Self Purging Liquid Trap

(SPLT™)

User’s Manual

© 1998-2009 DH Instruments, a Fluke Company

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases can be

released unexpectedly and with extreme force. High pressure systems should be assembled and operated

only by personnel who have been instructed in proper safety practices.

© 1998 - 2009 DH Instruments, a Fluke Company All rights reserved

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any form or

by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments 4765 East Beautiful

Lane Phoenix AZ 85044-5318 USA.

DH Instruments, a Fluke Company makes sincere efforts to ensure accuracy and quality of its published materials; however, no warranty,

expressed or implied, is provided. DH Instruments, a Fluke Company disclaims any responsibility or liability for any direct or indirect

damages resulting from the use of the information in this manual or products described in it. Mention of any product does not constitute an

endorsement by DH Instruments of that product. This manual was originally composed in English and was subsequently translated into

other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version and other language

versions, the English version takes precedence.

DH Instruments, a Fluke Company, DH , DHI, PPC, PPC2, PPC3, PPC, and PPC2 AF are trademarks, registered and otherwise.

100521

3152142 REV 103

Printed in the USA.

© 1998-2009 DH Instruments, a Fluke Company

TABLE OF CONTENTS

T

AABBLLEE OOFF

T

TABLE OF CONTENTS .................................................................. I

TABLES ..................................................................................... II

FIGURES

ABO

1. INTRODUCTION

2. INSTALLATION ..................................................................... 3

3. OPERATION .......................................................................... 5

UT THIS MANUAL ................................................................ III

1.1 PRODUCT OVERVIEW....................................................................................................................................... 1

1.2 SUBASSEMBLY DESCRIPTION AND LOCATION........................................................................................... 1

1.3 SPECIFICATIONS............................................................................................................................................... 2

2.1 PNEUMATIC........................................................................................................................................................ 3

2.2 ELECTRICAL ...................................................................................................................................................... 4

C

OONNTTEENNTTS

C

.................................................................................... II

..................................................................... 1

S

3.1 GENERAL OPERATING INSTRUCTIONS......................................................................................................... 5

4. MAINTENANCE...................................................................... 7

4.1 GENERAL............................................................................................................................................................ 7

4.2 REMOVING AND INSTALLING THE SPLT FILTER.......................................................................................... 7

4.3 SPLT EXHAUST VALVE REMOVAL AND REPLACEMENT............................................................................ 8

4.4 OVERHAUL......................................................................................................................................................... 8

4.5 PARTS................................................................................................................................................................. 9

Page I © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

T

AABBLLEES

T

Table 1. Parts Listing ...........................................................................................................................................9

F

IIGGUURREES

F

Figure 1. SPLT (Overall View) .............................................................................................................................1

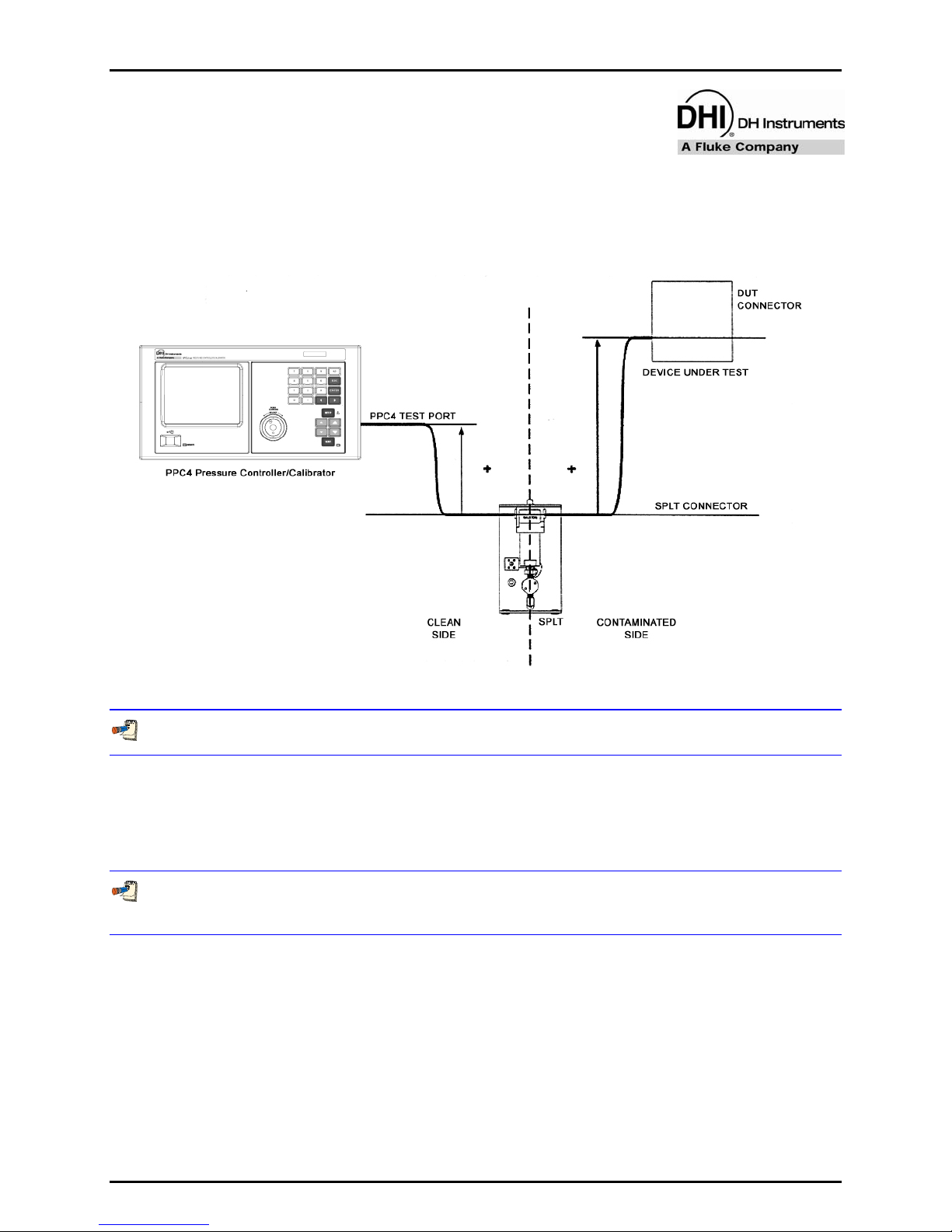

Figure 2. PPC with SPLT and DUT......................................................................................................................3

Figure 3. Front View (Left) and Side View (Right)................................................................................................9

S

S

© 1998-2009 DH Instruments, a Fluke Company Page II

ABOUT THIS MANUAL

A

BBOOUUTT

A

(CAUTION) is used in manual to identify user warnings and cautions.

(NOTE) is used in the manual to identify operating and applications advice and additional explanations.

T

T

HHIISS

M

AANNUUAAL

M

L

Manual Conventions

Page III © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2009 DH Instruments, a Fluke Company Page IV

1. INTRODUCTION

.

11.

I

NNTTRROODDUUCCTTIIOON

I

N

1.1 PRODUCT OVERVIEW

The SPLT is a free standing accessory designed to protect the PPC from liquid contamination returning from

the system or device under test.

The SPLT is made up of a stainless steel body with an internal X-Type coalescing filter and a bottom drain port

fitting with an electrically actuated purge valve. The filter and valve assembly is installed in a mounting stand.

1.2 SUBASSEMBLY DESCRIPTION AND LOCATION

1. Purge Tube - Exhaust liquids and contaminants 3. Pressure Connections – 1/4 in. NPT F to test and to

2. Exhaust Valve - Solenoid valve to release pressure 4. Electrical Connection - Terminal block connections to

Page 1 © 1998-2009 DH Instruments, a Fluke Company

PPC

PPC valve driver for activation of exhaust valve

Figure 1. SPLT (Overall View)

SPLT™ USER’S MANUAL

1.3 SPECIFICATIONS

Pressure Connections

Power Requirements

Weight

Dimensions

Maximum Working Pressure

Maximum Differential Across Filter

Operational Capacity of Filter Body

1/4 in. NPT F

Apply 12 V to actuate valve, 6 watts

1.7 kg (3.8 lb)

10 cm H x 10 cm W x 17.5 cm D (3.9 in. x 3.9 in. x 6.9 in.)

2 000 psi

80 psi

10 cc

© 1998-2009 DH Instruments, a Fluke Company Page 2

2. INSTALLATION

.

22.

I

NNSSTTAALLLLAATTIIOON

I

N

2.1 PNEUMATIC

Figure 2. PPC with SPLT and DUT

Be sure SPLT is at low point of pneumatic system.

The SPLT is intended to collect and exhaust liquid contaminants that may be present in the device or system

under test so that they do NOT return to the PPC.

The SPLT is installed in the test connection line at a low point between PPC and the device or system under

test. The SPLT pressure connections are 1/4 in. NPT female.

Teflon™ tape or another sealing material should be used to assure leak free connection of adaptors

installed in the SPLT pressure connections.

Proper SPLT operation is dependent on the gas flowing through it in the correct direction. Make sure to connect

the SPLT to the device or system under test and the PPC following the connector port labels on the SPLT.

Connect the SPLT electrically to the PPC rear panel DRIVER connection and to the SPLT term inal block (see

Section 2.2).

The SPLT must be mounted vertically with the purge valve at the bottom to perform properly. The SPLT MUST

be at a lower point in the system than the PPC and/or the device under test. In operation, liquid contaminants

collected from the device or system under test will be exhausted through the SPLT purge valve.

Page 3 © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

Liquid contaminants will be forcibly ejected from the SPLT purge tube. Provision for collecting the purged

liquids should be considered when installing the SPLT.

Excessively dirty or wet filter elements can adversely affect pressure control.

2.2 ELECTRICAL

In order to take advantage of the automatic purging feature of the PPC, the SPLT valve MUST be connected to

the PPC external driver #8.

Connect like this if drivers connector with attached cable was included with SPLT:

Connect drivers connector to DR IVERS connector on back panel of PPC. Attach the two wires to the

terminal block on the SPLT

Connect like this if you have SPLT without drivers connector:

Solder (2) 24 gauge wires of desired length to the 12-pin connector provided with the PPC. Connect

(1) wire to pin L and the other to pin B. Connect drivers connector to DRIVERS connector on back

panel of PPC. Attach the other end of these wires to the terminal block on the SPLT.

Polarity is NOT significant to the operation of the purge valve.

© 1998-2009 DH Instruments, a Fluke Company Page 4

3. OPERATION

.

33.

3.1 GENERAL OPERATING INSTRUCTIONS

See the section on Installing a Self Purging Liquid Trap in the PPC Operation and Maintenance manual.

O

PPEERRAATTIIOON

O

N

Page 5 © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

S

N

N

OOTTEES

© 1998-2009 DH Instruments, a Fluke Company Page 6

4. MAINTENANCE

.

44.

M

AAIINNTTEENNAANNCCE

M

E

4.1 GENERAL

The maintenance of the SPLT consists of cleaning or replacing the internal coalescing filter. A dirty filter should

be rinsed with a degreasing agent to remove oil and particulate matter. A filter with physical damag e should be

replaced.

4.2 REMOVING AND INSTALLING THE SPLT FILTER

See Section 4.5 for part number and figures referred to in the filter replacement procedure.

Remove power and pressure connections prior to disassembly.

The procedure for replacing the coalescing filter in the SPLT is as follows:

Disconnect pressure tubing to the SPLT if necessary.

Disconnect power leads to the exhaust valve solenoid (3137053).

Disconnect drain tube (3232357) from elbow adaptor (3133040).

Unscrew lower housing of filter using flats on the lower housing.

Lower the housing with attached valve and fittings through the slot in the mounting bracket.

Remove filter, clean cavity (3136996).

Install new filter.

Re-assemble SPLT.

Leak Check.

Page 7 © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

4.3 SPLT EXHAUST VALVE REMOVAL AND REPLACEMENT

See Section 4.5.

• Disconnect pressure tubing to the SPLT.

• Disconnect power leads to the exhaust valve solenoid (3137053).

• Remove solenoid valve from SPLT body (3136996).

• Remove fittings (3137066, 3133040) and drain tube (3232357) from exhaust valve.

• Install fittings (3137066, 3133040) and drain tube (3232357) onto the new exhaust valve.

• Reinstall exhaust valve onto SPLT body (3136996).

• Leak check assembly.

Any or all of the following items may be included as part of SPLT maintenance and overhaul:

• Clean or change filter (see Section 4.1).

• Clean internal portions of SPLT body using a degreasing agent.

• Check exhaust valve solenoid power leads.

• Check tightness of fittings on SPLT exhaust solenoid valve.

• Check drain tube and replace as necessary.

4.4 OVERHAUL

Any or all of the following items may be included as part of SPLT maintenance and overhaul:

• Clean or change filter (see Section 4.1).

• Clean internal portions of SPLT body using a degreasing agent.

• Check exhaust valve solenoid power leads.

• Check tightness of fittings on SPLT exhaust solenoid valve.

• Check drain tube and replace as necessary.

© 1998-2009 DH Instruments, a Fluke Company Page 8

4. MAINTENANCE

4.5 PARTS

Figure 3. Front View (Left) and Side View (Right)

Unless otherwise specified, Seal NPT Connections using Teflon™ tape.

Table 1. Parts Listing

PART NUMBER

2678004

3232357

3153533

3153741

3115728

3133040

3133921

3134409

3136981

3136996

3137053

3137066

3137142

3137156

3146329

PREVIOUS DHI

PART NUMBER

100970-Z

101392-Z

102088-Z

102461-Z

122587-Z

100321

101008

101468

102501

102502

102514

102516

102528

102530

122541

DESCRIPTION QTY REQUIRED

Hex nut, M 3 1

Drain tube, 1/8 in. O.D. 1

Split lock washer 2

Label 1

Label 1

Elbow adaptor 1

Allen screw, M3 X 20 1

Rubber grommet 6

Liquid trap 1

Filter 1

12 VDC solenoid valve 1

Reducer, adaptor 1

Terminal block 1

Allen screw, 1/4-20 X 1/2 2

Mounting bracket 1

Page 9 © 1998-2009 DH Instruments, a Fluke Company

SPLT™ USER’S MANUAL

N

N

OOTTEES

S

© 1998-2009 DH Instruments, a Fluke Company Page 10

Loading...

Loading...