This high performance model can run very fast. This model

(Standard and LCD versions) are designed and produced for people of 14+ years of age to

operate. Players under that age should be guided by adult supervision. Entry level players

should seek guidance and supervision from experienced model players. Players are

responsible for any/all accidental occurrences (human or animal injury, damage to property

and possessions, breakage of the model itself) due to improper operation of this model.

and the 2.4GHz transmitters

Optimus GP Maximus GP

Length : 19.4in (493mm) : 19.57" (497mm)

Width : 12.1in (307mm) : 15.32" (389mm)

Height : 6.76in (172mm) : 7.13" (181mm, not including body)

Wheelbase : 12.98in (330mm) : 12.98" (330mm)

Front track : 10.23in (260mm) : 12.05" (306mm)

Rear track : 10.43in (265mm) : 12.32" (313mm)

Tires : 4.6in (118mm) : Ф6.2”, 3.3”(Ф158,85m m)

Wheels : 3.2in (81mm) : Ф3.5”, 2.6” (Ф88,66m m)

Ground clearance : 1 .36in (34mm) : 1.96" (49.8 mm)

Weight : 2,9kgs(6.4LB s) (radio not included) : 3.32kgs (7.4LBs)

Gear ratio : 9.43:1 : 12.51:1

Engine : .21 class 3.5 cc : .21 class 3.5cc

Fuel tank : 150cc : 150cc

Steering servo : 9kgs with ball bearing met al gears : 9kgs wi th ball b earing m etal gears

Features : Metal gears, ball bearings

Working voltage : 6.0V

Speed (seconds/60Cº) : 0.16sec

Torqu e : 9kg/cm (88.3Ncm)

Net weight : 60g

Size(LxWxH) : 55x21x43mm

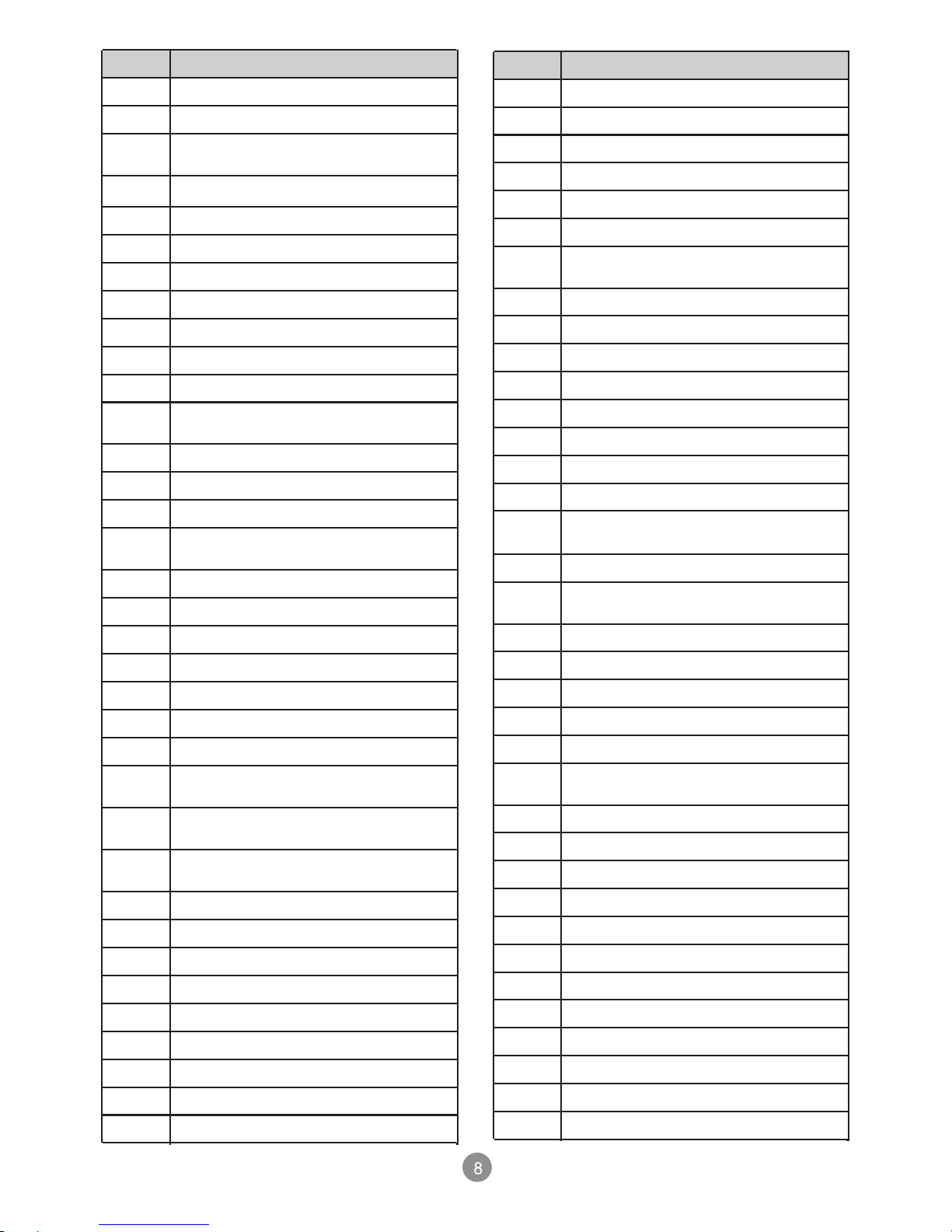

Part# Desc

8381-100 Assembly of dif f gear box

8381-101 Dif f set

8381-102 Dif f outdrive/pins (Ø2*10mm)

8381-103 Pins (Ø2*10mm) (16 pcs)

8381-104

Flathead screw -coarse thread

(KB2.6*10mm) (16 pcs)

8381-105

Crow n gear-41T (large)/pinion gear-11T

(small)

8381-106 Dif f case set/diff case cover/diff gasket

8381-107

Washer-A/washer-B (8 pcs each)

8381-108 Gear-18T (2 pcs)/gear-12T (4 pcs)

8381-109 O Ring (Ø8mm*Ø2mm) (16 pcs)

8381-110 Ball bearing (Ø10mm*Ø15*4mm) (2 pcs)

8381-111 Dif f pins (Ø4*25.8mm) (4 pcs)

8381-112 Assembly of the pinion gear

8381-113 Flathead screw (KM2.6X6mm) (16 pcs)

8381-114 Ball bearing (Ø8mm*Ø14*4mm) (2 pcs)

8381-115 Pins (Ø2*8mm) (16 pcs)

8381-116 Pinion gear outdrive/pins (Ø2*8mm)

8381-117 Ball bearing (Ø5mm*Ø11*4mm) (2 pcs)

8381-118 Dif f gear box-F/R

8381-119

B head screw -coarse thread

(BB3*16mm) (16 pcs)

9381-200 Central diff gear box (complete)

Part# Desc

9381-201

Central dif f set(With plastic gear 45T)

9381-20P Central dif f set (With metal gear 45T)

9381-202 Center diff outdrive

9381-203

Center diff gear box/center diff gear box

cover

8382-202 Spur gear-45T (plastic) (2 pcs)

8382-20P Spur gear-45T (metal) (1pcs)

8381-204

Set screws (M4*4mm) (16 pcs)

8381-300 Shock absorber complete (2 PCS)

8381-301 Shock cap (2 pcs)

8381-302

Shock connecting rod-upper/low er/O ring

(Ø12mm*Ø2mm)

8381-303

Shock adjust ring /O ring (Ø18.5mm*Ø

1.5mm) (2 pcs)

8381-304 Shock body (2 pcs)

8381-305 Shock ball (8 pcs)

8381-306 M3 nylon nut (8 pcs)

8381-307

Low er shock mount/piston/O ring (Ø

13mm*Ø1.5mm)

8381-308 O ring (16 pcs)

8381-309 Shock shaft (4 pcs)

8381-310 Shock spring (4 pcs)

8381-400 Anti-roll bar assembly

8381-40L Assembly of anti-roll bar linkage-Left

8381-40R Assembly of anti-roll bar linkage-Right

Part# Desc

8381-401

Anti-roll bar rod end (8 pcs)

8381-402 Anti-roll bar linkage (4 pcs)

8381-403

Anti-roll bar pivot ball-upper/low er (4

sets)

8381-404

Set screws (M3*3mm) (8 pcs)

8381-405 Anti-roll bar (Ø2.2mm) (2 pcs)

8381-50L Assembly of upper sus.arm-Left

8381-50R Assembly of upper sus.arm-Right

8381-501 Upper sus.arm ball (4 pcs)

8381-502 Upper sus.arm/rod end (2 sets)

8381-503 Upper sus.arm linkage (2 pcs)

9381-600 Servo saver assembly-complete

8382-601

Servo saver sus. Armupper/low er/steering sus. Arm

8381-601

Brass washer (4 pcs)

8381-602 Servo saver bushing/adjustment ring

8381-603 Servo saver spring (4 pcs)

8381-605

B head screw -coarse thread

(BB3*12mm) (16 pcs)

8381-606 Screw bushing (16 pcs)

8381-607 Steering plate

8381-608 Shaft (2 pcs)

8381-6Z0 Assembly of steering linkage (2 pcs)

8381-6Z1 Steering linkage (2 pcs)

8381-6Z2 Plastic rod end (8 pcs)

8381-6Z3 Double w ay ball end (8 pcs)

8381-701

Upper sus.arm mount-rear/suspension

mount

8381-702

B head screw -coarse thread

(BB3*14mm) (16 pcs)

8381-703

B head screw -coarse thread

(BB3*10mm) (16 pcs)

8381-706 Low er sus.arm-front (2 pcs)

8381-707 Drive shaft set/revolving shaft (2 sets)

8381-708 Wheel axle (2 pcs)

8381-709 Steering arm (2 pcs)

8381-710 Ball bearing (Ø6*Ø12*4mm) (2 pcs)

8381-714 C-hub (2 pcs)

8382-705 B head screw (BM3*24mm) (16 pcs)

8381-716

Set screws (M4*12mm) (16 pcs)

8381-717 Shock tow er (2 pcs)

Part# Desc

8381-718

Pivot ball mount (4 pcs)

8381-719 Upper sus.arm shaft (4 pcs)

8381-721 Low er sus.arm plate-front

8381-723 C-hub screw bushing (16 pcs)

8381-724 T head screw (TM4*12mm) (16 pcs)

8381-725 T head screw (TM4*22mm) (16 pcs)

8381-726

B head screw -coarse thread

(BB3*18mm) (16 pcs)

8381-727 B head screw (BM3*56mm) (8 pcs)

8381-728 B head screw (BM3*43mm) (8 pcs)

8381-729 Pins (Ø2*14mm) (16 pcs)

8381-801

Lower sus.arm-rear (2 pcs)

8381-802 Rear hub-L/R

8381-803 B head screw (BM3*18mm) (16 pcs)

8381-807 Pin-A (Ø1.5mm) (16 pcs)

9381-801 Rear brace holder (2 pcs)

9381-9B1

Brake arm//brake collar-A/brake collarB/set screws (M3*3mm)

9381-9B2 Brake pad (2 pcs)/brake disc

9381-9B3

Socket head cap screw (HM3*12) (12

pcs)

9381-9B4 Servo arm-B (2 pcs)

9381-9B5 B head screw (BM2.6*6) (12 pcs)

9381-9B6 Throttle spring (2 pcs)

9381-9B7 Throttle linkage/brake linkage

9381-9B8 Throttle linkage joint/linkage fitting/nut

9381-9B9

Collar-A/Collar-B/O-ring-A/revolving

brace

9381-9E1 Engine mount (2 pcs)

9381-9E2

Engile flywheel

9381-9E3

Flywheel nut

9381-9E4 Clutch shoes/clutch spring

9381-9E5 Ball bearing (Ø5mm*Ø10*4mm) (2 pcs)

9381-9E7 Air filter joint pipe

9381-9E8 Air filter set

9381-9S1 Servo mount

9381-9S2 Servo arm-A (2 pcs)

8381-9S3 B head screw (BM3*6mm) (16 pcs)

9381-9T0 Fuel tank 150cc

9381-9T1 Fuel cap (2 pcs)

Part# Desc

9381-9T2

Fuel tank spring (2 pcs)

9381-9T3 Fuel tank f ixture

8381-9Z0 Assembly of steering tie rod

8381-9Z1 Steering tie rod (2 pcs)

9381-001 Chassis

9381-002 Side guard-L/R

9381-003

Battery case upper/lower

9381-004

Front brace support/front

brace/support/steering servo mount

9381-005 Rear brace

9381-006

AA battery case (for 4 cells)/switch

9381-007 Body post-F/R/f uel tubing holders

9381-010 Fuel hose (Ø2.5*Ø5*250mm)

8381-008 Antenna tube (3 pcs)

8381-009 Pin-B (Ø1.2mm) (16 pcs)

8381-010

Screw washer (4pcs)

8381-011 Flathead screw (KM3X10mm) (16 pcs)

8381-012

Flathead screw -coarse thread

(KB3*10mm) (16 pcs)

8381-015 Flathead screw (KM3X18mm) (16 pcs)

8381-020 Hex driver H17

8381-022 17mm nut (4 pcs)

8382-005 Central drive shaft-C

8382-007 Upper deck-C

8382-008 Upper deck-D

H119 .21 class engine (SG crankshaft)

H120 Manifold/Muffler/Spring/Gasket/Joint

D301 Steering servo (9kg metal gears)

D304 Throttle servo (3kgs plastic gear )

D302T 2.4GHz transmitter

Note: The above parts are common for both

Optimus GP and M aximu s GP.

Parts that are specifically for Maximus GP

Part# Desc

9382-9E1

Engine gear-13T

8384-701 Hex adapter/M12 17mm nut

8382-702 Bumper/upper sus. arm mount-front

8382-703 Body post holder/body post

8382-704 Tire complete (2 pcs)

9382-001 Painted body (PV C)

9382-001C Clear body (PVC)

9382-002 Painted body (PC)

9382-002C Clear body (PC)

Upgrade parts

Part# Des c

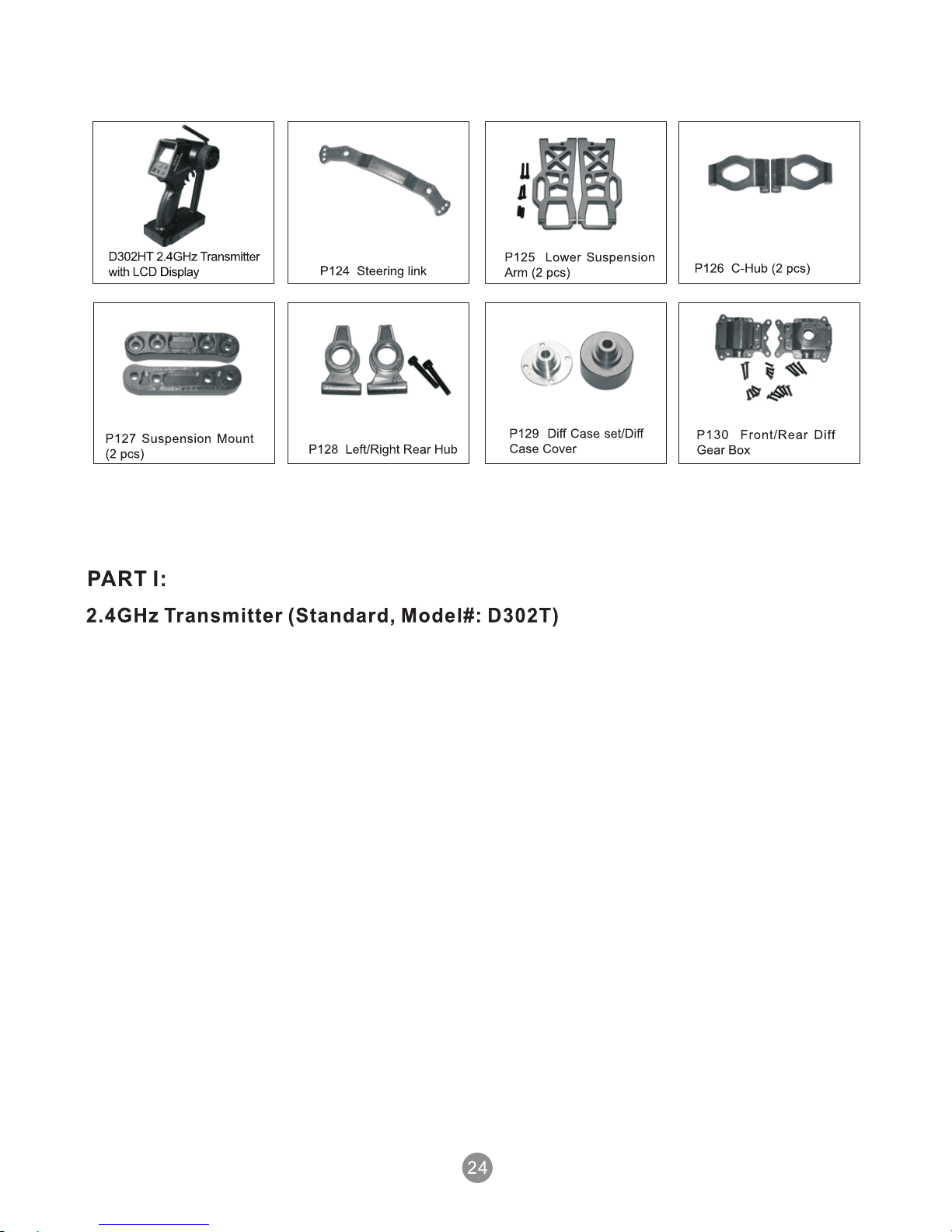

D302HT

2.4GHz LCD transmitter

P124 Steering link(CNC processed)

P125

Lower Suspension Arm (2 pcs)(CNC

processed)

P126 C-Hub (2 pcs)(CNC processed)

P127 Suspension Mount (2 pcs)(CNC processed)

P128 Left/Right Rear Hub(CNC processed)

P129

Diff Case set/Diff Case Cover(CNC

processed)

P130 Front/Rear Dif f Gear Box(CNC processed)

Parts that are specifically for Optimus GP

Part# Des c

9381-9E6

Engine gear-17T

8381-711 Hex adapter/M12 17mm nut

8381-720 Front bumper/upper sus. Arm mount

8381-722

Tire complete (white rims) (2 pcs)

8381-804

Wing mount/wing brace-L/R

8381-805 B head screw (BM3*10mm) (16 pcs)

8381-806

Rear wing rod-long/short

8381-808

Rear wing (white)

8131-009 Body post-F/R

9381-008 Painted body (PVC)

9381-008C Clear body (PVC)

9381-009 Painted body (PC)

9381-009C Clear body (PC)

ITEM NO DESCRIPTION

B001A

FRONT BALL BEARING, 7x19x6

B002 REAR BALL BEARING, 14x24x6

BR2101-1 BURN ROOM(UNDERHEA D)

CH2104 CYLINDER HEAD-BLACK

CK2107E CRANKCASE-SILVER

CM2113B COMPOSITE CARB MAIN BODY

CM2113D-1 COMPOSITE CARB COMPLETE SET

CN2515-1 THROTTLE NEEDLE

CP2104/5A CYLINDER SLEEVE/PISTON

CP2104/5A-1

CYLINDER SLEEVE/PISTON

COMPLTE SET

CR2106 CONNECTING ROD

CS2108 CRANKSHAFT SG

DC2111 DRIVE BRASS WASHER

DG2112 DRIVE GEAR

GP01 GLOW PLUG B4 HOT

HW2103 CYLINDER HEA D GASKET

HW009 WASHER

HW010 WASHER

L004 MAIN NEEDLE VALVE "O" RING

L002 CARBURETOR "O" RING

MN2125 MAIN NEEDLE VALVE HOLDER

MN2126 MAIN NEEDLE

OS2124A FUEL NIPPLE

P001 PISTON GUDEON PIN

S022

CYLINDER HEAD SCREW 3x16 4pcs

S2521 THROTTLE STOP ADJUST SCREW

SP2110 CARB PINCH BOLT

TC2117 DUST COVER

TD2118 THROTTLE SCREW CAP

TH2514

THROTTLE &COUNTER NEEDLE

VALVE

W001 PISTON PIN RETA INER - 2pcs

PULL STARTER ASSEMBLY

A PARTS-4 + B21C

RECOIL START UNIT ASSEMBLY

A PARTS-4

PLASTIC A PARTS ASSEMBLY W/

4PCS SCREWS

B21C

B PARTS ASSEMBLY W/ 4PCS

SCREWS

RS12/13C ONE WAY BEARING SET

RS17 STARTING DISK

RS14 CONNECTIVE SEAT

RS18 STARTING PIN

RS19 PRESSURE SPRING

L001 REAR COVER O RING

L006 O RING-CONNECTIVE SEAT

S011 SCREWS 2.6x7 - 4PCS

10

9381-201

8382-20P

9381-203

9381-203

9381-200 Assembly of the

center diff gear box

9381-202

8381-110

8381-111

8381-108

8381-107

8381-108

8381-109

8381-110

9381-20P

8381-109

8381-103

8381-106

8381-107

8381-108

8381-107

8381-108

8381-107

8381-106

8382-202

8381-104

8381-103

9381-202

9381-201

8381-50L Assembly of upper sus.arm-Left

8381-50L Assembly of upper sus.arm-Right

9381-600 Assembly of the

buffer set

8381-606

8381-300 Assembly of the

shocks

8381-400 Assembly of the

sway bar

8381-100 Assembly of the

diff gear box

8381-601

8381-405

8381-404

8381-403

8381-403

8381-402

8381-402

8381-401

8381-403

8381-401

8381-402

8381-401

8381-40R

8381-40L

8381-303

8381-308

8381-307

8381-304

8381-307

8381-307

8381-309

8381-306

8381-302

8381-301

8381-50R

8381-50L

8381-501

8381-501

8381-502

8381-503

8381-502

8381-502

8381-503

8381-502

8381-117

8381-605

8381-601

8381-608

8381-608

8381-601

8382-601

8381-607

8381-605

8381-606

8381-601

8381-602

8382-601

8382-601

8381-603

8381-602

8381-310

8381-305

8381-305

8381-302

8381-101

8381-112

8381-118

8381-118

8381-119

8381-110

8381-110

8381-112

8381-115

8381-105

8381-116

8381-107

8381-114

8381-113

8381-107

8381-108

8381-102

8381-111

8381-103

8381-106

8381-108

8381-107

8381-108

8381-109

8381-107

8381-101

8381-108

8381-107

8381-106

8381-105

8381-103

8381-109

8381-102

8381-104

11

8381-702

8381-803

8381-803

8381-9S3

9381-9S2

8384-701

8384-701

9381-9B7

8381-703

8381-703

D301

9381-9S1

9381-9B6

9381-9B7

9381-9B9

9381-9B8

9381-9B5

9381-9B1

9381-9B1

9381-9B3

9381-9B4

9381-9B2

8381-703

8381-703

D304

9381-9S1

8381-710

8381-711

8381-306

8381-306

8381-306

8381-306

8381-727

8381-727

8381-728

8381-728

Assembly of the

front sus.arm system

8381-708

8381-708

8381-726

8381-723

8381-400

8381-726

8381-100

8381-300

8381-300

8381-50L

8381-50R

8381-719

8381-719

8381-726

8381-721

8382-705

8382-705

8381-306

8381-718

8381-718

8381-717

8381-726

8381-716

8381-716

8381-725

8381-725

8381-723

8381-723

8381-723

8381-724

8381-714

8381-714

8381-724

8381-710

8381-703

8381-702

8381-119

8381-119

8381-022

8381-711

8381-729

8381-709

8381-110

8381-103

8381-708

8381-707

8381-729

8381-022

8381-711

8381-710

8381-709

8381-110

8381-707

8381-103

8381-707

8381-706

8381-706

8381-701

8381-701

9381-9T3

9381-9T3

9381-9T2

9381-9T1

8384-701

8384-701

8381-022

9381-801

8381-710

8381-703

8381-119

8381-710

8381-711

8381-306

8381-306

8381-728

8381-727

8381-306

8381-728

8381-727

Assembly of the

rear sus.arm system

8381-729

8382-705

8381-306

8381-306

8381-726

8381-721

8381-717

8381-718

8381-726

8381-300

8381-715

8381-300

8381-103

8381-103

8381-708

8381-708

8381-400

8381-110

8381-802

8381-100

8381-707

8381-707

8381-716

8381-119

8381-719

8381-50R

8381-726

8381-729

8381-50L

8381-726

8381-802

8381-702

8381-119

8381-801

8381-110

8381-711

8381-710

8381-022

8381-726

8381-716

8381-719

8381-701

9381-007

8381-702

8381-713

8381-703

8381-012

8381-012

9381-005

9381-004

9381-006

9381-003

9381-003

8381-009

8381-020

8381-703

8381-703

8381-703

8382-007

D302S

8382-008

8381-702

8381-010

8381-011

8381-012

8381-010

8381-012

9381-004

9381-600

8381-012

8381-012

8381-015

8381-012

8381-015

8381-012

8381-012

8381-012

8381-011

8381-010

8381-008

8382-005

8382-005

9381-002

9381-002

9381-001

8381-713

8381-703

8381-805

8381-805

8381-9Z0

9381-9Z1

8381-6Z3

8381-6Z3

8381-6Z2

8381-6Z2

8381-6Z3

8381-6Z3

8381-6Z2

8381-6Z2

8381-6Z1

8381-6Z0

9382

9381

8381-009

81311-009

8381-703

8381-703

8381-726

8381-119

8381-703

8382-702

8382-702

8382-703

8382-703

8381-807

8381-807

8381-009

8381-009

9382-9E1

9381-9E6

H120

H119

9381-9B3

8381-306

9381-9E7

9381-9E8

9381-9E5

8381-9S3

9381-9E5

9381-9E4

9381-9E3

9381-9E1

9381-9E2

8381-009

8131-009

8381-703

8381-808

8381-702

8381-808

8381-804

8381-807

8381-804

8381-805

8381-806

8381-805

8381-805

8381-605

8381-702

8381-804

8381605

8381-726

8381-726

8381-605

8381-804

8381-703

8381-119

8381-720

8381-720

8381-703

Crankshaft SG

Carburetor

Idle screw

High-end screw

Low-end screw

Engine needles and carburetor

Upgrade parts

Annex: 2.4GHz Transmitter Manual

1. The 2.4GHz transmitter and receiver are pre-bound at the factory.

2. Please always use the same receiver model from the factory to match your 2.4GHz

transmitter when you need to replace it. Receivers from other suppliers don't work on DHK

HOBBY 2.4GHz transmitter.

3. When you need to replace a receiver, please make sure that it is bound with the transmitter

before use.

4. Please operate the transmitter in vast areas where no radio interference exists. It's strongly

recommended that no humans, animals or high voltage grid should be nearby.

5. Please do not operate this transmitter during fatigue, sickness, intoxication or in bad mood.

6. Do not operate the transmitter at night time, in the rain and thunderstorm or at low visibility.

7. Always use the same types of batteries in the transmitter. Do not mix old and new batteries

in the transmitter. Please check the battery power before use. Replace batteries whenever the

power is low to avoid out of control. Ni-Mh or Ni-Cd rechargeable batteries can be used on this

transmitter. Please charge the batteries to full before use.

8. Before you operate the transmitter, please check the switch, batteries, servo and ESC for

proper connection. 9. ALWAYS switch on the transmitter first, and off last so as to avoid

possible radio interference from other sources. Failure to do so may cause out of control of

your vehicle.

10. Before operation, check the servo forward and reverse functions, motor range, and neutral

position. Modify it when necessary.

11. Please handle the transmitter with care. Store the transmitter in a dry and clean place

when it's not in use for some time.

Safety Precautions

Transmitter Specifications

1-Antenna: pull up the antenna straight before use.

2-Power switch: slide the switch to turn on or off.

3-Power LED: shows the power strength. Green LED shows full power, Yellow LED flashes

when the power is running short.

4-Chargin g port: charges Ni- Mh or Ni-Cd batteries only. Alkaline batteries are not

rechargeable. NEVER charge your alkaline batteries.

5-Throttle trigger: Please refer to the transmitter diagram.

6-Steering wheel: Please refer to the transmitter diagram.

7-ST-D/R trim: adjust the steering servo angle ranging from 0% to 120%.

8-TH-D/R trim: adjust the throttle servo angle ranging from 0% to 120%.

9-ST-TRIM: adjust the steering neutral position, from 0% to 20%.

10-TH-TRIM: adjust the throttle neutral position, from 0% to 20%.

11-ST-NOR/REV: slide to left or right to choose steering mode.

12-TH-NOR/REV: push the trigger or pull it back to choose the throttle mode.

13-Throttle trigger trim screws: use a hex driver to tighten or loosen the screw to a comfortable

level.

14-Battery compartment cover: to open the compartment, slide the cover to OPEN direction as

indicated, snap it to close the compartment.

15-Battery case: open the battery cover, install 4 pcs AA 1.5V alkaline or rechargeable

batteries based on the "+" & "-" poles. If the status LED flashes red, the transmitter batteries

may be weak, discharged or possibly installed incorrectly. Replace with new or freshly charged

batteries. The power indicator light does not indicate the charge level of the battery pack

installed in the model.

Parts Diagrams

3

Frequency range

2.4GHz modulation

Sensitivity

Working voltage

Working current

Size

Weight

: 2.4GHz

: AFHDS

: -100dbm

: DC4.8-6.0V

: 5.7*26*15.2mm

: 11.2g

Receiver Functions

1. Antenna: Pull out the antenna completely

2. Connecting ports: receiver power port and channel signal connecting ports

> ST/1: Channel 1, steering signal port

> TH/2: Channel 2, throttle servo or ESC signal port

> AUX/3: Auxiliary signal port

> BATT/4: Receiver power port, can be auxiliary signal port

3. Set keys & LED indicators

>Bind setup. Switch on the receiver, indicators flash slowly, press the setup key for 2 seconds

and release it, LED indicator flash in faster motion, binding starts. When the LED indicator is

on in stable status, the binding is complete. Note: To bind it quickly and effectively, please put

the receiver 40-50cm away from the transmitter.

>Failsafe. Switch on the transmitter and receiver, then you can see the LED indicator on

receiver is on. Adjust the throttle servo or ESC to brake or stop status, and keep it that way.

Press the setup key, then receiver LED indicator flashes, keep this for 3 seconds. After this,

release the setup key. Failsafe setup is complete.

>Disabling failsafe function. Switch on transmitter and receiver, once the signal is

connected, LED indicator is on. Press the setup key for 2 seconds, LED indicator flashes

quickly, at this point, keep pressing the setup key without release, press it for 2 more seconds,

LED indicator flashes slowly. Release the setup key, LED indicator is on. The setup is

complete.

Safety Precautions

Please refer to Safety Precautions in PART I

Transmitter Specifications

2.4GHz LCD Transmitter Parts and Functions

1. 2.4G transmitter antenna: before use, please pull the antenna straight up.

2. Power switch: Press down to turn on the transmitter, press the switch again to turn it off.

3. LCD display: shows transmitter menus, parameters and operation instructions.

4. Charging port: charging area is positive inside and negative outside. When Ni-Mh or Ni-Cd

rechargeable batteries are to be charged, right charger should be selected for re-charging the

batteries.

5. Throttle trigger: drag, push or make the throttle trigger to a neutral position to forward,

reverse or brake your RC model.

6. Steering wheel: turn the steering wheel counterclockwise to turn the model to left. Turn the

steering wheel clockwise to turn the model to right. Release it to neutral for straight driving.

7. Menu keys: Press Left key (<) or Right key (>), move the cursor to LCD display options.

8. DATA change keys: press Left key (+) or Right key (-) to change, adjust and save current

parameters.

9. Throttle trigger set screw: use a 2.5mm hex screw driver to move forward or backward to

adjust the throttle trigger to a comfortable hand feeling.

10. Battery compartment cover: Press the door to OPEN indicated direction to open the

battery compartment cover. Snap the compartment door into the slot to close the battery

compartment.

11. Installing batteries: open the battery compartment cover, install 4 pcs “AA” batteries (same

type) according to the indicated “+” “-“ orientations. Turn on the transmitter and check the

indicator status for a solid green light. Please take out the batteries when the transmitter is not

in use. If the status LED flashs red, the transmitter batteries may be weak, discharged or

possibly installed incorrectly. Replace with new or freshly charged batteries. The power

indicator light does not indicate the charge level of the battery pack installed in the model.

Parts Diagrams

LCD Functions and Operations

Key Operations

Menu keys:

Press Left key (<) to main command, and Right key (>) for secondary

command.

DATA keys:

Press Left key (+) or Right key (-) to adjust, set up and auto save the

current chosen function.

Display Interface

Switch on the transmitter, you will hear “beep” sound (beeps once), and

the LCD display mode will read the default parameters pre-set at the

factory and BATT status mode (main menu).

BATT: battery status, function reset settings

Battery level display. Battery voltage appears on LCD display. When the voltage is 4.4V, the

value flashes and you can hear warning sound. This means the battery voltage is deficient.

When battery voltage value shows 4.0V, the value blinks fast and warning sound keeps strong.

This indicates battery voltage is too low and batteries cannot be used. Please turn off the

transmitter and replace batteries. If rechargeable Ni-Mh or Ni-Cd batteries are used, please

charge the batteries with proper charger.

Function reposition. In case the parameters are messed up or if you don't know how to set

up, please turn off the power, press and hold MENU Left key (<). Then turn on the power and

you will hear “beep” sound after two seconds. Release all keys and all parameters will go back

to factory default values.

Frequency duplication setting. When two transmitters are used at the same time, a

frequency might be duplicated. In this case, you may choose the auto frequency function. First

turn off the power, then press and hold MENU Right key (<), and turn on the power. The display

will show hopping data. Release the key and the hopping data will stop. The digit shown on the

display is your frequency. Bind the transmitter with the receiver through binding keys.

MOD: Setting up mode and naming

15 group memory data for choice, it's easy to manage and use. At start status, press Left key

(+) or Right key (-) of the DATA to choose the necessary module (Screen shows main menu)

For easy control, you may name each module. Press Left key (<) on MENU (6 times on Main

Menu) until you see 000 01 on the screen and the first digit must flash, at this moment, you may

change the data here. Press Left key (+) or Right key (-) to choose necessary data. Once first

change is made, press Right key (>) on MENU to move the cursor to the next position, then

press Left key (-) or Right key (+) to choose the needed data. Based on the above, you can

rd

change data for the 3 data group. Once all is changed, press Left key (<) on the MENU

function to get back to Main Menu and save the setup. (Screen shows 000 01).

REV: Servo forward and reverse setup

Setting up Steering servo direction. Press MENU function Left key (<) or

Right key (>) (Press once under MAIN MENU) until you see” ***REV-ST”,

then press DATA function Left key (+) or Right key (-) to choose ON/OFF.

(Screen shows OFF REV-ST).

Setting up Throttle speed neutral position. Press MENU function Left

key (<) (Press once under the MAIN MENU) and then press twice of MENU

Right key (>) until you see ***REV-TH. Press DATA function Left key (+) or

Right key (-) ON/OFF. (Screen shows OFF REV-TH).

rd

Setting up t he 3 Channel: Press MENU function Left key (<) (Press once

under MAIN MENU), then press twice on Menu function Right key (>) until

you see ***REV-3C, press DATA function Left key (+) or Right key (-) to

choose ON/OFF. (Screen shows OFF REV-3C).

TRM: Servo neutral trim setup

Setting up steering servo(ST) neutral position parameters. Press

MENU function Left key (<) (Press twice under MAIN MENU) until you see

**% TRM ST and neutral value. Press DATA functi on Left key (+) or Right

key (-) to change the steering n eutral position. On the screen there is

steering neutral status L.F. U, R. B. D and percentag e values indicating

the neutral position at that setup. (Screen shows 00% TRM ST).

Setting up throttle speed (TH) neutral position parameters. Press

MENU function Left key (<) (Press twice under MAIN MENU), and press

MENU function Right key (<) until you see **% TRM TH a nd neutral value.

At this point, pre ss DATA function Left key (+) or Right key ( -) for

adjustment. On the screen you will see neutral position status indicator

L. F. U, R. B. D and percentage values. (Screen shows 00% TRM TH)

D/R: Servo angle adjustment setup

Set up Steering servo (ST) angle. Press Menu function Left key (<)

(Press 3 times on MAIN MENU) until you see **% D/R ST on the screen,

then press DATA function Left key (+) or Right key (-) to choose servo

angle parameter. (Screen shows 100% D/R ST).

Set up Throttle servo (TH) forward and reverse angle. Press MENU

function Left key (<) (Press 3 times on MAIN MENU), then press MENU

function Right key (>) once, the screen shows **% D/R TH, press DATA

function Left key (+) or Right key (-) for throttle angle parameters. (Screen

shows 100% D/R TH)

EPA: End point adjustment (servo single side angle setup)

Set up steering servo single side (left steering or right steering) travel

angle. Press MENU function Left key (<) (Press 4 times under MAIN

MENU) until the screen shows **% EPA ST. Turn the steering wheel

clockwise, the screen shows the EPA value of right steering R.B.D.-->;

Press DATA function Left key (+) or Right key (-) and change the data.

When you turn the steering wheel counterclockwise, the screen displays

the EPA value of left steering L. F. U on steering servo. Press DATA

function Left key (+) or Right key (-) for desired value. (Screen shows

100% EPA-ST)

Note: for this function, the steering servo travel angle is adjusted to a wider

or narrower range, hence the steering angle of the left or right tire is

adjusted to desired angle.

Set up throttle speed (forward or reverse). Press MENU function Left

key (<) (Press 4 times under MAIN MENU) and press once on MENU

function Right key (>), the screen shows **% EPA TH. Pull back the throttle

trigger and the screen displays L.F.U value of forward (F) speed. Press

DATA function Left key (+) or Right key (-) to change the value. Push

forward the throttle trigger and the screen shows reverse R.B.D value of

reverse speed, press DATA function Left key (+) or Right key (-) to change

the value. (Screen shows 100% EPA-ST)

Note: for this function, the throttle servo angle is adjusted (wider or

narrower) on nitro- (gas-) powered vehicles, and for EP vehicles, speed of

the electronic speed controller adjusted (faster or slower).

30

ABS: Setting up brake system

For each of the above setup, when one setting is selected, please wait for 5 seconds until you

see the main menu, then that setting is automatically saved as memory.

Set up throttle ABS brake system. Press MENU function Left key

(<) (Press 5 times under MAIN MENU), screen shows *** ABS- TH,

press DATA function Left key (+) or Right ke y (-) to cho ose ON/OFF. At

ON status, it prevents the tires from getting stuck in powerful griping

motion during brake. (Screen shows *** ABS- TH)

FCC Caution: Any changes or modifications not expressly approved y the party responsible for

compliance could void the user ’s authority to operation this equipment. This device complies

with Part 15 of the FCC Rules. Operation is subject to the this device must accept any

interference received, including interference that may cause undesired operation .

This device and its antenna(s) must not

be co-located or operating in conjunction with any other antenna or transmitter.

Loading...

Loading...