OPERATOR MANUAL

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

2

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

INDEX.

1. Important Safety Instructions ……………………………………………………………………………….

2. Notes on Usage and Storage ……………………………………………...………………………………..

3. Presenting the printer ………………………………………………………………………………………..

4. Turning ON and OFF the printer ……………………………………………………………..…………......

5. Loading ink ……………………………………………………………………………………………………

6. Loading the media …………………………………………………………………………….…………......

7. Nozzle check test print ………………………………………………………………………………………

8. Purge and Auto-cleaning ……………………………………………………………………………………

9. Global bidirectional adjustment ……………………………………………………………………………..

10. Feed Adjustment ………………………………………………………….………………………………..

11. Using the dryer …..………………………………………………………………………………………….

12. Exchanging media ……………….………………………………………………………………………...

13. Removing the Take-up roll ……………………………………………………………………..…………..

14. Problem solver ……………………………………………………………………………………………...

15. Appendix …………………………………………………………………………………………………….

3

3

5

13

15

17

26

31

34

37

40

43

45

47

50

THANK YOU FOR CHOOSING d·gen

Be sure to read this document carefully for a correct use of this printer.

The contents of this document are subject to change without notice.

Please inform us if any misprint or error is found in this document.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of d∙gen Inc. International.

The information contained herein is designed only for use with this d∙gen printer. d∙gen is not

responsible for any use of this information as applied to other printers.

Neither d∙gen Inc. International nor its affiliates assumes no responsibility to the purchaser of this

product or third parties for damages, losses, costs, or expenses incurred by the purchaser or third

parties as a result of accident, misuse, or abuse of this product or unauthorized modifications, repairs,

or alterations to this product, or failure to strictly comply with d∙gen Inc. International’s operating and

maintenance instructions.

d∙gen Inc. International shall not be liable for any damages or problems arising from the use of any

options or any consumable products other than those designated as original d∙gen products or d∙gen

approved products.

d∙gen Inc. International shall not be held liable for any damage resulting from electromagnetic

interference that occurs from the use of any interface cables other than those designated as original

d∙gen products or d∙gen approved products.

d∙gen Inc. International

73, Bupyeong-daero 297 beon-gil

Bupyeong-gu, Incheon 21315

Republic of Korea

Phone: (+82) 32 510 3503

Web page: www.dgen.com

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

3

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

1. IMPORTANT SAFETY INSTRUCTIONS.

When using this product.

Take care not to spill liquid on this product.

Do not attempt to service this product yourself.

Do not block or cover the openings in the printer.

Unplug this product and refer servicing to qualified service personnel under the following conditions:

The power cord or plug is damaged; liquid has entered the product; the product has been dropped or

the cabinet damaged; the product does not operate normally or exhibits a distinct change in

performance.

Do not move the print head by hand; otherwise you may damage this product.

When handling the ink bottles.

Wear protective eyewear and gloves when refilling ink tanks or replacing the waste ink bottle.

Keep ink packs out of the reach of children and do not drink the ink.

If fluid adheres to your skin, immediately wash it off using large volumes of soapy water. Consult a

physician if the skin appears irritated or is discolored.

If fluid enters your eyes, rinse immediately with water. Failure to observe this precaution could result in

bloodshot eyes or mild inflammation.

If fluid enters your mouth, consult a physician immediately.

If fluid is swallowed, do not force the person to vomit, and consult with a physician immediately. If the

person is forced to vomit, fluid may get caught in the trachea, which can be dangerous.

2. NOTES ON USAGE AND STORAGE.

When using the printer.

Keep the printer running in a stable and controlled environment under these temperature and humidity

values: 20°C ~ 25°C (68°F ~ 41°F) and 45% ~ 65% of relative humidity.

Be sure the operating conditions suit the media. For more information, see the documentation supplied

with the media.

Also, when operating in dry areas, air-conditioned environment, or under direct sunlight, maintain the

appropriate humidity.

Do not bend or tug the waste ink tube. Ink could spill inside or around the printer.

Avoid using the printer in locations with heat sources or locations that are exposed to direct drafts from

ventilators or air conditioners. The print head nozzles could dry out and clog.

When the power is on, do not remove the power plug or cut the power at the breaker. The carriage may

not be capped properly. In this case, turn on the power and wait until capping is performed

automatically.

Be sure that the waste ink bottle is installed whenever the printer is on.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

4

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

When not using the printer.

If you do not print for a long time, the print head nozzles may become clogged. Turn the printer on at

least once a week to prevent the print head clogging.

Leaving the printer for too long without turning it on may result in a malfunction. Repair work for such

malfunction will be charged.

If you will not be using the printer for more than 2 weeks, maintenance must be performed by a service

engineer before and after this period. This maintenance work will be charged.

Note that even if proper maintenance has been done before a long period of non-use, repair may be

necessary when doing maintenance for reusing the printer, depending on the period and conditions of

storage. In such a case, the repair work will also be charged. Contact your local dealer or

support@dgen.com for more information.

The media may also become wavy or curled, causing jams or resulting in the media coming into contact

with the print head. Remove the media before storing the printer.

Store the printer after confirming that the print head has been capped. If the print head is left uncapped

for a long time, the print quality may decline.

Close all covers before placing the printer in storage. If you are not using the printer for a long time, put

the gray anti-static cover (provided with the printer) on the printer to prevent dust build-up. The print

head nozzles are very small, and they can become clogged easily if fine dust gets on the print head,

and you may not be able to print properly.

If you have not used the printer for a long time, check the print head for clogging before you start

printing. Perform head cleaning if the print head is clogged.

When storing the printer, be sure that it is level: do not store it on an angle, on end, or upside down.

When handling the ink bottles.

Store the ink bottles at room temperature out of direct sunlight.

To ensure print quality, use all the ink in the ink bottle before the expiry date. (One year after the

manufacture date).

If the ink bottle has been stored in a cold location for a long period of time, keep at room temperature

for at least 24 hours before using.

Be sure not to leave any ink in the ink bottle after refilling the Big Ink System.

Refill the Big Ink System as soon as possible after opening the ink bottle.

When handling the media before printing.

Do not fold the media or damage the printable surface.

Do not touch the printable surface. Moisture and oils from your hands can affect print quality.

When handling media, hold it by both edges. We recommend wearing cotton gloves.

Keep the media dry.

Packaging materials can be used to store media and should not be thrown away.

Avoid locations that are subject to direct sunlight, excessive heat, or humidity.

When not in use, media should be removed from the printer, rewound, and inserted in its original

packaging for storage. Leaving media in the printer for extended periods may cause it to deteriorate.

When handling the media just after being printed.

Do not rub or scratch the printed surface. If it is rubbed or scratched, the ink may peel off.

Do not touch the printed surface, as this may remove the ink.

Make sure printouts are completely dry before folding or stacking, as otherwise discoloration or other

marks may appear where the prints touch. These marks will disappear if the prints are immediately

separated and dried but will become permanent if the surfaces are not separated.

Avoid direct sunlight.

To prevent discoloration, display and store prints as instructed in the documentation supplied with the

media.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

5

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

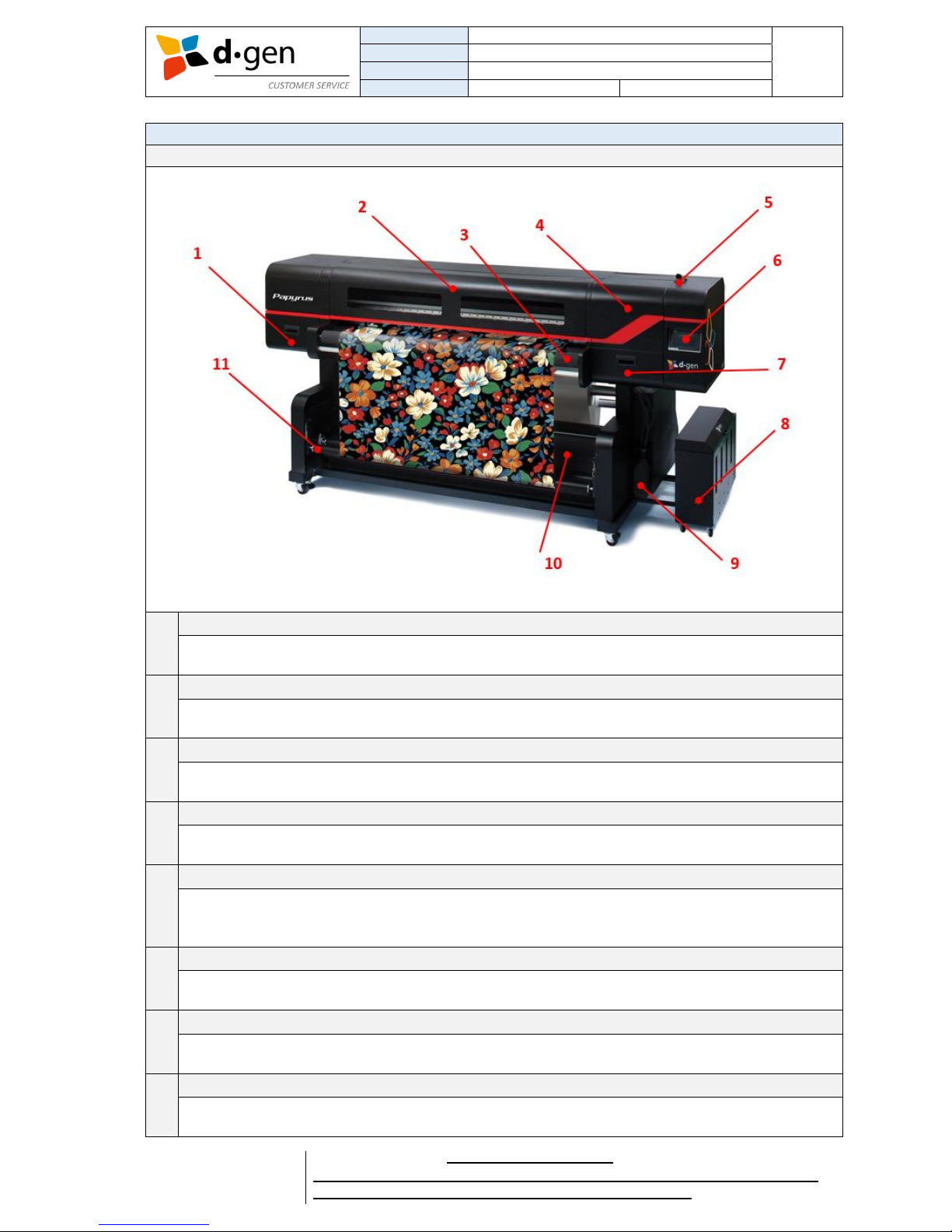

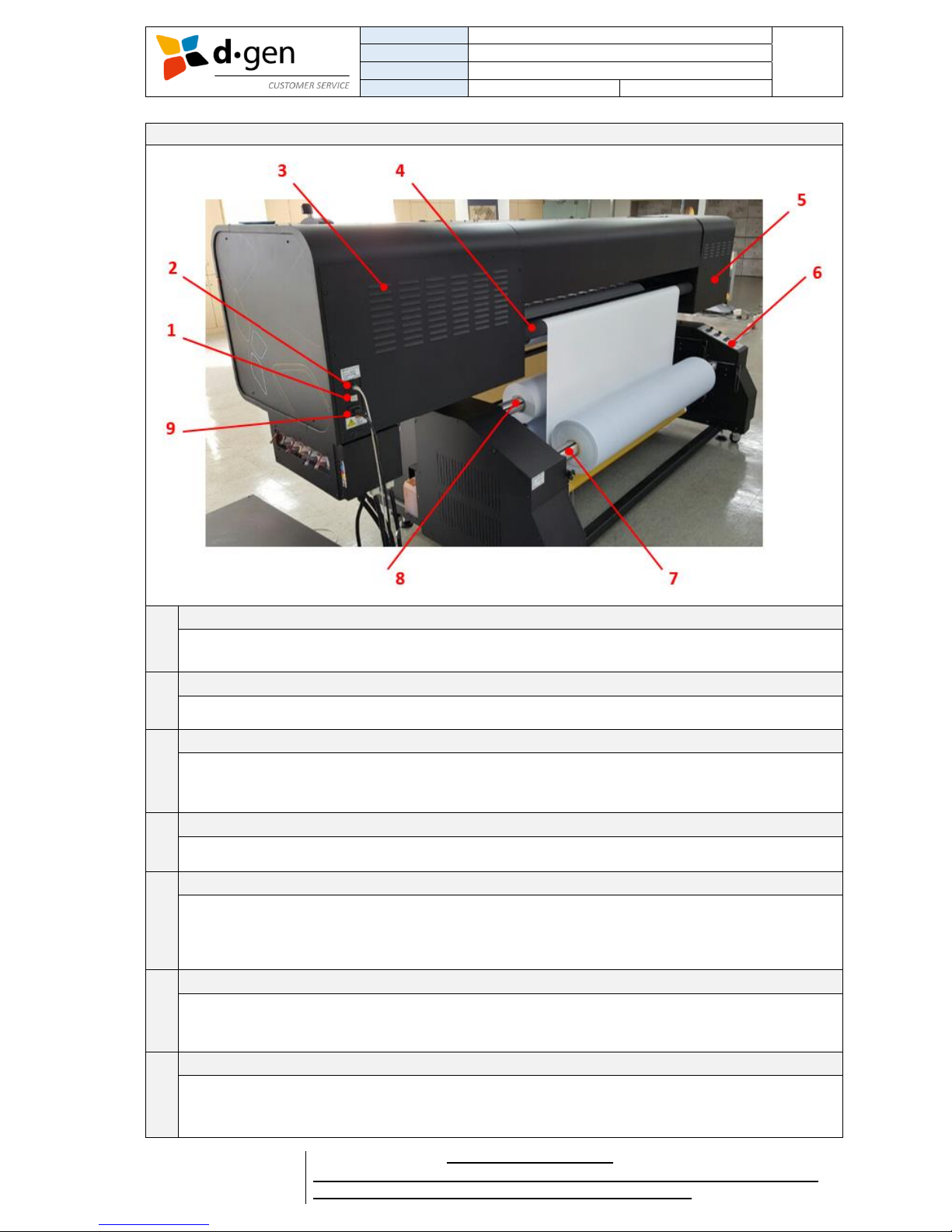

3. PRESENTING THE PRINTER.

FRONT

1

Left side maintenance front cover.

Open this cover to clean the area around the print head. It is normally closed when the printer is in

use.

2

Front cover.

Open when loading media, cleaning the inside of the printer, or removing jammed media. Normally

closed when using the printer.

3

Front roller.

This roller stretches the media’s fibers while moving it downwards to the front dancing bar.

4

Carriage cover.

This cover is opened for maintenance purposes, such as manual purge of the print heads, cleaning

of the wipers and the capping station, etc.… Normally closed when using the printer.

5

Pinch roller lever.

With this lever is possible to move up/down the pinch rollers when mounting, unmounting or

advancing the media. Move the lever backwards to lift the pinch rollers. Move the lever to the front

to lower the pinch rollers.

6

Touch operating panel.

For a full control of the printer without using a computer.

7

Lower carriage cover.

This cover is opened for maintenance purposes taken in the capping station. Also, to switch on the

control PC by pressing the green led button. Normally closed when using the printer.

8

Big Ink System.

Designed to be refilled with inks while printing. Level of ink is easy to check visually or by sensor.

Provided with a double filtering system to protect against harmful substances.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

6

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

9

Waste ink drain bottle.

Designed to collect the ink waste coming from the capping system and flushing stage. Collects up to

2 L of waste ink. So, we recommend to check how full the bottle is every time when flushing or

purging the heads.

10

Dryer (printer’s base).

Equipped with 8 blowers, 8 heating rods and 2 rubber heaters, this drying system has the enough

ability to dry up the wet media before it gets back to the take-up unit.

11

Front dancing bar.

The printer comes with two types of dancing bars. One heavier than the other. Depending on the

media’s characteristics it is used either the heavier or lighter dancing bar.

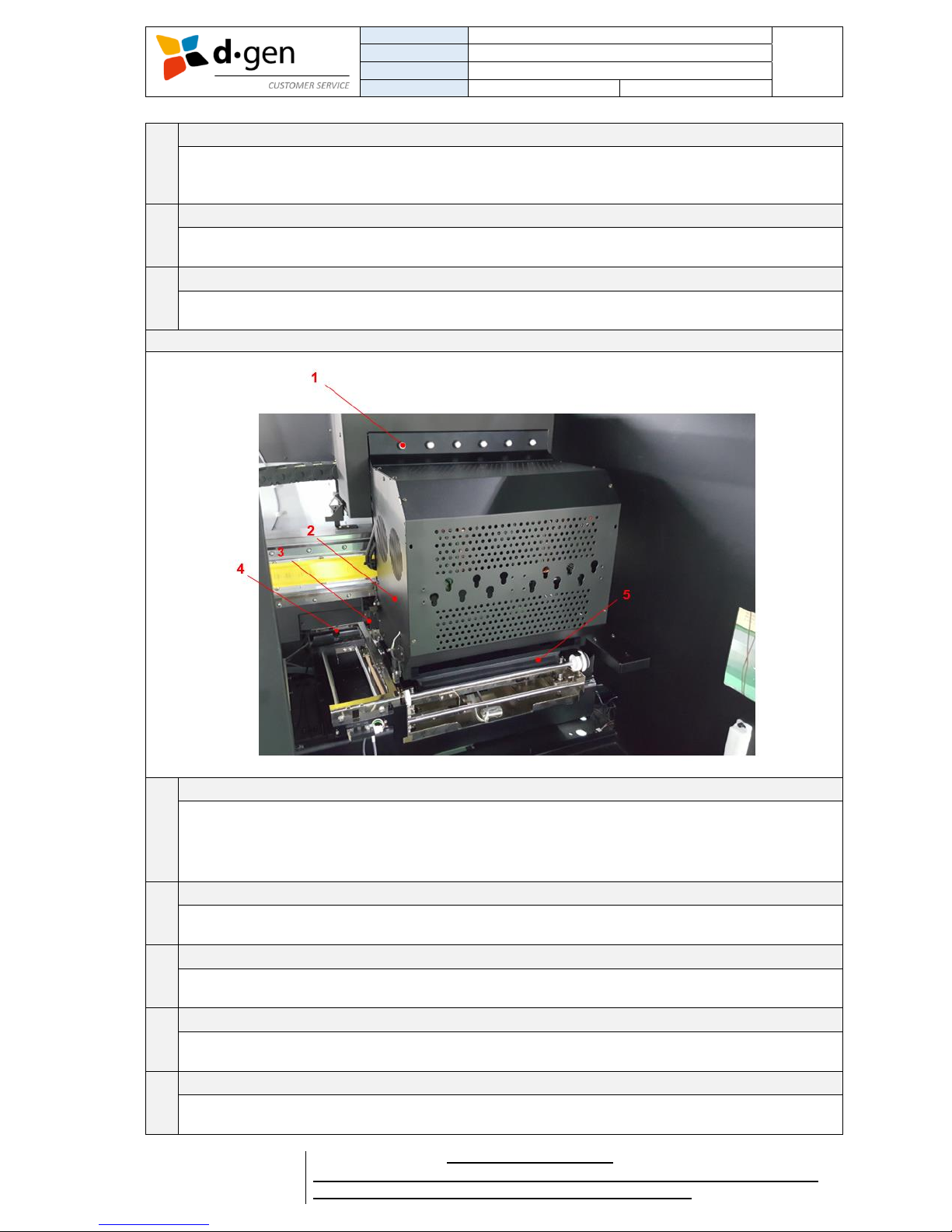

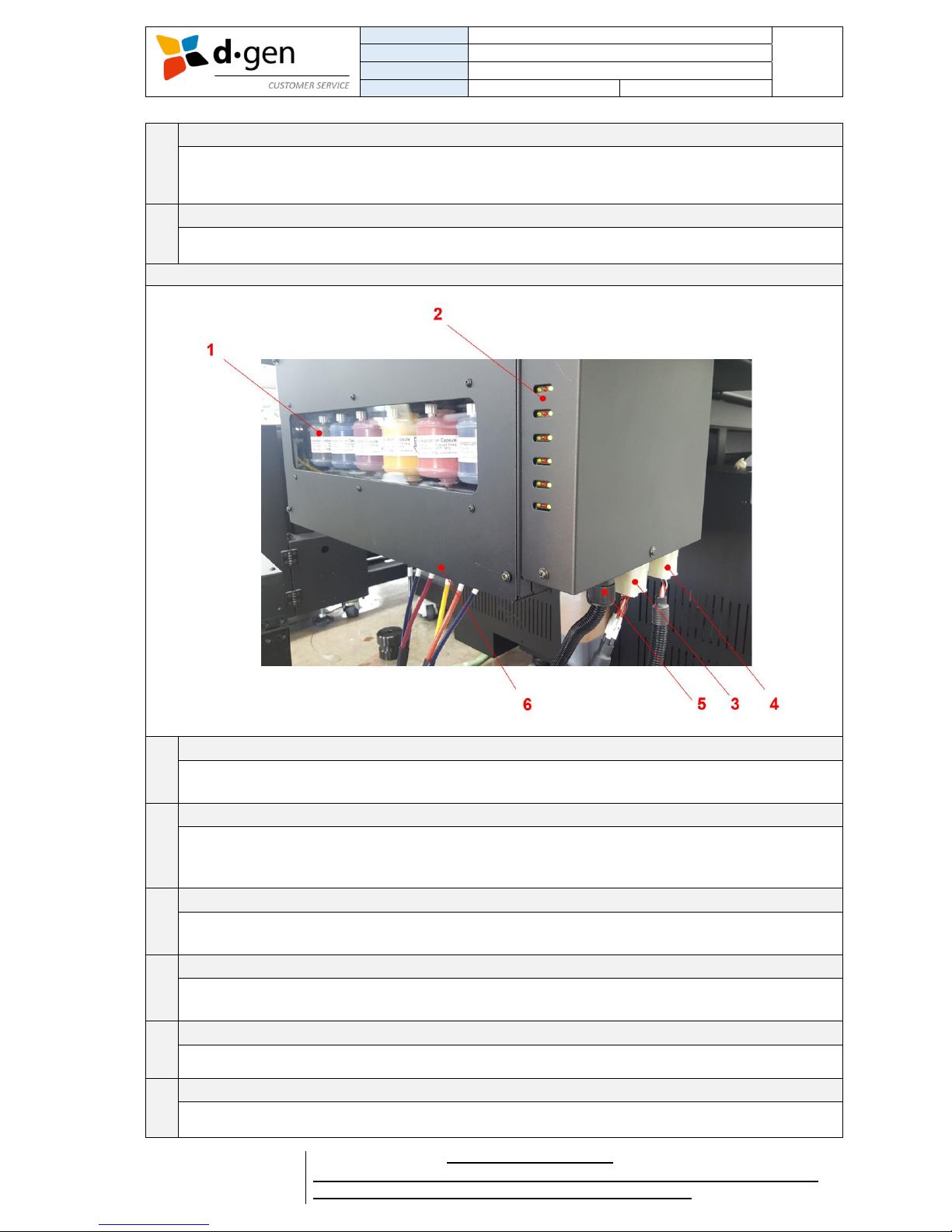

INTERIOR (CARRIAGE)

1

Solenoid valves.

The solenoid valve is opened if the LED is turned on. Having the solenoid valve opened allows free

circulation of negative air pressure between the vacuum pump and the head. Making the heads to

bleed for long purging is possible by closing the solenoid valve (LED switched off) right after the

purge button is pressed in the touch panel.

2

Carriage.

The carriage prints by moving left and right while firing ink. Periodical cleaning is required.

3

Carriage height adjustment lever.

This lever regulates the carriage height in 3 positions. Low, medium and high. Depending the

thickness of the media. There is a difference of 1 mm between positions.

4

Automated wiper unit.

If user executes Auto cleaning, this wiper will work automatically. To increase the wiper’s

performance, remove ink residue on wiper periodically.

5

Automated capping unit.

Except during printing, this capping station covers the print head nozzles to prevent them from

drying out. Cleaning may be required.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

7

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

INTERIOR (CAPPING)

6

Home position sensor.

The carriage as soon as it gets to this sensor will adjust its speed to match its print heads with the

capping station’s location.

7

Right limit sensor.

For safety, this sensor brings the machine in an emergency state if the carriage crashes against the

right stopper.

8

Right stopper.

This machine is provided with 2 side stoppers to prevent the carriage damaging the side limit

sensors.

9

Flushing stage.

The flushing unit is used to keep the print heads unclogged. Every time the carriage leaves the

home position for printing right to left, the heads flush a very small quantity of ink in order to keep

the nozzles always unclogged.

10

Automated wiper unit’s front limit sensor.

Also, provided with a rear sensor. Brings the wipers to a complete stop reached this limit sensor.

11

Automated capping unit’s down limit sensor.

Brings the capping unit to a complete stop when reached its lowest point.

12

PC control box’s main switch.

To turn ON/OFF the software side of the printer.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

8

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

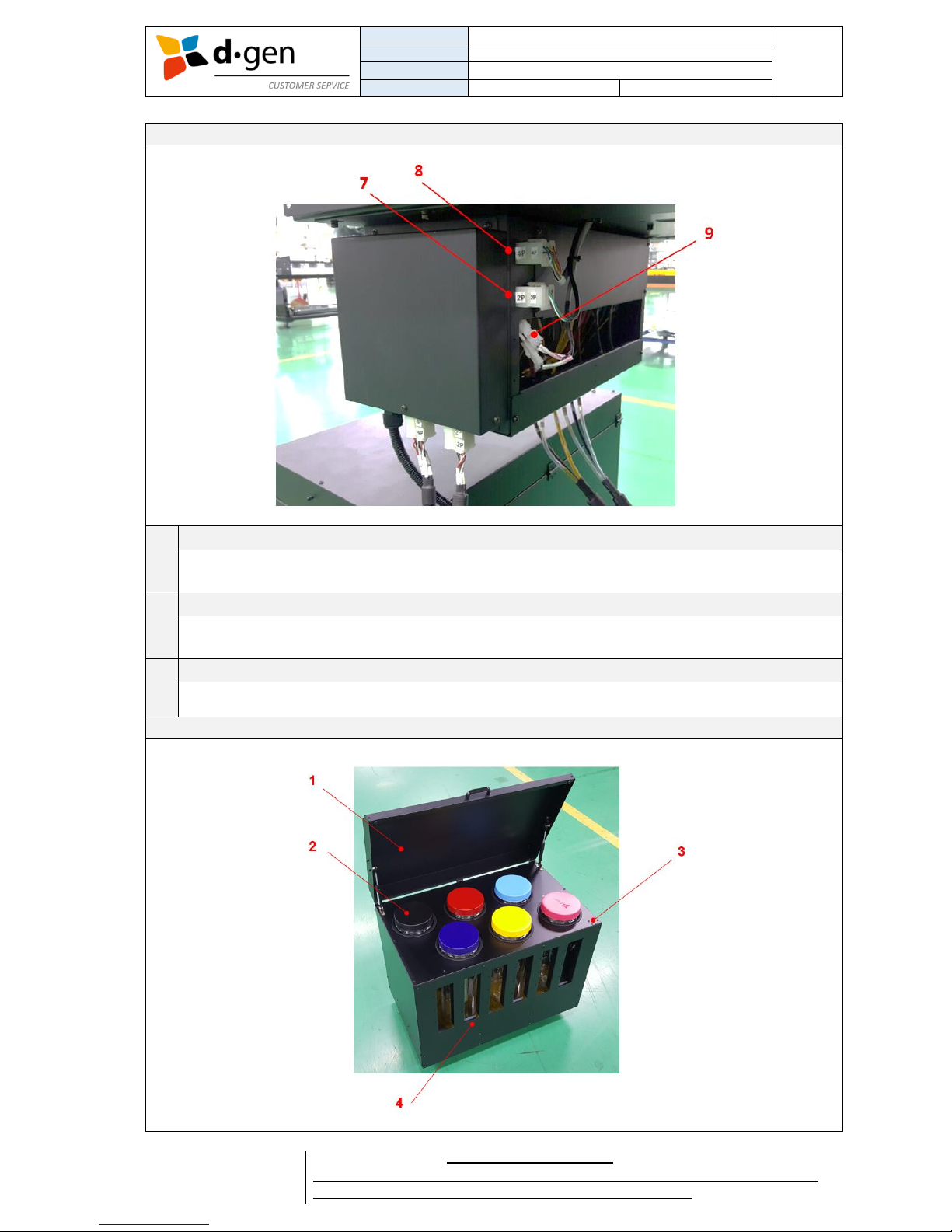

BACK

1

Printer’s main ON/OFF switch.

This switch turns ON/OFF the printer. The base has its own main switch separately. Is located at the

printer’s base control panel.

2

LAN port.

Connects the LAN cable. Use a shielded twisted pair cable (category 5 or higher).

3

Electric panel.

This electrical panel contains hazardous components. Risk of Electrical Shock. It is used for

maintenance purposes. Only Authorized personnel can access this electric panel. Normally closed

when using the printer.

4

Rear rubber free roller.

With the rear control panel is possible to switch it ON/OFF, regulate the feeder’s speed and mode.

5

Negative/Positive pressure system.

Behind this cover there are a series of pumps and valves that creates enough negative pressure in

the heads for stable printing or enough positive pressure to purge the heads for cleaning its nozzles.

When printing, is normal to hear the pump functioning. Cover normally closed when using the

printer.

6

Printer’s base control panel.

Through this control panel is possible to regulate the take-up and the feeder unit’s speed and

direction of rotation. The control panel is also provided with a thermostat to control the temperature

in the dryer.

7

Take-up unit.

The take-up unit consists of a pneumatic shaft able to withstand jumbo rolls between 100 and 150

Kg (220~330 lbs.). The air valve is located on the right side. Is needed an air compressor able to

inflate the shaft over 5 bar (72.5 psi).

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

9

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

8

Feeder unit.

The feeder unit consists of a pneumatic shaft able to withstand jumbo rolls between 100 and 150 Kg

(220~330 lbs.). The air valve is located on the right side. Is needed an air compressor able to inflate

the shaft over 5 bar (72.5 psi).

9

AC 220V 1Ø + N + PE POWER INPUT.

AC 220 single-phase power supply input. The cable is provided with the accessory box.

RIGHT SIDE

1

Ink filter.

One ink filter for color to supply filtered ink to the print heads. This filter needs to be replaced

periodically or when changing the chemistry/color of the ink.

2

Ink LED indicator.

Two LED lights per color. The red LED turns on when the level of ink in the Big Ink System is

critically low. Green LED is turns on if refilled. Buzzer will sound to indicate low level of ink in one of

the ink cylinders.

3

Big Ink System K C M Y sensor level cables.

These cables come from the photo reflecting sensors located in the Big Ink System activating the

green LED indicator when full, and activating the red LED indicator when empty.

4

Big Ink System SP1 SP2 sensor level cables.

These cables come from the photo reflecting sensors located in the Big Ink System activating the

green LED indicator when full, and activating the red LED indicator when empty.

5

Big Ink System’s white LED power supply cord.

To power up the white LED in the Big Ink System.

6

Ink inlets.

Ink hoses from the Big Ink System are connected to this side of the printer.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

10

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

RIGHT SIDE (BACK)

7

Connector for SP1 and SP2 ink supply pumps.

This connector comes from the Ink Supply System board located in the rear electric panel. Activates

SP1 and SP2 ink pumps when the sub-tanks are needed to be refilled.

8

Connector for K C M Y ink supply pumps.

This connector comes from the Ink Supply System board located in the rear electric panel. Activates

K C M Y ink pumps when the sub-tanks are needed to be refilled.

9

White LED and Ink sensor level board DC 24 V power supply.

These cables power up both Ink sensor level board and the white LED lamp in the Big Ink System.

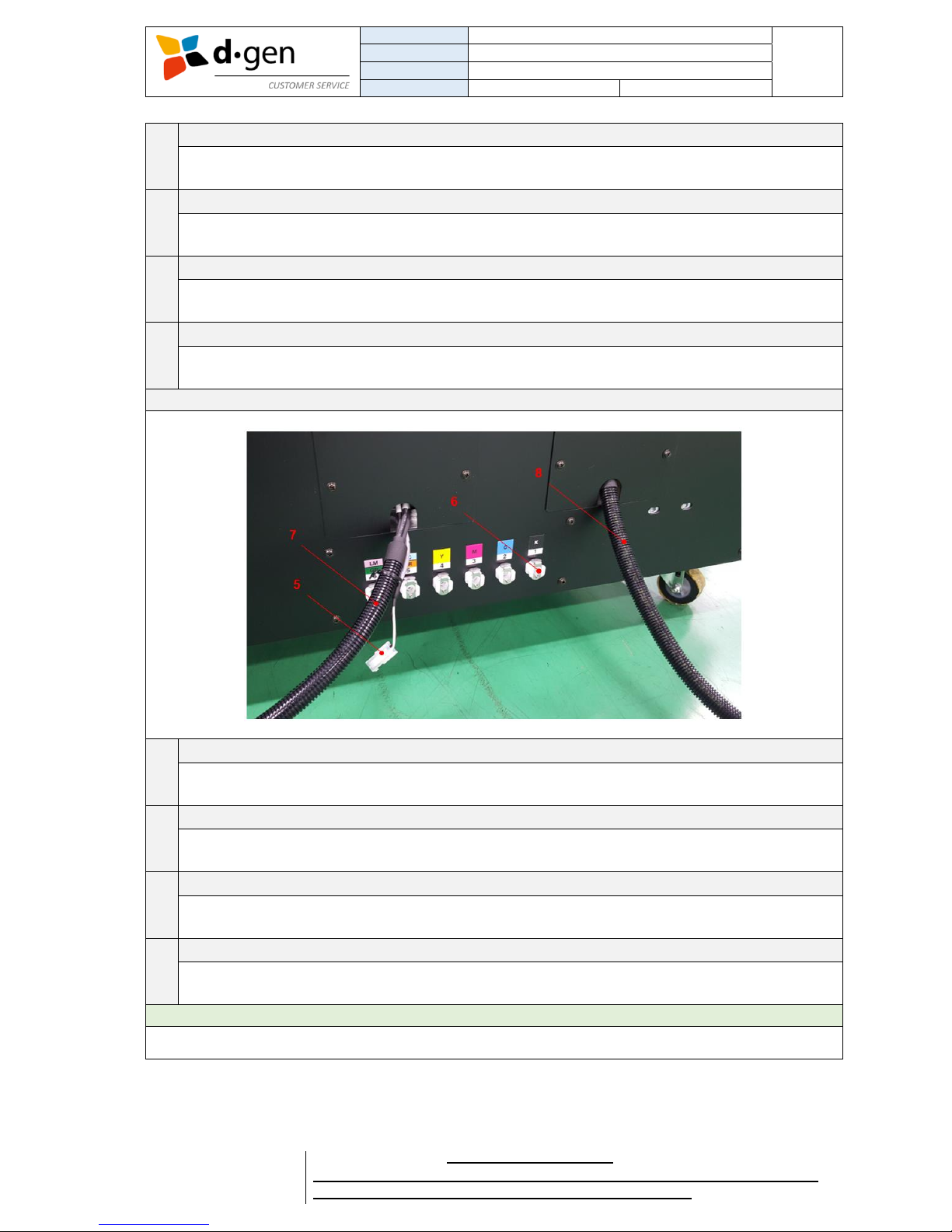

BIG INK SYSTEM

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

11

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

1

Cover.

Buzzer can be heard if this cover is opened. Cover normally closed when using the printer.

2

Lid and ink filter.

We suggest to pour the ink on the filter. Also, is suggested not to close the lid totally to let the air

flow in while the cylinder is getting empty.

3

Cover switch.

This device activated the buzzer when the cover is opened for refilling the inks.

4

Ink level photo sensor.

This photo sensor measures the ink level with a laser beam. Keep this area always free of ink.

BIG INK SYSTEM (BACK SIDE)

5

White LED bar’s power connector.

This cable powers up the white LED light bar in the Big Ink System.

6

Ink outlets.

By pushing down the silver fastening is possible to release or insert the ink line without spilling ink.

7

Sensor level connector (K C M Y inks).

This connector sends the signal from the photo-sensors located in the Big Ink System (to measure

the ink level in the cylinder) to the LED ink level indicators.

8

Sensor level connector (SP1 and SP2 inks).

This connector sends the signal from the photo-sensors located in the Big Ink System (to measure

the ink level in the cylinder) to the LED ink level indicators.

Important

Keep always the ink level’s photo sensor emitter and reflector free of ink and dust.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

12

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

SAFETY DEVICES

1

Emergency push type switch for the printer.

Two at the front on each side. Pushing one of the switches will bring a total stop the carriage and

other moving elements.

2

Open cover switch.

Opening either the front or carriage cover will activate the emergency switch bringing the carriage to

a pause state returning to the home position.

Note

In case the printer exceeds its operation limits such as over-speed, operational temperature, etc., the

operator may use the emergency switches to bring the printer into an emergency stop.

Note

In case one of the safety devices is broken we strongly recommend the user to replace it with the help of

a qualified technician.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

13

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

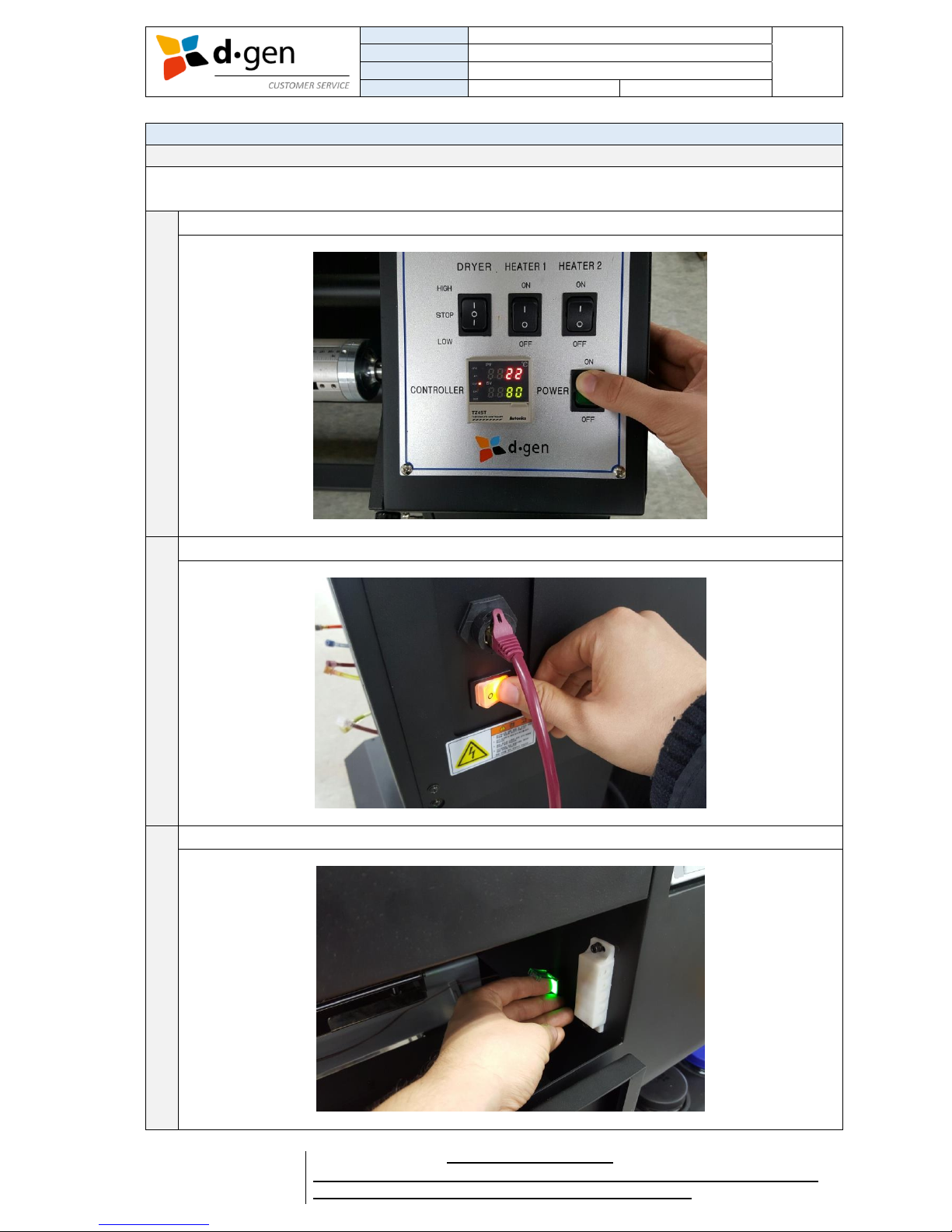

4. TURNING ON AND OFF THE PRINTER.

Turning ON the printer.

The operator must follow the following steps to correctly turn ON the printer.

1

Turn on the dryer (printer’s base).

2

Turn on the printer by pressing the white switch at the back of it.

3

Turn on the PC control box by pressing the green switch.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

14

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

4

Wait for the touch panel to display “Jetting”.

Turning OFF the printer.

Turn off the PC control box by pressing the green switch.

As soon as a beep is heard, turn off the printer by pressing the white switch at the back of it.

Leave the dryer running with no heating. To cool down the unit.

Once cooled, turn off the dryer. By pressing the green switch located in its control panel.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

15

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

5. LOADING INK.

The operator must follow the following steps to correctly load with ink the Big Ink System.

1

Open the Big Ink System’s cover. Buzzer will be activated.

2

Open the lid. Make sure the filter is present and correctly positioned.

3

Pour gently to avoid spilling ink outside the cylinder. Do not pour the ink too fast. Leave some time

to let the ink go through the filter before pouring some more.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

16

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

4

Close the lid. Do not close the lid too tight to let the air go into the cylinder as it gets empty when

printing.

Important

Do not wait until the cylinder gets completely empty. Risk of clogging the ink filter / damaging the heads

with the deposited ink sediments at the bottom. We strongly suggest to refill the tank as soon as the

buzzer is heard.

Important

When pouring ink, foam will be created. Do not let the foam get into the printer. This may negatively

affect the quality of your printings. Therefore, we suggest to refill the tank as soon as the buzzer is heard.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

17

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

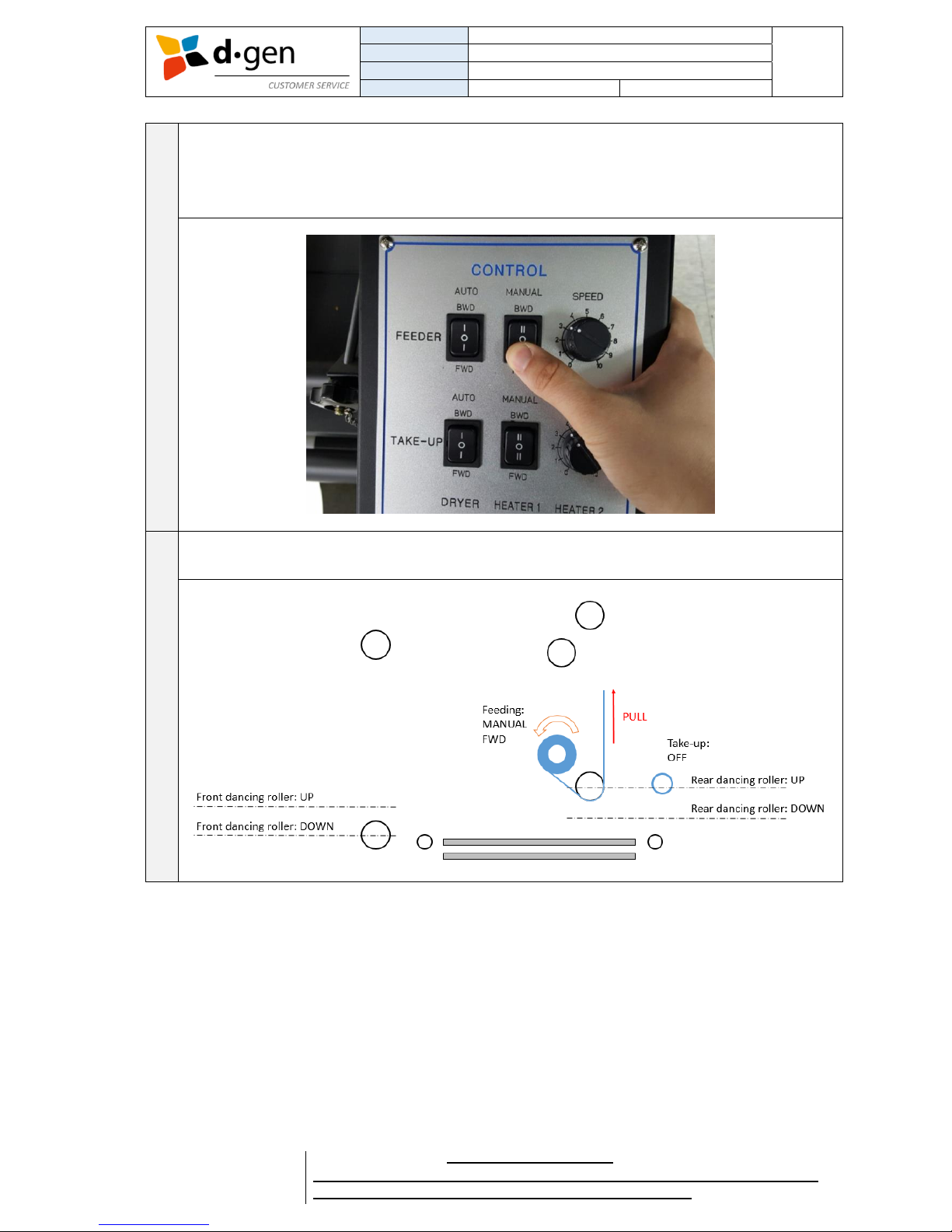

6. LOADING THE MEDIA.

Introducing the printer’s base control panel.

Feeder unit control panel.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

18

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Take-up unit control panel.

1

Release the latches at both side of the feeding unit to remove the pneumatic shaft.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

19

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

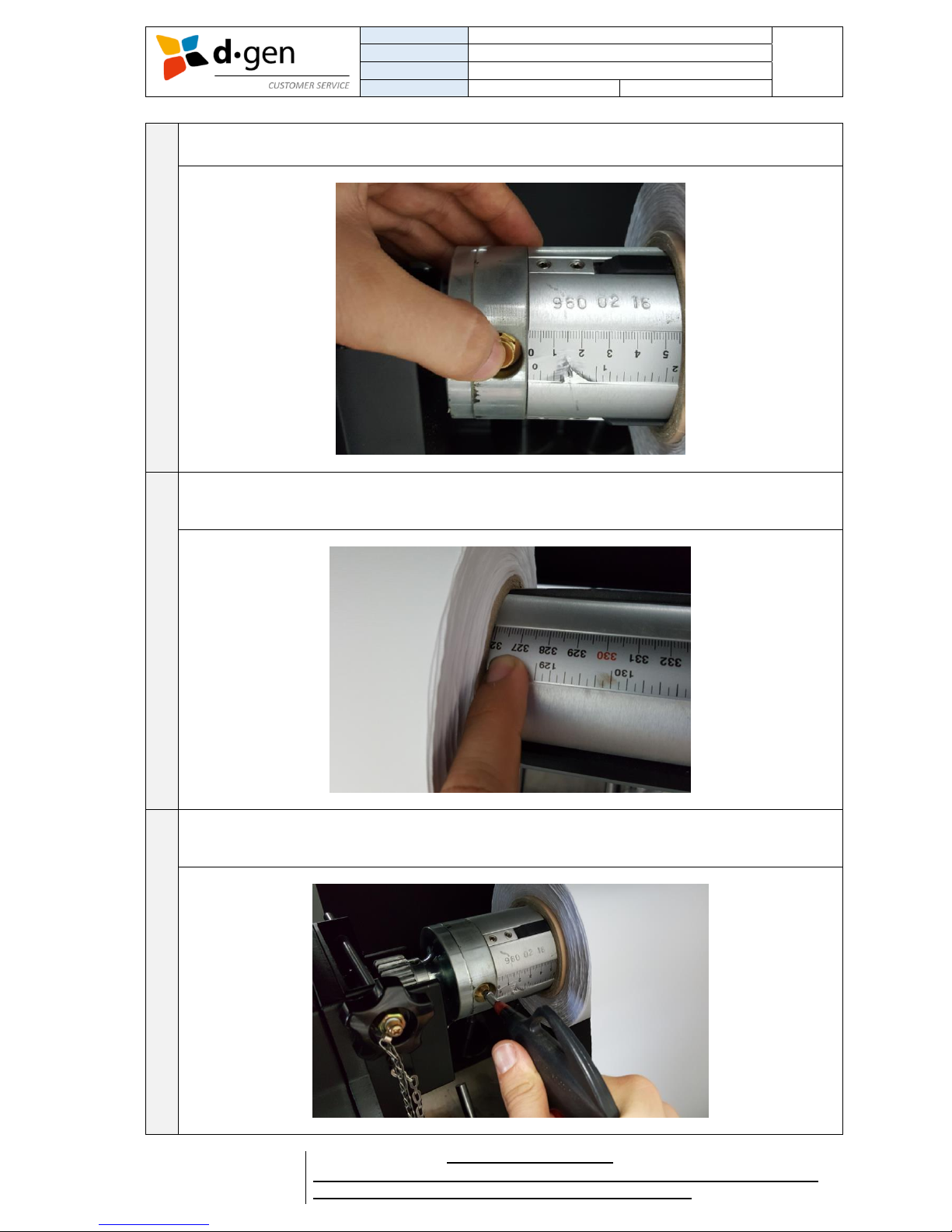

2

Press the golden valve to release all the air inside the pneumatic tube.

3

Place the pneumatic shaft in the media’s core oriented to make the printable side facing upwards

when going through the printing table. Make sure the roll is centered using the measuring tape as a

reference.

4

With the help of an air compressor (only the air gun is provided) stick the gun to the golden valve

and apply compressed air until an approximate value of 5 bars is reached.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

20

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

5

Lift the pneumatic shaft with the roll fastened and place it carefully in the feeder unit. Insert back the

latches at both sides of the feeder unit to safely secure the pneumatic shaft. Using the rear control

panel unwind a certain length of media to make it go through the rear dancing bar. Depending on

how the media’s core is oriented push the MANUAL BWD or FWD to unwind media.

6

Make the media pass the rear dancing bar as shown in the illustration below. Unwind media while

pulling upwards its ends.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

21

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

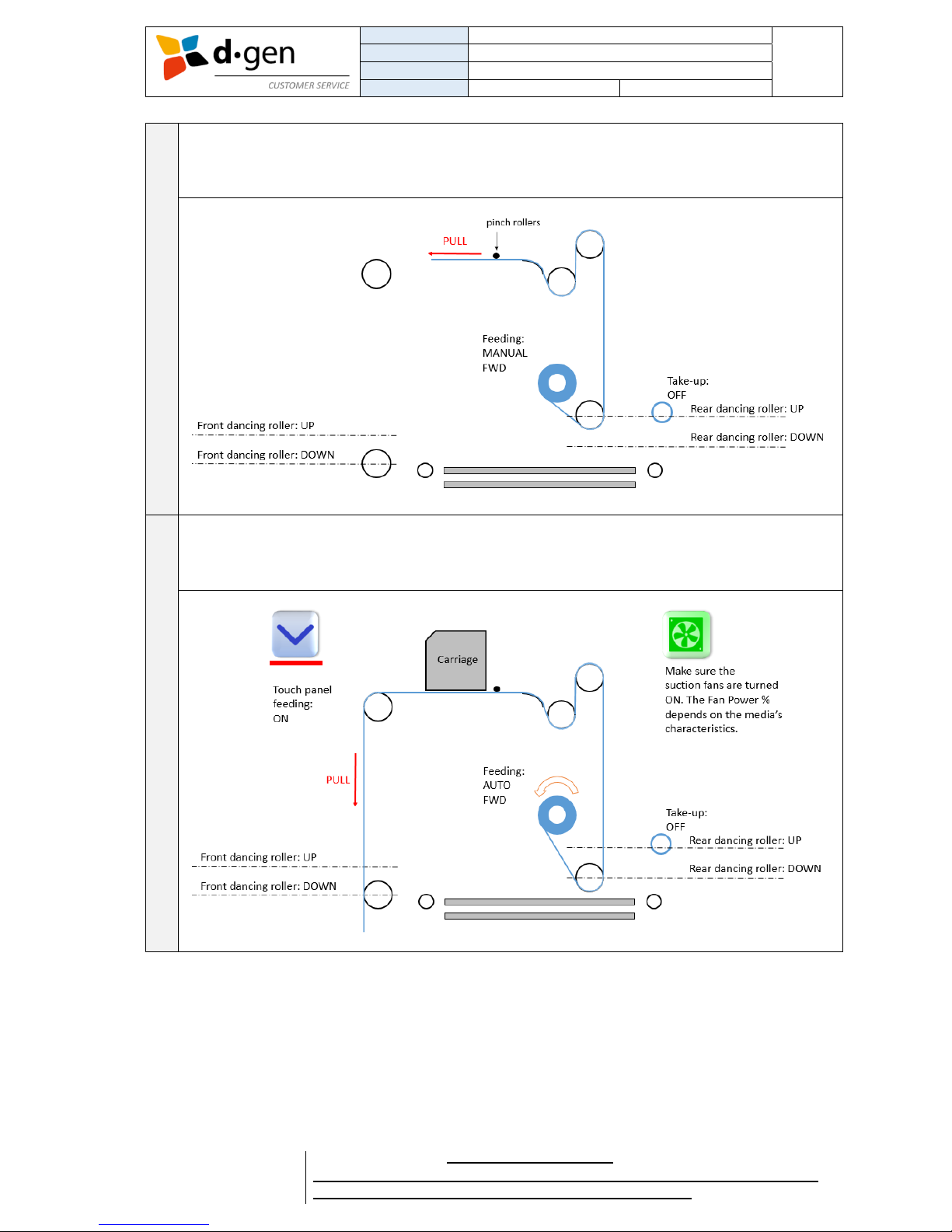

7

Stop unwinding when the media reached a higher point than the free roller. Make the media go

through the free roller. Make sure the media’s edges are aligned with the jumbo roll installed in the

feeder unit.

8

Then make it go through the rubber roller. Make sure the media is aligned by ensuring that the

distance between the edge of the media and the printer’s frame is the same at all points.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

22

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

9

Check the pinch rollers are lifted by moving the lever towards the back of the printer.

Send the media to the front. Always keeping the media perfectly aligned with the printer’s frame at

all points. Once the media is on the front side of the printer, under tension, a second person can

lower the pinch rollers.

10

Change the feeder to AUTO mode FWD. The feeder unit will feed media until the rear dancing bar

reaches its lowest point. On the touch panel press the feeding FWD button. Make sure the suction

fans under the printing table are switched on. Advance media unit reaching the front dancing’s bar

lowest point.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

23

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

11

Insert the media into the dryer. Then advance the media pressing the feeding FWD button on the

touch panel. A second person will be on the printer’s back side to grab the media’s end.

12

Once the media reached the other side of the dryer you may pause advancing media. Align the

media with the rear dancing bar.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

24

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

13

Using a paper tape attach the media’s end to the core. Always keeping the media well aligned. Once

is done, you may turn the take-up unit to AUTO FWD. The front dancing bar will go down to its lower

position. Before printing you may turn on the dryer by pressing in DRYER the high/low mode and

HEATER 1 to ON.

Caution

The drying unit may be hot; observe all necessary precautions. Failure to observe the necessary

precautions could result in burns.

Caution

Keep the drying unit always free of intrusive elements. Risk of fire.

Caution

Please be careful not to trap your hands or fingers when opening or closing the front cover. Failure to

observe this precaution could result in injury.

Caution

Secure the media in place by the following procedure. Injury may occur if the media falls.

Caution

Since the media is heavy, it should not be carried by one person. When loading or removing the media,

use at least two persons.

Important

Load media immediately before printing. The pressure rollers may crease media left in the printer. The

media may also become wavy or curled, causing jams or resulting in the media coming into contact with

the print head.

Important

Do not place exposed media directly on the floor. Media should be rewound and inserted in its original

packaging for storage.

Important

If media is loaded and the right and left edges of the roll are uneven, media feeding problems may cause

the media to move around during printing. Either rewind to align the edges or use a roll without any

issues.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

25

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Caution

After finishing installing the media, please use the media guide plates on the bed plate to ensure the

carriage will not hit the edges of the media.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

26

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

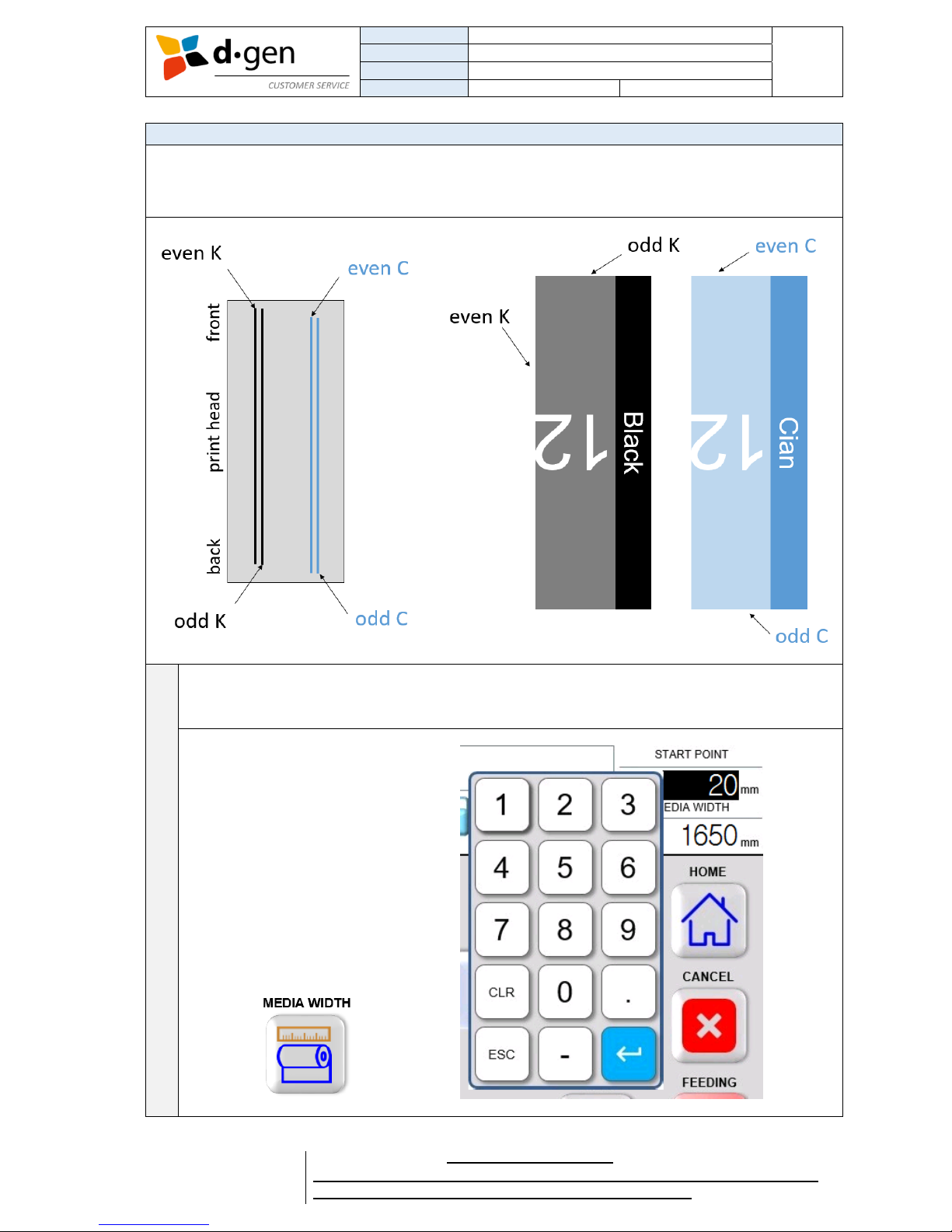

7. NOZZLE CHECK TEST PRINT.

The nozzle check test print allows the user to check the current state of the nozzles in the print head.

Helps to determine if the nozzles are firing as they should or not. Probably caused by dried ink or air in

the system.

1

Once the media is correctly loaded you may proceed to check the media’s width by pressing the

button MEDIA WIDTH. The media’s width will be displayed under “MEDIA WIDTH” in mm. Then set

the desired point of origin (START POINT).

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

27

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

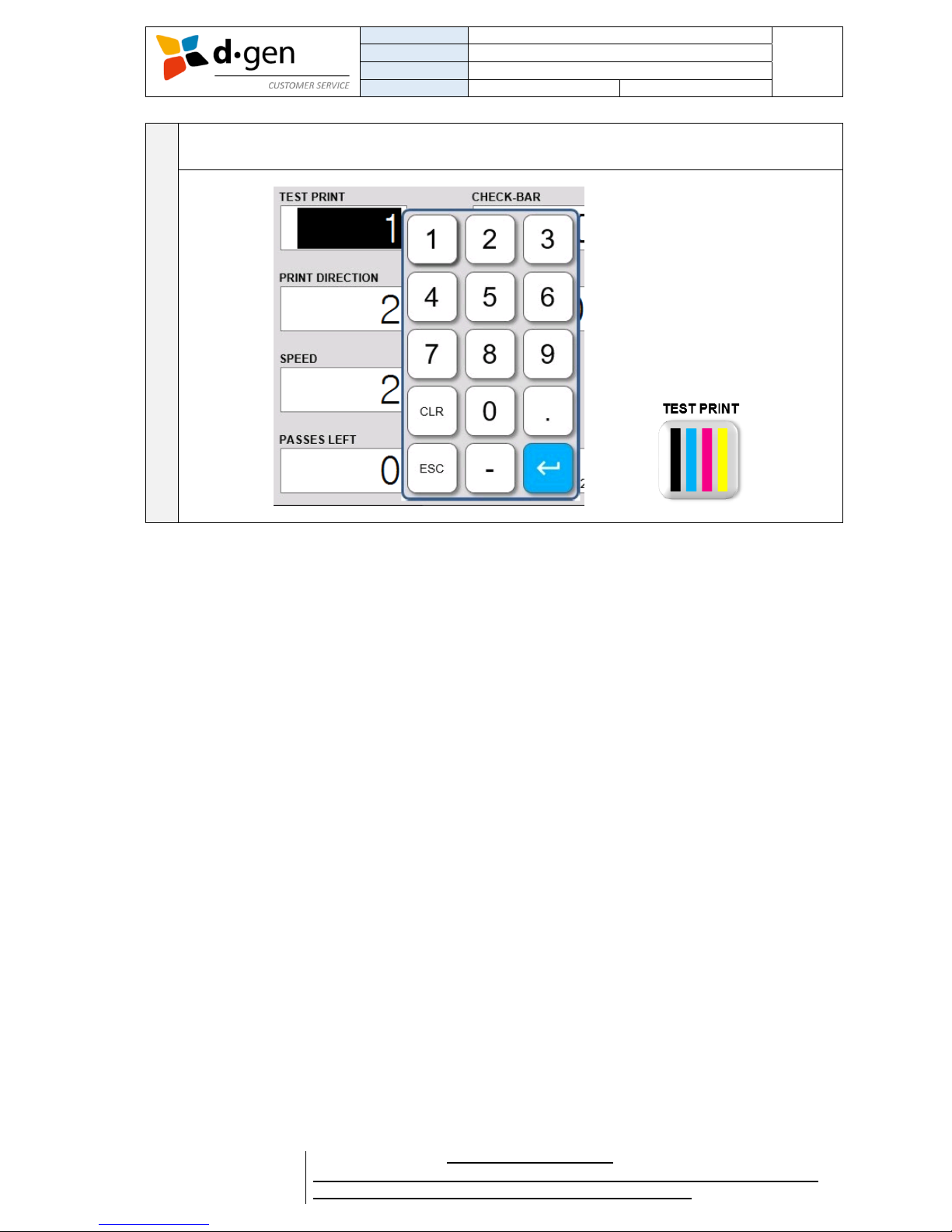

2

In VALUES MENU screen select test pattern number 1 and then press the TEST PRINT button to

print the nozzle check test print.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

28

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

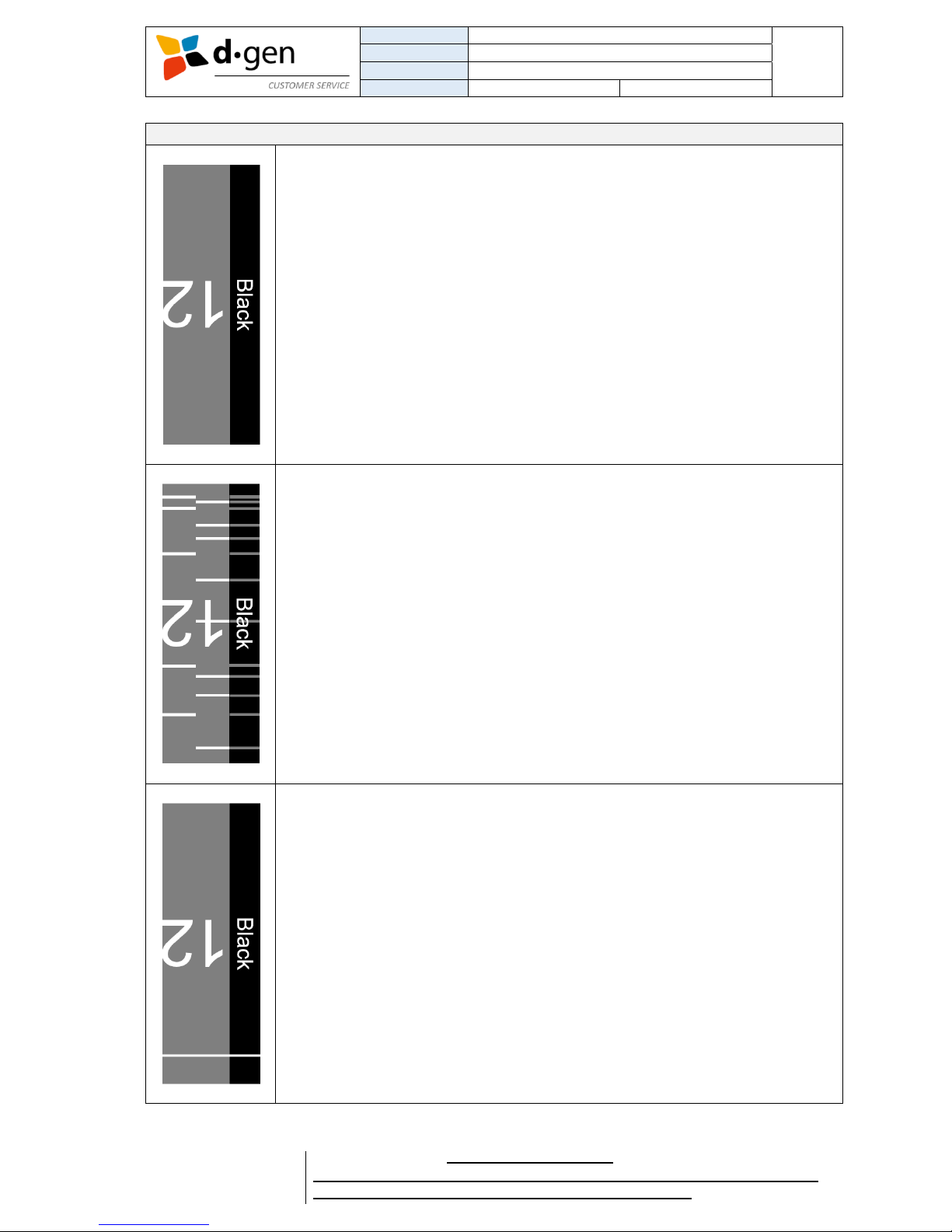

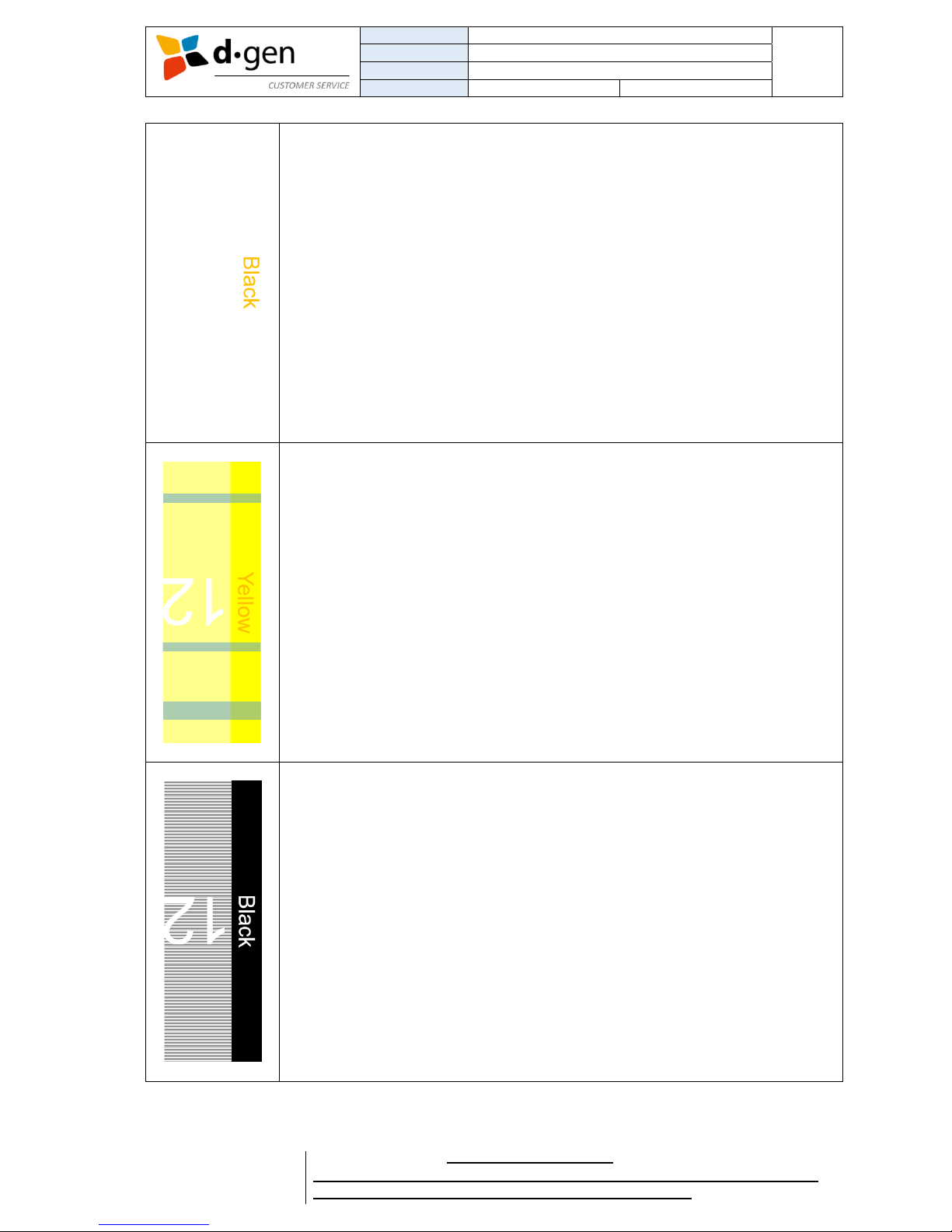

HOW DOES YOUR TEST PRINT LOOKS LIKE?

All the nozzles are firing correctly presenting no gaps in the test print.

A certain number of nozzles are not firing independently from which row number they

belong to.

A certain number of nozzles may be clogged.

Perform several cleanings until getting a perfect test pattern.

Is the printer’s negative pressure too high?

(Usually a value of -3.50 KPA is used).

One or few couple of missing nozzles affecting both channels equally.

Perform several cleanings until getting a perfect test pattern.

Move the carriage to the service position (printer’s left end) and check the print

head has no scratches.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

29

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

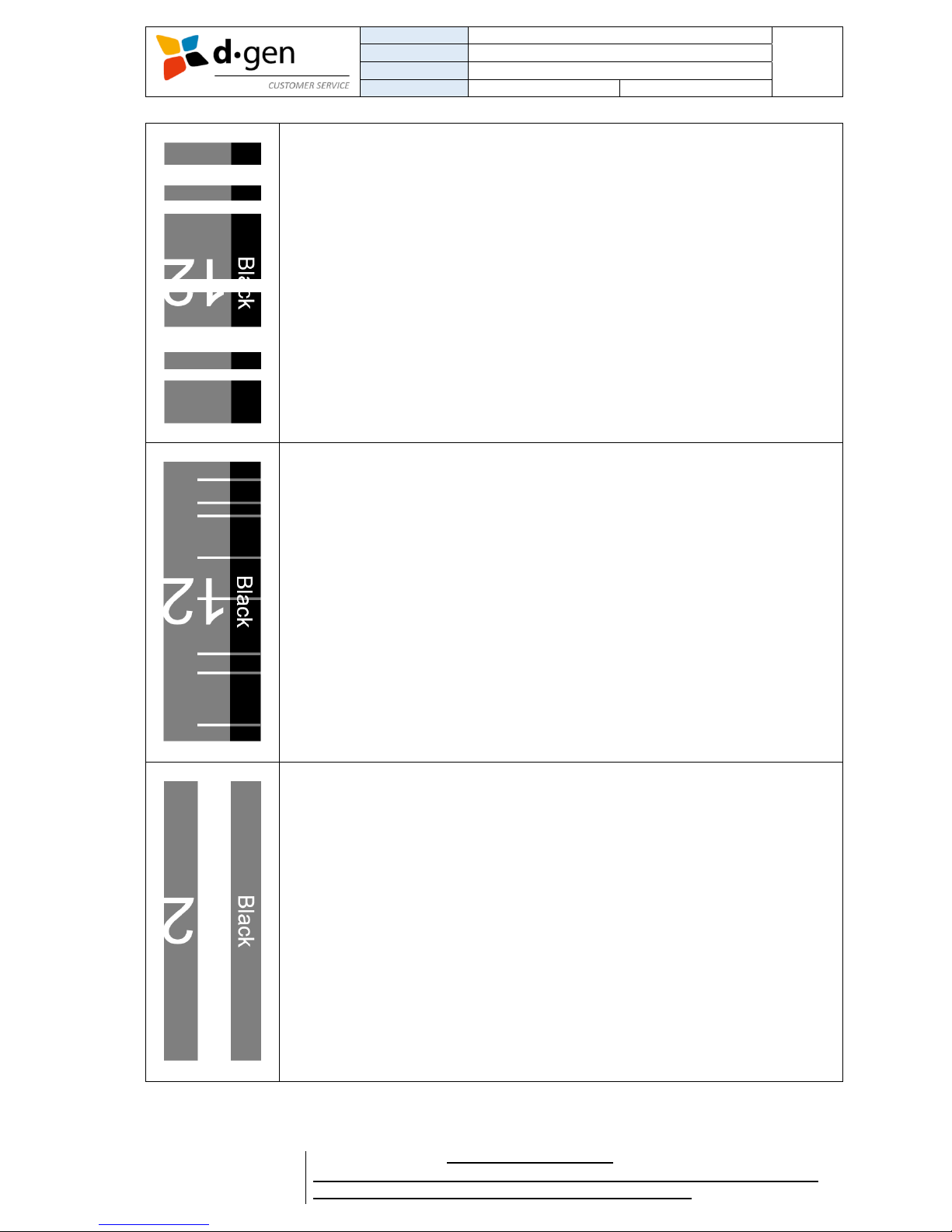

Big number of missing nozzles affecting both channels equally.

Perform several cleanings until getting a perfect test pattern.

Make sure the ink tubes are free of air and bubbles.

Keep service hoses always full on ink and free of air and bubbles.

Is the printer’s negative pressure too low?

(Usually a value of -3.50 KPA is used).

Still can see drops on the head even after wiping it?

Missing nozzles affecting one channel.

Perform several cleanings until getting a perfect test pattern.

Make sure the ink tubes are free of air and bubbles.

Keep service hoses always full on ink and free of air and bubbles.

Is the printer’s negative pressure too low?

(Usually a value of -3.50 KPA is used).

Still can see drops on the head even after wiping it?

One row of nozzles is basically gone.

Make sure the gray flat cables are well connected to the head driver board.

Make sure print head is well connected to the head driver board.

Is the head driver board displaying any alert noise/led?

Is that row of nozzles disabled in the JCC?

Swap the head driver board with another one and see if the issue moves to the other

color.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

30

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

No nozzles being fired.

All the nozzles may be clogged.

Perform several cleanings until getting a perfect test pattern.

Make sure the gray flat cables are well connected to the head driver board.

Make sure print head is well connected to the head driver board.

Check the head driver board is getting 36 V.

Is the head driver board disabled in the JCC?

Is the head driver board displaying any alert noise/led?

Swap the head driver board with another one and see if the issue moves to the other

color.

Another color is detected on the test pattern.

Perform several cleanings until getting a perfect test pattern.

Make sure the ink in the line is not contaminated with anther color.

Make sure the print head is not contaminated with another color.

Make sure the print head’s base plate is not contaminated with another color.

Make sure the wipers are clean.

A certain number of nozzles are deflected.

Make sure the room temperature is cooled.

Make sure the ink temperature is cooled.

Check the temperature and humidity values are in the operating range.

Make sure the ink is not older than one year.

Make sure to have loaded the correct waveforms.

Use our cleaning solution CL-1000Z. Contact your local dealer or support@dgen.com

for more information.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

31

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Blank space between row of nozzles.

Make sure the bidirectional alignments were correctly performed.

BDR value should be the same in both row of nozzles.

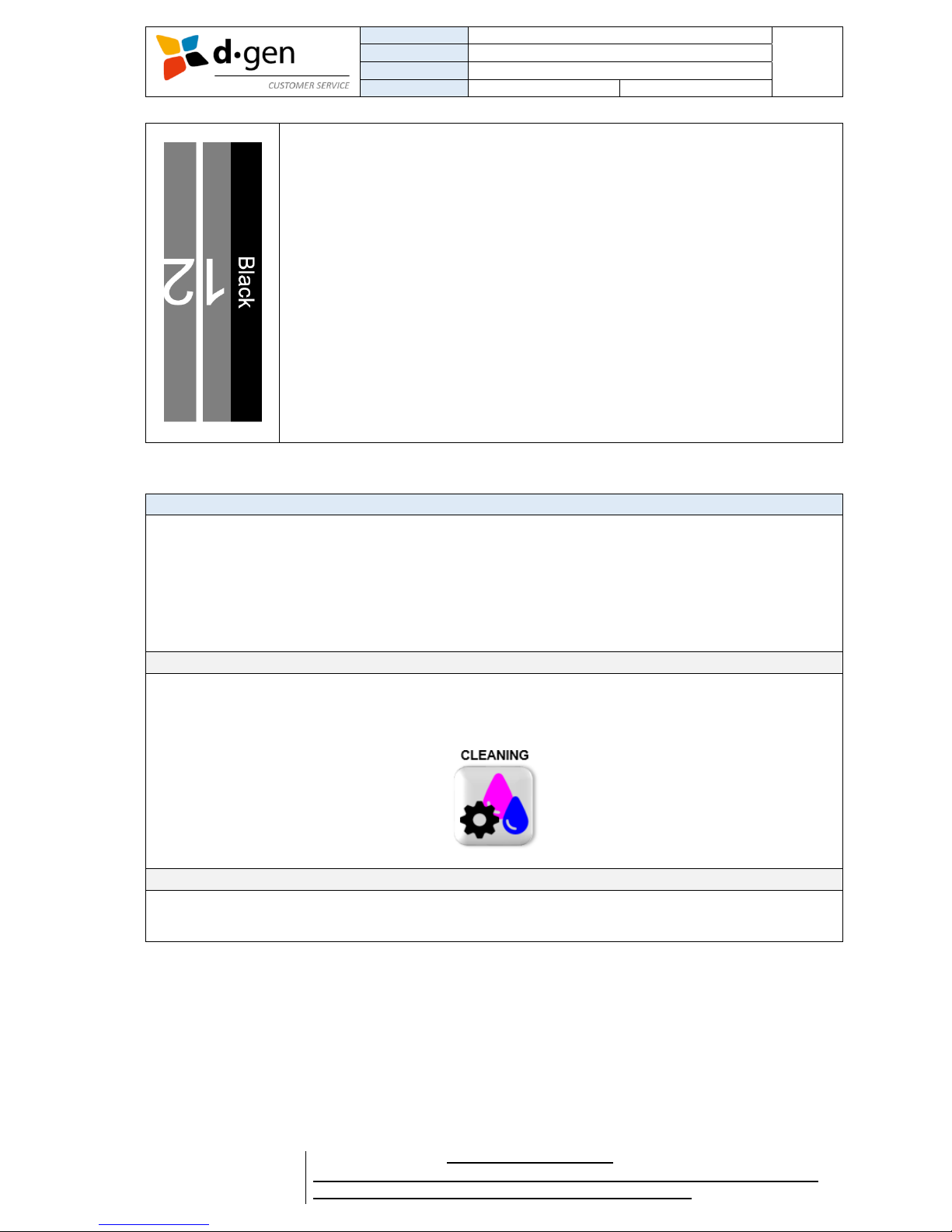

8. PURGE AND AUTO-CLEANING.

There are 2 types of print head cleanings.

1. Auto-cleaning. Performed by pressing the CLEANING button in the touch panel.

2. Long purge. Performed by pressing the PURGE button in the touch panel and close the solenoid valves

to keep the positive pressure in the heads drip ink constantly.

Auto-cleaning.

The CLEANING button will purge the print heads with ink and automatically wipe them with the automated

wiping system.

Long purge.

In case the missing nozzles persists, we recommend the user to follow the following steps.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

32

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

1

Press the PURGE button. The air pump will kick in.

2

Giving approximately 3 to 5 seconds, before the vacuum pumps kicks back, close the solenoid

valves by pressing the white LED buttons at the carriage.

3

Keeping the positive pressure between the subtanks and the print heads it is possible to keep them

dripping ink. Several subtanks will get empty during this process.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

33

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

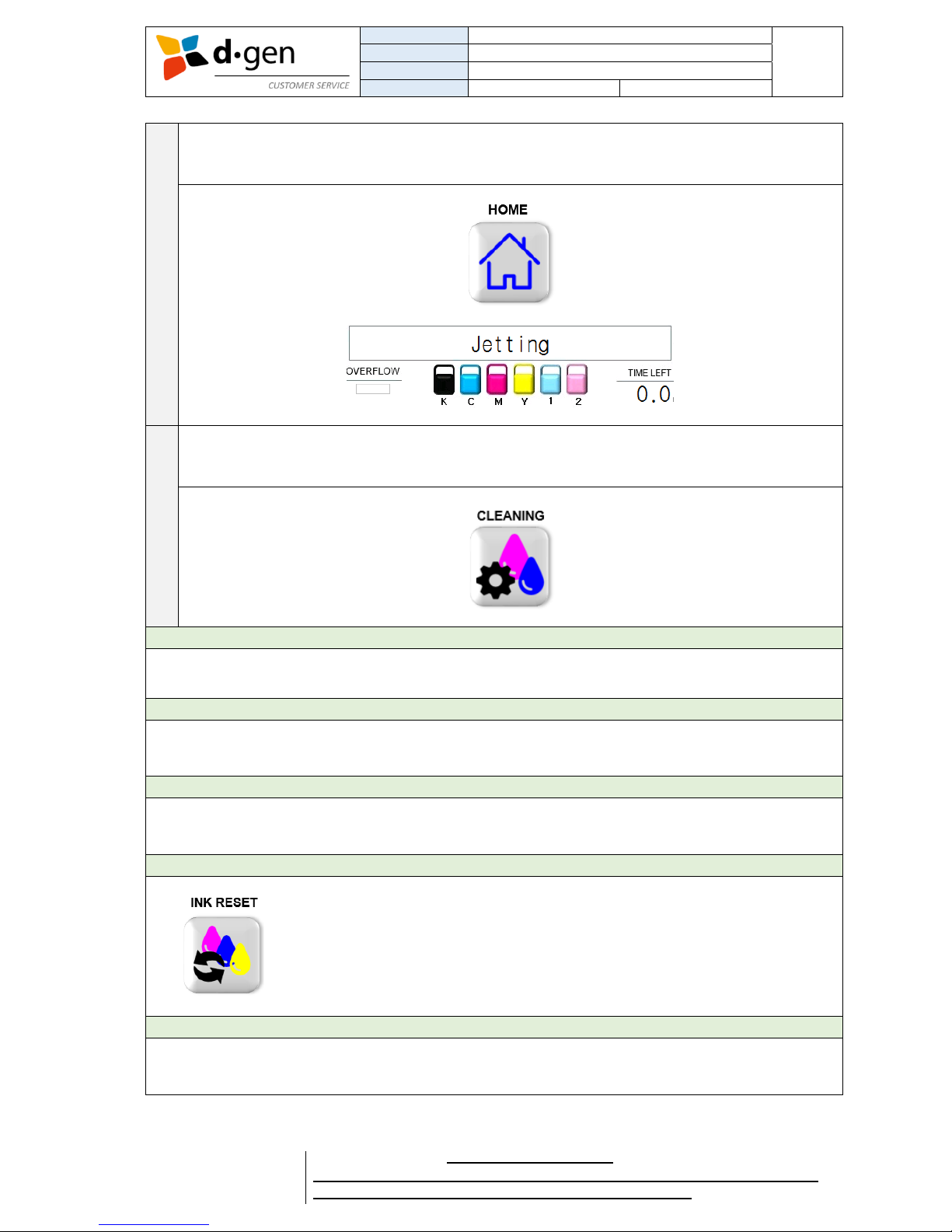

4

To stop the heads dripping ink, open the solenoid valves again by switching ON the white LED

buttons. Press the HOME button to raise the capping station. Wait until all the subtanks are full and

the JETTING message is displayed.

5

Press the CLEANING button to purge and wipe the heads. After this process is done the operator

may perform a nozzle check test print to see if the nozzles recovered.

Important

Do not press the CANCEL button when purging ink.

Important

The printer cannot purge or clean the print heads having one of the subtanks empty. To purge or clean

the print heads, all subtanks must be full and displaying the JETTING message in the touch panel.

Important

Every time before purging or cleaning the print heads verify the ink drain bottle is empty.

Note

The ink supply pump will be activated 10 times until the subtank is refilled. If the

subtank still didn’t get refilled after the 10 attempts, the printer will activate a

buzzer and become to a pause. Make sure the Big Ink System has enough ink.

Press the INK RESET button in the SETTINGS MENU to activate the ink supply

pump another 10 times.

Note

It is possible to purge or clean only one color. Switch OFF the white LED buttons for the remaining colors

leaving ON only the color you want to purge or clean. Then do the previously mentioned steps.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

34

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

9. GLOBAL BIDERECTIONAL ADJUSTMENT.

The bidirectional alignment is performed (by a qualified technician) using a specific media and carriage

height (usually middle position). If the user wants to change the media’s thickness and/or change the

carriage height for whatever reason, the bidirectional compensation factor needs to be regulated to make

the heads fire exactly on the same spot when printing from right to left and left to right.

After changing the media’s characteristics and/or changing the carriage height is required to check if the

machine is still aligned bidirectionally by printing test pattern number 3 in the touch panel.

1

In SETTINGS press the HEAD ALIGNMENT button to enter.

2

In the HEAD ALIGNMENT screen turn ON the TEST MODE and turn OFF the FEEDING functions.

Feed a certain length (for example 200mm) at a certain speed and adjust the START POINT. Select

TEST PATTERN NUMBER 3 to print the bidirectional alignment pattern. Press the TEST PRINT to

print.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

35

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

3

The test print will look something like the image below. Using a loop or a microscope is possible to

check the middle line. If BDL and BDR are were not fired on the same spot means the bidirectional

compensation factor needs to be corrected.

4

In VALUES menu enter the BI-DIR COMPENSATION screen. Increase or decrease the BI-DIR

COMPENSATION value certain units. As a reference, if the carriage was moved to the highest point,

a value of 5 is introduced.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

36

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

5

Repeat steps 1 to 4 adjusting the BI-DIR COMPENSATION value until getting a test print similar to

the illustration below.

Important

Do not forget to switch OFF the TEST button and turn ON the FEEDING before resuming production with

the new media and/or carriage height.

Note

The carriage height is regulated using the lever located at the left side of the carriage.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

37

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

10. FEED ADJUSTMENT.

A proper feed adjustment will help to obtain good quality prints without having feeding banding issues.

There are two steps to adjust the feeding. First, before start to print, is recommended to take a look at the

speed dials located at the take-up and feeder units. Then while printing, through the touch panel is possible

to adjust the feeding correction more precisely.

When turning at same speeds, an empty roll will turn less distance than a new/full one. It is easy to see

why in the illustration below.

For this reason, we suggest to set a higher speed to the empty roll and a lower speed to the new/full roll.

Like described in the illustration below.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

38

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Once the feeder and take-up units are correctly adjusted is time to start adjusting the feeding distance

more precisely to eliminate the banding effect.

Light band between passes. Means the feeding system has to feed

less distance while printing in order to eliminate the distance

between passes. To reduce the feeding compensation, in the touch

panel press the “VALUES” button and then proceed to press the

“minus” button as many times needed until no distance between

passes can be seen.

Dark band between passes. Means the feeding system has to feed

more distance while printing in order to eliminate the overlap

between passes. To increase the feeding compensation, in the

touch panel press the “VALUES” button and then press the “plus”

button as many times needed until no overlap between passes is

shown.

Note

To make the FEEDING COMPENSATION field effective, the PASSES field

must have the same number of passes as stated in the RIP software.

For example: if my RIP software is using an ICC profile of 4 passes, the

PASSES field must have an inputted value of 4. Otherwise the FEEDING

COMP. field will not work.

Note: even though the resample is ON printing at 8 passes but the RIP

software is using an ICC profile of 4 passes, the PASSES field must have

an inputted value of 4.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

39

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Front dancing bar’s weight.

Depending on the media’s characteristics we suggest to use either the light (grey) or heavy (black) front

dancing bar.

The purpose is, before printing, have the dancing bars applying the correct tension to the media without

breaking it or destabilizing the feeding system.

To change the front dancing bar just pause/cancel the print, release the latches at both sides. Then place

the second dancing bar.

Note

It is also possible to insert both light and heavy dancing bars to add extra tension to the media.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

40

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

11. USING THE DRYER.

The drying unit in the printer’s base and is composed of eight heating rods and eight blowers.

We suggest to turn on the drying unit minutes before printing to give time for the heating rods to heat up.

Depending on the quantity of ink on the media and the printing speed:

You may regulate the speed of the fans by pressing the high or low button at the control panel.

If it is not enough just by using fan power, you may turn on the 8 heating rods and the front rubber

heater by turning ON HEATER 1.

Possible to regulate the temperature by using the thermostat. Usually is used a temperature between

60 to 90°C (140 to 194°F).

Check if the printed images at the take-up roll are dried enough. If not, you may increase the Set

temperature at the thermostat and/or turn ON HEATER 2. Heater number 2 is the rear rubber heater.

Works as an extra heater when printing dark images or when printing at very high speeds.

Note

We suggest to turn on the drying unit minutes before printing to give time for the heating rods to heat up.

After using the dryer, we suggest to leave only the fans turned on to cool down the heating rods and then

proceed to switch off the whole system.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

41

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

How to use the thermostat (AUTONICS TZ4ST SERIES).

1

PV.

Processing value indicator (Red).

2

SV.

Setting value indicator (Green).

3

Move, up and down keys.

Key shifting the display.

4

Information table.

Use this table as a reference when the thermostat displays a certain code.

5

AT key.

This mode key turns on the auto tuning function.

6

MD key.

This is the mode key. Is pressed to set the SV after modifying with the move, u and down keys.

7

EV2.

Event number 2 output signal lamp.

8

EV1.

Event number 1 output signal lamp.

9

OUT.

Output signal lamp.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

42

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

10

AT.

The signal lamp blinks while Auto tuning is being executed.

11

SV2.

Is turned on when SV2 is operating.

Note

To set the temperature in the thermostat just press the left arrow. Then change the value by using the up

and down arrows. Once got the desired value you may press the MD button to set the target temperature

SV.

Caution

The drying unit may be hot; observe all necessary precautions. Failure to observe the necessary

precautions could result in burns.

Caution

Keep the drying unit always free of intrusive elements. Risk of fire.

Note

As a safety function, to turn on either HEATER 1, HEATER 2 or both, DRYER must be turned on.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

43

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

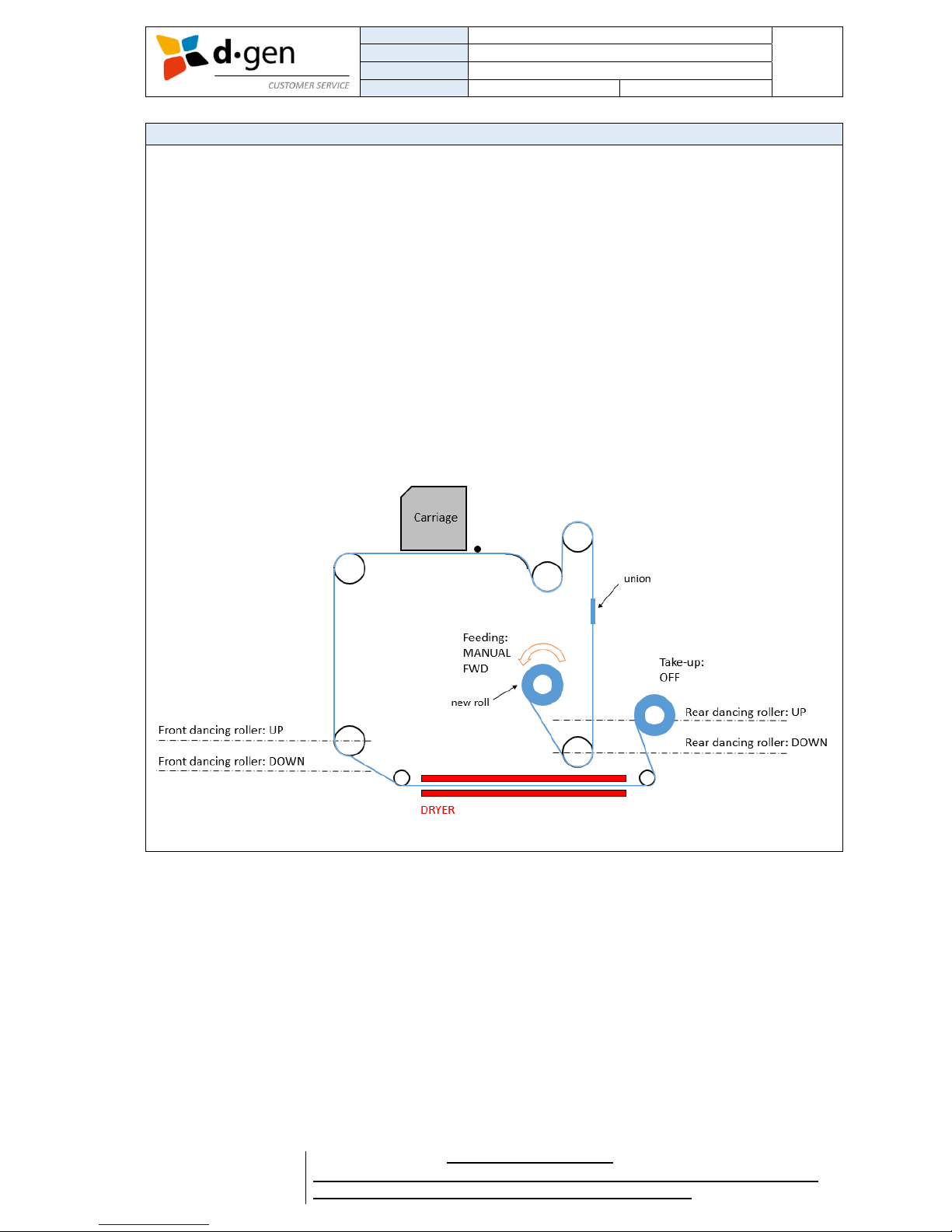

12. EXCHANGING THE MEDIA.

Exchanging the media is possible after pausing/cancelling the printing process.

Pause/Cancel the current job.

Switch off the take-up and the feeder. Use only MANUAL mode.

Make sure the rear dancing bar is in the lowest position. If not, you may feed media manually.

You may cut now between the rear dancing bar and the back roller.

Release the latches at both side of the feeding unit to remove the pneumatic shaft.

Press the golden valve to release all the air inside the pneumatic tube.

Remove the pneumatic shaft from the media’s core.

Place the pneumatic shaft in the new media’s core, orientating the printable side upwards when going

through the printing table.

With the help of an air compressor (only the air compressor gun is provided) stick the gun to the golden

valve and apply compressed air until an approximate value of 5 bar (72.5 psi) is reached.

Lift the pneumatic shaft with the roll fastened and place it carefully in the feeding unit. Need two persons

for this operation. Recommended the use of a roll lifter.

Insert back the latches at both sides of the feeding unit to safely secure the pneumatic shaft.

Feed media manually MANUAL FWD passing it under the rear dancing bar.

Attach the end to the previously used media with paper tape.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

44

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

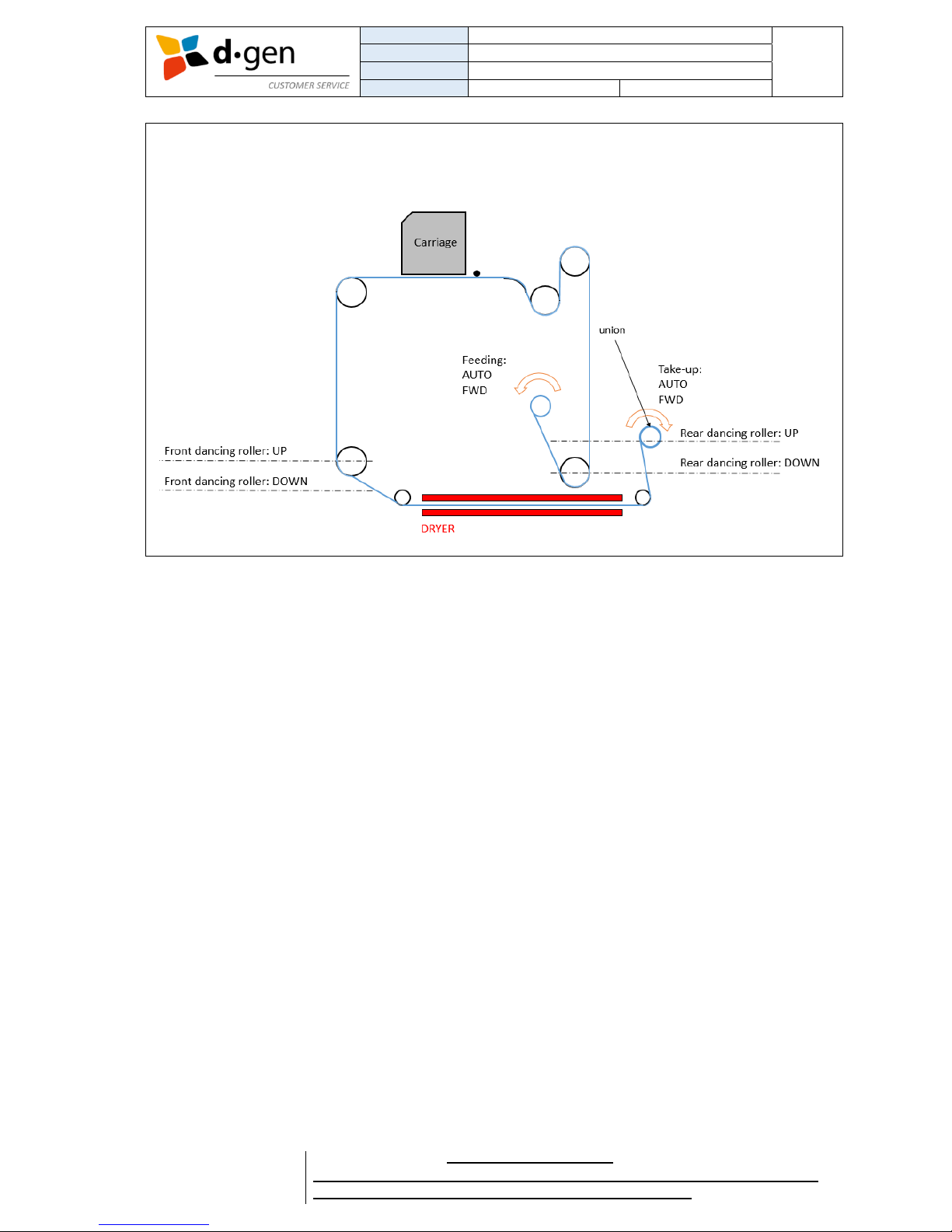

Turn on both take-up and feeder units. Feeder and take-up at AUTO FWD mode.

Press the forward button in the touch panel to move the union to the front side after passing the

carriage.

Once the union is about half way between the front roller and the front dancing bar, you may stop the

media feeding. Make sure the printing table is free of wrinkles and place back the media guide plates.

Resume printing.

Important

We recommend the use of paper tape to make the union between the new roll and the previously used

media. Careful not to damage the media guide plates and the pinch rollers when passing the union through

the printing table.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

45

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

13. REMOVING THE TAKE-UP ROLL.

Removing the take-up roll is possible after pausing/cancelling the printing process.

Pause/Cancel the current job.

Switch off the take-up and the feeder. Use only MANUAL mode.

Make sure the front dancing bar is in the lowest position. If not, you may rotate the take-up roll

backwards to lower the front dancing bar. MANUAL BWD.

Once the front dancing bar is in the lowest point you may cut the media.

Release the latches at both sides of the take-up unit to remove the pneumatic shaft.

Remove the roll with the help of a roll lifter. If not, 2 persons is required for this operation.

Press the golden valve to release all the air inside the pneumatic tube.

Remove the pneumatic shaft from the media’s core.

Place the pneumatic shaft in the empty core orientating the printed side to the inside when winding.

With the help of an air compressor (only the air gun is provided) stick the gun to the golden valve and

apply compressed air until an approximate value of 5 bars is reached.

Lift the pneumatic shaft with the empty core fastened and place it carefully in the take-up unit.

Insert back the latches at both sides of the take-up unit to safely secure the pneumatic shaft.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

46

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Feed a little bit more media to attach its end to the empty core using paper tape.

Change feeder unit to AUTO FWD and Take-up unit to AUTO FWD.

Resume printing.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

47

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

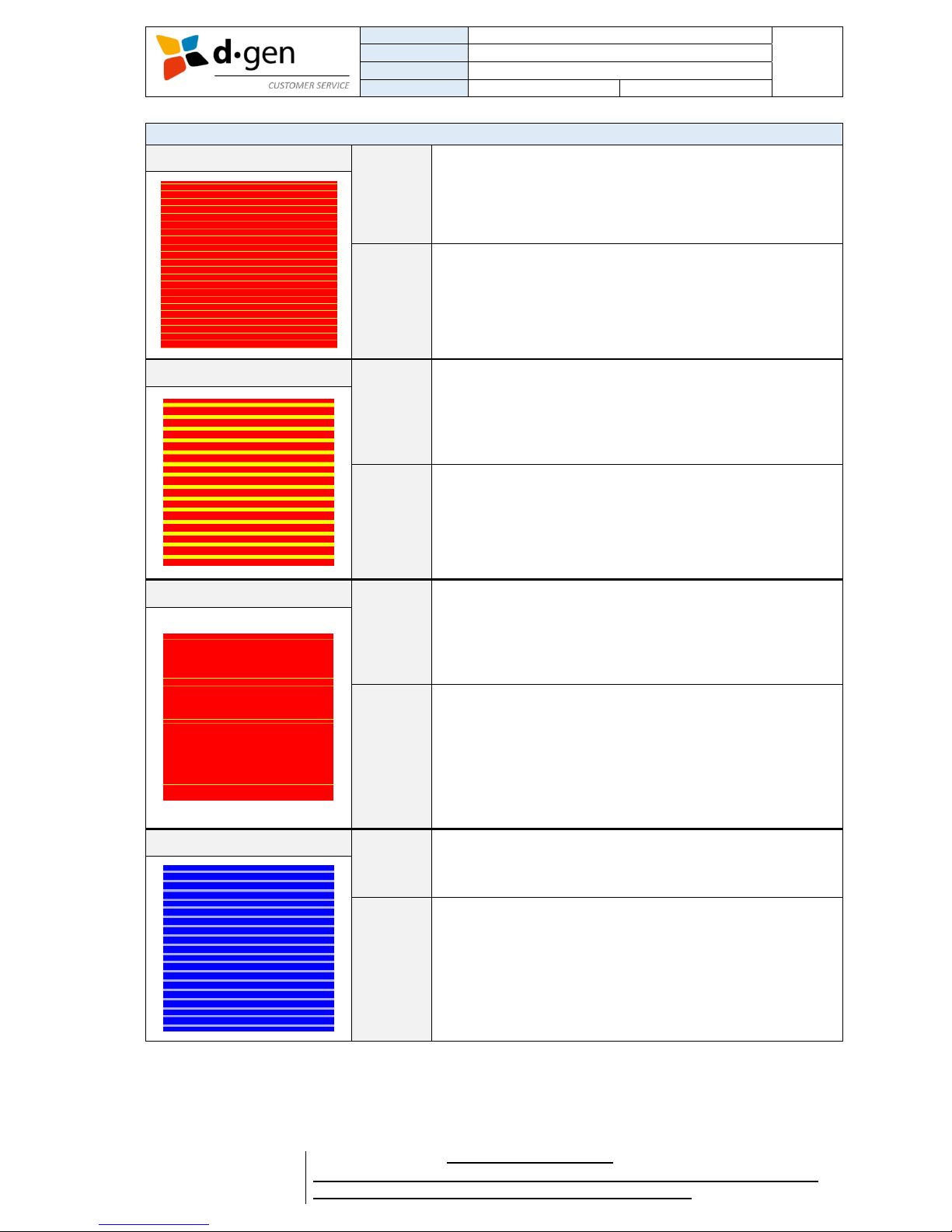

14. PROBLEM SOLVER

PRINT LOOKS LIKE THIS?

REASON

Missing nozzles on the image. For example, yellow lines can

be seen on a red area means a certain number of magenta

nozzles are not firing.

Nozzles may be clogged.

Negative pressure may be unstable.

ACTION

Perform a test print pattern number one.

Check for clogged nozzles.

Perform several cleanings until getting a perfect test print.

Check the RPM and KPA values in the touch panel.

Check environmental conditions.

PRINT LOOKS LIKE THIS?

REASON

Big number of nozzles on the image. For example, yellow

wide lines can be seen on a red area means a certain

number of magenta nozzles are not firing.

Nozzles may be clogged.

Negative pressure may be unstable.

ACTION

Perform a test print pattern number one.

Check for clogged nozzles.

Check for air in the system.

Check if the negative pressure is too low.

Perform several cleanings until getting a perfect test print.

Service hoses must be filled with ink. No air in them.

PRINT LOOKS LIKE THIS?

REASON

Intermittent nozzles. For example, yellow lines can be seen

on a red area after an indeterminate number of passes.

Means one or two magenta nozzles are not firing every after

an indeterminate number of passes.

Negative pressure may be unstable.

Ink demand may be too high.

ACTION

Perform a test print pattern number one.

Check for clogged nozzles.

Check for air in the system.

Check if the negative pressure is too low.

Perform several cleanings until getting a perfect test print.

Service hoses must be filled with ink. No air in them.

Make a new profile that uses a smaller ink quantity of

magenta.

PRINT LOOKS LIKE THIS?

REASON

Lighter colors between passes.

The printer is feeding a longer distance than it should.

ACTION

Check the feeding compensation at 2 passes (in case

running with a 2-pass profile).

While printing, try to lower the feeding compensation value

(in steps of 0.1) in the touch panel until getting no space

between passes.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

48

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

PRINT LOOKS LIKE THIS?

REASON

Darker colors between passes.

The printer is feeding less distance than it should.

ACTION

Check the feeding compensation at 2 passes (in case

running with a 2-pass profile).

While printing, try to increase the feeding compensation

value (in steps of 0.1) in the touch panel until getting no

space between passes.

PRINT LOOKS LIKE THIS?

REASON

Darker and lighter colors between passes.

Inconsistent feeding.

ACTION

Check the pneumatic silver bars are inflated.

Check the tension is correct in the media.

Check the weights setting is correct in the dancing bars.

Check the speed at the take up and feeding units are similar

and equilibrated (not too fast or too slow).

Perform a feeding motion K value calibration.

Check correct tension in the Y feeding timing belts.

Check no feeding pulley lost traction from the shaft.

Using optimization may resolve the issue.

PRINT LOOKS LIKE THIS?

REASON

Some passes are lighter than others.

Chromatic banding (soccer filed effect).

Bi-directional alignment may be incorrectly done.

ACTION

Chromatic banding (soccer filed effect).

Check if using unidirectional printing the issue disappears.

Check the bi-directional alignment is correctly done.

Perform a scan motion K value calibration.

Make sure the room temperature is cooled.

Make sure the ink temperature is cooled.

Check the temperature and humidity values are in the

operating range.

See “notes when using the printer” in chapter 2.

Make sure the ink is not older than one year.

Make sure to have loaded the correct waveforms.

May be ink issue. Report us by sending the ink’s batch/lot

number.

Check you are using d·gen genuine inks.

Using optimization may resolve the issue.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

49

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

PRINT LOOKS LIKE THIS?

REASON

Ink drops on the print.

Pressure in the heads may be too low.

ACTION

Make sure all the solenoid valves are open (LED on).

Make sure the negative pressure is not too low.

Make sure the head’s base plate is not dirty.

PRINT LOOKS LIKE THIS?

REASON

Stains due to head striking.

ACTION

Heavy amounts of ink may cause waves in the media.

Is the carriage height too low? Make sure to change the bidirectional compensation factor to 5 when moving the

carriage to the highest point.

Is the tension in the media too low?

If media is stored inappropriately or left loaded in the printer,

wrinkles and waviness may occur. If media is used in this

state, the print head and the raised surface of the media may

contact and cause staining.

If the media loading method, heating temperature, tension

and other settings are inappropriate, wrinkles and waviness

occur on the media.

Make sure media is being loaded on the auto take-up reel

unit correctly.

PRINT LOOKS LIKE THIS?

REASON

Blurry images and low sharpness.

Carriage angle may be not aligned.

Bi-directional alignment may be incorrectly done.

ACTION

Check if using unidirectional printing the issue disappears.

Make sure to redo the bi-directional alignment.

Make sure the belt in the carriage has the proper tension.

Try to perform a scan motion K value calibration.

Check the encoder strip is cleaned.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

50

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

15. APPENDIX.

Printing area and margins.

Print quality is greatly affected by the type and quality of media used. Choose a media suited to the task

at hand. For information on use, refer to the documentation supplied with the media or contact the

manufacturer. We recommend that you print a test run and check the results before purchasing media in

large quantities.

Width

297 to 1880 mm (11.6’’ to 74’’)

A

Roll outer diameter

Maximum 350 mm (13.7’’)

B

Paper pipe (core) inner

diameter

76.2 mm (3’’)

C

Media thickness

Maximum 2.5 mm (1/10’’)

Roll weight

Maximum 150 kg (331 lb.)

Unavailable conditions

Media whose end is attached to the paper pipe (core).

Media that is severely warped or has a strong tendency

to re-roll.

Media that cannot withstand the heat of the dryer unit.

Media that cannot withstand the tensioning of the media

take-up or feed system.

Media whose paper pipe (core) is bent or crushed.

Media that bends under its own weight when loaded.

TITLE

OPERATOR MANUAL

PAGE

PRINTERS

PAPYRUS G5/H4, PAPYRUS G5/H6

51

VERSION

2017JAN23/1

OUT OF

REVISED BY

MUNOZ, ANTONIO

support@dgen.com

51

FOR THE USER

d·gen International, Inc. - COMPANY PRIVATE (LEVEL 1)

NOT TO BE DISCLOSED TO UNAUTHORIZED PERSONS – PROHIBIDA SU DIVULGACIÓN A PERSONAS NO AUTORIZADAS

DO NOT REPRODUCE WITHOUT AUTHORIZATION – NO REPRODUCIR SIN AUTORIZACIÓN

Printing area and margins.

The light grey area in the illustration below shows the printable area. The arrow indicates the feeding

direction.

A

Total width

1880 mm

74’’

B

Between image and media clamp

10 mm

2/5’’

C

Between image and media’s edge

20 mm

4/5’’

Contacting d·gen support.

d·gen provides technical support and information on the installation, configuration, and operation of

professional printing products through this email address: support@dgen.com and telephone number:

(+82) 32 510 3503 from 8:30 AM to 5:30 PM, Korea Standard Time (UTC +9:00), Monday through Friday.

When sending an email please write the title of the email as follows:

Name of the company / Printer Model / Printer serial number / Issue

When contacting by phone please have ready your printer’s model and serial number.

For further documentation, software, firmware, drivers, ICC profiles, etc., you can access to our cloud at

any time through this link: https://app.box.dgen.com/v/dgenAS. Available in PC and cell phone.

Important

The cloud available for users and technicians is not intended for users to repair the machine by

themselves. All technical documentation, software and firmware are intended to be used only by

d·gen authorized technicians.

Loading...

Loading...