P/N 8514-031-001A

05/08

WCNDHCS-

MODEL

lb CAPACITY

THE

OPL (Computer) WASHER

DEXTER

COMPANY

OWNER'S BOOKLET

INSTALLATION & OPERATION

INSTRUCTIONS

TABLE OF CONTENTS Page #

Safety Warnings 2

Maintenance Hints 2

Installation Instructions 3

Foundation Requirements 3

Mounting 3

Plumbing 3

Drain 3

Electrical 6

Fusing Requirements 6

Electrical Connections 6

Chemical Injection 7

Chemical Injection Hoses 7

Final Checkout 7

Operating Controls 9

Operating Instructions 10

End Of Cycle 11

Safety Door Lock 11

Motor Drive Indications 11

Computer Control Cycle Description 11

Programming Instructions - Editing Existing Cycle 12

Programming Instructions - Entering New Cycle 13

Washer Diagnostic Cycles 14

Cycle 31 Sequence 14

Rapid Advance Mode 16

Preset Cycle Information 18

LIST OF FIGURES

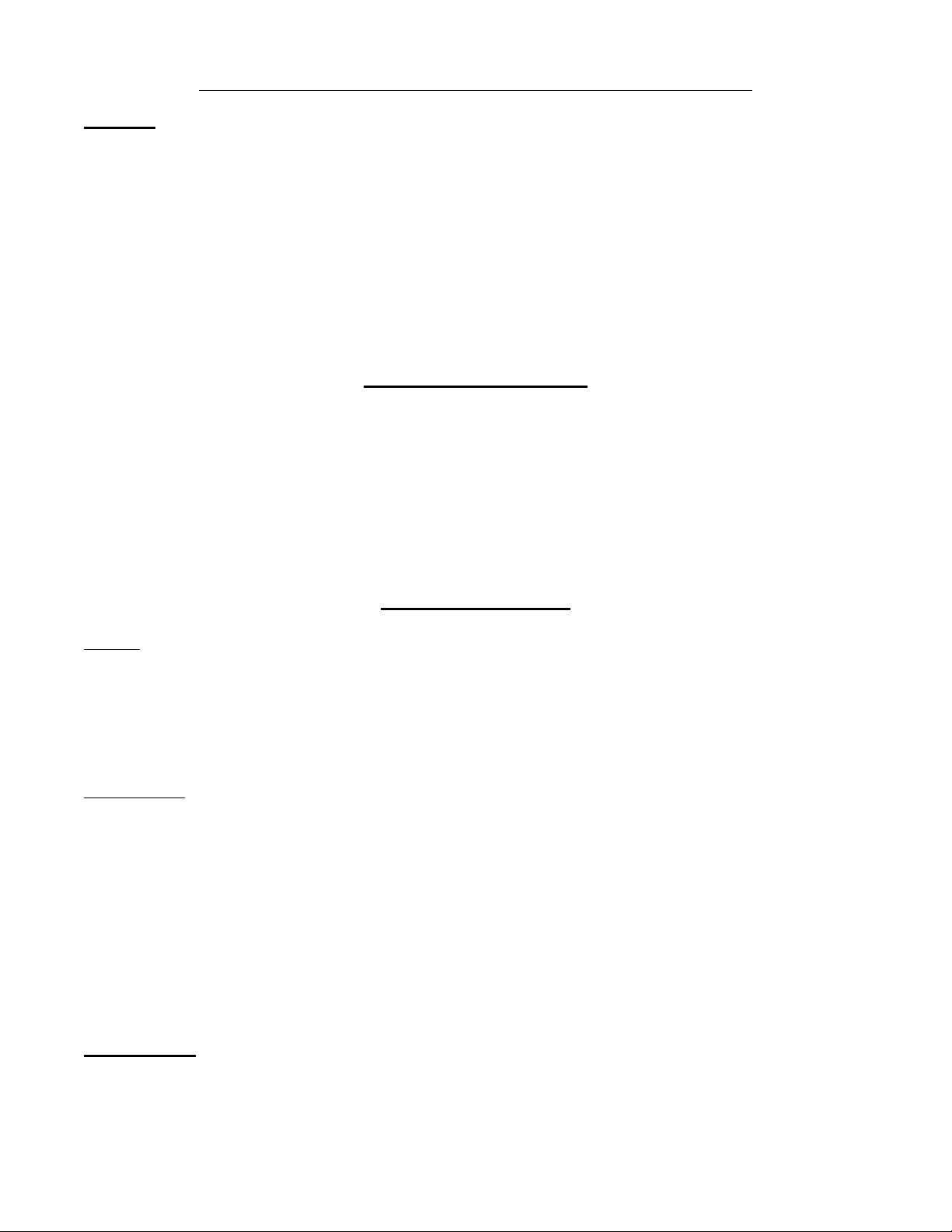

Figure 1-1 - Pedestal Mounting 4

Figure 1-2 - Floor Outline 4

Figure 1-3 - Machine Mounting Detail 4

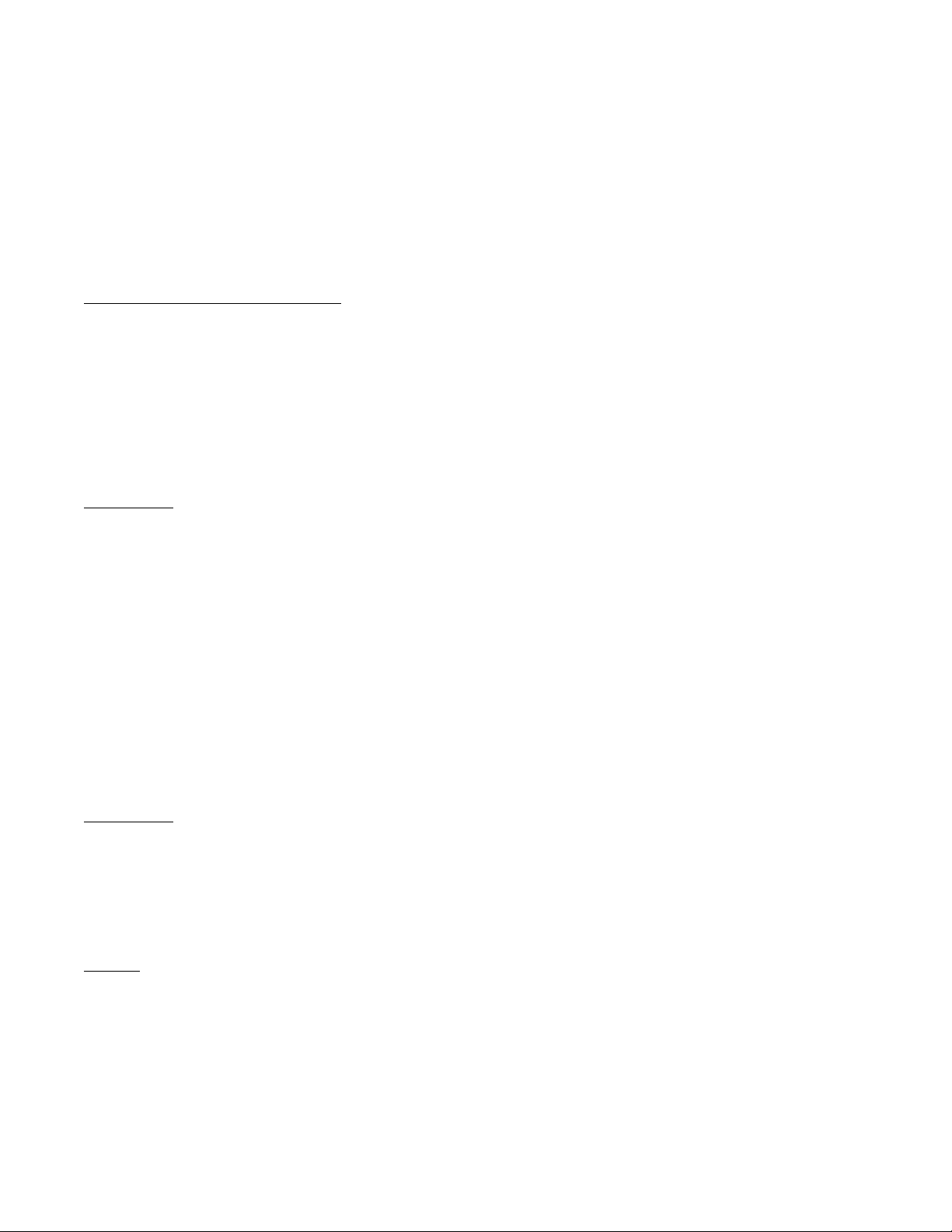

Figure 2 - Washer Dimensions 5

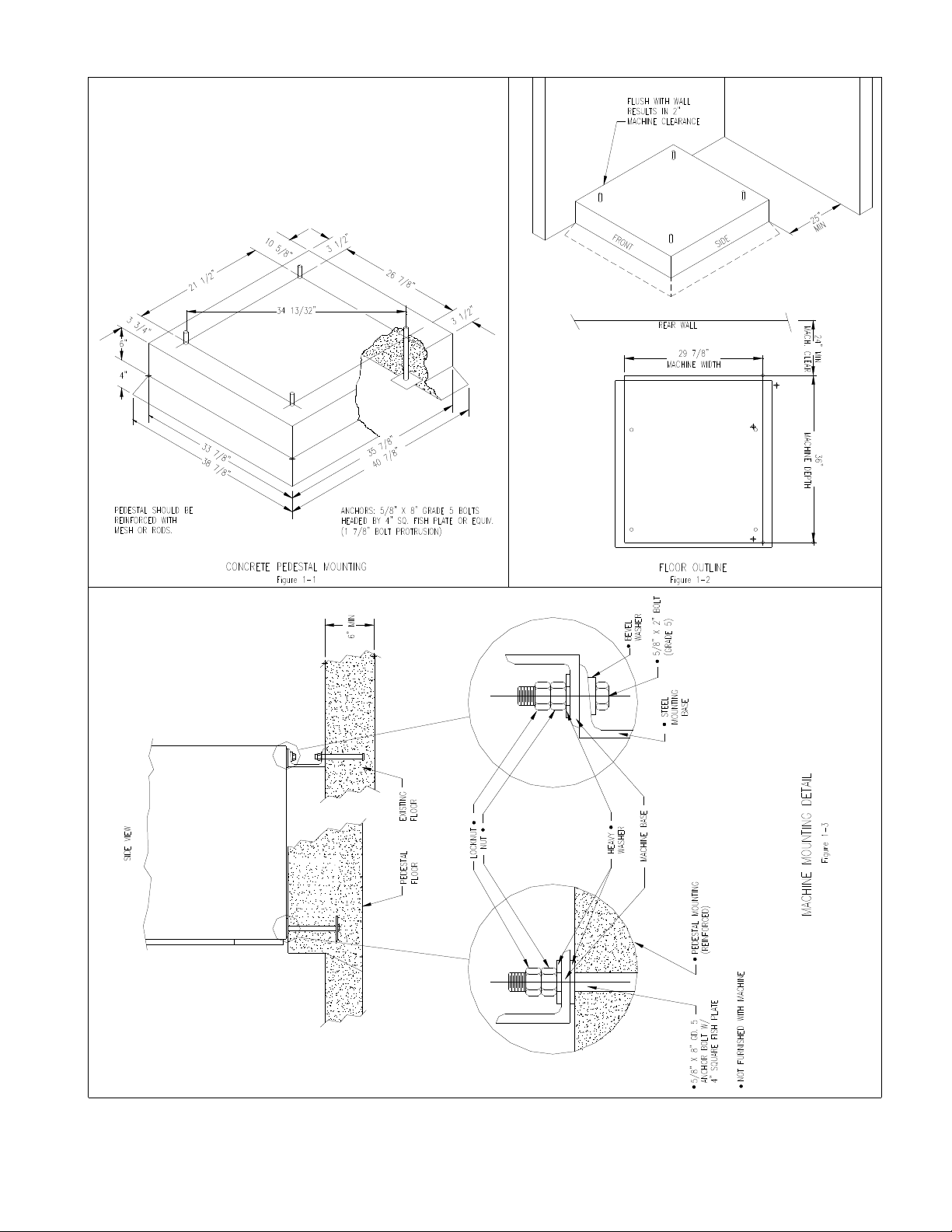

Figure 3 - Electrical Power Connections 6

Figure 4 - Injection Signal and Connections 7

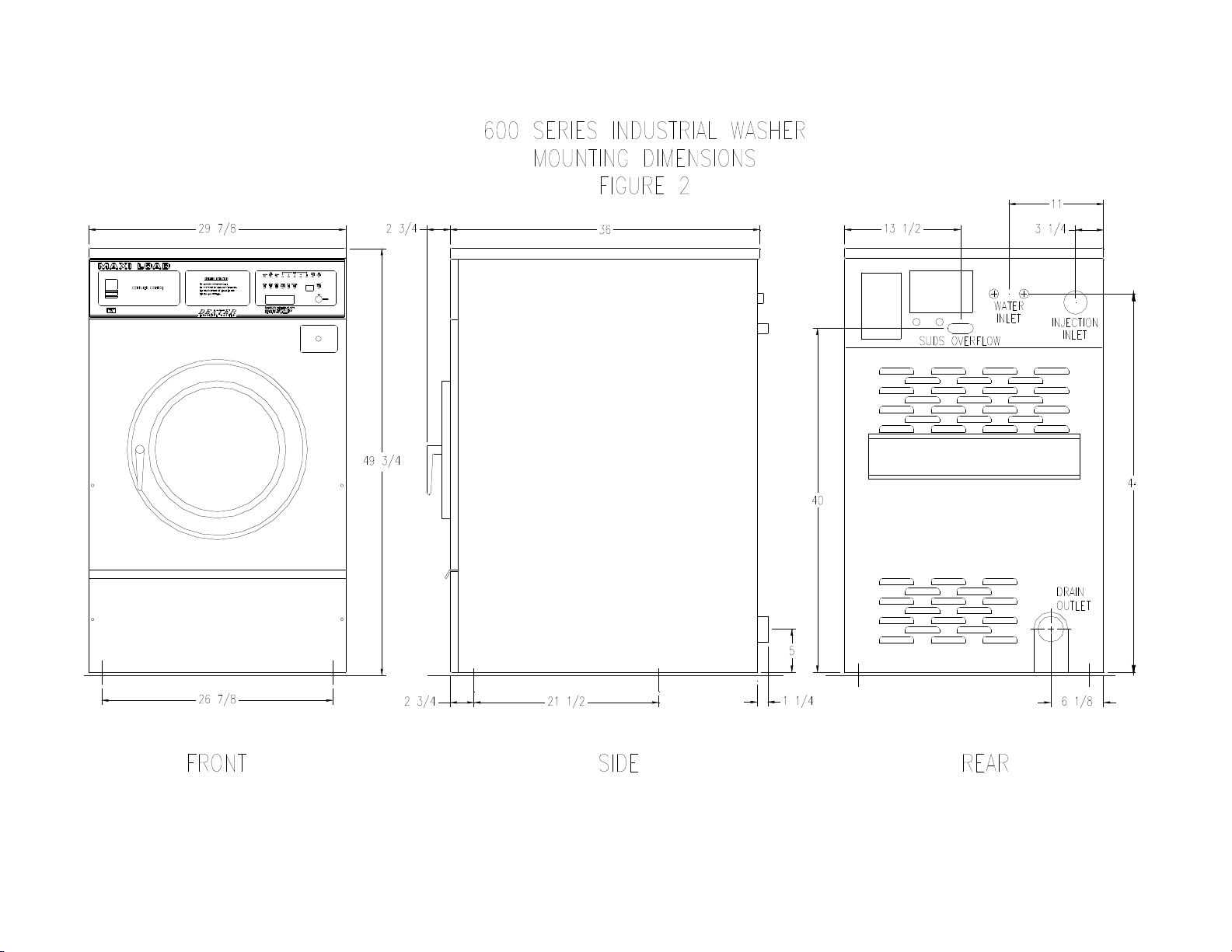

Figure 5 - Specifications Thoroughbred 900 8

Figure 6 - Water Usage 8

Figure 7 - Push-button Control Switches 9

Figure 8 - Recommended Detergent Quantity 10

Figure 9 - Bath Setting Limits 11

Please read this information and retain for reference.

WARNING - THIS WASHER IS EQUIPPED WITH DEVICES AND FEATURES RELATING TO ITS

SAFE OPERATION. TO AVOID INJURY OR ELECTRICAL SHOCK, DO NOT PERFORM

ANY SERVICING UNLESS QUALIFIED TO DO SO.

IT IS THE RESPONSIBILITY OF THE OWNER TO CHECK THIS EQUIPMENT ON A

FREQUENT BASIS TO ASSURE ITS SAFE OPERATION.

A machine should not be allowed to operate if any of the following occur:

! Excessively high water level.

! If machine is not connected to a properly grounded circuit.

! If the door does not remain securely locked during the entire cycle.

! Vibration or shaking from an inadequate mounting or foundation.

WARNING - FOR SAFETY

1. Always shut off power and water supply and wait a minimum of one minute

before servicing.

2. Do not overload the washer.

3. Do not bypass any safety devices of this washer.

4. Do not use volatile or flammable substances in or near this washer.

5. Do not attempt to open door when cylinder is in motion or it contains

water.

6. Keep all panels in place. They protect against shock and injury and add

rigidity to the washer.

MAINTENANCE HINTS

DAILY

! Clean the top and the cabinet to remove residue.

! Clean the soap dispenser and lid.

! Check the drain valve for leaking and that it opens properly.

! Check the loading door for leaks. Clean the door seal of all foreign matter.

! Leave the loading door open to aerate the washer when not in use.

QUARTERLY

Always shut off power and water supply and wait a minimum of one minute

before servicing.

! Check the V-belts for wear and proper tension.

! Clean lint and other foreign matter from around motor.

! Check all water connections for leaks.

! Wipe and clean the inside of the washer and check that all electrical

components are free of moisture and dust.

! Remove and clean water inlet hose filters. Replace if necessary.

! Check anchor bolts - retighten if necessary

IMPORTANT:

and/or quarterly maintenance.

Replace any and all panels that were removed to perform daily

3

INSTALLATION INSTRUCTIONS

All washers must be installed in accordance with all local, state and

national building, electrical, plumbing and other codes in effect.

WARNING - THESE INSTALLATION AND SERVICING INSTRUCTIONS ARE FOR

USE BY QUALIFIED PERSONNEL ONLY. TO AVOID INJURY AND ELECTRIC

SHOCK DO NOT PERFORM ANY SERVICING UNLESS QUALIFIED.

FOUNDATION REQUIREMENTS

This machine is designed for use on or over bare concrete floor - not to be

used above combustible flooring. The washer must be securely bolted to a

substantial concrete floor, or mounted upon a suitable base which is, in turn,

securely bolted to a substantial concrete floor. CARE MUST BE STRESSED WITH

ALL FOUNDATION WORK TO INSURE A STABLE UNIT INSTALLATION, ELIMINATING

POSSIBILITIES OF EXCESSIVE VIBRATION. All installations must be made on sound

concrete floors, 6" or thicker. Anchor bolts must be of a quality grade and a

minimum of 5/8" diameter. Four (4) mounting bolts must be used.

MOUNTING

A concrete pedestal or steel mounting base which elevates the machine

approximately 6" above the floor level is recommended to provide easy access to

the loading door. Actual base height should be determined by application

considering access to loading door, access to soap dispenser and height of

loading carts. Allow a minimum of 24" of clearance behind the rear of the

machine, to provide access for motor removal. Refer to Fig. 1-1 & 1-2 for

machine bolt-down dimensions. Refer to Fig. 2 for overall washer dimensions.

If an elevated concrete pedestal is desired, it should be embedded into the

existing floor. Anchor bolts should be 5/8" x 8", grade 5 or better, headed by

a 4 inch square fish plate and should protrude 1 7/8 inches above the finished

surface of the pedestal. EXPANSION ANCHORS ARE NOT RECOMMENDED FOR USE IN

CONCRETE FLOORS OR PEDESTALS, BECAUSE THE ANCHORS ARE TOO CLOSE TO AN EDGE,

CAUSING IT TO BREAK OUT. (See Fig. 1-1 and 1-3.)

PLUMBING

Water supply hoses are furnished with each machine. The threaded connections

on the hoses are 3/4-11 2 NHT.

Separate hot and cold water lines must be provided, maintaining 30 PSI to 120

PSI water flow pressure.

DRAIN

The drain outlet tube at the rear of the machine is 3 inches in diameter. Any

drain hose used must be lower than the drain valve to assure proper draining.

4

5

ELECTRICAL

WARNING

SHUT OFF POWER AND WATER BEFORE OPENING ANY SERVICE PANELS.

Dexter T600 washing machines are intended to be permanently installed

appliances. The machine should be connected to an individual branch circuit

not shared by lighting or other equipment. The connection should be sheathed

in liquid-tight flexible conduit, or equivalent, with conductors of the proper

size and insulation. No power cord is provided. Such connections should be

made by a qualified electrician, in accordance with the wiring diagram.

(Suggest minimum wire size of 12 ga.)

FUSING REQUIREMENTS

15 Amp Time Delay (Dual Element) Fuse(s) (or equivalent circuit breaker).

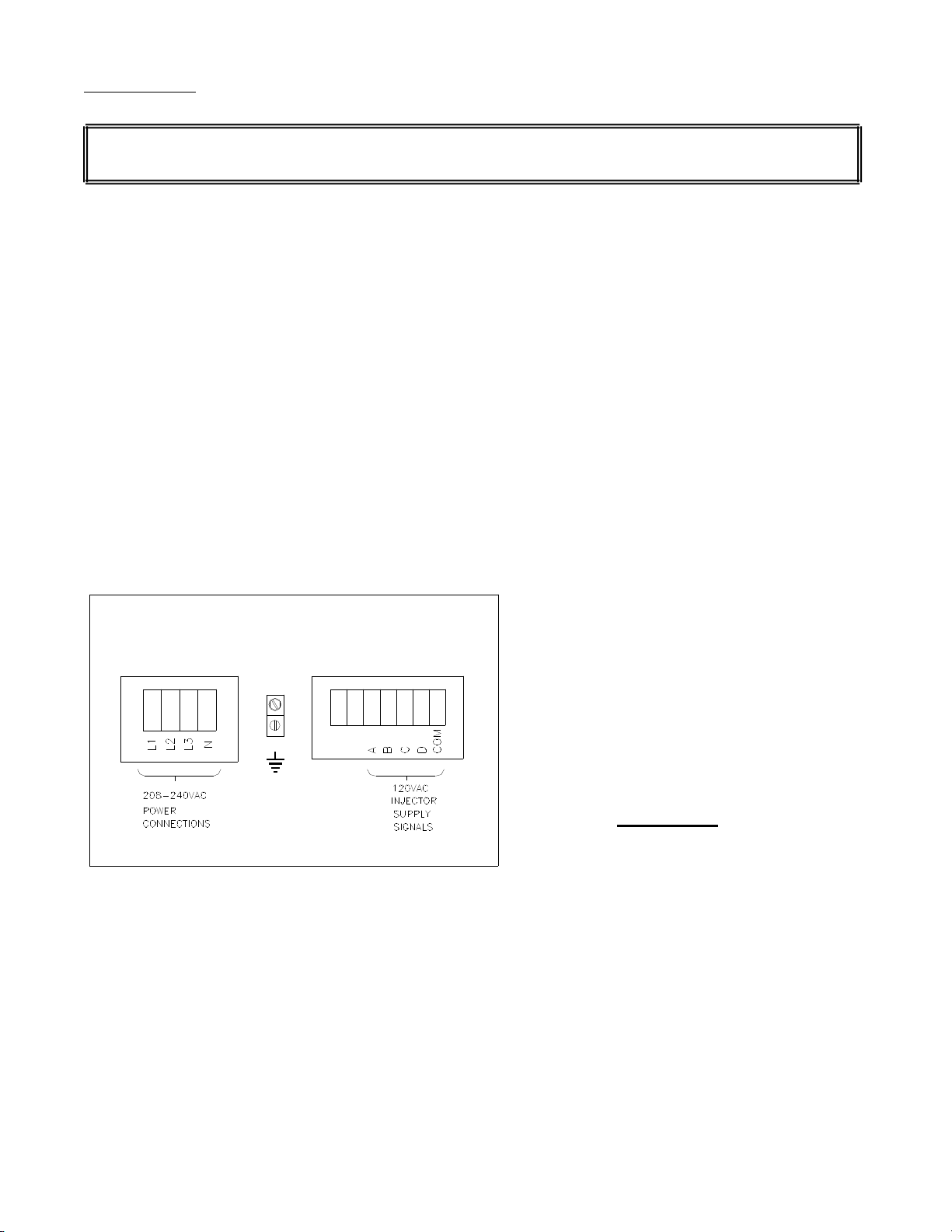

TO MAKE ELECTRICAL CONNECTIONS:

Remove screw and lift out cover located on upper left of machine (viewed from

back).

Figure 3 - Electrical Power Connections

If power is 208-240-3PH-60HZ

connect L1, L2, L3 and ground.

(If there is a high phase it must

be connected to L3.)

If power is 208-240-1PH-60HZ

connect L1, L2 and ground.

IMPORTANT

FOR SAFETY AND PROPER EQUIPMENT

OPERATION THE GROUND LUG MUST BE

CONNECTED TO A GOOD EXTERNAL

GROUND.

7

CHEMICAL INJECTION

Dexter T600 washing machines are intended to be permanently installed

appliances. The machine is intended to have a chemical injection system

operating with it. There are convenient electrical connection points for the

injection pumps shown in Figure 3. Up to four (4) independent pumps can be

controlled through the signals A, B, C and D. The injection pump signals are

115 VAC. The COM shown in Figure 3 is the common or return for these injection

signals. The complete injection system can be connected to FL1 and FL2 for

system power if other sources are not available. These connections require

fusing which are not provided by Dexter (Dashed lines shown in Figure 3). The

maximum current of the complete injection system is 7 Amps.

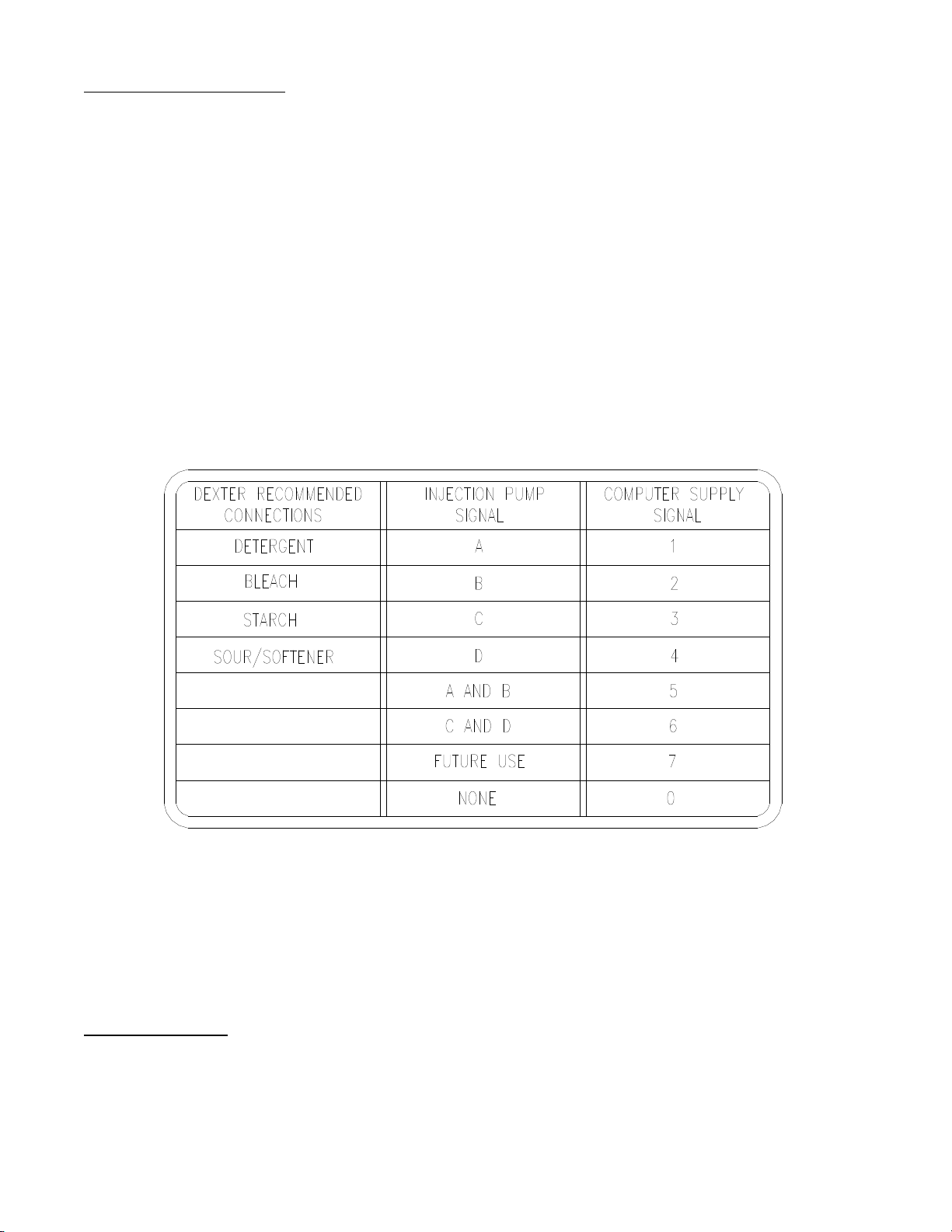

The four injection pump signals (A, B, C and D) are individually selected or in

combinations by the programming within the selected cycle. The recommended

signal connections are shown in Figure 4. The selection of the signal is

explained in the Programming Instructions section of this manual.

FIGURE 4 - INJECTION SOURCE SIGNALS AND CONNECTION RECOMMENDATION

CHEMICAL INJECTION HOSES

Chemical Injection hoses are to be inserted into the injection inlet at the

upper right rear of the washer. These hoses should be inserted into the round

PVC pipe a minimum of 14" and a maximum of 18" to eliminate chemical buildup in

the pipe and/or restrict water flow to the tub. Secure the hoses as required.

FINAL CHECKOUT

After all mounting, plumbing and electrical work is completed, the washer

should be checked for water leaks and proper functioning by first running each

step in the diagnostic cycle (cycle # 31) and by running a complete cycle.

8

FIGURE 5 - THOROUGHBRED 600 SPECIFICATIONS

MODEL

CAPACITY

CYLINDER DIM.

GROSS WEIGHT

NET WEIGHT

ELECTRICAL

EXTRACTION FORCE

WASH SPEED

SPIN SPEED

DRIVE SYSTEM

WATER INLET

DRAIN VALVE

PROGRAM CYCLES

WCN40AFH

6 CUBIC FT.

(UP TO 40#)

25" DIA. x 21 1/8" DEPTH

656 POUNDS

622 POUNDS

208-240 VAC, 60 HZ, 1 PH OR 3 PH

100 g=s

43 R.P.M.

531 R.P.M.

SOFT START REVERSING AC MOTOR DRIVE

2 SOLENOID OPERATED VALVES

FLOW RATE, 9 GAL./MIN. EACH

FLOW PRESSURE, 30-120 PSI

3" OUTSIDE DIAMETER

30 USER PROGRAMMABLE CYCLES

(29 OF 30 PREPROGRAMMED AT THE FACTORY)

CYCLES TAILORED FOR SHIRT LAUNDRY,

HOTEL/HOTEL, HEALTH CARE AND FOOD & BEVERAGE

(SEE PRESET CYCLE INFORMATION TABLE)

TEST CYCLE

TEMPERATURES

MACHINE CONTROL:

KEYLOCK

MEMBRANE

DIAGNOSTIC TEST PROGRAM

USER SELECTABLE FROM 4 SETTINGS

ADVANCE/RUN/PROGRAM

STOP/EXIT

START/ENTER

SCROLL UP

SCROLL DOWN

FIGURE 6 - WATER USAGE

USAGE/BATH LOW LEVEL HIGH LEVEL

FILL FILL

EMPTY CYLINDER - NO LOAD 12.6 gals. 18.6 gals.

FULL CYLINDER - LOADED

Water required to fill bath gals. gals.

starting with a dry load.

Water required to fill bath preceded 10.6 gals. 16.4 gals.

by a drain without a spin.

Water required to fill bath preceded gals. 21.4 gals.

by a drain with a spin.

9

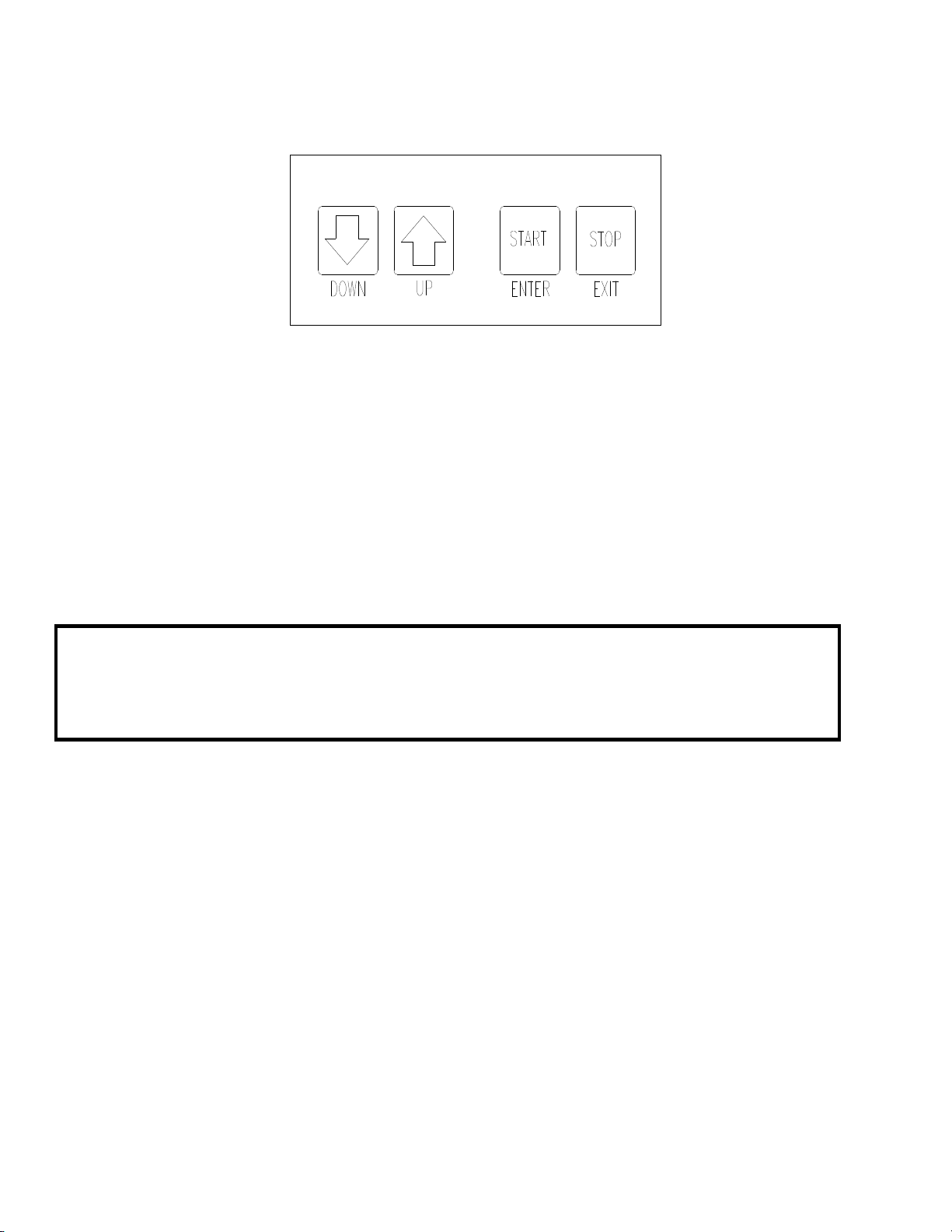

OPERATING CONTROLS

There are four (4) switches that control the washer operation. Each switch is

shown below followed by an explanation of each switch.

Figure 7 - Push-button Control Switches

STOP (RED) Push-button - Depress momentarily.

Stops the washer during the cycle. All washer cycle information is retained,

the door remains locked and the water remains in the tub.

STOP (RED) Push-button - Depress and hold for 3 seconds or longer.

Stops the washer and clears the cycle. All washer cycle information is

cleared, the water is drained and the door is unlocked. The washer is ready

for the next wash cycle.

NOTE: The door lock safety mechanism will prevent the door from opening for up

to 3 mins. when the washer is stopped during a cycle and the cycle

cleared.

WARNING

DEPRESSING AND HOLDING THE STOP IS AN EMERGENCY STOP BUTTON.

THIS DOES NOT DISCONNECT THE MACHINE FROM THE INPUT POWER.

START (GREEN) Push-button - Depress momentarily.

Starts the cycle shown on the display. If the cycle was stopped in the middle,

depressing the START will begin the cycle from the point at which the cycle was

stopped.

SCROLL UP ARROW (BLUE) Push-button - Depress momentarily / depress and hold.

Scroll Up increases the cycle number displayed by one each time the switch is

depressed. When the Scroll Up is held, the display cycle numbers will continue

to increase until cycle # 30 (cycle # 31 in Programming Mode) is reached at

which time the cycle number displayed will rollover back to cycle # 1.

SCROLL DOWN ARROW (BLUE) Push-button - Depress momentarily / depress and hold.

Scroll Down decreases the cycle number displayed by one each time the switch is

depressed. When the Scroll Up is held, the display cycle numbers will continue

to decrease until cycle # 1 is reached at which time the cycle number displayed

will rollover to cycle # 30 (cycle # 31 in Programming Mode).

10

OPERATING INSTRUCTIONS

1. Ensure that power is on to the washer.

2. Ensure that the ADVANCE/RUN/PROGRAM keylock is in the RUN position.

3. Load the clothes loosely in the cylinder and latch the door securely. Be

sure clothing does not get caught between the door gasket and tub front

when closing the door.

NOTE: To begin closing the door, the handle must be in the horizontal

position. After moving the door to the closed position, the

handle must be turned down to the vertical position in order

to latch the door for machine operation.

4. Select one of thirty cycles by using the SCROLL UP/SCROLL DOWN buttons to

change the number indicated in the two digit LED display. The selection

is made when the number indicated corresponds with the desired cycle.

5. If you are manually adding wash compounds, add low sudsing powdered

detergent in the amount shown below into the detergent compartment on top

of the machine. Location is illustrated on the black cover on the top of

the machine. This compartment will be flushed during the WASH segment of

the cycle. Rinse conditioners may be added to their own compartment if

desired. This compartment will be flushed during the FINAL RINSE segment

of the cycle.

POWERED

DETERGENT REQUIREMENT

THOROUGHBRED 600

Figure 8 - Recommended Detergent Quantity

6. If you wish to manually add bleach during the cycle, add bleach in the

round opening in the top of the machine. Location is illustrated on the

black cover on the top of the machine.

NOTE: Any additional washing compounds may be added at the appropriate

time by pouring into the round opening in the top.

7. Push the green START button to start the cycle.

The cycle time remaining is displayed throughout the cycle. The cycle

number in operation can to displayed by pushing and holding START, then

push SCROLL UP. The cycle number will be displayed as long as these two

buttons are depressed.

Soak - At any time during the cycle, the red STOP button can be depressed

to stop the washer. All washer cycle information is retained and the

door remains locked. The washer will soak the load for 15 minutes, then

agitate for 30 seconds. This will repeat until the cycle is started

again. This feature allows for an extended soak if required. The washer

cycle will continue when the START button is depressed.

The selected cycle can be cleared at any time by depressing and holding

1/3 to 1/2 CUP

11

the STOP button for a minimum of three seconds.

12

Loading...

Loading...