Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

DWX726

Rolling Miter Saw/Planer Stand

Plate-forme mobile pour scie à onglet/raboteuse

Base de soporte rodante para sierra para corte de ingletes/cepiladora

Page 2

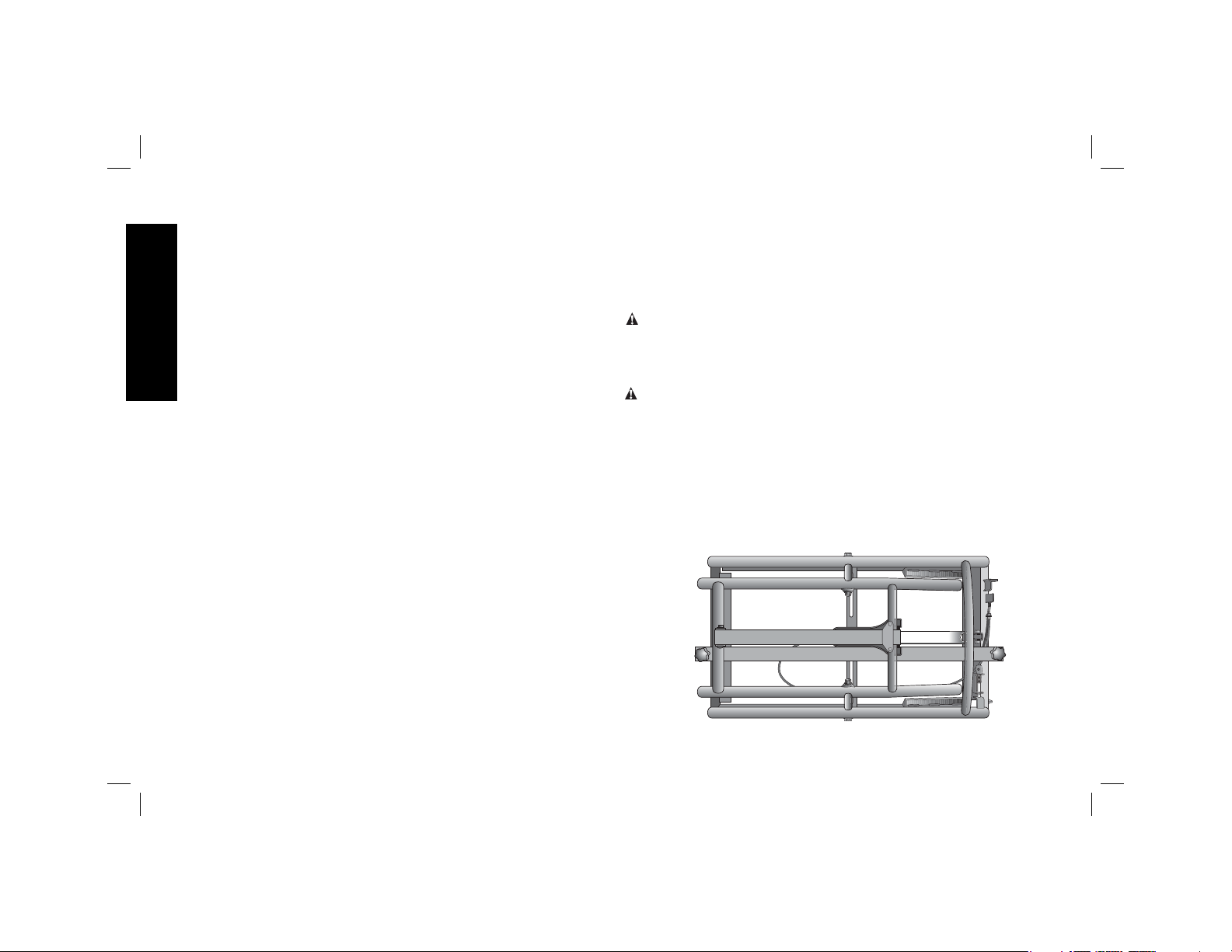

DWX726 Universal Miter Saw/Planer Stand

Components List

A. Mounting rails

B. Work support arm

C. Storage foot

English

D. Wheels

E. Leg extension

F. Vertical locking knob

G. Horizontal locking knob

H. Extension arm

I. Handle

I

FIG. 1

H

H

A

B

G

F

C

D

E

2

Page 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay attention

to these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

E

(1-800-433-9258).

This Rolling Miter Saw/Planer Stand is a stand designed to

accommodate most miter saws and planers and to provide portability

for those units, both in the field and in the shop. If you have any

problem with alignment or mounting, call 1-800-4-D

433-9258).

WALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

EWALT (1-800-

SAFETY RULES

WARNING: For your own safety, read the tool instruction

manual before using any accessory. Failure to heed these

warnings may result in personal injury and serious damage to

the tool and the accessory. When servicing this tool, use only

identical replacement parts.

WARNING: Failure to follow these rules may result in serious

personal injury.

WARNING: To reduce the risk of injury, keep both hands on

handle when raising and lowering the stand. The stand has

gas assist lifting and may raise unexpectedly when lever is

released.

• This product was designed to be used as a stand for miter

saws and planers. The stand will support up to 300 lbs (136 kg).

Any misuse or abuse can result in product damage or personal

injury.

• Do not stand on the work table. It is unsafe to climb, sit or stand

on the stand. Do not use the support extensions as a ladder or

scaffolding.

• Properly secure the miter saw or planer to the stand before

operation. Follow the mounting instructions carefully. Fasten the

tool to the saw mounting rails securely as instructed.

• Place the stand on a flat and level surface to prevent rocking

or tipping.

• Take care during the raising and lowering of the product to

reduce the hazard of pinching hands and fingers.

• Check the legs and other supports to see that they are

properly locked in place before operation.

• Do not modify or use the stand for any operation for which

it is not intended.

• ALWAYS use eye protection. All users and bystanders must wear

eye protection that conforms to ANSI Z87.1.

• ALWAYS use safety glasses. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty.

ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

English

1

Page 4

Carton Contents

1 Rolling miter saw/planer stand

1 Leg extension

1 Storage foot

2 Wheel/storage foot connector (left and right)

2 Extension work support assembly

1 Handle

English

2 Wheel

2 Axle

2 Work support arms (1 with black cap)

1 Hardware bag:

2 Cord wrap brackets (L, R)

6 M8 x 15 mm buttonhead screws

1 M8 x 25 mm buttonhead screw

6 Curved washers

2 Extension locking knobs

1 M8 lock washer

1 M6 x 10 mm button head screw

1 M6 lock washer

1 Hex wrench

Tools Required

• Hex wrench (supplied)

• Adjustable crescent wrench

• 1/2 inch open end wrench

• 3/4 inch open end wrench

UNPACKING AND CLEANING

Carefully unpack the product and all loose items from the shipping

container(s). Remove the rust-preventative oil from unpainted surfaces

using a soft cloth moistened with mineral spirits, paint thinner or

denatured alcohol.

NOTICE: Do not use highly volatile solvents such as gasoline,

naphtha, acetone or lacquer thinner for cleaning your stand.

Components (Fig. 1)

WARNING: Never modify the stand or any part of it. Damage or

personal injury could result.

Refer to Figure 1 for Components List.

ASSEMBLY

WARNING: PINCH HAZARD. To reduce the risk of serious

personal injury, do not raise or lower stand until the assembly of the

extension work supports is complete.

WRENCH STORAGE (FIG. 3)

The supplied hex wrench (J) comes in the wrench storage location in

the corner of the stand.

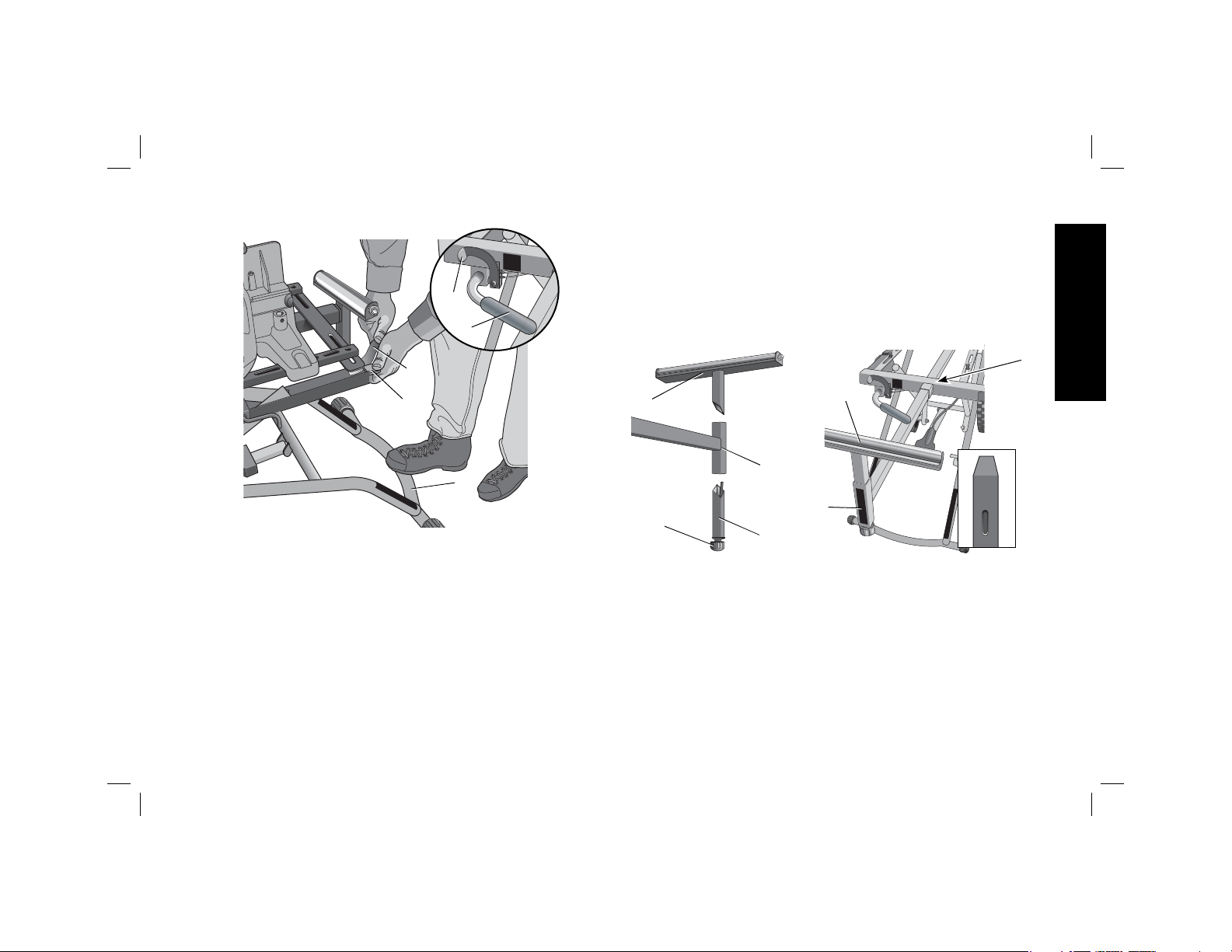

ATTACHING THE LEG EXTENSION (FIG. 2, 3)

IMPORTANT: Place stand upside down on the floor or on a level,

stable table as shown in Figure 2.

FIG. 2

2

Page 5

1. With stand upside down, insert the leg extension (E) in the

stand(K).

2. Align the holes and install two M8 x 15 mm buttonhead screws (L)

with curved washers (M).

3. Tighten securely with the supplied hex wrench.

FIG. 3

E

L, M

K

J

FIG 4

N

English

L, M

O

J

ATTACHING THE WHEEL AND STORAGE FOOT CONNECTOR

(FIG. 4)

1. With stand still upside down, insert the wheel/storage-foot

connector (N) to the stand (K) with wheel extension (O) facing

outward.

2. Align the hole and loosely install one M8 x 15 mm buttonhead

screw (L) with curved washer (M) for later adjustment.

NOTE: The screw will be tightened completely later in the

assembly.

3. Attach the other wheel/storage-foot connector in the same

manner.

K

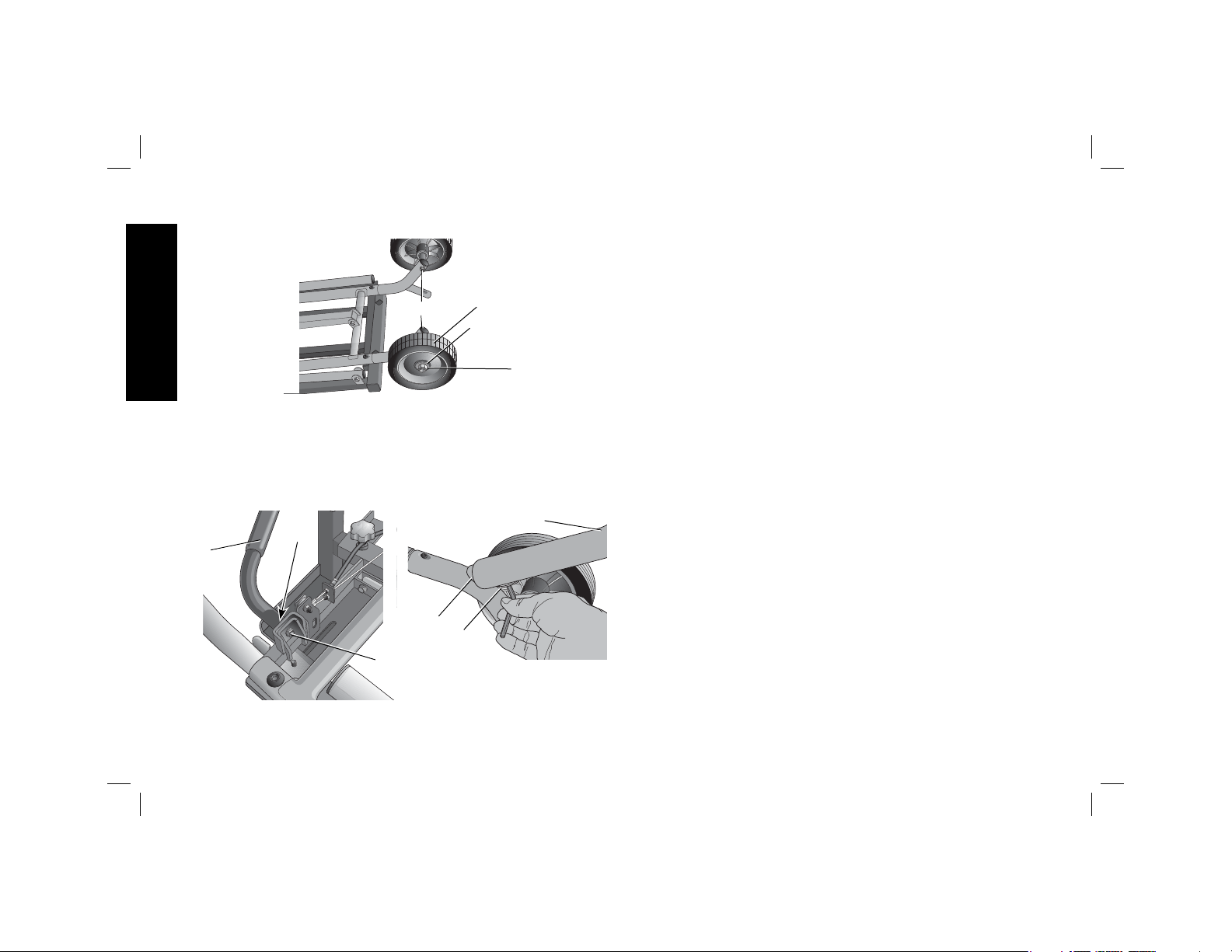

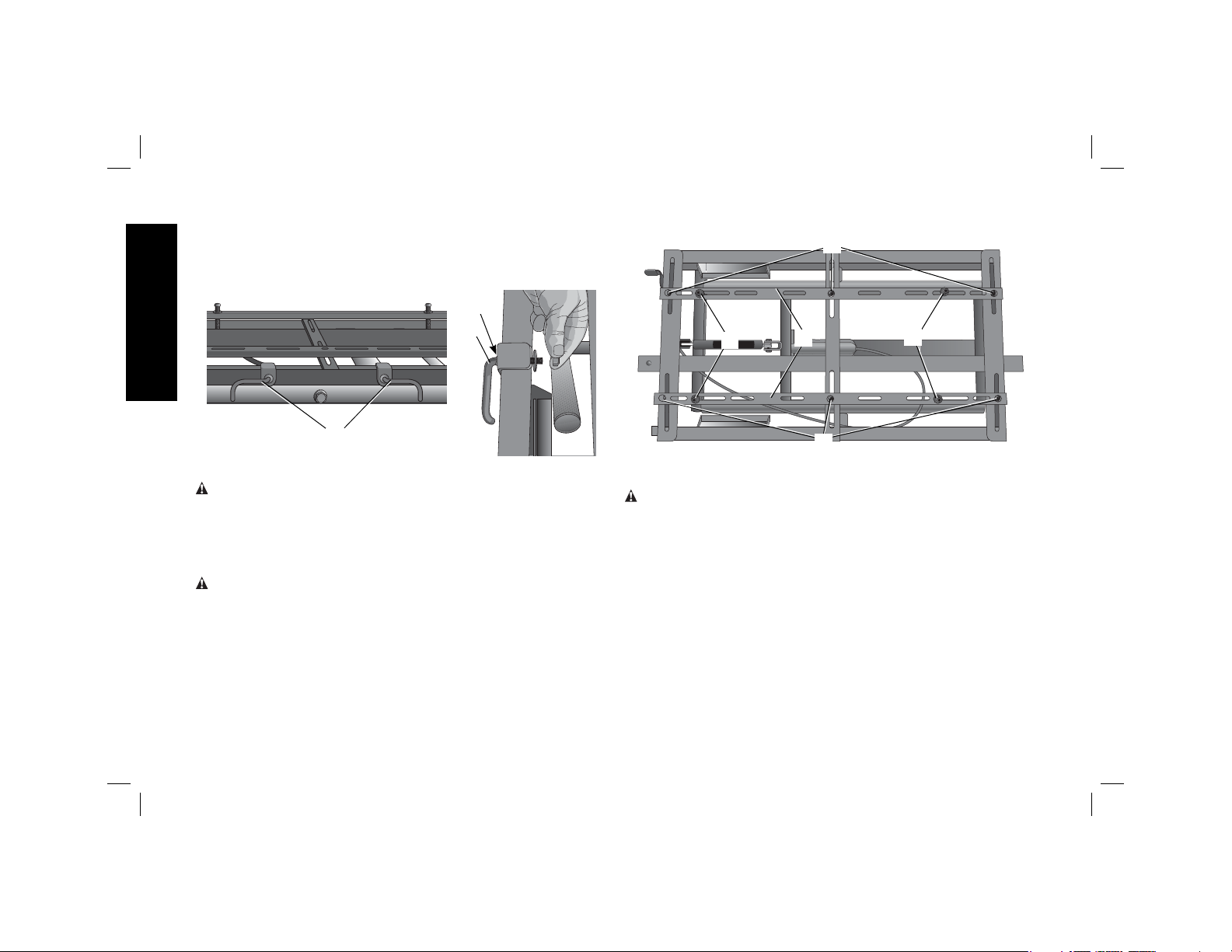

ATTACHING THE WHEELS (FIG. 5)

1. Continuing with stand upside down, remove washer/nut (Q, R)

from axle. Insert axle (P) from the inside of the wheel/storage-foot

connector.

2. Place one of the wheels (D) on the axle with the longer side of the

wheel hub facing inward.

3. Place the washer (Q) on the axle and attach the nut (R). Tighten

the nut.

NOTE: Do not overtighten. Overtightening may cause wheel

rotation to be impaired.

3

Page 6

4. Attach the other wheel in the same manner.

FIG. 5

P

D

Q

English

R

ATTACHING THE HANDLE (FIG. 6)

1. With stand upside down, attach the handle (I) on the end of the

stand opposite the wheels with one M8 x 25 mm buttonhead

screw (S) and lock washer on one side and one M6 x 10 mm

buttonhead screw (T) and lock washer on the other side.

2. Tighten securely with the supplied hex wrench.

FIG. 6

T

I

FIG. 7

N

L, M

S

C

ATTACHING THE STORAGE FOOT (FIG. 7)

IMPORTANT: Turn the stand right side up so the wheels and leg

extension sit level on the floor but the stand is not in a raised position.

1. With stand right side up, place the storage foot (C) over the

indentations of the wheel and storage-foot connector (N) so when

the stand is upright, the storage foot will angle upward.

2. Align the holes in storage foot and storage foot connector. Install

two M8 x 15 mm buttonhead screws (L) with curved washers (M)

to attach storage foot and the connector.

3. Tighten screws securely with the supplied hex wrench.

4. Securely tighten the storage-foot connector screws that were

loosely installed in Attaching the Wheel and Storage Foot

Connector.

TO RAISE AND LOWER THE STAND (FIG. 8)

1. Place your right foot on the bottom of the extension leg (E).

2. Grasp the handle (I) with both hands.

3. Use the thumb of your left hand to push down on the red activating

lever (V).

4. Lift up on the handle to release the safety mechanism, then raise

or lower the stand. After raising the stand a few inches, release the

red activating lever. The stand will automatically lock into place at

the next height setting.

The stand will adjust to two heights. Select the desired height and

lock into place.

4

Page 7

FIG. 8

4. Insert the assembled extension work support arm (B) with the

small black cap (inset, Fig. 10) into the hole (W) of the stand

closest to the red activating lever. Push the arm in to lock in place.

5. Repeat for other work support arm on opposite end. Push the arm

V

I

I

V

in to lock in place.

NOTE: The internal locking mechanism keeps the work supports from

disengaging.

FIG. 9

H1

FIG. 10

H

English

W

E

ATTACHING THE EXTENSION WORK SUPPORTS (FIG. 9, 10)

IMPORTANT: Be sure the longer side of the “T” in the work support

arm (B) is oriented down as shown in Figure 9. Refer to the label with

the arrow pointing down.

1. With the stand raised to desired height, place the top piece (H1)

of the work support into the top of the work support arm (B) hole.

Insert the bottom piece (H2) of the work support into the bottom

hole of the arm, with proper orientation to the top piece.

2. Tighten the vertical lock knob (F).

3. Repeat with the other extension work support.

B

B

F

H2

ATTACHING THE CORD WRAPS (FIG. 11, 12)

NOTE: Place the cord wraps (X) in opposite positions to hold the cord

securely.

1. Place the cord wrap screw (X) into the hole (Z) from outside of

stand. Place the washer and nut on cord wrap screw and finger

tighten nut.

5

Page 8

2. Using a crescent wrench or 1/2 inch open end wrench, tighten the

screw securely.

3. Repeat for the other cord wrap.

FIG. 11 FIG. 12

Z

X

English

FIG. 13

BB

AA

A

BB

X

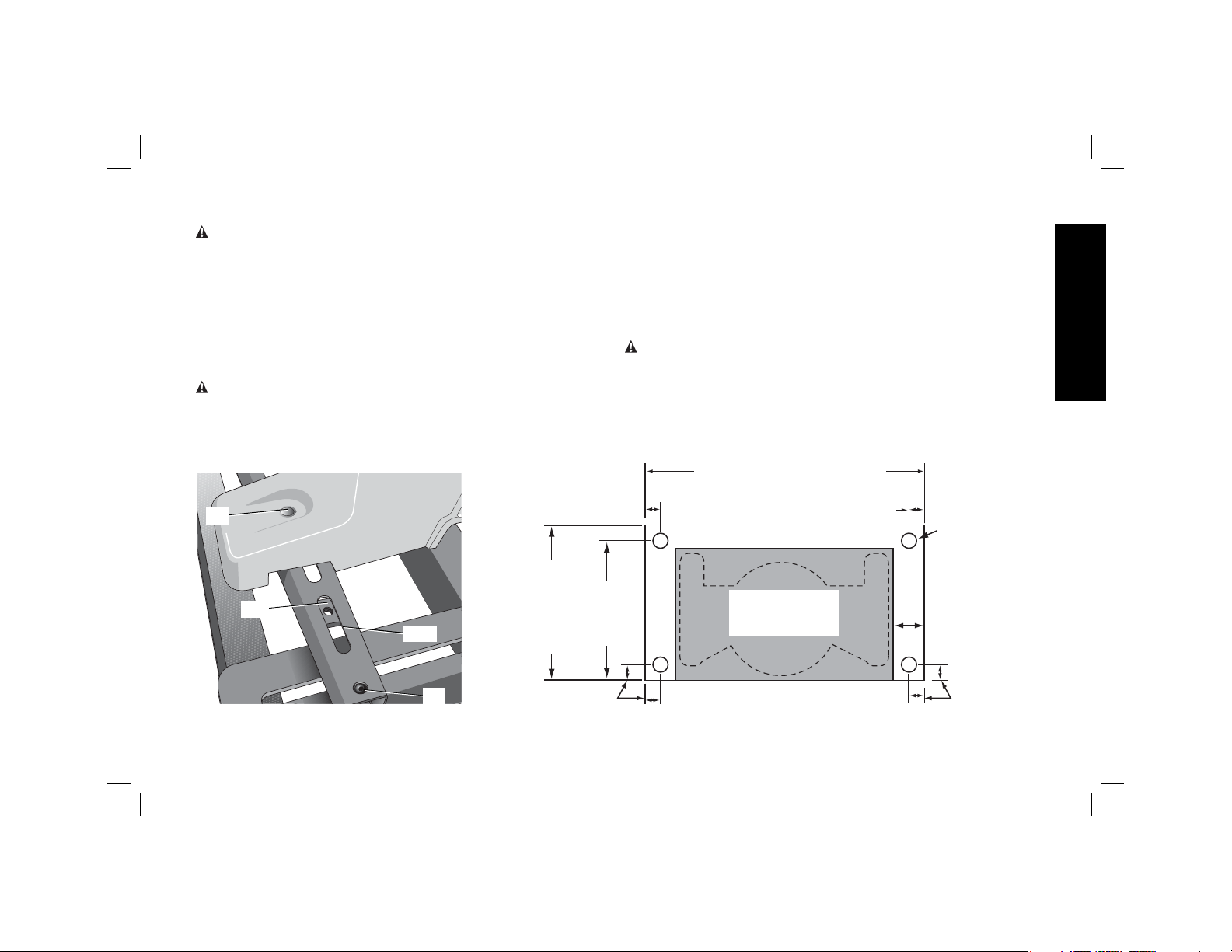

ATTACHING THE TOOL (FIG. 13–16)

WARNING: STABILITY HAZARD. Refer to your tool manufacturer’s

instructions regarding the securing of your miter saw or planer to a

stand or supporting surface. Secure the tool according to both the

instructions in this manual and those in your tool manufacturer’s

manual before operating. Failure to heed these warnings may result in

serious personal injury and serious damage to the tool.

WARNING: To reduce the risk of injury, turn miter saw or

planer off, disconnect the tool from the power source before

assembling the miter saw or planer to the stand. An accidental

start-up can cause injury.

1. Loosen the 6 rail screws (AA) with the supplied hex wrench.

Remove the mounting bolts/flat washers (BB) from the mounting

rails.

AA

2. Slide the mounting rails (A) to fit the width of the tool. Ensure the

mounting slots align the with holes in the tool’s feet.

WARNING: Planers MUST be mounted in the orientation shown in

Figure 16.

3. Place miter saw or planer on the mounting rails (A). Center the tool,

both forward and backward and side to side, on the stand.

4. Ensure the mounting holes (CC) in the tool’s feet align with the rail

slots (DD) and the captured nuts (EE) located in the mounting rails.

5. Once the two rails are in place, tighten the rail screws (AA)

loosened in STEP 1.

6. Insert the mounting bolts/flat washers (BB) (removed in STEP1)

through each of the tool’s feet into the captured nut (EE). Tighten

securely.

IMPORTANT: The miter saw or planer MUST be positioned so the tool

is bolted squarely to the mounting rails. If this is not possible, please

call 1-800-4-D

6

EWALT (1-800-433-9258) for technical assistance.

Page 9

WARNING: STABILITY HAZARD. If the tool’s mounting holes do

not line up with the slots in the mounting rails, mount the miter saw

or planer to a piece of 3/4 inch (19 mm) plywood (See Figure15 for

dimensions). The plywood must be a minimum of 4 inch (101.6mm)

wider than the tool base being mounted and a minimum depth of

16inch (406.4 mm). Plywood must be at least as deep as the tool

base being mounted. Drill 3/8inch (9.4 mm) holes near both ends of

the plywood to align with the slots in the mounting rails as described in

Attaching the Tool. Other hardware (not supplied) may be necessary

under these circumstances.

WARNING: STABILITY HAZARD. All purchased hardware must

be a minimum of Grade2. Hardware should be 1-1/4 inch (31.8mm)

longer than the thickness of the tool base you are assembling.

NOTICE: To prevent binding and/or inaccuracy, ensure the plywood

is not warped or uneven. If binding and/or inaccuracy occurs, replace

the plywood with a non-warped, even piece of plywood.

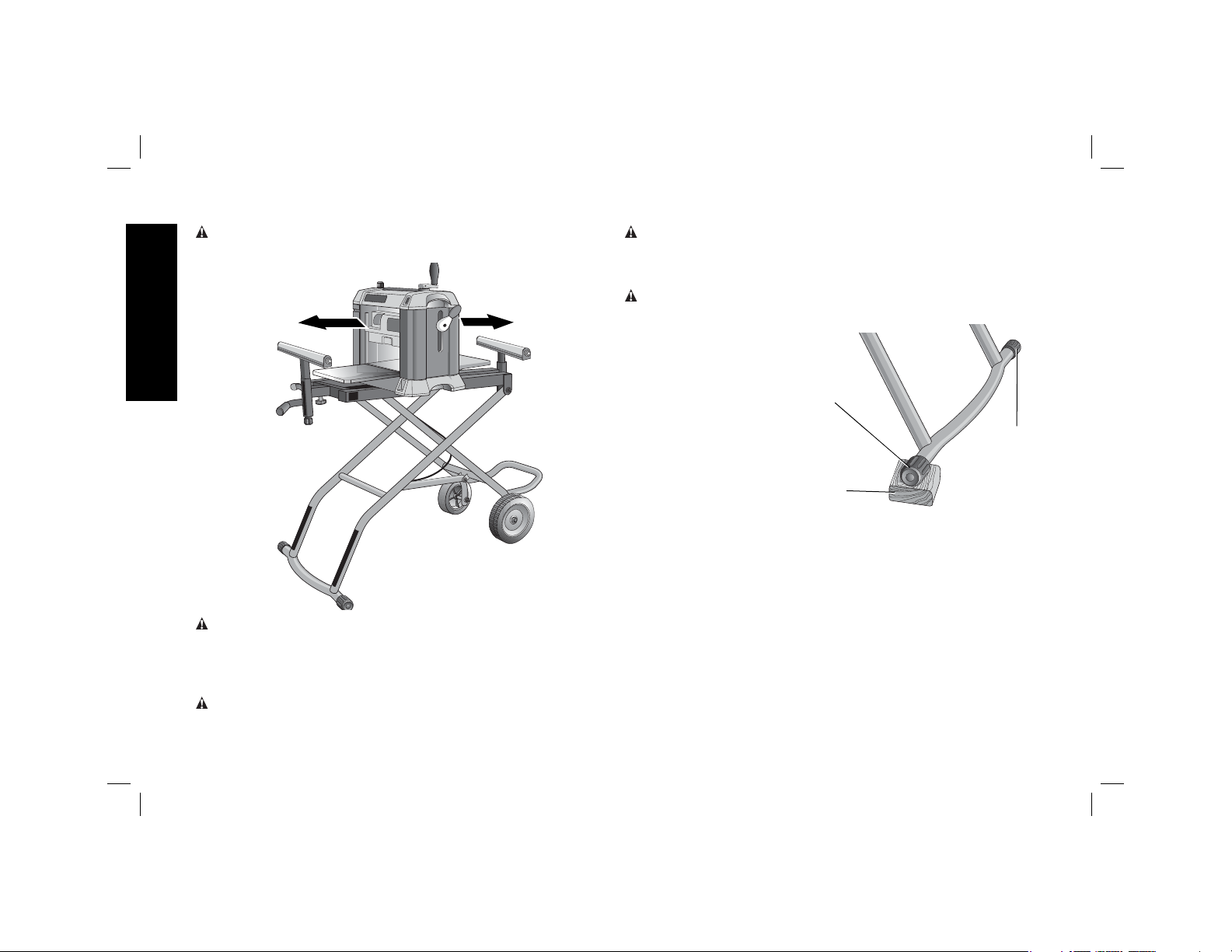

PRODUCT STABILITY TEST (FIG. 16–17)

The rolling miter saw/planer stand is designed to be used in

conjunction with a wide variety of miter saws, compound miter saws,

sliding compound miter saws and planers.

WARNING: Any tool used with this stand must be properly

positioned and secured to ensure stability and to prevent inadvertent

tipping.

English

FIG. 14

CC

EE

DD

AA

FIG. 15

MINIMUM OF

16" (406.4mm)

MUST BE AT

LEAST AS

DEEP AS THE

SAW BEING

MOUNTING

1" (25.5mm)

15"

((381mm)

BOTH

SIDES

7

WIDTH OF SAW + 4" (101.6mm)

1" (25.5mm)

MOUNT MITER

SAW IN SHADED

AREA

1" (25.5mm)

3/8" (9.5mm)

DIAMETER

HOLES, ALL 4

CORNERS

2" (50.8mm)

MINIMUM BOTH

SIDES

1" (25.5mm)

Page 10

WARNING: Planers MUST be mounted in the orientation shown

in Figure 16.

FIG 16

English

WARNING: To reduce the risk of serious personal injury, turn

tool off and disconnect tool from power source before installing

and removing accessories, before adjusting or changing setups or when making repairs. An accidental start-up can cause

injury.

WARNING: For your own safety, use two or more people to

perform the stability test or serious injury could result.

WARNING: The cuttinghead MUST be raised on all miter

saws, compound miter saws and sliding compound miter saws.

All sliding compound miter saws MUST be locked in the rear

position. Failure to do so may result in serious personal injury.

WARNING: STABILITY HAZARD. Stay alert. The stand may tip

during this procedure. Serious injury may result.

1. Ensure the tool is

FIG 17

securely mounted to

the stand and is turned

off and disconnected

from power source.

GG

2. Place a 2-1/2 inch

(63.5 mm) thick block

of wood (FF) under

HH

the front leg (GG) of

the stand so that the

front leg is raised 2-1/2

inches (63.5 mm) off

FF

the floor.

3. With one person in front of the stand, and the other person

behind, lift the front of the stand slightly, remove the block of wood,

and allow the stand to drop to the floor.

4. Perform this same test with the block of wood under the rear

leg(HH).

5. If the stand tends to tip to the front, reposition the tool toward the

rear of the stand. If the stand tends to tip to the rear, reposition the

tool forward. Make your adjustment, then repeat the test.

8

Page 11

OPERATION

WARNING: To reduce the risk of injury, keep both hands on

handle and the right foot on the extension leg when raising and

lowering the stand. The stand has gas assist lifting and may

raise unexpectedly when lever is released.

Refer to To Raise and Lower the Stand under Assembly to adjust

the stand to the desired height.

TO EXTEND THE EXTENSION WORK SUPPORTS (FIG. 18)

1. Turn the horizontal lock knob (G) counterclockwise.

2. Slide the extension work support (H) out or in, depending on the

length of the workpiece.

3. Tighten the horizontal lock knob.

4. Repeat with the other side.

FIG 18

TO ADJUST EXTENSION WORK SUPPORT HEIGHT

1. Turn the vertical lock knob (F).

2. Adjust the extension work support to the desired height.

3. Tighten the vertical lock knob.

4. Repeat with the other extension work support.

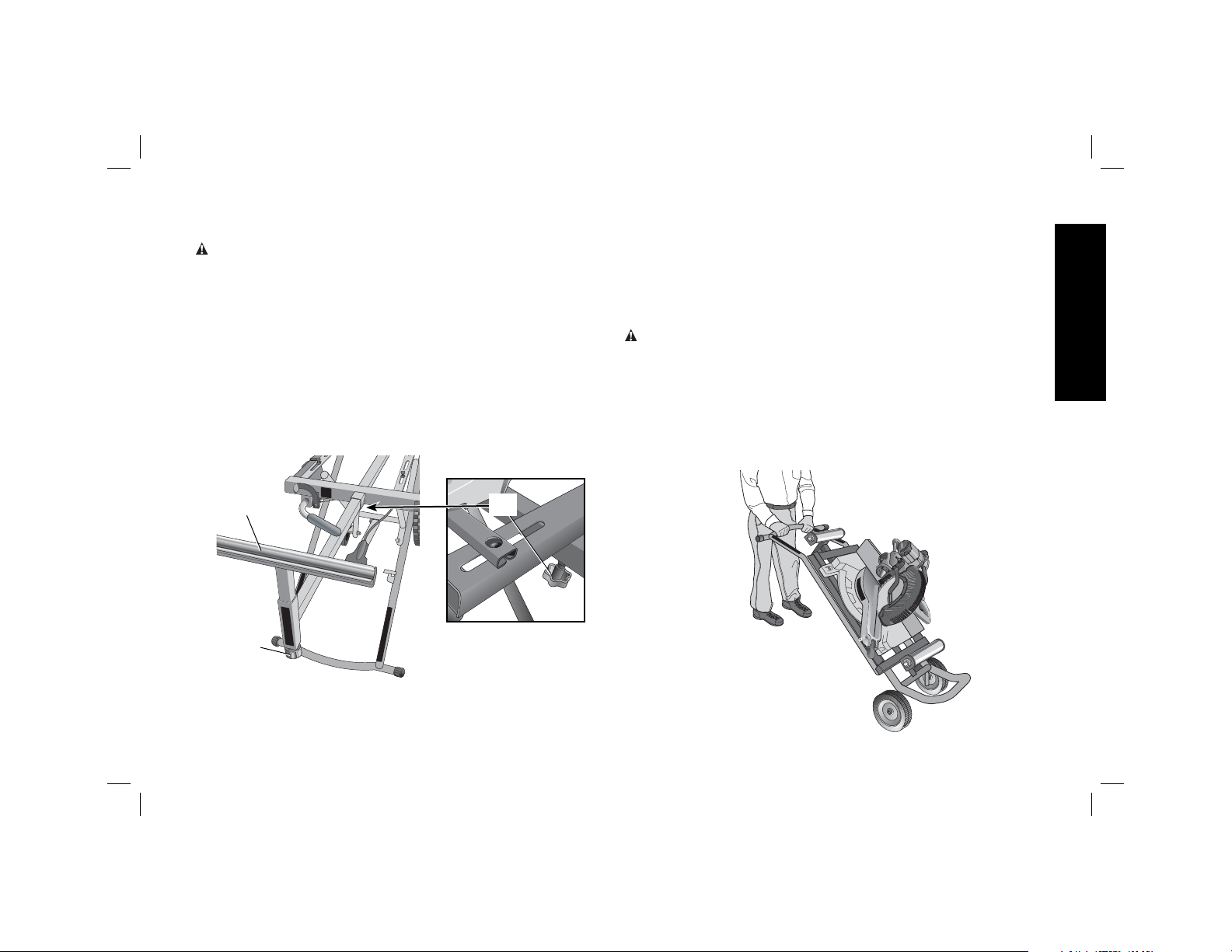

STORAGE AND TRANSPORTATION

WARNING: TIPPING HAZARD. The stand may tip when

storing or transporting the stand close to or in the vertical

position. Transport or store the stand in the horizontal position

to reduce the risk of the stand tipping.

To lower the stand into the storage position, push down on the red

activating lever, lift up on the handle, then exert downward pressure

on the handle.

Refer to Figure 19 for proper transporting position.

FIG 19

English

H

F

G

9

Page 12

Accessories

WARNING: Since accessories, other than those offered by DEWALT,

have not been tested with this product, use of such accessories with

this tool could be hazardous. To reduce the risk of injury, only D

recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

English

need assistance in locating any accessory, please contact D

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-D

EWALT (1-800-433-9258) or visit our website www.

dewalt.com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustments should be performed by a D

center, a D

EWALT authorized service center or other qualified service

EWALT factory service

personnel. Always use identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-D

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

EWALT (1-800-433-9258).

EWALT,

EWALT

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

EWALT will maintain the tool and replace worn parts caused by

D

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

EWALT Power Tool, Laser, or Nailer for any reason, you can return it

D

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific

warranty information contained either in the packaging, call the local

company or see website for warranty information.

10

Page 13

FREE WARNING LABEL REPLACEMENT: If your warning labels become

illegible or are missing, call 1-800-4-D

replacement.

EWALT (1-800-433-9258) for a free

English

11

Page 14

Plate-forme mobile pour scie à onglet/raboteuse DWX726

Description de l’établi

A. Rails de fixation

B. Bras de support d’ouvrage

C. Pied de rangement

D. Roues

E. Rallonge de pied

F. Bouton de verrouillage vertical

G. Bouton de verrouillage horizontal

H. Rallonge

I. Poignée

Français

I

FIG. 1

H

H

A

B

G

F

C

D

E

12

Page 15

Défi nitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Lire le mode d’emploi et porter

une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui,

si elle n’est pas évitée, entraînera la mort ou des blessures

graves.

AVERTISSEMENT : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner la mort

ou des blessures graves.

ATTENTION: indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée, pourrait entraîner des blessures

légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait pour

l’éviter, pourrait poser des risques de dommages matériels.

EN CAS DE QUESTIONS OU DE COMMENTAIRES SUR CET

E

OUTIL OU SUR TOUT AUTRE OUTIL D

NOUS SANS FRAIS AU NUMÉRO SUIVANT : 1 (800) 4-D

(1 (800) 433-9258)

Cette plate-forme mobile pour scie à onglet/raboteuse a été conçue

pour accommoder la plupart des scies à onglet et raboteuses et pour

assurer la portabilité de ces outils, que ce soit sur un chantier ou en

atelier. Pour tout problème au niveau de l’alignement ou du montage,

veuillez appeler le 1-800-4-D

EWALT (1-800-433-9258).

WALT, APPELEZ-

E

WALT

RÈGLES DE SÉCURITÉ

AVERTISSEMENT: pour votre sécurité, lire le manuel de

l’utilisateur respectif à l’outil avant l’utilisation de tout

accessoire. Tout manquement à ces avertissements augmente

les risques de blessures, et les risques d’endommager

sérieusement l’appareil et ses accessoires. Lors de la

maintenance de cet outil, n’utiliser que des pièces de rechange

identiques.

AVERTISSEMENT: tout manquement aux règles suivantes

comporte des risques de dommages corporels graves.

AVERTISSEMENT: pour réduire tout risque de dommages

corporels, soulever ou abaisser la plateforme avec les deux

mains sur les poignées. La plateforme par pression à gaz peut

s’élever brusquement lorsque le levier est libéré.

• Ce produit à été conçu pour être utilisé comme support de

scies à onglet et de raboteuses. Il peut soutenir jusqu’à 136kg

(300lb). Tout emploi abusif ou erroné de ce produit comporte des

risques de dommages corporels ou matériels.

• Ne pas monter sur la table de travail. Il est dangereux de

grimper, s’asseoir ou se tenir debout sur la plateforme. Ne pas

utiliser les rallonges comme échelle ou échafaudage.

• Arrimer soigneusement la scie à onglet ou la raboteuse à la

plateforme avant toute utilisation. Suivre soigneusement les

instructions d’installation. Arrimer soigneusement l’outil aux rails de

fixation de la scie comme indiqué.

• Disposer la plateforme sur une surface plane et stable pour

prévenir toute chute ou culbute.

• Prendre des précautions lors de l’élévation ou la baisse de la

plateforme pour éviter de se pincer les mains ou les doigts.

• Vérifier que les pieds, et tout autre support, sont correctement

verrouillés en place avant toute utilisation.

Français

13

Page 16

• Ne pas modifier la plateforme ou l’utiliser à des fins pour

lesquelles elle n’a pas été conçue.

• Porter SYSTÉMATIQUEMENT une protection oculaire. Tout

utilisateur ou individu présent doit porter une protection oculaire

homologuée ANSI Z87.1.

• Porter SYSTÉMATIQUEMENT des lunettes de protection. Les

lunettes courantes NE sont PAS des lunettes de protection. Utiliser

aussi un masque antipoussières si la découpe doit en produire

beaucoup. PORTER SYSTÉMATIQUEMENT UN ÉQUIPEMENT DE

SÉCURITÉ HOMOLOGUÉ:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3;

• Protection auditive ANSI S12.6 (S3.19);

• Protection des voies respiratoires NIOSH/OSHA/MSHA

Contenu du carton

1 Plate-forme mobile de scie à onglet/raboteuse

1 Rallonge de pied

1 Pied de rangement

Français

2 Raccord de roue/pied de rangement (droit et gauche)

2 Supports télescopiques

1 Poignée

2 Roues

2 Essieux

2 Bras de support (1 avec embout noir)

1 Sac de quincaillerie:

2 Crochets pour enrouler le cordon électrique (G, D)

6 Vis à tête ronde M8x15mm

1 Vis à tête ronde M8x25mm

6 Rondelles d’appui courbées

2 Boutons de verrouillage de rallonge

1 Rondelle de blocage M8

1 Vis à tête ronde M6x10mm

1 Rondelle de blocage M6

1 Clé hexagonale

Outils nécessaires

• Clé hexagonale (fournie)

• Clé à molette

• Clé à fourche de 1/2 po

• Clé à fourche de 3/4 po.

DÉBALLAGE ET NETTOYAGE

Déballer soigneusement le produit et ses accessoires de leur

conditionnement d’origine. Retirer toute huile anticorrosion des

surfaces non peintes à l’aide d’un chiffon doux humidifié d’essence

minérale, de diluant ou d’alcool dénaturé.

AVIS : ne pas utiliser des solvants hautement volatils tels que

l’essence, le pétrole, l’acétone, ou l’essence légère pour nettoyer votre

plateforme.

Description (Fig.1)

AVERTISSEMENT : ne jamais modifier l’outil ni aucun de ses

composants, car il y a risques de dommages corporels ou matériels.

Se reporter à la figure1 pour la Description de l’établi.

MONTAGE

AVERTISSEMENT : RISQUES DE PINCEMENT. Pour réduire

tout risque de dommages corporels graves, ne pas élever ou abaisser

la plateforme tant que le montage des supports télescopiques n’est

pas terminé.

STOCKAGE DE LA CLÉ (FIG. 3)

La clé hexagonale (J) fournie avec l’outil est rangée dans un coin de

la plateforme.

14

Page 17

INSTALLATION DE LA RALLONGE DE PIED (FIG. 2, 3)

IMPORTANT: Disposer la plateforme à l’envers sur le sol ou sur une

table plane et stable, comme illustré en figure 2.

FIG. 2

INSTALLATION DU RACCORD DE ROUE/PIED DE

RANGEMENT (FIG. 4)

1. Avec la plateforme toujours à l’envers, insérez le raccord de roue/

pied de rangement (N) dans la plateforme (K) avec la rallonge de

roue (O) orientée vers l’extérieur.

2. Alignez le trou et insérez une vis à tête ronde M8 x 15mm (L) avec

une rondelle d’appui courbée (M) pour un futur serrage.

REMARQUE: la vis sera resserrée complètement plus tard.

3. Rattachez l’autre raccord de roue/pied de rangement de la même

manière.

FIG 4

N

Français

1. Avec la plateforme à l’envers, insérez la rallonge de pied (E) dans

la plateforme (K).

2. Alignez les trous puis installez deux vis à tête ronde M8 x 15mm

(L) avec leurs rondelles d’appui courbées (M).

3. Serrez fermement à l’aide de la clé hexagonale fournie à cet effet.

FIG. 3

E

L, M

J

K

J

L, M

O

K

INSTALLATION DES ROUES (FIG. 5)

1. Toujours avec la plateforme à l’envers, retirez la rondelle/l’écrou

(Q, R) de l’essieu. Insérez l’essieu (P) à partir de l’intérieur du

raccord de roue/pied de rangement.

15

Page 18

2. Installez l’une des roues (D) sur l’essieu avec la partie la plus

longue du moyeu orientée vers l’intérieur.

3. Placez la rondelle (Q) sur l’essieu et rattachez un écrou (R).

Resserrez l’écrou.

REMARQUE: attention à ne pas trop serrer. Trop serrer pourrait

compromettre la rotation de la roue.

4. Rattachez l’autre roue de la même manière.

FIG. 5

FIG. 6

I

FIG. 7

T

N

L, M

S

C

P

D

Q

R

Français

INSTALLATION DE LA POIGNÉE (FIG. 6)

1. Avec la plateforme à l’envers, rattachez la poignée (I) à l’autre

extrémité de la plateforme, à l’opposé des roues, à l’aide d’une

vis à tête ronde M8 x 25mm (S) et d’une rondelle de blocage sur

un côté et une vis à tête ronde M6x10mm (T) et une rondelle de

blocage sur l’autre côté.

2. Serrez fermement à l’aide de la clé hexagonale fournie à cet effet.

INSTALLATION DU PIED DE RANGEMENT (FIG. 7)

IMPORTANT: retourner la plateforme à l’endroit de façon à ce que

les roues et la rallonge de pied soient au raz du sol, et non en position

haute.

1. Avec la plateforme à l’endroit, installez le pied de rangement (C)

sur les indentations du raccord de roue/pied de rangement (N),

de façon à ce que lorsque la plateforme sera sur pied, le pied de

rangement sera incliné vers le haut.

2. Alignez les trous sur le pied de rangement avec ceux du raccord

du pied de rangement. Installez deux vis à tête ronde M8 x 15mm

(L) avec des rondelles d’appui courbées sur (M) pour arrimer le

pied de rangement et le connecteur.

3. Serrez fermement les vis à l’aide de la clé hexagonale fournie à cet

effet.

4. Resserrez fermement les vis du raccord de pied de rangement qui

avaient été juste insérées à la section Installation du raccord de

roue/pied de rangement.

16

Page 19

POUR LEVER ET ABAISSER LA PLATEFORME (FIG. 8)

1. Placez votre pied droit sur le pied de la rallonge de pied (E).

2. Attrapez à deux mains la poignée (I).

3. À l’aide du pouce de la main gauche, abaissez le levier d’activation

rouge (V).

4. Relevez la poignée pour libérer le mécanisme de sécurité, puis

levez ou abaissez la plateforme. Après avoir élevé la plateforme

de quelques pouces, relâchez le levier d’activation rouge. La

plateforme se verrouillera automatiquement en place au réglage

de hauteur suivant.

La plateforme pourra être réglée sur deux niveaux. Sélectionnez la

hauteur désirée puis verrouillez-la en place.

FIG. 8

V

I

I

V

E

INSTALLATION DES SUPPORTS TÉLESCOPIQUES (FIG. 9, 10)

IMPORTANT: S’assurer que le côté le plus long du «T» sur le bras

de support (B) est orienté vers le bas, comme illustré en figure9. Se

reporter à l’étiquette avec la flèche orientée vers le bas.

1. Avec la plateforme ajustée à la hauteur désirée, placez la partie

supérieure (H1) du support de travail dans le haut du trou du bras

de support (B). Insérez la partie inférieure (H2) du support de travail

dans le trou inférieur du bras, en l’orientant correctement par

rapport à la partie supérieure.

2. Resserrez le bouton de verrouillage vertical (F).

3. Faire de même avec l’autre support télescopique.

4. Insérez le dispositif du bras de support télescopique (B) avec

le petit embout noir (encadré, fig. 10) dans le trou (W) de la

plateforme le plus proche du levier d’activation rouge. Repoussez

le bras pour le verrouiller en place.

5. Faire de même pour le bras de support opposé. Repoussez le

bras pour le verrouiller en place.

REMARQUE : le mécanisme interne de verrouillage maintient le

support de travail bloqué.

FIG. 9

H1

B

F

H2

B

FIG. 10

H

W

Français

17

Page 20

INSTALLATION DES CROCHETS POUR ENROULER LE

CORDON ÉLECTRIQUE (FIG. 11, 12)

REMARQUE: installer les crochets (X) à l’opposé l’un de l’autre pour

maintenir soigneusement le cordon.

1. Placez la vis (X) du crochet pour enrouler le cordon dans le trou (Z),

de l’extérieur de la plateforme vers l’intérieur. Placez une rondelle

et un écrou sur la vis du crochet puis serrez l’écrou à la main.

2. À l’aide de la clé à molette ou la clé à fourche de 1/2 po resserrez

la vis fermement.

3. Répétez l’opération pour l’autre crochet.

FIG. 11 FIG. 12

Z

X

Français

AVERTISSEMENT: pour réduire tout risque de dommages

corporels, arrêter et débrancher la scie à onglet ou la raboteuse

du secteur avant de les assembler à la plateforme. Tout

démarrage accidentel comporte des risques de dommages corporels.

1. Desserrez les 6 vis de rail (AA) avec la clé hexagonale fournie à cet

effet. Retirez les boulons/rondelles plates de montage (BB) des

rails de fixation.

FIG. 13

BB

AA

A

BB

X

INSTALLATION DE L’OUTIL (FIG. 13–16)

AVERTISSEMENT : RISQUES D’INSTABILITÉ. Pour arrimer

votre scie à onglet ou raboteuse à la plateforme, ou à une surface

de support, se reporter aux instructions du fabricant de votre outil.

Avant toute utilisation, arrimer soigneusement l’outil en suivant

les instructions de ce manuel et celui du fabricant de l’outil. Tout

manquement à ces avertissements pose des risques de dommages

corporels et matériels graves.

AA

2. Faites glisser les rails de fixation (A) pour les ajuster à la largeur de

l’outil. Assurez-vous que les orifices de montage sont bien alignés

avec les trous dans les pieds de l’outil.

AVERTISSEMENT : les raboteuses DOIVENT être installées

comme illustré en figure 16.

3. Placez la scie à onglet ou la raboteuse sur les rails de fixation (A).

Centrez l’outil sur la plateforme (longitudinalement et latéralement).

18

Page 21

4. Assurez-vous que les trous de montage (CC) sur les pieds de

l’outil s’alignent bien avec les orifices du rail (DD) et les écrous

captifs (EE) logés dans les rails de fixation.

5. Une fois les rails en place, resserrez les vis (AA) de rail desserrées

lors de la PREMIÈRE ÉTAPE.

6. Insérez les boulons/rondelles plates de montage (BB) (retirés lors

de l’ÉTAPE 1) dans chacun des pieds de l’outil au travers des

écrous captifs (EE). Resserrez fermement.

IMPORTANT: La scie à onglet, ou la raboteuse, DOIT être positionnée

de façon à ce que l’outil soit arrimé parfaitement sur les rails de

fixation. Dans cette impossibilité, composer le 1(800) 4-D

EWALT

(1-800-433-9258) pour une assistance technique.

AVERTISSEMENT : RISQUES D’INSTABILITÉ. Si les trous

de montage de l’outil ne s’alignent pas sur les orifices des rails de

fixation, installer la scie à onglet ou la raboteuse sur un morceau

de contreplaqué de 19mm (3/4po) (se reporter à la figure 15 pour

les dimensions). Le contreplaqué doit dépasser d’un minimum de

101,6mm (4po) la base de l’outil à installer, et avoir une profondeur

minimum de 406,4mm (16po). Le contreplaqué doit être au moins

aussi large que la base de l’outil installé. Percez des trous de 9,4 mm

(3/8po) près du bord, aux deux extrémités du contreplaqué, pour les

aligner avec les orifices des rails de fixation, comme décrit à la section

Installation de l’outil. Vous pouvez avoir besoin dans ces circonstances

de matériel supplémentaire (non fourni avec l’outil).

Français

FIG. 14

CC

EE

DD

AA

FIG. 15

406,4mm

(16po) MINIMUM

DOIT ÊTRE

AUSSI LARGE

QUE LA BASE

DE LA SCIE

INSTALLÉE

25,5mm (1po)

381mm

(15po) DE

CHAQUE

CÔTÉ

19

LARGEUR DE SCIE + 101,6mm (4po)

25,5mm (1po)

MONTAGE DE LA SCIE DE

BÂTI DANS LE

SECTEUR OMBRAGÉ

25,5mm (1po)

DIAMÈTRE DE

TROUS: 9,5mm

(3/8po), DANS

LES

4 COINS

MINIMUM DE

50,8mm (2po) DE

CHAQUE CÔTÉ

25,5mm (1po)

Page 22

AVERTISSEMENT: RISQUES D’INSTABILITÉ. Toute quincaillerie

utilisée doit être d’un grade 2 minimum. Elle doit dépasser d’au moins

31,8mm (1-1/4po) la base de la scie installée.

AVIS : pour prévenir tout grippage et/ou toute perte de précision,

s’assurer que le contreplaqué n’est ni gondolé ni irrégulier. Dans cette

éventualité, le remplacer par un morceau lisse et plane.

FIG 16

Français

TEST DE STABILITÉ (FIG. 16–17)

La plateforme mobile pour scie à onglet/raboteuse a été conçue pour

être utilisée avec une grande variété de scies à onglet, scies à onglet

composé, de scies à onglet composé coulissantes et de raboteuses.

AVERTISSEMENT:

être positionnés et arrimés correctement pour en assurer la stabilité et

en prévenir la culbute.

AVERTISSEMENT : les raboteuses DOIVENT être installées

comme illustré en figure 16.

AVERTISSEMENT: pour réduire tout risque de dommages

corporels graves, arrêter et débrancher l’outil du secteur avant

d’installer ou retirer tout accessoire, avant tout réglage ou

changement de configuration, ou pour faire toute réparation.

Tout démarrage accidentel comporte des risques de dommages

corporels.

AVERTISSEMENT: pour votre sécurité, effectuer le test de

stabilité avec deux ou trois personnes pour prévenir tout risque

de dommages corporels graves.

AVERTISSEMENT: la tête de coupe des scies à onglet, scies

à onglet composé, et scies à onglet composé coulissantes

DOIT être en position haute. Toutes les scies à onglet composé

coulissantes DOIVENT être verrouillées en position arrière.

Tout manquement à cette règle comporte des risques de

dommages corporels graves.

AVERTISSEMENT: RISQUES D’INSTABILITÉ. Rester prudent.

La plateforme pourrait culbuter lors de cette procédure. Des

blessures graves pourraient en résulter.

les outils utilisés avec cette plateforme doivent

20

Page 23

1. Assurez-vous que l’outil

FIG 17

est solidement arrimé à

la plateforme, et est

arrêté et déconnecté

du secteur.

GG

2. Placez un bloc de bois

épais de 63,5 mm

(2-1/2 po) (FF) sous le

HH

pied avant (GG) de la

plateforme, de façon à

la surélever du sol de

FF

cette hauteur.

3. Avec une personne à l’avant de la plateforme, une autre à l’arrière,

soulevez légèrement l’avant de la plateforme, retirez le bloc de

bois, et laissez la plateforme retomber sur le sol.

4. Effectuez le même test avec un bloc de bois placé sous le pied

arrière (HH).

5. Si la plateforme a tendance à basculer vers l’avant, repositionnez

l’outil vers l’arrière de celle-ci. Si la plateforme a tendance à

basculer vers l’arrière, repositionnez l’outil vers l’avant. Effectuez

les ajustements nécessaires puis répétez ce test.

UTILISATION

AVERTISSEMENT: Pour réduire tout risque de dommages

corporels, soulever ou abaisser la plateforme avec les deux

mains sur la poignée et le pied droit sur la rallonge de pied.

La plateforme par pression à gaz peut s’élever brusquement

lorsque le levier est libéré.

Se reporter à la section Pour lever et abaisser la plateforme sous

le paragraphe Assemblage pour ajuster la plateforme à la hauteur

désirée.

EXTENSION DES SUPPORTS TÉLESCOPIQUES (FIG. 18)

1. Tournez le bouton de verrouillage horizontal (G) vers la gauche.

2. Étirez ou repoussez le support télescopique (H), en fonction de la

longueur de la pièce à travailler.

3. Resserrez le bouton de verrouillage horizontal.

4. Répétez l’opération de l’autre côté.

RÉGLAGE VERTICAL DU SUPPORT TÉLESCOPIQUE

1. Tournez le bouton de verrouillage vertical (F).

2. Ajustez le support télescopique à la hauteur désirée.

3. Resserrez le bouton de verrouillage vertical.

4. Répétez l’opération avec l’autre support télescopique.

FIG 18

H

F

G

Français

21

Page 24

STOCKAGE ET TRANSPORT

AVERTISSEMENT: RISQUES DE CULBUTE. Le stockage ou

le transport de la plateforme en position repliée ou verticale

pose des risques de culbute. Transporter ou entreposer la

plateforme en position horizontale pour réduire tout risque de

culbute.

Pour mettre la plateforme en position de stockage, appuyez sur

le levier d’activation rouge, soulevez la poignée, puis exercez une

pression verticale sur la poignée.

Reportez-vous à la figure 19 pour une illustration de la position

correcte de transport.

FIG 19

Français

Accessoires

AVERTISSEMENT : puisque les accessoires autres que ceux

offerts par D

de ceux-ci avec l’outil pourrait s’avérer dangereuse. Pour réduire le

risque de blessures, utiliser exclusivement les accessoires D

recommandés avec le présent produit.

Les accessoires recommandés pour votre outil peuvent être achetés

auprès du distributeur local ou d’un centre de réparation agréé. Si vous

avez besoin d’assistance pour trouver un accessoire pour votre outil,

veuillez contacter D

Baltimore, MD 21286, États-Unis, composer le 1(800) 4-D

(1-800-433-9258) ou visiter notre site Web à www.dewalt.com.

EWALT n’ont pas été testés avec ce produit, l’utilisation

EWALT

EWALT Industrial Tool Co., 701 East Joppa Road,

EWALT

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations,

l’entretien et les réglages doivent être réalisés par un centre de

réparation en usine D

ou par un personnel de réparation professionnel. Toujours utiliser des

pièces de rechange identiques.

EWALT, un centre de réparation autorisé DEWALT

Garantie limitée trois ans

DEWALT réparera gratuitement tous les problèmes dus à des défauts

de matériau ou de fabrication pendant trois ans à compter de la date

d’achat. Cette garantie ne couvre pas des défaillances de pièce dues

à une usure normale ou à une mauvaise utilisation de l’outil. Pour

plus de détails relatifs à la couverture de la garantie et aux réparations

sous garantie, visiter le site Web www.dewalt.com ou composer le

1-800-4-D

pas aux accessoires ni aux dommages causés par des réparations

réalisées ou tentées par des tiers. Cette garantie vous accorde des

droits légaux spécifiques et il est possible que vous ayez d’autres

droits qui varient d’un État ou d’une province à l’autre.

EWALT (1-800-433-9258). Cette garantie ne s’applique

22

Page 25

En plus de la garantie, les outils DEWALT sont couverts par

notre :

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

EWALT entretiendra l’outil et remplacera les pièces usées

D

par une utilisation normale et ce, gratuitement, à tout instant

pendant la première année à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances

de votre outil électrique, laser ou de votre marteau-cloueur

D

EWALT pour quelque raison que ce soit, vous pouvez le

retourner accompagné d’un reçu dans les 90 jours suivant

la date d’achat et nous vous rembourserons entièrement sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux

produits vendus en Amérique latine. Pour ceux-ci, veuillez

consulter les informations relatives à la garantie spécifique

présente dans l’emballage, appeler l’entreprise locale ou

consulter le site Web pour les informations relatives à cette

garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D’AVERTISSEMENT : si les étiquettes d’avertissement

deviennent illisibles ou sont manquantes, composer le

1-800-4-D

EWALT (1-800-433-9258) pour en obtenir le

remplacement gratuit.

Français

23

Page 26

DWX726 Base de soporte rodante para sierra para corte de ingletes/cepiladora

Lista de piezas

A. Rieles de montaje

B. Brazo de apoyo de la pieza

de trabajo

C. Pie para almacenamiento

D. Ruedas

E. Extensión de la pata

F. Pomo de bloqueo vertical

G. Pomo de bloqueo horizontal

H. Brazo de extensión

I. Barra de sujeción

Español

I

FIG. 1

H

H

A

B

G

F

C

D

E

24

Page 27

Defi niciones: Normas de

seguridad

Las siguientes definiciones describen el nivel de gravedad

de cada palabra de señal. Lea el manual y preste atención

a estos símbolos.

PELIGRO: Indica una situación de peligro inminente que,

si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro potencial

que, si no se evita, podría provocar la muerte o lesiones

graves.

ATENCIÓN: Indica una situación de peligro potencial

que, si no se evita, posiblemente provocaría lesiones

leves o moderadas.

AVISO: Se refiere a una práctica no relacionada a

lesiones corporales que de no evitarse puede resultar en

daños a la propiedad.

SI TIENE ALGUNA DUDA O ALGÚN COMENTARIO SOBRE ÉSTA

U OTRA HERRAMIENTA D

GRATUITO: 1-800-4-D

La base de soporte rodante para sierra para corte de ingletes/

cepilladora es una base diseñada para ser compatible con la mayoría

de las sierras para cortes de ingletes y cepilladoras, y para brindar la

función de portabilidad a estas unidades, tanto en el campo como en

el taller. Si tiene algún problema con el alineamiento o montaje de la

base, llame a 1-800-4-D

EWALT, LLÁMENOS AL NÚMERO

EWALT (1-800-433-9258)

EWALT (1-800-433-9258).

REGLAS DE SEGURIDAD

ADVERTENCIA : Para su seguridad, lea el manual de

instrucciones de la herramienta antes de utilizar cualquier

accesorio. De no seguir estas advertencias podrían

producirse lesiones corporales y graves daños a la herramienta

y al accesorio. Cuando realice el mantenimiento de esta

herramienta, utilice únicamente repuestos originales.

ADVERTENCIA: El incumplimiento con estas reglas puede

resultar en lesiones corporales graves.

ADVERTENCIA: Para reducir el riesgo de lesiones, mantenga

ambas manos en la barra de sujeción cuando suba o baje

el soporte. El soporte cuenta con elevación a gas y puede

elevarse inesperadamente al soltar la palanca.

•. Este producto fue diseñado para ser utilizado como un

soporte para sierras ingleteadoras y máquinas cepilladoras.

El soporte puede sostener hasta 136 Kg. (300 libras de peso). El

mal uso o abuso de este producto puede dañar el mismo o resultar

en lesiones corporales.

• No se pare encima de la mesa de trabajo. Es peligroso treparse,

sentarse o pararse sobre el soporte. No use las extensiones del

soporte como si fueran escaleras o andamios.

• Asegure debidamente la sierra ingleteadora o máquina

cepilladora al soporte antes de operar las mismas. Siga

detenidamente las instrucciones de montaje. Sujete bien la

herramienta a los rieles de montaje de la sierra, como se indica.

• Coloque el soporte sobre una superficie plana y nivelada

para evitar que se balancee o se vuelque.

• Tenga cuidado al subir o bajar el producto para reducir el

riesgo de pellizcarse las manos o los dedos.

• Revise las patas y otros puntos de apoyo para verificar

que estén debidamente asegurados antes de comenzar la

operación de la herramienta.

• No modifique ni use el soporte para propósitos para los

cuales no fue diseñado.

Español

25

Page 28

• SIEMPRE use protección ocular. Todos los usuarios y las personas

circunstantes deben llevar protección ocular en conformidad con

ANSI Z87.1.

• Use SIEMPRE gafas de seguridad. Los anteojos de diario NO

SON gafas de seguridad. Utilice además un cubrebocas o una

mascarilla antipolvo si la operación de corte genera demasiado

polvo. SIEMPRE LLEVE EQUIPO DE SEGURIDAD CERTIFICADO:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3),

• Protección auditiva ANSI S12.6 (S3.19),

• Protección respiratoria NIOSH/OSHA/MSHA.

Contenido de la caja

1 Base de soporte rodante para sierra para corte de

ingletes/cepiladora

1 Pata de extensión

1 Pie para almacenamiento vertical

2 Conector de la rueda/pie para almacenamiento

(izquierdo y derecho)

2 Unidad de extensión del soporte para tareas

1 Barra de sujeción

2 Rueda (2)

2 Eje (2)

2 Brazos de soporte para tareas (1 con tapa negra)

1 Bolsa con accesorios de montaje:

2 Soportes para enrollar el cable (I, D)

6 Tornillos de cabeza abombada M8 de 15 mm

1 Tornillo de cabeza abombada M8 de 25 mm

Español

6 Arandelas curvas

2 Pomos de bloqueo de la extensión

1 Arandela de fijación M8

1 Tornillo de cabeza abombada M6 de 10 mm

1 Arandela de fijación M6

1 Llave hexagonal

Herramientas requeridas

• Llave hexagonal (incluida)

• Llave sueca ajustable

• Llave fi ja de 1/2 pulg.

• Llave fi ja de 3/4 pulg.

DESEMBALAJE Y LIMPIEZA

Desembale cuidadosamente el producto y todos los artículos sueltos

del (o de los) contenedor(es) de transporte. Con un paño suave

humedecido con esencia mineral, diluyente para pinturas o alcohol

desnaturalizado quite el aceite anti-óxido de las superficies sin pintar.

AVISO: No utilice solventes altamente volátiles como gasolina, nafta,

acetona, o diluyente de esmalte para limpiar su soporte.

Componentes (Fig. 1)

ADVERTENCIA: Nunca modifique el soporte, ni tampoco ninguna

de sus partes. Podría producir lesiones corporales o daños.

Remítase a la Figura 1 para obtener la Lista de componentes.

ENSAMBLAJE

ADVERTENCIA: RIESGO DE PELLIZCO. Para reducir el riesgo

de lesiones corporales graves, no suba ni baje el soporte hasta

completar el ensamblaje de las extensiones del soporte para tareas.

ALMACENAMIENTO DE LA LLAVE (FIG. 3)

La llave hexagonal que viene incluida (J) viene puesta en el lugar de

almacenamiento de la llave en la esquina del soporte.

26

Page 29

INSTALACIÓN DE LA PATA DE EXTENSIÓN (FIG. 2, 3)

IMPORTANTE: Coloque el soporte boca abajo sobre el piso o sobre

una mesa nivelada y estable como lo muestra la Figura 2.

FIG. 2

1. Con el soporte boca abajo, inserte la pata de extensión (E) en el

soporte (K).

2. Alinee los orificios e instale dos tornillos de cabeza abombada M8

de 15 mm (L) con arandelas curvas (M).

3. Ajuste bien con la llave hexagonal incluida.

FIG. 3

E

L, M

J

K

J

INSTALACIÓN DEL CONECTOR DE LA RUEDA Y PIE PARA

ALMACENAMIENTO (FIG. 4)

1. Con el soporte aún boca abajo, inserte el conector de la rueda/pie

para almacenamiento (N) en el soporte (K), con la extensión de la

rueda (O) mirando hacia afuera.

FIG 4

N

L, M

O

K

2. Alinee el orificio e instale sin ajustar mucho un tornillo de cabeza

abombada M8 de 15 mm (L) con arandela curvas (M) para un

ajuste mayor.

NOTA: El tornillo se ajustará completamente más adelante en el

proceso de ensamblaje.

3. Instale el otro conector de rueda/pie para almacenamiento en la

misma forma.

INSTALACIÓN DE LAS RUEDAS (FIG. 5)

1. Siguiendo con el soporte boca abajo, retire la arandela/tuerca

(Q, R) del eje. Inserte el eje (P) desde la parte interior del conector

de rueda/pie para almacenamiento.

Español

27

Page 30

2. Coloque una de las ruedas (D) en el eje con la parte más larga del

cubo de la rueda mirando hacia adentro.

3. Coloque la arandela (Q) en el eje e instale la tuerca (R). Ajuste la

tuerca.

NOTA: No ajuste excesivamente. Si la ajusta demasiado, podría

hacer que la rueda no gire bien.

4. Instale la otra rueda de la misma manera.

FIG. 5

P

D

Q

R

INSTALACIÓN DE LA BARRA DE SUJECIÓN (FIG. 6)

1. Con el soporte boca abajo, instale la barra de sujeción (I) en el

extremo del soporte opuesto a las ruedas con un tornillo de cabeza

abombada M8 x 25 mm (S) y una arandela de fijación en un lado,

y con un tornillo de cabeza abombada M6 x 10 mm (T) y arandela

de fijación en el otro lado.

2. Ajuste bien con la llave hexagonal incluida.

Español

FIG. 6

T

I

FIG. 7

N

L, M

S

C

INSTALACIÓN DEL PIE PARA ALMACENAMIENTO (FIG. 7)

IMPORTANTE: Dé vuelta el soporte de modo que las ruedas y la pata

de extensión queden asentadas sobre el suelo en forma pareja, pero sin

que el soporte quede elevado.

1. Con el soporte en la posición correcta, coloque el pie para

almacenamiento (C) sobre las hendiduras del conector de rueda y

pata de extensión (N) de modo que cuando el soporte esté recto,

el pie para almacenamiento esté en un ángulo, apuntando hacia

arriba.

2. Alinee los orificios del pie para almacenamiento con los del

conector del pie para almacenamiento. Instale dos tornillos de

cabeza abombada M8 de 15 mm (L) con arandelas curvas en (M)

para instalar el pie para almacenamiento y el conector.

3. Ajuste bien los tornillos con la llave hexagonal incluida.

4. Ajuste bien los tornillos del conector del pie para almacenamiento

que instaló sin ajustar en Instalación del conector de la rueda

y del pie para almacenamiento.

28

Page 31

PARA SUBIR O BAJAR EL SOPORTE (FIG. 8)

1. Coloque su pie derecho en la parte de abajo de la pata de

extensión (E).

FIG. 8

V

I

I

V

INSTALACIÓN DE LA EXTENSIÓN DEL SOPORTE PARA

TAREAS (FIG. 9, 10)

IMPORTANTE: Asegúrese de que el extremo más largo de la “T” en

el brazo de soporte para tareas (B) esté mirando hacia abajo, como

lo muestra la Figura 9. Remítase a la etiqueta con la flecha apuntando

hacia abajo.

1. Una vez fijado en la altura deseada, coloque la pieza superior

(H1) del soporte para tareas en la parte superior del orificio para

el brazo del soporte para tareas (B). Inserte la pieza inferior (H2)

del soporte para tareas en el orificio inferior del brazo, con la

orientación debida hacia la pieza superior.

2. Ajuste la perilla de fijación vertical (F).

FIG. 9

FIG. 10

W

E

2. Sujete la barra de sujeción (I) con ambas manos.

3. Use el pulgar de su mano izquierda para presionar la palanca de

activación roja (V).

4. Levante la barra de sujeción para liberar el mecanismo de

seguridad y luego levante o baje el soporte. Luego de elevar el

soporte un par de pulgadas, libere la palanca de activación roja. El

soporte se fijará automáticamente en la siguiente altura disponible.

El soporte se puede ajustar en dos alturas. Seleccione la altura deseada

y fíjelo en ella.

H1

B

F

H2

H

B

3. Repita con la otra extensión de soporte para tareas.

4. Inserte el brazo ensamblado de la extensión del soporte para

tareas (B) con la tapa negra pequeña (recuadro, Fig. 10) en el

orificio (W) del soporte más cercano a la palanca de activación

roja. Empuje hacia abajo el brazo para fijarlo en su lugar.

29

Español

Page 32

5. Repita para el otro brazo de soporte para tareas en el extremo

opuesto. Empuje hacia abajo el brazo para fijarlo en su lugar.

NOTA: El mecanismo de fijación interno previene que los soportes

para tareas se separen.

INSTALACIÓN DE LOS SOPORTES PARA ENROLLAR EL

CABLE (FIG. 11, 12)

NOTA: Coloque los soportes para enrollar el cable (X) en posiciones

opuestas para que sujeten bien el cable.

1. Coloque el tornillo para el soporte para enrollar el cable (X) en el

orificio (T) desde la parte externa del soporte. Coloque la arandela

y la tuerca en el tornillo del soporte para enrollar el cable y ajuste

con los dedos.

2. Con una llave sueca o con una llave fija de 1/2 pulg. ajuste bien el

tornillo.

3. Repita para el otro soporte para enrollar el cable.

FIG. 11 FIG. 12

Z

X

manual como las del manual del fabricante de su herramienta antes de

operarla. El no respetar estas advertencias puede resultar en lesiones

corporales graves y daños serios a la herramienta.

ADVERTENCIA: Para reducir el riesgo de lesiones, apague

la sierra ingleteadora o máquina cepilladora, desenchufe la

herramienta de la fuente de electricidad antes de ensamblar

la sierra ingleteadora o máquina cepilladora en el soporte. Un

arranque accidental puede causar lesiones.

1. Afloje los 6 tornillos del riel (AA) con la llave hexagonal incluida.

Retire los pernos de montaje/arandelas planas (BB) de los rieles

de montaje.

FIG. 13

BB

AA

A

BB

X

INSTALACIÓN DE LA HERRAMIENTA (FIG. 13–16)

Español

ADVERTENCIA: PELIGRO DE INESTABILIDAD. Remítase a las

instrucciones del fabricante de su herramienta con respecto a asegurar

su sierra ingleteadora o máquina cepilladora a un soporte o superficie de

apoyo. Asegure la herramienta siguiendo tanto las instrucciones de este

AA

2. Deslice los rieles de montaje (A) de modo que calcen con el

ancho de la herramienta. Verifique que las ranuras de montaje se

alineen con los orificios de los pies de la herramienta.

ADVERTENCIA: Las máquinas cepilladoras DEBEN ser montadas

en la dirección que se muestra en la Figura 16.

30

Page 33

3. Coloque la sierra ingleteadora o máquina cepilladora en los rieles

de montaje (A). Centre la herramienta en el soporte, tanto por

delante y por detrás como de lado a lado.

4. Verifique que los orificios de montaje (CC) en los pies de la

herramienta queden alineados con las ranuras de los rieles (DD) y

las tuercas prisioneras (EE) ubicadas en los rieles de montaje.

5. Una vez que los dos rieles estén en su lugar, ajuste los tornillos del

riel (AA) que aflojó en el PASO 1.

6. Inserte los pernos de montaje/arandelas planas (BB) (que quitó en

el PASO 1) en cada uno de los pies de la herramienta y la tuerca

prisionera correspondiente (EE). Ajuste firmemente.

IMPORTANTE: La sierra ingleteadora o máquina cepilladora DEBE

ubicarse de modo que la herramienta quede directamente apernada

en los rieles de montaje. Si esto no es posible, por favor llame al

1-800-4-D

EWALT (1-800-433-9258) para recibir asistencia técnica.

ADVERTENCIA: PELIGRO DE INESTABILIDAD. Si los orificios

de montaje de la herramienta no quedan alineados con las ranuras

de los rieles de montaje, monte la sierra ingleteadora o máquina

cepilladora en una pieza de contrachapado de 19 mm (3/4 pulg.)

(Remítase a la Figura 15 para ver las dimensiones). El contrachapado

debe ser un mínimo de 101,6 mm (4 pulg.) más ancho que la base

de la herramienta que se está montando y tener una profundidad

mínima de 406,4 mm (16 pulg.). El contrachapado debe tener como

mínimo la misma profundidad de la base de la herramienta que se

está montando. Perfore orificios de 9,4 mm (3/8 pulg.) cerca de

cada uno de los extremos del contrachapado para alinearlos con las

ranuras en los rieles de montaje como se describe en Instalación de

la herramienta. Puede que requiera de otros accesorios de montaje

(no incluidos) en estas circunstancias.

FIG. 14

CC

EE

DD

AA

FIG. 15

MÍNIMO DE

406,4mm

(16pulg.) LA

PROFUNDIDAD

DEBE DE SER

POR LO MENOS

IGUAL A LA

SIERRA

MONTADA

381mm

(15 pulg.)

LOS DOS

LADOS

31

ANCHURA DE LA SIERRA

+ 101,6mm (4 pulg.)

25,5mm (1pulg.)

SIERRA DEL INGLETE

DEL MONTAJE EN

ÁREA SOMBREADA

25,5mm (1pulg.)

AGUJEROS CON

UN DIÁMETRO

DE 9,5mm

(3/8 pulg.) EN

LAS CUATRO

ESQUINAS

MÍNIMO DE 50,8mm

(2pulg.) LOS DOS

LADOS

25,5mm (1pulg.)25,5mm (1pulg.)

Español

Page 34

ADVERTENCIA: PELIGRO DE INESTABILIDAD. Todos los

accesorios de montaje que utilice deberán ser como mínimo grado2.

Los accesorios de montaje deberán tener 31,8 mm (1-1/4 pulg.)

más de largo que el grosor de la base de la herramienta que está

montando.

AVISO: ara evitar que la herramienta se trabe y/o que su precisión

se vea afectada, verifique que el contrachapado no esté combado

o que sea disparejo. Si la herramienta se traba y/o si su precisión

se ve afectada, cambie el contrachapado por una pieza que no esté

combada y que sea pareja.

FIG 16

Español

PRUEBA DE ESTABILIDAD DEL PRODUCTO (FIG. 16–17)

La base de soporte rodante para sierra para corte de ingletes/

cepilladora está diseñado para ser utilizado con una gran variedad

de sierras ingleteadoras, sierras ingleteadoras compuestas, sierras

ingleteadoras compuestas corredizas y máquinas cepilladoras.

ADVERTENCIA:

soporte debe ser debidamente colocada y asegurada para garantizar

su estabilidad y para prevenir que se vuelque inadvertidamente.

ADVERTENCIA: Las máquinas cepilladoras DEBEN ser montadas

en la dirección que se muestra en la Figura 16.

ADVERTENCIA: Para reducir el riesgo de lesiones corporales,

apague la herramienta y desenchúfela antes de instalar o

quitar accesorios, antes de realizar ajustes o de cambiar

configuraciones, y cuando se la repare. Un arranque accidental

puede causar lesiones.

ADVERTENCIA: Para su seguridad, realice la prueba de

estabilidad con la ayuda de dos personas o más; de lo

contrario, podría resultar en lesiones graves.

ADVERTENCIA: El cabezal de corte DEBE estar elevado

en toda sierra ingleteadora, sierra ingleteadora compuesta,

y sierra ingleteadora compuesta corrediza. Todas las sierras

ingleteadoras compuestas corredizas DEBEN ser fijadas en

la posición posterior. El incumplimiento con lo anterior puede

resultar en lesiones corporales graves.

ADVERTENCIA: PELIGRO DE INESTABILIDAD. Permanezca

alerta. El soporte puede volcarse durante este procedimiento.

Pueden producirse lesiones graves.

Cualquier herramienta que se utilice con este

32

Page 35

1. Verifique que la

FIG 17

herramienta quede bien

montada en el soporte

y que esté apagada y

desenchufada.

GG

2. Coloque un bloque

de madera gruesa de

63,5 mm (2-1/2 pulg.)

HH

(FF) debajo de la pata

delantera (GG) del

soporte, de modo que

la pata delantera quede

FF

a 63,5 mm (2-1/2 pulg.)

del piso.

3. Con una persona delante del soporte y la otra detrás, levante

la parte delantera del soporte ligeramente, quite el bloque de

madera y permita que el soporte caiga al suelo.

4. Realice la misma prueba con el bloque de madera debajo de la

pata trasera (HH).

5. Si el soporte tiende a inclinarse hacia adelante, vuelva a posicionar

la herramienta más hacia la parte posterior del soporte. Si el

soporte tiende a inclinarse hacia atrás, vuelva a posicionar la

herramienta más hacia adelante. Haga sus ajustes y repita la

prueba.

OPERACIÓN

ADVERTENCIA: Para reducir el riesgo de lesiones, mantenga

ambas manos en la barra de sujeción y el pie derecho en la

pata de extensión cuando suba o baje el soporte. El soporte

cuenta con elevación a gas y puede elevarse inesperadamente

al soltar la palanca.

Remítase a Para subir o bajar el soporte bajo Montaje para ajustar

el soporte a la altura deseada.

PARA EXTENDER LAS EXTENSIONES DE SOPORTE PARA

TAREAS (FIG. 18)

1. Gire la perilla de fijación horizontal (G) en dirección contraria a las

manillas del reloj.

2. Deslice la extensión del soporte para tareas (H) hacia afuera o

hacia adentro, dependiendo del largo de la pieza de trabajo.

3. Ajuste la perilla de fijación horizontal.

4. Repita con el otro lado.

FIG 18

H

F

G

PARA AJUSTAR LA ALTURA DE LA EXTENSIÓN DEL

SOPORTE PARA TAREAS

1. Gire la perilla de fijación vertical (F).

2. Ajuste la extensión del soporte para tareas a la altura deseada.

3. Ajuste la perilla de fijación vertical.

4. Repita con la otra extensión de soporte para tareas.

Español

33

Page 36

ALMACENAMIENTO Y TRANSPORTE

ADVERTENCIA: PELIGRO DE VOLCAMIENTO. El soporte

puede volcarse al ser almacenado o transportado en posición vertical

o casi vertical. Transporte o almacene el soporte en posición horizontal

para reducir el riesgo de volcamiento del soporte.

Para bajar el soporte a la posición de almacenamiento, presione hacia

abajo la palanca de activación roja, levante la barra de sujeción y luego

empújela hacia abajo.

Remítase a la Figura 19 para ver la posición correcta para transportar

el soporte.

FIG 19

Español

Accesorios

ADVERTENCIA: Debido a que no se han probado con este

producto otros accesorios que no sean los que ofrece D

EWALT, el

uso de dichos accesorios podría ser peligroso. Para reducir el riesgo

de lesiones, con este producto deben usarse sólo los accesorios

D

EWALT recomendados.

Los accesorios que se recomiendan para la herramienta están

disponibles para la compra en su distribuidor local o en el centro

de mantenimiento autorizado. Si necesita ayuda para localizar

algún accesorio para su herramienta, comuníquese con D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

llame al 1-800-4-D

EWALT (1-800-433-9258) o visite nuestro sitio Web

www.dewalt.com.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio D

autorizadas. Estas organizaciones prestan servicio a las herramientas

EWALT y emplean siempre refacciones legitimas DEWALT.

D

PARA REPARACIÓN Y SERVICIO DE SUS HERRAMIENTAS

ELÉCTRICAS, FAVOR DE DIRIGIRSE AL

CENTRO DE SERVICIO MÁS CERCANO

CULIACAN, SIN

Blvd.Emiliano Zapata 5400-1 Poniente

Col. San Rafael (667) 717 89 99

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

EWALT u otras organizaciones

34

Page 37

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero 831 Poniente - Col. Centro (818) 375 23 13

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. San Roque 274 - Col. San Gregorio (442) 2 17 63 14

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES:

Si se encuentra en México, por favor llame al (55) 5326 7100

Si se encuentra en U.S., por favor llame al

1-800-433-9258 (1-800 4-D

EWALT)

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: ______________ Mod./Cat.: ______________

Marca: _____________________ Núm. de serie _________________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: _____________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

___________________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como

en materiales y mano de obra empleados para su fabricación.

Nuestra garantía incluye la reparación o reposición del producto y/o

componentes sin cargo alguno para el cliente, incluyendo mano

de obra, así como los gastos de transportación razonablemente

erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta y

esta póliza sellada por el establecimiento comercial donde se adquirió

el producto, de no contar con ésta, bastará la factura de compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones

distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con

el instructivo de uso que se acompaña;

• Cuando el producto hubiese sido alterado o reparado por

personas distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía limitada de tres años

DEWALT reparará sin cargo cualquier defecto ocasionado por

materiales defectuosos o mano de obra, durante tres años a partir

de la fecha de compra. Esta garantía no cubre fallas en las piezas

que resulten del desgaste normal de la herramienta o de su utilización

inadecuada. Para obtener información detallada sobre la cobertura

de la garantía y sobre reparaciones, visite nuestra página Web www.

dewalt.com o llame al 1-800-4-D

EWALT (1-800-433-9258). Esta

Page 38

garantía no se extiende a los accesorios o a los daños

causados por terceros al intentar realizar reparaciones.

Esta garantía le concede derechos legales específicos;

usted goza también de otros derechos que varían según

el estado o provincia.

Además de la garantía, las herramientas D

EWALT están

cubiertas por nuestro:

SERVICIO GRATUITO DE 1 AÑO

EWALT realizará el mantenimiento de la herramienta y

D

reemplazará las piezas gastadas tras el uso normal, sin

costo alguno, en cualquier momento durante el primer año

después de la compra.

GARANTÍA DE REEMBOLSO DE DINERO

DE 90 DÍAS

Si por alguna razón no estuviera plenamente satisfecho

con el rendimiento de la herramienta eléctrica, el láser o la

clavadora D

EWALT, puede devolver el producto dentro de

los 90 días siguientes a la fecha de compra acompañado

del recibo de compra. De esta manera, se le reintegrará el

importe total del producto sin formularle pregunta alguna.

AMÉRICA LATINA: Esta garantía no se aplica a los

productos que se venden en América Latina. Para los

productos que se venden en América Latina, debe

consultar la información de la garantía específica del país

que viene en el empaque, llamar a la compañía local o

visitar el sitio Web a fin de obtener esa información.

REEMPLAZO GRATUITO DE LAS ETIQUETAS DE

ADVERTENCIA: si sus etiquetas de advertencia se tornan

ilegibles o faltan, llame al 1-800-4-D

EWALT (1-800-433-

9258) para que se las reemplacen gratuitamente.

SOLAMENTE PARA PROPÓSITO DE MÉXICO:

IMPORTADO POR: D

BOSQUES DE CIDROS, ACCESO RADIATAS NO.42

3A. SECCIÓN DE BOSQUES DE LAS LOMAS

DELEGACIÓN CUAJIMALPA,

05120, MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

EWALT S.A. DE C.V.

Page 39

Page 40

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

(JUN11) Part No. N116787 DWX726 Copyright © 2011 D

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array

EWALT

of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...