACBUS6

33

ACBUS7

34

BDBUS0

38

BDBUS1

39

BDBUS2

40

BDBUS3

41

BDBUS4

43

BDBUS5

44

BDBUS6

45

BDBUS7

46

BCBUS0

48

BCBUS1

52

BCBUS2

53

BCBUS3

54

BCBUS4

55

BCBUS5

57

BCBUS6

58

BCBUS7

59

VREGIN

50

VREGOUT

49

RESET

14

PWREN

60

SUSPEND

36

EECS

63

EECLK

62

EEDATA

61

REF

6

U_CTS

U_RTS

U_TX

U_RX

To

voltage

translator

(UART)

To U11

USB HUB To current

sense

USB SERIAL/SPI INTERFACE

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

20 of 80

© 2019 Dialog Semiconductor

Figure 14: USB to JTAG (U4)

4.2.4 Voltage Translator

● Voltage translation is applied to the UART and JTAG signals. The voltage translation is from 3.3

V to V

DDIO

and vice versa.

● V

DDIO

is generated from U1A, where V3 (V

BAT_HIGH

) is used as a reference. Consequently, there is

no additional power consumption on the power circuitry of DA14531 PRO-MB due to voltage

translation.

Figure 15: Voltage Translator Circuitry of DA14531 PRO-MB

R8 150

R12

10.0k

TP1

VDD_CR

C6

100nF

R11

10.0k

LP2

500mA_470 OHM

VBUS_HUB

R14 150

R10

10.0k

C18 18pF

C7

100nFC8100nF

TP3

C16 10nF

C17 18pF

TP9

DBLED

C9

100nF

R13

100.0K

C10

100nF

TP8

C11

100nF

R19 39

C14

10uF

R21

6.8k

C19

10pF

C12

100nF

R20 39

C15

10uF

TP6

C13

100nF

J7

TagConnect

1 2

3 4

5 6

TP7

TP10

TP5

TFBGA-100

ATSAM3U2CA-CU

U4

XIN

A2

XOUT

A3

XIN32

A10

NRST

B7

XOUT32

B10

TMS/SWDIO

C7

NRSTB

C8

JTAGSEL

C9

TST

D7

FWUP

D8

TCK/SWCLK

A7

TDO/TRACESWO

B8

TDI

B9

ERASE

D6

VBG

A1

DFSDP

C1

DHSDP

C2

VDDBU

C10

DFSDM

D1

DHSDM

D2

VDDPLL

D3

VDDCORE1

D4

VDDIO3

E6

VDDCORE2

E7

VDDIO1F3VDDIO2

F5

VDDCORE4F9VDDCORE5G5VDDCORE6

H1

ADVREF

J3

VDDANA

K2

AD12BVREF

K4

PB17

A4

PB21

A5

PB23

A6

VDDIN

A8

VDDOUT

A9

VDDCORE3

B1

GNDUTM I

B2

VDDUTM I

B3

PB10

B4

PB18

B5

PB24

B6

GNDPLL

C3

PB14

C4

PB19

C5

PB22

C6

PB20

D5

PA11/PGMD3/URXD

D9

PA12/PGMD4/UTXD

D10

PA29

E1

GND2

E2

PA28

E3

PB9

E4

GNDBU

E5

PA10/PGMD2

E8

PA9/PGMD1

E9

PA8/PGMD0

E10

PB1

F1

PB12

F2

PA31

F4

GND1

F6

PB16

F7

PA6/PGMM2

F8

PA7/PGMM3

F10

PB11

G1

PB2

G2

PB0

G3

PB13

G4

GND3

G6

PB15

G7

PA3/PGMNVALID

G8

PA5/PGMM1

G9

PA4/PGMM0

G10

PB5

H2

PA27

H3

PA22/PGMD14

H4

PA13/PGMD5

H5

PA15/PGMD7

H6

PA18/PGMD10

H7

PA24

H8

PA1/PGMRDY

H9

PA2/PGMNOE

H10

PB6

J1

PB8

J2

PA30

J4

PB3

J5

PA16/PGMD8

J6

PA19/PGMD11

J7

PA21/PGMD13

J8

PA26

J9

PA0/PGMNCMD

J10

PB7

K1

GNDANA

K3

PB4

K5

PA14/PGMD6

K6

PA17/PGMD9

K7

PA20/PGMD12

K8

PA23/PGMD15

K9

PA25

K10

VDD_3V3_PERF

VDD_CORE VDD_3V3_PERF

VDD_3V3_PERFVDD_CORE

VDD_CORE

VDD_3V3_PERF

VDD_3V3_PERF

TP4

XOUT

USB_DP

PA15

PA18

VDD_3V3_PERF

DFSDM

PA22

DFSDP

VBG

TDIin

PA29

PA4

To VDDBU

NRSTB

FWUP

TCK/SWCLK

TRSTout

TRSTin

PA17

TDIout

TRSTout

TRSTin

Needed for Segger software

NRST

TDIout

TDIin

NRST

TDI

For programming SAM3U2C

ERASE

XIN

SWO/TDO

A_D4_2

NRST

TP76

SWDIO

TP77

SWCLK

D2

Led_Green

21

R18

330

TMS/SWDIO

T_SWCLK

T_SWDIO

T_RESET

R9

150

USBDP_1

USBDM_1

Y1

12.0000MHZ

R16 150 R17 100

R15 100

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

21 of 80

© 2019 Dialog Semiconductor

4.2.5 Power Section

● The DA14531 SoC in the DA14531 PRO-MB is supplied from the V

LDO

voltage rail generated

from U5, LDO.

● V

LDO

can be set to four different voltage levels. This is arranged by J5 settings.

● Generated power flows through the current sensing circuit to the DA14531 PRO-DB power

supply pins:

○ V1 is connected to V

BAT_LOW

○ V3 is connected to V

BAT_HIGH

● By applying proper jumpers on header J4, users can enable buck, boost, or bypass mode of

operation for the DA14531 DCDC converter.

● For power configuration settings, refer to section 6.

VLDO

U5

U1

DA14531

BUCK

BOOST

Bypass

U2

LDO

1.1V

Pwr Sw

SW1

J2

VBAT_Hi

VBAT_Lo

R33

2.2uH

2.2u

10u

Set SW1

for BUCK

Not

Mounted

V3

V1

NP

PRO-MB

376-18-B

PRO-DB

376-04-F

376-05-E

J1-mating connector on PCB

C1

C2

L1

VBAT

Vin

Current

Sense

circuitry

J5

J4

VLDO

J9

Figure 16: Power Topology for DA14531 PRO-MB and PRO-DB

Figure 17: Power Circuit for DA14531 PRO-MB

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

22 of 80

© 2019 Dialog Semiconductor

5 GPIOs and Pin Assignment and Functions of DA14531 DK PRO

All signals of the DA14531 PRO-DBs are provided to DA14531 PRO-MB. The signal names are

specific for the PRO-MB and do not have the same names as the signals of the PRO-DBs. The

reason is that the PRO-MB can be used for both DA14531 SoC and DA1458x family of SoCs,

whereas DA14531 SoC has fewer pins than DA1458x SoCs.

Please note that signals of DA14531 SoC (P0_0 to P0_10) are provided to ports 2 and 3 of the PROMB (P2_0 to P2_9, P3_0, and P3_1). So, on the breakout header J2 of the PRO-MB, the pins of

DA14531:

● P0_0 to P0_11 are mapped to P2_x, P3_0 and P3_1 for FCGQFN24

● P0_0 to P0_5 are mapped to P2_0 to P2_5 for WLCSP17

Figure 18: J2, Breakout Header of DA14531 PRO-MB

Due to the low GPIO count, function multiplexing is applied. Every function of the DA14531 DK PRO

is practically dependent on the PRO-MB GPIO configuration, as the configuration of the PRO-DB

requires soldering and de-soldering of resistors.

The PRO-MB configuration is realized with jumpers or cables. J1 on the PRO-MB is the main

configuration header (Figure 19).

PRO-DB configuration is also feasible. Please refer to Appendix D.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

23 of 80

© 2019 Dialog Semiconductor

Figure 19: J1, Configuration Header on DA14531 PRO-MB

The DA14531 PRO-DB GPIO pin assignment as well the configuration settings for the GPIOs of the

PRO-MB are presented below. The DA14531 DK PRO signals connectivity is depicted in the Table 2

where the GPIOs of DA14531 PRO-DB are mapped to the breakout header (J2) and the

configuration header (J1) of PRO-MB.

Table 2 also presents the available functions for every GPIO of DA14531.

Table 2: PRO-MB to DA14531 Signal Correspondence and Function Multiplexing

PRO_MB

Signals

DA14531 PRO-DB

Function 1

Function 2

Function 3

Signals

J2

FCGQFN24

WLCSP17

Enabled by J1

Settings

mikroBUS & Arduino

(MBUS & ARD)

Enabled by

Jumpers

P0_0

P0_4

P0_4

SCK

J1:5-6

(Default)

SCK_1

MBus1/ARD

P0_1

No available pins from

DA14531

AN_1

MBus1/ARD

P0_2

TX_1

MBus1/ARD

P0_3

P0_1

P0_1

FCS

J1:7-8

(Default)

A2

ARD

P0_4

P0_0

P0_0

UTX

J1:17 to

J2:21

(cable)

SDA_1

MBus1/ARD

P0_5

P0_3

P0_3

MISO

J1:9-10

(Default)

MISO_1

MBus1

URX

J1:15-16

P0_6

P0_0

P0_0

MOSI

J1:3-4

(Default)

MOSI_1

MBus1

SW2

J19:1-2

UCTS

J1:11-12

P0_7

P0_4

P0_4

URTS

J1:13 to

J2:25

(cable)

SCL_1

MBus1/ARD

SWCLK

P0_2

P0_2

SWCLK

J1:21-22

(Default)

SWDIO

P0_10

P0_5

SWDIO

J1:23-24

(Default)

P1_0

P0_9

PWM_1

MBus1/ARD

LED

J8:1-2

(Default)

P1_1

P0_10

RX_1

MBus1/ARD

SW3

J19:4-5

P1_2

No Available pins from

DA14531

INT_1

MBus1/ARD

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

24 of 80

© 2019 Dialog Semiconductor

PRO_MB

Signals

DA14531 PRO-DB

Function 1

Function 2

Function 3

Signals

J2

FCGQFN24

WLCSP17

Enabled by J1

Settings

mikroBUS & Arduino

(MBUS & ARD)

Enabled by

Jumpers

P1_3

P0_11

CS_1

MBus1

CTRIG

J8:3-4

(Default)

P2_0

P0_0

P0_0

RST

J1: 25-26

(Default)

MOSI_2

MBus2

P2_1

P0_1

P0_1

AN_2

ARD

P2_2

P0_2

P0_2

SCL_2

MBus2/ARD

P2_3

P0_3

P0_3

MISO_2

MBus2

P2_4

P0_4

P0_4

SCK_2

MBus2

P2_5

P0_5

P0_5

RxTx

J1:19-20

TX_2

MBus2/ARD

J10:1 to

J1:15

J10:2 to

J1:17

P2_6

P0_6

RX_2

MBus2/ARD

P2_7

P0_7

CS_2

MBus2/ARD

P2_8

P0_8

SDA_2

MBus2/ARD

P2_9

P0_9

PWM_2

MBus2

P3_0

Note1

BRSTn

MBus1,2/ARD

P3_1

P0_11

INT_2

ARD

SW2

J19:2-3

(Default)

P3_2

No available pins from

DA14531

D2

ARD

P3_3

D3

ARD

P3_4

D4

ARD

P3_5

D5

ARD

P3_6

D6

ARD

P3_7

D7

ARD

Note 1 P3_10 is assigned to P0_10 (SWDIO) through the resistor R11 on DA14531 FCGQFN24 PRO-DB.

R11 is not populated.

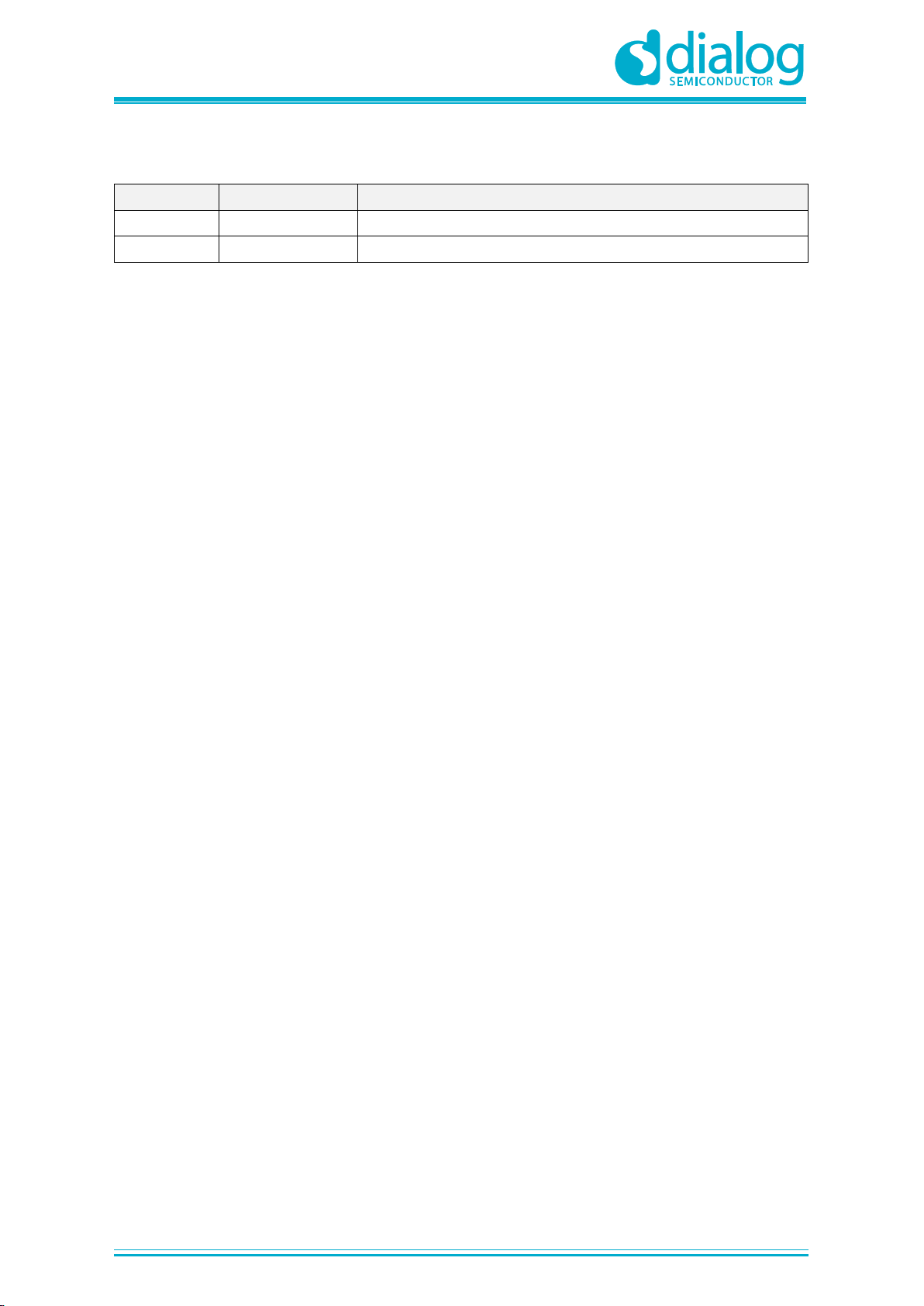

5.1 DA14531 WLCSP17 PRO-DB, Default Setup

● The default configuration of D14531 WLCSP17 PRO-DB is:

○ Reset

○ JTAG and SPI data flash

● Dual UART or full UART are not enabled. To enable UART, refer to section 5.3.4

● Crystal 32.768 kHz is not enabled. To enable the crystal 32.768 kHz, refer to section F.1

● Resistor matrix for DA14531 WLCSP17 PRO-DB (and DA145xx-DEVKT-P PRO-MB signals are

presented in E.1.

● Please note that signals of DA14531 WLCSP17 PRO-DB are renamed on PRO-MB. The reason

is that PRO-MB can be used for the PRO-DBs of DA1458x family

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

25 of 80

© 2019 Dialog Semiconductor

● For detailed description of the connection capabilities of DA14531 WLCSP17 PRO-DB circuitry,

please refer to Appendix D

Table 3: DA14531 WLCSP Signals Assignment

DA14531 PRO-DB

WLCSP17

PRO-MB

Signals

Signal Name

J1 & J2

Pin Number

Functions Enabled by Jumpers

Function

J1 Pins

P0_0

P2_0

J2:21

RST

J1:26

RST

J1: 25-26 (Default)

P0_6

J2:11

MOSI (Flash)

J1:3-4 (Default)

P0_1

P2_1

J2:22

P0_3

J2:8

FCS (Flash)

J1:7-8 (Default)

P0_2

P2_2

J2:23

SW_CLK

J1:22

SWCLK

J1:21-22 (Default)

P0_3

P2_3

J2:24

P0_5

J2:10

MISO (Flash)

J1:9-10 (Default)

P0_4

P2_4

J2:25

P0_0

J2:5

SCK (Flash)

J1:5-6 (Default)

P0_5

P2_5

J2:26

SW_DIO

J1:24

SWDIO

J1:23-24 (Default)

5.2 DA14531 FCGQFN24 PRO-DB, Default Setup

● The default configuration of DA14531 FCGQFN24 PRO-DB is:

○ Reset

○ JTAG

○ SPI data flash

○ and single wire UART

To enable these functions, apply the appropriate jumpers to the DA14531 PRO-MB

● Dual UART or full UART are not enabled. To enable UART, see section 5.3.4

● Crystal 32.768 kHz is not enabled. For enabling crystal 32.768 kHz, refer to section F.1

● Resistor matrix for FCGQFN24 PRO-DB and DA145xx-DEVKT-P PRO-MB signals are presented

in section E.2.

● Please note that signals of DA14531 FCGQFN24 PRO-DB are renamed on PRO-MB. The

reason is that PRO-MB can be used for the daughterboards of DA1458x family

● For detailed description of the connection capabilities of DA14531 FCGQFN24 PRO-DB circuitry,

please refer to Appendix D

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

26 of 80

© 2019 Dialog Semiconductor

Table 4: DA14531 FCGQFN24 PRO-DB and PRO-MB Signals Assignment (Default)

DA14531

PRO-DB

FCGQFN24

PRO-MB

Signals

Signal

Name

J1&J2 Pin

Number

Functions Enabled by

Jumpers

Multiplexed Functions

Function

Jumpers

Function

Interface

Header

Pins

Numbers

P0_0

P2_0

J2:21

MOSI_2

MBus2

J17:6

RST

J1:26

J1: 25-26

(Default)

P0_6

J2:11

MOSI

(Flash)

J1:3-4

(Default)

P0_1

P2_1

J2:22

AN_2

Arduino

J12:9

P0_3

J2:8

FCS

(Flash)

J1:7-8

(Default)

P0_2

P2_2

J2:23

SCL_2

MBus2 &

Arduino

J18:5

SW_CLK

J1:22

SWCLK

J1:21-22

(Default)

P0_3

P2_3

J2:24

MISO_2

MBus2

J17:5

P0_5

J2:10

MISO

(Flash)

J1:9-10

(Default)

P0_4

P2_4

J2:25

SCK_2

MBus2

J17:4

P0_0

J2:5

SCK

(Flash)

J1:5-6

(Default)

P0_5

P2_5

J2:26 and

J1:20

RxTx

J1: 19-20

J10:1-J1:15

J10:2-J1:17

TX_2

MBus2 &

Arduino

J18:4 to

J12:4

P0_6

P2_6

J2:27

RX_2

MBus2 &

Arduino

J18:3 to

J12:5

P0_7

P2_7

J2:28

CS_2

MBus2 &

Arduino

J17:3

toJ12:6

P0_8

P2_8

J2:29

SDA_2

MBus2 &

Arduino

J18:6

toJ14:1

P0_9

P2_9

J2:30

PWM_2

MBus2

J18:1

P1_0

J2_13

LED

J8:1-2

(Default)

P0_10

SW_DIO

J1:24

SWDIO

J1:23-24

(Default)

P0_11

P3_1

J2:31

SW2

J19:2-3

(Default)

INT_2

Arduino

J14:2

P1_3

J2:16

C_TRIG

J8:3-4

(Default)

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

27 of 80

© 2019 Dialog Semiconductor

5.3 PRO-MB Setup

The PRO-MB provides several debug interfaces and tools that can be used for development.

The DA14531 pin assignment for the available functions are presented in the following sections.

5.3.1 Reset

At power-on and before booting in the chip, reset is active high, and it is assigned to on P0_0. After

booting, reset assignment and operation is handled by software.

● On a DA14531 PRO-DB, the reset signal provided by the PRO-MB is connected to P0_0 for

WLCSP17 and FCGQFN24 through a 1 kΩ resistor

● On the PRO-MB, reset can be enabled either from the JTAG interface (T-RESET) or by pressing

the push button SW1

Please note that, to enable reset on an application, P0_0 must be enabled in both hardware and

software

Figure 20: RESET Circuit on DA14531 PRO-MB

Figure 21: Reset Pin Assignment on PRO-DBs for FCGQFN24 and WLCSP17

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

28 of 80

© 2019 Dialog Semiconductor

5.3.2 JTAG

JTAG uses the Serial Wire Debug (SWD) protocol and consists of the SWDIO and SWCLK lines.

Depending on the package of DA14531, the SWDIO signal is assigned to different pins (Table 5).

Table 5: Configuration Settings for JTAG In DA14531 DK Pro

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Jumpers

J2

FCGQFN24

WLCSP17

SW_CLK

J1:21-22 (Default)

SWCLK

P0_2

P0_2

SW_DIO

J1:23-24 (Default)

SWDIO

P0_10

P0_5

JTAG signals are also available on DA14531 PRO-DBs on headerJ4 (Figure 22).

Figure 22: Optional Debug Port

5.3.3 SPI Data Flash (U2)

SPI data flash is enabled by default. The SPI data flash is the MX25R2035 from Macronix (2 Mbit)

and located on DA14531 PRO-MB.

Ext-SPI slave mode is used to connect DA14531 to SPI data flash.

The flash is absolutely isolated from the rest of the circuit unless appropriate jumpers are. The

configuration for SPI data flash is presented in Table 6.

Table 6: Configuration Settings for SPI Data Flash in DA14531 DK Pro

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Jumpers

J2

FCGQFN24

WLCSP17

MOSI

J1:3-4 (Default)

P0_6

P0_0

P0_0

FCS

J1:7-8 (Default)

P0_3

P0_1

P0_1

MISO

J1:9-10 (Default)

P0_5

P0_3

P0_3

SCK

J1:5-6 (Default)

P0_0

P0_4

P0_4

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

29 of 80

© 2019 Dialog Semiconductor

V_FL

J1:1-2 (Default)

V3

VH-

VH-

Flash Voltage.

It is supplied with the voltage rail

of V

BAT_HIGH

Figure 23: SPI Data Flash Circuit in DA14531 DK Pro

5.3.4 UART

In the DA14531 DK PRO, UART is not enabled by default. Three modes can be used: single-wire

UART (section 0), 2-wire UART (section 5.3.4.1), or full UART (section 5.3.4.2). For the 2-wire or full

UART, the SPI data flash must be disabled.

Any GPIO pin can be set as UART. In the DA14531 DK PRO, specific pins are used for UART

signals (Table 7). Use short cables on DA14531 PRO-MB to bridge J2 pins (P2_0 to P3_1) and pins

of J1 (odd pin-numbers).

Table 7: UART Signals Assignment in DA14531 DK PRO

Function

The signals

Comments

PRO-MB

DA14531 PRO-DB

J2

FCGQFN24

WLCSP17

UTX

2-wire or Full Transmit

P2_0

P0_0

P0_0

Signals reused for SPI

Data Flash

URX

2-wire or Full UART

Receive

P2_1

P0_1

P0_1

UCTS

2-wire or Full UART

Clear to Send

P2_3

P0_3

P0_3

URTS

2-wire or Full UART

Request To Send

P2_4

P0_4

P0_4

RxTx

Single wire UART

Receive and Transmit

P2_3 P0_3

P2_5

P0_5

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

30 of 80

© 2019 Dialog Semiconductor

Single-wire UART

● DA14531-WLCSP17: use P0_3 for single-wire UART. It is supported from SmartSnippet Toolbox.

A wire bridge must be used on PRO-MB.

● DA14531-FCGQFN24: use P0_5 for single-wire UART. it is supported from SmartSnippet

Toolbox. There is no need for bridge wire (Table 8).

Table 8: Single-wire UART Pin Assignment

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Jumper/Wire-Bridge

J2

FCGQFN24

WLCSP17

RxTx

Jumper: J1: 19-20

P2_5

P0_5

No need to disable SPI Data

Flash.

Jumper: J10:1-J1:15

Jumper: J10:2-J1:17

wire: J1:19 to J2:24

P2_3

P0_3

In order not to conflict with

MISO, disable SPI Data

Flash. Remove jumpers:

J1: 1-2/J1: 3-4/J1:5-6/J1:78/J1:9-10

Jumper: J10:1-J1:15

Jumper: J10:2-J1:17

Figure 24: Single-wire UART for DA14531 WLCSP17 PRO-DB

5.3.4.1 2-wire UART Configuration

● UTX and URX signals are multiplexed with FCS (chip select) and MISO of SPI data bus

● Two wires are required to connect UTX and URX to DA14531 PRO-DBs

● Disable SPI data flash by removing jumpers on J1

● JTAG and Reset can be used

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

31 of 80

© 2019 Dialog Semiconductor

Table 9: 2-wire UART Pin Assignment

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Wire-Bridge

J2

FCGQFN24

WLCSP17

UTX

J1:17 to J2:21

P2_0

P0_0

P0_0

Remove jumper J1: 3-4

URX

J1:15 to J2:22

P2_1

P0_1

P0_1

Remove jumper J1: 7-8

Figure 25: 2-wire UART Connectivity

5.3.4.2 Full UART (4-wire) Configuration

● UTX and URX as well as UCTS and URTS signals are multiplexed with FCS, MISO, MOSI, and

SCK of the SPI data bus, respectively

● Four wires are required to connect UART signals to DA14531 PRO-DBs

● Disable SPI data flash by removing jumpers on J1

● JTAG and Reset can be used

Table 10: Full UART Pin Assignment

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Wire-Bridge

J2

FCGQFN24

WLCSP17

UTX

J1:17 to J2:21

P2_0

P0_0

P0_0

Remove jumper J1: 3-4

URX

J1:15 to J2:22

P2_1

P0_1

P0_1

Remove jumper J1: 7-8

UCTS

J1:11 to J2:24

P2_3

P0_3

P0_3

Remove jumper J1: 9-10

URTS

J1:13 to J2:25

P2_4

P0_4

P0_4

Remove jumper J1: 5-6

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

32 of 80

© 2019 Dialog Semiconductor

Figure 26: Full UART (4-wire) Connectivity

5.3.5 Push Buttons

● There are two available push buttons, SW2 and SW3, on DA14531 PRO-MB

● Push buttons are available mainly for DA14531 FCGQFN24 PRO-DB

● SW3 is connected to SWDIO signal (P0_10 for DA14531 FCGQFN24). Users must enable SW3

on software

● SW2 is assigned to P0_11 of DA14531 FCGQFN24 (P3_1 of PRO-MB)

Figure 27: Miscellaneous Peripherals

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

33 of 80

© 2019 Dialog Semiconductor

Table 11: Configuration settings for push buttons

Function

PRO-MB

The Signals

Comments

DA14531 PRO-DB

Enabled by Jumpers

J2

FCGQFN24

WLCSP17

SW2

J19:1-2

P0_6

P0_0

P0_0

Reused in Flash, Reset, UART,

and mikroBUS. Before enabling

the signal, ensure that there is no

conflict on system operation.

J19:2-3

(Default)

P3_1

P0_11

SW3

J19:4-5

P1_1

P0_10

P0_10 is not available on

DA14531 for this function.

5.3.6 User LED (D5) and C-Trig (Software Cursor)

The user LED (D5) and the software cursor trigger (C-trig) are available only for DA14531

FCGQFN24 PRO-DB. The user LED is enabled by default and it is driven from P0_9 of DA14531

FCGQFN24 PRO-DB (P1_0 of PRO_MB). The C-Trig is used by the power profiler of SmartSnippet

Toolbox to enable the software cursor. It is connected to P0_11 of DA14531 FCGQFN24 PRO-DB

through a 1 kΩ resistor.

Figure 28: User LED and Software Trigger Circuit and Jumpers

Table 12: Configuration settings for miscellaneous peripherals

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Enabled by Jumpers

J2

FCGQFN24

WLCSP17

LED

J8:1-2 (Default)

P1_0

P0_9

NA

C_TRIG

J8:3-4 (Default)

P1_3

P0_11

NA

Also assigned to SW2.

In order not to disturb C-

TRIG operation, remove

the jumper from J18:2-3.

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

34 of 80

© 2019 Dialog Semiconductor

5.3.7 mikroBUS 2 Interface

● mikroBUS 2 is used for DA14531 PRO-DB

● Two female headers (8 position 0.100", through hole, socket type) must be mounted on J17 and

J18

● DA14531 FCGQFN24 PRO-DB is suitable for mikroBUS operation due to its available pins

● SPI data bus is shared with SPI data flash or UART

Table 13: mikroBUS 2 Signals

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Available on Headers

J2

FCGQFN24

WLCSP17

MOSI_2

J17:5

P2_0

P0_0

P0_0

Also used from SPI Data Flash or

UART.

SCL_2

J18:5

P2_2

P0_2

P0_2

MISO_2

J17:6

P2_3

P0_3

P0_3

SCK_2

J17:4

P2_4

P0_4

P0_4

TX_2

J18:4

P2_5

P0_5

P0_5

Used for SWDIO of WLCSP17.

Used for single-wire UART of

FCGQFN24.

RX_2

J18:3

P2_6

P0_6

CS_2

J17:3

P2_7

P0_7

SDA_2

J18:6

P2_8

P0_8

PWM_2

J18:1

P2_9

P0_9

BRSTn

J17:2

P3_0

It is not enabled.

BRSTn can be connected to P0_10

(SWDIO) by mounting R11 on

FCGQFN24 PRO-DB.

V3

J17:7 V

BAT_HIGH

The same voltage rail applied to

V

BAT_HIGH

pin of DA14531 SoC.

V5

J18:7

Voltage provided from USB port,

V

BUS_HUB

= 5 V through R305.

Figure 29: MikroBus 2 Circuit

UM-B-114

DA14531 Development Kit Pro Hardware User Manual

User Manual

Revision 1.1

25-Oct-2019

CFR0012

35 of 80

© 2019 Dialog Semiconductor

5.3.8 Arduino Interface

Four female headers (0.100", through hole, socket type) must be mounted on J11, J12, J13, and J14.

Table 14: Arduino Signals

Function

The Signals

Comments

PRO-MB

DA14531 PRO-DB

Available on Headers

J2

FCGQFN24

WLCSP17

SCK_1

J13:4

P0_0

P0_4

P0_4

Multiplexed with SPI, UART, and

other Arduino Interface signals.

A2

J13:3

P0_3

P0_1

P0_1

SDA_1

J12:1