Page 1

LULU

An

"0 Z

O_<{

>-o

o_>

--©

wz

c_3--

itl

8

co

cow

O,M

z

_,,, .

_o

wo

_>_

_C3

o< 2

O7- M

_Z m

cr <_ cr

@

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the

switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or

a key left attached to a rotating part of the power tool may result in personal injury,

e) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection can

reduce dust-related hazards.

4) POWER TOOL USE AND CARE

@ Do not force the power tool Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source andlor the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally,

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tooL

Power tools are dangerous in the hands of untrained users.

A

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the power tool's operation. If

damaged, have the power tool repaired before use. Many accidents are caused by

poorly maintained power tools.

f)

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control

Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could result

in a hazardous situation.

5) SERVICE

@ Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SPECIFIC SAFETY RULES

m

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286

The following are trademarks for one or more DEWAKr power tools: the yellow and black color scheme, the "D" shaped air

intake grill, the array of pyramids on the handgrip, the kit box con%uration, and the array of lozenge-shaped humps on the

surface of the tool.

(SEP12) Part No. N179726 DWE5Ol 0

Copyright © 2012 DEWALT

F_ Definitions: Safety Guidelines

The definitions below describe the levelof severity for each signal word. Please read the manual

and pay attention to these symbols.

_DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

_ WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

_CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

J

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL

US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}

WARNING: Toreduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

A ARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury,

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not

use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the

power tool Keep cord away from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault

circuff interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

@ Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury,

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

Safety Warnings for Drill

Wear ear protectors when impact drilling. Exposure to noise can cause hearing loss.

Use auxiliary handle(s), if supplied with the tool. Loss of control can cause personal injury,

Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring or its own cord. Cutting

accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and

could give the operator an electric shock.

Use clamps or other practical way to secure and support the workpiece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to loss of

control.

Wear safety goggles or other eye protection. Drilling operations cause chips to fly, Flying

particles can cause permanent eye damage.

• Bits and tools get hot during operation. Wear gloves when touching them.

• Keep handles dry, clean, free from oil and grease, it is recommended to use rubber

gloves. This will enable better control of the tool.

• Air vents often cover moving parts and should be avoided. Loose clothes, jeweller}! or

long hair can be caught in moving parts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is

16gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0

6

10

12

Not More

Than

6

10

12

16

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use

face or dust mask if cutting operation is dusty, ALWAYS WEAR CERTIFIED SAFETY EQUIPMENX

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI $12.6 ($3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

i_,WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are."

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. Toreduce

your exposure to these chemicals." work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

,_,WARNING: Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury, Always use NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles away from face and body,

_WARNING: Always wear proper personal hearing protection that conforms to ANSI

$12.6 ($3.19) during use. Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

• The label on your tool may include the following symbols. The symbols and their definitions are

as follows."

V.................. volts

Hz................ hertz

min .............. minutes

---. .......... direct current

_) ................ Class I Construction

(grounded)

[] ................ Class II Construction

(double insulated)

.../min .........per minute

IPM.............. impacts per minute

SPM ............ strokes per minute

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

18

18

16

14

16

16

16

12

16 14

14 12

14 12

Not Recommended

A ................... amperes

W.................. watts

"_ ................ alternating current

................ alternating or direct current

no ................. no load speed

n ................... rated speed

@.................. earthing terminal

.................. safety alert symbol

BPM.............. beats per minute

RPM.............. revolutions per minute

sfpm.............. surface feet per minute

Page 2

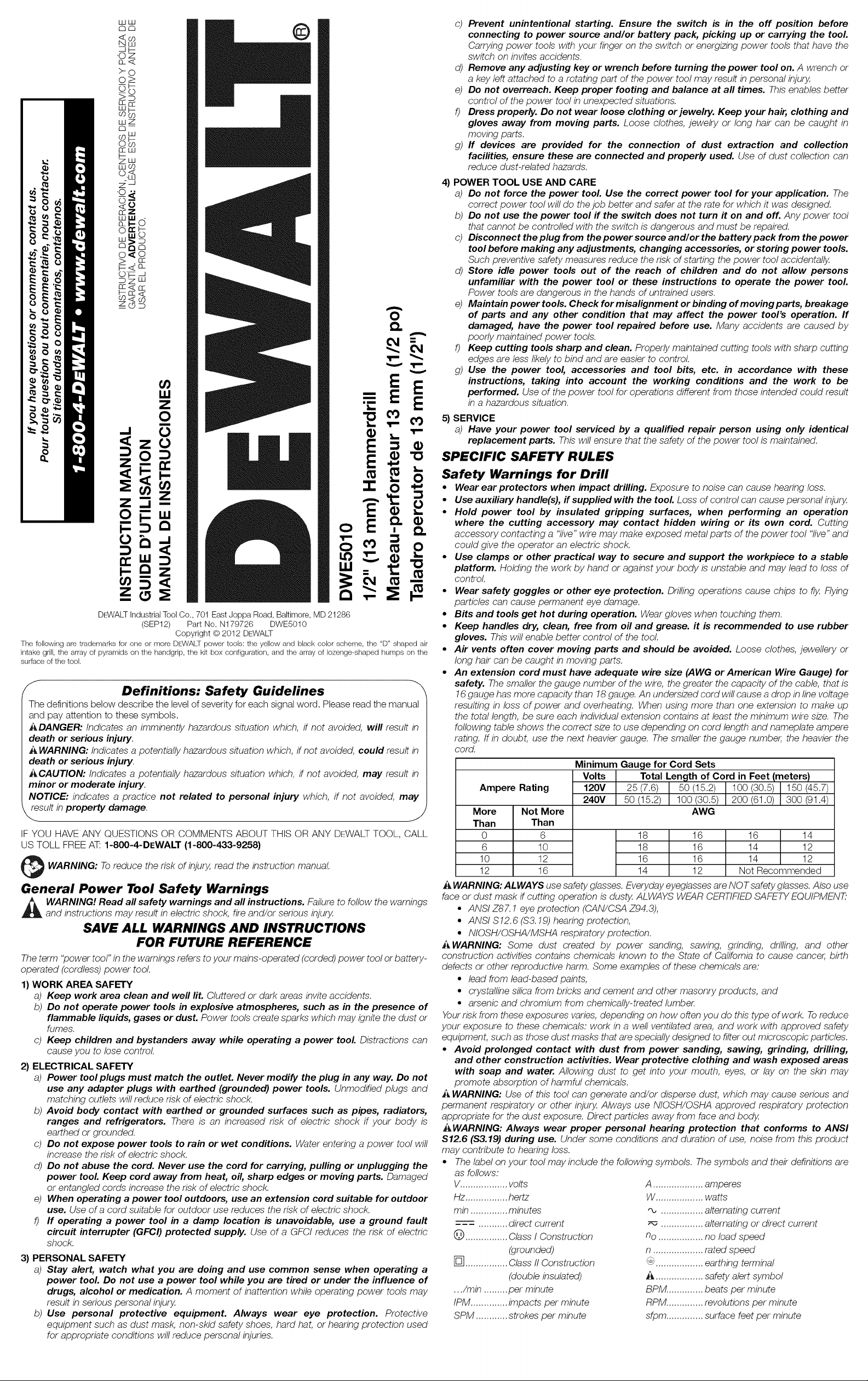

DESCRIPTION (FIG. 1)

_ WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. Variable speed trigger switch F. Cord set

B. Lock-on button G. Side handle

C. Forward/reverse button H. Depth adjustment rod

D. Chuck I. Mode selector

E. Cord protector with key holder J. Main handle

INTENDED USE

These heavy-duty V.S.R. drills are designed for professional drilling.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

These heavy-duty drills are professional power tools. DO NOT let children come into contact with

the tool. Supervision is required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

_ WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Side Handle (Fig. 1)

_WARNING: Toreduce the risk of personal injury, ALWAYS operate the tool with the side handle

properly installed. Failure to do so may result in the side handle slipping during tool operation and

subsequent loss of control Hold tool with both hands to maximize control.

A side handle comes assembled with the DWE5010. The side handle (G) can be fitted to suit both

right-hand and left-hand users.

TO ADJUST THE SIDE HANDLE

1. Loosen the side handle (G) by turning it counterclockwise.

2. Rotate the side handle to the desired position.

3. Tighten the side handle by turning it clockwise.The side handle must be tightened sufficiently

to resist the twisting action of the tool if the accessory binds or stalls. Be sure to grip the side

handle at the far end to control the tool during a stall.

TO CHANGE SIDES

For right-hand users: slide the side handle clamp over the chuck, handle at the left.

For left-hand users: slide the side handle clamp over the chuck, handle at the right.

Forward/Reverse Lever (Fig. 1)

The forward/reverse lever (C)is used for withdrawing bits from tight holes and removing screws. It

is located above the trigger switch.

To reverse the motor, release the trigger switch FIRST and then push the lever to the right (viewed

when holding the drill in the operating position).

After any reversing operations, return lever to forward position.

Mode Selector (Fig. 2)

NOTICE: Tool must come to a complete stop before activating the mode selector button or

damage to the tool may result.

Select the required operating mode by sliding the mode selector (I)to the corresponding symbol.

DRILL-ONLY MODE

Use drill-only mode for wood, metal, and plastics.

FIG. 1

D

\

B

DWE5010

E

F

C

SHOWN IN FORWARD POSITION

ILLUSTRE EN POSITION AVANT

APARECE EN POSICION NORMAL

FIG. 2 FIG. 3

H

FIG. 4 FIG. 5 FIG. 6 j

T HAMMERDRILLING MODE

Use hammerdrilling mode for simultaneous rotating and impacting for masonry,

brick and concrete.

Setting the Drilling Depth (Fig. 3)

1. Insertthe required drill bit intothe chuck.

2. Loosen the side handle (G).

3. Fit the depth adjustment rod (H) through the hole in the side handle clamp.

4. Adjust the drilling depth as shown in Figure 3.

5. Tighten the side handle.

Keyed Chuck (Fig. 1, 4, 5)

DWE5010

The DWE5010 features a keyed chuck (D).

TO INSERT A DRILL BIT OR OTHER ACCESSORY

1. Open the chuck jaws by turning collar by hand and insert the shank of the bit about 19 mm

(3/4") into chuck. Tighten the chuck collar by hand.

2. Place chuck key in each of the three holes, and tighten in clockwise direction. It's important to

tighten chuck with all three holes.

Torelease the bit, turn the chuck counterclockwise injust one hole, then loosen the chuck by hand.

REMOVAL OF KEYED CHUCK (FIG. 4}

Tighten the chuck around the shorter end of a hex key. Using a soft hammer, strike the key sharply

in the counterclockwise direction when viewed from the front of the tool. This will loosen the chuck

so that it can be removed by hand.

KEYED CHUCK INSTALLATION (FIG. 5}

Screw the chuck on by hand as far as it will go. Insert the shorter end of a hex key and strike it in

the clockwise direction with a soft hammer.

OPERATION

A WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

_AVERTISSEMENT : Pour r_duire tout risque de dommages corporels, s'assurer

SYSTEMATIQUEMENT que /a piece est ancree ou arrimee so/idement. Pour percer des

materiaux fins, utiliser un morceau de bois _ de renfort _pour eviter de les endommager.

J_AVERTISSEMENT : Ne pas essayer de resserrer ou desserrer les meches (ou tout autre

accessoire) en agrippant la pattie avant du mandrin tout en mettant I'outil en marche. Cela pourrait

endommager le mandrin et poser des risques de dommages corporels.

Trigger Switch (Fig. 1)

Tostart the drill, depress the trigger switch; to stop the drill, release the trigger switch.

NOTE: Use lower speeds for starting holes without a center punch, drilling in metal or plastics,

driving screws or drilling ceramics. Higher speeds are better for drilling wood and composition

boards and using abrasive and polishing accessories.

VARIABLE SPEED

A variable speed trigger switch (A) permits speed control--the farther the trigger is depressed, the

higher the speed of the drill.

For continuous operation, depress fully and hold the variable speed trigger switch, press the lock-

on button (B)in, then release the switch.

Do not lock the switch on when drilling by hand so that you can instantly release the trigger switch

if the bit binds in the hole.

The lock-on button (B) is for use only when the drill is mounted in a drill press stand or otherwise

held stationary.

Tostop continuous operation, press the switch briefly and release it. Always switch the tool off when

work is finished and before unplugging.

Proper Hand Position (Fig. 6)

_ WARNING: Toreduce the risk of serious personal injury,ALWAYS use proper hand position as

shown in Figure 6.

J_,WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation

of a sudden reaction.

Proper hand position requires one hand on the main handle (J), with the other hand on the side

handle (G).

Drilling

_ WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or

clamped firmly, If drilling thin material, use a wood "back-up" block to prevent damage to the

material.

1. Use sharp drill bits only. For WOOD, use twist drill bits, spade bits, power auger bits, or hole

saws. For METAL, use steel twist drill bits or hole saws. For MASONRY, such as brick, cement,

cinder block, etc., use carbide-tipped bits rated for percussion drilling.

2. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the drill.

A WARNING: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip

the drill firmly with both hands to control the twisting action and avoid injury,

4. IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE

TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO

NOT CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL --

THIS CAN DAMAGE THE DRILL.

5. To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit

through the last fractional part of the hole.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

7. With variable speed drills there is no need to center punch the point to be drilled. Use a slow

speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

DRILLING IN METAL

Start drilling with slow speed and increase to full power while applying firm pressure on the tool.

A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when

drilling metals. The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large [5/16" (8 ram) to 1/2" (13 ram)] holes in steel can be made easier ifa pilot hole [5/32"

(4 ram) to 3/16" (5 ram)] is drilled first.

DRILLING IN WOOD

Start drilling with slow speed and increase to full power while applying firm pressure on the tool.

Holes in wood can be made with the same twist drills used for metal. These bits may overheat

unless pulled out frequently to clear chips from the flutes. Work that is apt to splinter should be

backed up with a block of wood.

DRILLING IN MASONRY

When drilling in masonry, use carbide-tipped bits rated for percussion drilling and be certain that

the bits are sharp. Use a constant and firm force on the tool to drill most effectively. A smooth, even

flow of dust indicates the proper drilling rate.

MAINTENANCE

_ WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect tool

from power source before making any adjustments or removing/installing attachments

or accessories. An accidental start-up can cause injury,

Cleaning

_WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper

ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory

protection when performing this.

AWARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool,"never immerse any

part of the tool into a liquid.

Lubrication

Self-lubricating bearings are used inthe tool and periodic relubrication isnot required. Inthe unlikely

event that service is ever needed, take your tool to an authorized service location.

Accessories

A WARNING: Since accessories, other than those offered by DEWALT, have not been tested with

this product, use of such accessories with this tool could be hazardous. Toreduce the risk of injury,

only DEWALT,recommended accessories should be used with this producL

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. Ifyou need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-

9258) or visit our website www.dewalt.com.

_ CAUTION: To reduce the risk of injury, the following accessories should be used only in sizes up

to the maximums shown in the table below.

Page 3

MAXIMUM RECOMMENDED CAPACITIES

DWE5010

Chuck capacity 1/2" (13 mm)

Bits, metal drilling 1/2" (13 mm)

Wood, flat boring 1" (25 mm)

Masonry 5/8" (16 mm)

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including

brush inspection and replacement) should be performed by a DEWALT factory service center,

a DEWALT authorized service center or other qualified service personnel. Always use identical

replacement parts.

Register Online

Thank you for your purchase. Register your product now for:

• WARRANTY SERVICE: Registering your product will help you obtain more efficient warranty

service in case there is a problem with your product.

• CONFIRMATION OF OWNERSHIP: In case of an insurance loss, such as fire, flood or theft,

your registration of ownership will serve as your proof of purchase.

• FOR YOUR SAFETY: Registering your product will allow us to contact you in the unlikely event

a safety notification is required under the Federal Consumer Safety Act.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

DEWALTwill repair: without charge: any defects due to faulty materials or workmanship for three

years from the date of purchase. This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you

specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DFWALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or

Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for

a full refund - no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products

sold in Latin America, see country specific warranty information contained in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing,

call 1-800-4-DEWALT (1-800-433-9258) for a free replacement.

t'*i_iliRIVVVV 1/2" 13ram

lIJ V V A.A.A.A HAI_MERDRILL/ DRILLDRIVE_

TOREDUCE THE RiSKOF iNJURY,

MANUAL. ALWAYS USE PROPEREYE AND RESPIRATORY

PROTECTION.

0EWALTINDUSTRIALTOOLCO.,OALTIMORE,MO21286U.S.A.

FORSERVICEINFORMAl10N, CALL1-800-4-OEWALT

USER MUST READ iNSTRUCTiON

www.D_WALT.com

3) S#CURIT# PERSONNELLE

a) E-tre vigilant, surveiller le travail effectu_ et faire preuve de jugement Iorsqu'un outil

_lectrique est utilis_. Ne pas utiliser d'outil _lectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un simple moment d'inattention

en utilisant un outil dectrique peut entra_nerdes blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle. Toujours porter une protection

oculaire. L'utilisation d'equipements de protection comme un masque antipoussiere, des

chaussures antiderapantes, un casque de securite ou des protecteurs auditifs Iorsque la

situation le requiert reduira les risques de blessures corporelles.

c) Emp_cher les d_marrages intempestifs. S'assurer que I'interrupteur se trouve a la

position d'arr_t avant de relier routil a une source d'alimentation et/ou d'ins_rer un

bloc-piles, de ramasser ou de transporter I'outil. Transporter un outi/ e/ectrique a/ors

que le doigt repose sur I'interrupteur ou brancher un outil dectrique dont I'interrupteur est

la position de marche risque de provoquer un accident.

d) Retirer toute cl_ de r_glage ou cl_ avant de d_marrer I'outil. Une cle ou une cle de

reglage attachee a une pattie pivotante de I'outil dectrique peut provoquer des blessures

corporelles.

e) Ne pas trop tendre les bras. Conserver son _quilibre en tout temps. Cela permet de

mieux ma_triser I'outil dectrique dans les situations imprevues.

t) S'habiller de mani_re appropri_e. Ne pas porter de v_tements amples ni de bijoux.

Garder les cheveux, les v_tements et les gants a I'_cart des pi_ces mobiles. Les

v_tements amples, les bijoux ou les cheveux longs risquent de rester coinces dans les pieces

mobiles.

g) Sides composants sent fournis pour le raccordement de dispositifs de d_poussi_rage

et de ramassage, s'assurer que ceux-ci sent bien raccord_s et utilis_s. L'uti/isation

d'un dispositif de depoussierage peut reduire les dangers engendres par les poussieres.

4} UTILISATION ET ENTRETIEN D'UN OUTIL #LECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique appropri_ a rapplication.

L'outil dectrique approprie effectuera un mei/leur travail, de faqon plus sore eta la vitesse

pour laquelle il a ete conqu.

b) Ne pas utiliser un outil _lectrique dont rinterrupteur est d_fectueux. Tout outil

dectrique dont /'interrupteur est defectueux est dangereux et doit _tre repare.

c) D_brancher la fiche de la source d'alimentation et/ou du bloc-piles de I'outil

_lectrique avant de faire tout r_glage ou changement d'accessoire ou avant de

ranger routil. Ces mesures preventives reduisent les risques de demarrage accidentel de

I'outil dectrique.

d) Ranger les outils _lectriques hers de la pottle des enfants et ne permettre

aucune personne n'_tant pas famili_re avec un outil _lectrique ou son mode

d'emploi d'utiliser cet outil. Les outi/s dectriques deviennent dangereux entre/es mains

d'utilisateurs inexperimentes.

e) Entretien des outils _lectriques. V_rifier si les pi_ces mobiles sent mal align_es ou

coinc_es, si des pi_ces sent bris_es ou pr_sentent toute autre condition susceptible

de nuire au ben fonctionnement de routil _lectrique. En cas de dommage, faire

r_parer I'outil _lectrique avant toute nouvelle utilisation. Beaucoup d'accidents sont

causes par des outils dectriques mal entretenus.

f) S'assurer que les outils de coupe sent aiguis_s et propres. Les outils de coupe bien

entretenus et affOtes sont moins susceptibles de se coincer et sont plus faciles a ma_triser.

g) Utiliser I'outil _lectrique, les accessoires, les forets, etc. conform_ment aux

pr_sentes directives en tenant compte des conditions de travail et du travail

effectuer. L'utilisation d'un outil dectrique pour toute operation autre que celle pour laquelle

ila ete conquest dangereuse.

5) RI_PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur professionnel en n'utilisant que

des pi_ces de rechange identiques. Celapermettra de maintenir une utilisation securitaire

de I'outil dectrique.

CONSIGNES DE SECURITE PARTICULIERES

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour chaque mot-indicateur

employe. Veuillez lire le mode d:emploi et porter une attention particuliere a, ces

symboles.

i_DANGER : indique une situation dangereuse imminente qui, si elle n'est pas

evitee, causera la mort ou des blessures graves.

_VERTISSEMENT : indique une situation potentie//ement dangereuse qui, si e//e n'est

pas evitee, pourraff se solder par un d_c_s ou des blessures graves.

_LATTENTION : indique une situation potentiellement dangereuse

qui, si elle n'est pas evitee pourrait se solder par des b/essures mineures ou

modifies.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais

qui par contre, si rien n'est fait pour I'eviter, pourrait poser des risques de dommages

materiels.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIFA CET OUTIL OU APROPOS DE

TOUT AUTRE OUTIL DEWALT, COMPOSER SANS FRAIS LE: 1-800-4-DEWALT (1-800-433-

9258).

AVERTISSEMENT : afin de reduire /e risque de b/essures, /ire /e mode d'emp/oi de/'outi/.

Avertissements de s_curit_ g_n_raux pour les outils

_lectriques

Le non-respect des avertissements et des directives pourrait se solder par un choc

_ AVERTISSEMENT ! Life tousles avertissements de s_curit_ et toutes les directives.

dectrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES LES

DIRECTIVES POUR UN USAGE ULTERIEUR

Le terme _outil dectrique _ cite dans les avertissements se rapporte a votre outil electrique

alimentation sur secteur (avec ill) ou par piles (sans fil).

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les Iieux encombres ou sombres sont

propices aux accidents.

b) Ne pas faire fonctionner d'outils _lectriques clans un milieu d_flagrant, tel qu'en

presence de liquides, de gaz ou de poussi_res inflammables. Les outi/s e/ectriques

produisent des etincelles qui pourraient enflammer la poussiere ou les vapeurs.

c) E-Ioigner les enfants et les personnes a proximit_ pendant rutilisation d'un outil

_lectrique. Une distraction pourrait en faire perdre la ma_trisea I'utilisateur.

2) SI_CURITI_ EN MATIERE D'I_LECTRICITI_

a) Les fiches des outils _lectriques doivent correspondre a la prise. Ne jamais modifier

la fiche d'aucune faqon. Ne jamais utiliser de fiche d'adaptation avec un outil

_lectrique mis a la terre. Le risque de choc dectrique sera reduit par I'utilisation de fiches

non modifiees correspondant a laprise.

b) E-viter tout contact physique avec des surfaces mises a la terre comme des tuyaux,

des radiateurs, des cuisini_res et des r_frig_rateurs. Le risque de choc dectrique est

plus deve si votre corps est mis a la terre.

c) Ne pas exposer les outils _lectriques a la pluie ou a I'humidit_. La penetration de I'eau

dans un outil dectrique augmente le risque de choc dectrique.

d) Ne pas utiliser le cordon de fa_on abusive. Ne jamais utiliser le cordon pour

transporter, tirer ou d_brancher un outil _lectrique. Tenir le cordon _loign_ de

la chaleur, de I'huile, des bords tranchants et des pi_ces mobiles. Les cordons

endommages ou enchev_tres augmentent les risques de choc dectrique.

e) Pour rutilisation d'un outil _lectrique a I'ext_rieur, se servir d'une rallonge

convenant a cette application. L'uti/isation d'une ra//onge conque pour/'exterieur reduira

les risques de choc dectrique.

S'il est impossible d'_viter I'utilisation d'un outil _lectrique clans un endroit

humide, brancher I'outil clans une prise ou sur un circuit d'alimentation dot_s d'un

disjoncteur de fuite a la terre (GFCI). L'utilisation de ce type de disjoncteur reduit les

risques de choc dectrique.

Consignes de s_curit_ propres aux perforatrices

• Porter une protection auditive lots du per_age a percussion. Une exposition au bruit peut

entra_nerune perte auditive.

• Utiliser la/les poign_e(s) auxiliaire(s) si fournie(s) avec I'outil. Une perte de contr61e de

I'outil pourrait occasionner des dommages corporels.

• Tenir I'outil par les surfaces isol_es pr_vues a cet effet pendant toute utilisation o_

I'organe de coupe pourraff entrer en contact avec des ills _lectriques caches ou son

propre cordon. Tout contact de/'organe de coupe avec un fi/ sous tension mettra /es parties

meta//iques exposees de/'outi/sous tension et dectrocutera /'uti/isateur.

• Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le mat_riau sur

une surface stable. Tenir lapiece a la main ou contre son corps offre une stabi/ite insuffisante

qui pourrait vous en faire perdre le contr61e.

• Porter des lunettes de protection ou toute autre protection oculaire. Le pergage

pourrait faire voltiger des eclats. Des particules volantes pourraient occasionner des dommages

oculaires permanents.

• Les m_ches et I'outil peuvent devenir br_lants au toucher pendant I'utilisation. Porter

des gants avant tout contact.

• Maintenir les poign_es propres et s_ches, exempts d'huile ou de graisse. // est

recommande d'utiliser des gants en caoutchouc. Cela offrira une prise plus solide.

• Prendre des precautions a proximit_ des _vents car ils cachent des pi_ces mobiles.

V_tements amples, bijoux ou cheveux longs risquent de rester coinces dans ces pieces mobiles.

• Pour la s_curit_ de liutilisateur, utiliser une rallonge de calibre ad_quat (AWG,

American Wire Gauge [calibrage am_ricain normalis_ des ills _lectriques]). Plus /e

calibre est petit, et plus sa capacite est grande. Un calibre 16, par exemple, a plus de capacite

qu'un calibre 18. L'usage d'une rallonge de calibre insuffisant causera une chute de tension

entra_nantperte de puissance et surchauffe. Si plus d'une rallonge est utilisee pour obtenir une

certaine Iongueur, s'assurer que chaque rallonge presente au moins le calibre de fil minimum.

Le tableau ci-dessous illustre les calibres a utiliser selon la Iongueur de rallonge et I'intensite

nominale indiquee sur la plaque signaletique. En cas de doute, utiliser le calibre suivant. Plus le

calibre est petit, plus la rallonge peut supporter de courant.

Calibre minimum pour rallonge

Volts Longueur totale du cordon

Intensit_ nominale

120V 7,6 (25) 30,5 (100) 45,7 (150)

240V 15,2 (50) 61,0 (200) 91,4 (300)

Plus de

0

6

10

12

Pas plus de

6

10

12

16

5,5 (18)

5,5 (18)

4,9(16)

4,3 (14)

_AVERTISSEMENT : porter SYSTEMATIQUEMENT des lunettes de protection. Les lunettes

courantes NE sont PAS des lunettes de protection. Utiliser aussi un masque antipoussieres si

la decoupe doit en produire beaucoup. PORTER SYSTEMATIQUEMENT UN EQUIPEMENT DE

SECURITE HOMOLOGUE :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) ;

• Protection auditive ANSI S 12.6 ($3.19) ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

i_,AVERTISSEMENT : les scies, meules, ponceuses, perceuses ou autres outils de construction

peuvent produire des poussieres contenant des produits chimiques reconnus par I'Etat califomien

pour causer cancers, malformations congenitales ou _tre nocifs au systeme reproducteur. Parmi

ces produits chimiques, on retrouve :

• Le plomb dans les peintures a base de plomb ;

• La silice cristallisee dans les briques et le ciment, ou autres produits de maqonnerie ; et

• L'arsenic et le chrome dans le bois ayant subi un traitement chimique.

Le risque associe a de telles expositions peut varier selon la frequence avec laquelle on effectue ces

travaux. Pour reduire I'exposition a de tels produits, il faut travailler dans un endroit bien ventile et

utiliser I'equipement de securite approprie tel un masque anti-poussieres specialement conqu pour

filtrer les particules microscopiques.

• Eviter tout contact prolong_ avec la poussi_re soulev_e par cet outil ou autres outils

_lectriques. Porter des v_tements de protection et nettoyer les parties expos_es du

en mbtres (en pieds)

15,2 (50)

30,5 (100)

AWG

4,9 (16)

4,9 (16)

4,9 (16)

3,7 (12)

4,9 (16) 4,3 (14)

4,3 (14) 3,7 (12)

4,3 (14) 3,7 (12)

Non recommande

Page 4

corps avec de I'eau savonneuse. S'assurer de bien se proteger afin d'eviter d'absorber par

la bouche, les yeux ou la peau des produits chimiques nocifs.

i_AVERTISSEMENT : Cet outil peut produire et repandre de la poussiere susceptible de causer

des dommages serieux et permanents au systeme respiratoire, Toujours utiliser un appareil

respiratoire anti-poussieres approuve par le NIOSH ou I'OSHA. Diriger les particules dans le sens

oppose du visage et du corps.

AAVERTISSEMENT : Pendant rutilisation, porter syst_matiquement une protection

auditive individuelle adequate homologu_e ANSI $12.6 ($3.19). Sous certaines conditions et

suivant la Iongueur d'utilisation, le bruit emanant de ce produit pourrait contribuer a une perte de

I'acuite auditive.

• L'etiquette apposee sur I'outil peut comprendre les symboles suivants, Voici les symboles et

leurs • L'etiquette apposee sur votre outil peut inclure les symboles suivants. Les symboles et

leur definition sont indiques ci-apres :

V..................... volts

Hz................... hertz

min ................. minutes

- --. ............. courant continu

_) ................... classe I fabrication

(mis a la terre)

[] ................... fabrication classe II

(double isolation)

.../min ............ par minute

IPM ................. impacts par minute

sfpm ............... pieds lineaires par minute (plpm)

SPM (FPM)..... frequence par minute

A.................... amperes

W................... watts

"_ ................. courant altematif

_-_................. courant altematif ou

continu

no.................. vitesse a vide

n.................... vitesse nominale

@ .................. borne de terre

_ ................... symbole d' avertissement

BPM .............. battements par minute

r/min .............. tours par minute

DESCRIPTION (Fig. 1)

j_4VERTISSEMENT : Ne jamais modifier I'outil dectrique ni aucun de ses composants. II y a

risques de dommages corporels ou materiels.

A. Gb,chette a,vitesse variable F.Cordon amovible

B. Bouton de verrouillage en position de G. Poignee laterale

marche H. Tige de reglage de profondeur

C. Bouton de marche avant/arriere I. Selecteur de mode

D. Mandrin J. Poignee principale

E. Protege cordon avec porte cle

USAGE PR#VU

Ces perforatrices industriellesVSR ont et6 congues pour le pergage professionnel.

NE PAS les utiliser en milieu ambiant humide ou en presence de liquidesou de gaz inflammables.

Ces perforatrices industrielles sont des outils de professionnels. NE PAS les laisser a,la portee des

enfants. Une supervision est necessaire aupres de tout utilisateur non experimente.

ASSEMBLAGE ET AJUSTEMENTS

_AVERTISSEMENT : Pour r_duire tout risque de dommages corporels graves, arr_ter et

d_brancher I'outil avant tout r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Un demarrage accidentel peut provoquer des blessures.

Poign_e lat_rale (Fig. 1)

_AVERTISSEMENT : pour reduire tout risque de dommages corporels, utiliser

SYST£-MATIQUEMENT I'outil avec sa poignee laterale installee correctement. Tout manquement

cette directive pourrait faire que la poignee laterale glisse pendant I'utilisation de I'outil et entra_ner

la perte du contr61e de celui-cL Maintenir I'outil fermement a deux mains pour un contr61e optimal

Le modele DWE5010 vient avec une poignee laterale preassemblee. La poignee laterale (G) peut

_tre installee pour pouvoir servir a,un droitier ou a,un gaucher.

INSTALLATION DE LA POIGN#E LAT#RALE

1. Desserrez la poignee laterale (G) en la faisant tourner vers la gauche.

2. Faites tourner la poignee laterale sur la position desiree.

3. Resserrez la poignee laterale en la faisant tourner vers la droite. La poignee laterale doit _tre

suffisamment resserree pour resister a,toute torsion de routil si raccessoire venait a,caler ou

a,se bloquer. Assurez-vous de bien saisir la poignee laterale a,son extremite pour conserver le

contrOle de I'outil en cas d'arr_t brutal.

POUR CHANGER DE COT#

Pour les droitiers : inserez le dispositif de fixation de la poignee laterale par-dessus le mandrin,

avec la poignee a,gauche.

Pour les gauchers : inserez le dispositif de fixation de la poignee laterale par-dessus le mandrin,

avec la poignee a,droite.

Levier de marche avant/arri_re (Fig. 1)

Le levier de marche avant/arriere (C) est utilise pour retirer les meches des trous etroits et pour

devisser les vis. II est situe au-dessus de la gb,chette.

Pour mettre le moteur en marche arriere, rel_,chezD'ABORD la gb,chette puis poussez le levier vers

la droite (vu alors que ron tient la perceuse en position de pergage).

Apres toute operation en marche arriere, retournez le levier dans sa position de marche avant.

S_lecteur de mode (Fig. 2)

AVIS : pour prevenir tout dommage materiel, attendre I'arr_t complet de I'outil avant d'activer le

bouton sdecteur de mode,

Selectionnez le mode d'utilisation en poussant leselecteur de mode (I)sur lesymbole correspondant.

MODE PERQAGE SEULEMENT

Utilisez le mode pergage seulement pour le bois, le metal et les plastiques.

T MODE MARTELAGE-PERFORAGE

Utilisez le mode martelage-perforage pour le pergage rotatif a,percussion de la

magonnerie, de la brique et du beton.

R_glage de la profondeur de per(;age (Fig. 3)

1. Inserez la meche requise dans le mandrin.

2. Desserrez la poignee laterale (G).

3. Inserez la tige de reglage de profondeur (H) dans le trou de la fixation de la poignee laterale.

4. Ajustez la profondeur de pergage comme illustre en figure 3.

5. Resserrez la poignee laterale.

Mandrin _ cl_ (Fig. 1, 4, 5)

DWE5010

La DWE5010 est equipee d'un mandrin a,cle (D).

POUR INS#RER UNE MIeCHE OU TOUT AUTRE ACCESSOIRE

1. Ouvrez les m_,choires du mandrin en faisant tourner la bague manuellement puis inserez-y la

tige de la meche sur une Iongueur d'environ 19 mm (3/4 po). Resserrez le collier du mandrin

manuellement.

2. Inserez la cle de mandrin dans chacun des trois trous puis serrez vers la droite. II est important

de serrer le mandrin a,raide des trois trous.

Pour liberer la meche, faites tourner la cle du mandrin vers la gauche a,I'aide d'un seul trou, puis

desserrez le mandrin manuellement.

RETRAIT DU MANDRIN .ACL# (FIG. 4)

Resserrez le mandrin sur I'extremite la plus courte d'une cle hexagonale. Utilisez un marteau souple

pour donner un coup sec sur la cle vers la gauche (vu depuis ravant de I'outil). Cela desserrera le

mandrin et permettra de le retirer manuellement.

INSTALLATION DU MANDRIN ._,CL# (FIG. 5}

Vissez a,fond le mandrin manuellement. Inserez I'extremite courte d'une cle hexagonale et, a,I'aide

d'un marteau souple, donnez un coup sec sur la cle vers la droite.

FONCTIONNEMENT

_AVERTISSEMENT : Pour r_duire tout risque de dommages corporels graves, arr_ter et

d_brancher I'outil avant tout r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Un demarrage accidentel peut provoquer des blessures.

_AVERTISSEMENT : pour r_duire tout risque de dommages corporels, s'assurer

SYSTE-MATIQUEMENT que la piece est ancree ou arrimee solidement. Pour percer des

materiaux fins, utiliser un morceau de bois _ de renfort _pour eviter de les endommager.

_,AVERTISSEMENT : ne pas essayer de resserrer ou desserrer les meches (ou tout autre

accessoire) en agrippant la pattie avant du mandrin tout en mettant I'outil en marche. Cela pourrait

endommager le mandrin et poser des risques de dommages corporels.

G_chette (Fig. 1)

Pour demarrer la perforatrice, appuyez sur la gb,chette. Pour I'arr_ter, rel_,chez la gb,chette.

REMARQUE : utilisez une vitesse reduite pour commencer un trou sans pointeau, pour percer

le metal ou les plastiques, enfoncer des vis ou percer la ceramique. Les vitesses elevees sont

recommandees pour percer le bois et les panneaux d'agglomere, et pour utiliser des accessoires

abrasifs ou de polissage.

VITESSE VARIABLE

La gb,chette a,vitesse variable (A) permet de contr01er la vitesse. Plus on appuie sur la gb,chette,

plus la vitesse de la perceuse est elevee.

Pour un travail continu, appuyez a, fond sur la gb,chette a,vitesse variable et maintenez-la ainsi,

enfoncez le bouton de verrouillage en position de marche (B)puis relb,chez I'interrupteur.

Ne verrouillez pas rinterrupteur en position de marche pour percer manuellement de fagon a,

pouvoir rel_,cher instantanement la gb,chette si la meche venait a,rester coincee dans le trou.

Le bouton de verrouillage en position de marche (B)est utilise seulement Iorsque la perforatrice est

montee sur un support de perceuse a, colonne ou maintenue fixe par toute autre maniere.

Pour arr_ter le travail continu, appuyez brievement sur I'interrupteur puis rel_,chez-le. Mettez

systematiquement rinterrupteur en position d'arr_t une fois le travail termine et avant de debrancher

I'outil.

Position correcte des mains (Fig. 6)

_AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, maintenir

SYST£-MATIQUEMENT I'outil en respectant la position des mains illustree en figure 6.

_AVERTISSEMENT : pour reduire tout risque de dommages corporels graves, maintenir

SYST£-MATIQUEMENT I'outil fermement pour anticiper toute reaction soudaine.

La position correcte des mains requiert une main sur la poignee principale (J), et I'autre sur la

poignee laterale (G).

Per_;age

_AVERTISSEMENT : pour r_duire tout risque de dommages corporels, s'assurer

SYSTEMATIQUEMENT que la piece est ancree ou arrimee solidement. Pour percer des materiaux

fins, utiliser un morceau de bois _de renfort _ pour eviter de les endommager.

1. Utilisez seulement des meches bien affOtees. Pour le BOIS, utilisez : meches helico'l'dales,

forets a,trois pointes, meches torsadees ou emporte-piece. Pour le MC:TAL,utilisez : meches

helico'l'dalesen acier ou emporte-piece. Pour la MA(_ONNERIE, comme la brique, le ciment, les

blocs beton, etc., utilisez des meches a,pointe de carbure pour le pergage a,percussion.

2. Appliquez systematiquement une certaine pression tout en restant dans raxe de la meche.

Utilisez assez de pression pour que la perceuse avance, mais sans pousser excessivement

pour eviter de bloquer le moteur ou devier la meche.

3. Maintenez fermement I'outil a,deux mains pour contrOler raction de torsion de la perceuse.

_AVERTISSEMENT : la perceuse peut caler si on la force et causer une torsion, S'attendre

systematiquement a un blocage. Maintenir fermement la perceuse a deux mains pour contr61er

toute torsion et eviter tout risque de dommages corporels.

4. SI LA PERFORATRICE SE BLOGUE, c'est en general parce qu'elle est surchargee ou

utilisee incorrectement. RELACHEZ ALORS LA GACHE'R'E IMMIeDIATEMENT, retirez

la meche de la piece puis determinez quelle est la cause du blocage. N'APPUYEZ PAS

R#P#TITIVEMENT SUR LA GACHETTE POUR TENTER DE RED#MARRER UNE

PERFORATRICE BLOQU#E. CELA POURRAIT ENDOMMAGER LA PERFORATRICE.

5. Pour minimiser tout blocage ou rupture du materiau, reduisez la pression sur la perforatrice

pour faciliter le passage de la meche dans la partie finale du trou.

6. Laissez le moteur en marche alors que vous retirez la meche du trou pour eviter tout grippage.

7. Les pointeaux sont inutiles Iorsqu'on utilise une perforatrice a, vitesse variable. Utilisez une

vitesse reduite pour commencer un trou, puis accelerez en appuyant plus fort sur la gb,chette

Iorsque le trou est assez profond pour que la meche ne ressorte pas.

PERQAGE DU M#TAL

Commencez a, percer a,une vitesse reduite puis passez a, pleine puissance tout en maintenant une

pression ferme sur I'outil. Un jet fluide et regulier de debris metalliques sera indicateur d'une vitesse

adequate. Utilisez un lubrifiant de coupe pour percer les metaux, a,I'exception de la fonte et du

laiton qui doivent _tre perces a,sec.

REMARQUE : les trous larges [de 8 mm (5/16 po) a, 13 mm (1/2 po)] dans I'acier peuvent _tre

facilites si I'on perce d'abord un trou pilote [de 4 mm (5/32 po) a,5 mm (3/16 po)].

PERQAGE DU BOIS

Commencez a, percer a,une vitesse reduite puis passez a, pleine puissance tout en maintenant une

pression ferme sur I'outil, Les trous dans le bois peuvent _tre effectues avec les m_mes meches

helico'l'dalesque pour le metal. Ces meches peuvent surchauffer si on ne les retire pas frequemment

du trou pour en eliminer les debris. Tout materiau risquant d'eclater doit _tre renforce par un

morceau de bois.

PERQAGE DE LA MAQONNERIE

Pour percer la magonnerie, utilisez des meches b,pointe de carbure pour le pergage a,percussion

et assurez-vous que la pointe est aceree. Appliquez une force solide et constante sur I'outil pour

optimiser le pergage. Un jet fluide et regulier de debris sera indicateur d'une vitesse adequate.

MAINTENANCE

_AVERTISSEMENT : Pour r_duire tout risque de dommages corporels graves, arr_ter et

d_brancher I'outil avant tout r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Un demarrage accidentel peut provoquer des blessures.

Entretien

i_AVERTISSEMENT : Expulser tout debris ou poussiere des events a I'aide d'un jet d'air sec

au moins une lois par semaine. Porter une protection oculaire ANSI Z87.1 (CAN/CSA Z94.3) et

respiratoire NIOSH/OSHA/MSHA adequates pour effectuer cette operation.

,_AVERTISSEMENT : Ne jamais utiliser de solvants ou tout autre produit chimique decapant

pour nettoyer les parties non metalliques de I'outil. Ces produits chimiques pourraient attaquer les

materiaux plastiques utilises. Utilisez un chiffon humidifie avec de I'eau et un savon doux. S'assurer

qu'aucun liquide ne penetre dans I'outil ; ne jamais immerger aucune partie de I'outil dans un liquide.

Lubrification

Des roulements autolubrifiants sont utilises dans cet appareil et aucune lubrification periodique n'est

necessaire. Dans I'eventualite peu probable oO une maintenance s'avererait necessaire, amener

I'outil dans un centre de reparation agree.

Accessoires

_,AVERTISSEMENT : Comme les accessoires autres que ceux offerts par DEWALT n'ont pas ete

testes avec ce produit, leur utilisation avec cet appareil pourrait comporter un danger. Pour reduire

tout risque de dommages corporels, seuls des accessoires DEWALT recommandes doivent _tre

utilises avec cet appareil.

Les accessoires recommandes pour cet outil sont vendus separement au centre de service

de votre region. Pour obtenir de raide concernant I'achat d'un accessoire, communiquer avec

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 aux Etats-Unis;

composer le 1 800 433-9258 (1 800 4-DEWALT) ou visiter notre site Web : www.dewalt.com.

_ATTENTION : pour reduire tout risque de dommages corporels, utiliser les accessoires suivants

seulement dans les limites de capacite illustrees par le tableau ci-dessous.

CAPACITIES MAXIMALES RECOMMANDIeES

DWE5010

Capacite de mandrin 13 mm (1/2 po)

Meches, pergage du metal 13 mm (1/2 po)

Bois, alesage plat 25 mm (1 po)

Magonnerie 16 mm (5/8 po)

R_paration

Pour assurer la S¢:CURIT¢:et la FIABILIT¢:du produit, les reparations, rentretien et les reglages (y

compris I'inspection et le remplacement des balais) doivent _tre realises par un centre de reparation

en usine DEWALT,un centre de reparation autorise DEWALTou par un personnel d'entretien quali%.

Toujours utiliser des pieces de rechange identiques.

Page 5

Registre en ligne

Merci pour votre achat. Enregistrez des maintenant votre produi:

• R#PARATIONS SOUS GARANTIE: cette carte remplie vous permettra de vous prevaloir du

service de reparations sous garantie de fagon plus efficace dans le cas d'un probleme avec le

produit.

• CONFIRMATION DE PROPRII_TI_: en cas de perte provoquee par un incendie, une

inondation ou un vol, cette preuve de propriete vous servira de preuve aupres de votre

compagnie d'assurances.

• SI_CURITI_: I'enregistrement de votre produit nous permettra de communiquer avec vous dans

I'eventualit6 peu probable de I'envoi d'un avis de securit6 regi par la Ioifederale americaine de

la protection des consommateurs.

Registre en ligne a.www.dewalt.com/register.

Garantie limit_e de trois ans

DEWALT reparera, sans frais, tout produit defectueux cause par un defaut de materiel ou de

fabrication pour une periode de trois ans a. compter de la date d'achat. La presente garantie ne

couvre pas les pieces dont la defectuosite a et6 causee par une usure normale ou I'usage abusif

de I'outil. Pour obtenir de plus amples renseignements sur les pieces ou les reparations couvertes

par la presente garantie, visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-DEWALT). Cette garantie ne s'applique pas aux accessoires et ne vise pas les dommages causes

par des reparations effectuees par un tiers. Cette garantie confere des droits legaux particuliers a.

I'acheteur, mais celui-ci pourrait aussi beneficier d'autres droits variant d'un etat ou d'une province

a.I'autre.

En plus de la presente garantie, les outils DEWALT sont couverts par notre :

CONTRAT D'ENTRETIEN GRATUlT D'UN AN

DFWALTentretiendra I'outil et remplacera les pieces usees au cours d'une utilisation normale et ce,

gratuitement, pendant une periode d'un an a.compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas entierement satisfait, pour quelque raison que ce soit, du rendement de

I'outil electrique, du laser ou de la cloueuse DEWALT,celui-ci peut le retourner, accompagne d'un

regu, dans les 90 jours a.compter de la date d'achat pour obtenir un remboursement integral, sans

aucun probleme.

AMI_RIQUE LATINE : cette garantie ne s'applique aux produits vendus en Amerique latine.

Pour ceux-ci, veuillez consulter les informations relatives a.la garantie specifique presente dans

I'emballage, appeler I'entreprise locale ou consulter le site Web pour les informations relatives a.

cette garantie.

REMPLACEMENT GRATUIT DES I_TIQUETTES D'AVERTISSEMENT : si les etiquettes

d'avertissement deviennent illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-DEWALT) pour en obtenir le remplacement gratuit.

DWXXXX

MANUAL. ALWAYS USE PROPER EYE AND RESPIRATORY

PROTECTJON.

DEWALT iNDUSTRiAL TOOL CO., 0ALTIMORE, MD 21286 U.S.A.

FORSERVICE iNFORMATiON, CALL 1-80R-4-DEWALT

HAMMERDRILL / DRILL DRIVER

TO REDUCE THE RiSK OF iNJURY,

USER MUST READ iNSTRUCTiON

F Definiciones: Normas de seguridad h

Las siguientes definiciones describen el nivel de gravedad de cada palabra de

sepal, Lea el manual y preste atenci6n a estos s[mbolos,

@ELIGRO: indica una situacidn de peligro inminente que, si no se evita,

provocara la muerte o lesiones graves.

_4DVERTENCIA: indica una situacidn de peligro potencial que, si no se evita,

podria provocar la muerte o lesiones graves.

_.ATENCI(_N: indica una situacidn de peligro potencial que, si no se evita,

posiblemente provocarfa lesiones leves o moderadas.

AVISO: se refiere a una practica no relacionada a lesiones corporales que de

no evitarse puede resultar en dafios a la propiedad.

J

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE ESTA U OTRA HERRAMIENTA

DEWALT,LLAMENOS AL NOMERO GRATUITO: 1-800-4-DEWALT (1-800-433-9258}

ADVERTENCIA: Para reducir el riesgo de lesiones, lea el manual de instrucciones.

Advertencias generales de seguridad para herramientas

eldctricas

incumplimiento de las advertencias e instrucciones puede provocar descargas electricas,

A iADVERTENCIA! Lea todas las advertencias de seguridad e instrucciones. El

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E INSTRUCCIONES

PARA FUTURAS CONSULTAS

El termino "herramienta electrica" incluido en las advertencias hace referencia alas herramientas

electricas operadas con corriente (con cable electrico) o alas herramientas electricas operadas

con baterfas (inalambricas).

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga el area de trabajo limpia y bien iluminada. Las areas abarrotadas y oscuras

propician accidentes.

b) No opere las herramientas el_ctricas en atmosferas explosivas, come ambientes

donde haya polvo, gases o liquidos inflamables. Las herramientas e/ectricas originan

chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los nifios y a los espectadores de la herramienta el_ctrica en

funcionamiento. Las distracciones pueden provocar la perdida de control

2} SEGURIDAD EL#CTRICA

a) Los enchufes de la herramienta el_ctrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningEm enchufe adaptador con

herramientas el_ctricas con conexidn a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reduciran el riesgo de descarga electrica.

b) Evite el contacto corporal con superficies con descargas a tierra como, per

ejemplo, tuberias, radiadores, cocinas el_ctricas y refrigeradores. Existe mayor riesgo

de descarga electrica si su cuerpo esta puesto a tierra.

c) No exponga las herramientas el_ctricas a la Iluvia o a condiciones de humedad. Si

entra agua a una herramienta electrica, aumentara el riesgo de descarga electrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o desenchufar

la herramienta el_ctrica. Mantenga el cable alejado del calor, el aceite, los bordes

filosos y las piezas moviles. Los cables dahados o enredados aumentan el riesgo de

descarga electrica.

e) AI operar una herramienta el_ctrica en el exterior, utilice un cable prolongador

adecuado para tal use. Utilice un cable adecuado para uso en exteriores a fin de reducir

el riesgo de descarga electrica.

f) Si el use de una herramienta el_ctrica en un lugar h_medo es imposible de evitar,

utilice un suministro protegido con un interrupter de circuito per falla a tierra

(GFCI). El uso de un GFCI reduce el riesgo de descargas electricas.

3} SEGURIDAD PERSONAL

a) Permanezca alerta, controle Io que esta haciendo y utilice el sentido comEm

cuando emplee una herramienta el_ctrica. No utilice una herramienta el_ctrica si

esta cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta electrica puede provocar lesiones personales

graves.

b) Utilice equipos de proteccion personal Siempre utilice proteccidn para los ojos. En

las condiciones adecuadas, el uso de equipos de proteccidn, como mascaras para polvo,

calzado de seguridad antideslizante, cascos o proteccidn auditiva, reducira las lesiones

personales.

c) Evite el encendido por accidente. Aseg_rese de que el interruptor est_ en la

posicion de apagado antes de conectarlo a la fuente de energia o paquete de

baterias, o antes de levantar o transportar la herramienta. Transportar herramientas

electricas con el dedo apoyado en el interruptor o enchufar herramientas electricas con el

interruptor en la posicidn de encendido puede propiciar accidentes.

d) Retire la clavija de ajuste o la Ilave de tuercas antes de encender la herramienta

el_ctrica. Una I/ave de tuercas o una clavija de ajuste que quede conectada a una pieza

giratoria de la herramienta electrica puede provocar lesiones personales.

e) No se estire. Conserve el equilibrio y parese adecuadamente en todo memento.

Esto permite un mejor control de la herramienta electrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el cabello,

la ropa y los guantes alejados de las piezas en movimiento. Las ropas ho/gadas, /as

joyas o el cabello largo pueden quedar atrapados en las piezas en movimiento.

g) Si se suministran dispositivos para la conexion de accesorios con fines de

recoleccidn y extraccion de polvo, asegdrese de que est_n conectados y que se

utilicen correctamente. Eluso de dispositivos de recoleccidn de polvo puede reducir los

peligros relacionados con el polvo.

4} USO Y MANTENIMIENTO DE LA HERRAMIENTA EL#CTRICA

a) No fuerce la herramienta el_ctrica. Utilice la herramienta el_ctrica correcta para el

trabajo que realizara. Sise la utiliza ala velocidad para la que rue disehada, la herramienta

electrica correcta permite trabajar mejor y de manera mas segura.

b) No utilice la herramienta el_ctrica si no puede encenderla o apagarla con el

interrupter. Toda herramienta electrica que no pueda set controlada mediante el interruptor

es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energia o el paquete de baterias de la

herramienta el_ctrica antes de realizar ajustes, cambiar accesorios o almacenar

la herramienta el_ctrica. Estas medidas de seguridad preventivas reducen el riesgo de

encender la herramienta electrica en forma accidental.

d) Guarde la herramienta el_ctrica que no est_ en use fuera del alcance de los nifios y

no permffa que otras personas no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas electricas son peligrosas si son operadas pot

usuarios no capacitados.

e) Realice el mantenimiento de las herramientas el_ctricas. Revise que no haya piezas

en movimiento mal alineadas o trabadas, piezas rotas o cualquier otra sffuacidn

que pueda afectar el funcionamiento de la herramienta el_ctrica. Si encuentra

darius, haga reparar la herramienta el_ctrica antes de utilizarla. Se producen muchos

accidentes a causa de las herramientas electricas que carecen de un mantenimiento

adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de corte

con mantenimiento adecuado y con los bordes de corte afilados son menos propensas a

trabarse y son mas faciles de controlar.

g) Utilice la herramienta el_ctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de /a herramienta e/ectrica para

operaciones diferentes de aqudlas para las que rue disehada podrfa originar una situacidn

peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que realice el mantenimiento

de su herramienta el_ctrica y que solo utilice piezas de repuesto id_nticas. Esto

garantizara la seguridad de la herramienta electrica.

NORMAS ESPECIFICAS DE SEGURIDAD

Advertencias de seguridad para taladros

• Cuando use el taladro percutor, use protectores auditivos. La exposicidn al ruido puede

ocasionar la perdida de la audicidn.

• Utilice el (los) mango(s) auxiliares, si alguno viene con la herramienta. Perder el control

de la herramienta podrfa causar lesiones corporales.

• Use abrazaderas u otra manera practica de fijar y sujetar la pieza de trabajo a una

plataforma estable. Sujetar la pieza con la mano o contra el cuerpo es inestable y resultara

en que pierda el control.

• Lleve lentes de seguridad u otra proteccion ocular. Durante la perforacidn pueden

salir disparados pedazos de material. Las partfculas despedidas pueden provocar lesiones

irreversibles en los ojos.

• Las brocas y las herramientas se calientan durante la operacidn. Utilice guantes para

tocarlas.

• Mantenga los mangos secos y limpios, libres de aceite y grasa. Se recomienda el uso

de guantes de goma. Esto permitira un mejor control.

• Las rejillas de ventilacion suelen cubrir piezas en movimiento, per Io que se debe

evitar el contacto con elias. Las piezas en movimiento pueden atrapar prendas de vestir

sueltas, joyas o cabellos largos.

• E1 cable de extension deben set de un calibre apropiado para su seguridad. Mientras

menor sea el calibre del hilo, mayor la capacidad del cable. Es decir, un hilo calibre 16 tiene

mayor capacidad que uno de 18. Un cable de un calibre insuficiente causara una cafda en la

tensidn de la Ifnea dando pot resultado una perdida de energfa y sobrecalentamiento. Cuando

se utilice mas de un alargador para completar el largo total, asegdrese que los hilos de cada

alargador tengan el calibre mfnimo. La tabla siguiente muestra el tamaho correcto a utilizar,

dependiendo de la Iongitud del cable y del amperaje nominal de la placa de identificacidn. Si

tiene dudas sobre cual calibre usar, use un calibre mayor. Cuanto mas pequeho sea el ndmero

del calibre, mas resistente sera el cable.

Calibre minimo para juegos de cables

Voltios Largo total del cable en metros (en pies)

Capacidad nominal 120V 7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

en amperios 240V f5,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

Desde Hasta AWG

0 6 18 16 16 14

6 f0 18 16 14 12

f0 12 16 16 14 12

f 2 f 6 f 4 f 2 No recomendado

_DVERTENCIA: Use SIEMPRE /entes de seguridad. Los anteojos de uso diario NO son/entes

de seguridad. Utilice tambien mascaras faciales o para polvo si los cortes producen polvil/o.

UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

• Proteccidn para los ojos ANSI Z87.1 (CAN/CSA Z94.3),

• Proteccidn auditiva ANSI $12.6 ($3.19),

• Proteccidn respiratoria segdn las normas NIOSH/OSHA/MSHA.

i_,ADVERTENCIA: Algunas partfculas de polvo generadas al lijar, serrar, esmerilar y taladrar

con herramientas electricas, asf como al realizar otras actividades de construccidn, contienen

qufmicos que el Estado de California sabe que pueden producir cancer, defectos congenitos u

otras afecciones reproductivas. Ejemplos de estos qufmicos son."

• plomo de algunas pinturas en base a plomo,

• polvo de sflice proveniente de ladrillos y cemento y otros productos de albahilerfa, y

• arsenico y cromo provenientes de madera tratada qufmicamente.

El riesgo al contacto con estas substancias varfa, segdn la frecuencia en que se haga este tipo de

trabajo. Para reducir la exposicidn a esas substancias qufmicas: trabaje en un area bien ventilada, y

trabaje con equipos de seguridad aprobados, tales como mascaras contra el polvo especialmente

disehadas para filtrar las partfculas microscdpicas.

• Evite el contacto prolongado con pelves originados per lijar, aserrar, esmerilar, taladrar

y otras actividades constructivas. Vista ropas protectoras y lave las areas expuestas

con agua y jabon. Permitir que el polvo se introduzca en su boca, ojos, o dejarlo sobre la piel

promueve la absorcidn de qufmicos dahinos.

_,ADVERTENCIA: La utilizacidn de esta herramienta puede originar polvo o dispersarlo, Io que

podrfa causar dahos graves y permanentes al sistema respiratorio, asf como otras lesiones.

Siempre use proteccidn respiratoria aprobada pot NIOSH/OSHA, apropiada para su uso en

condiciones de exposicidn al polvo. Procure que las partfculas no se proyecten directamente sobre

su rostro o su cuerpo.

Page 6

J_4DVERTENCIA: Siempre Ileve la debida proteccion auditiva personal en conformidad

con ANSI $12.6 ($3.19) durante el use de esta herramienta. Bajo algunas condiciones y

duraciones de uso, el ruido producido pot este producto puede contribuir a la perdida auditiva.

• La etiqueta de su herramienta puede incluir los siguientes sfmbolos. A continuacidn se indican

los sfmbolos y sus definiciones:

V.................. voltios

Hz................ hertz

min .............. minutos

- --. .......... corriente directa

Q ................ Construccidn de Clase I

(tierra)

[] ................ Construccidn de Clase II)

(doble aislamiento)

.../min ......... pot minuto

IPM ............. impactos pot minuto

sfpm ............ pies de superficie por minuto

SPM ............ pasadas pot minuto

A................... amperios

W.................. vatios

% ................ corriente altema

................ corriente altema o directa

no ................. velocidad sin carga

n ................... velocidad nominal

................. terminal de conexidn a tierra

,_J,.................. sfmbolo de advertencia de

seguridad

BPM ............. golpes pot minuto

RPM ............. revoluciones pot minuto

COMPONENTES (Fig. 1)

_ADVERTENCIA: Nunca modifique la herramienta electrica, ni tampoco ninguna de sus

piezas. Podrfa producir lesiones corporales.

A. Gatillo conmutador de velocidad variable

B. Bot6n de bloqueo en encendido

C. Bot6n de avance y reversa

D. Mandril

E. Protector de cable con sujeta Ilaves

USO DEBIDO

Estos taladros para trabajos pesados VSR estO,n dise_ados para operaciones de perforaci6n

industriales

NO utilice la herramienta en condiciones h0medas o en la presencia de liquidos o gases inflamables.

Estos taladros industriales son herramientas electricas profesionales.

NO permita que un niBo juegue con ellos. Si el operador no tiene experiencia operando esta

herramienta, su uso debera ser supervisado.

F.Cable

G. Mango lateral

H. Wstago de ajuste de profundidad

I. Selector de modalidad

J. Mango principal

MONTAJE Y AJUSTES

_ WARNING: To reduce the risk of injury, turn unit off and disconnect it from power

source before installing and removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Mango lateral (Fig. 1)

JL4DVERTENCIA: Para reducir el riesgo de lesiones corporales, SIEMPRE opere la herramienta

con el mango lateral debidamente instalado y ajustado. Elincumplimiento con Io anterior podrfa

resultar en que el mango lateral se suelte durante la operacidn de la herramienta y que el

operador pierda el control como consecuencia. Sostenga la herramienta con ambas manos para

maximizar control

El mango lateral viene ensamblado con el DWE5010. El mango lateral (G) puede ser instalado

para acomodar a zurdos y diestros.

PARA AJUSTAR EL MANGO LATERAL

1. Afloje el mango lateral (G) girO.ndolo en el sentido contrario a las manecillas del reloj.

2. Rote el mango lateral a la posiciOn deseada.

3. Ajuste el mango lateral girandolo en sentido horario. El mango lateral debe ajustarse

firmemente para que resista la acci6n de giro de la herramienta si el accesorio se traba o

detiene. Aseg0rese de agarrar el mango lateral por el extremo para controlar la herramienta

durante una parada.

PARA CAMBIAR DE LADO

Para usuarios diestros: deslice el soporte del mango lateral por encima del mandril, con el

mango hacia la izquierda.

Para usuarios zurdos: deslice el soporte del mango lateral por encima del mandril, con el

mango hacia la derecha.ht.

Palanca de avance y retroceso (Fig. 1)

La palanca de avance y retroceso (C) se utiliza para poder retirar la broca de orificios ajustados

y para destornillar tornillos. Se ubica encima del gatillo conmutador.

Para invertir la direcciOn del motor, suelte PRIMERO el gatillo conmutador y luego empuje la

palanca a la derecha (si sostiene el taladro en su posiciOn de operaciOn).

Luego de cualquier operaciOn realizada en reversa, devuelva la palanca a su posiciOn de avance.

Selector de modalidad (Fig. 2)

AVISO: La herramienta debe estar completamente parada antes de activar el botdn selector de

modalidad, a fin de evitar dahos a la herramienta.

Deslice el selector de modalidad (I)al dmbolo correspondiente para seleccionar la modalidad de

operaciOn que requiere.

MODALIDAD DE SOLO TALADRADO

Utilice la modalidad de s61otaladrado para madera, metales y plO,sticos.

T MODO DE TALADRADO DE PERCUSION

Use el modo de taladrado de percusiOn para rotar e impactar simultO.neamente

para mamposter[a, ladrillo y concreto.

Selecci6n de la profundidad de taladrado (Fig. 3)

1. Inserte la broca que requiere en el mandril.

2. Afloje el mango lateral (G).

3. Inserte el vastago de ajuste de profundidad (H) en el orificio en el soporte del mango lateral.

4. Ajuste la profundidad de taladrado como se muestra en la Figura 3.

5. Ajuste el mango lateral.

Mandril con Ilave (Fig. 1, 4, 5)

DWE5010

El DWE5010 viene con un mandril con Ilave (D).

PARA INSERTAR UNA BROCA DE TALADRO U OTRO ACCESORIO

1. Gire el collarin con la mano para abrir el mandril e inserte el vO.stagode la broca unos 19 mm

(3/4 pulg.) en el mandril. Ajuste el collarin del mandril con la mano.

2. Coloque la Ilave del mandril en cada uno de los tres orificios y ajuste en el sentido de las

manillas del reloj. Es importante que ajuste el mandril con los tres orificios.

Para liberar la broca, gire el mandril en sentido contrario a las manillas del reloj valiendose

solamente de un orificio y afloje a continuaciOn el mandril con la mano.

RETIRO DEL MANDRIL CON LLAVE (FIG. 4}

Ajuste el mandril entorno al extremo corto de una Ilavehexagonal. Con un martillo blando, dele a la Ilave

un golpe preciso en direcci6n contraria a las manillas del reloj (vista desde el frente de la herramienta).

De esta forma se soltara el mandril para poderse retirar con la mano.

INSTALACI(_)N DEL MANDRIL CON LLAVE (FIG. 5}

Atomilleel mandril con lamano Io mO,sque pueda. Inserteel extremo mO,s corto de una Ilavehexagonal