OPERATOR'S MANUAL

8514-201-001PR

03/01/2010

For DDAD30HC-59 Series Dryers

The dryer must not be stored or installed where it will be exposed to water and/or weather and is

suitable for use in room temperatures between 5C and 45C.

WARNING: For your safety the information in this manual must be followed to

minimize the risk of fire or explosion or to prevent property damage, personal

injury or death.

-Do not store or use gasoline or other flammable vapours and liquids in the vicinity of

this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

-Do not try to light any appliance.

-Do not touch any electrical switch: do not use any telephone in your building.

-Clear the room, building or area of all occupants.

-Immediately call your gas supplier from a neighbor’s telephone. Follow the

gas supplier’s instructions.

-If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

You, the purchaser, must post in a prominent location instructions to be followed in the event the user smells

gas. Consult your local gas supplier for procedure to be followed if the odour of gas is present.

Post the following

“For Your Safety” caution in a prominent location:

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapours or liquids in the vicinity of this or any other appliance.

FOR YOUR SAFETY

THIS MACHINE IS FOR DRYING ONLY FABRICS CLEANED IN WATER. To

avoid possibility of fire, including spontaneous combustion, do not dry oiled floor mops, items

containing foam rubber or similarly textured rubberlike materials or any material on which you

have used a cleaning solvent or which contains flammable liquids or solids (such as petrol,

kerosene, waxes, etc.)

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance. It is important that you read this

Manual and retain it for future reference. For service or replacement parts, contact the distributor in your area or:

Dexter Laundry, Inc

2211 West Grimes Avenue

Fairfield, Iowa 52556

TABLE OF CONTENTS

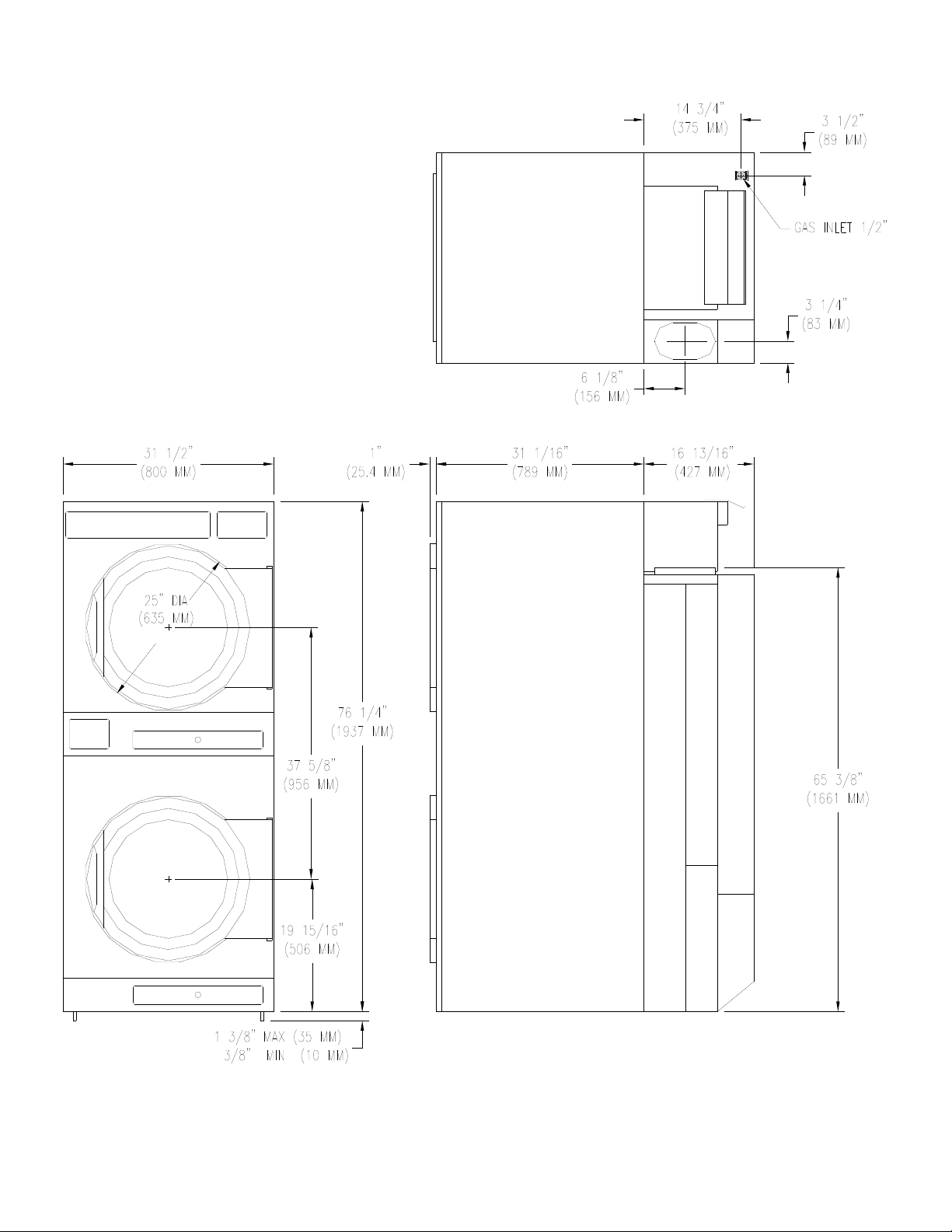

DRYER DIMENSIONS (Figure 1) 3

UNCRATING 4

INSTALLATION CLEARANCE (Figure 2) 5

DRYER EXHAUST SYSTEM (Figure 3) 10

DRYER SHUTDOWN 10

TOUCH PAD LAYOUT (Figure 4) 11

DRYER DEFAULT SETTINGS 12

DRYER FAULT CODES 12

TOUCH PAD DESCRIPTION 13

OPERATING INSTRUCTIONS 15

PROGRAMMING INSTRUCTIONS 17

SERVICING DRYER 23

PREVENTATIVE MAINTENANCE 23

WARNINGS ABOUT USE AND OPERATION

It is ABSOLUTELY ESSENTIAL that the dryer be connected to a good earth connection. This

is not only for personal safety, but is necessary for proper operation.

KEEP SHIELDS, GUARDS AND COVERS IN PLACE. These safety devices are provided

to protect everyone from injury.

A DRYER SHOULD BE CONNECTED TO POWER FOR THREE (3) MINUTES before it

is operated or before a program change is made. Operation or program changes, which occur

during this “power up” period, are subject to loss in case of power interruption. After the initial

three minutes, all programmed data is protected from power interruptions of any length and the

customer’s individual cycle is protected up to 3 seconds. This is done without batteries.

LEAVE THE ELECTRICAL POWER TO THE DRYER ON AT ALL TIMES except when

necessary for service or other similar activities. The hour meter function adds only full hours to

its reading. If the power is shut off every night, any fraction of an hour of time that is on the

machine at that time will be lost. Turning the power off every night could also have some effect

on the long-term life of the memory after a number of years. Turning power off occasionally

won’t affect the unit.

THIS DRYER IS EQUIPPED WITH A MANUALLY RESETTABLE OVERTEMPERATURE THERMOSTAT located on the end of the burner housing above the gas

valve. Should the dryer cease to operate, refer to your “Service Procedure and Parts Data” book

for instructions.

CHECK THIS THERMOSTAT WHEN INSTALLING DRYER to assure it is not tripped.

Impacts, such as rough handling in shipment, may trip the thermostat. It may be reset by

inserting a wooden (nonconductive) pencil or dowel through the guide bushing in the cover.

2

Figure 1, 30# Stack Dryer Dimensions, inches (mm)

3

INSTALLATION AND OPERATING INSTRUCTIONS

Note: Before installation, check that the local distribution conditions, nature of gas and

pressure, and the adjustment of the appliance are compatible.

UNCRATING AND PLACING DRYER

Tools Required: 3/4" (19 mm) hex socket & ratchet driver, wood block 4" (100 mm) or 5" (125

mm) thick, a knife and a groove joint pliers, which will open to 1 3/8" (35 mm).

1. Remove and discard the packaging.

2. The crate base is attached to the dryer by (4) cap screws driven upward from below the crate

base. Remove the crate base from the dryer, by tipping the dryer sidewise and place the block

under the crate base rail in the center of the dryer. Using a ratchet and a 3/4" (19 mm) hex

socket, remove and discard the (2) crating bolts from the side, which is raised. Remove the

block from under the crate base. Repeat for the other side.

3. Install leveling legs. Using a walking motion, move dryer sideways about 6" (150 mm) off of

the crate base. Tip the dryer up and place the block under the edge of the dryer. Thread two

leveling legs about two-thirds into the T-nuts on the base from which the crating bolts were

removed. Remove the block from under the dryer.

With a walking motion, move the dryer completely off the crate base. Discard the crate base.

Tip the dryer sidewise, as previously done, and place the block under the edge of the dryer on the

raised side. Thread the leveling legs into the nuts as was done for the first side.

Slide the unit into the position where it will be installed. Adjust the leveling legs, using the

groove joint pliers, to level and align the dryer with adjacent units.

DRYER INSTALLATION

1. CODE CONFORMITY: All commercial dryer installations must conform to the local and

national codes for the location of installation

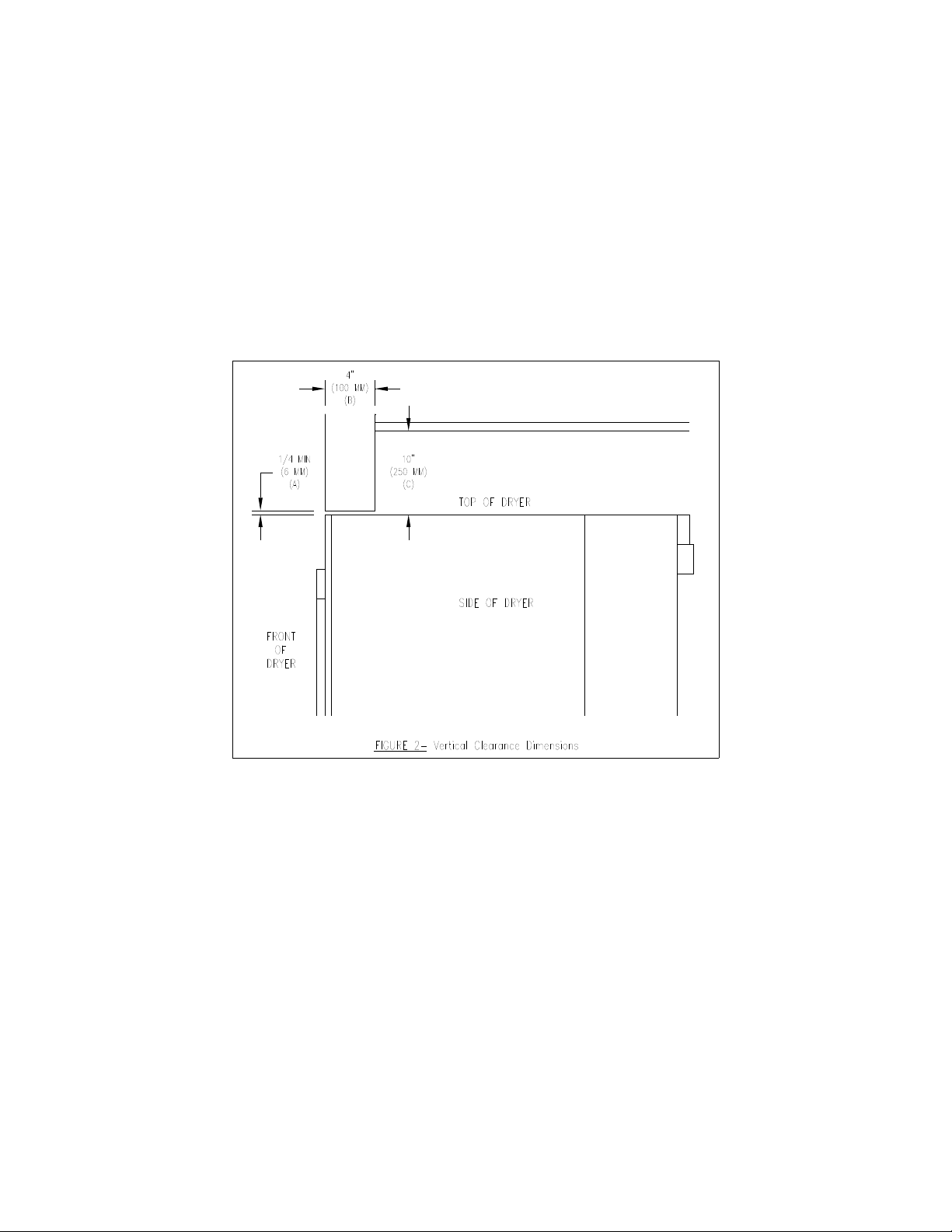

2. INSTALLATION CLEARANCES: This unit may be installed at the following alcove

clearances.

I Left side 0 in.

II Right side 0 in.

III Back 18 in. (450 mm) clearance is necessary behind the belt guard to allow for

servicing and maintenance.

IV Front 48 in. (1200 mm) to allow use of dryer.

V Top Refer to figure labeled “Vertical Clearance Dimensions”.

AB. 0 in. clearance at the top, 4 in. (100 mm) back from the front.

and ventilation requirements.

4

However 1/4 in. (6 mm) clearance should be allowed in case the dryer

needs moving.

C. A 10 in. (250 mm) clearance is required from top at all other points.

VI. Floor This unit may be installed upon a combustible floor.

Do not obstruct the flow of combustion and ventilation air.

Maintain minimum of 1 in. (25 mm) clearance between duct and combustible material.

Refer to the installation label attached to the Belt Guard on the rear of the dryer for other

installation information and start-up instructions.

3

3. MAKE-UP AIR. Adequate make-up air (600CFM/DRUM (17 m

/min.),

1200CFM/DRYER (34 m3/min)) must be supplied to replace the air exhausted by dryers on all

types of installations. Provide a minimum of 1.5 ft² (0.14 m²) make-up air opening to the outside

for each dryer. This is a net requirement of effective area. Screens, grills or louvers, which will

restrict the flow of air, must be considered. Consult the supplier to determine the free area

equivalent for the grill being used.

The source of make-up air should be located sufficiently away from the dryers to allow an

even airflow to the air intakes of all dryers. Multiple openings should be provided.

NOTE: The following considerations must be observed for gas dryer installations where dry

cleaners are installed. The sources of all make-up air and room ventilation air movement to all

dryers must be located away from any dry cleaners. This is necessary so that solvent vapours

will not be drawn into the dryer inlet ducts. Dry cleaner solvent vapours will decompose in

5

contact with an open flame such as the gas flame present in clothes dryers. The decomposition

products are highly corrosive and will cause damage to the dryer(s), ducts and clothes loads.

The operation of this appliance may affect the operation of other types of gas appliances,

which take their air for safe combustion from the same room. Adequate ventilation must be

provided to avoid back flow of gasses from other appliances in the same room. All other gas

appliances should be tested with the Dexter dryer in operation and all the windows and doors

closed. If in doubt, consult the appliance manufacturer(s).

4. ELECTRICAL REQUIREMENTS. The electrical power requirements necessary to

operate the unit satisfactorily are listed on the serial plate located on the back panel of each

dryer. The electrical connection should be made to the terminal board in the control box, on the

rear of the unit, using copper conductors of 20A minimum capacity. It is absolutely necessary

that the dryer be grounded to a known ground.

The installation must meet the National Electrical Requirements of the country of

installation. Individual 20A circuit breakers for each dryer are required. The installer must

provide a disconnect switch, which will interrupt both lines. It may be a local or national

requirement to provide an electrical interruption switch visible and accessible from the room in

which the dryer is installed. The wiring diagram is located in the control box on the back of the

dryer.

5. GAS REQUIREMENTS. The complete gas requirements necessary to operate the dryer

satisfactorily are listed on the serial plate located on the back panel of the dryer.

This appliance is adjusted for a G20 gas supply; please refer to the table below for country and

regulator setting.

NATURAL GAS

HEAT INPUT 90000 BTU/HR (26.38kW) GROSS

72000 BTU/HR (21.12kW) NET PER DRUM MAX

GAS FLOW RATE 2.2 m3 PER HOUR PER DRUM

BURNER PRESSURE 3.5 in. H2O (8.7 mbar)(0.87 kPa)

INJECTOR SIZE NO. 32 DRILL (2.95 mm)

ADJUSTMENT REQUIRED PER COUNTRY

COUNTRY CATEGORY SUPPLY PRESSURE

Normal / Minimum mbar

GB, IE, ES, PT, FI,

I2H 20 / 17 8.7 (0.87)

AT, IT, DK, SE, GR

REGULATOR SETTING

mbar (kPa)

FR I2Er 20 / 17 8.7 (0.87) (G20) / 12.0 (1.20) (G25)

DE I2E 20 / 17 8.7 (0.87)

NL I2L 25 / 20 12.0 (1.20)

The inlet gas connection to the unit is ISO 7-RC 3/4 thread. The connection to the appliance

6

shall be made with a flexible hose suitable for the appliance category in accordance with national

installation regulations. The size of the piping to supply the dryer should be determined by

reference to national installation practice and consultation with the local gas supplier.

A joint compound resistant to all fuel gases must be employed in making threaded pipe

connections.

A 1/8 inch NPT plugged tapping, accessible for test gage connection, must be installed

immediately upstream of the gas supply connection to the dryer.

A drip tee is provided in the unit gas piping to catch dirt and other foreign articles.

All pipe connections should be checked for leakage with soap solution. Never check with an

open flame.

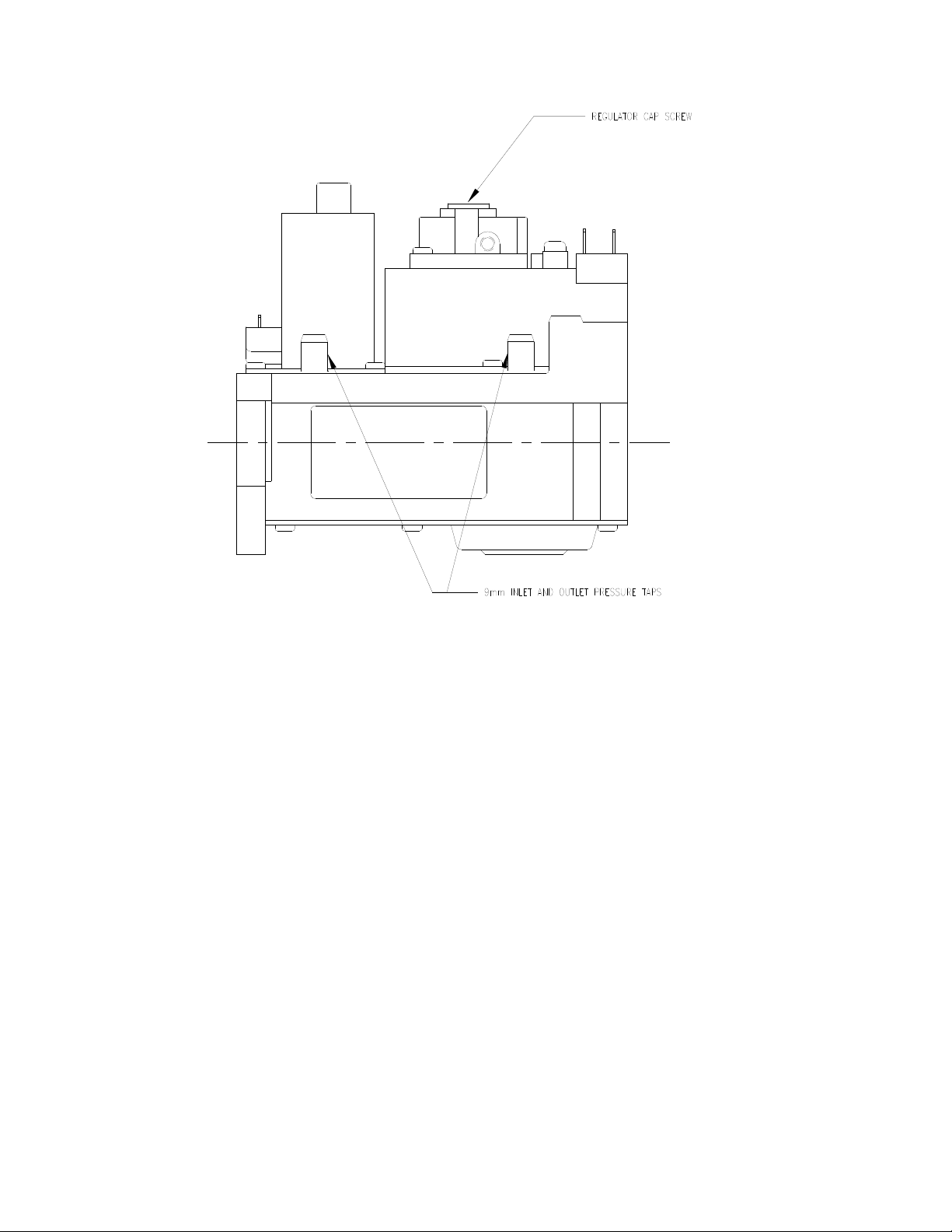

Note: There are two 9 mm pressure taps, one at the inlet side, one at the outlet side of the gas

valve, for use, if it is necessary, to check either pressure.

PRESSURE REGULATOR ADJUSTMENT

Adjustments should be made by qualified personnel only.

1. With dryer off , unscrew the outlet pressure tap on the gas control valve a half turn

and slip pressure gauge tube over nipple. Ensure that screw is retightened after the

regulator is adjusted.

2. Remove regulator cap screw to expose regulator adjustment screw.

3. Start the dryer. Using a screwdriver, slowly turn the adjustment until the required

burner pressure is indicated on the pressure gauge. Turn adjustment screw clockwise to

increase and counter-clockwise to decrease gas pressure to burner. Turn dryer off.

4. Replace pressure regulator cap screw.

5. Remove pressure gauge and retighten pressure tap screw.

7

CAUTION: The dryer and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½

psig (35 mbar). The dryer must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply piping system at

test pressures equal to or less than ½ psig (35 mbar).

6. EXHAUST INSTALLATION. (Refer to Figure 3 at the end of section 6.) Exhausting of

the dryer(s) should be planned and constructed so that no air restrictions occur. Any restriction

due to pipe size or type of installation can cause slow drying time, excessive heat, and lint in the

room.

From an operational standpoint, incorrect or inadequate exhausting can cause a cycling of the

high limit thermostat, which shuts off the main burners and results in inefficient drying.

The oval exhaust duct connection near the top of the dryer will accept a compressed 8” round

duct. Individual exhausting of the dryers is recommended. All heat, moisture, and lint should be

exhausted outside by attaching a pipe of the proper diameter to the dryer adapter collar and

extending it out through an outside wall. This pipe must be very smooth on the inside, as rough

surfaces tend to collect lint, which will eventually clog the duct and prevent the dryer from

exhausting properly. All elbows must be smooth on the inside. All joints must be made so the

8

Loading...

Loading...