Page 1

Model P2201 Cat. No. DDF211022P

P2201

R2200

P2201

OPERATING INSTRUCTION MANUAL

Low Velocity Powder

Actuated Fastening Tool

DO NOT OPERATE THE P2201 TOOL UNTIL

YOU HAVE READ THIS MANUAL AND RECEIVED THE PROPER TRAINING

ACCORDING TO ANSI STANDARD A 10.3-1995.

STUDY THIS MANUAL CAREFULLY AND DEVELOP A THOROUGH

UNDERSTANDING OF THE CONTENTS.

PROPER TRAINING ACCORDING TO THE CURRENT ANSI

STANDARD A 10.3, SAFETY REQUIREMENTS FOR POWDER

ACTUATED FASTENING SYSTEMS MUST BE COMPLETED AND

A D

EWALT QUALIFIED OPERATOR CARD MUST BE OBTAINED

PRIOR TO OPERATION OF THE TOOL. STATE, LOCAL, OR

OTHER REGULATIONS SHOULD ALSO BE FOLLOWED. LAWS,

REGULATIONS, AND STANDARDS REGARDING THE USE

OF POWDER ACTUATED TOOLS MAY PERIODICALLY BE

REVISED. ANY SUCH REVISIONS MAY CHANGE THE SAFETY

AND OPERATING PROCEDURES DESCRIBED IN THIS MANUAL.

D

EWALT, INC. IS NOT RESPONSIBLE FOR ANY SUCH REVISIONS

WHICH OCCUR AFTER PUBLICATION OF THIS MANUAL. IT IS THE

RESPONSIBILITY OF THE USER TO MAINTAIN FAMILIARITY WITH

THE CURRENT LAWS, REGULATIONS, AND STANDARDS THAT

APPLY TO THE POWDER ACTUATED TOOL.

NEVER CLOSE TOOL WITH ANY PART OF HAND OVER MUZZLE END.

TOOL IS LOADED.

DO NOT PLACE A

FINGER ON THE

TRIGGER

OF LOADED TOOL UNTIL MUZZLE END IS AGAINST WORK

SURFACE AND YOU ARE READY TO MAKE A FASTENING. NEVER

PLACE YOUR HAND OVER THE MUZZLE WITH A POWDER LOAD IN

THE TOOL. IF THE TOOL ACCIDENTALLY DISCHARGES THE PISTON

OR FASTENER MAY PENETRATE YOUR HAND RESULTING IN

SERIOUS INJURY.

TOOL WARRANTY WILL NOT BE VALID UNTIL THE TEST IS

RECEIVED, WITH A COPY OF YOUR RECEIPT, AND REVIEWED

BY D

EWALT, INC.

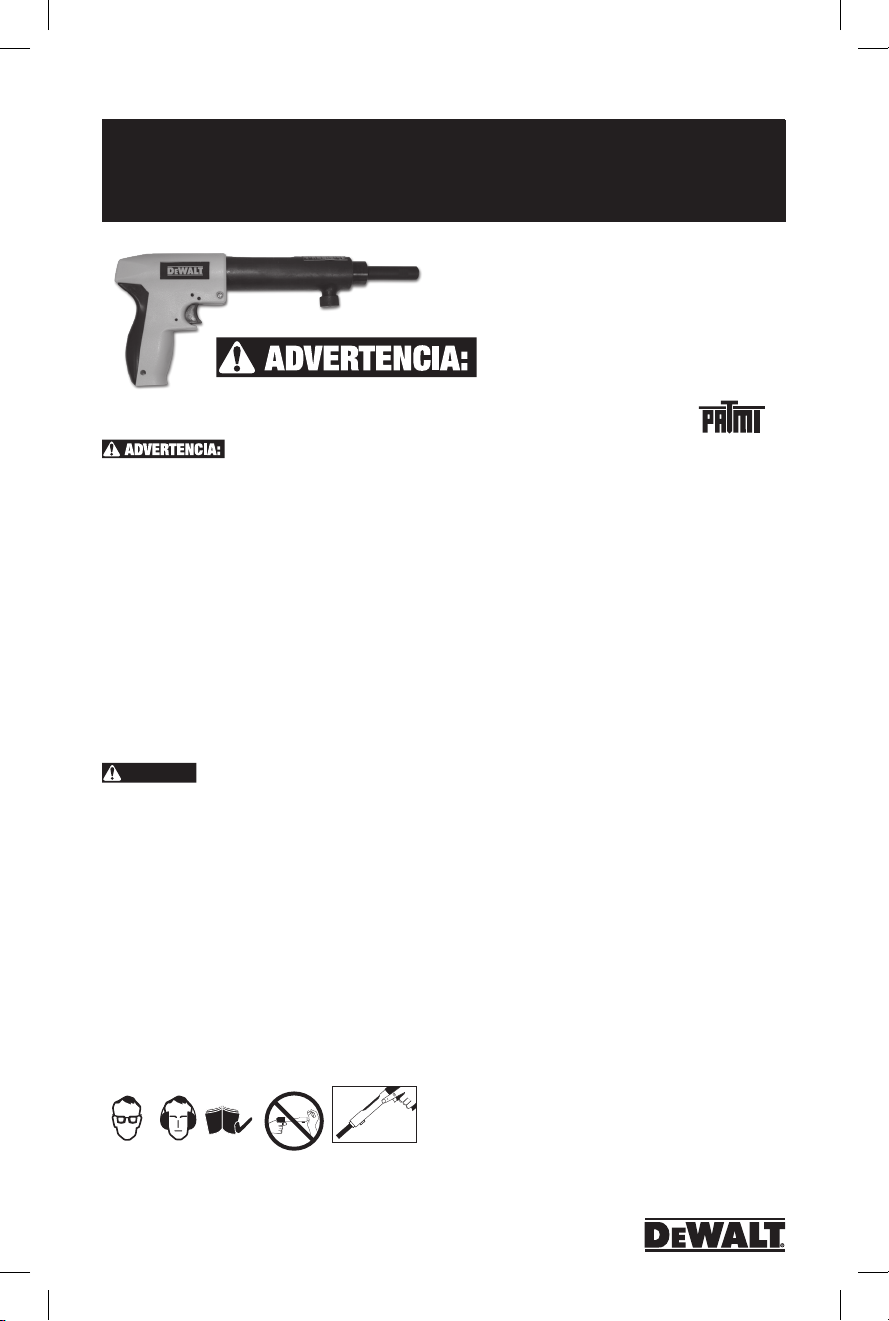

PRIOR TO OPERATING THE P2201 TOOL,

TO AVOID SERIOUS INJURY OR DEATH:

OPERATORS AND BYSTANDERS MUST WEAR

EYE AND HEARING PROTECTION.

TOOL OPERATION MUST READ AND UNDERSTAND

THE ENTIRE TOOL MANUAL AND MUST COMPLETE

THE OPERATOR’S EXAM ON THE LAST PAGE. THE

R2200

ALWAYS

ASSUME

Warranty

Three Year Limited Warranty

D

EWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty

coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This

warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others. This

warranty gives you specific legal rights any you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

D

EWALT will maintain the tool and replace worn parts caused

by normal use, for free, any time during the first year after

purchase.

If you are not completely satisfied with the performance of

your D

return it within 90 days from the date of purchase with a

receipt for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT:

If your warning labels become illegible or are missing call

1-800-4-DEWALT (1-800-433-9258) for a free replacement.

90 DAY MONEY BACK GUARANTEE

EWALT Powder Actuated Tool for any reason, you can

EWALT tools are covered by our:

1 YEAR FREE SERVICE

Introduction

Thank you for purchasing the DEWALT P2201 low velocity

powder actuated tool. This tool will provide you with excellent

performance provided the steps for proper operation and

maintenance are followed. Powder actuated fastening

systems can provide a cost effective method of attaching

fixtures for light duty, static load conditions. The systems

provided by D

installation tools, and powder loads which are designed to

function in combination to provide optimum performance.

While powder actuated tools can provide one of the fastest

and economical means of fastening, they can also be

dangerous if they are not operated properly.

Prior to operating the P2201 tool, you must be properly

trained in the operation and maintenance of this tool and be

issued a D

tool, you must have this card in your possession. As part

of the training process, you should read and understand

the contents of this instruction manual especially the safety

EWALT consist of specially designed fasteners,

EWALT Qualified Operator Card. When using the

™

1

POW2273_manual_P2201_dewalt.indd 1 3/10/14 12:41 PM

Page 2

P2201

Model P2201 Cat. No. DDF211022P

precautions.

Stop

Spall

Powder actuated tools may be operated only by properly

trained operators as described in ANSI Standard A 10.3,

Safety Requirements for Powder Actuated Fastening

Systems. For complete tool operation details, contact your

local D

EWALT Branch office or distributor for training.

Remember, safety begins with you! It is your primary

responsibility when operating this tool. Failure to follow the

proper operating, maintenance, and safety procedures can

result in serious injury or death to yourself or bystanders.

In addition to the training provided, you should be familiar

with any local, state, and federal regulations. If you have any

questions which are not covered in this manual, contact your

local D

EWALT Branch office or distributor.

Size Range

1/2” to 3” pin lengths, .22 caliber

Tool Description

The P2201 is a low velocity, single shot, .22 caliber tool

which can be used to install .300 head drive pins, 8mm

head drive pins and 1/4”-20 threaded studs, up to 3” in total

length. The P2201 is designed for maintenance or residential

contractors.

Technical Data

TOOL BODY PIN LENGTH TOOL LENGTH

Engineered Plastic 1/2” to 3” Total Length 12-1/2”

LOAD TYPE TOOL WEIGHT POWER LEVEL

.22 Caliber in 4.3 lbs. Gray (1), Brown (2)

Crimped “A” Load Green (3), Yellow (4)

PIN TYPE

Ballistic Point Drive Pin, .300 Head Drive Pin, 8mm Head Drive Pin,

1/4”-20 Threaded Stud

P2201 Selection Guide

CAT NO. DESCRIPTION STD CTN.

DFC211022D P2201 Tool (Blister Pack) 1

52522 Piston 1

52510 Nose Piece 1

52512 Piston Reset Pin 1

Fastener Functioning

Prior to learning the safe operating

procedures for this tool, it is important

to understand how a powder actuated

fastener works. A powder actuated

fastener is considered to be a direct

drive or forced entry type of fastener

because it is driven directly into the

base material. The driving action causes tremendous forces

to be applied to the fastener. D

EWALT powder actuated

fasteners are specially designed and manufactured using

an austempering process to withstand the forces imposed

during the driving operation. Only fasteners manufactured or

supplied by D

EWALT should be used in this tool.

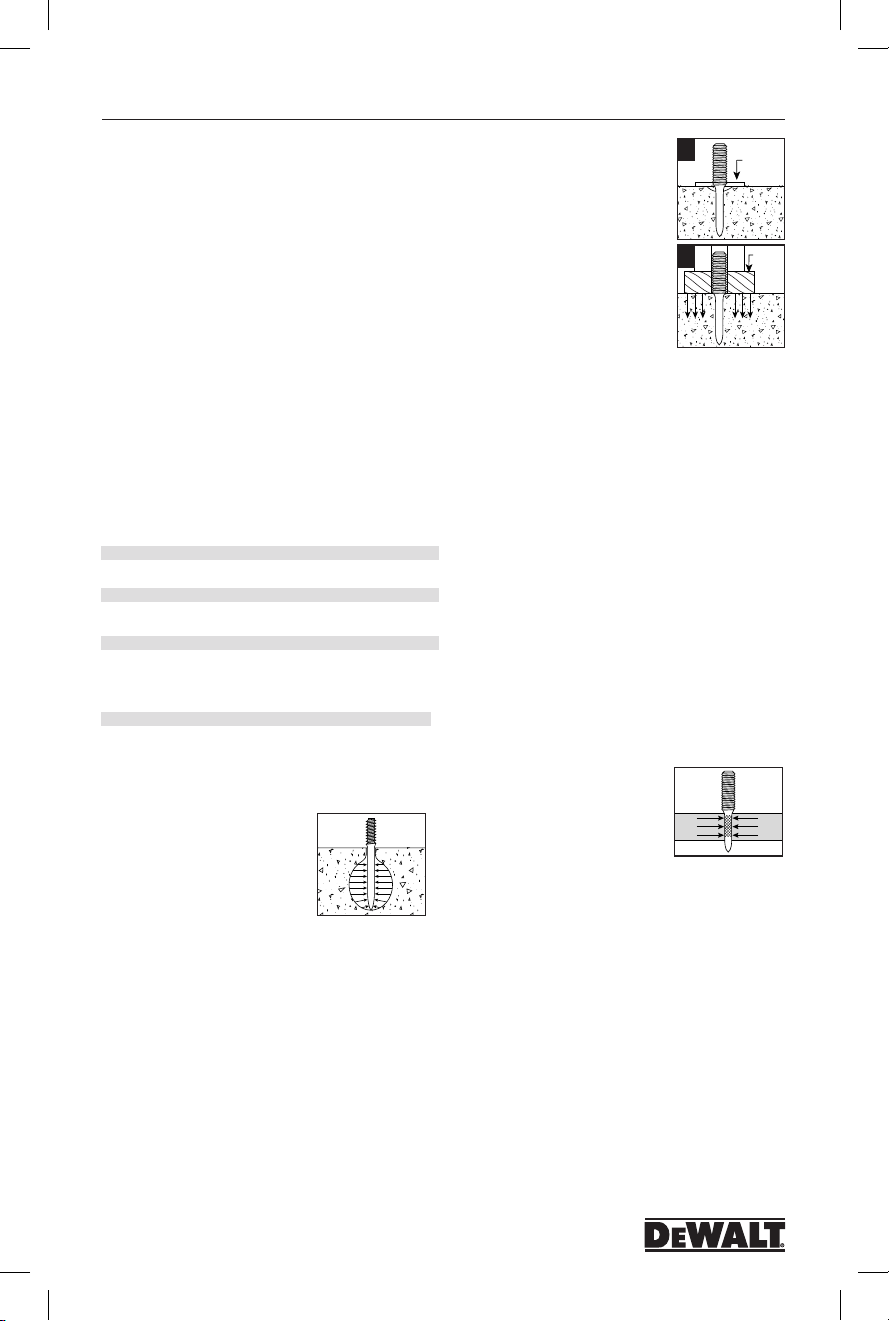

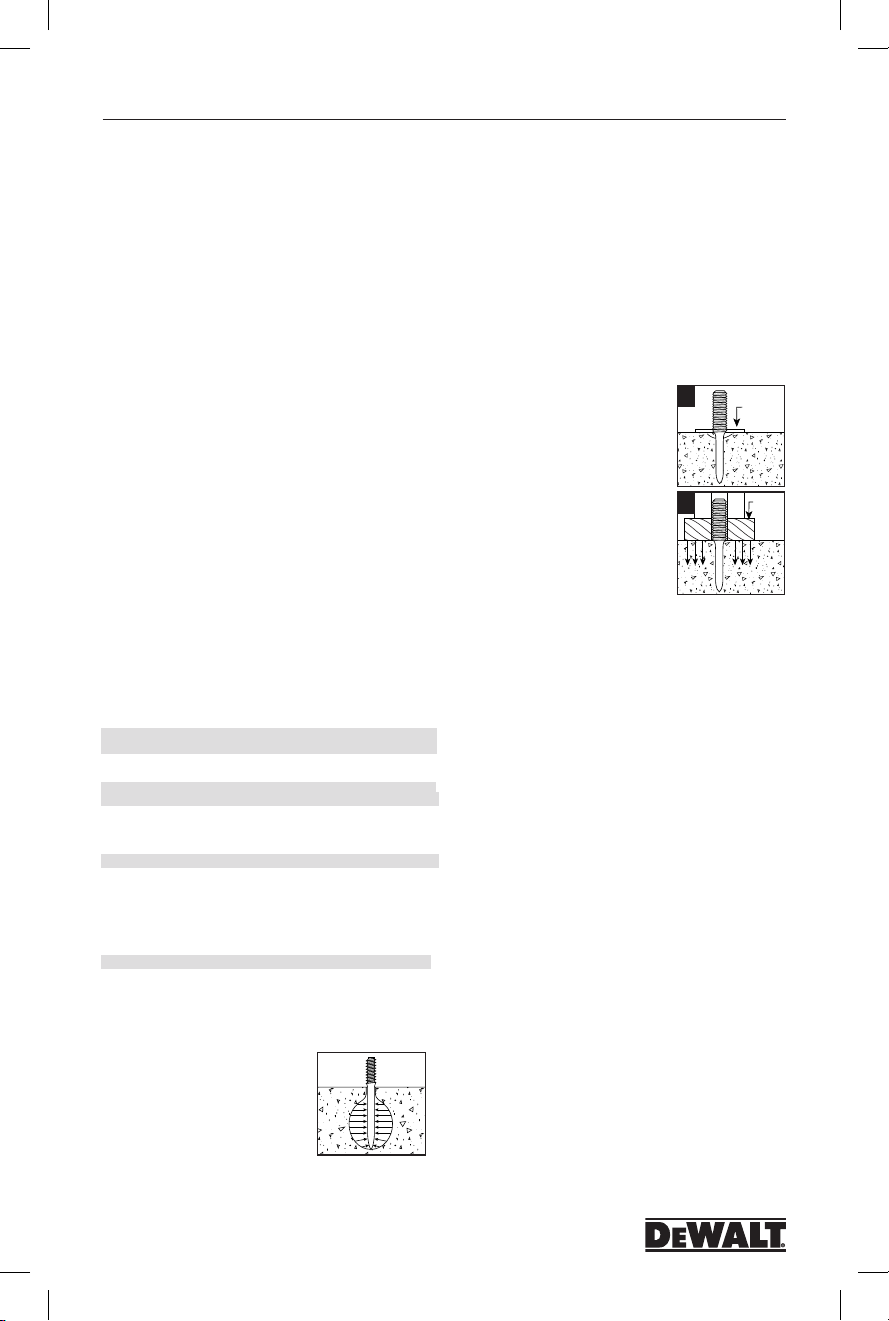

Functioning In Concrete

The performance of a powder actuated fastener when

installed into concrete or masonry base materials is based on

the following factors:

1. Strength of the base material

2. Hardness and concentration of the aggregate

3. Shank diameter of the fastener

4. Depth of embedment into the base material

5. Fastener spacing and edge distance

In addition to these factors, installation

tool accessories such as a stop

1

spall which reduces the tendency of

the concrete surface to spall during

the driving action can increase the

performance of the fastener.

When a powder actuated fastener

is driven into concrete, it displaces the

2

volume of concrete around the embedded

area of the fastener shank. As this

occurs, the concrete directly surrounding

the fastener is compressed and in turn

presses back against the shank of the

fastener. Additionally, the driving action

generates heat which causes particles within the concrete

to fuse to the shank of the fastener. This combination of

compression and fusion holds the fastener in the concrete

base material. A similar action occurs when fastening into

block masonry.

Generally, the performance of the fastener in a given

concrete strength will increase with greater embedment

depths in a certain range. Depending on the fastener style

and base material strength, embedment depths range from

5/8” to 1-1/2”. For depths greater than this range, there is

the possibility of fastener bending or fishhooking which may

decrease expected load capacities and create a safety hazard.

During the driving action, some localized surface spalling

of the

concrete may occur. Normally, this is a surface effect which

does not effect the performance of the fastener. However,

it may pose an aesthetic problem for exposed applications

where a fixture is not used. In cases such as this, two

methods can be used to improve the appearance of the

fastening. A stop spall adapter mounted on the powder

actuated tool can help to reduce surface spalling. Another

method used is to drive the fastener through a steel washer

to improve the appearance of the application.

Functioning In Steel

The load performance of a powder

actuated fastener when installed into

steel base materials is based on the

following factors:

1. Thickness of the steel

2. Tensile strength of the steel

3. Shank diameter of the fastener

4. Depth of point penetration through the steel

5. Fastener spacing and edge distance.

When a powder actuated fastener is driven into steel, it

displaces the steel laterally 360˚ around the shank of the

fastener. Since steel is an elastic material, it presses back

against the shank of the fastener to hold it in place. As the

diameter of the fastener shank is increased, the load capacity

obtained will generally increase provided the steel thickness

is sufficient to accept the fastener. To further increase

fastener performance in steel, some fasteners have a knurled

shank which allows the steel to form a key lock into the

grooves to provide higher capacities than those obtained with

a smooth shank. For optimum performance, the fastener

point should completely penetrate the steel. Normally, a

minimum of 1/4” is allowed for the point length. An increase

in performance can be expected until the fastener no longer

completely penetrates through the steel. At this point, the

elastic properties of the steel cause a compression force to

be developed at an angle against the fastener point which

2

Washer

Stop

Spall

POW2273_manual_P2201_dewalt.indd 2 3/10/14 12:41 PM

Page 3

Model P2201 Cat. No. DDF211022P

P2201

reduces load capacity. In thicker steel base materials,

adequate load capacities may be obtained for applications in

which the point of the fastener does not fully penetrate the

steel. Job site performance tests are recommended.

Fasteners should not be used in areas that have been

welded or cut with a torch as these procedures may have

caused local hardening of the steel. Over driving of the fastener should be avoided as the rebound created may reduce

the load capacity or cause damage to the fastener. When

fastening into unsupported long steel members, it may be

necessary to provide support in the area of the fastening to

prevent spring action which can cause inconsistent penetration and a reduction in load capacity.

Suitable Base Material

While powder actuated fasteners can be used successfully in

concrete, certain masonry materials, and A 36 steel, some

materials are completely unsuitable. Fasteners should never

be fired into hard or brittle materials such as cast iron, tile,

glass, or rock. These materials can shatter easily resulting in

a potential safety hazard. In addition, soft base materials

such as wallboard, plaster, or wood are

Point

Flattens

1

not appropriate as the fastener could

pass completely through these

materials. The user should never guess

when fastening into any base material.

Failure to follow the recommended

No

Indent

Surface

Shatters

2

installation and safety guidelines can

result in severe injury or death to the

tool operator and/or bystanders.

Center Punch Test

A center punch test should always be

performed to determine the suitability

of the base material for a powder

actuated fastening. This test is relatively

Material

Cracks

simple and can help to insure a safe,

successful fastening. Be sure to wear

the appropriate eye protection when

3

performing this test. To begin, select

the fastener to be used for the job.

Then, place the point of the fastener

Fastener Sinks in

with Average

Hammer Blow

against the proposed base material.

Strike the fastener with a single

hammer blow, then examine the point.

If the point of the fastener is not blunted and the base

material has a clear point indentation, it is acceptable to

proceed with the first test installation.

Use of a powder actuated system is not recommended if

the following occurs during the center punch test:

1. The fastener point has been blunted. This indicates that the

base material is too hard.

2. The base material cracks or shatters. This indicates that

the base material is too brittle.

3. When using an average hammer blow, the fastener

penetrates the base material easily. This indicates that the

base material is too soft.

Fastener Installation Requirements

It is important to understand the required minimum base

material thickness requirements along with the minimum

spacing and edge distance requirements. Failure to follow

these requirements can result in an unsuccessful fastening

and create a safety hazard.

Base Material Thickness

Concrete base material should be at

least three (3) times as thick as the

fastener embedment penetration. If the

Penetration

concrete is too thin, the compressive

forces forming at the fasteners point can

cause the free face of the concrete to

break away. This can create a dangerous

condition from flying concrete and/

or the fastener and also results in a reduction of fastener

holding power. For applications in the face shell of concrete

masonry block, select a fastener length which will not

exceed the thickness of the face shell.

Fastener Penetration Guide

The following table lists typical embedment or penetration

depths expected in the base materials listed. The

penetration will vary depending on the density of the

material. This table should be used as a guide since the

consistency of these materials varies. When in doubt, a job

site performance test should be conducted.

DENSITY TYPICAL BASE MATERIAL PENETRATION

Soft Masonry Concrete block 1” -1-1/4”

Average Concrete Poured concrete 3/4” - 1”

Dense Concrete Pre-stressed/ 5/8” - 3/4”

pre-cast concrete

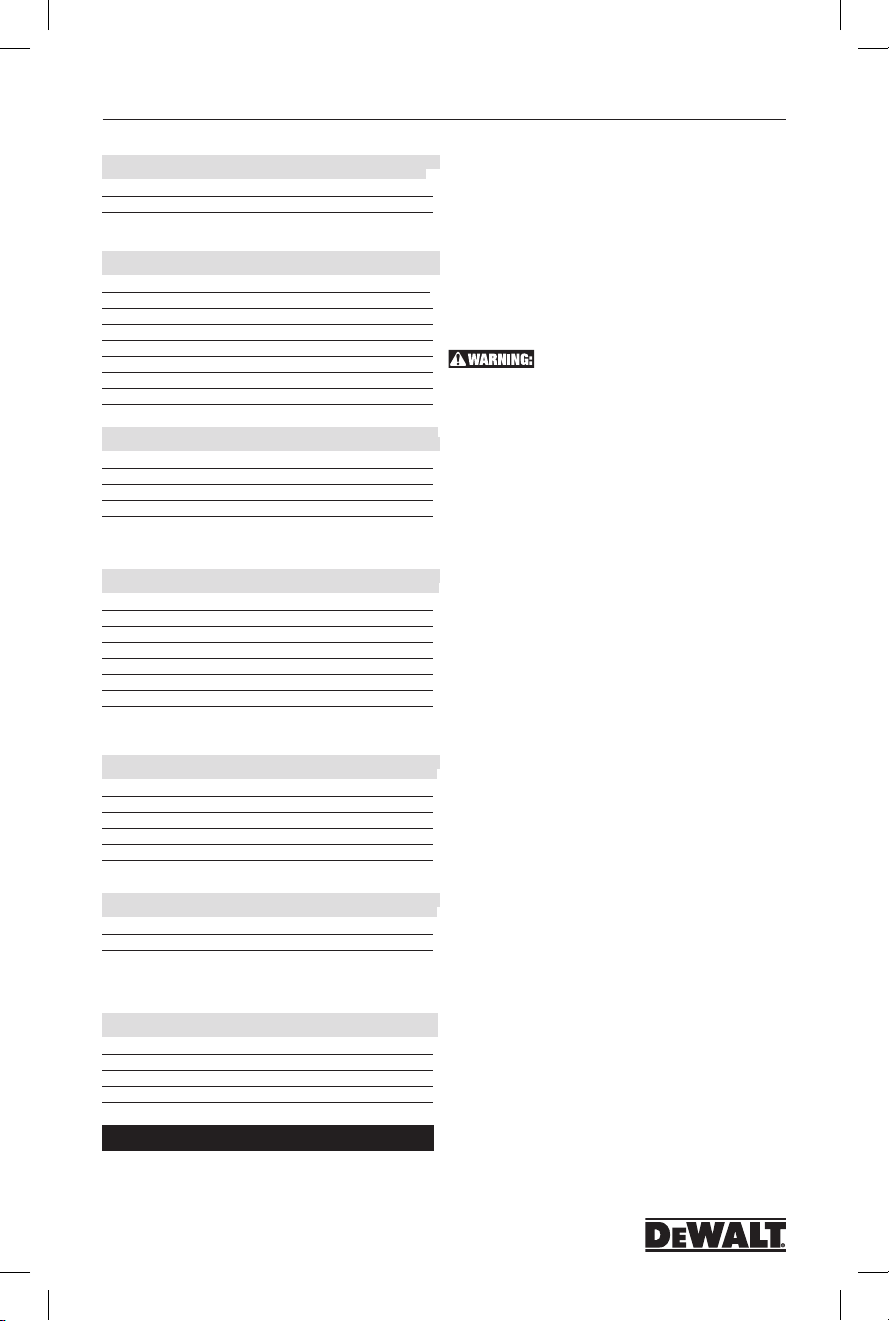

Edge Distance

Do not fasten closer than 3” from

the edge of concrete. If the concrete

cracks, the fastener may not hold.

Closer edge distances for applications

such as sill plates may be permitted

if specific fastener testing has been

conducted.

Spacing

Setting fasteners too close together

in concrete or masonry can cause

cracking. The recommended minimum

distance between fasteners is 3” center to center.

Fastener Length Selection In Concrete

For permanent applications using pins in concrete, first

determine the thickness of the fixture to be fastened. To this,

add the required embedment or penetration into the base

material. This will be the fastener shank length required.

For applications in the face shell of masonry block, select a

fastener length which will not exceed the thickness of the

face shell.

For removable applications with threaded studs, the

shank length required is equal to the embedment depth

required. To determine the minimum threaded length, add

the thickness of the fixture and the nut / washer thickness.

The nut and washer thickness is equal to the nominal thread

diameter. Do not over tighten threaded

parts. Maximum tightening torque

values are listed in the table below.

Use of a nut setter is recommended to

reduce the possibility of over tightening

the fasteners. For critical applications,

perform a job site test.

MAXIMUM TORQUE FOR 1/4” STUD MAXIMUM TORQUE FOR 3/8” STUD

(FT.-LBS.) (FT.-LBS)

2 4

Penetration

3"

3"

3x

Fixture

Embedment

3

POW2273_manual_P2201_dewalt.indd 3 3/10/14 12:41 PM

Page 4

P2201

Model P2201 Cat. No. DDF211022P

Installation In Steel

The following guidelines are based on the installation of a

fastener in ASTM A 36 structural steel with the point fully

penetrating the steel member. Recommended steel material

thickness ranges from a minimum of 1/8” to a maximum of

3/8”. For use in higher strength structural steel, applications

where the point does not penetrate the steel member, or a

thickness of steel greater than 3/8”, job site performance

tests are recommended.

Base Material Thickness

Steel base materials should be a

minimum of 1/8” in thickness.

Edge Distance

For installations in A 36 steel, 1/2”

is the recommended minimum edge

1/2"

distance.

Spacing

The recommended minimum distance

1-1/2"

Fastener Selection Guide

.300 Head Diameter Drive Pins

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3011000

1/2” K 100 5000 .300 .143 .5

DDF3011050

5/8” K 100 5000 .300 .143 .5

DDF3001100

3/4” 100 5000 .300 .143 .5

DDF3001150

1” 100 5000 .300 .143 .6

DDF3001200

1-1/8” 100 1000 .300 .143 .7

DDF3001250

1-1/4” 100 1000 .300 .143 .8

DDF3001300

1/8"

1-1/2” 100 1000 .300 .143 .9

DDF3001350

1-3/4” 100 1000 .300 .143 1.1

DDF3001400

2” 100 1000 .300 .143 1.2

DDF3001450

2-1/4” 100 1000 .300 .143 1.2

DDF3001500

2-3/8” 100 1000 .300 .143 1.3

DDF3001550

2-1/2” 100 1000 .300 .143 1.4

DDF3001600

2-3/4” 100 1000 .300 .143 1.6

DDF3001650

3” 100 1000 .300 .143 1.9

between fastenings is 1-1/2” center

to center for installations in ASTM A

36 steel.

Fastener Length Selection In Steel

For permanent applications when using pins in steel, first

determine the thickness of the fixture to be fastened. To this,

add the thickness of the steel base material plus a minimum

of 1/4” to allow for proper point penetration. This will be the

minimum fastener shank length required. Do not select a

fastener length longer than that required for the application.

An excessively long shank can burnish or polish the hole

created in the steel resulting in a reduction in load capacity.

For removable applications with threaded studs, the

shank length required is equal to the thickness of the steel

base material plus a minimum of 1/4” to allow for proper

point penetration. This will be the minimum fastener shank

length required. Do not select a shank length longer than

that required for the application. An excessively long shank

can burnish or polish the hole created in the steel resulting

in a reduction in load capacity. To determine the minimum

threaded length, add the thickness of the fixture and the nut

/ washer thickness. The nut and washer thickness is equal to

the nominal thread diameter.

Do not over tighten threaded studs, the maximum

tightening torque is listed in the table below. Use of a nut

setter is recommended to reduce the possibility of over

tightening the fasteners. For critical applications, perform a

job site test.

.300 Head Diameter Drive Pins with Top Hat

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3031000

1/2” K 100 5000 .300 .143 .5

DDF3031050

5/8” K 100 5000 .300 .143 .5

DDF3031100

3/4” 100 5000 .300 .143 .5

DDF3031150

1” 100 5000 .300 .143 .6

.300 Head Diameter Step Shank Pins

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3041000

3/4” Step Shank 100 1000 .300 .143/130 .5

DDF3041050

1” Step Shank 100 1000 .300 .143/130 .6

.300 Head Diameter Drive Pins - Master Pack

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF301100M

1/2” K 1000 5000 .300 .143 .5

DDF301105M

5/8” K 1000 5000 .300 .143 .5

DDF300110M

3/4” 1000 5000 .300 .143 .5

DDF300115M

1” 1000 5000 .300 .143 .6

DDF300125M

1-1/4” 1000 5000 .300 .143 .8

DDF303100M

1/2” K TH 1000 5000 .300 .143 .5

DDF303105M

5/8” K TH 1000 5000 .300 .143 .5

DDF303110M

3/4” TH 1000 5000 .300 .143 .5

DDF303115M

1” TH 1000 5000 .300 .143 .6

.300 Head Diameter Drive Pins with 3/4” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3051100

3/4” 100 1000 .300 .143 1.6

DDF3051200

2-1/2” 100 1000 .300 .143 2.5

.300 Head Diameter Drive Pins with 7/8” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3061150

1” 100 1000 .300 .143 1.9

DDF3061250

1-1/4” 100 1000 .300 .143 2.0

DDF3061300

1-1/2” 100 1000 .300 .143 2.1

DDF3061400

2” 100 1000 .300 .143 2.4

DDF3061550

2-1/2” 100 1000 .300 .143 2.7

DDF3061650

3” 100 1000 .300 .143 3.0

.300 Head Diameter Drive Pins with 1” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3071000

1-1/4” 100 1000 .300 .143 2.2

DDF3071050

1-1/2” 100 1000 .300 .143 2.3

DDF3071250

2” 100 1000 .300 .143 2.6

DDF3071150

2-1/2” 100 1000 .300 .143 2.9

DDF3071200

3” 100 1000 .300 .143 3.2

4

POW2273_manual_P2201_dewalt.indd 4 3/10/14 12:41 PM

Page 5

Model P2201 Cat. No. DDF211022P

P2201

.300 Head Diameter Drive Pins with 1-7/8” Insulation Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

DDF3081000

1-1/2” 100 1000 .300 .143 2.1

DDF3081050

2-1/2” 50 500 .300 .143 2.7

1/4”-20 Threaded Studs

CAT. THREAD SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH LENGTH BOX CTN. DIA. DIA. 100

DDF3811020

1/2” 1/2”K 100 5000 1/4” .143 .8

DDF3811000

3/4” 1/2”K 100 1000 1/4” .143 1.1

DDF3811050

3/4” 3/4” 100 1000 1/4” .143 1.2

DDF3811100

1/2” 1” 100 1000 1/4” .143 1.2

DDF3811150

3/4” 1” 100 1000 1/4” .143 1.4

DDF3811180

1/2” 1-1/4” 100 1000 1/4” .143 1.4

DDF3811200

3/4” 1-1/4” 100 1000 1/4” .143 1.5

DDF3811250

1-1/4” 1-1/4” 100 1000 1/4” .143 1.7

.300 Head Diameter Pins with Ceiling Clips

CAT. SHANK STD. STD. HEAD SHANK WIRE WT./

NO. LENGTH BOX CTN. DIA. DIA. HOLE 100

DDF4111050

1” 100 1000 .300 .143 0.278” 3.5

DDF4151000

1” 100 1000 .300 .143 0.278” 3.0

DDF4111100

1-1/4” 100 1000 .300 .143 0.278” 3.7

DDF4111150

1-1/4” 100 1000 .300 .143 0.278” 3.2

.300 Head Diameter Drive Pins with

BX Cable Straps and Conduit Clips

CAT. STD. STD. HEAD SHANK WT./

NO. SHANK LENGTH BOX CTN. DIA. DIA. 100

DDF4111150

1” 100 1000 .300 .143 3.5

DDF4131050

1-1/4” 100 1000 .300 .143 3.7

DDF4121000

1/2” EMT 1” pin 100 1000 .300 .143 3.3

DDF4121050 3/4” EMT 1-1/4”pin

DDF4121100

DDF4121150

DDF4121200 1” EMT 1” pin TH

K=Knurled TH=Top Hat

.300 Head Diameter Pins with Rebar Basket Clip

CAT. STD. STD. HEAD SHANK WT./

NO. DESCRIPTION BOX CTN. DIA. DIA. 100

DDF4251000

DDF4251050

DDF4251150

DDF4252000

DDF4252500

Forming Pins

CAT. STD. STD. HEAD SHANK WT./

NO. DESCRIPTION BOX CTN. DIA. DIA. 100

DDF3951050

DDF3951000

3/4” EMT 1” pin TH

3/4” EMT 1” pin 100 1000 .300 .143 3.3

32mm w/ basket clip 100 100 8mm .143 4.0

37mm w/ basket clip 100 100 8mm .143 4.1

37mm w/ basket clip 100 100 8mm .143 4.4

37mm w/ basket clip 100 100 8mm .143 4.6

37mm w/ basket clip 100 100 8mm .143 4.8

62mm - 2-1/2” 100 1000 .205 .143 1.4

44mm - 1-5/8” 100 1000 .205 .143 1.2

Powder Load Selection Guide

CAT. POWER LOAD STD. STD. MASTER WT./

NO. LEVEL COLOR SIZE BOX CTN. CTN. 100

DDF1111100

1 Grey .22A 100 1000 20000 .33

DDF1111200

2 Brown .22A 100 1000 20000 .33

DDF1111300

3 Green .22A 100 1000 20000 .33

DDF1111400

4 Yellow .22A 100 1000 20000 .33

100 1000 .300 .143 3.5

100 500 .300 .143 3.4

25 250 .300 143 3.2

FETY INSTRUCTIONS

SAFETY INSTRUCTIONS

Safety is your primary responsibility when operating

any powder actuated tool. You must read and understand

the contents of this manual. You must be familiar with all

functional and safety requirements of the tool. It is your

responsibility to obtain proper training and a D

EWALT operator

card prior to using this tool in compliance with the current

American National Standard A10.3 Safety Requirements

for Powder Actuated Fastening Systems and the Federal

Occupational Safety and Health Administration Standards

(OSHA). Existing state or local regulations should also be

followed. When using this tool, you must have the qualified

operators card in your possession.

Revocation of card - Failure to comply with any of the rules and

regulations for safe operation of powder actuated tools shall be

cause for the immediate revocation of your qualified operator card.

Failure to following safety instructions

can result in serious injury or death to operators or

bystanders.

Prior to Operating the Tool

1. Warning signs should always be posted within the area in

which a powder actuated tool is to be used. These signs

should be at least 8” x 10” in size with boldface type that

is not less than 1” in height. The sign should state

“Powder Actuated Tool In Use”.

2. Approved eye protection should always be worn by operator or bystander, to protect their eyes from flying particles.

Hearing protection should always be worn by the operator

and bystanders when using a powder actuated tool. Other

personal safety protection as required should also be used.

3. Never modify or fabricate parts for use in your D

tool. Use only D

EWALT fasteners, loads, and tool parts.

4. Hands or other body parts must never be placed in front

of muzzle/barrel. Accidental discharge can cause piston

and/or fastener to pass through the operator’s hand.

5. Never compress the tool against any part of the body.

Serious injury or death may result in the event of an

accidental discharge.

6. Always point tool in a safe direction at all times.

Intended Purpose

7. Keep all other people, especially children, away from the

work area.

8. Use only in a well-lit, well-ventilated work area.

Preparation for Loading the Tool

1. Tools must be checked prior to operating to make sure

they are not fully or partially loaded with a powder load or

fastener.

2. To insure safe operation, perform the daily function test

described in this manual. Be sure the tool is not loaded

prior to performing this test.

3. Do not operate this tool unless all its parts are in place

and operating appropriately. Never attempt to use a

malfunctioning tool. Call 1-800-4-DEWALT for assistance.

4. Never guess about the suitability of a base material. If

you are uncertain about the suitability of a base material,

perform a center punch test.

5. Do not operate the tool until you learn and understand the

color code / numbering system used to identify the power

level of powder loads.

Operating the Tool

1. Only use fasteners and powder loads designed for this

tool as supplied by D

EWALT.

2. Do not use powder actuated tools in the presence of

flammable fumes or vapor or an explosive atmosphere.

3. Do not fire a tool without a fastener. The piston will

EWALT

5

POW2273_manual_P2201_dewalt.indd 5 3/10/14 12:41 PM

Page 6

P2201

Model P2201 Cat. No. DDF211022P

R2200

impact the work surface possibly causing serious injury to

the operator or bystanders along with damage to the tool.

4. Do not load the tool until you are ready to make a

fastening. Check the power load level before inserting it into

the tool chamber.

5. Fastener must be loaded prior to loading the powder load,

to prevent injury to operator or bystander in the event of

an accidental discharge.

6. Do not close tool against work surface. The tool should be

manually closed, with hand away from muzzle/barrel to

prevent accidental discharge.

7. Hold the tool perpendicular to the work surface at all

times. Use a spall guard (part # 52166) wherever possible.

This will limit the possibility of fastener ricochet which

could cause serious injury or death to the operator or

bystanders. To order optional spall guard at no charge call

1-800-4-DEWALT.

8. Always perform a test fastening with the lightest load level

designed for use in the tool. If the lightest load fails to set

the fastener, try the next highest load until the proper level

is attained. Failure to follow this procedure may cause the

fastener to be overpowered. If this occurs, the fastener

may fully penetrate the base material causing serious

injury or death to someone. Overpowering the fastener can

also damage the tool, creating a safety hazard to both the

operator or bystanders.

9. Do not fasten into cast iron, tile, glass, or other types of

brittle materials. These materials can shatter and create

sharp fragments which may cause injury.

10. Do not fire tool within 3” (three inches) of the edge of a

concrete base material or within 1/2” (one-half inch) of

the edge of a steel base material.

11. Do not attempt to install a fastener closer than 3” (three

inches) to another previously inserted fastener in concrete

or 1-1/2” (one and one-half inch) in steel.

12. Do not fasten into a concrete base material less than 3

times as thick as the fastener penetration or into a steel

base material thinner than 1/8”.

13. Never attempt to install a fastener in a cracked or spalled

area in concrete. Place fastener at least 3” (three inches)

away from a spalled area to prevent the possibility of the

fastener bending and striking an operator or bystander.

14. Do not attempt to install fasteners in areas that have been

welded or cut with a torch as these procedures may have

caused local hardening of the steel.

15. Do not fasten through a pre-drilled hole unless proper

guidance is provided.

16. If you decide not to make a fastening after the tool has

been loaded, you must always remove the powder load first

followed by the fastener.

17. Never attempt to override the safety features of this tool.

18. Stay Alert, watch what you are doing, and use common

sense. Do not use tool when you are tired or under the

influence of drugs or alcohol.

19.Maintain proper footing and balance. Do not over reach.

20. Check that no one is present directly behind or below the

work surface.

Handling the Tool And Powder Loads

1. Never leave a loaded tool unattended. Once the tool is

loaded, make the fastening immediately or unload the tool.

2. Always unload the tool before work breaks, changing parts,

cleaning or servicing, and when storing.

3. To prevent accidental discharge of loads, never carry the

powder loads in the same container as the fasteners or

other hard objects.

4. Always store the powder loads in the containers provided

or in an enclosure provided for them. Never intermix the

various power levels. Keep them segregated in clearly

identified containers.

5.

Powder loads should never be used in firearms. They are normally

more powerful that the cartridges supplied with the firearms.

6.

Powder actuated tools and powder loads should always be stored

under lock and key. Tools must be unloaded when not in use.

Tool Malfunction

1. In the event that a load fails to discharge after the trigger

is pulled, the tool must be kept depressed against the

work surface for a minimum of 30 (thirty) seconds in case

of a delayed load discharge. Then carefully remove the

entire load strip. and dispose of it in a can of water or

other nonflammable liquid. Never attempt to force or pry a

load out of a tool chamber.

2. Never discard unfired powder loads into a trash container.

3. Do not attempt to unload or disassemble a jammed,

stuck or broken tool as improper handling may cause

it to discharge and strike operator and/or bystander. A

jammed tool must be pointed in a safe direction at all

times. Tag the tool and lock it up. Call your D

representative for proper assistance.

Tool Operation

the safety precautions and training in this manual before

attempting to operate the tool. (Check to be sure the tool is

not loaded, the piston moves freely within the barrel, and no

foreign objects or fasteners are in the barrel.) Perform the

daily function test before using the tool.

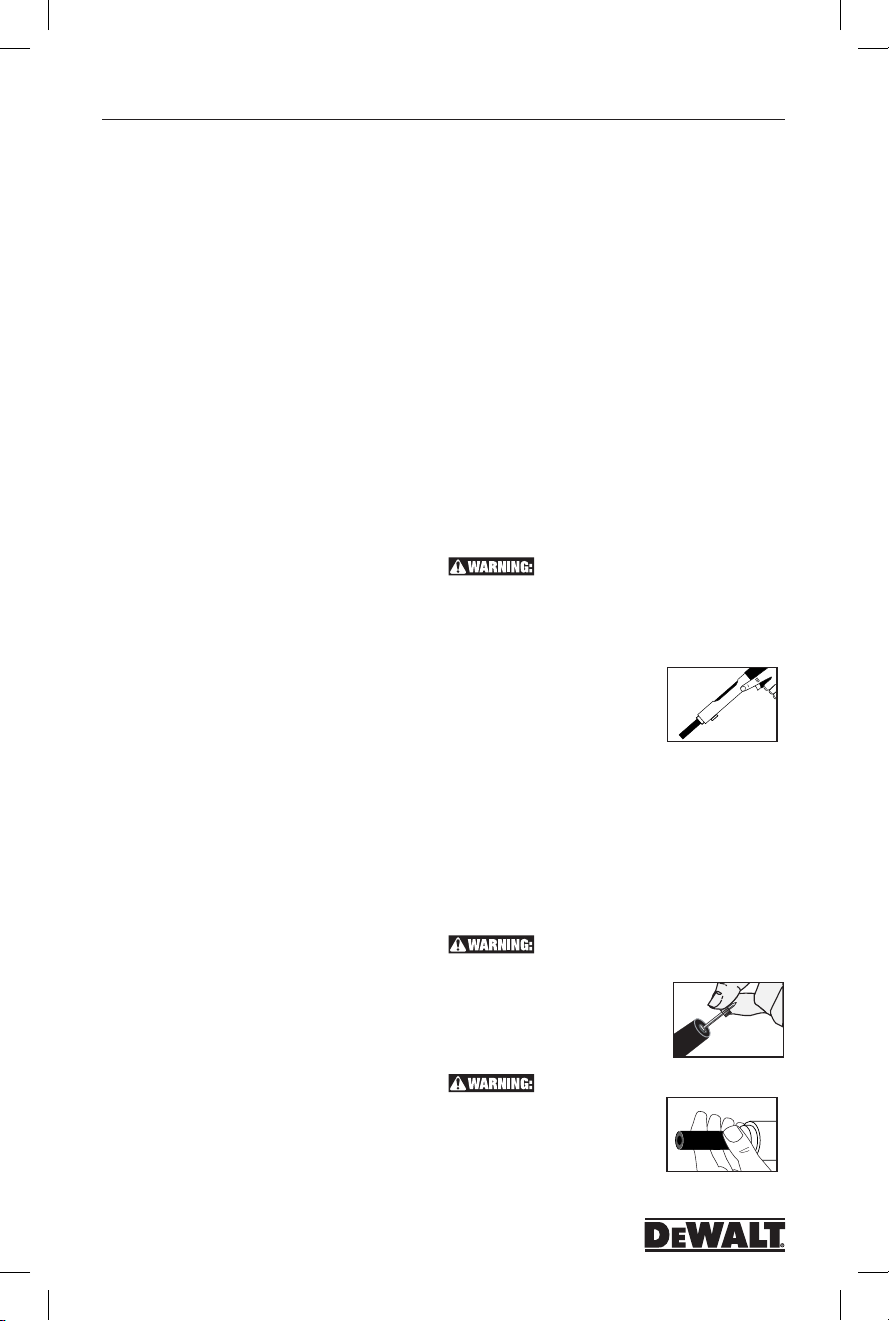

Operation

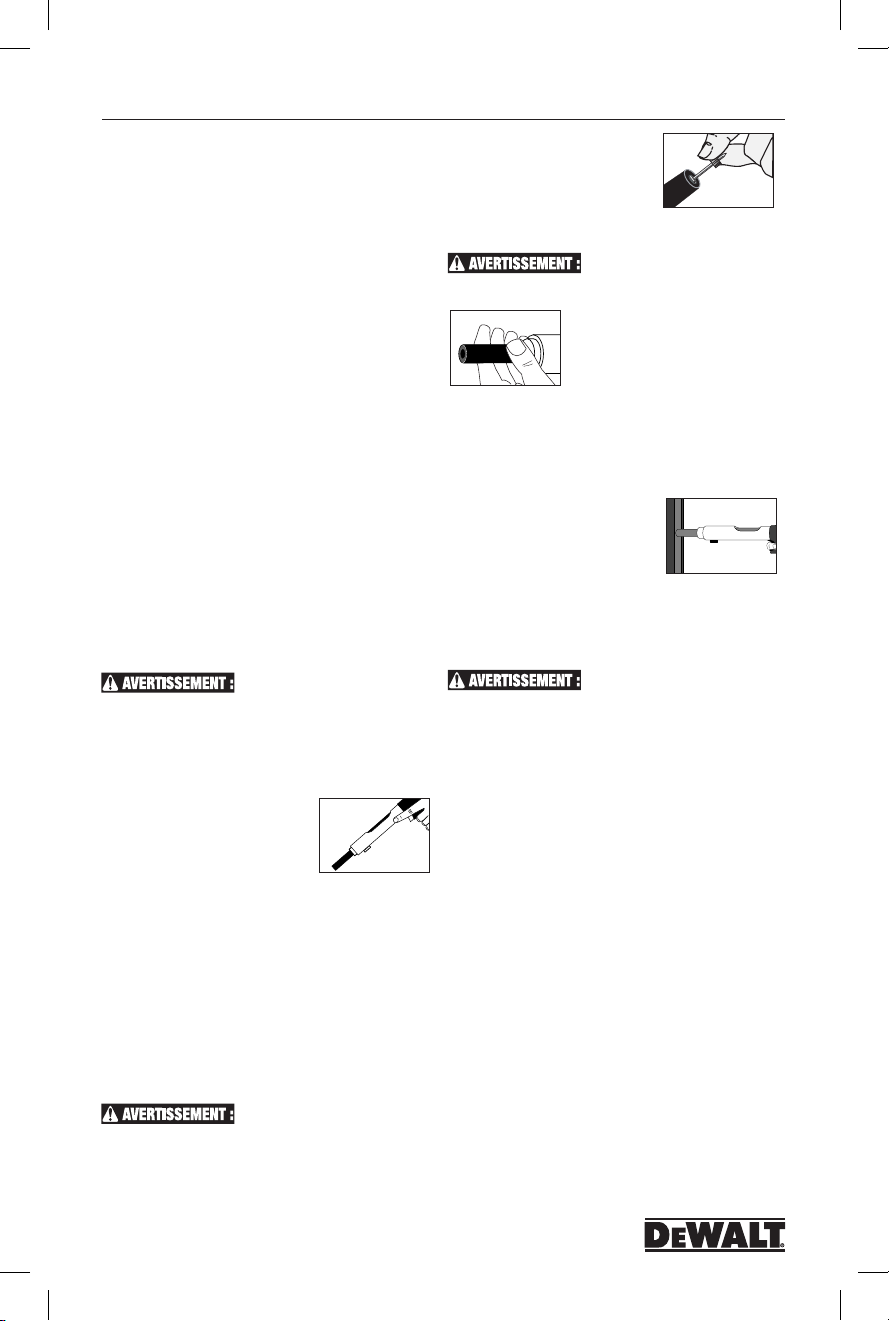

1. Always point the tool in a safe

direction away from bystanders

and the operator. Slide the barrel

forward. This can be done by

snapping your wrist. The barrel should be pulled fully

forward to reset the piston for the next fastening. Loss of

power may result from an im properly positioned piston.

2. Always load the fastener before inserting powder load to

prevent injury to the operator or bystanders in the event of

an accidental discharge. Place the fastener, point out, into

the end of the nose piece until the fluted tip fits inside.

Do not use excessive force when inserting the fastener. If

excessive force is required, stop and determine why the

fastener can not be inserted. Correct the problem before

proceeding.

listed in the fastener selection section of this manual.

3. Make sure the breech is clear. Insert

the powder load starting with the

lowest power level. If this Load does

not fully set the fastener, try the next

higher power level until the proper

level is found.

cause a safety hazard.

4. Pull the barrel all the way back to

close the tool. Do not attempt to

close the tool by exerting force on

the front of the nose piece. Never

place your fingers or hands over

muzzle bushing. The safe position for hands and fingers

Be sure to read and understand all of

Do not use fasteners longer than 3” as

Over driving or over powering a fastener can

6

EWALT

POW2273_manual_P2201_dewalt.indd 6 3/10/14 12:41 PM

Page 7

Model P2201 Cat. No. DDF211022P

P2201

are as shown in the diagram. Hands must never be

placed in front of the tool muzzle or nose piece. In the

event of an accidental discharge, the piston and/or

fastener can pass through the operators hand.

5. Once the tool is in the closed

position, place it against the work

surface. Hold the tool firmly with

two hands and completely depress

the barrel. Then squeeze the

trigger. Always hold the tool perpendicular to the work

surface. Hold the tool firmly against the work surface to

avoid excessive recoil. Never depress the tool against

anything except the work surface.

In the event that the load does not discharge

after the trigger is pulled, continue to hold the tool depressed

against the work surface for at least 30 (thirty) seconds in

case of a delayed load discharge. Then carefully remove the

entire load strip and dispose of it in a can of water or other

non flammable liquid. Never attempt to force or pry a load

out of a tool chamber. Do not discard unfired loads into a

trash container.

6. To prepare for the next fastening, point the tool in a safe

direction. Snap the barrel forward as described in step 1.

This action will eject the spent powder load and properly

reset the piston. Always insert a new fastener before

loading powder load in the chamber. Do not attempt to

unload or disassemble a jammed, stuck or broken tool

as improper handling may cause it to discharge and

strike operator and/or bystander. A jammed tool must be

pointed in a safe direction at all times. Tag the tool and

lock it up. Call your D

proper assistance.

EWALT Fasteners representative for

Maintenance & Cleaning

MAKE SURE THE TOOL IS NOT LOADED.

BE SURE THE TOOL IS NOT HOT PRIOR TO ATTEMPTING

DISASSEMBLY OR CLEANING.

Daily Function Test

Check the functioning of the tool, without a powder load

or fastener in the tool, by pushing down against the work

surface, pulling the trigger, and releasing the tool from the

work surface. Function the unloaded tool several times and

insure that the breech parts and firing mechanism operate

freely before fastening with the tool.

Your D

EWALT Authorized representative should be asked

to assist the first time you disassemble and clean your tool.

If you ever have any trouble reassembling the tool, or have

any doubt about worn parts, call your D

Powder Distributor.

Cleaning

AIl parts should be cleaned with detergent oil and the wire

brushes supplied with your tool kit. Remove heavy dirt buildup with the brush. After cleaning with oil, all parts should be

wiped thoroughly dry. Excess oil will tend to collect dirt and

dust. Wear eye protection when cleaning the tool. The piston

rod, barrel assembly, and receiver should all be cleaned of

excess dirt on a daily basis. Check the condition of the piston

for damage from wear and deformation.

To maintain this tool in good working condition, it is

necessary to disas semble and clean the entire tool if dirt

EWALT Authorized

is evident in the breech face, or if the tool appears to lose

power. All parts should be cleaned with oil and wire brushes.

Remove heavy dirt. All parts should be wiped thoroughly dry

after cleaning with oil.

General tool mainte nance should be performed at six

month intervals or more frequently as required by the

frequency of tool use.

Replacing or Repairing the Piston

The piston is an expendable part and must be replaced

periodically. Typical signs of a worn out piston are: breaking,

bending or mushrooming. Prior to

servicing the tool make sure there is no

powder load in the tool. Use caution and

do not lose or damage any tool parts.

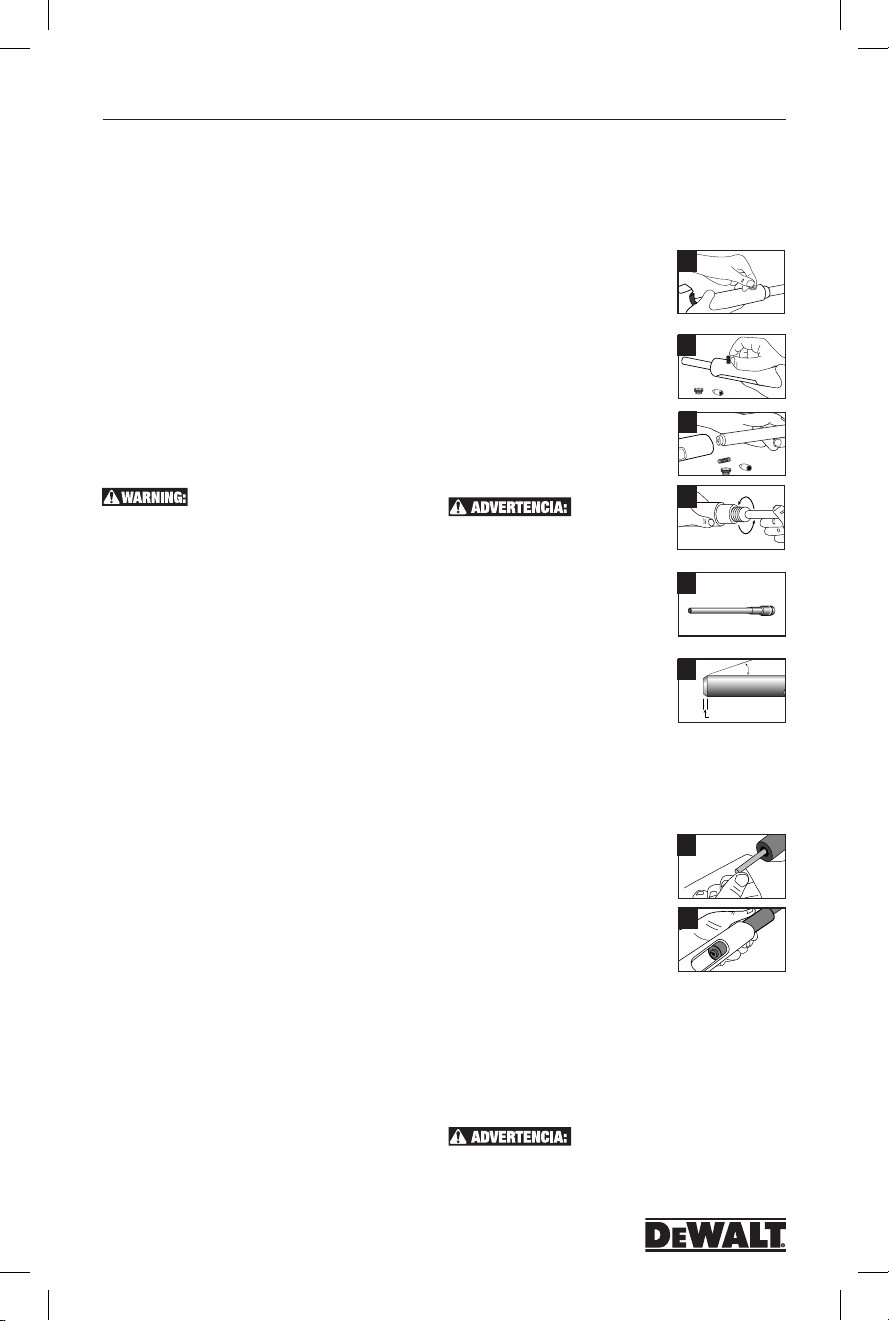

1. Loosen the cap on the reset pin by

turning it counter clockwise. Remove the

reset pin cap.

2. Hold the barrel in place, then remove

the reset pin spring and reset pin.

3. Slide the barrel from the receiver by

pulling it forward. If excessive dirt is built

up inside the receiver, clean it with a wire

brush.

4. Unthread the nose piece from the

barrel by turning it counter clockwise.

Pull the piston forward out of the barrel.

If a vise clamp is used

to hold the barrel, protect the bar rel from

damage.

5. Clean the piston using a wire brush.

Inspect it for worn or damaged piston ring,

chipped end, or bending. Apply lubricant to

the piston shank to minimize piston sticking

from an overdrive con dition. Wipe the piston

dry.

6. If a piston tip is damaged, it can be

shortened a maximum of 0.20 inches.

The tip of the piston should be grooved

flat and at 90 degrees to the shank of

the piston. The cham fer of the piston

must also be reground as shown. Piston

grinding should be performed by qualified per sonnel using

the proper equipment.

Reassembly:

7. Press the piston into the barrel.

Thread the nose piece into the barrel

and tighten it clockwise until finger tight.

Be sure the nose piece is fully seated.

8. Align the slot in the barrel with the

reset pin opening in the bottom of

the receiver. Insert the barrel into the

receiver. Insert the reset pin, and reset

pin spring. Tighten the reset pin cap

clockwise until it is finger tight and fully seated.

Upon reassembly of the tool perform the following test.

Depress the tool against a flat, hard surface and pull the

trigger. The barrel assembly should slide smoothly inside the

tool receiver. The firing pin should release after the trigger has

been pulled.

1

2

3

4

5

6

7

8

THIS TEST SHOULD BE PERFORMED

WITHOUT A PIN OR POWDER LOAD IN THE TOOL.

10°

0.120"

7

POW2273_manual_P2201_dewalt.indd 7 3/10/14 12:41 PM

Page 8

P2201

Model P2201 Cat. No. DDF211022P

#

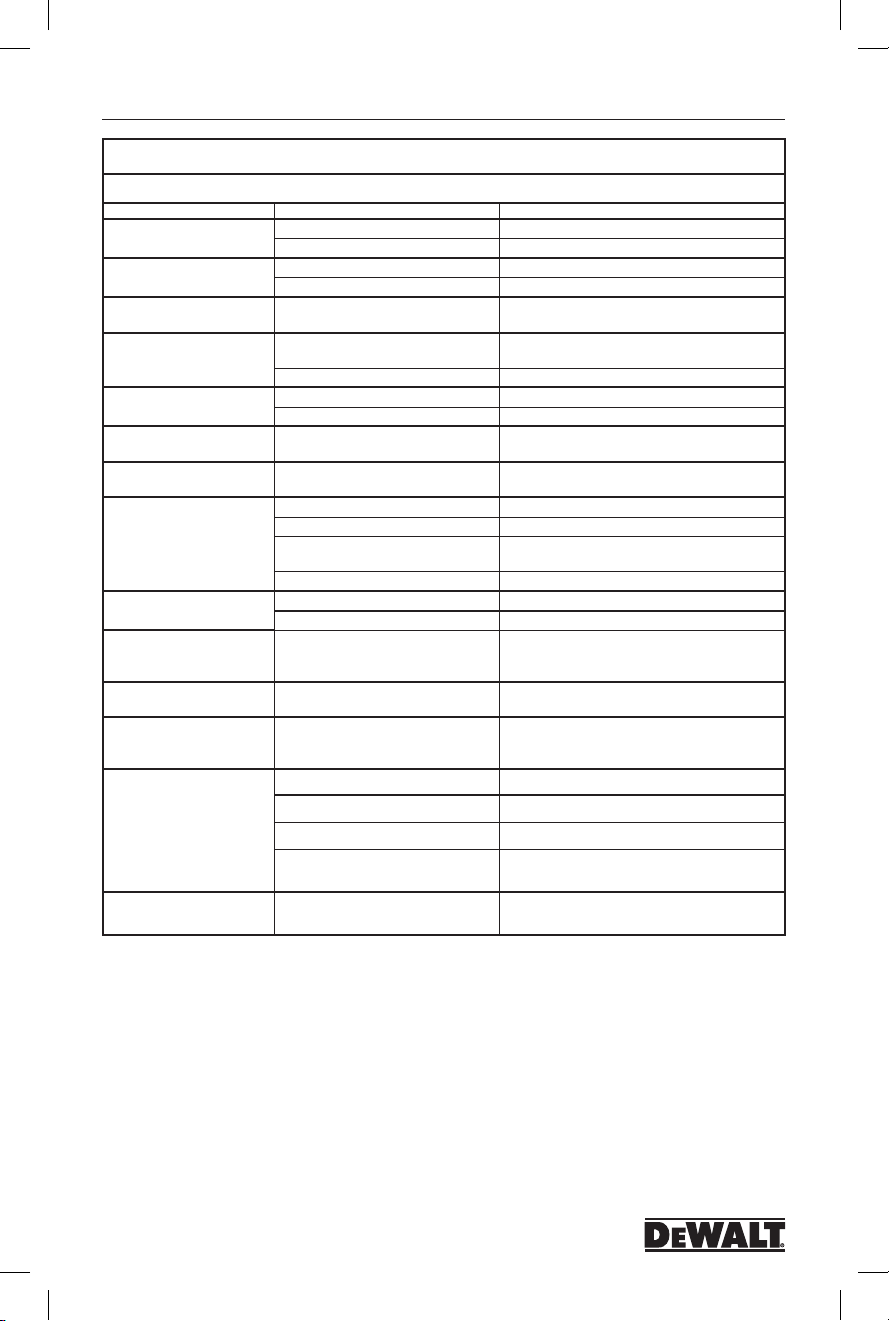

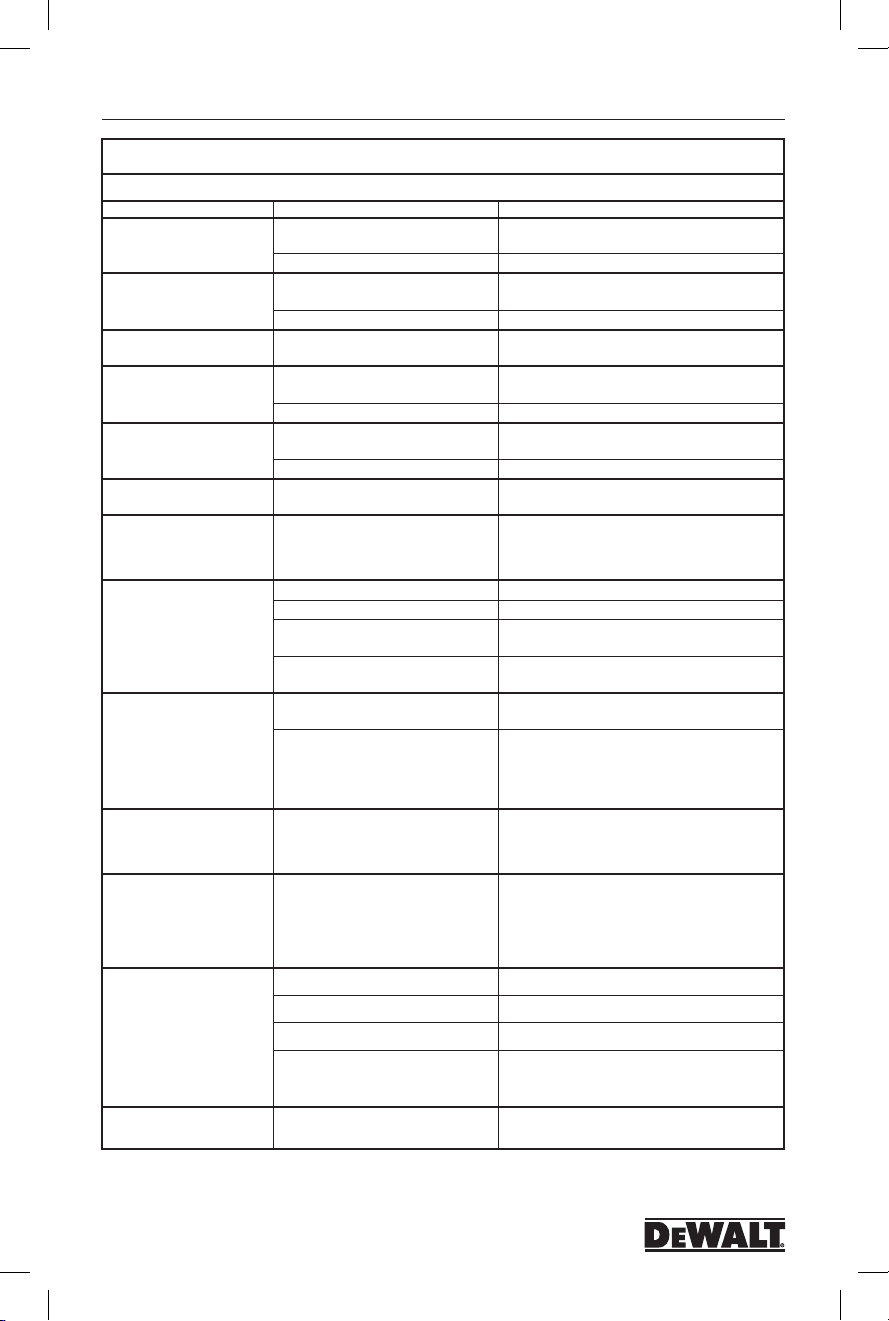

Troubleshooting

ALWAYS CHECK INSTRUCTION MANUAL FOR PROPER ASSEMBLY OF PARTS

PROBLEM POSSIBLE CAUSE SOLUTION

Fastener Overdriving Power level too high / Pin too short Use a lower powder load level number or a longer pin

Tool does not fire Tool not depressed completely See “Tool does not depress completely” section below

Tool does not depress completely Damaged firing pin parts, ejector, etc. Parts

Power reduction or inconsistent

fastener penetra tion

Load strip cannot be

inserted into tool

Load strip will not advance Worn advance lever guide Replace advance lever guide. This should be performed

Load will not fire when

trigger is pulled

Load will not fire when tool is fully

depressed and trigger is pulled

Tool cannot be opened

or cycled

Piston stuck in the forward

position

Chipped or damaged piston Tool not held on work surface squarely.

Piston guide will not open easily Bent shear clip Remove and replace shear clip

Piston guide opens too easily Annular ball spring or steel annular ball

Soft base material Check base material suitability section

Firing pin damaged Replace damaged part(s)

assembled improperly

Barrel is not pulled fully forward when

cycling tool.

Worn or damaged piston Replace piston or piston ring

Improper loading Insert strip from the bottom of the tool handle

Wrong caliber strip Use proper strip

Tool is not fully depressed Follow safety procedure for misfired load then attempt to

Load is already fired Cycle tool

Load misfire Follow safety procedure

Broken firing pin Replace firing pin nut. This should be performed by

Broken or missing Replace firing pin nut. This firing pin nut should be

Lack of proper cleaning Clean tool thoroughly

Damaged or bent piston Remove and replace piston

Broken or damaged parts Tag tool with warning “Defective - Do Not Use” place in

Piston has been overdriven and is jammed

against piston reset pin

This allows the piston to slip off the head of

the pin and cause damage to the piston

Excessive build-up of dirt Disassemble and clean tool

Piston stop is damaged Replace piston stop

Foreign material jammed between the

piston guide and steel liner assembly

have worn

Check the parts for damage or improper assembly

Barrel must be pulled out completely to properly reset

the piston

by qualified individuals

fully depress tool before pulling trigger

qualified individuals

locked container and contact your D

representative for service

Tap the piston against a hard surface

Machine piston as shown on page 11. Piston regrinding

may be performed only by

qualified individuals

Disassemble and remove foreign particles

Remove and replace with a new spring and/or ball

EWALT Authorized

8

POW2273_manual_P2201_dewalt.indd 8 3/10/14 12:41 PM

Page 9

Model P2201 Cat. No. DDF211022P

P2201

COMPANY NAME

COMPANY PHONE

QUALIFIED TOOL OPERATOR EXAMINATION

#

OPERATOR’S NAME

HOME ADDRESS

AGE DATE OF BIRTH

3

☐

Check the correct answer

1 It is necessary to read the Operator’s Manual prior

to operating a D

☐

2 When fastening into concrete, the base material

should be greater than the shank penetration by at

least:

3 When operating a powder actuated tool, your hand

should never be placed:

☐

☐

☐

4 To determine the suitability of a base material, use

the fastener as a center punch.

• Ifthefastenerisblunted,donotfasten;thematerial

is too:

☐

• Ifthefastenerpenetrateseasily,donotfasten;the

material is too:

☐

• Ifthematerialcracksorshatters,donotfasten;the

material is too:

☐

5 Unsafe applications for powder actuated tools may

be caused by which of the following?

☐

☐

☐

☐

☐

☐

☐

6 Which one of the following building materials is not

suitable as a receiving material (base material) for

powder actuated fasteners?

☐

☐

EWALT low velocity tool.

True ☐ False

☐

1 time ☐2 times ☐3 times

around the tool body

in front of the tool muzzle

over the tool handle

soft

☐

hard ☐brittle

soft ☐hard ☐brittle

soft ☐hard ☐brittle

a soft base material

improper powder load

fastening too close to an unsupported edge

a malfunctioning tool

fastening into a spalled area

fastening through a pre-existing hole

all of the above

sheet rock ☐ wood ☐fiberglass

sheet metal ☐all of the above

7 When considering the safety of a particular

application, the operator must think about:

☐

the base material

☐

the powder load power level

☐

the operator’s safety

☐

the safety of bystanders and fellow workers

☐

all of the above

8 The proper loading procedure is: insert fastener first,

powder load second. The fastener should always be

placed in the tool prior to the load.

☐

True ☐False

9 Which one of the following materials is usually

suitable for powder actuated fastenings?

☐

poured concrete ☐hollow tile

☐

surface hardened steel ☐glazed brick

10 In concrete, a fastener should be driven no closer to

an unsupported edge than:

☐

1/2” ☐1-1/2” ☐3”

11 Fishhooking is a condition which can occur when

a powder actuated fastener strikes a piece of hard

aggregate or very hard concrete, bends and comes

out of the work surface. A fishhook can cause a

serious injury or death.

☐

True ☐False

12 Placing a hand over the muzzle bushing of a

loaded tool can result in serious injury from piston

overdrive or an escaping fastener if the tool is

discharged accidentally.

☐

True ☐False

13 Piston overdrive is caused by overpowering of

the tool or by discharging the tool against a soft

surface.

☐

True ☐False

14 Malfunctioning tools cannot be used and must be

removed from service immediately.

☐

True ☐False

COMPANY ADDRESS

SIGNATURE DATE

15 After conducting a Center Punch Test,the best

way to check the base material is to set several

fasteners using the least powerful load.

☐

True ☐False False

16 Eye protection and hearing protection should not be

worn by the operator and any necessary bystanders

when using the tool.

☐

True ☐False

17 A powder actuated tool cannot be safely used in an

explosive or flammable atmosphere.

☐

True ☐False

18 List the proper powder load level number

(1-6) next to each color listed.

Red ___ Brown ___ Green ___

Yellow ___ Gray ___ Purple ___

19 The weakest power level should be used when

making the first fastening.

☐

True ☐False

20 You can fasten into welded areas of steel.

☐

True ☐False

P2201

• Theproperprocedureifapowderloadfailstoignite

is to hold the tool against the work surface and wait

30 seconds, then proceed exactly as directed in the

Operator’s Manual.

☐

True ☐False

• D

EWALT powder loads for the P2100 are .22

caliber, “A” tapered, neck down, rim fire, short

crimped cartridges. No other powder load may be

used in this tool.

• OperatorsshouldnevercompresstheP2201orany

other powder actuated tool against any part of their

body.

• IfapistonbufferfortheP2201becomesdeformed,

simply remove it, and use the tool without the

buffer?

☐

True ☐False

☐

True ☐False

☐

True ☐False

LICENSE AND WARRANTY ACTIVATION

THE P2201 TOOL IS WARRANTED FOR 3 YEARS FROM DATE OF PURCHASE ON MANUFACTURERS DEFECTS.

I certify that I have read and understand the P2201 Tool Operating Instruction Manual and have taken the Operator’s exam. I understand the

TRIM ALONG DOTTED LINE, PLACE IN ENVELOPE, ADDRESS AS SHOWN AND AFFIX POSTAGE

importance of following all safety procedures and that failure to read, comprehend, and follow the detailed rules and warnings regarding the

safe operation of powder actuated tools can result in serious injury or death to the tool operator or bystanders. I agree to conform to all the

rules and regulations regarding the use of powder actuated tools.

THE SERIAL NUMBER ON MY TOOL IS:

PLEASE SEND MY TOOL LICENSE TO:

NAME

ADDRESS

CITY STATE ZIP PHONE

(Please print clearly)

MAIL TO: Tool License Coordinator • D

EWALT, Inc.• 2 Powers Lane, Brewster, NY 10509

9

POW2273_manual_P2201_dewalt.indd 9 3/10/14 12:41 PM

Page 10

P2201

Modelo P2201 N.˚ de Cat. DDF211022P

R2200

P2201

MANUAL DE INSTRUCCIONES

PARA OPERAR LA HERRAMIENTA

Herramienta de sujeción

accionada por pólvora de

baja velocidad

DO NOT OPERATE THE P2201

TOOL UNTIL YOU HAVE READ THIS MANUAL AND RECEIVED THE

PROPER TRAINING ACCORDING TO ANSI STANDARD A 10.3-1995.

P3500, LEA ATENTAMENTE ESTE MANUAL Y ASEGÚRESE DE

ENTENDER COMPLETAMENTE EL CONTENIDO.

DEBE RECIBIR UNA CAPACITACIÓN ADECUADA SEGÚN LO INDICA

LA NORMA A 10.3 VIGENTE DE ANSI, RESPETAR LOS REQUISITOS

DE SEGURIDAD PARA LOS SISTEMAS DE SUJECIÓN ACCIONADOS

POR PÓLVORA Y OBTENER LA TARJETA DE OPERADOR CALIFICADO

DE DEWALT ANTES DE OPERAR LA HERRAMIENTA. TAMBIÉN DEBE

CUMPLIR CON LAS REGULACIONES ESTATALES, LOCALES, ENTRE

OTRAS. ES POSIBLE QUE LAS LEYES, REGULACIONES Y NORMAS

RESPECTO DEL USO DE LAS HERRAMIENTAS ACCIONADAS POR

PÓLVORA SE REVISEN PERIÓDICAMENTE. CUALQUIER REVISIÓN

PUEDE MODIFICAR LOS PROCEDIMIENTOS DE SEGURIDAD Y

OPERACIÓN DESCRITOS EN ESTE MANUAL. D

SE HACE RESPONSABLE DE NINGUNA REVISIÓN POSTERIOR A

LA PUBLICACIÓN DE ESTE MANUAL. ES RESPONSABILIDAD DEL

USUARIO MANTENERSE ACTUALIZADO RESPECTO DE LAS LEYES,

REGULACIONES Y NORMAS VIGENTES QUE SE APLIQUEN A LA

HERRAMIENTA ACCIONADA POR PÓLVORA.

PELIGRO:

E INCLUSO LA MUERTE: NUNCA CIERRE LA HERRAMIENTA

COLOCANDO ALGUNA PARTE DE LA MANO SOBRE EL EXTREMO

DE LA BOCA DEL CAÑÓN.

LOS OPERADORES Y DEMÁS PERSONAS QUE SE ENCUENTREN EN

EL LUGAR DEBEN UTILIZAR PROTECCIÓN OCULAR Y AUDITIVA.

SIEMPRE ASUMA QUE LA HERRAMIENTA ESTÁ CARGADA. NO

COLOQUE LOS DEDOS EN EL GATILLO DE LA HERRAMIENTA

CARGADA HASTA QUE EL EXTREMO DE LA BOCA DEL CAÑÓN

ESTÉ CONTRA LA SUPERFICIE DE TRABAJO Y USTED ESTÉ LISTO

PARA REALIZAR UNA SUJECIÓN. NUNCA COLOQUE LA MANO

SOBRE LA BOCA DEL CAÑÓN CON UNA CARGA DE PÓLVORA

EN LA HERRAMIENTA. SI LA HERRAMIENTA SE DISPARA

ACCIDENTALMENTE, EL PISTÓN O SUJETADOR PUEDE PENETRAR

EN LA MANO Y OCASIONAR LESIONES GRAVES.

OPERACIÓN DE LA HERRAMIENTA DEBE LEER Y COMPRENDER EL

MANUAL DE LA HERRAMIENTA Y DEBE COMPLETAR EXAMEN DEL

OPERADOR EN LA ÚLTIMA PÁGINA. LA HERRAMIENTA GARANTÍA

NO SERÁ VÁLIDA HASTA QUE SE RECIBA LA PRUEBA, CON UNA

COPIA DE SU RECIBO, Y REVISADO POR D

ANTES DE OPERAR LA HERRAMIENTA

EWALT, INC. NO

A FIN DE EVITAR LESIONES GRAVES

EWALT, INC.

R2200

Garantía

Tres años de garantía limitada

D

EWALT reparará, sin cargo, cualquier defecto ocasionado

por materiales defectuosos o mano de obra durante

tres años a partir de la fecha de compra. Esta garantía

no cubre fallas de las piezas causadas por su desgaste

normal o abuso a la herramienta. Para mayores detalles

sobre la cobertura de la garantía e información de

reparación en garantía, visite www.dewalt.com o llame al

1-800-4-DEWALT (1-800-433-9258). Esta garantía no

aplica a accesorios oa daños causados se han hecho o

intentado hacer reparaciones por otros. Esta garantía le

otorga derechos legales específicos cualquiera puede tener

otros derechos que varían de estado a estado.

Además de la garantía, las herramientas DEWALT están cubiertas por:

D

EWALT mantendrá la herramienta y reemplazará las

piezas gastadas por su uso normal, sin cobro, en cualquier

momento durante el primer año después de la compra.

Si usted no está completamente satisfecho con el desempeño

de su máquina herramienta accionadas por pólvora D

por cualquier motivo, puede devolverla dentro de los 90 días

a partir de la fecha de compra con su recibo y obtener el

reembolso completo - sin hacer preguntas.

ETIQUETAS DE ADVERTENCIA GRATUITO DE REEMPLAZO:

Si sus etiquetas de advertencia se vuelven ilegibles o se

pierden, llame al 1-800-4-DEWALT (1-800-433-9258) para

obtener un reemplazo gratis.

1 AÑO DE SERVICIO GRATUITO

90 DíAS GARANTíA DE REEMBOLSO

Introducción

Gracias por comprar la herramienta accionada DEWALT

P2201 polvo de baja velocidad de usted. Esta herramienta

le ofrecerá un excelente rendimiento siempre que se sigan

los pasos para la operación y el mantenimiento adecuado.

Sistemas de fijación accionadas por pólvora pueden

proporcionar un método rentable de adjuntar accesorios para

trabajo liviano, condiciones de carga estática. Los sistemas

proporcionados por D

de fijación especialmente diseñados, herramientas de

instalación, y cargas de pólvora que están diseñados para

funcionar en combinación para proporcionar un rendimiento

óptimo. Mientras que las herramientas accionadas por

pólvora pueden proporcionar uno de los medios más rápidos

y económicos de la atadura, sino que también pueden ser

peligrosos si no se operan correctamente.

EWALT consisten de elementos

™

EWALT

10

POW2273_manual_P2201_dewalt.indd 10 3/10/14 12:41 PM

Page 11

Modelo P2201 N.˚ de Cat. DDF211022P

P2201

Antes de operar la herramienta P2201, debe estar

Stop

Spall

debidamente capacitado en la operación y mantenimiento de

esta herramienta y emitirá una Tarjeta Operador Calificado

D

EWALT. Al utilizar la herramienta, debe tener esta tarjeta

en su posesión. Como parte del proceso de formación,

debe leer y comprender el contenido de este manual de

instrucciones en especial las medidas de seguridad.

Herramientas accionadas por pólvora solamente debe

ser utilizado por los operadores debidamente capacitados

como se describe en la norma ANSI A 10.3, Requisitos de

seguridad para Polvo Sistemas de sujetadores accionados.

Para detalles completos de la operación de la herramienta,

póngase en contacto con su oficina sucursal DEWALT o

distribuidor local para la formación.

Recuerde, la seguridad comienza con usted! Es su

responsabilidad principal cuando utilice esta herramienta.

Si no se siguen los procedimientos de operación,

mantenimiento y seguridad adecuadas, pueden producirse

lesiones graves o la muerte a usted oa otras personas.

Además de la formación impartida, usted debe estar

familiarizado con cualquier, estatales y federales locales.

Si usted tiene alguna pregunta que no se incluyen en

este manual, póngase en contacto con su oficina sucursal

D

EWALT o distribuidor local.

Size Range

Longitudesdelpasadorde1/2”a3”;calibre0,22

Tool Description

La P2201 es una velocidad baja, un solo disparo, calibre .22

herramienta que puede utilizarse para instalar pasadores de

arrastre 0.300 la cabeza, pasadores de arrastre con cabeza

de 8 mm y 1/4 “-20 espárragos roscados, de hasta 3” de

longitud total. El P2201 está diseñado para el mantenimiento

o contratistas residenciales.

DATOS TÉCNICOS

CUERPO DE LA LONGITUD LONGITUD DE LA

HERRAMIENTA DEL PASADOR HERRAMIENTA

plástico de ingeniería 1/2 “a 3” Longitud total 12-1/2”

TIPO DE CARGA PESO DE LA NIVEL DE

HERRAMIENTA POTENCIA

Calibre 0,22 en 4,3 libras. Gris (1), Marrón (2),

Crimped “A” Load

TIPO DE PASADOR

Pasador de arrastre Ballistic Point, pasador de arrastre con cabeza

de 0,300”, pasador de arrastre con cabeza de 8 mm, espárrago roscado

de 1/4”-20

Verde (3), Amarillo (4)

P2201 Selection Guide

CAT NO. DESCRIPTION STD CTN.

DFC211022D P2201 Tool (Blister Pack) 1

52522 Piston 1

52510 Nose Piece 1

52512 Piston Reset Pin 1

Funcionamiento del sujetador

Antes de aprender los procedimientos

seguros de operación para esta

herramienta, es importante entender

cómo funciona un sujetador accionado

en el material de base. La acción de conducción provoca

tremendas fuerzas que han de aplicarse al elemento de

sujeción. Sujetadores accionados polvo DEWALT están

especialmente diseñados y fabricados utilizando un proceso

austempering para soportar las fuerzas impuestas durante

la operación de conducción. Sólo los elementos de fijación

fabricados o suministrados por DEWALT deben ser utilizados

en esta herramienta.

Funcionamiento En Concreto

El rendimiento de un elemento de fijación accionado en polvo

cuando se instala en los materiales de base de hormigón o

mampostería se basa en los siguientes factores:

1. Fuerza del material de base

2. La dureza y la concentración del agregado

3. Diámetro del vástago del elemento de

fijación

4. Profundidad de empotramiento en el

1

material de base

5. Espaciamiento de sujetadores y

distancia al borde

Además de estos factores, accesorios

de la herramienta de instalación como por

ejemplo un esquirlas parada que reduce

2

la tendencia de la superficie de hormigón

a astillarse durante la acción de conducir

pueden aumentar el rendimiento del

elemento de fijación.

Cuando un elemento de fijación

accionado en polvo es impulsado en el hormigón, que

desplaza el volumen de hormigón alrededor de la zona

incrustada del vástago del sujetador. Mientras esto ocurre,

el hormigón que rodea directamente el elemento de fijación

es comprimido y, a su vez presiona contra el vástago del

sujetador. Además, la acción de conducción genera calor

que hace que las partículas dentro del hormigón se fusionen

al vástago del elemento de fijación. Esta combinación de

compresión y de fusión mantiene el elemento de fijación en el

material de base de hormigón. Una acción similar se produce

cuando la fijación en el bloque de mampostería.

En general, el rendimiento del elemento de fijación en

una determinada resistencia del hormigón aumentará con

mayores profundidades de empotramiento en un cierto rango.

Dependiendo del estilo de sujetador y la resistencia del

material base, profundidades de empotramiento van desde

5/8 “a 1-1/2”. Para profundidades superiores a este rango,

existe la posibilidad de flexión sujetador o fishhooking que

puede disminuir la capacidad de carga esperadas y crear un

peligro de seguridad.

Durante la acción de conducir, se puede producir algún

desprendimiento localizada en la superficie del hormigón.

Normalmente, este es un efecto de superficie que no afecta el

rendimiento del elemento de fijación. Sin embargo, se puede

plantear un problema estético para aplicaciones expuestas

en los que no se utiliza un accesorio. En casos como este,

dos métodos se pueden utilizar para mejorar la apariencia

de la fijación. Un adaptador de parada spall montado en la

herramienta accionada por pólvora puede ayudar a reducir el

desconchado de la superficie. Otro método utilizado es para

accionar el sujetador a través de una arandela de acero para

mejorar la apariencia de la aplicación.

por pólvora. Un elemento de fijación

accionado en polvo se considera que

es un accionamiento directo o tipo de entrada forzada de

elemento de fijación, ya que es impulsado directamente

Washer

Stop

Spall

11

POW2273_manual_P2201_dewalt.indd 11 3/10/14 12:41 PM

Page 12

P2201

Modelo P2201 N.˚ de Cat. DDF211022P

Funcionamiento En Acero

El rendimiento de la carga de un

sujetador accionado polvo cuando se

instala en materiales base de acero se

basa en los siguientes factores:

1. Espesor del acero

2. Resistencia a la tracción del acero

3. Diámetro del vástago del elemento de fijación

4. La profundidad del punto de penetración a través del acero

5. Espaciamiento de sujetadores y distancia al borde.

Cuando un elemento de fijación accionado en polvo es

impulsado en acero , que desplaza el acero lateralmente

360 ˚ alrededor del vástago del elemento de fijación .

Dado que el acero es un material elástico , que presiona

hacia atrás contra el vástago del elemento de fijación para

mantenerlo en su lugar . A medida que aumenta el diámetro

del vástago del sujetador , la capacidad de carga obtenido

generalmente aumentará siempre que el espesor del acero

es suficiente para aceptar el elemento de fijación . Para

aumentar aún más el rendimiento de fijación de acero ,

algunos elementos de fijación tienen un vástago moleteado

que permite que el acero para formar un bloqueo de llave

en los surcos para proporcionar capacidades más altos que

los obtenidos con un vástago liso . Para un rendimiento

óptimo , el punto de fijación debe penetrar completamente

el acero . Normalmente , se permite un mínimo de 1/ 4 “

para la longitud de punto . Un aumento en el rendimiento

se puede esperar hasta que el elemento de fijación ya no

penetra completamente a través del acero . En este punto

, las propiedades elásticas del acero causan una fuerza

de compresión a ser desarrollado en un ángulo contra el

punto de sujeción que reduce la capacidad de carga . En

materiales de base de acero más gruesas , capacidades de

carga adecuados se pueden obtener para aplicaciones en las

que el punto del elemento de sujeción no penetra totalmente

el acero . Se recomiendan las pruebas de rendimiento del

sitio de trabajo .

soldadas o cortadas con una antorcha ya que estos

procedimientos pueden haber causado el endurecimiento

local de la de acero. Durante la conducción del elemento

de fijación se debe evitar el rebote creado puede reducir

la capacidad de carga o causar daños al elemento de

sujeción. Cuando la fijación en miembros de acero largos no

compatibles, puede ser necesario para proporcionar soporte

en la zona de la fijación para evitar la acción del resorte que

puede causar la penetración inconsistente y una reducción

en la capacidad de carga.

Centro de pruebas de perforación

Una prueba de punzón siempre se debe realizar para

determinar la idoneidad del material de base para fijar por

este medio. Esta prueba es relativamente simple y puede

ayudar a asegurar una, de fijación seguro y exitoso.

Asegúrese de usar la protección adecuada para los ojos

cuando se realiza esta prueba. Para comenzar, selecciona el

dispositivo de fijación que se utilizará para el trabajo. A

continuación, coloque el punto de la fijación contra el

material de base propuesta. Golpee el elemento con un solo

golpe de martillo, a continuación, examinar la cuestión. Si el

punto del elemento de fijación

no está embotado y el material de

1

base tiene un punto de indentación

claro, es aceptable para proceder con

la primera instalación de prueba.

El uso de un sistema de

accionamiento de polvo, no se

recomienda si ocurre lo siguiente

durante la prueba de punzón:

1. El punto de fijación se ha mitigado.

2

Esto indica que el material de base

es demasiado duro.

2. Las grietas del material base o se

rompe. Esto indica que el material

de base es demasiado frágil.

3. Cuando se utiliza un golpe promedio

de martillo, el sujetador penetra en

el material base con facilidad. Esto

3

indica que el material de base es

demasiado suave.

Fastener Sinks in

with Average

Hammer Blow

Requisitos de instalación de fijaciones

Es importante entender los requisitos de espesor de material

de base mínimos requeridos, junto con la separación mínima

y requisitos de distancia del borde. El incumplimiento de estos

requisitos puede dar lugar a una fijación sin éxito y crear

un peligro de seguridad.

Base Material Espesor

Material de base de concreto debe

ser por lo menos tres (3) veces

más grueso que la penetración

Penetration

de empotramiento sujetador. Si el

concreto es muy delgada, las fuerzas

de compresión que forman en el

Adecuado Base Material

Mientras que los sujetadores accionadas por pólvora

pueden ser utilizados con éxito en concreto, ciertos materiales

de mampostería, y A de acero 36, algunos materiales son

totalmente inadecuados. Los sujetadores no deben ser des

pedidos en materiales duros y frágiles como el hierro fundido,

cerámica, vidrio o roca. Estos materiales pueden romperse

fácilmente dando lugar a un riesgo de seguridad potencial.

Además, los materiales de base blandos tales como paneles

de yeso, yeso o madera no son apropiados como el elemento

de fijación puede pasar completamente a través de estos

materiales. El usuario nunca debe adivinar cuándo la fijación

en un material base. Si no sigue las pautas de instalación y

seguridad recomendadas puede provocar lesiones graves o la

muerte del operador y / o los espectadores de la herramienta.

punto sujetadores pueden causar la

cara libre del hormigón para romper.

Esto puede crear una condición peligrosa de hormigón de

vuelo y / o el elemento de fijación y también se traduce en

una reducción de la potencia de sujeción que sostiene. Para

aplicaciones en la cáscara cara del bloque de mampostería

de hormigón, seleccione una longitud de sujeción que no

excederá el espesor de la cáscara de la cara.

Guía de sujetadores Penetración

La siguiente tabla muestra típicos de empotramiento o

de penetración de profundidad que se esperan de los

materiales de base enumerados. La penetración variará

dependiendo de la densidad del material. Esta tabla debe

ser utilizado como una guía ya que la consistencia de estos

materiales varía. En caso de duda, deberá realizarse una

prueba de rendimiento del sitio de trabajo.

Point

Flattens

No

Indent

Surface

Shatters

Material

Cracks

3x

Penetration

12

POW2273_manual_P2201_dewalt.indd 12 3/10/14 12:41 PM

Page 13

Modelo P2201 N.˚ de Cat. DDF211022P

P2201

DENSIDAD MATERIAL BASE TÍPICO PENETRACIÓN

Albañilería Soft Bloque de concreto 1”-1-1/4”

Concreto Normal Concreto vertido 3/4” - 1”

hormigón denso Concreto pretensado/ premoldeado 5/8”- 3/4”

DENSITY TYPICAL BASE MATERIAL PENETRATION

Soft Masonry Concrete block 1” -1-1/4”

Concreto Normal Poured concrete 3/4” - 1”

hormigón denso Pre-stressed/ 5/8” - 3/4”

pre-cast concrete

Distancia del borde

No sujete a una distancia menor

que 3” del borde de concreto. Si el

concreto se agrieta, es posible que el

sujetador no se fije. Se pueden permitir

3"

distancias más cercanas al borde

para aplicaciones de, por ejemplo,

durmientes si se le han realizado al

sujetador las pruebas específicas.

Separación

3"

Fijar los sujetadores demasiado cerca

en concreto o mampostería puede producir grietas. La

distancia mínima recomendada entre los sujetadores es de

3” de centro a centro.

Selección de la longitud del

sujetador en concreto

Para aplicaciones permanentes que

utilizan pasadores en concreto,

primero determine el espesor del

accesorio que se va a sujetar. Para hacerlo, agregue el

empotramiento o la penetración requeridos al material base.

Esto será la longitud requerida de la espiga del sujetador.

Para aplicaciones en el revestimiento de bloques de

mampostería, seleccione una longitud del sujetador que no

exceda el espesor del revestimiento. .

Para aplicaciones desmontables con espárragos

roscados, la longitud de la espiga requerida es igual a la

profundidad de empotramiento requerida. Para determinar

la longitud mínima de los espárragos roscados, sume el

espesor del accesorio y el espesor de la tuerca/arandela.

El espesor de la tuerca y arandela es igual al diámetro

nominal del espárrago roscado. No ajuste demasiado las

piezas roscadas. Los valores máximos de la torsión de ajuste

se enumeran en la tabla a continuación. Se recomienda

el uso de un destornillador para tuercas para disminuir

la posibilidad de ajustar demasiado los sujetadores. Para

aplicaciones críticas, realice una prueba en el lugar de

trabajo.

TORSIÓN MÁXIMA PARA UN TORSIÓN MÁXIMA PARA UN

ESPÁRRAGO DE 1/4” (LIBRAS-PIE) ESPÁRRAGO DE 3/8” (LIBRAS-PIE)

2 4

Instalación en acero

Las siguientes pautas se basan en la instalación de un

sujetador en acero estructural conforme a la norma A 36

de la ASTM con una penetración completa de la punta en

la pieza de acero. El espesor recomendado de la pieza de

acero varía de un mínimo de 1/8” a un máximo de 3/8”.

Para utilizarlo en acero estructural de mayor resistencia y

aplicaciones donde la punta no penetra en la pieza de acero

o el espesor del acero es mayor a 3/8”, se recomienda

realizar pruebas de rendimiento en el lugar de trabajo.

Espesor del material base

Los materiales base de acero deben tener 1/8” de espesor

como mínimo.

Distancia del borde

Para instalaciones en acero A 36, la distancia del borde

mínima recomendada es de 1/2”.

Separación

La distancia mínima recomendada entre las sujeciones es

de 1-1/2” de centro a centro para las instalaciones en acero

conforme a la norma A 36 de la ASTM.

Selección de la longitud del

sujetador en acero

1/8"

Para aplicaciones permanentes que

1/2"

utilizan pasadores en acero, primero

determine el espesor del accesorio que

se va a sujetar. Para hacerlo, sume el

espesor del material base de acero más

1-1/2"

un mínimo de 1/4” para permitir una

penetración adecuada de la punta. Esto

será la longitud mínima requerida de la

espiga del sujetador. No seleccione una

longitud de sujetador más larga que la

requerida para la aplicación. Una espiga excesivamente larga

puede bruñir o lustrar el orificio creado en el acero, lo que

producirá una reducción de la capacidad de carga.

Fixture

Para aplicaciones desmontables con espárragos

roscados, la longitud requerida de la espiga es igual al

Embedment

espesor del material base de acero más un mínimo de 1/4”

para permitir la penetración adecuada de la punta. Esto será

la longitud mínima requerida de la espiga del sujetador. No

seleccione una longitud de espiga más larga que la requerida

para la aplicación. Una espiga excesivamente larga puede

bruñir o lustrar el orificio creado en el acero, lo que producirá

una reducción de la capacidad de carga. Para determinar

la longitud mínima de los espárragos roscados, sume el

espesor del accesorio y el espesor de la tuerca/arandela. El

espesor de la tuerca y arandela es igual al diámetro nominal

del espárrago roscado.

No ajuste demasiado los espárragos roscados, la torsión

máxima de ajuste se enumera en la tabla a continuación.

Se recomienda el uso de un destornillador para tuercas para

disminuir la posibilidad de ajustar demasiado los sujetadores. Para

aplicaciones críticas, realice una prueba en el lugar de trabajo.

Guía de selección del sujetador

Pasadores de arrastre con cabeza

de 0,300” de diámetro

N.˚ LONGITUD CAJA CARTÓN DÍAM. DÍAM. PESO/

DE CAT. DE ESPIGA EST. EST. DE CABEZA DE ESPIGA 100

DDF3011000

1/2” K 100 5000 0,300 0,143 0,5

DDF3011050

5/8” K 100 5000 0,300 0,143 0,5

DDF3011100

3/4” 100 5000 0,300 0,143 0,5

DDF3011150

1” 100 5000 0,300 0,143 0,6

DDF3011200

1-1/8” 100 1000 0,300 0,143 0,7

DDF3011250

1-1/4” 100 1000 0,300 0,143 0,8

DDF3011300

1-1/2” 100 1000 0,300 0,143 0,9

DDF3011350

1-3/4” 100 1000 0,300 0,143 1,1

DDF3011400

2” 100 1000 0,300 0,143 1,2

DDF3011450

2-1/4” 100 1000 0,300 0,143 1,2

DDF3011500

2-3/8” 100 1000 0,300 0,143 1,3

DDF3011550

2-1/2” 100 1000 0,300 0,143 1,4

DDF3011600

2-3/4” 100 1000 0,300 0,143 1,6

DDF3011650

3” 100 1000 0,300 0,143 1,9

13

POW2273_manual_P2201_dewalt.indd 13 3/10/14 12:41 PM

Page 14

P2201

Modelo P2201 N.˚ de Cat. DDF211022P

Pasadores de arrastre con cabeza de 0,300” de

diámetro y casquete

N.˚ LONGITUD CAJA CARTÓN DÍAM. DÍAM. PESO/

DE CAT. DE ESPIGA EST. EST. DE CABEZA DE ESPIGA 100

DDF3031000

1/2” K 100 5000 0,300 0,143 0,5

DDF3031050

5/8” K 100 5000 0,300 0,143 0,5

DDF3031100

3/4” 100 5000 0,300 0,143 0,5

DDF3031150

1” 100 5000 0,300 0,143 0,6

Pasadores de espiga escalonada con cabeza de

0,300” de diámetro

N.˚ LONGITUD CAJA CARTÓN DÍAM. DÍAM. PESO/

DE CAT. DE ESPIGA EST. EST. DE CABEZA DE ESPIGA 100

DDF3041000 Espiga escalonada de 3/4”

DDF3041050 Espiga escalonada de 1”

100 1000 0,300 0,143/130 0,5

100 1000 0,300 0,143/130 0,6

Pasadores de arrastre con cabeza de 0,300” de

diámetro - Paquete maestro

N.˚ LONGITUD CAJA CARTÓN DÍAM. DÍAM. PESO/

DE CAT. DE ESPIGA EST. EST. DE CABEZA DE ESPIGA 100

DDF301100M

1/2” K 1000 5000 .300 .143 .5

DDF301105M

5/8” K 1000 5000 .300 .143 .5