DH Instruments VACUUM PUMP KIT FOR MOLBLOC-S, 401940, 401883 Installation And Use Instructions Manual

The use of a vacuum pump, connected downstream of

the molbloc-S, increases the usable flow range of

each element. The installation and operation of the

vacuum should be in accordance with all applicable

local electrical, plumbing, building, and safety codes.

This instruction sheet is a guide to the application of

the vacuum system and use with the molbloc-S and

molbox Mass Flow Calibration System. Please follow

the recommendations and installation information

provided in the Pump’s Operation manual published

by its manufacturer and provided with the pump.

Installation and Use of Medium-Flow

Vacuum Pump Kit for molbloc-S

P/N 401940 & 401883

Installation Instructions

• In order to minimize the back-pressure applied to

the exhaust of the pump, plumbing should be as

short and as large in diameter as is practical, but

no smaller than the pump’s exhaust fitting size.

Inlet plumbing length and diameter should follow

the same guidelines in order to maximize the

efficiency of the vacuum pump. Restrictions in the

inlet plumbing will reduce the pumping speed of

the pump.

• In cyclic operations, such as flow meter calibrations

with molbloc-S, the pump should not be switched

off during cycles. Continue to run the pump with

the gas ballast valve open and the inlet port closed.

Power consumption is minimal when the pump is

operating at its ultimate pressure. Limit starting

the pump to no more than a few times per day.

®

VACUUM PUMP INSTALLATION,

GENERAL CONSIDERATIONS

• The vacuum pump should be located in a place

where there is adequate ventilation for cooling.

Consideration of the noise and heat generated by

the pump should be made. It might be desirable

to install the pump in a location outside of the

laboratory in which the molbloc/molbox system is

operating.

• Caution should be exercised when calibrating in

gases other than air. Asphyxiation of personnel

within a confined space into which the pump

exhausts is a real threat when calibrating at high

flow rates. Venting of the exhaust gas stream

outdoors or into a large ventilated space is

recommended.

TECHNICAL DATA

Pumping Speed

Average Noise Level

Main Voltage

Motor Power

Nominal Speed

Weight w/oil

Oil Capacity

Inlet/Outlet Connection

64 cu m/hr. (37.7 cfm)

69 dB(A)

(free field measurement at 1 m)

50/60 Hz Volts

230/460 (± 10 %), 3-Phase Supply

1.8 kW (2.5 hp)

1 750 RPM

47 kg (103.4 lb)

2.0 l (2.11 qt)

1 1/4 in. Female NPT

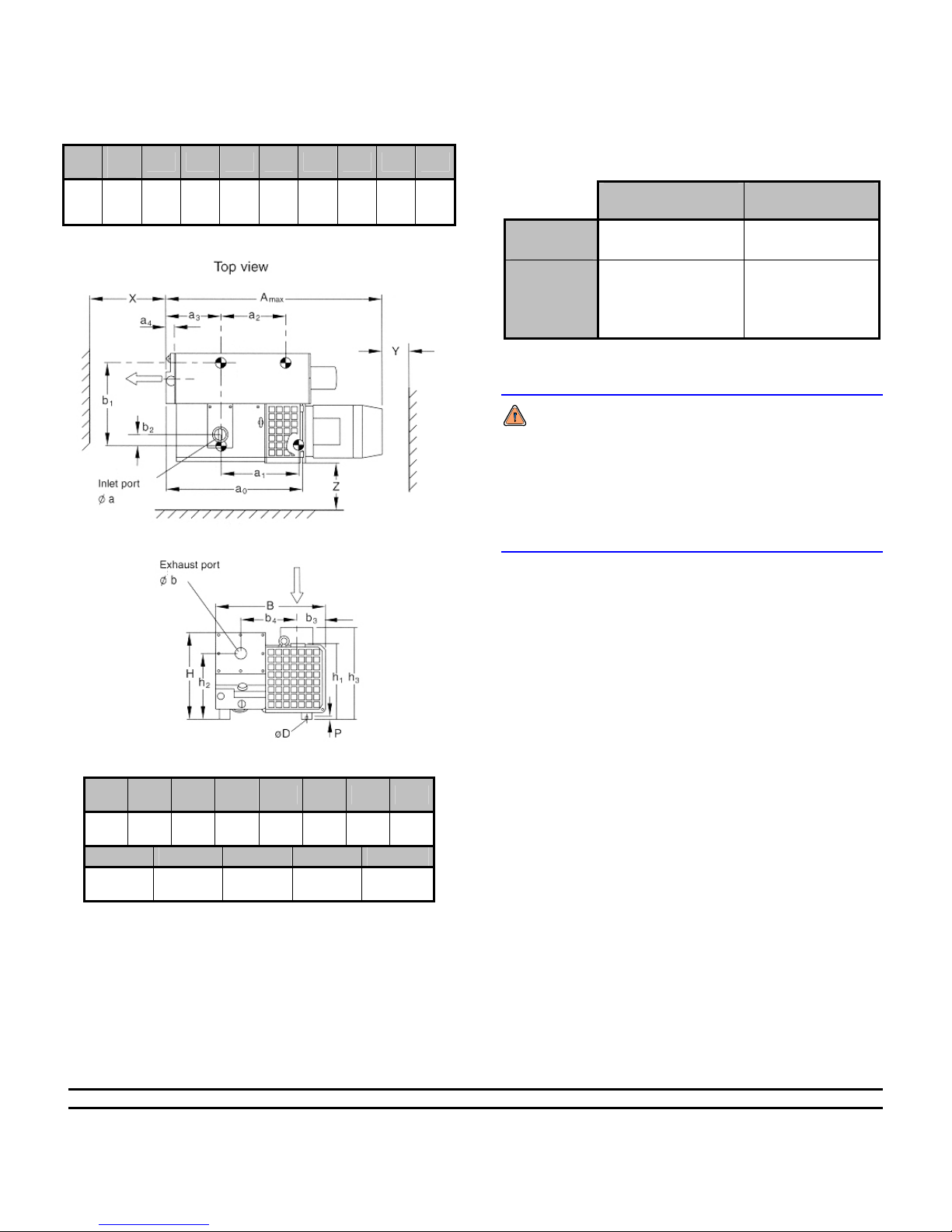

DIMENSIONAL DATA, mm (in.)

Ø a

Ø b

A

H h1 h2 h3 X Y Z

in.

max

695

(27.4

)

260

(10.2

)

237

(9.3)

216

(8.5)

270

(10.6

)

NPT

1 1/4

in.

NPT

1 1/4

350

(13.8

)

100

3.9

150

(5.9)

VARIATIONS, mm (in.)

This pump kit is available in two versions.

STANDARD PUMP KIT

P/N 401940

LUBRICATION

TYPE

SERVICE

DETAILS

Paraffin-base

Mineral Oil

General Purpose

– pumping air and

chemically inert

permanent gases

Please read and understand the enclosed Installation

and Operation Manual, Material Safety Data Sheet,

and all other enclosed data. Personal injury and/or

property damage could result if this equipment is not

installed and operated properly. This system should

be assembled and operated only by personnel who

have been instructed in proper safety practices.

PFPE PUMP KIT

P/N 401883

Perfluorinated

Polyether (PFPE)

Special Purpose

– pumping strong

oxidants such as

oxygen, ozone,

nitrogen oxides

Ø a

Ø b

A

a0 a1 a2 a3 a4

NPT

NPT

1 1/4

1 1/4

in.

in.

B b1 b2 b3 Ø D/P

100

3.9

max

695

(27.4)

150

(5.9)

260

(10.2)

1 1/4

in.

237

(9.3)

(8.5)

216

1 1/4

in.

270

(10.6)

350

(13.8)

695

(27.4)

molbloc-S is a trademark, registered and otherwise, of DH Instruments, Inc.

Document 560053-01 030502

DH Instruments, Inc.

4765 East Beautiful Lane

Phoenix AZ 85044-5318

USA

Tel 602.431.9100

Fax 602.431.9559

dhi@dhinstruments.com

www.dhinstruments.com

Loading...

Loading...