Dexter Laundry T-80 User Manual

8514-052-001E

10/09

OPERATOR’S MANUAL

for

DTCK80/DCTD80KC/DCWD80KC Series Dryers

The dryer must not be stored or installed where it will be exposed to water and/or weather.

WARNING: For your safety the

infor-mation in this manual must be

fol-lowed to minimize the risk of fire

or

explosion or to prevent property d am age, personal injury or loss of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Clear the room, building or area of all

occupants.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

– Installation and service must be performed by

a qualified installer, service agency or the

Post the following “For Your Safety” caution in a

gas supplier.

prominent location:

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

It is important that you read this Manual and retain it for

future reference. For service or replacement parts,

contact the distributor in your area or the manufacturer.

FOR YOUR SAFETY

Dexter Laundry, Inc.

2211 W. Grimes

Fairfield, Iowa 52556 USA

AVERTISSEMENT. Assurez-vouz de

bien suivre les instructions

données dans cette notice pour

réduire au minimum le risque

d'incendie ou d'explosion ou pour

éviter tout dommage matérial, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d'essence ni d'autres

vapeurs ou liquides inflammables dans le voisinage

de cet appareil ou de tout autre appareil.

– QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d'allumer d'appareil.

• Ne touchez à aucun interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous vous trouvez.

• Évacuez la pièce, le bâtiment ou la zone.

• Appelez immédiatement votre

fournisseour de gaz depuis un voisin.

Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incendies.

– L'installation et l'entretien doivent être assurés par

un installateur ou un service d'entretien qualifié ou

par le fournisseur de gaz.

Ne pas enteposer ni utiliser d'essence ni d'autres

vapeurs ou liquides inflammables dans le voisinage

de cet appareil ou de tout autre appareil.

You, the purchaser, must post in a prominent location instructions to be followed in the event the user

smells gas. Consult your local gas supplier for

procedure to be followed if the odor of gas is

present.

POUR VOTRE SÉCURITÉ

TABLE OF CONTENTS

PAGE NO.

DRYER DIMENSIONS (Figure 1)........................................................................... 3

UNCRATING.......................................................................................................... 4

DRYER INSTALLATION.........................................................................................4

DRYER EXHAUST SYSTEM (Figure 2)................................................................. 6

DRYER SHUTDOWN............................................................................................. 7

OPERATING INSTRUCTIONS............................................................................... 8

PROGRAMMING THE DRYER......................................................................... 9-14

SERVICING DRYER............................................................................................ 15

PREVENTATIVE MAINTENANCE....................................................................... 15

WARNINGS ABOUT USE AND OPERATION

It is ABSOLUTELY ESSENTIAL that the dryer be grounded to a known earth (zero) ground. This is not only for

personal safety, but is necessary for proper operation.

KEEP SHIELDS, GUARDS AND COVERS IN PLACE. These safety devices are provided to protect everyone

from injury.

A DRYER SHOULD BE CONNECTED TO POWER FOR THREE (3) MINUTES before it is operated or before

a program change is made. Operation or program changes, which occur during this "power up" period, are subject

to loss in case of power interruption. After the initial three minutes, all programmed data is protected from power

interruptions of any length and the customer's individual cycle is protected up to 3 seconds. This is done without

batteries.

LEAVE THE ELECTRICAL POWER TO THE DRYER ON AT ALL TIMES except when necessary for

service or other similar activities. The hour meter function adds only full hours to its reading. If the power is shut

off every night, any fraction of an hour of time that is on the machine at that time will be lost. Turning the power off

every night could also have some effect on the long-term life of the memory after a number of years. Turning

power off occasionally won't affect the unit.

THIS DRYER IS EQUIPPED WITH AN OVER-TEMP ERATURE THERMOSTAT located on the right side

of the return lint hood assembly (open lower service door). Should the dryer cease to operate, refer to your

“Service Procedure and Parts Data” book for instructions.

CHECK THIS THERMOSTAT WHEN INSTALLING DRYER to assure it is not tripped. Impacts such as rough

handling in shipment, may trip the thermostat.

2

3

INSTALLATION AND OPERATING INSTRUCTIONS

COMMERCIAL DRYER

UNCRATING

1. Remove cardboard container and innerpack.

2. Complete the uncrating as described in the procedure listed on the instruction sheet taped to the loading door

glass.

DRYER INSTALLATION

1. CODE CONFORMITY. All commercial dryer installations must conform with local codes or, in the absence of

local codes, with the latest edition of the National Fuel Gas Code ANSI Z223. 1. Canadian installations must comply

with current Standard CAN/CGA-B149 (.1 or .2) Installation Code for Gas Burning Appliances or Equipment, and

local codes if applicable. The appliance, when installed, must be electrically grounded in accordance with the latest

edition of the National Electric Code, ANSI/NFPA70, or, when installed in Canada, with Standard CSA C22.1

Canadian Electrical Code Part 1.

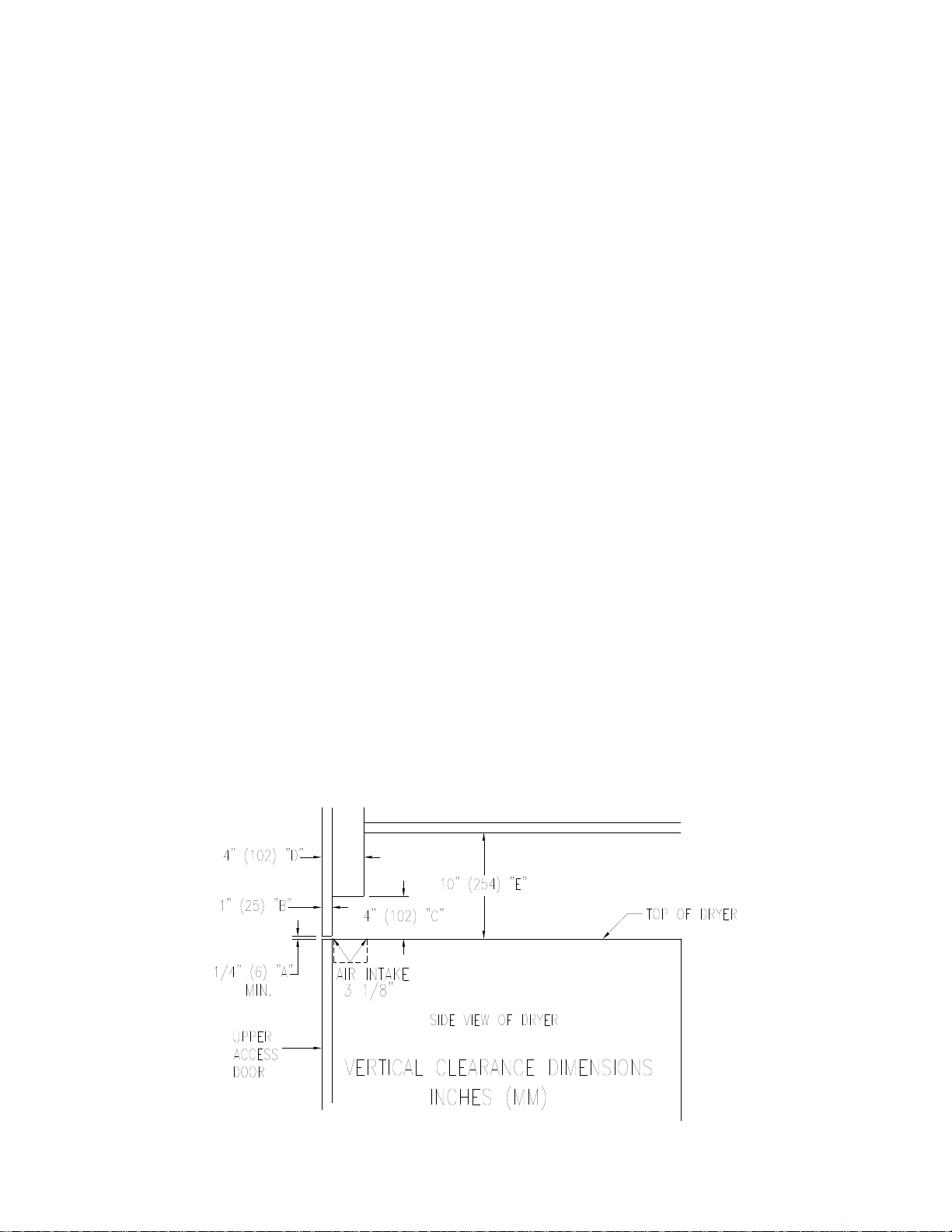

2. INSTALLATION CLEARANCES: This unit may be installed at the following alcove clearance. (millimeters)

I. Left Side 0"

II. Right Side 0"*

III. Back 18" (457) (Certified for 1" (25) clearance; however, 18" (457) clearance is necessary behind the

belt guard to allow servicing and maintenance.)

IV. Front 48" (1220) (to allow use of dryer)

V. Top Refer to figure labeled “Vertical Clearance Dimensions”.

AB. Certification allows 0" clearance at the top 1" (25) back from the front. However, a 1/2" (12)

clearance is required to allow opening the upper service door.

CD. A 4" (102) clearance is required at the top between 1" (25) and 4" (102) from front.

E. A 10" (254) clearance is required from top at all other points.

VI. Floor This unit may be installed upon a combustible floor.

*Units may be installed in direct contact with an adjacent dryer, providing allowance is made for opening upper and

lower service doors.

Do not obstruct the flow of combustion and ventilation air.

Maintain minimum of 1" (25) clearance between duct and combustible material.

Refer to installation label attached to the inside surface of the upper door of the dryer for other installation

information.

4

3. MAKE-UP AIR. Adequate make-up air (1200 CFM) must be supplied to replace air exhausted by dryers on all

types of installations. Provide a minimum of 1.25 square foot make-up air opening to the outside for each dryer. This

is a net requirement of effective area. Screens, grills or louvers, which will restrict the flow of air, must be considered.

Consult the supplier to determine the free area equivalent for the grill being used.

The source of make-up air should be located sufficiently away from the dryers to allow an even airflow to the air

intakes of all dryers. Multiple openings should be provided.

NOTE: The following considerations must be observed for gas dryer installations where dry cleaners are

installed. The sources of all make-up air and room ventilation air movement to all dryers must be located

away from any dry cleaners. This is necessary so that solvent vapors will not be drawn into the dryer inlet

ducts. Dry cleaner solvent vapors will decompose in contact with an open flame such as the gas flame

present in clothes dryers. The decomposition products are highly corrosive and will cause damage to the

dryer(s), ducts and clothes loads.

4. ELECTRICAL REQUIREMENTS. (Refer to schematic and wiring diagram). This dryer is equipped with a

reconnectable motor and control transformer for use on 208–240V–1PH–60Hz or 110–125V–1PH–60Hz. The control

voltage is 24V, 60 Hz. The electrical power requirements necessary to operate the unit satisfactorily are listed on the

serial plate located on the back panel of each dryer. The electrical connection should be made to the terminal in the

control box on the rear of the unit, using a wire size adequate to handle the amperage and voltage listed on the serial

plate, but never smaller than No.12 AWG wire. The ground lug must be connected to a good external ground.

Individual circuit breakers for each unit are recommended. The schematic and wiring diagram is located on the

belt guard on the back of the machine.

5. GAS REQUIREMENTS. The complete gas requirements necessary to operate the dryer satisfactorily are listed

on the serial plate located on the back panel of the dryer.

The inlet gas connection to the unit is 1/2-inch pipe thread. However, the size of the piping to supply the dryer should

be determined by reference to the National Fuel Gas Code ANSI Z223.1A and consultation with the local gas supplier.

A joint compound resistant to the action of liquefied petroleum gases should be employed in making pipe

connections.

A drip tee should be provided in the gas piping entering the unit to catch dirt and other foreign articles.

All pipe connections should be checked for leakage with soap solution. Never check with an open flame.

For altitudes above 2,000 feet (610m) it is necessary to derate the BTU input. Contact your local distributor for

instructions.

L.P. gas conversion kits are available for this dryer. Contact your local distributor.

6. PRESSURE TESTING. The dryer and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of 1/2 psig.

The dryer must be isolated from the gas supply piping system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig.

7. EXHAUST INSTALLATION. (Refer to Figure 2 at the end of section 7.) Exhausting of the dryer(s) should be

planned and constructed so that no air restrictions occur. Any restriction due to pipe size or type of installation can

cause slow drying time, excessive heat, and lint in the room.

From an operational standpoint, incorrect or inadequate exhausting can cause a cycling of the high limit thermostat,

which shuts off the main burners and results in inefficient drying.

Individual exhausting of the dryers is recommended. All heat, moisture, and lint should be exhausted outside by

attaching a pipe of the proper diameter to the dryer adapter collar and extending it out through an outside wall. This

pipe must be very smooth on the inside, as rough surfaces tend to collect lint, which will eventually clog the duct and

prevent the dryer from exhausting properly. All elbows must be smooth on the inside. All joints must be made so the

exhaust end of one pipe is inside the next one downstream. The addition of an exhaust pipe tends to reduce the amount

of air the blower can exhaust. This does not affect the dryer operation if held within practical limits. For the most

efficient operation, it is recommended that no more than 20 feet (6m) of straight 8" diameter pipe be used with two

right angle elbows. When more than two elbows are used, two feet of straight pipe should be removed for each

additional elbow. No more than four right angle elbows should be used to exhaust a dryer.

5

Loading...

Loading...