Page 1

(FEB18) Part No. 200-3090-B DXCM024-0344 Copyright © 2017,2018 D

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

MAT Industries, LLC, Long Grove, IL 60047

e

WA LT

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZA DE GARANTÍA. ADVERNTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

DXCM024-0344

1/2" x 50' Auto Retracting Steel Hose Reel

Carrete Autoretráctil De Acero Para Manguera - 12,7 mm x 15,2 m

Dévidoir Autorétractable En Acier Pour Tuyay - 12,7 mm x 15,2 m

Page 2

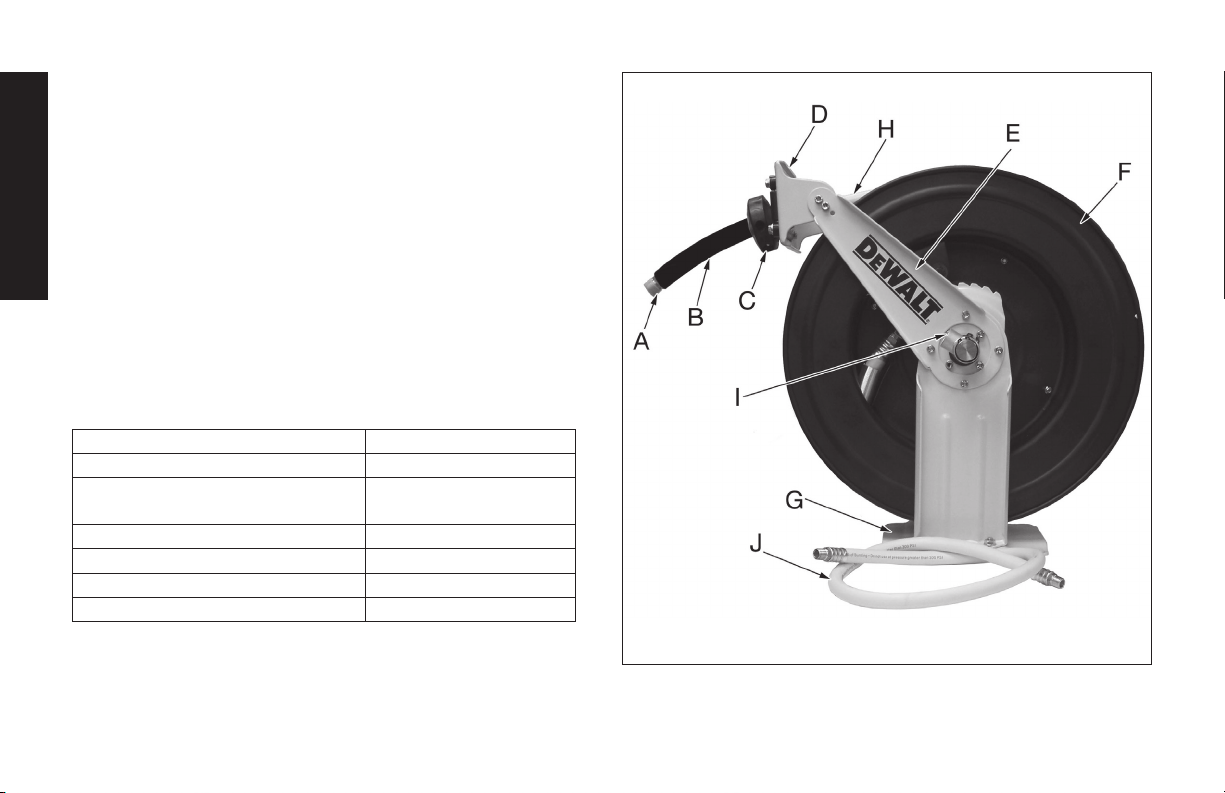

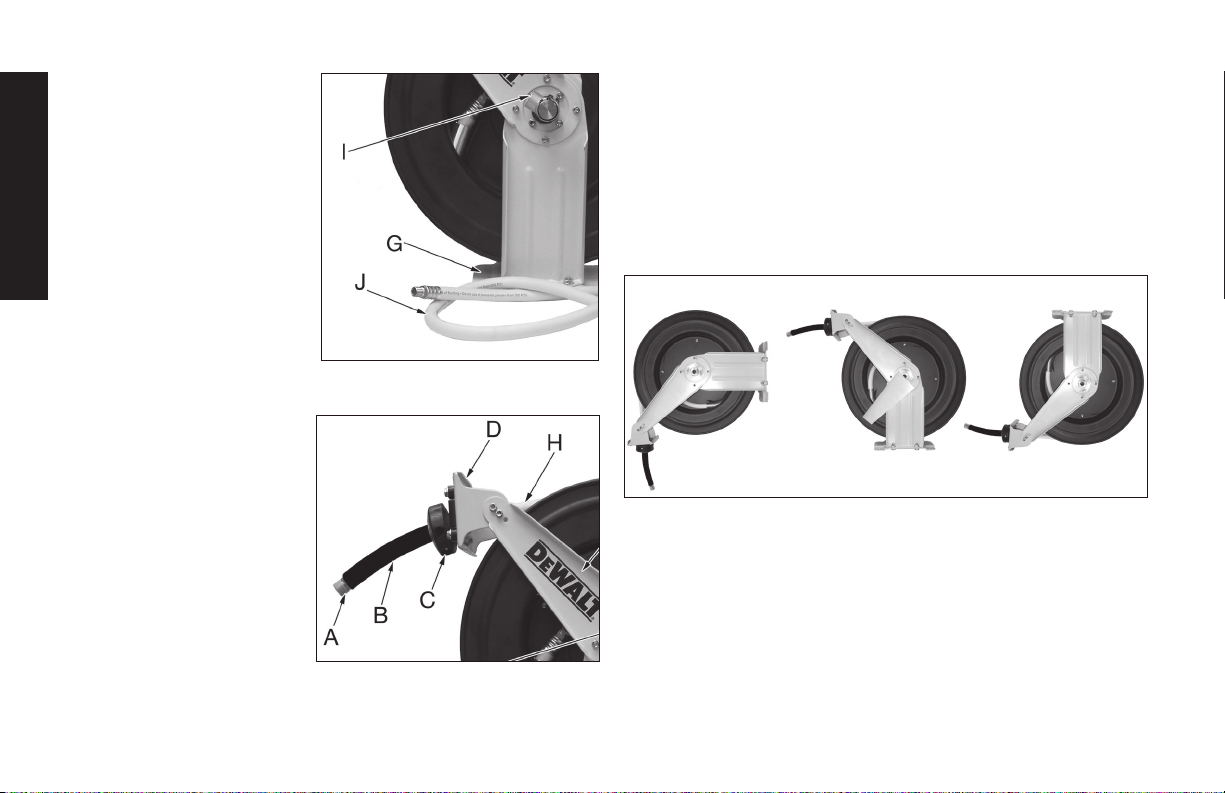

DXCM024-0344 Air Hose Reel

A. Air line outlet (to air tool/accessory)

B. Hose bend restrictor

C. Ball stop

D. Hose guide roller bracket

E. Hose guide arm

English

F. Hose reel drum

G. Mounting bracket

H. Air hose

I. Air line inlet swivel connector (from compressor)

J. Lead-in air hose

Specications

MODEL DXCM024-0344

NET WEIGHT 46.3 lbs. (21 kg)

AIR INLET SIZE 1/2" NPT (12,7 mm)

(female/hembra/femelle)

HOSE TYPE Rubber

AIR HOSE SIZE 1/2" (12,7 mm)

MAX. AIR PRESSURE 250 PSI (1,724 kPa)

AIR HOSE LENGTH 50' (15,2 m)

FIG. 1

2

Page 3

Denitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION: Used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT

THIS OR ANY D

1-800-4-D

EWALT (1-800-433-9258)

e

WALT TOOL, CALL US TOLL FREE AT:

Important Safety Instructions

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some example of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry

products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, al ways wear OSHA/MSHA/NIOSH approved, properly

fit ting face mask or res pi ra tor when us ing such tools. When

using air tools, basic safety precautions should always be followed

to reduce the risk of personal injury.

WARNING: This product contains chemicals, known to the

State of California to cause cancer, and birth defects or other

reproductive harm. Wash hands after handling.

SAVE THESE INSTRUCTIONS

WARNING:

Improper operation or maintenance of this product

could result in serious injury and property

damage. Read and understand all warnings and

operating instructions before using this

equipment. When using air tools, basic safety

precautions should always be followed to reduce

the risk of personal injury.

WARNING:

Read and understand this instruction manual and tool

labels before installing, operating or servicing this tool.

Keep these instructions in a safe accessible place.

Operators and others in work area must wear ANSI Z87.1

CAN/CSA Z94.3 approved safety glasses with side shields.

Operators and others in work area must wear ear

protection.

English

3

Page 4

WARNING:

• Do Not Use oxygen or reactive gases; explosion may occur.

• Do Not Exceed air pressure of 250 PSI.

• Read all manuals included with this product carefully.

Be thoroughly familiar with the controls and the proper use

of the equipment.

• Do not exceed any pressure rating of any component

English

in the system.

• Disconnect the air tool from air supply before changing tools

or attachments and during non-operation.

• Always use attachments designed for use with air

powered tools.

• Do not use damaged or worn attachments.

• Check air hoses for weak or worn condition before each use.

Make sure all connections are secure.

• Keep all nuts, bolts and screws tight and ensure equipment is

in safe working condition.

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Exceeding the maximum

pressure rating of tools

accessories could cause an

explosion resulting

in serious injury.

• Use compressed air regulated to a maximum pressure

at or below the rated pressure

of any attachments.

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Abrasive tools, such as

grinders, sanders, and

cut-off tools generate dust

and abrasive materials which

can be harmful to human

lungs and respiratory system.

CAUTION: RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Long term exposure to noise

produced from the operation

of air tools can lead to

permanent hearing loss.

• Always wear MSHA/NIOSH

approved, properly fitting face

mask or respirator when using

such tools.

• Always wear ANSI (S3.19)

hearing protection.

4

Page 5

WARNING: RISK OF INJURY

WHAT CAN HAPPEN HOW TO PREVENT IT

• Air tools can propel loose

objects or other materials

throughout the work area.

• Exceeding the pressure rating

of air hoses can cause them

to explode or fly apart, and

could result in serious injury.

• Keep work area clean and free

of clutter. Keep children and

others away from work area

during operation of the tool.

• Keep work area well lit.

•

Use compressed air regulated

to a maximum pressure at or

below the rated pressure of

any attachments.

•

Never use oxygen, carbon

dioxide or other bottled gases

as a power source for air tools.

•

Protect air lines from damage

or puncture.

•

Check air hoses for weak or

worn condition before each

use. Make sure all connections

are secure.

WARNING: RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Air powered equipment and

power tools are capable of

propelling materials such as

metal chips, saw dust, and

other debris at high speed,

which could result in serious

eye injury.

• Compressed air can be

hazardous. The air stream

can cause injury to soft tissue

areas such as eyes, ears, etc.

Particles or objects propelled

by the stream

can cause injury.

• Always wear ANSI Z87.1 CAN/

CSA Z94.3 approved safety

glasses with side shields.

• Never leave operating tool

unattended. Disconnect air

hose when tool is not in use.

• For additional protection use an

approved face shield in addition

to safety glasses.

SAVE THESE INSTRUCTIONS FOR FUTURE

USE

English

5

Page 6

AIR LINE INLET SWIVEL

CONNECTOR

The air line inlet swivel

connector(I) is 1/2" NPT and is

located on the on the side of

the hose reel. This allows for

easy hook up to an air source.

English

MOUNTING BRACKET

The mounting bracket (G) is a

powder coated metal plate that

can be easily mounted on a

wall, ceiling or floor.

LEAD-IN AIR HOSE

The lead-in hose (J) is 1/2" x 4'

long and has a swivel connection on one end to prevent the hose

from twisting or kinking. This gets attached to the air line inlet (I).

AIR LINE OUTLET

The air line outlet (A) is 1/2"

NPT and is located on the end

of the air hose (H) for

convienient connection to air

accessories or tools.

AIR HOSE

The air hose (H) is 1/2" x 50'

and is attached to the hose

reel.

BALL STOP

The ball stop (C) is adjustable

and allows the desired length

of hose to be permanently stored outside the hose real.

HOSE BEND RESTRICTOR

The hose restrictor (B) reduces bending stress near the fitting,

preventing damage and extending the life of the hose (H).

INSTALLATION

1. Choose a mounting location that is free of electrical wiring or

other obstructions and is sturdy enough to support the weight of

the hose reel and hose as well as the force used to extend and

retract it. The hose reel can be mounted on the oor, ceiling or

wall (see Figure 2).

Figure 2

Wall Floor Ceiling

2. Use the included mounting template to mark and drill the hole

locations.

3 Mount the hose reel in the desired location. Purchase the appro-

priate fasteners at your local hardware store. Different mounting

positions require different types of hardware.

4. If an adjustment needs to made to increase or decrease the

length of hose that is outside of the hose reel, pull out the hose

slowly until it latches at the desired length. Loosen the ball stop

(C) bolts and slide the hose stop to a position close to the hose

6

Page 7

guide roller bracket (D). Retighten the ball stop bolts. Do not overtighten the bolts.

WARNING:

1) Make sure the hose reel is secure before each use.

2) Never connect to an air source that is greater than 250 PSI.

3) Inspect the air hose before each use to make sure there are

no leaks.

4) Do not wrap the hose around any parts of the body.

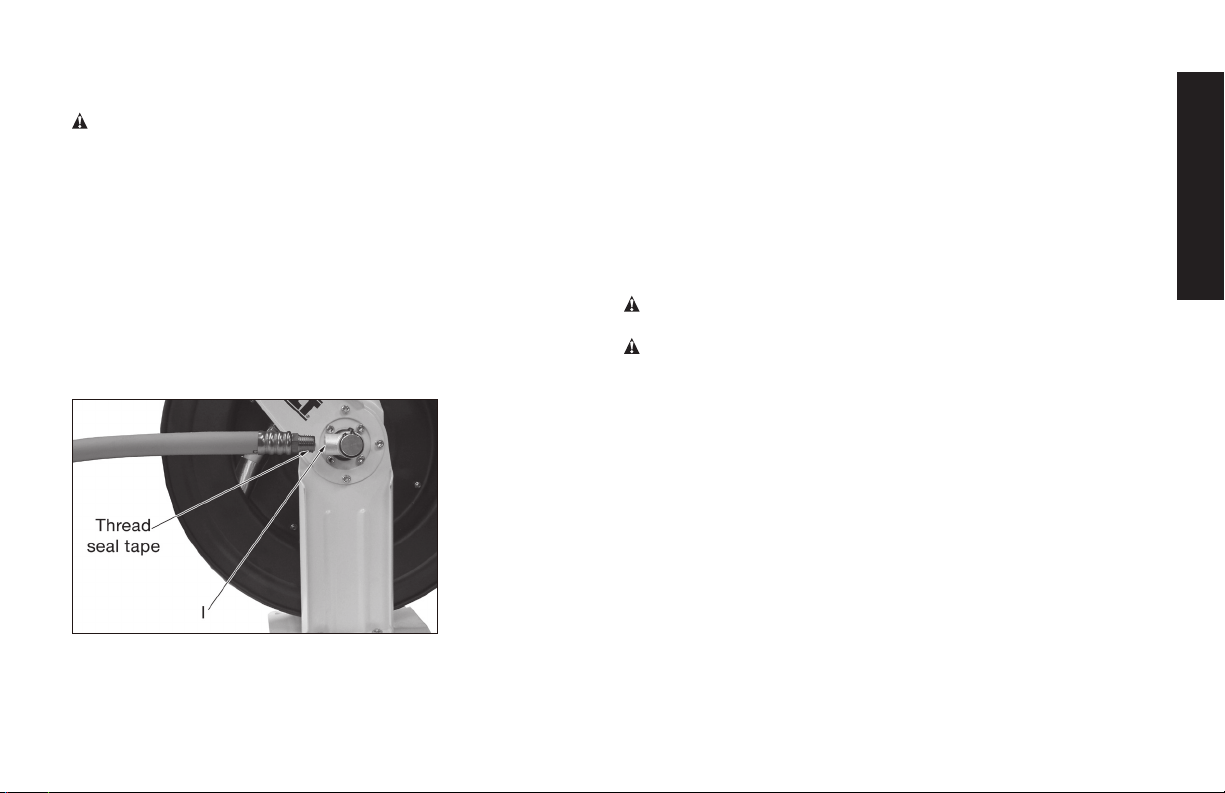

COMPRESSOR HOOK-UP

The hose reel includes a 1/2" x 4' lead-in hose for hooking up the

hose reel to your air source. Apply Teflon tape to the male threads

of the lead-in house and thread the non swivel end into the air hose

inlet (I). Thread and connect the other end into your air source.

Attach air tool or accessory to the air outlet of the air hose in the

hose reel.

OPERATION

Check the operation of the reel by slowly pulling out the hose. You

will hear a clicking noise.

LOCKING HOSE REEL

Pull out the hose slowly until the desire length of hose is reached,

allow it to retract after hearing a series of clicks.

UNLOCKING HOSE REEL

Pull out the hose slowly until the the clicking noise stops, allow it to

retract until the ball stop rests against the hose guide roller bracket.

DO NOT LET GO OF THE HOSE!

WARNING: Risk of Injury. Do not let go of the hose when

retracting.

WARNING: Always disconnect air tool or accessory attached to

the hose reel from air supply before making any adjustments and

changing accessories.

ADJUSTING RECOIL TENSION

1. Disconnect the air supply to the hose reel.

2 Pull out about 2 feet of air hose and lock in place (see locking

hose reel).

3. Remove the 2 piece ball stop by removing the 2 phillips head

screws, washers and nuts.

4. Feed the hose back through the hose guide roller bracket. (Note:

keep the hose reel drum locked at all times).

5. To increase tension, pull the hose around the drum one time.

6. To decrease tension, unwrap the hose one time around the

drum.

7. Push the hose back through the hose guide roller bracket

and pull out the hose from the hose reel to check the tension.

English

7

Page 8

Reinstall the ball stop.

8. Connect incoming air supply.

WARNING: The reel is under tension so use caution so that the

reel's latching mechanism does not release while adjusting the

tension.

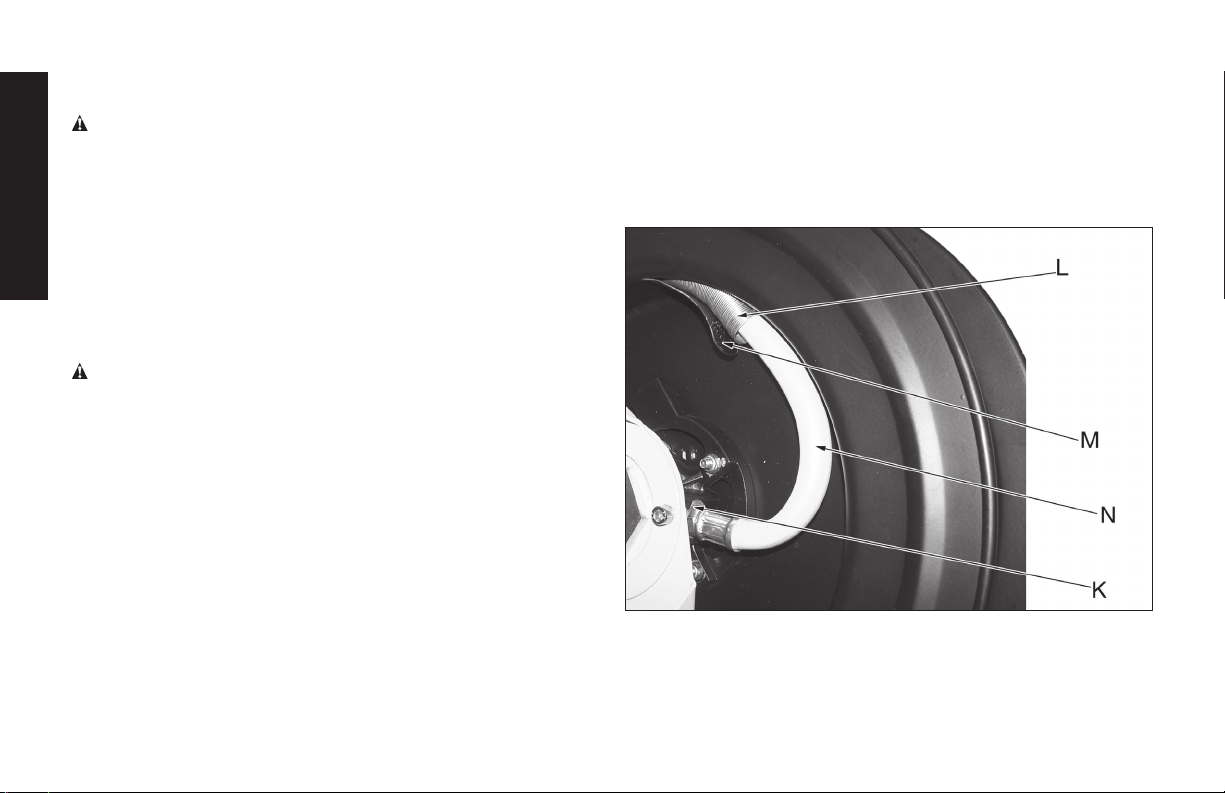

HOSE REPLACEMENT

1. Disconnect the air supply and remove the leader hose from the

English

hose reel.

2. Remove the 2 piece ball stop by removing the 2 phillips head

screws, washers and nuts. Set aside.

3. Carefully pull all of the air hose from the hose reel until the clamp

that holds the hose to the hose reel drum is visable then make

sure the hose reel is locked

WARNING: The reel is under tension so do not turn the hose

reel drum or pull on the hose while it is locked.

4. Remove the hose clamp (located inside the hose reel drum - not

shown) and set aside.

5. Carefully disconnect the hose end (K) from the side of the hose

reel and remove the old hose.

6. Remove the hose protection spring (L) from the old hose. Place

the protection spring (L) on the new hose and then feed the hose

through the hose guide roller bracket and the slot on the drum

(M).

7. Apply thread seal tape to the hose threads and connect to the

hose reel (K) then tighten.

8. Attach the hose to the inside of the drum with the hose clamp.

Make sure the hose has a wide curve (N) to it and is not kinked

before tightening the hose clamp.

9. Make sure the hose protector spring (L) is in the correct location

(reference Figure 3).

10. Pull the hose to unlock and slowly rewind the air hose. Do not let

go of the hose.

11. Re-attach the ball stop to the desired location on the hose.

12. Reconnect the lead-in hose to the hose reel and turn on the air

supply. Check all connections to make sure there are no leaks.

Figure 3

SERVICE INFORMATION

Please have the following information available for all service calls:

Model Number _____________________________________________

Date and Place of Purchase _________________________________

8

Page 9

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

replacement.

EWALT for a free

WARRANTY

ONE YEAR LIMITED WARRANTY: DEWALT Industrial Tools (the

Company) warrants that for a period of twelve (12) months from

the date of purchase, it will replace or repair, free of charge, for

the original retail purchaser only, any part or parts, manufactured

by the Company, found upon examination by the Company

or its assigned representatives, to be defective in material

or workmanship or both. All transportation charges for parts

submitted for replacement or repair under this warranty must be

borne by the original retail purchaser. This is the exclusive remedy

under this warranty.

Failure by the original retail purchaser to install, maintain and

operate said equipment in accordance with good industry

practices, or failure to comply with the specific recommendations

of the Company set forth in the owner’s manual, shall render

this warranty null and void. The Company shall not be liable for

any repairs, replacements, or adjustments to the equipment

or any costs for labor performed by the purchaser without the

Company’s prior written approval. The effects of corrosion,

erosion and normal wear and tear are specifically excluded from

this warranty.

THE COMPANY MAKES NO OTHER WARRANTY OR

REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED EXCEPT THAT OF TITLE. ALL

IMPLIED WARRANTIES, INCLUDING ANY WARRANTY

OF MERCHANTABILITY AND FITNESS FOR PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED. LIABILITY FOR

CONSEQUENTIAL AND INCIDENTAL DAMAGES UNDER ANY

AND ALL WARRANTIES, OTHER CONTRACTS, NEGLIGENCE,

OR OTHER SORTS IS EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW.

Notwithstanding the above, any legal claim against the Company

shall be barred if legal action thereon is not commenced

within twenty-four (24) months from the date of purchase or

delivery whichever occurs last. This warranty constitutes the

entire agreement between the Company and the original retail

purchaser and no representative or agent is authorized to alter

the terms of same without expressed written consent of the

Company.

English

9

Page 10

DXCM024-0344 Enrouleur de tuyaux

pneumatique

A. Sortie d'air (vers outil/accessoire pneumatique)

B. Limiteur de courbure

C. Butée sphérique

D. Support cylindrique de guide tuyau

E. Bras de guide tuyau

F. Tambour d'enrouleur de tuyaux

G. Support de fixation

H. Tuyau pneumatique

I. Raccord pivotant de l'admission d'air (depuis le compresseur)

J. Tuyau pneumatique d'alimentation

Spécications

MODÈLE DXCM024-0344

POIDS NET 46.3 lbs. (21 kg)

Français

ADMISSION D'AIR 1/2" NPT (12,7 mm)

(female/hembra/femelle)

TYPE DE TUYAU PNEUMATIQUE Rubber

TAILLE DU TUYAU

PNEUMATIQUE

PRESSION OPÉRATIONNELLE

MAXIMALE DU TUYAU

LONGUEUR DU TUYAU

PNEUMATIQUE

1/2" (12,7 mm)

250 PSI (1,724 kPa)

50' (15,2 m)

FIG. 1

10

Page 11

Dénitions : lignes directrices en matière

de sécurité

Les définitions ci-dessous décrivent le niveau de gravité pour

chaque symbole. Veuillez lire le mode d’emploi et porter une

attention particulière à ces symboles.

DANGER : Indique une situation dangereuse imminente

qui, si elle n’est pas évitée, causera la mort ou des blessures

graves.

AVERTISSEMENT :

dangereuse qui, si elle n’est pas évitée, pourrait se solder par

un décès ou des blessures graves.

ATTENTION : Indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée pourrait se solder par

des blessures mineures ou modérées.

AVIS : Indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages

matériels.

ISI VOUS AVEZ DES QUESTIONS OU DES COMMENTAIRES SUR

CE PRODUIT OU TOUT AUTRE OUTIL D

GRATUITEMENT AU: 1-800-4-D

Indique une situation potentiellement

e

WALT APPELEZ-NOUS

EWALT (1-800-433-9258)

Consignes de sécurité importantes

AVERTISSEMENT: certaines poussières qui se forment lors

du ponçage mécanique, du sciage, de l'affûtage, du fraisage

ou d'autres activités de construction contiennent des produits

chimiques qui, selon l'État de Californie, peuvent provoquer des

cancers, des malformations à la naissance ou d'autres problèmes

de reproduction. Voici certains exemples de ces produits

chimiques:

• Le plomb provenant des peintures à base de plomb

• La silice cristalline provenant des briques, du ciment et

d'autres produits de maçonnerie

• L'arsenic et le chrome provenant du bois traité chimiquement

Le risque d'exposition dépend de la fréquence à laquelle vous

effectuez ce genre de tâches. Afin de réduire l'exposition à ces

produits chimiques: travaillez dans un environnement ventilé en

portant un équipement de sécurité adéquat, et portez toujours

un équipement approuvé par les institutions OSHA/MSHA/

NIOSH, ainsi qu'un masque facial ou un respirateur à votre taille

lorsque vous utilisez ces outils. Lorsque vous utilisez des outils

pneumatiques, respectez en permanence les mesures de sécurité

élémentaires afin de réduire le risque de dommages corporels.

AVERTISSEMENT: ce produit contient des produits chimiques

qui, selon l'État de Californie, peuvent provoquer des cancers,

des malformations à la naissance ou d'autres problèmes de

reproduction. Se laver les mains après manipulation.

CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

Toute mauvaise utilisation ou maintenance de ce

produit peut entraîner des blessures graves et des

dégâts matériels. Lisez attentivement les

avertissements et le mode d'emploi avant d'utiliser

cet équipement. Lorsque vous utilisez des outils

pneumatiques, respectez en permanence les

mesures de sécurité élémentaires afin de réduire

le risque de dommages corporels.

VERTISSEMENT

Lisez attentivement ce mode d'emploi et les étiquettes

des outils avant d'installer, d'utiliser ou d'entretenir cet

enrouleur de tuyaux. Conservez ces instructions dans un

Français

11

Page 12

endroit sûr et accessible.

Les opérateurs et autres personnes présentes dans la

zone de travail doivent porter des lunettes de sécurité

conformes à l'ANSI Z87.1 CAN/CSA Z94.3 avec

protections latérales.

Les opérateurs et autres personnes présentes dans la

zone de travail doivent porter des protections auditives.

AVERTISSEMENT:

• N'utilisez jamais d'oxygène ou de gaz réactifs. Cela pourrait

provoquer une explosion.

• La pression de l'air ne doit jamais dépasser les 250 psi (17 bar).

• Lisez attentivement tous les manuels inclus avec ce produit.

Familiarisez-vous avec les commandes et apprenez à utiliser

cet équipement correctement.

• Ne dépassez jamais la pression nominale d'un composant du

système.

Français

• Déconnectez l'outil pneumatique de l'alimentation en air avant

de changer les outils ou les accessoires et lorsqu'il est à l'arrêt.

• Utilisez toujours des accessoires conçus pour être utilisés avec

des outils pneumatiques.

• N'utilisez jamais d'accessoires usés ou endommagés.

• Contrôlez les tuyaux pneumatiques avant chaque utilisation afin

de vous assurer qu'ils ne sont ni usés ni endommagés.

Assurez-vous que tous les raccordements sont sécurisés.

• Assurez-vous que les écrous, les boulons et les vis sont bien

serré(e)s et que l'équipement fonctionne dans des conditions

de travail sûres.

DANGER: RISQUE D'EXPLOSION OU D'INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L'EMPÊCHER

• Dépasser la pression nominale maximale des accessoires peut provoquer une

explosion et entraîner des

blessures graves.

DANGER: RISQUE DE DIFFICULTÉS RESPIRATOIRES

CE QUI PEUT SE PRODUIRE COMMENT L'EMPÊCHER

• Des outils abrasifs, comme

des meuleuses, des

ponceuses et des outils de

coupe peuvent produire de

la poussière et des matériaux

abrasifs qui peuvent être

dangereux pour les poumons

et le système respiratoire.

ATTENTION: RISQUE ASSOCIÉ AU BRUIT

CE QUI PEUT SE PRODUIRE COMMENT L'EMPÊCHER

• Utiliser de l'air comprimé

régulé à une pression maximale inférieure ou égale à

la pression nominale

de chaque accessoire.

(ASPHYXIE)

• Portez toujours un équipement

approuvé par la MSHA/

NIOSH, ainsi qu'un masque

facial ou un respirateur à votre

taille lorsque vous utilisez ces

outils.

12

Page 13

• Une exposition prolongée

aux bruits produits par des

outils pneumatiques en

fonctionnement peut entraîner

une perte de l'audition

permanente.

AVERTISSEMENT: RISQUE DE PROJECTION

CE QUI PEUT SE PRODUIRE COMMENT L'EMPÊCHER

• Les équipements et outils

pneumatiques peuvent

propulser des matériaux

comme des copeaux

métalliques, de la sciure et

d'autres débris à une vitesse

élevée, ce qui peut provoquer

des graves blessures

oculaires.

• L'air comprimé peut s'avérer

dangereux. Le flux d'air peut

provoquer des blessures

au niveau des tissus mous

comme les yeux, les oreilles,

etc. Les particules et les

objets propulsés par le flux

d'air peuvent entraîner des

blessures.

• Portez toujours des protections

auditives conformes à l'ANSI

(S3.19).

• Portez toujours des lunettes

de sécurité conformes à l'ANSI

Z87.1 CAN/CSA Z94.3 avec

protections latérales.

• Ne laissez jamais un outil

en fonctionnement sans

surveillance. Déconnectez le

tuyau pneumatique lorsque

l'outil est à l'arrêt.

• Pour être mieux protégé,

utilisez un masque de

protection approuvé en plus

des lunettes de sécurité.

ATTENTION: RISQUÉ DE BLESSURE

CE QUI PEUT SE PRODUIRE COMMENT L'EMPÊCHER

• Les outils électriques peuvent

lancer des matériaux dans

toute la zone de travail.

• Dépasser la pression

maximale nominale des

accessoires de l’outil peut

causer une explosion

causant des blessures

graves.

• Keep work area clean and free

Conserver la zone de travail

propre et en bon ordre. Éloigner

les enfants et autrui de la zone

de travail durant l’utilisation de

l’outil.

• Conserver les lieux bien

illuminés.

•

Utiliser de l’air comprimé réglé

à une pression maximale près

ou au-dessous de la pression

nominale des accessoires.

•

Ne jamais utiliser de gaz

oxygène, de dioxyde de

carbone ou autres gaz en

bouteille comme source

d’énergie pour les outils

pneumatiques.

•

Protégez les conduits d’air des

dommages et des perforations.

•

Vérifiez les boyaux d’air en cas

d’usure ou de détérioration

avant chaque emploi.

S’assurer que tous les

raccords sont bien branchés.

Français

CONSERVEZ CES INSTRUCTIONS POUR UNE FUTURE

UTILISATION

13

Page 14

FONCTIONNALITÉS

RACCORD PIVOTANT DE L'ADMISSION D'AIR

Le raccord pivotant de

l'admission d'air (I) mesure 1/2"

(1,2 cm) NPT et est situé sur le

côté de l'enrouleur de tuyaux.

Cela permet de le brancher

rapidement à une source

d'alimentation en air.

SUPPORT DE FIXATION

Le support de fixation (G) est

une plaque de métal laqué qui

peut être facilement fixée sur un

mur, au plafond ou au sol.

TUYAU PNEUMATIQUE

D'ALIMENTATION

Le tuyau d'alimentation (J)

Français

mesure 1/2" (1,2 cm) x 4' (1,2

m) de long et est équipé d'un

raccord pivotant sur l'une de

ses extrémités afin d'éviter que

le tuyau ne se torde ou ne

s'emmêle. Il se connecte à

l'admission d'air (I).

SORTIE D'AIR

La sortie d'air (A) mesure

1/2" (1,2 cm) NPT et est

située à l'extrémité du tuyau

pneumatique (H) pour être facilement connectée aux outils et

accessoires pneumatiques.

TUYAU PNEUMATIQUE

Le tuyau pneumatique (H) mesure 1/2" (1,2 cm) x 50' (15 m) et est

attaché à l'enrouleur de tuyaux.

BUTÉE SPHÉRIQUE

La butée sphérique (C) est réglable et permet de sortir la longueur

de tuyau souhaitée de façon permanente.

LIMITEUR DE COURBURE

Le limiteur de courbure (B) réduit la tension provoquée par le

pliage du tuyau au niveau du raccord, ce qui permet d'éviter les

dommages et de prolonger la durée de vie du tuyau (H).

INSTALLATION

1. Choisissez un emplacement de xation ne présentant aucun

câble électrique ou autre obstacle, et sufsamment robuste pour

supporter le poids de l'enrouleur et du tuyau, ainsi que la force

exercée lorsqu'il est étendu et rétracté. L'enrouleur de tuyaux

peut être xé sur le sol, au plafond ou sur un mur (voir Figure 2).

Figure 2

Mur Sol Plafond

2. Utilisez le gabarit de xation inclus an de marquer

l'emplacement des trous et de percer à ces endroits.

3 Fixez l'enrouleur de tuyaux à l'emplacement souhaité. Achetez les

éléments de xation adéquats dans votre magasin de bricolage.

14

Page 15

Les différentes positions de xation requièrent différents types

d'équipements.

4. Si vous souhaitez augmenter ou réduire la longueur du tuyau

située à l'extérieur de l'enrouleur, tirez doucement sur le tuyau

jusqu'à ce qu'il soit verrouillé à la longueur souhaitée. Desserrez

les boulons de la butée sphérique (C) et faites-la glisser pour la

rapprocher du support cylindrique du guide tuyau (D). Resserrez

les boulons de la butée sphérique. Ne serrez pas les boulons de

manière excessive.

AVERTISSEMENT:

1) Assurez-vous que l'enrouleur est bien fixé avant chaque

utilisation.

2) Ne le connectez jamais à une source d'alimentation en air dont

la pression est supérieure à 250 psi (17 bar).

3) Inspectez le tuyau pneumatique avant chaque utilisation afin

de vous assurer qu'il ne présente aucune fuite.

4) N'enroulez jamais le tuyau autour d'une partie de votre corps.

BRANCHEMENT DU COMPRESSEUR

L'enrouleur de tuyaux est

accompagné d'un tuyau

d'alimentation 1/2" (1,2

cm) x 4' (1,2 m) pour le

connecter à une source

d'alimentation en air.

Appliquez le ruban de

téflon aux filetages mâles

du tuyau d'alimentation,

puis insérez l'extrémité

non pivotante dans

l'admission d'air du tuyau

(I). Connectez l'autre

extrémité à votre source d'alimentation en air. Attachez l'outil ou

accessoire pneumatique à la sortie d'air du tuyau pneumatique de

l'enrouleur.

UTILISATION

Assurez-vous du bon fonctionnement de l'enrouleur en tirant

doucement sur le tuyau. Vous entendrez un cliquètement.

VERROUILLER L'ENROULEUR

Tirez doucement sur le tuyau jusqu'à atteindre la longueur souhaitée,

puis laissez-le se rétracter après la série de cliquètements.

DÉVERROUILLER L'ENROULEUR

Tirez doucement sur le tuyau jusqu'à ce que le cliquètement s'arrête,

puis laissez-le se rétracter jusqu'à ce que la butée sphérique soit

bloquée par le support cylindrique du guide tuyau. NE LÂCHEZ

JAMAIS LE TUYAU!

AVERTISSEMENT: risque de blessure. Ne lâchez jamais le

tuyau lorsqu'il se rétracte.

AVERTISSEMENT: déconnectez toujours l'outil ou accessoire

pneumatique attaché à l'enrouleur de l'alimentation en air avant

d'effectuer des réglages ou de changer d'accessoire.

RÉGLER LA TENSION DE RECUL

1. Déconnectez l'alimentation en air de l'enrouleur de tuyaux.

2 Tirez sur le tuyau pneumatique sur environ 50 centimètres, puis

verrouillez-le (voir Verrouiller l'enrouleur).

3. Retirez la butée sphérique en deux parties en retirant les 2 vis

cruciformes, les rondelles et les écrous.

4. Ramenez le tuyau vers l'arrière en le faisant passer par le support cylindrique du guide tuyau (remarque: le tambour de

l'enrouleur doit toujours rester verrouillé).

5. Pour augmenter la tension, enroulez le tuyau une fois autour du

Français

15

Page 16

tambour.

6. Pour diminuer la tension, déroulez le tuyau une fois.

7. Faites repasser le tuyau par le support cylindrique du guide

tuyau, puis tirez dessus pour vérier la tension. Réinstallez la

butée sphérique.

8. Connectez l'alimentation en air.

AVERTISSEMENT: étant donné que l'enrouleur est tendu,

soyez prudent et assurez-vous que le mécanisme de verrouillage

ne se relâche pas pendant que vous réglez la tension.

REMPLACER LE TUYAU

1. Déconnectez l'alimentation en air et retirez le tuyau d'alimentation

de l'enrouleur.

2. Retirez la butée sphérique en deux parties en retirant les 2 vis

cruciformes, les rondelles et les écrous. Mettez ces éléments de

côté.

3. Tirez délicatement sur le tuyau pneumatique pour le sortir complètement de l'enrouleur jusqu'à ce que le collier qui relie le tuyau

Français

au tambour de l'enrouleur soit visible, puis assurez-vous que

l'enrouleur est bien verrouillé.

AVERTISSEMENT: étant donné que l'enrouleur est sous ten-

sion, assurez-vous de ne pas tourner le tambour de l'enrouleur

ou de ne pas tirer sur le tuyau tant qu'il est verrouillé.

4. Retirez le collier du tuyau (situé à l'intérieur du tambour de

l'enrouleur - non illustré) et mettez-le de côté.

5. Déconnectez délicatement l'extrémité du tuyau (K) du côté de

l'enrouleur, puis retirez le tuyau à remplacer.

6. Retirez le ressort de protection (L) du tuyau à remplacer. Installez

le ressort de protection (L) sur le nouveau tuyau et faites passer

le tuyau par le support cylindrique du guide tuyau, puis dans

l'encoche située dans le tambour (M).

7. Appliquez un joint d'étanchéité sur les letages du tuyau, connectez le tuyau à l'enrouleur (K), puis serrez-le.

8. Attachez le tuyau à l'intérieur du tambour à l'aide du collier de

serrage. Avant de serrer le collier, faites en sorte que le tuyau ait

une courbe large (N) et qu'il ne présente aucun nœud.

9. Assurez-vous que le ressort de protection du tuyau (L) a été placé

au bon endroit (voir Figure 3).

10. Tirez sur le tuyau pneumatique pour déverrouiller l'enrouleur, puis

rembobinez-le lentement. Ne lâchez jamais le tuyau.

11. Attachez de nouveau la butée sphérique à l'emplacement souhaité sur le tuyau.

12. Reconnectez le tuyau d'alimentation à l'enrouleur, puis activez

l'alimentation en air. Inspectez tous les raccords pour vérier

qu'ils ne présentent aucune fuite.

Figure 3

RENSEIGNEMENTS POUR L'ENTRETIEN

Merci de communiquer les renseignements suivants lors de chaque

16

Page 17

appel au service clientèle:

Numéro du modèle _______________________________________

Date et lieu d'achat _________________________________

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D'AVERTISSEMENT: si vous perdez vos étiquettes

d'avertissement ou qu'elles deviennent illisibles, appelez le

1-800-4-D

e

WA LT pour les remplacer gratuitement.

GARANTIE

GARANTIE LIMITÉE D'UN AN: DeWA LT Industrial Tools (la

Société) s'engage, pendant une période de douze (12) mois

à compter de la date d'achat, à remplacer ou à réparer

gratuitement, pour l'acheteur d'origine uniquement, toute pièce

fabriquée par la Société qui, après examen de la Société ou

de ses représentants légaux, s'avèrerait défectueuse en raison

d'un vice de matière, de fabrication, ou les deux. Tous les frais

de transport induits par un remplacement ou une réparation de

pièce en vertu de la présente garantie devront être pris en charge

par l'acheteur d'origine. Il s'agit du seul recours possible en vertu

de la présente garantie.

L'incapacité de l'acheteur d'origine à installer, entretenir et

utiliser ledit équipement conformément aux bonnes pratiques de

l'industrie, ou son incapacité à respecter les recommandations

spécifiques de la Société établies dans le manuel du propriétaire

annulera les termes de la présente garantie. La Société rejette

toute responsabilité pour les réparations, remplacements ou

ajustements à l’équipement ou pour tous coûts reliés au travail

effectué sur l’équipement par l’acheteur sans l’autorisation

préalable écrite de la Société. La corrosion, l'érosion, ainsi que

l'usure et les fissures normales sont expressément exclues de la

présente garantie.

LA SOCIÉTÉ N’OFFRE AUCUNE AUTRE GARANTIE,

NI REPRÉSENTATION DE QUELQUE SORTE QUE CE

SOIT, EXPRESSE OU IMPLICITE, EXCEPTION FAITE DE

LA PROPRIÉTÉ. TOUTES LES GARANTIES IMPLICITES

SONT REJETÉES PAR LA PRÉSENTE, EN PARTICULIER

TOUTES LES GARANTIES DE COMMERCIALISATION

ET D’ADÉQUATION À UN USAGE PARTICULIER. TOUTE

RESPONSABILITÉ POUR DES DOMMAGES INDIRECTS EN

VERTU D’UNE OU DE TOUTES LES GARANTIES, D’AUTRES

CONTRATS, DE LA NÉGLIGENCE OU D’AUTRES DÉLITS

CIVILS EST EXCLUE CONFORMÉMENT AUX CLAUSES

D’EXCLUSION AUTORISÉES PAR LA LOI.

Nonobstant ce qui précède, toute revendication légale

à l'encontre de la Société sera impossible si l'action légale

en question débute plus de vingt-quatre (24) mois après la

date d'achat ou de livraison, selon ce qui survient en dernier.

La présente garantie constitue l'intégralité de l'accord entre

la Société et l'acheteur d'origine, et aucun représentant ou

agent n'est autorisé à modifier les termes de la présente sans

l'autorisation écrite expresse de la Société.

Français

17

Page 18

Carrete de manguera de aire DXCM024-0344

A. Salida de la línea de aire (hacia la herramienta/el accesorio de

aire)

B. Limitador de flexión de la manguera

C. Retén de bola

D. Soporte del rodillo guía de la manguera

E. Brazo guía de la manguera

F. Tambor del carrete de manguera

G. Soporte de montaje

H. Manguera de aire

I. Conector pivotante de entrada de línea de aire (del compresor)

J. Manguera de aire de entrada

Especicaciones

MODELO DXCM024-0344

PESO NETO 46.3 lbs. (21 kg)

ENTRADA DE AIRE 1/2" NPT (12,7 mm)

(female/hembra/femelle)

TIPO DE MANGUERA DE AIRE Rubber

TAMAÑO DE LA MANGUERA DE

AIRE

PRESIÓN MÁXIMA DE

OPERACIÓN DE LA MANGUERA

LONGITUD DE LA MANGUERA

Español

DE AIRE

1/2" (12,7 mm)

250 PSI (1,724 kPa)

50' (15,2 m)

FIG. 1

18

Page 19

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada advertencia. Lea el manual y preste atención a estos

símbolos.

PELIGRO: Indica una situación de peligro inminente que,

si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro

potencial que, si no se evita, podría provocar la muerte o

lesiones graves.

ATENCIÓN: Indica una situación de peligro potencial

que, si no se evita, puede provocar lesiones leves o

moderadas.

AVISO: Se refiere a una práctica no relacionada a lesiones

corporales que de no evitarse puede resultar en daños a

la propiedad.

SI TIENE PREGUNTAS O COMENTARIOS ACERCA DE ESTA O

DE CUALQUIER OTRA HERRAMIENTA D

NÚMERO GRATUITO: 1-800-4-D

e

WALT (1-800-433-9258).

e

WALT, LLÁMENOS AL

Instrucciones de seguridad importantes

ADVERTENCIA:Algunos polvos que se producen al lijar,

cortar, esmerilar o perforar con herramientas eléctricas, así como

en otras actividades de construcción, contienen químicos que

el estado de California sabe que provocan cáncer, defectos

congénitos u otros daños al aparato reproductor. Algunos

ejemplos de estos químicos son:

• plomo en las pinturas a base de plomo;

• sílice cristalino en los ladrillos, el cemento y en otros

productos de mampostería;

• arsénico y cromo en la madera tratada con químicos.

El riesgo de estas exposiciones varía en función de la

frecuencia con la que se realice este tipo de trabajo. Para

reducir la exposición a estos químicos, cuando utilice dichas

herramientas: trabaje en un área bien ventilada, utilice equipo

de seguridad aprobado y use siempre una máscara o un

respirador que se ajusten correctamente y que estén aprobados

por la Administración de Seguridad y Salud Ocupacional

(Occupational Safety and Health Administration, OSHA)/la

Administración de Seguridad y Salud de Minas (Mine Safety

and Health Administration, MSHA)/el Instituto Nacional

de Seguridad y Salud Ocupacional (National Institute for

Occupational Safety and Health, NIOSH). Al usar herramientas

de aire, siempre se deben seguir precauciones de seguridad

básicas para reducir el riesgo de sufrir lesiones personales.

ADVERTENCIA: Este producto contiene químicos que según

el estado de California provocan cáncer, defectos congénitos u

otros daños al aparato reproductor. Lávese las manos antes de

manipular.

CONSERVE ESTAS INSTRUCCIONES

ADVERTENCIA:

La operación o el mantenimiento incorrectos de

este producto podrían provocar lesiones graves y

daños materiales. Lea todas las advertencias e

instrucciones de operación antes de usar este

equipo, y asegúrese de entenderlas. Al usar

herramientas de aire, siempre se deben seguir

precauciones de seguridad básicas para reducir el

riesgo de sufrir lesiones personales.

Español

19

Page 20

ADVERTENCIA:

Antes de instalar, operar o dar servicio a este carrete de

manguera, lea este manual de instrucciones y las

etiquetas de la herramienta, y asegúrese de entenderlas.

Mantenga estas instrucciones en un lugar seguro y

accesible.

Los operadores y el personal presentes en el área de

trabajo deben usar gafas de seguridad, con protectores

laterales, aprobadas según los estándares ANSI Z87.1 y

CAN/CSA Z94.3.

Los operadores y el personal presentes en el área de

trabajo deben usar protección para los ojos.

ADVERTENCIA:

• No use oxígeno ni gases reactivos; se podría producir una

explosión.

• No supere una presión de aire de 250 PSI.

• Lea detenidamente todos los manuales que se incluyen con

este producto. Familiarícese bien con los controles y el uso

correcto del equipo.

• No supere las capacidades nominales de presión de los

componentes del sistema.

• Desconecte la herramienta de aire del suministro de aire antes

de cambiar herramientas o accesorios, y cuando no se esté

usando.

• Siempre use accesorios diseñados para usarse con

herramientas neumáticas.

• No use accesorios dañados o desgastados.

Español

• Revise las mangueras de aire en busca de condiciones de

desgaste o debilitamiento antes de cada uso. Confirme que

todas las conexiones estén bien aseguradas.

• Mantenga todas las tuercas, los pernos y los tornillos

apretados y asegúrese de que el equipo esté en condiciones

de funcionamiento seguro.

PELIGRO: RIESGO DE EXPLOSIÓN O INCENDIO

LO QUE PUEDE OCURRIR CÓMO EVITARLO

• Superar la capacidad

nominal de presión máxima

de los accesorios de herramientas podría provocar

una explosión que ocasione

lesiones graves.

PELIGRO: RIESGO PARA LA RESPIRACIÓN (ASFIXIA)

LO QUE PUEDE OCURRIR CÓMO EVITARLO

• Las herramientas abrasivas,

como las esmeriladoras, las

lijadoras y las herramientas

de corte producen polvo y

materiales abrasivos que

pueden ser dañinos para

los pulmones y el sistema

respiratorio humano.

PRECAUCIÓN: RIESGO POR RUIDO

• Use aire comprimido

regulado a una presión

máxima igual o menor

a la presión nominal

de los accesorios.

• Cuando utilice dichas

herramientas, use siempre

una máscara o un respirador

que se ajusten correctamente

y que estén aprobados por la

MSHA/el NIOSH.

20

Page 21

LO QUE PUEDE OCURRIR CÓMO EVITARLO

• La exposición al ruido a largo

plazo que se produce con la

operación de herramientas de

aire puede provocar pérdida

auditiva permanente.

ADVERTENCIA: RIESGO DE OBJETOS QUE SALEN

LO QUE PUEDE OCURRIR CÓMO EVITARLO

• El equipo neumático y las

herramientas eléctricas

pueden lanzar materiales

como virutas metálicas,

serrín y otros residuos a alta

velocidad, lo que podría

provocar lesiones oculares

graves.

• El aire comprimido puede

ser peligroso. El chorro de

aire puede provocar lesiones

en áreas de tejido blando

como los ojos, los oídos, etc.

Las partículas o los objetos

que lanza el chorro pueden

provocar lesiones.

• Siempre use protección

auditiva según los estándares

ANSI (S3.19).

DISPARADOS

• Siempre use gafas de

seguridad, con protectores

laterales, aprobadas según los

estándares ANSI Z87.1 y CAN/

CSA Z94.3.

• Nunca deje herramienta

funcionando sin supervisión.

Desconecte la manguera de

aire cuando no se esté usando

la herramienta.

• Para mayor protección, use un

protector facial además de las

gafas de seguridad.

ADVERTENCIA: RIESGO DE RIESGO DE LESIÓN

LO QUE PUEDE OCURRIR CÓMO EVITARLO

• Las herramientas neumáticas

pueden despedir objetos flojos

u otros materiales en el área

de trabajo.

• El exceder la clasificación

máxima presión de la

herramienta o de los

accesorios podrá causar una

explosión resultando en

lesiones graves.

• Mantenga el área de trabajo

limpia y libre de obstrucciones.

Mantenga a los niños y otros

alejados del área de trabajo

mientras opera la herramienta

• Mantenga el área bien

alumbrada.

•

Use aire comprimido regulado

a la presión máxima o por

debajo de la clasificación de

presión de cualquier accesorio.

•

Nunca use oxígeno, dióxido de

carbono u otro gas

embotellado como fuente

deenergía para las

herramientas neumáticas.

•

Proteja la manguera de aire de

daños y perforaciones.

•

Revise las mangueras de aire

para ver si están desgastadas

o débiles antes de cada uso.

Asegúrese de que todas las

conexiones estén seguras.

CONSERVE ESTAS INSTRUCCIONES PARA

USARLAS EN EL FUTURO

Español

21

Page 22

CARACTERÍSTICAS

CONECTOR PIVOTANTE DE ENTRADA DE LÍNEA DE AIRE

El conector pivotante de

entrada de línea de aire (I) tiene

rosca NPT de 1/2” y se encuentra

en el lado del carrete de

manguera. Esto permite

conectarlo fácilmente a una

fuente de aire.

SOPORTE DE MONTAJE

El soporte de montaje (G) es

una placa metálica con pintura

en polvo que se puede montar

fácilmente en una pared, un techo

o un piso.

MANGUERA DE AIRE DE

ENTRADA

La manguera de entrada (J) es

de 1/2” x 4 ft de largo y tiene una

conexión pivotante en un extremo

para evitar que la manguera se

retuerza. Se conecta a la entrada

de línea de aire (I).

SALIDA DE LA LÍNEA DE AIRE

La salida de la línea de aire (A)

tiene rosca NPT de 1/2” y se

encuentra en el extremo de la

manguera de aire (H) para una

Español

conexión conveniente de los accesorios o las herramientas de aire.

MANGUERA DE AIRE

La manguera de aire (H) es de 1/2” x 50 ft y está conectada al

carrete de manguera.

RETÉN DE BOLA

El retén de bola (C) es ajustable y permite guardar de forma

permanente la longitud de manguera deseada fuera del carrete de

manguera.

LIMITADOR DE FLEXIÓN DE LA MANGUERA

El limitador de la manguera (B) reduce la tensión de flexión cerca

del accesorio, lo que previene los daños y alarga la vida útil de la

manguera (H).

INSTALACIÓN

1. Elija un lugar de montaje que esté libre de cableado eléctrico

u otras obstrucciones y que sea lo suficientemente resistente para soportar el peso del carrete de manguera y de la

manguera, así como la fuerza que se usa para desenrollar la

manguera y retraerla. El carrete de manguera se puede montar

en el piso, el techo o la pared (vea la figura 2).

Pared Piso Techo

Figura 2

2. Use la plantilla de montaje incluida para marcar y perforar los

lugares de los orificios.

3. Monte el carrete de manguera en el lugar deseado. Compre los

sujetadores adecuados en su ferretería local. Necesitará

distintos tipos de material para cada posición de montaje.

22

Page 23

4. Si es necesario hacer un ajuste para aumentar o disminuir la

longitud de la manguera que sale del carrete de manguera, jale

la manguera lentamente hasta que se trabe a la longitud

deseada. Afloje los pernos del retén de bola (C) y deslice el retén

de la manguera hasta una posición cercana al soporte del rodillo

guía de la manguera (D). Vuelva a apretar los pernos del retén de

bola. No apriete excesivamente los pernos

ADVERTENCIA:

1) Asegúrese de que el carrete de manguera esté seguro antes

de cada uso.

2) Nunca lo conecte a una fuente de aire que tenga más de 250

PSI.

3) Inspeccione la manguera de aire antes de cada uso para

asegurarse de que no tenga fugas.

4) No enrolle la manguera en ninguna parte del cuerpo.

CONEXIÓN AL COMPRESOR

El carrete de manguera

incluye una manguera de

entrada de 1/2” x 4 ft para

conectar el carrete de

manguera a la fuente de

aire. Aplique cinta de teflón

a la rosca exterior de la

manguera de entrada y

enrosque el extremo no

pivotante en la entrada de

la manguera de aire (I). Enrosque y conecte el otro extremo a la

fuente de aire. Conecte la herramienta o el accesorio de aire a la

salida de aire de la manguera de aire en el carrete de manguera.

FUNCIONAMIENTO

Revise el funcionamiento del carrete jalando lentamente la manguera

para desenrollarla. Oirá un chasquido.

CÓMO TRABAR EL CARRETE DE MANGUERA

Jale la manguera lentamente para desenrollarla hasta alcanzar la

longitud deseada de manguera, deje que se retraiga después de

que oiga una serie de chasquidos.

CÓMO DESTRABAR EL CARRETE DE MANGUERA

Jale la manguera lentamente para desenrollarla hasta que se

detenga el ruido de chasquido, deje que se retraiga hasta que

el retén de bola descanse sobre el soporte del rodillo guía de la

manguera. ¡NO SUELTE POR COMPLETO LA MANGUERA!

ADVERTENCIA: Riesgo de lesiones. No suelte por completo

la manguera al dejar que se retraiga.

ADVERTENCIA: Siempre desconecte la herramienta o el

accesorio de aire que esté conectado al carrete de manguera del

suministro de aire antes de hacer cualquier ajuste o de cambiar

accesorios.

CÓMO AJUSTAR LA TENSIÓN DE

REBOBINADO

1. Desconecte el suministro de aire del carrete de manguera.

2. Desenrolle unos 60 cm de manguera de aire y trábela en su sitio

(consulte “Cómo trabar el carrete de manguera”).

3. Retire el retén de bola de 2 piezas: saque los 2 tornillos de cabeza Phillips, las arandelas y las tuercas.

4. Vuelva a meter la manguera por el soporte del rodillo guía de

la manguera. (Nota: Mantenga el tambor del carrete de

manguera trabado en todo momento).

5. Para aumentar la tensión, enrolle la manguera en el tambor una

vez.

23

Español

Page 24

6. Para disminuir la tensión, desenrolle la manguera del tambor una

vez.

7. Meta la manguera por el soporte del rodillo guía de la manguera

y desenrolle la manguera del carrete de manguera para vericar

la tensión. Vuelva a instalar el retén de bola.

8. Conecte el suministro de aire de entrada.

ADVERTENCIA: El carrete se encuentra bajo tensión, así que

tenga cuidado de que el mecanismo de traba del carrete no se

suelte mientras ajusta la tensión.

REEMPLAZO DE LA MANGUERA

1. Desconecte el suministro de aire y retire la manguera guía del

carrete de manguera.

2. Retire el retén de bola de 2 piezas: saque los 2 tornillos de cabeza Phillips, las arandelas y las tuercas. Colóquelo a un lado.

3. Desenrolle con cuidado toda la manguera de aire del carrete

de manguera hasta que pueda ver la abrazadera que sujeta la

manguera al tambor del carrete de manguera; luego, asegúrese

de que el carrete de manguera esté trabado.

ADVERTENCIA: El carrete está bajo tensión, así que no gire el

tambor del carrete de manguera ni jale la manguera cuando el

carrete esté trabado.

4. Retire la abrazadera de la manguera (se encuentra en el interior

del tambor del carrete de manguera, no se muestra) y colóquela

a un lado.

5. Desconecte con cuidado el extremo de la manguera (K) del lateral del carrete de manguera y retire la manguera vieja.

6. Retire el resorte de protección de la manguera (L) de la manguera

Español

vieja. Coloque el resorte de protección (L) en la nueva manguera

y luego meta la manguera por el soporte del rodillo guía de la

manguera y por la ranura del tambor (M).

7. Aplique cinta selladora de rosca a la rosca de la manguera y

conecte esta última al carrete de manguera (K) y apriétela.

8. Fije la manguera al interior del tambor con la abrazadera de

la manguera. Asegúrese de que la manguera tenga una curva

amplia (N) y que no esté retorcida antes de apretar la abrazadera

de la manguera.

9. Asegúrese de que el resorte de protección de la manguera (L)

esté en el lugar correcto (consulte la gura 3).

10. Jale la manguera para destrabarla y rebobine lentamente la

manguera de aire. No suelte por completo la manguera.

11. Vuelva a instalar el retén de bola en el lugar deseado de la

manguera.

12. Vuelva a conectar la manguera de entrada al carrete de

manguera y active el suministro de aire. Revise todas las conexiones para asegurarse de que no haya fugas.

Figura 3

24

Page 25

INFORMACIÓN DE SERVICIO

Tenga la siguiente información disponible para todas las llamadas

de solicitud de servicio:

Número de modelo ________________________________________

Fecha y lugar de compra _________________________________

REEMPLAZO GRATUITO DE ETIQUETAS DE ADVERTENCIA:

Si las etiquetas de advertencia ya no pueden leerse o ya no están,

llame a 1-800-4-D

e

WALT para obtener reemplazos gratuitos.

GARANTÍA

GARANTÍA LIMITADA DE UN AÑO: DeWA LT Industrial Tools (la

Compañía) garantiza que durante un periodo de doce (12) meses

a partir de la fecha de compra reemplazará o reparará, sin cargo

alguno y únicamente para el comprador original, cualquier pieza

fabricada por la Compañía, cuya inspección por parte de la

Compañía, o de sus representantes designados, determine que

presentan defectos en los materiales y/o la mano de obra. Todos

los cargos de transporte de las piezas que se envíen para su

reemplazo o reparación al amparo de esta garantía deberán ser

cubiertos por el comprador original. Este es el remedio exclusivo

que brinda esta garantía.

Si el comprador original no instala, mantiene y opera dicho

equipo según las buenas prácticas del sector, o si no cumple

con las recomendaciones específicas de la Compañía que se

estipulan en el manual del propietario, esta garantía quedará

anulada. La Compañía no será responsable de reparaciones,

reemplazos o ajustes del equipo, ni de costos de mano de obra

realizada por el comprador sin la aprobación previa por escrito

de la Compañía. Los efectos de la corrosión, la erosión y el

desgaste normal quedan específicamente excluidos de esta

garantía.

LA COMPAÑÍA NO DA NINGUNA OTRA GARANTÍA NI

MANIFESTACIÓN DE NINGÚN TIPO, YA SEA EXPRESA

O IMPLÍCITA, A EXCEPCIÓN DE LA DEL TÍTULO DE

PROPIEDAD. POR LA PRESENTE, LA COMPAÑÍA NO

ASUME NINGUNA GARANTÍA IMPLÍCITA, INCLUIDAS LAS

GARANTÍAS DE COMERCIABILIDAD Y DE IDONEIDAD

PARA UN PROPÓSITO ESPECÍFICO. SE EXCLUYE

TODA RESPONSABILIDAD POR DAÑOS Y PERJUICIOS

EMERGENTES O INCIDENTALES EN VIRTUD DE

CUALQUIER OTRA GARANTÍA, OTROS CONTRATOS,

NEGLIGENCIA U OTROS ACTOS DE AGRAVIO, EN LA

MEDIDA EN QUE LA LEY ASÍ LO PERMITA.

Sin perjuicio de lo anterior, cualquier reclamación legal en contra

de la Compañía estará prohibida si la acción legal no comienza

dentro de los veinticuatro (24) meses de la fecha de compra o de

la entrega, lo que ocurra después. Esta garantía constituye todo

el acuerdo entre la Compañía y el comprador original, y ningún

representante o agente está autorizado a alterar los términos de

25

la misma sin el consentimiento escrito de la Compañía.

Español

Page 26

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(FEB18) Part No.DXCM024-0344 Copyright © 2017, 2018 D

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill;

EWALT

the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...