Page 1

User Manual

DA1469x State of Charge (SoC)

Functionality

UM-B-134

Abstract

This user manual describes the use of Dialog Semiconductor's State of Charge (SoC) software.

Besides the State of Charge calculation, an overview is given of the whole process of charging and

discharging a battery. The amount of charge- and discharge current has an impact on the State of

Charge and because of that the battery needs to be characterized (profiled) to minimize errors. The

battery profiling process is also described in this manual. There is also a brief description on the

influence of temperature and aging on a battery.

Page 2

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

2 of 22

© 2020 Dialog Semiconductor

Contents

Abstract ................................................................................................................................................ 1

1 Terms and Definitions ................................................................................................................... 4

2 References ..................................................................................................................................... 4

3 Introduction .................................................................................................................................... 5

3.1.1 State of Charge Estimation Concepts ................................................................... 6

3.1.2 Effect of Temperature on State of Charge ............................................................ 8

4 Charging Process for Li-ion Batteries ...................................................................................... 11

4.1 Phases of the Charging Process ........................................................................................ 11

4.1.1 Phase 1: Pre-Charging ........................................................................................ 11

4.1.2 Phase 2: Constant Current .................................................................................. 11

4.1.3 Phase 3: Constant Voltage .................................................................................. 11

5 SoC Process Overview ............................................................................................................... 12

5.1 Overall Process ................................................................................................................... 12

5.2 Battery profiling process...................................................................................................... 13

5.3 Resulting LUTs .................................................................................................................... 15

6 SoC Algorithm ............................................................................................................................. 16

6.1 Concept ............................................................................................................................... 16

6.2 SOC Calculation .................................................................................................................. 16

6.3 Various Considerations ....................................................................................................... 18

6.3.1 SoC Reporting Error ............................................................................................ 18

6.3.2 Accumulation Error .............................................................................................. 18

6.3.3 Half Battery Charging .......................................................................................... 18

6.3.4 Battery Aging ....................................................................................................... 18

7 Conclusions ................................................................................................................................. 18

Appendix A Battery Conditions and Parameters ........................................................................... 19

A.1 State of Charge (SoC) (%) .................................................................................................. 19

A.2 Depth of Discharge (DoD) (%) ............................................................................................ 19

A.3 Terminal Voltage (V) ........................................................................................................... 19

A.4 Open-Circuit Voltage (OCV) ............................................................................................... 19

A.5 Internal Resistance ............................................................................................................. 19

A.6 Nominal Voltage (V) ............................................................................................................ 19

A.7 Cutoff Voltage ..................................................................................................................... 19

A.8 Capacity or Nominal Capacity (Ah for a Specific C-Rate) .................................................. 19

A.9 Charge Voltage ................................................................................................................... 19

A.10 Float Voltage ....................................................................................................................... 20

A.11 (Recommended) Charge Current ....................................................................................... 20

Revision History ................................................................................................................................ 21

Page 3

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

3 of 22

© 2020 Dialog Semiconductor

Figures

Figure 1: Li-ion Battery at Different States of Charge ........................................................................... 5

Figure 2: Open Circuit Voltage versus State of Charge for Different Discharge Rates ........................ 5

Figure 3: OCV vs SoC where DVL= Discharge Voltage Limit, CVL = Charge Voltage Limit ................ 7

Figure 4: Effect of Temperature on Battery Capacity for Li-ion ............................................................. 9

Figure 5: LUTs for Low- and High Discharging Currents .................................................................... 10

Figure 6: Charging Phases for a Li-ion Battery ................................................................................... 11

Figure 7: Overview of the Process for Characterizing the SoC Algorithm .......................................... 12

Figure 8: Bench Setup for Battery Profiling ......................................................................................... 13

Figure 9: Battery Profiling Process ...................................................................................................... 14

Figure 10: SoC Algorithm Concept Overview...................................................................................... 16

Figure 11: SoC Graph ......................................................................................................................... 17

Tables

Table 1: Lookup Tables for OCV vs SoC for High Load-, Low Load- and Charge Currents ................ 8

Table 2: Generated Lookup Tables ..................................................................................................... 15

Page 4

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

4 of 22

© 2020 Dialog Semiconductor

1 Terms and Definitions

SoC State of Charge

OCVL Open Circuit Voltage for low discharge current

OCVH Open Circuit Voltage for high discharge current

2 References

[1] DA1469x Datasheet, Revision 3.2, Dialog Semiconductor

[2] UM-B-090, DA1469x Getting Started User Manual (PDF), Dialog Semiconductor

Page 5

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

5 of 22

© 2020 Dialog Semiconductor

3 Introduction

Batteries are the main source for storing electrical energy. For wearable systems running on a

rechargeable battery the user would like to know what the remaining amount of energy in the battery

is, to estimate when the device has to be re-charged.The percentage of stored energy is measured

with the parameter called State of Charge (SoC). The SoC is defined as the remaining energy in the

battery as a percentage of a fully charged battery. Normally the rated capacity, expressed in mAh is

used as the reference for SoC estimation. Figure 1 shows the State of Charge of a battery from full

state to empty state.

Figure 1: Li-ion Battery at Different States of Charge

A precise estimation of a battery’s SoC is required to inform the user how long the application can

still work before the battery will need to be recharged. From a safety perspective, SoC makes sure

that battery is not overcharged once 100% is reached. With SoC estimation the user gets an idea of

how long the device can be used before the next charge cycle. A fully charged battery has an SoC of

100% and an empty battery corresponds to a SoC of 0%. SoC can be effectively used to predict how

well the battery system functions relative to its nominal (rated) and end (failed) states. SoC drops

faster for higher load profiles and the provided SoC algorithm takes this into account. SoC

measurements help to select an appropriate charge and discharge profile for a longer life of the

battery.

SoC is proportional to the terminal voltage (Open Circuit Voltage or OCV) of the battery. SoC

decreases along with the decreasing battery voltage. An example graph with the plots of the SoC

against the battery Open Circuit Voltage and the load current is given in Figure 2.

Figure 2: Open Circuit Voltage versus State of Charge for Different Discharge Rates

Page 6

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

6 of 22

© 2020 Dialog Semiconductor

Figure 2 is taken from a typical (Li-ion) battery, discharged at different C-rates. It is well evident that

the SoC is related to the battery voltage and the load/discharge current. The applied load/discharge

current is mentioned as 0.2C, 0.5C, 1C and 2C.

The capacity of a battery is commonly rated at 1C, meaning that a fully charged battery rated at

200 mAh should provide 200 mA for one hour. The same battery discharging at 0.5C should provide

100 mA for two hours, and at 2C the battery delivers 400 mA for 30 minutes.

The SoC and the voltage drop faster for higher discharge currents. The green line in Figure 2

corresponds to a discharge rate of 2C and is the highest. The black line corresponds to the lowest

discharge rate of 0.2C. The voltage drops much slower for 0.2C compared to 2C. Hence the SoC

drops faster for 2C compared to 0.2C. In Figure 2, the value 3.2 V corresponds to the Battery Empty

state. This is the cutoff voltage and the SoC corresponds to 0%.

Every brand and type of battery has its own charge and discharge characteristics. For the algorithm

to provide an accurate SoC estimation, the battery needs to be profiled to determine the relation

between voltage and SoC at various C-rates. Dialog Semiconductor can provide software to run the

battery profiling (or characterization) using lab equipment. This is described in Section 5.12.

3.1.1 State of Charge Estimation Concepts

SoC is the ratio of the currently stored charge Q to the total capacity C. The total capacity can be

found from the battery specification.

SoC = 1 corresponds to a fully charged battery and SoC = 0 corresponds to an empty battery.

Two states at interval tα and tβ are considered for a charge/discharge operation. Qα and Qβ are the

charges corresponding to tα and tβ. Hence the stored/drained charge would be Qα – Qβ.

As Qα changes to Qβ, the SoC changes from SOCα = SOC(tα) to SOCβ = SOC(tβ). By using equation

(1) for tα as well as for tβ and (2), the total capacity of the battery cell can be calculated with:

Equation (3) shows that two accurate SoC measurements and the integrated current between these

two values are enough to calculate the resulting capacity C at tβ.

The SoC and Open Circuit Voltage (OCV) are related and when the SoC changes from SOCα to

SOCβ, the OCV does from OCVα = OCV (tα) to OCVβ = OCV (tβ).

Page 7

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

7 of 22

© 2020 Dialog Semiconductor

Equation (4) can be written as follows:

The linear interpolation relationship of OCV vs SoC can be represented graphically as shown in

Figure 3:

Figure 3: OCV vs SoC where DVL= Discharge Voltage Limit, CVL = Charge Voltage Limit

From the above equation (4) the current capacity of a battery can be found from the amount of

charge, charged or discharged, State of Charge and the Open Circuit Voltage.

As stated in the introduction, for an accurate estimation of the state of charge, the battery needs to

be profiled (or characterized). The role of battery profiling is to charge and discharge the battery with

a known current and to measure the corresponding OCV voltage. Battery profiling starts by preparing

the battery to be at a fully charged level so that SoC corresponds to 100 percent. The battery

profiling tool will draw a certain current for a certain duration that equals to 5% drop in SoC value.

The measured voltage corresponding to this SoC values is recorded. The same is valid for charging

the battery. The battery profiling tool will now charge the battery with a certain current for a certain

duration that equals to 5% increase in SoC value.

Battery profiling generates lookup tables (lut) with SoC and voltages measured for high (hlut)- and

low (llut/OCV) load- and charge currents (clut). The lookup tables generated by the battery profiling

are inserted into the DA1469x SoC software, which can be downloaded from

www.dialog-semiconductor.com.

The SoC software can be added to a customer application and during run time of the application this

will be used to calculate the State of Charge at any point in time.

Details of the battery profiling process are described in Section 5.2 Battery profiling process.

Page 8

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

8 of 22

© 2020 Dialog Semiconductor

An example of the lookup tables is given in Table 1 for reference.

Table 1: Lookup Tables for OCV vs SoC for High Load-, Low Load- and Charge Currents

SoC (%)

llut (mV)

(OCV)

hlut (mV)

clut (mV)

100

4290

4290

4329

95

4185

4160

4326

90

4130

4106

4325

85

4075

4052

4315

80

4025

4001

4261

75

3972

3952

4240

70

3900

3880

4169

65

3876

3856

4124

60

3839

3819

4094

55

3810

3790

4061

50

3786

3766

4033

45

3765

3745

4010

40

3744

3724

3993

35

3722

3702

3981

30

3704

3684

3967

25

3686

3666

3954

20

3670

3650

3932

15

3645

3625

3906

10

3630

3610

3878

5

3545

3525

3815

0

3233

3213

3564

Where llut contains the voltages measured when the battery is discharged with a (very) low current.

The hlut contains the voltages measured when the battery is discharged with a high current and the

clut contains the voltages measured when the battery is charged.

NOTE

The values in the lookup tables need to be measured with the battery in the customer’s

application.

3.1.2 Effect of Temperature on State of Charge

Temperature has a significant influence on the capacity and the state of charge of the Li-ion

batteries. The effect of temperature becomes more significant at low temperatures and when the load

demand is high. The open circuit voltage drops faster at lower temperatures and the voltage drop

rate is even faster when the load demand is high during low temperatures. Hence State of Charge

drops also during low temperature.

Page 9

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

9 of 22

© 2020 Dialog Semiconductor

Figure 4 shows the effect that temperature has on the SoC of Li-ion Batteries.

Figure 4: Effect of Temperature on Battery Capacity for Li-ion

Figure 4 shows that the cell capacity has reduced considerably at subzero temperatures for both

charging and discharging modes in comparison to that at ambient temperatures of 10 °C and 25 °C.

At lower temperatures the internal resistance of the battery increases considerably, and that impacts

the current driving capability of the battery. As a result, the capacity and the State of Charge drops

for a Li-ion battery.

Depending on the requirements, temperature compensation must be considered for battery profiling

and SoC software. Especially for applications that have high load profiles in combination with high

and/or low temperatures.

NOTE

If the battery is used with discharging currents below 0.2C, the temperature does not have that much impact

as long as the operating temperature is > 5 °C and < 35 °C.

NOTE

Since the majority of applications are not exposed to sub-zero temperatures or very high temperatures, the

example SoC software does not use temperature dependent lookup tables. Instead single lookup tables are

used for low-, high- and charge current profiles.

Page 10

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

10 of 22

© 2020 Dialog Semiconductor

Figure 5 is an example lookup table for 21 steps of OCV, for high and low current load at a fixed

temperature (25 oC).

const int16_t socf_lluts[SOCF_TEMP_NUM][VOL2SOC_LUT_SIZE] = {

{ 3233, 3545, 3630, 3645, 3670, 3686, 3704, 3722, 3744, 3765, 3786, 3810, 3839, 3876, 3900,

3972, 4025, 4075, 4130, 4185, 4290 }, //low discharging at 25 oC

};

const int16_t socf_hluts[SOCF_TEMP_NUM][VOL2SOC_LUT_SIZE] = {

{ 3213, 3525, 3610, 3625, 3650, 3666, 3684, 3702, 3724, 3745, 3766, 3790, 3819, 3856, 3880,

3952, 4001, 4052, 4106, 4160, 4290 }, //high discharging at 25 oC

};

Figure 5: LUTs for Low- and High Discharging Currents

Page 11

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

11 of 22

© 2020 Dialog Semiconductor

4 Charging Process for Li-ion Batteries

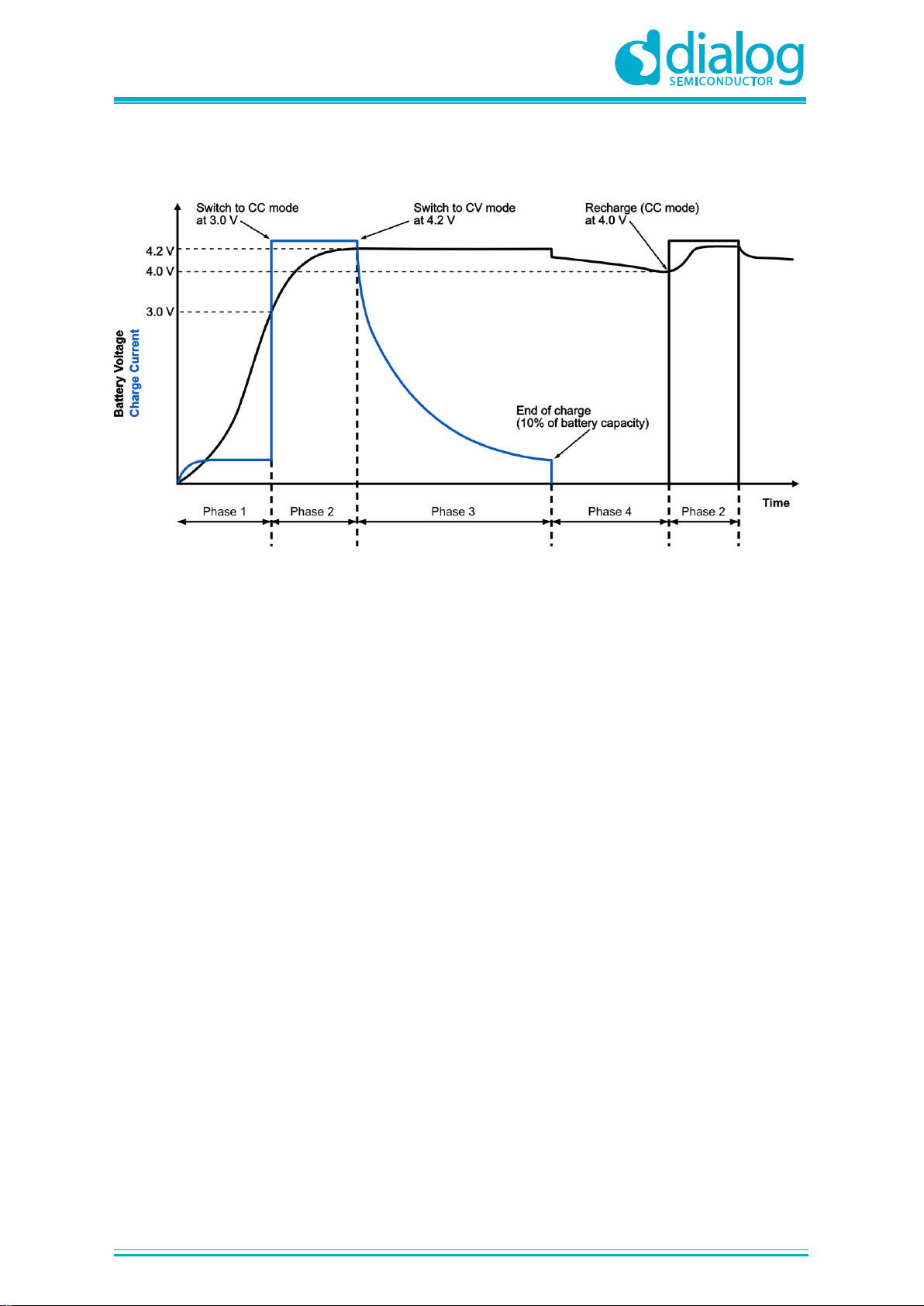

Figure 6: Charging Phases for a Li-ion Battery

Figure 6 shows the charging process of Lithium-ion batteries with the characteristics of battery

voltage, charging current and the phases of the charging process. The 3 steps involved in the battery

charging process are: pre-charging, constant current charging and constant voltage charging.

4.1 Phases of the Charging Process

4.1.1 Phase 1: Pre-Charging

When the battery is in the empty stage (once the battery voltage is less than the cutoff voltage), the

battery must be charged with a low current so that the battery voltage will rise above the cutoff

voltage. This is called Pre-Charging. The charging current in this phase is known as pre-charge

current (IPRECHG). In general the pre-charge current will be less than or equal to 0.1C. Phase 1

corresponds to Pre-Charging.

4.1.2 Phase 2: Constant Current

Once the battery voltage increases to the VPRECHG threshold, the prescribed maximum charge current

can flow. The recommendation is that the charging current is set to 50 to 70% of the battery’s

capacity. This phase is known as the Constant-Current charging phase. For a longer battery life, the

advice is to select a lower value for the charging current. So, 50% would be a good option to go for

when we consider the battery life. But, the charging process will be faster with a higher charging

current.

4.1.3 Phase 3: Constant Voltage

After the battery voltage increases to the set regulation voltage, the charging process enters the

phase known as the Constant Voltage charging phase. In this phase the charging current reduces

until the current equals 10% of the battery capacity after which the charging process stops and the

battery is regarded as fully charged. The typical regulation voltage is 4.2 V for Lithium-ion batteries.

Page 12

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

12 of 22

© 2020 Dialog Semiconductor

5 SoC Process Overview

5.1 Overall Process

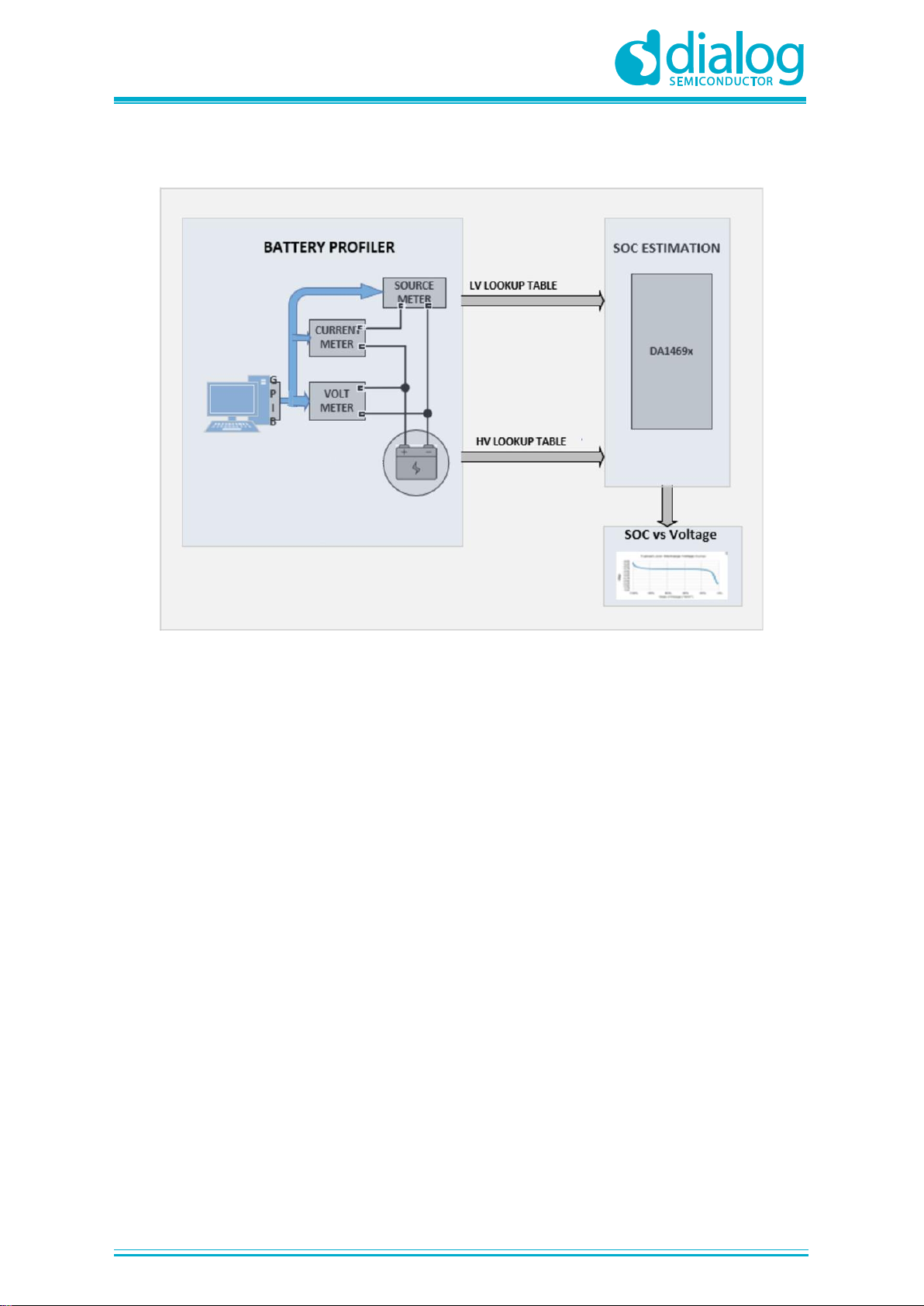

The process for characterizing the SoC algorithm consists mainly of two major steps:

1. Battery profiling.

2. SoC algorithm testing.

Figure 7 shows the process in a flowchart.

Figure 7: Overview of the Process for Characterizing the SoC Algorithm

Page 13

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

13 of 22

© 2020 Dialog Semiconductor

The bench setup for battery profiling and the State of Charge estimation is shown in Figure 8.

Figure 8: Bench Setup for Battery Profiling

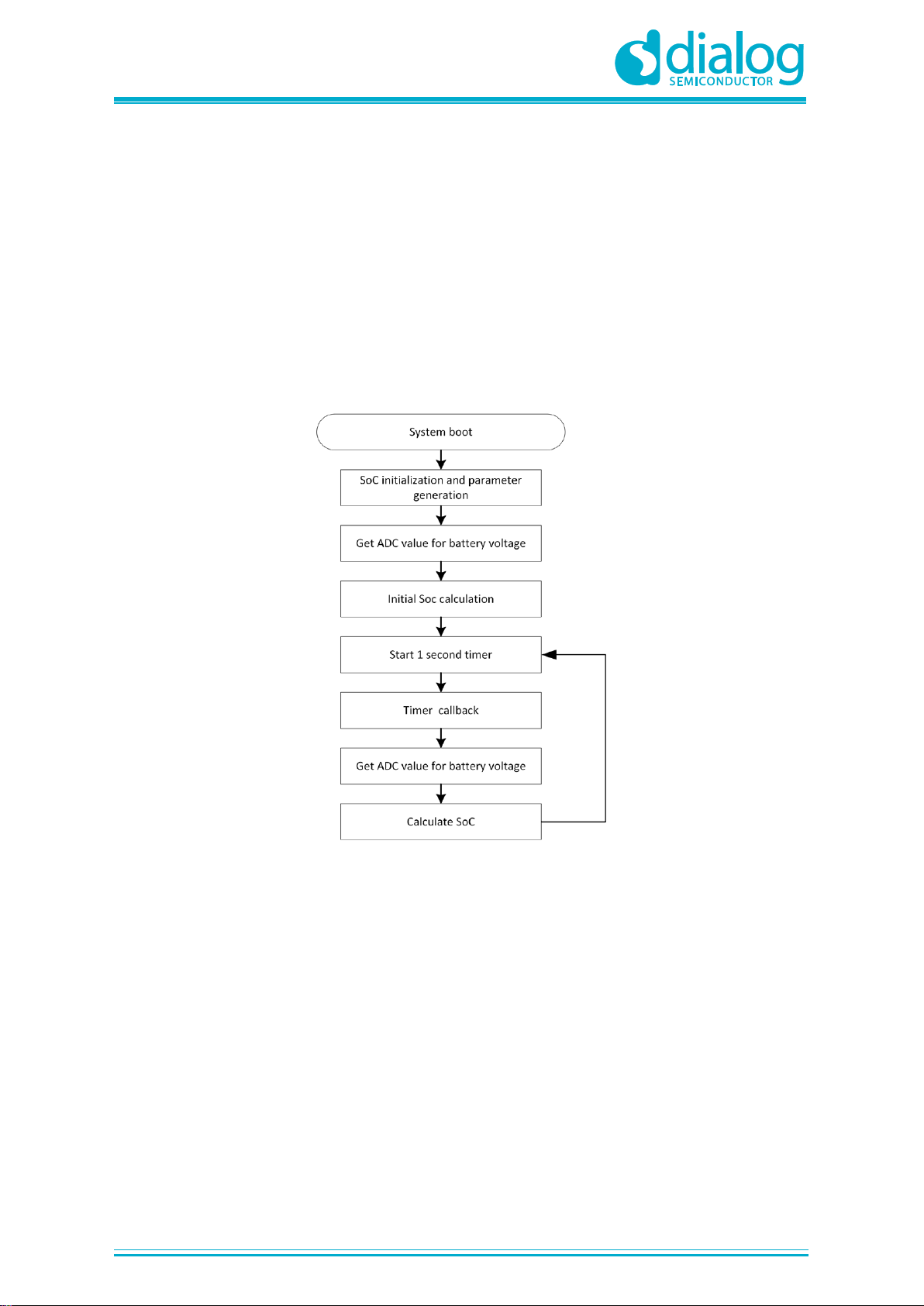

5.2 Battery profiling process

The aim of battery profiling is to produce the “Voltage-SoC” LUTs described in detail in section 3.1.1.

For the specific cases with a high current load profile, the battery profiling is done as follows:

1. The Source meter will fully charge the battery at a 0.5C/1C Charge Current (depending on the

battery) until the charge current falls below the 5% EOC limit.

2. Log Vbat, using a fixed sampling interval equal to the number of LUT entries (generates clut).

3. Allow 15 minutes for the battery to rest without any load.

4. Discharge the battery with the high load profile based on the customer requirement.

5. Log Vbat, using a fixed sampling interval equal to the number of LUT entries. Wait 15 minutes for

the battery to recover and measure Vbat again. The first Vbat value goes into hlut and the

second value goes into the llut (OCV).

6. Basic llut, hlut and clut at 25 °C are generated as shown in Figure 9.

Page 14

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

14 of 22

© 2020 Dialog Semiconductor

Figure 9 shows the flowchart for battery profiling.

Figure 9: Battery Profiling Process

Page 15

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

15 of 22

© 2020 Dialog Semiconductor

5.3 Resulting LUTs

There are a number of LUTs generated for the SoC algorithm, as shown in Table 2.

Table 2: Generated Lookup Tables

Number

Name

Description

1

llut

Contains the battery voltage that corresponds to the open circuit voltage (OCV) over a

step of 5% (number of LUT entries) of battery capacity measured at 25 oC

2

hlut

Contains the battery voltage that corresponds to a constant load of average high load

current over a step of 5% of battery capacity measured at 25 oC

3

clut

Contains the battery voltage that corresponds to charging of the battery over a step of 5%

of battery capacity measured at 25 oC

These LUTs only serve the discharging operation and charging operation at a fixed temperature.

Moreover, the number of samples stored in each LUT could be increased for higher precision of the

algorithm (currently contains 21 samples).

NOTE

Temperature compensation is not required if the load demand is less than 0.2C.

Page 16

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

16 of 22

© 2020 Dialog Semiconductor

6 SoC Algorithm

6.1 Concept

The DA1469x SoC software example has several functions to calculate the State of Charge, which

can be integrated in a customer application.

The algorithm used in the SoC software is based on the following assumptions:

● Voltage drop is somehow linear to the discharging current

● The battery voltage under constant power consumption at each SOC is unique

● Voltage change in 5% intervals of SOC under constant discharging current is linear

The basic algorithm flow is shown in Figure 10.

Figure 10: SoC Algorithm Concept Overview

Algorithm input parameters are:

● Battery voltage ADC_V(n): This is acquired by reading the GPADC VBAT channel. A single read

providing a 10bit value

● Elapsed time T, between ADC_V(n) and ADC_V(n+1). This is implemented with use of a

hardware timer, currently set at 1 second

The idea - in short - is to read the initial battery voltage assuming an initial SoC value, and then try to

estimate the actual load current and the voltage drop rate. The latter two parameters can be used to

calculate the next point on the graph VBAT/SoC, which in turn will provide the SOC value.

6.2 SOC Calculation

Every LUT can be illustrated as a number of points on a 2-dimensional diagram where the X-axis

shows the state of charge (SoC) values in % and the Y-axis has the battery voltage (VBAT) values in

V. The number of samples are defined by the step during the LUT generation, in this case the step

was 5% (VBAT was read every 5% SoC loss) hence there are 21 samples in this diagram. These 21

samples define a curve that shows the battery voltage decrease over the state of charge.

Page 17

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

17 of 22

© 2020 Dialog Semiconductor

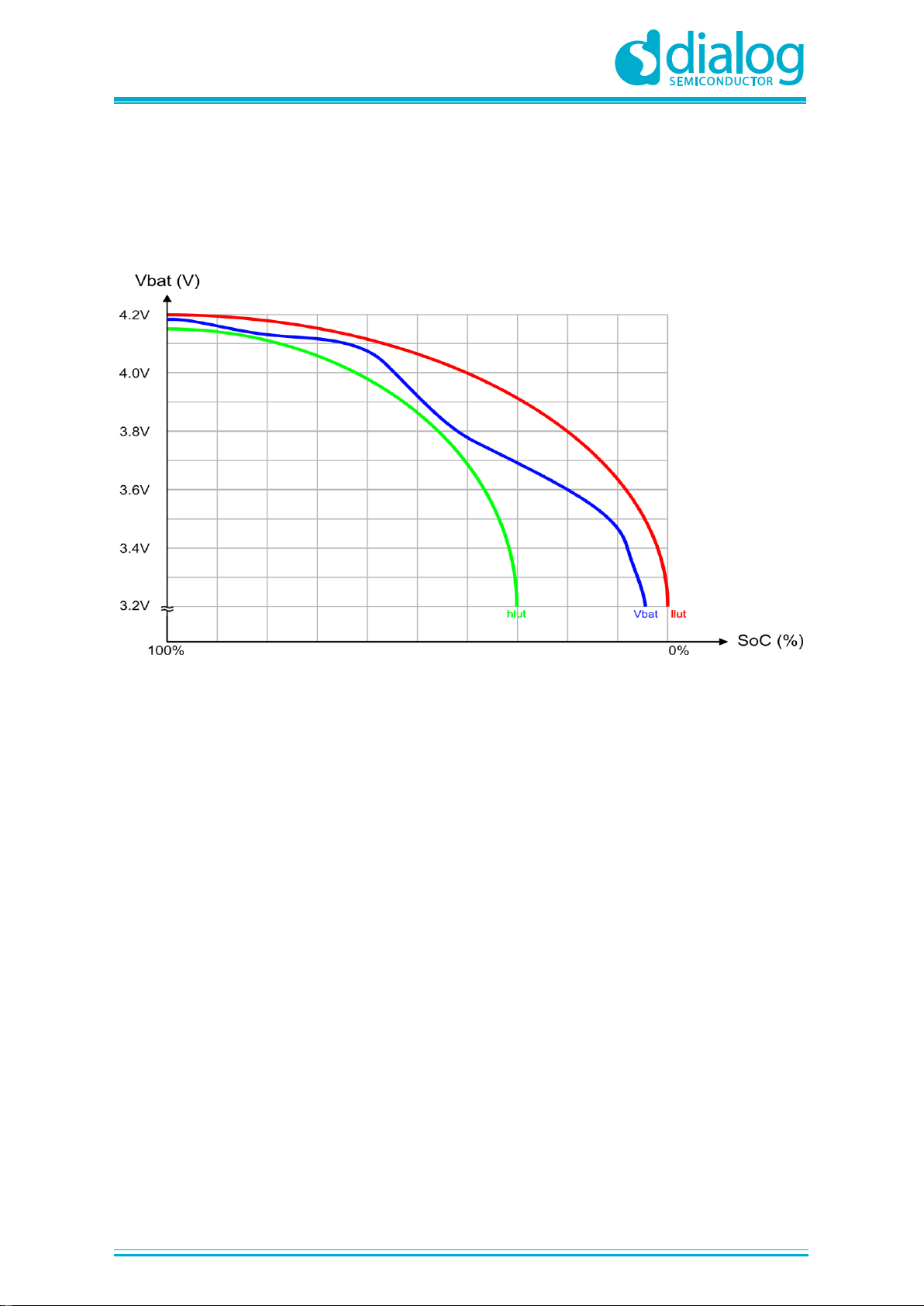

Plotting the llut and hlut on the same diagram will result in what is shown in Figure 11. The green line

represents the hlut while the red line represents the llut. The actual battery voltage over SOC is

defined by the blue line. The algorithm tries to predict the next point on the llut curve, which, by

projecting to the X axis, will provide the next SoC estimate. The aim of the algorithm is to use all

available information to translate the current state of the battery onto the llut curve, from which the

SoC estimate is derived.

Figure 11: SoC Graph

The first step is to estimate the actual current load using inter/extrapolation.

The second step is to calculate the voltage drop rate (dV/T) based on the estimated current load.

This in combination with the previous voltage value, will provide a way to calculate the next point on

the estimated curve.

Finally, the projection of the X coordinate on the SoC (llut) axis will provide the actual state of charge.

As already explained, the assumption is that if the voltage change is small, SoC steps are linear over

a constant current load.

Page 18

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

18 of 22

© 2020 Dialog Semiconductor

6.3 Various Considerations

6.3.1 SoC Reporting Error

The SoC measuring software has been extensively tested with different load profiles, both statically

and dynamically. And with accurate battery profiling the reported State of Charge is well within 5% of

the actual value.

6.3.2 Accumulation Error

Since the first measurement estimates the SoC value, there will be an error. The error might appear

to be higher in the beginning, but will be smoothly adjusted over time.

6.3.3 Half Battery Charging

Even if the highest battery voltage has been reached, but EOC has not yet been reached, the

algorithm will initially make a few large errors, but will gradually get adjusted since the voltage drop

rate will move to the calculated llut curve accordingly. In practical tests, no glitches are observed

whatsoever.

6.3.4 Battery Aging

Battery aging is taken care of by the algorithm since aging will affect the starting battery capacity.

7 Conclusions

Under constant battery load current the Open Circuit Voltage is proportional to the change in State of

Charge. The algorithm can estimate the State of Charge from the graph plotted with the lookup

tables generated by battery profiling well within 5% accuracy.

Page 19

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

19 of 22

© 2020 Dialog Semiconductor

Appendix A Battery Conditions and Parameters

This section explains the parameters used to represent the state or condition of a battery. The

parameters are described below.

A.1 State of Charge (SoC) (%)

An expression of the present battery capacity as a percentage of maximum capacity. SoC is

generally calculated using current integration to determine the change in the battery capacity over

time.

A.2 Depth of Discharge (DoD) (%)

The percentage of battery capacity that has been discharged expressed as a percentage of the

maximum capacity. A discharge to at least 80 % DoD is seen as a deep discharge.

A.3 Terminal Voltage (V)

The voltage between the battery terminals with load applied. Terminal voltage varies with the SoC

and the discharge/charge current.

A.4 Open-Circuit Voltage (OCV)

The voltage between the battery terminals with no load applied. The open-circuit voltage depends on

the battery state of charge and increases along with the state of charge.

A.5 Internal Resistance

Internal resistance is the resistance within the battery and is generally different for charging and

discharging. It also depends on the battery state of charge. As internal resistance increases, the

battery efficiency decreases, and thermal stability is reduced as more of the charging energy is

converted into heat.

A.6 Nominal Voltage (V)

Nominal voltage is the reported or reference voltage of the battery by the vendor.

A.7 Cutoff Voltage

The minimum allowable voltage. It is this voltage that generally defines the “empty” state of the

battery.

A.8 Capacity or Nominal Capacity (Ah for a Specific C-Rate)

The coulometric capacity, the total Amp-hours available when the battery is discharged at a certain

discharge current (specified as a C-rate) from 100 percent state-of-charge to the cutoff voltage.

Capacity is calculated by multiplying the discharge current (in Amps) by the discharge time (in hours)

and decreases with an increasing C-rate.

A.9 Charge Voltage

Charge Voltage is the voltage that the battery is charged to when charged to full capacity. Charging

schemes generally consist of a constant current charging until the battery voltage reaches the charge

voltage, then there is constant voltage charging, allowing the charge current to taper until it is very

small.

Page 20

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

20 of 22

© 2020 Dialog Semiconductor

A.10 Float Voltage

The voltage at which the battery is maintained after being charged to 100 percent SoC to maintain

that capacity by compensating for self-discharge of the battery.

A.11 (Recommended) Charge Current

The ideal current at which the battery is initially charged (to roughly 50 to 70 percent SoC) under

constant charging scheme before transitioning into constant voltage charging.

Page 21

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

21 of 22

© 2020 Dialog Semiconductor

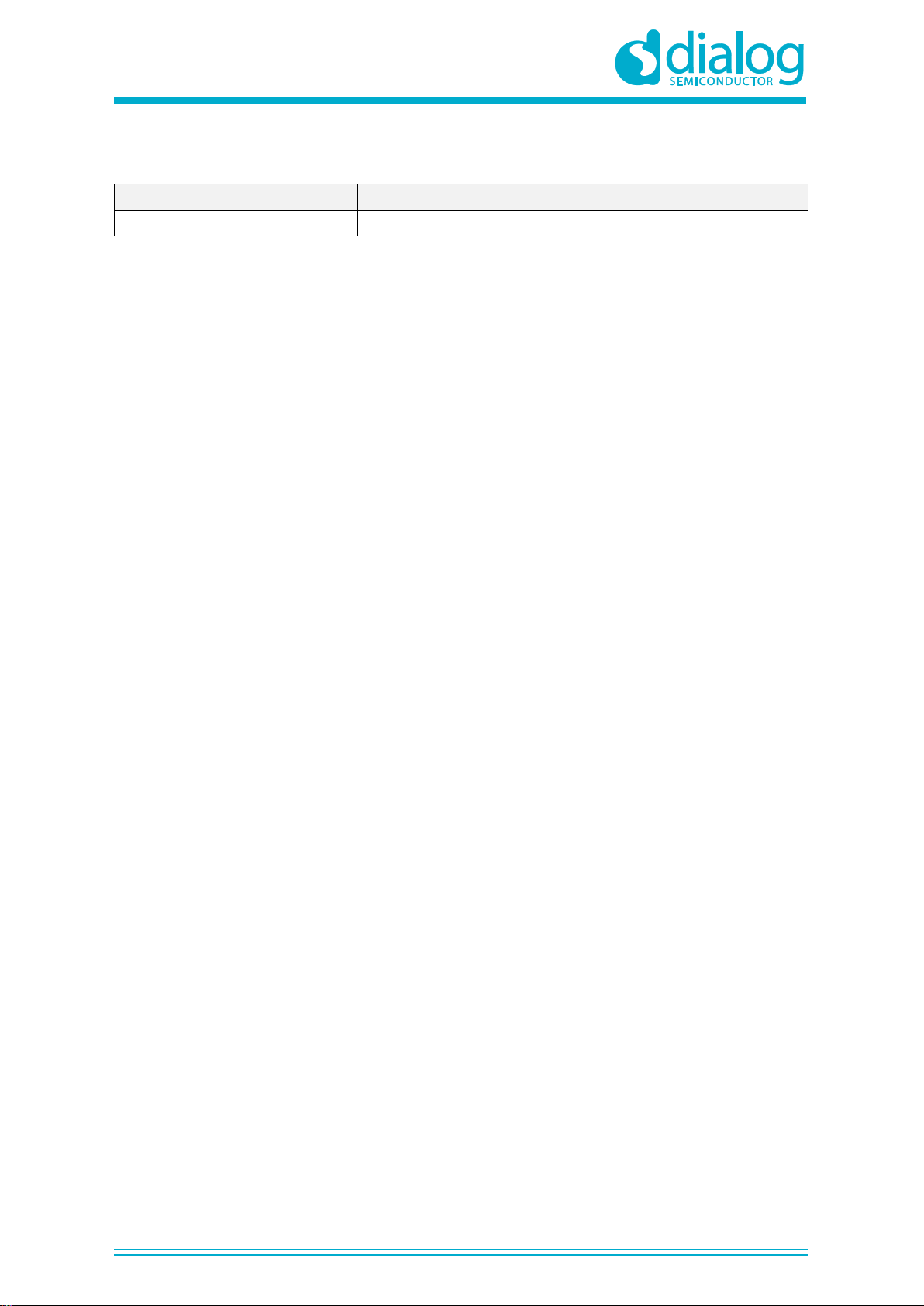

Revision History

Revision

Date

Description

1.0

17-Nov-2020

Initial Release

Page 22

UM-B-134

DA1469x State of Charge Functionality

User Manual

Revision 1.0

17-Nov-2020

22 of 22

© 2020 Dialog Semiconductor

Status Definitions

Status

Definition

DRAFT

The content of this document is under review and subject to formal approval, which may result in modifications or

additions.

APPROVED

or unmarked

The content of this document has been approved for publication.

Disclaimer

Unless otherwise agreed in writing, the Dialog Semiconductor products (and any associated software) referred to in this document are not

designed, authorized or warranted to be suitable for use in life support, life-critical or safety-critical systems or equipment, nor in applications

where failure or malfunction of a Dialog Semiconductor product (or associated software) can reasonably be expected to result in personal injury,

death or severe property or environmental damage. Dialog Semiconductor and its suppliers accept no liability for inclusion and/or use of Dialog

Semiconductor products (and any associated software) in such equipment or applications and therefore such inclusion and/or use is at the

customer’s own risk.

Information in this document is believed to be accurate and reliable. However, Dialog Semiconductor does not give any representations or

warranties, express or implied, as to the accuracy or completeness of such information. Dialog Semiconductor furthermore takes no

responsibility whatsoever for the content in this document if provided by any information source outside of Dialog Semiconductor.

Dialog Semiconductor reserves the right to change without notice the information published in this document, including, without limitation, the

specification and the design of the related semiconductor products, software and applications. Notwithstanding the foregoing, for any automotive

grade version of the device, Dialog Semiconductor reserves the right to change the information published in this document, including, without

limitation, the specification and the design of the related semiconductor products, software and applications, in accordance with its standard

automotive change notification process.

Applications, software, and semiconductor products described in this document are for illustrative purposes only. Dialog Semiconductor makes

no representation or warranty that such applications, software and semiconductor products will be suitable for the specified use without further

testing or modification. Unless otherwise agreed in writing, such testing or modification is the sole responsibility of the customer and Dialog

Semiconductor excludes all liability in this respect.

Nothing in this document may be construed as a license for customer to use the Dialog Semiconductor products, software and applications

referred to in this document. Such license must be separately sought by customer with Dialog Semiconductor.

All use of Dialog Semiconductor products, software and applications referred to in this document is subject to Dialog Semiconductor’s Standard

Terms and Conditions of Sale, available on the company website (www.dialog-semiconductor.com) unless otherwise stated.

Dialog, Dialog Semiconductor and the Dialog logo are trademarks of Dialog Semiconductor Plc or its subsidiaries. All other product or service

names and marks are the property of their respective owners.

© 2020 Dialog Semiconductor. All rights reserved.

RoHS Compliance

Dialog Semiconductor’s suppliers certify that its products are in compliance with the requirements of Directive 2011/65/EU of the European

Parliament on the restriction of the use of certain hazardous substances in electrical and electronic equipment. RoHS certificates from our

suppliers are available on request.

Contacting Dialog Semiconductor

United Kingdom (Headquarters)

Dialog Semiconductor (UK) LTD

Phone: +44 1793 757700

Germany

Dialog Semiconductor GmbH

Phone: +49 7021 805-0

The Netherlands

Dialog Semiconductor B.V.

Phone: +31 73 640 8822

North America

Dialog Semiconductor Inc.

Phone: +1 408 845 8500

Japan

Dialog Semiconductor K. K.

Phone: +81 3 5769 5100

Taiwan

Dialog Semiconductor Taiwan

Phone: +886 281 786 222

Hong Kong

Dialog Semiconductor Hong Kong

Phone: +852 2607 4271

Korea

Dialog Semiconductor Korea

Phone: +82 2 3469 8200

China (Shenzhen)

Dialog Semiconductor China

Phone: +86 755 2981 3669

China (Shanghai)

Dialog Semiconductor China

Phone: +86 21 5424 9058

Email:

enquiry@diasemi.com

Web site:

www.dialog-semiconductor.com

Loading...

Loading...