Page 1

DWE4887N

Page 2

English (original instructions) 3

Français (traduction de la notice d’instructions originale) 11

(ﺓﻲﻠﺻﻷا تﺎﻤﻴﻠﻌﺘﻟا ﻦﻋ ﻢﺟﺮﺘﻣ) :ﺔﻴﺑﺮﻌﻟﺍ 20

2

Copyright DEWALT

Page 3

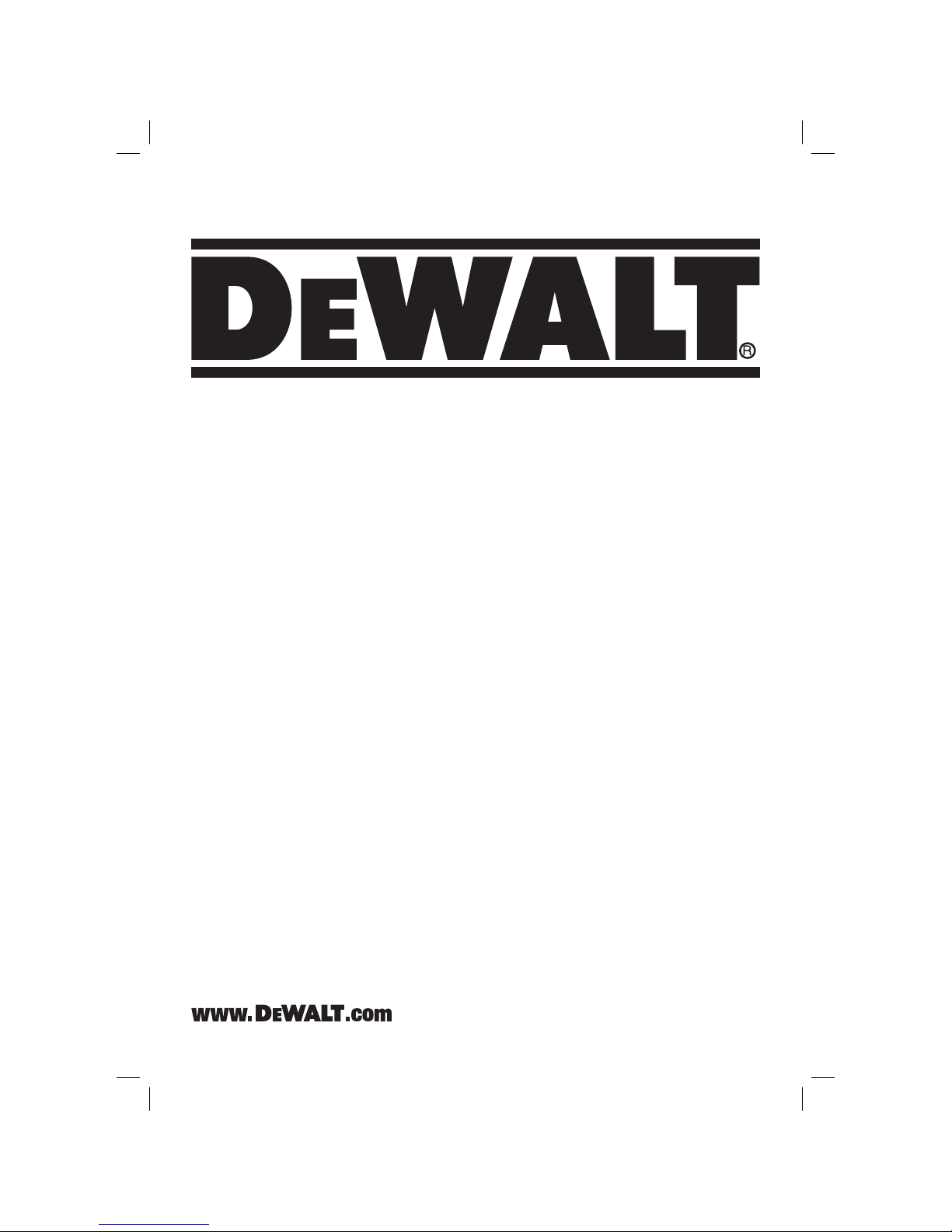

Figure 1

1 ﻞﻜﺷ

c

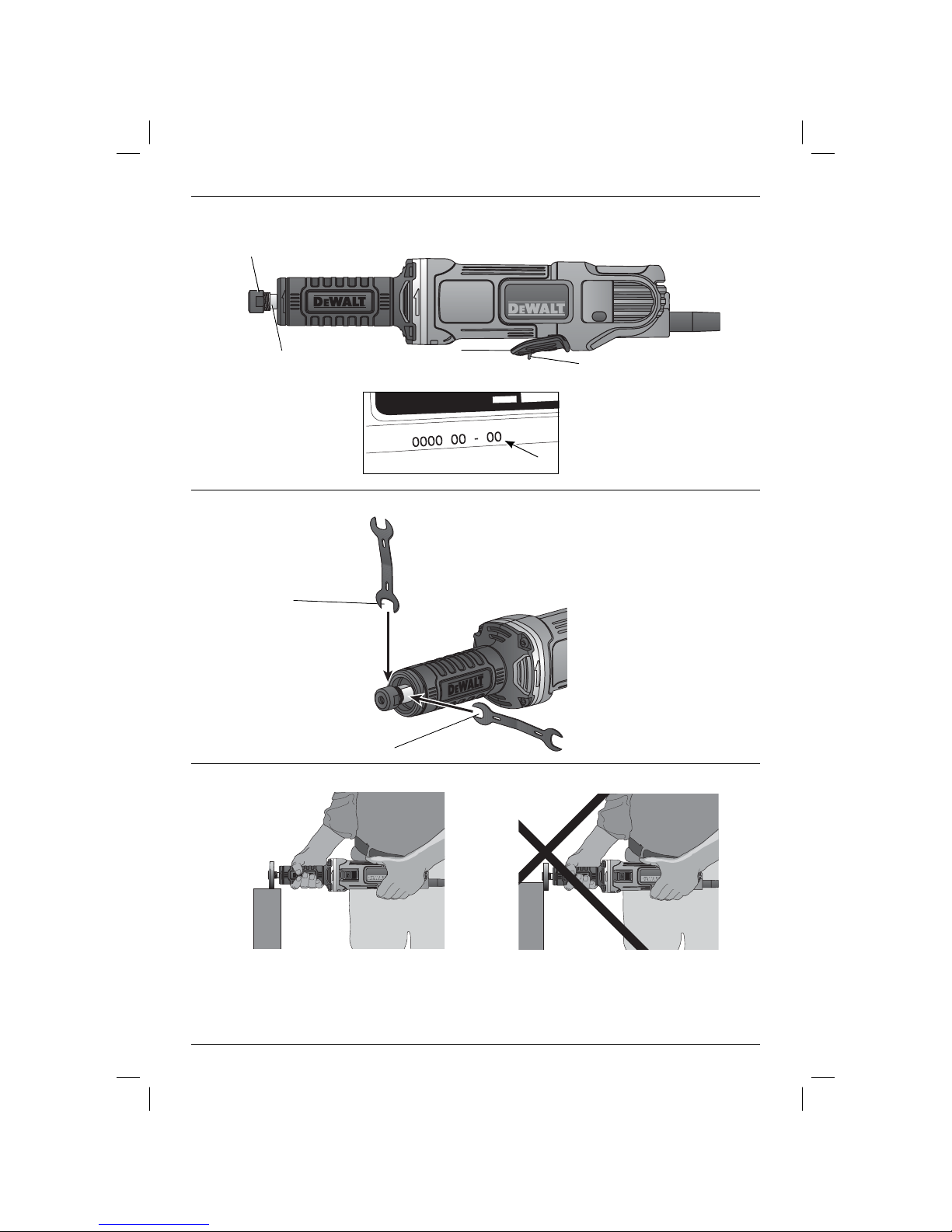

Figure 2

2 ﻞﻜﺷ

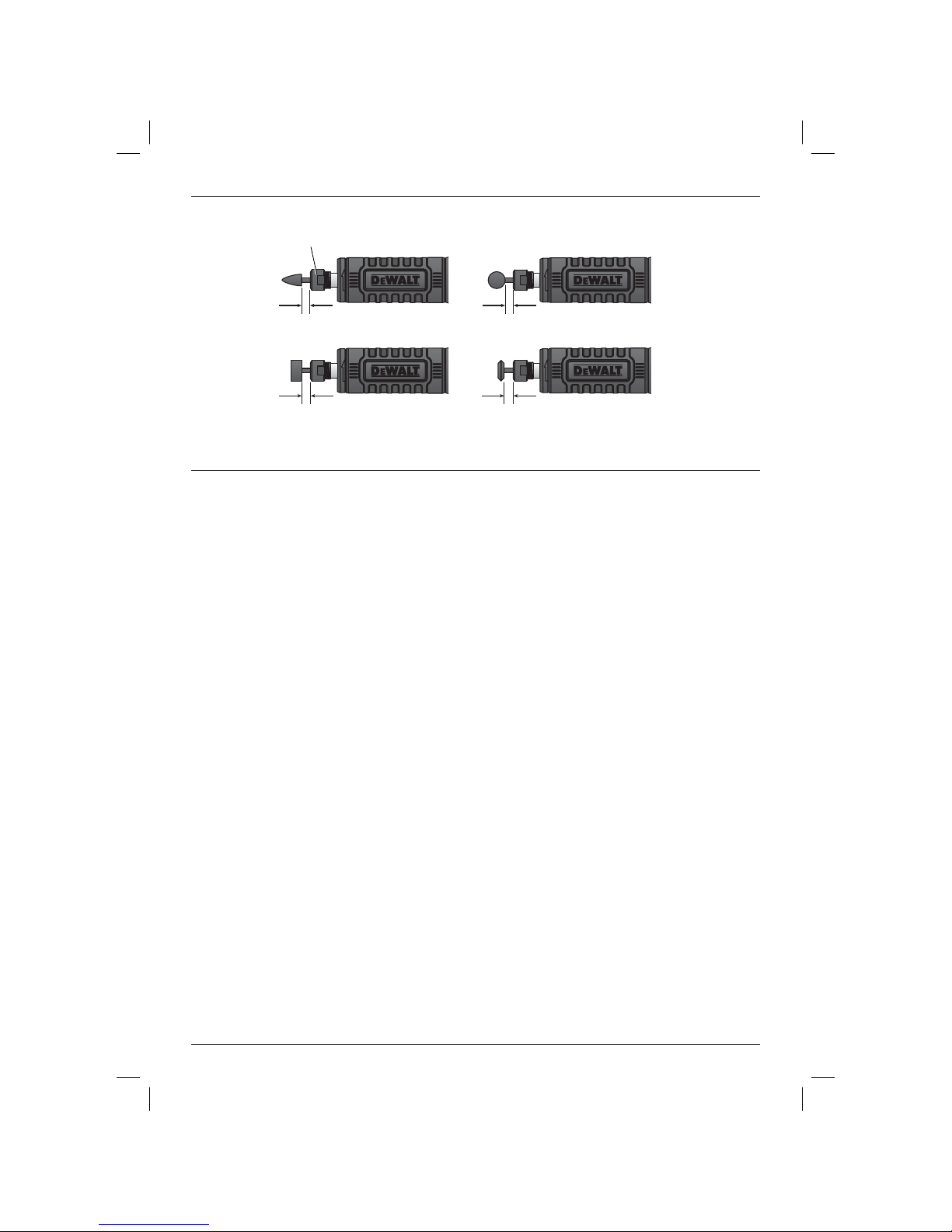

Figure 3

3 ﻞﻜﺷ

b

g

f

a

d

e

1

Page 4

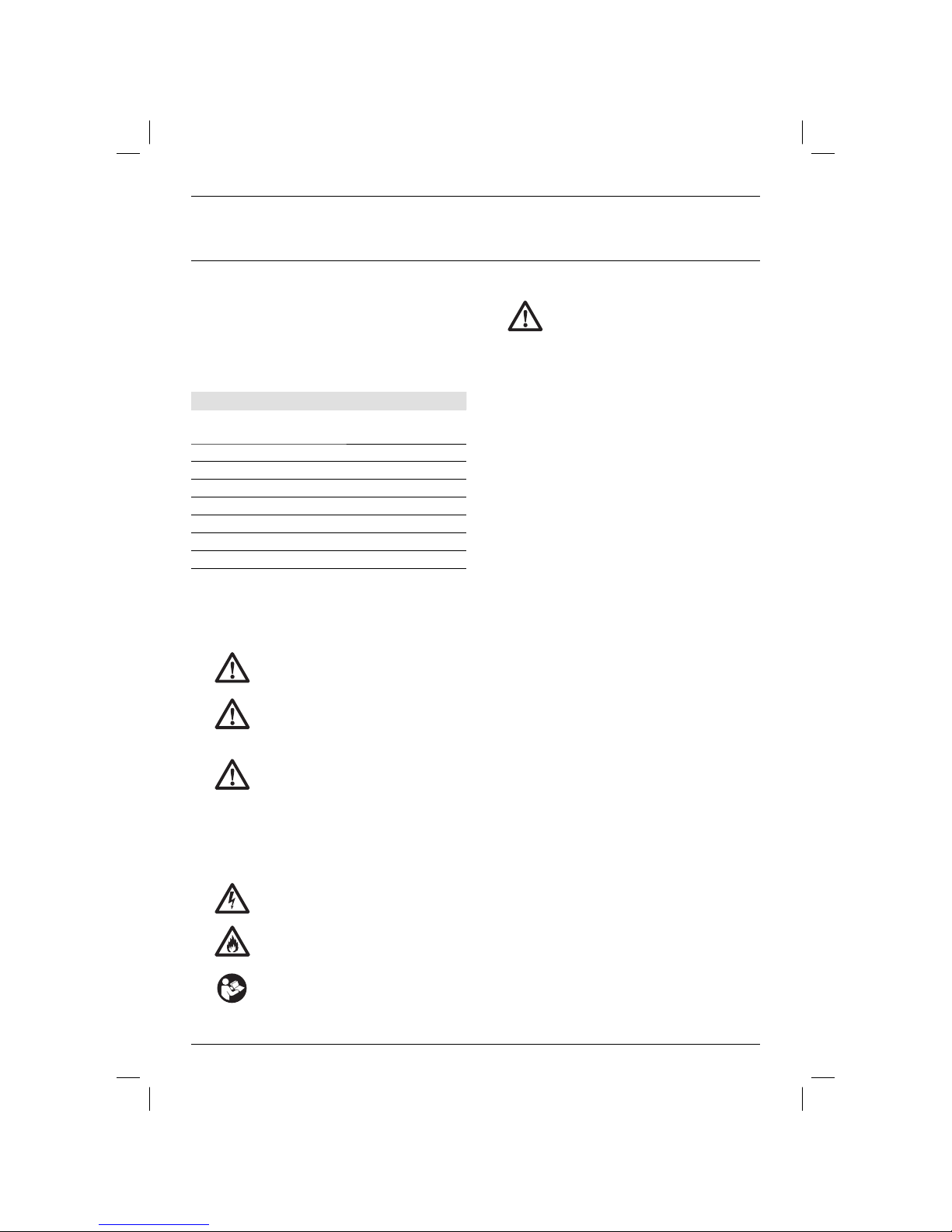

Figure 4

4 ﻞﻜﺷ

c

10 mm max. 10 mm max.

10 mm max. 10 mm max.

2

Page 5

DIE GRINDER

DWE4887N

ENGLISH

Congratulations!

You have chosen a DEWALT tool. Years of

experience, thorough product development and

innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical Data

DWE4887N

Voltage V

Type 1

Power input W 450

No load speed min

Maximum wheel diameter mm 38

Spindle M15

Collet size mm 6

Weight kg 1.6

AC

-1

220–240

127

25000

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

DANGER: Indicates an imminently

WARNING: Indicates a potentially

CAUTION: Indicates a potentially

NOTICE: Indicates a practice not

Denotes risk of electric shock.

Denotes risk of fire.

WARNING: To reduce the risk of injury,

hazardous situation which, if not avoided,

will result in death or serious injury.

hazardous situation which, if not

avoided, could result in death or

serious injury.

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

related to personal injury which, if

not avoided, may result in property

damage.

read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions may result

in electric shock, fire and/or serious

injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or batteryoperated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

3

Page 6

ENGLISH

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g) Use the power tool, accessories and

tool bits etc., in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety Instructions for All Operations

a) This power tool is intended to function

as a grinder. Read all safety warnings,

instructions, illustrations and specifications

provided with this power tool. Failure to follow

all instructions listed below may result in electric

shock, fire and/or serious injury.

b) Operations such as sanding, wire

brushing, polishing and cutting-off are not

recommended to be performed with this

power tool. Operations for which the power

tool was not designed may create a hazard and

cause personal injury.

c) Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer. Just because the

accessory can be attached to your power tool,

it does not assure safe operation.

4

Page 7

ENGLISH

d) The rated speed of the accessory must be at

least equal to the maximum speed marked

on the power tool. Accessories running faster

than their rated speed can break and fly apart.

e) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories can not be adequately guarded or

controlled.

f) The arbour size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

with arbour holes that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

g) Mandrel mounted wheels, sanding drums,

cutters or other accessories must be

fully inserted into the collet or chuck. If

the mandrel is insufficiently held and/or the

overhang of the wheel is too long, the mounted

wheel may become loose and be ejected at

high velocity.

h) Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheel for chips and cracks, backing

pad for cracks, tear or excess wear, wire

brush for loose or cracked wires. If power

tool or accessory is dropped, inspect for

damage or install an undamaged accessory.

After inspecting and installing an accessory,

position yourself and bystanders away from

the plane of the rotating accessory and run

the power tool at maximum no-load speed

for one minute. Damaged accessories will

normally break apart during this test time.

i) Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection must

be capable of stopping flying debris generated

by various operations. The dust mask or

respirator must be capable of filtrating particles

generated by your operation. Prolonged

exposure to high intensity noise may cause

hearing loss.

j) Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

k) Hold power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and

could give the operator an electric shock.

l) Always hold the tool firmly in your hand(s)

during start up. The reaction torque of the

motor, as it accelerates to full speed, can cause

the tool to twist.

m) Use clamps to support workpiece whenever

practical. Never hold a small workpiece in

one hand and the tool in the other while in

use. Clamping a small workpiece allows you

to use your hand(s) to control the tool. Round

material such as dowel rods, pipes or tubing

have a tendency to roll while being cut, and

may cause the bit to bind or jump toward you.

n) Position the cord clear of the spinning

accessory. If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

o) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and

pull the power tool out of your control.

p) After changing bits or making any

adjustments, make sure the collet nut, chuck

or any other adjustment devices are securely

tightened. Loose adjustment devices can

unexpectedly shift, causing loss of control, loose

rotation components will be violently thrown.

q) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

r) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

s) Do not operate the power tool near

flammable materials. Sparks could ignite these

materials.

t) Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

5

Page 8

ENGLISH

FURTHER SAFETY INSTRUCTIONS

FOR ALL OPERATIONS

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging causes

rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation at

the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward

or away from the operator, depending on direction

of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be

avoided by taking proper precautions as given

below:

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control

over kickback or torque reaction during start

up. The operator can control torque reaction or

kickback forces, if proper precautions are taken.

b) Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

c) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control.

d) Always feed the bit into the material in

the same direction as the cutting edge is

exiting from the material (which is the same

direction as the chips are thrown). Feeding

the tool in the wrong direction causes the

cutting edge of the bit to climb out of the work

and pull the tool in the direction of this feed.

e) When using rotary files, cut off wheels, high-

speed cutters or tungsten carbide cutters,

always have the work securely clamped.

These wheels will grab if they become slightly

canted in the groove, and can kickback. When

a cut-off wheel grabs, the wheel itself usually

breaks. When a rotary file, high speed cutter or

tungsten carbide cutter grabs, it may jump from

the groove and you could lose control of the

tool.

Safety Warnings Specifi c for

Grinders

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot

be adequately guarded and are unsafe.

b) For threaded abrasive cones and plugs

use only undamaged wheel mandrels with

an unrelieved shoulder flange that are of a

correct size and length. Proper mandrels will

reduce the possibility of breakage.

c) Do not position your hand in line with or

behind a rotating wheel. When the wheel,

at the point of operation, is moving away from

your hand, the possible kickback may propel

the wheel and the power tool directly at you.

d) Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed

under the workpiece near the line of the cut and

the edge of the workpiece on both sides of the

wheel.

Additional Safety Information

• For accessories mounted by flanges, the arbor

hole of the accessory must fit the locating

diameter of the flange. Accessories that do not

match the mounting hardware of the power tool

will run out of balance, vibrate excessively and

may cause loss of control.

Residual Risks

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

– Impairment of hearing.

– Risk of personal injury due to flying particles.

– Risk of burns due to accessories becoming hot

during operation.

– Risk of personal injury due to prolonged use.

6

Page 9

ENGLISH

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual before use.

Wear ear protection.

Wear eye protection.

DATE CODE POSITION (FIG. 1)

The date code (e), which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX XX

Year of Manufacture

Package Contents

The package contains:

1 die grinder

2 wrenches

1 Instruction manual

1 Exploded drawing

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Description (fi g. 1)

WARNING: Never modify the power

tool or any part of it. Damage or

personal injury could result.

a. Paddle switch

b. Spindle

c. Collet nut

d. Lock-off lever

e. Date code

f. Small spanner (13 mm)

g. Large spanner (17 mm)

DO NOT use under wet conditions or in presence of

flammable liquids or gases.

This die grinder is a professional power tool.

DO NOT let children come into contact with the

tool. Supervision is required when inexperienced

operators use this tool.

• Young children and the infirm. This appliance

is not intended for use by young children or

infirm persons without supervision.

• This product is not intended for use by persons

(including children) suffering from diminished

physical, sensory or mental abilities; lack of

experience, knowledge or skills unless they are

supervised by a person responsible for their

safety. Children should never be left alone with

this product.

Electrical Safety

The electric motor has been designed for one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

Your DEWALT tool is double insulated in

accordance with EN 60745; therefore no

earth wire is required.

WARNING: 127 V units have to

be operated via a fail-safe isolating

transformer with an earth screen

between the primary and secondary

winding.

If the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DEWALT service organisation.

Mains Plug Replacement

(Middle East and Africa)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in

the plug.

• Connect the blue lead to the neutral terminal.

WARNING: No connection is to be

made to the earth terminal.

Follow the fitting instructions supplied with good

quality plugs. Recommended fuse: 13 A.

INTENDED USE

Your die grinder has been designed for professional

grinding applications. The tool can be used with the

complete range of commercial grinding tools with a

maximum diameter of 38 mm and approved speed

of 25000/min.

Using an Extension Cable

If an extension cable is required, use an approved

extension cable suitable for the power input of this

tool (see Technical Data). The minimum conductor

size is 1.5 mm

2

; the maximum length is 30 m.

7

Page 10

ENGLISH

When using a cable reel, always unwind the cable

completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing

set-ups or when making repairs.

Before reconnecting the tool, depress

and release the trigger switch to ensure

that the tool is off. An accidental startup can cause injury.

Install Grinding Wheels (fi g. 1, 2, 4)

WARNING: Accessories must be rated

at least equal to the maximum speed

marked on the tool. Accessories running

faster than their rated speed can break

and fly apart.

WARNING: Accessories must be within

the capacity rating marked on the tool.

Incorrectly sized accessories cannot be

adequately controlled.

WARNING: Do not use accessories

with a mandrel length exceeding 40

mm. Ensure that the exposed mandrel

length is no more than 10 mm after

inserting accessory into collet.

WARNING: Never tighten the collet nut

without an accessory in the collet.

1. Hold the spindle (b) using the 13mm wrench (f)

provided.

2. Loosen the collet nut (c) with the 17mm

wrench(g) by turning it counterclockwise.

3. Insert the shank of the accessory (minimum

20mm) into the collet.

4. Securely tighten the collet nut (c) using the

spanner provided.

NOTE: The shank overhang, amount that sticks

out past the collet nut (c), should not exceed

10mm. Refer to figure 4.

OPERATION

Instructions for Use

WARNING: Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing

set-ups or when making repairs.

Before reconnecting the tool, depress

and release the trigger switch to ensure

that the tool is off. An accidental startup can cause injury.

WARNING:

• Ensure all materials to be ground or

• Use clamps or a vice to hold

• Secure the workpiece. A workpiece

• Support panels or any oversized

• Always wear regular working gloves

• The gear case becomes very hot

• Apply only a gentle pressure to the

• Avoid overloading. Should the tool

• The best grinding results are achieved

cut are secured in place.

and support the workpiece to a

stable platform. It is important to

clamp and support the workpiece

securely to prevent the movement

of the workpiece and loss of control.

Movement of the workpiece or loss

of control may create a hazard and

cause personal injury.

clamped with clamping devices or in

a vice is held more secure than by

hand.

workpiece to minimize the risk of

wheel pinching and kickback. Large

workpieces tend to sag under their

own weight. Supports must be

placed under the workpiece near the

line of cut and near the edge of the

workpiece on both sides of the wheel.

while operating this tool.

during use.

tool. Do not exert side pressure on the

disc.

become hot, let it run a few minutes

under no load condition.

when setting the machine at an angle

of 90°. Move the machine back and

forth with moderate pressure. In

this manner, the workpiece will not

become too hot, does not discolour

and no grooves are formed.

WARNING: Grasp tool firmly with both

hands to maintain control of the tool at

start up and during use and until the

wheel or accessory stops rotating. Make

8

Page 11

ENGLISH

sure the wheel has come to a complete

stop be fore laying the tool down.

Put the work in a vise or clamp it securely. Use a

face mask over the nose and mouth if the operation

raises dust. Treat the wheel with respect. Do not

jam the wheel into the work or use unnecessary

pressure. Grind only on the face of the wheel unless

you have a special wheel specifically make to permit

grinding on the side of the wheel.

Proper Hand Position (fi g. 3)

WARNING: To reduce the risk of

serious personal injury, ALWAYS use

proper hand position as shown.

WARNING: To reduce the risk of

serious personal injury, ALWAYS hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one hand on the body,

with the other hand on the neck of the die grinder,

as shown in figure 3.

Switches

WARNING: Before connecting the tool

to a power source depress and release

the switch once without depressing the

lock-off lever to ensure that the switch is

off. Depress and release the switch as

described above after any interruption

in power supply to the tool, such as the

activation of a ground fault interrupter,

throwing of a circuit breaker, accidental

unplugging, or power failure. If the

switch is locked on, the tool will start

unexpectedly when it is reconnected.

WARNING: Grasp tool firmly with both

hands to maintain control of the tool at

start up and during use and until the

wheel or accessory stops rotating. Make

sure the wheel has come to a complete

stop be fore laying the tool down.

WARNING: To reduce unexpected tool

movement, do not switch the tool on or

off while under load conditions. Allow

the grinder to run up to full speed before

touching the work surface. Lift the tool

from the surface before turning the tool

off.

PADDLE SWITCH (FIG. 1)

The lock-off lever (d), located on the paddle switch,

is a safety feature that prevents accidental activation

of the grinder.

To turn the tool on, push the lock-off lever (d) toward

the back of the tool, then depress the paddle switch

(a). The tool will run while the switch is depressed.

Turn the tool off by releasing the paddle switch.

WARNING: Do not disable the lock-off

lever. If the lock-off lever is disabled, the

tool may start unexpectedly when it is

laid down.

WARNING: Allow the tool to reach

full speed before touching tool to the

work surface. Lift the tool from the work

surface before turning the tool off.

Metal Applications

When using the tool in metal applications, make

sure that a residual current device (RCD) has been

inserted to avoid residual risks caused by metal

swarf.

If the power supply is shut off by the RCD, take the

tool to authorised DEWALT repair agent.

WARNING: In extreme working

To avoid build-up of metal swarf inside the machine,

we recommend to clear the ventilation slots on a

daily basis. See Maintenance.

conditions, conductive dust can

accumulate inside the machine housing

when working with metal. This can

result in the protective insulation in the

machine becoming degraded with a

potential risk of an electrical shock.

MAINTENANCE

Your DEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

WARNING: To reduce the risk of

injury, turn unit off and disconnect

machine from power source before

installing and removing accessories,

before adjusting or changing

set-ups or when making repairs.

Before reconnecting the tool, depress

and release the trigger switch to ensure

that the tool is off. An accidental startup can cause injury.

Motor Brushes

Keep brushes clean and sliding freely in their guides.

Carbon brushes have varying symbols stamped

into them, and if the brush is worn down to the line

closest to the spring, they must be replaced. New

brush assemblies are available at your local service

center.

9

Page 12

ENGLISH

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of

the main housing with dry air as often as

dirt is seen collecting in and around the

air vents. Wear approved eye protection

and approved dust mask when

performing this procedure.

WARNING: Never use solvents or

other harsh chemicals for cleaning the

non-metallic parts of the tool. These

chemicals may weaken the materials

used in these parts. Use a cloth

dampened only with water and mild

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

into a liquid.

Optional Accessories

WARNING: Since accessories, other

than those offered by DEWALT, have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only DEWALT recommended

accessories should be used with this

product.

Consult your dealer for further information on the

appropriate accessories.

Local regulations may provide for separate collection

of electrical products from the household, at

municipal waste sites or by the retailer when you

purchase a new product.

D

EWALT provides a facility for the collection and

recycling of DEWALT products once they have

reached the end of their working life. To take

advantage of this service please return your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

D

EWALT office at the address indicated in this

manual. Alternatively, a list of authorised DEWALT

repair agents and full details of our after-sales

service and contacts are available on the Internet at:

www.2helpU.com.

Protecting the Environment

Separate collection. This product must

not be disposed of with normal

household waste.

Should you find one day that your DEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products and

packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollution and reduces

the demand for raw materials.

10

Page 13

MEULE À RECTIFIER LES MATRICES

DWE4887N

FRANÇAIS

Félicitations!

Vous avez choisi un outil DEWALT. Des années

d’expertise dans le développement et l’innovation

de ses produits ont fait de D

privilégié des utilisateurs professionnels d’outils

électriques.

EWALT, le partenaire

Caractéristiques techniques

DWE4887N

Tension V

Type 1

Puissance absorbée W 450

Vitesse à vide min

Diamètre maximum du

disque

Arbre M15

Taille de pince mm 6

Poids kg 1,6

AC

-1

mm 38

220–240

127

25000

Défi nitions: consignes de sécurité

Les définitions ci-après décrivent le degré de risques

associé à chaque balise. Lire soigneusement la

notice d’instructions et respecter ces symboles.

DANGER: indique une situation

AVERTISSEMENT: indique une

ATTENTION: indique une situation

AVIS: indique une pratique ne posant

Indique des risques de décharges

de danger imminent qui, si rien

n’est fait pour l’éviter, aura comme

conséquences la mort ou des

dommages corporels graves.

situation de danger potentiel qui, si

rien n’est fait pour l’éviter, pourra avoir

comme conséquences la mort ou des

dommages corporels graves.

de danger potentiel qui, si rien n’est

fait pour l’éviter, pourrait avoir comme

conséquences des dommages

corporels mineurs ou moindres.

aucun risque de dommages

corporels, mais qui par contre, si rien

n’est fait pour l’éviter, pourrait poser

des risques de dommages matériels.

électriques.

Indique des risques d’incendie.

AVERTISSEMENT: pour réduire tout

risque de dommages corporels, lire la

notice d’instructions

Consignes de sécurité générales

propres aux outils électriques

AVERTISSEMENT! lire toutes les

Le terme «outil électrique» mentionné dans les

avertissements ci-après se rapporte aux outils

alimentés sur secteur (avec fil) ou par piles (sans fil).

1) SÉCURITÉ – AIRE DE TRAVAIL

a) Maintenir l’aire de travail propre et bien

b) Ne pas utiliser un outil électrique dans un

c) Maintenir à l’écart les enfants, ou toute

2) SÉCURITÉ – ÉLECTRICITÉ

a) La fiche électrique de l’outil doit

b) Éviter tout contact corporel avec des

directives et consignes de sécurité.

Tout manquement aux directives et

consignes ci-incluses comporte des

risques de décharges électriques,

d’incendie et/ou de dommages

corporels graves.

CONSERVER TOUTES CES DIRECTIVES ET

CONSIGNES À TITRE DE RÉFÉRENCE

éclairée. Les lieux sombres ou encombrés

sont propices aux accidents.

milieu déflagrant, comme en présence de

liquides, gaz ou poussières inflammables.

Les outils électriques peuvent produire des

étincelles qui pourraient enflammer toute

émanation ou poussière ambiante.

autre personne, lors de l’utilisation d’un

outil électrique. Toute distraction pourrait

faire perdre la maîtrise de l’appareil.

correspondre à la prise murale. Ne

modifier la fiche en aucune façon. Ne

pas utiliser de fiche d’adaptation avec

un outil électrique mis à la terre (masse).

L’utilisation de fiches d’origine et de prises

appropriées réduira tout risque de décharges

électriques.

éléments mis à la terre comme: tuyaux,

radiateurs, cuisinières ou réfrigérateurs.

Les risques de décharges électriques

augmentent lorsque le corps est mis à la

terre.

11

Page 14

FRANÇAIS

c) Ne pas exposer les outils électriques à

la pluie ou à l’humidité. Tout contact d’un

outil électrique avec un liquide augmente les

risques de décharges électriques.

d) Ne pas utiliser le cordon de façon

abusive. Ne jamais utiliser le cordon

pour transporter, tirer ou débrancher un

outil électrique. Protéger le cordon de

toute source de chaleur, de l’huile, et

de tout bord tranchant ou pièce mobile.

Les cordons endommagés ou emmêlés

augmentent les risques de décharges

électriques.

e) En cas d’utilisation d’un outil électrique à

l’extérieur, utiliser systématiquement une

rallonge conçue à cet effet. Cela diminuera

tout risque de décharges électriques.

f) Si on ne peut éviter d’utiliser un outil

électrique en milieu humide, utiliser

un circuit protégé par un dispositif de

courant résiduel (RCD). Cela réduira tout

risque de décharges électriques.

3) SÉCURITÉ INDIVIDUELLE

a) Rester systématiquement vigilant et faire

preuve de jugement lorsqu’on utilise un

outil électrique. Ne pas utiliser d’outil

électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de

médicaments. Tout moment d’inattention

pendant l’utilisation d’un outil électrique

comporte des risques de dommages

corporels graves.

b) Porter un équipement de protection

individuel. Porter systématiquement un

dispositif de protection oculaire. Le fait

de porter un masque anti-poussières, des

chaussures antidérapantes, un casque

de sécurité ou un dispositif de protection

auditive, lorsque la situation le requiert,

réduira les risques de dommages corporels.

c) Prévenir tout démarrage accidentel.

S’assurer que l’interrupteur est en

position d’arrêt avant de brancher l’outil

sur le secteur et/ou à la batterie, ou de le

ramasser ou le transporter. Transporter un

outil le doigt sur l’interrupteur ou brancher un

outil électrique alors que l’interrupteur est en

position de marche invite les accidents.

d) Retirer toute clé de réglage avant de

démarrer l’outil. Une clé laissée sur une

pièce rotative d’un outil électrique comporte

des risques de dommages corporels.

e) Adopter une position stable. Maintenir les

pieds bien ancrés au sol et conserver son

équilibre en permanence. Cela permettra

de mieux maîtriser l’outil électrique en cas de

situations imprévues.

f) Porter des vêtements appropriés. Ne

porter aucun vêtement ample ou bijou.

Maintenir cheveux, vêtements et gants

à l’écart des pièces mobiles, car ils

pourraient s’y faire prendre.

g) Lorsqu’un dispositif de connexion

à un système de dépoussiérage ou

d’élimination est fourni, s’assurer qu’il est

branché et utilisé correctement. L’utilisation

de ces dispositifs peut réduire les risques

engendrés par les poussières.

4) UTILISATION ET ENTRETIEN DES OUTILS ÉLECTRIQUES

a) Ne pas forcer un outil électrique. Utiliser

l’outil approprié au travail en cours. L’outil

approprié effectuera un meilleur travail, de

façon plus sûre et à la vitesse pour laquelle il

a été conçu.

b) Ne pas utiliser un outil électrique dont

l’interrupteur est défectueux. Tout appareil

dont l’interrupteur est défectueux est

dangereux et doit être réparé.

c) Débrancher la fiche du secteur et/ou

la batterie de l’outil électrique avant

d’effectuer tout réglage, de changer tout

accessoire, ou avant de le ranger. Ces

mesures préventives réduiront tout risque de

démarrage accidentel de l’appareil.

d) Après utilisation, ranger les outils

électriques hors de portée des enfants

et ne permettre à aucune personne non

familière avec son fonctionnement (ou sa

notice d’instructions) de l’utiliser. Les outils

peuvent être dangereux entre des mains

inexpérimentées.

e) Entretenir les outils électriques. Vérifier

les pièces mobiles pour s’assurer qu’elles

sont bien alignées et tournent librement,

qu’elles sont en bon état et ne sont

affectées d’aucune condition susceptible

de nuire au bon fonctionnement de l’outil.

En cas de dommage, faire réparer l’outil

électrique avant toute nouvelle utilisation.

De nombreux accidents sont causés par des

outils mal entretenus.

f) Maintenir tout organe de coupe propre

et bien affûté. Les outils de coupe bien

entretenus et affûtés sont moins susceptibles

de se coincer et sont plus faciles à contrôler.

g) Utiliser un outil électrique, ses

accessoires, mèches, etc., conformément

aux présentes directives et suivant la

manière prévue pour ce type particulier

d’outil électrique, en tenant compte des

conditions de travail et de la tâche à

effectuer. L’utilisation d’un outil électrique

à des fins autres que celles prévues est

potentiellement dangereuse.

12

Page 15

FRANÇAIS

5) RÉPARATION

a) Faire entretenir les outils électriques par

un réparateur qualifié en n’utilisant que

des pièces de rechange identiques. Cela

permettra de préserver l’intégrité de l’outil

électrique et la sécurité de l’utilisateur.

RÈGLES PARTICULIÈRES DE

SÉCURITÉ ADDITIONNELLES

a) Cet outil électrique est prévu pour être

utilisé en tant que meuleuse. Lire toute

directive de sécurité, consigne, illustration et

spécification fournie avec l’outil électrique.

Tout manquement aux directives suivantes

pose des risques de décharges électriques,

d’incendie et/ou de blessures graves.

b) Les opérations telles que le ponçage, le

brossage métallique, le polissage et la

découpe ne sont pas recommandées avec

cet outil électrique. Toute opération pour

laquelle l’outil n’a pas été conçu comporte des

risques de dommages matériels et corporels.

c) Ne pas utiliser des accessoires qui n’ont pas

été spécifiquement conçus et recommandés

par le fabricant de l’outil. Le fait que

l’accessoire peut être rattaché à l’outil électrique

ne veut pas automatiquement dire que son

utilisation ne posera aucun risque.

d) La vitesse nominale des accessoires

doit être équivalente ou supérieure

à celle recommandée sur l’étiquette

d’avertissement de l’outil. Les accessoires

utilisés à une vitesse plus rapide que leur vitesse

nominale peuvent éclater ou se détacher de

l’outil.

e) Le diamètre externe et l’épaisseur de

l’accessoire utilisé doivent se conformer

aux spécifications de la plaque signalétique

de l’outil électrique. Les accessoires aux

spécifications incorrectes ne peuvent être ni

maintenus ni contrôlés de façon adéquate.

f) L’alésage des meules, brides, tampons de

soutien, ou de tout autre accessoire, doit

correspondre parfaitement à la taille de la

broche de l’outil électrique. Les accessoires

dont l’alésage ne correspond pas au dispositif

d’installation de l’outil électrique ne tourneront

pas correctement, vibreront de façon excessive

et pourront causer la perte de contrôle de l’outil.

g) Les disques montés sur mandrin, les

rouleaux à poncer, les outils de découpe

et les autres accessoires doivent être

complètement insérés dans la douille de

serrage ou le mandrin. Si le mandrin n’est

pas suffisamment maintenu et/ou si le porte à

faux du disque est trop long, ce dernier peut se

desserrer et être éjecté à très haute vitesse.

h) Ne pas utiliser d’accessoires endommagés.

Avant toute utilisation, vérifier tous les

accessoires, par exemple que les meules

abrasives ne sont ni ébréchées ni fendues,

les tampons de soutien ne sont ni fendus ni

usés excessivement, les brosses métalliques

ne comportent aucun élément brisé ou

lâche. En cas de chute, vérifier que l’outil

n’a pas été endommagé et remplacer tout

accessoire abîmé. Après avoir inspecté

et installé un accessoire, se situer, soimême et tout individu présent, hors du

plan de rotation de l’accessoire et laisser

tourner l’outil une minute à sa vitesse à

vide maximale. En général, tout accessoire

endommagé se brisera lors du temps d’essai.

i) Porter un équipement de protection

individuel. Selon l’application, utiliser une

protection faciale et des lunettes ou un

masque de protection. Si approprié, porter

un masque anti-poussières, une protection

auditive, des gants et un tablier d’atelier

capables de vous protéger contre toute

projection abrasive ou tout fragment. La

protection oculaire doit être capable d’arrêter

toute projection de débris engendrés par des

opérations diverses. Le masque anti-poussières

doit être capable de filtrer les particules

engendrées par l’opération en cours. Toute

exposition prolongée à un haut niveau de

décibels peut occasionner une perte de l’acuité

auditive.

j Maintenir à distance toute personne

étrangère au travail en cours. Toute

personne à l’intérieure de l’aire de travail

doit porter un équipement de protection

individuel. Des débris provenant de la pièce

à travailler ou d’un accessoire brisé pourraient

être éjectés et causer des dommages corporels

au-delà de l’aire de travail immédiate.

k) Tenir l’outil par les surfaces isolées prévues

à cet effet pendant toute utilisation où

l’organe de coupe pourrait entrer en contact

avec des fils électriques cachés ou son

propre cordon. Tout contact de l’organe de

coupe avec un fil sous tension peut mettre les

parties métalliques exposées de l’outil sous

tension et électrocuter l’utilisateur.

l) Maintenez toujours fermement l’outil entre

vos mains pendant le démarrage. Le couple

de réaction du moteur, lorsqu’il accélère à pleine

vitesse, peut provoquer la torsion de l’outil.

13

Page 16

FRANÇAIS

m) Utilisez un dispositif de fixation pour

maintenir la pièce travaillée, pour plus de

practicité. Ne tenez jamais les petites pièces

dans une main et l’outil dans une autre

lorsque vous travaillez. La fixation de la pièce

travaillée vous permet d’utiliser vos deux mains

pour contrôler l’outil. Les matériaux ronds tels

que les tiges de goupille, les tuyaux ou les tubes

ont tendance à rouler lors de leur découpe, la

mèche peut se plier ou être éjectée dans votre

direction.

n) Maintenir le cordon électrique éloigné de la

partie rotative de l’outil. En cas de perte de

contrôle, le cordon pourrait être sectionné ou

abîmé, et les bras ou mains pourraient entrer en

contact avec l’organe rotatif.

o) Attendre systématiquement l’arrêt complet

de l’outil avant de le déposer. L’organe rotatif

pourrait s’accrocher à la surface utilisée et

rendre l’outil dangereusement imprévisible.

p) Après avoir remplacer les mèches ou avoir

effectuer des réglages, assurez-vous que

l’écrou de la douille de serrage, le mandrin

ou les autres dispositifs de réglage sont

resserrés de façon sûre. Les dispositifs de

réglage desserrés peuvent se déplacer de façon

inattendue provoquant la perte de contrôle, les

éléments rotatifs desserrés peuvent alors être

projetés violemment..

q) Ne pas laisser l’outil électrique en marche

alors qu’il est accroché à votre côté. Tout

contact accidentel de l’organe rotatif pourrait

faire que ce dernier s’accroche aux vêtements

et qu’un accessoire entre en contact avec le

corps.

r) Nettoyer régulièrement les orifices

d’aération de l’outil. Le ventilateur du moteur

attirera de la poussière à l’intérieur du boîtier

et une accumulation excessive de poussières

métalliques pourrait poser des risques

d’électrocution/incendie.

s) Ne pas utiliser cet outil électrique à

proximité de matériaux inflammables, car

des étincelles pourraient les enflammer.

t) Ne pas utiliser d’accessoires nécessitant

l’utilisation d’un réfrigérant fluide. L’utilisation

d’eau ou de tout autre réfrigérant fluide pourrait

poser des risques d’électrocution ou de

décharges électriques.

14

CONSIGNES GÉNÉRALES DE

SÉCURITÉ COMPLÉMENTAIRES

Causes et prévention anti-rebonds

Les rebonds sont la conséquence du grippage

ou coinçage d’une meule, d’un tampon de

soutien, d’une brosse en rotation ou de tout autre

accessoire. Tout grippage ou coinçage causera

rapidement le blocage de l’accessoire en rotation,

ce qui lancera l’outil non contrôlé dans la direction

opposée à l’accessoire en rotation au point du

grippage.

Par exemple, si une meule abrasive reste accrochée

ou pincée dans une pièce à travailler, le bord

de la meule engagée au point de grippage peut

s’enfoncer dans la surface du matériau et faire

tressauter ou rebondir la meule. La meule peut alors

rebondir vers ou à l’opposé de l’utilisateur, selon la

direction du mouvement de la meule au point de

grippage. Dans ces conditions, il peut aussi arriver

que les meules abrasives se brisent.

Les rebonds proviennent d’une utilisation impropre

de l’outil ou de conditions ou procédures

d’exécution incorrectes, et peuvent être évités

en prenant les précautions adéquates énoncées

ci-dessous:

a) Maintenir la scie fermement en positionnant

le corps et les bras de façon à pouvoir

résister à toute force de rebonds. Utiliser

systématiquement la poignée latérale,

si fournie avec l’outil, pour un contrôle

maximal de l’outil en cas de rebonds ou

retour de couple au démarrage. L’utilisateur

peut contrôler le retour de couple ou les forces

de rebonds si des précautions adéquates sont

prises.

b) Prendre des précautions supplémentaires

pour travailler des coins, des bords acérés,

etc. Éviter que l’accessoire sursaute ou

reste accroché. Les coins, bords acérés ou les

sursauts ont tendance à retenir l’accessoire en

rotation et causer la perte de contrôle de l’outil,

ou des rebonds.

c) Ne pas rattacher une lame à chaîne

coupante, à sculpter ou une lame dentée.

Ces lames posent des risques de rebonds

fréquents et de perte de contrôle de l’outil.

d) Insérez toujours la mèche dans la matière

dans le même sens que celui par lequel le

bord de coupe quitte la matière (le même

sens que celui vers lequel les copeaux sont

évacués). L’insertion de l’outil dans le mauvais

sens entraîne le bord de coupe de la mèche

à grimper sur l’ouvrage et à tirer l’outil vers ce

sens d’avancement.

Page 17

FRANÇAIS

e) Lorsque vous utilisez des limes rotatives,

des outils de découpe à haute vitesse ou

en carbure de tungstène, fixez toujours

l’ouvrage de façon sûre. Ces disques peuvent

se bloquer s’ils sont légèrement inclinés dans

la rainure et ils peuvent alors rebondir. Il est

fréquent que le disque de découpe casse

lorsqu’il se coince. Il est possible qu’une lime

rotative, un outil de découpe à haute vitesse

ou en carbure de tungstène saute de la rainure

lorsqu’il se coince. Vous pourriez alors perdre le

contrôle de l’outil.

Consignes de sécurité spécifi ques

pour les meuleuses

a) Utiliser uniquement des types de meules

recommandés pour votre outil électrique

ainsi que le carter spécifiquement conçu

pour la meule choisie. Les meules non

conçues pour un outil électrique ne peuvent être

adéquatement protégées et sont dangereuses.

b) Pour les cônes abrasifs et les bouchons

filetés, n’utilisez que des mandrins rotatifs

en bon état dont la bride d’épaulement est

exempt de détalonnage et qui ont la bonne

taille et la bonne longueur. Des mandrins

appropriés permettent de réduire les casses

potentielles.

c) Ne placez pas votre main dans l’alignement

du disque rotatif ou derrière lui. Si le disque,

en cours d’utilisation, quitte votre main, le

rebond possible peut le propulser avec l’outil

électrique directement dans votre direction.

d) Maintenez les panneaux ou toute autre pièce

travaillée de grande taille afin de minimiser

le risque de pincement et de rebond

du disque. Les pièces de grande taille ont

tendance à s’affaisser sous leur propre poids.

Des supports doivent être positionnés sous et

au bord de la pièce travaillée, près de la ligne

de coupe, de chaque côté du disque.

Informations de sécurité

supplémentaires

• Pour les accessoires montés avec des brides,

l’alésage de l’accessoire doit correspondre

au diamètre de positionnement de la bride.

Les accessoires qui ne correspondent pas

au dispositif d’installation de l’outil électrique

ne tourneront pas correctement, vibreront de

façon excessive et pourront causer la perte de

contrôle de l’outil.

Risques résiduels

En dépit de l’application des règlementations de

sécurité correspondantes et de la mise en œuvre

des dispositifs de sécurité, certains risques résiduels

ne peuvent pas être évités. À savoir:

– Diminution de l’acuité auditive.

– Risques de dommages corporels dus à des

projections de particules.

– Risques de brûlures provoquées par des

accessoires ayant surchauffé pendant leur

fonctionnement.

– Risques de dommages corporels dus à un

usage prolongé.

Étiquettes sur l’appareil

On trouve les diagrammes suivants sur l’outil:

Lire la notice d’instructions avant

toute utilisation.

Porter un dispositif de protection auditive.

Porter un dispositif de protection oculaire.

EMPLACEMENT DE LA DATE CODÉE DE FABRICATION

(FIG. 1)

La date codée de fabrication (e), qui comprend aussi

l’année de fabrication, est imprimée sur le boîtier.

Exemple:

2014 XX XX

Année de fabrication

Contenu de l’emballage

Ce carton comprend:

1 Meule à rectifier les matrices

2 Clés plates

1 Notice d’instructions

1 Dessin éclaté

• Vérifier que l’appareil et ses pièces ou

accessoires n’ont pas été endommagés lors du

transport.

• Prendre le temps de lire attentivement et

comprendre cette notice d’instructions avant

toute utilisation de l’appareil.

15

Page 18

FRANÇAIS

Description (fi g. 1)

AVERTISSEMENT: ne jamais modifier

l’outil ni aucun de ses composants, car

cela pose des risques de dommages

corporels ou matériels.

a. Interrupteur à gâchette

b. Arbre

c. Écrou de la pince

d. Levier de verrouillage

e. Date codée

f. Petite clé (13mm)

g. Grande clé (17 mm)

USAGE PRÉVU

Votre meuleuse à rectifier les matrices a été conçue

pour les applications de meulage professionnelles.

L’outil peut être utilisé avec la gamme complète

d’outils de meulage commerciaux avec un diamètre

maximum de 38mm et une vitesse approuvée de

25000/min.

NE PAS utiliser ces outils en milieu ambiant humide

ou en présence de liquides ou de gaz inflammables.

Ces meuleuses à rectifier les matrices sont des outils

électriques professionnels. NE PAS le laisser à la

portée des enfants. Une supervision est nécessaire

auprès de tout utilisateur non expérimenté.

• Jeunes enfants et personnes handicapées.

Cet appareil n’est pas prévu pour être utilisé

par de jeunes enfants ou de personnes

handicapées sans surveillance..

• Ce produit n’est pas prévu pour être utilisé par

des personnes (y compris les enfants) dont les

capacité physiques, sensorielles ou mentales

sont réduites ou qui manquent d’expérience

ou d’aptitudes, sauf si ces personnes sont

surveillées par une autre personne responsable

de leur sécurité. Ne jamais laisser les enfants

seuls avec ce produit.

Sécurité électrique

Le moteur électrique a été conçu pour fonctionner

sur une tension unique. Vérifier systématiquement

que la tension du secteur correspond bien à la

tension indiquée sur la plaque signalétique.

Votre outil DEWALT à double isolation

est conforme à la norme EN60745; un

branchement à la terre n’est donc pas

nécessaire.

AVERTISSEMENT: les appareils à

127V doivent être utilisés avec des

transformateurs d’isolation à l’épreuve

des pannes doté d’un écran de

terre entre l’enroulement primaire et

secondaire.

Remplacement de la fi che

d’alimentation (Moyen-Orient et

Afrique)

Si une nouvelle fiche d’alimentation doit être

montée:

• Mettre soigneusement au rebut l’ancienne fiche.

• Raccorder le fil marron à la borne de phase

dans la fiche.

• Raccorder le fil bleu à la borne de neutre.

AVERTISSEMENT: aucun

branchement ne doit être fait à la borne

de terre.

Suivez les instructions de montage fournies avec

des fiches de bonne qualité. Fusible recommandé:

13 A.

Utilisation d’une rallonge

Si une rallonge s’avère nécessaire, utiliser une

rallonge homologuée et compatible avec la tension

nominale de cet outil (se reporter à la section

Caractéristiques techniques). La section

minimale du conducteur est de 1mm2 pour une

longueur maximale de 30m.

En cas d’utilisation d’un dévidoir, dérouler

systématiquement le câble sur toute sa longueur.

MONTAGE ET RÉGLAGES

AVERTISSEMENT: pour réduire

tout risque de dommages

corporels, arrêter l’outil et

débrancher l’appareil du secteur

avant d’installer ou de retirer tout

accessoire, avant tout réglage

ou changement de configuration

ou lors de réparations. Avant de

rebrancher l’outil, pressez puis relâchez

la gâchette pour vous assurer que

l’outil est bien à l’arrêt. Tout démarrage

accidentel pourrait causer des

dommages corporels.

Montage des meules (fi g. 1, 2, 4)

AVERTISSEMENT: les accessoires

doivent être conçus pour au moins

la même vitesse maximale que celle

indiquée sur l’outil. Les accessoires qui

fonctionnent plus vite que leur vitesse

nominale peuvent se casser et voler en

éclats.

16

Page 19

FRANÇAIS

AVERTISSEMENT: la capacité

AVERTISSEMENT: ne serrez jamais

1. Tenez l’axe (b) à l’aide de la clé de 13mm (d)

2. Desserrez l’écrou de la douille de serrage (c)

3. Introduisez la tige de l’accessoire (au moins

4. Serrez fermement l’écrou de la douille de

des accessoires doit correspondre

à la capacité nominale de l’outil.

Les accessoires mal dimensionnés

ne peuvent pas être contrôlés

correctement.

AVERTISSEMENT: n’utilisez pas

d’accessoires avec un mandrin dont la

longueur est supérieure à 40 mm.

Assurez-vous que la longueur exposée

du mandrin n’excède pas 10 mm après

avoir inséré l’accessoire dans la douille

de serrage.

l’écrou de la douille de serrage sans

accessoire.

fournie.

avec la clé de 17mm(e) en le tournant dans le

sens inverse des aiguilles d’une montre.

20 mm) dans la douille de serrage.

serrage (c) à l’aide de la clé anglaise fournie.

REMARQUE: Le porte à faux de la tige, la

partie qui dépasse de l’écrou de la douille

de serrage (c), ne doit pas excéder 10mm.

Consultez la figure 4.

FONCTIONNEMENT

Consignes d’utilisation

AVERTISSEMENT: respecter

AVERTISSEMENT: pour réduire

AVERTISSEMENT:

• s’assurer que le matériau à meuler ou

systématiquement les consignes de

sécurité et les normes en vigueur.

tout risque de dommages

corporels, arrêter l’outil et

débrancher l’appareil du secteur

avant d’installer ou de retirer tout

accessoire, avant tout réglage

ou changement de configuration

ou lors de réparations. Avant de

rebrancher l’outil, pressez puis relâchez

la gâchette pour vous assurer que

l’outil est bien à l’arrêt. Tout démarrage

accidentel pourrait causer des

dommages corporels.

à tronçonner est fermement arrimé.

• utilisez les pinces ou un étau pour

fixer et soutenir l’ouvrage sur une

plateforme stable. Il est important pour

serrer et soutenir l’ouvrage de manière

sûre afin d’éviter le mouvement de

l’ouvrage et la perte de contrôle. Le

mouvement de l’ouvrage ou la perte

de contrôle peuvent représenter

un risque et causer des blessures

personnelles.

• fixez la pièce. Une pièce fixée avec

des dispositifs de serrage ou un étau

est maintenue bien mieux qu’avec les

mains.

• soutenir les panneaux, ou toute pièce

surdimensionnée, pour minimiser tout

risque de grippage ou rebond de la

meule. Les pièces larges ont tendance

à s’affaisser sous leur propre poids.

Un support doit être installé sous la

pièce à travailler, près de la ligne de

coupe, et près des bords, de chaque

côté de la meule.

• portez toujours des gants de travail

appropriés lors de l’utilisation de cet

outil.

• le boîtier d’engrenage devient très

chaud pendant l’utilisation.

• Appliquer seulement une pression

légère sur l’outil. Ne pas exercer de

pression latérale sur le disque.

• Éviter toute surcharge. Si l’outil venait

à surchauffer, le laisser fonctionner à

vide quelques minutes.

• Les meilleurs résultats de meulage

sont obtenus en orientant la machine

selon un angle de 90°. Déplacez

la machine d’avant en arrière avec

une pression modérée. De cette

manière, la pièce ne deviendra pas

trop chaude, ne se décolorera pas et

aucune rainure ne sera formée.

AVERTISSEMENT: Saisir l’outil

fermement des deux mains pour garder

le contrôle de l’outil au démarrage

et pendant son utilisation, et ce,

jusqu’à arrêt complet de la meule

ou de l’accessoire. Avant de poser

l’outil, s’assurer que la meule s’est

complètement arrêtée de tourner.

Placez l’ouvrage dans un étau ou fixez-le

solidement. Utilisez un masque pour couvrir votre

nez et votre bouche si l’opération génère de la

17

Page 20

FRANÇAIS

poussière. N’abusez pas de la meule. Ne bloquez

pas la meule dans l’ouvrage et ne forcez pas trop

dessus. Meulez seulement sur la face de la meule

sauf si vous disposez d’une meule spécialement

conçue pour permettre le meulage sur le côté de la

meule.

Position correcte des mains (fi g. 3)

AVERTISSEMENT: pour réduire tout

risque de dommages corporels graves,

adopter SYSTÉMATIQUEMENT la

position des mains illustrée.

AVERTISSEMENT: pour réduire

tout risque de dommages corporels

graves, maintenir fermement et

SYSTÉMATIQUEMENT l’outil pour

anticiper toute réaction soudaine de

sa part.

La position correcte des mains requiert une main sur

le corps et l’autre sur le col de la meule à rectifier les

matrices, comme illustré en figure 3.

Interrupteurs

AVERTISSEMENT : avant de brancher

l’outil à une source d’alimentation,

enfoncez et relâchez l’interrupteur

une fois, sans appuyer sur le bouton

de verrouillage pour vérifier que

l’interrupteur est en position d’arrêt.

Enfoncez et relâchez l’interrupteur,

comme indiqué, après toute coupure

l’alimentation sur l’outil (par ex.

activation d’un disjoncteur de défaut

de terre, déclenchement d’un coupecircuit, débranchement accidentel ou

panne de courant). Si l’interrupteur

est verrouillé, l’outil pourrait démarrer

accidentellement lorsqu’il est rebranché.

AVERTISSEMENT: saisir l’outil

fermement des deux mains pour garder

le contrôle de l’outil au démarrage

et pendant son utilisation, et ce,

jusqu’à arrêt complet de la meule

ou de l’accessoire. Avant de poser

l’outil, s’assurer que la meule s’est

complètement arrêtée de tourner.

AVERTISSEMENT: pour réduire tout

mouvement inattendu de l’outil, ne pas

arrêter ou démarrer l’outil lorsqu’il est en

contact avec une surface quelconque.

Laisser la meuleuse à disque tourner

à plein régime avant de la mettre en

contact avec la surface à travailler.

Retirer l’outil de la pièce à travailler avant

de l’arrêter.

INTERRUPTEUR À GÂCHETTE (FIG. 1)

Le levier de verrouillage (d), situé sur l’interrupteur à

gâchette, est un dispositif de sécurité qui empêche

l’activation accidentelle de la meuleuse.

Pour mettre l’outil en marche, poussez le levier de

verrouillage (d) vers l’arrière de l’outil, puis appuyez

sur l’interrupteur à gâchette (a). L’outil fonctionne

tant que l’interrupteur reste enfoncé. Pour arrêter

l’outil, relâchez l’interrupteur à gâchette.

AVERTISSEMENT: ne désactivez pas

le levier de verrouillage. Si le levier de

verrouillage était désactivé, l’outil peut

démarrer accidentellement alors qu’il est

reposé..

AVERTISSEMENT: laissez l’outil

tourner à plein régime avant de le mettre

en contact avec la surface à travailler.

Soulevez l’outil de la surface à travailler

avant de l’arrêter.

Applications métal

Avant d’utiliser l’outil pour des applications métal,

assurez-vous que le dispositif à courant résiduel

(DCR) a été inséré pour prévenir tout risque résiduel

inhérent aux limailles.

Si le courant venait à être coupé par le DCR,

rapportez l’outil chez un réparateur agréé DEWALT.

AVERTISSEMENT: dans des

conditions de travail extrêmes, des

poussières conductrices peuvent

s’accumuler à l’intérieur du boîtier

de l’appareil lors du travail du métal.

Cela pourra provoquer la dégradation

de l’isolation protectrice de l’appareil

et poser des risques de décharges

électriques.

Pour éviter toute accumulation de limailles à

l’intérieur de l’appareil, il est recommandé de

nettoyer quotidiennement les fentes d’aération. Se

reporter à la section Maintenance.

MAINTENANCE

Cet outil DEWALT a été conçu pour fonctionner

longtemps avec un minimum de maintenance. Le

fonctionnement continu et satisfaisant de l’outil

dépend d’un entretien adéquat et d’un nettoyage

régulier.

AVERTISSEMENT: pour réduire

tout risque de dommages

corporels, arrêter l’outil et

débrancher l’appareil du secteur

avant d’installer ou de retirer tout

accessoire, avant tout réglage

18

Page 21

FRANÇAIS

ou changement de configuration

ou lors de réparations. Avant de

rebrancher l’outil, pressez puis relâchez

la gâchette pour vous assurer que

l’outil est bien à l’arrêt. Tout démarrage

accidentel pourrait causer des

dommages corporels.

Charbons du moteur

Maintenir les brosses propres et coulissant

librement dans leurs guides. Les brosses à charbon

possèdent différents symboles imprimés et si la

brosse est usée jusqu’à la ligne la plus proche

du ressort, elle doit être remplacée. De nouveaux

assemblages de brosse sont disponibles auprès de

votre centre de service local.

Lubrifi cation

Votre outil électrique ne requiert aucune lubrification

additionnelle.

Entretien

AVERTISSEMENT: éliminer poussière

et saleté du boîtier principal à l’aide d’air

comprimé chaque fois que les orifices

d’aération semblent s’encrasser. Porter

systématiquement des lunettes de

protection et un masque anti-poussières

homologués au cours de cette

procédure.

AVERTISSEMENT: ne jamais utiliser

de solvants ou tout autre produit

chimique décapant pour nettoyer

les parties non métalliques de l’outil.

Ces produits chimiques pourraient en

attaquer les matériaux utilisés. Utiliser

un chiffon humidifié avec de l’eau et

un savon doux. Protéger l’outil de tout

liquide et n’immerger aucune de ses

pièces dans aucun liquide.

seuls des accessoires D

recommandés doivent être utilisés avec

cet appareil.

Veuillez consulter votre revendeur pour plus

d’informations sur les accessoires appropriés.

EWALT

Protection de l’environnement

Collecte sélective. Ne pas jeter ce produit

avec les ordures ménagères.

En fin de durée de vie ou d’utilité de votre

produit DEWALT, ne pas le jeter avec les ordures

ménagères, mais dans les conteneurs de collecte

sélective.

La collecte sélective des produits et

emballages usagés permet de recycler et

réutiliser leurs matériaux. La réutilisation

de matériaux recyclés aide à protéger

l’environnement contre la pollution et à

réduire la demande en matière première.

Selon les réglementations locales, il peut être offert:

service de collecte sélective individuel des produits

électriques, ou déchetterie municipale ou collecte

sur les lieux d’achat des produits neufs.

DEWALT dispose d’installations pour la collecte et

le recyclage des produits DEWALT en fin de vie.

Pour profiter de ce service, veuillez rapporter votre

produit auprès d’un centre de réparation agréé qui le

recyclera en notre nom.

Pour connaître l’adresse d’un centre de réparation

agréé près de chez vous, veuillez contacter votre

distributeur DEWALT local à l’adresse indiquée dans

cette notice d’instructions, ou consulter la liste des

centres de réparation agréés DEWALT, l’éventail de

notre SAV et tout renseignement complémentaire

sur Internet à l’adresse: www.2helpU.com.

Accessoires en option

AVERTISSEMENT: comme les

accessoires autres que ceux offerts par

DEWALT n’ont pas été testés avec ce

produit, leur utilisation avec cet appareil

pourrait être dangereuse. Pour réduire

tout risque de dommages corporels,

19

Page 22

ﺔﻴﺑﺮﻌﻟﺍ

ﺔﻘﻴﻀﻟﺍ ﺎﻳﺍﻭﺰﻟﺍ ﺔﺧﻼﺟ

DWE4887N

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻰﻟإ تاﺮﻳﺬﺤﺘﻟا ﻲﻓ «ﺔﻴﺋﺎﺑﺮﻬﻛ ةادأ» ﺢﻠﻄﺼﻤﻟا ﺮﻴﺸﻳ

ةادﻷا وأ (ﻲﺋﺎﺑﺮﻬﻛ ﻚﻠﺴﺑ ةدوﺰﻣ) ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻗﺎﻄﻟﺎﺑ ﻞﻤﻌﺗ ﻲﺘﻟا

.(ﻲﺋﺎﺑﺮﻬﻛ ﻚﻠﺴﺑ ةدوﺰﻣ ﺮﻴﻏ) ﺔﻳرﺎﻄﺒﻟﺎﺑ ﻞﻤﻌﺗ ﻲﺘﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﺚﻴﺣ .ةﺪﻴﺟ ﺔﻘﻳﺮﻄﺑ ةءﺎﻀﻣو ﺔﻔﻴﻈﻧ ﻞﻤﻌﻟا ﺔﻘﻄﻨﻤﺑ ﻆﻔﺘﺣا (أ

عﻮﻗو ﻰﻟإ يدﺆﺗ ﺔﻤﻠﻈﻤﻟا وأ مﺎﻈﻧ ﺮﻴﻐﺑ ﺔﺳﺪﻜﺘﻤﻟا ﻖﻃﺎﻨﻤﻟا نأ

،ةﺮﺠﻔﺘﻤﻟا ءاﻮﺟﻷا ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻞﻴﻐﺸﺘﺑ ﻢﻘﺗ ﻻ (ب

.لﺎﻌﺘﺷﻼﻟ ﻞﺑﺎﻗ رﺎﺒﻏ وأ تازﺎﻏ وأ ﻞﺋاﻮﺳ نﺎﻜﻤﻟﺎﺑ ﺪﺟﻮﻳ نﺄﻛ

لﺎﻌﺘﺷا ﻲﻓ تاراﺮﺷ ثﺪﺤﺗ ﻲﺘﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا يدﺆﺗ ﺪﻗ

ً

ءﺎﻨﺛأ

اﺪﻴﻌﺑ ﻦﻳﺪﻫﺎﺸﻤﻟا صﺎﺨﺷﻷاو لﺎﻔﻃﻷا ﻰﻠﻋ ﻆﻓﺎﺣ

ناﺪﻘﻓ ﻰﻟإ هﺎﺒﺘﻧﻻا ﺖﺘﺸﺗ يدﺆﻳ ﺪﻘﻓ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ

رﺎﻴﺘﻟا رﺪﺼﻣ ﻊﻣ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺲﺑﺎﻗ ﻖﺑﺎﻄﺘﻳ نأ ﺐﺠﻳ (أ

يﺄﺑ ﺲﺑﺎﻘﻟا ﻰﻠﻋ ﻞﻳﺪﻌﺗ ءاﺮﺟﺈﺑ ﺎ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ﻊﻣ لﻮﺤﻤﻟا ﺲﺑﺎﻗ مﺪﺨﺘﺴﺗ ﻻ .ﺔﻘﻳﺮﻃ

ﺔﻟﺪﻌﻤﻟا ﺮﻴﻏ ﺲﺑﺎﻘﻤﻟا ﻞﻠﻘﺘﺳ ﺚﻴﺣ .(ﺎﻬﻀﻳرﺄﺗ ﻢﺗ) ﺔﺿرﺆﻤﻟا

ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻦﻣ ﺔﻘﺑﺎﻄﺘﻤﻟا ﻲﺋﺎﺑﺮﻬﻜﻟا رﺎﻴﺘﻟا ردﺎﺼﻣو

ﺔﺿرﺆﻤﻟا وأ ﺔﻴﺿرﻷا ﺢﻄﺳﻷا ﻊﻣ ﺪﺴﺠﻟا ﺲﻣﻼﺗ ﺐﻨﺠﺗ (ب

ﺮﻄﺧ ﺪﺟﻮﻳ ﺚﻴﺣ .تﺎﺟﻼﺜﻟاو تﺎﻗﺎﻄﻨﻟاو عﺎﻌﺸﻤﻟا ،ﺐﻴﺑﺎﻧﻷﺎﻛ

وأ ﺎ

ﺿرﺆﻣ كﺪﺴﺟ نﺎﻛ اذإ ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﻦﻣ ﺪﻳاﺰﺘﻣ

ً

ءﺎﻤﻟا يدﺆﻴﺳ ذإ .ﻞﻠﺒﻟا وأ ﺮﻄﻤﻠﻟ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا تاودﻷا ضﺮﻌﺗ ﻻ (ج

ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ةدﺎﻳز ﻰﻟإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﺧﺪﻳ يﺬﻟا

ﺎًﻘﻠﻄﻣ مﺪﺨﺘﺴﺗ ﻻ .ﺔﺌﻃﺎﺧ ﺔﻘﻳﺮﻄﺑ ﻞﺑﺎﻜﻟا مﺪﺨﺘﺴﺗ ﻻ (د

ةادﻷا ﺲﺑﺎﻗ عﺰﻨﻟ وأ ﺎﻬﺒﺤﺳ وأ ءﺎﻴﺷﻷا ﻞﻤﺣ ﻞﺟأ ﻦﻣ ﻚﻠﺴﻟا

فاﻮﺤﻟا وأ تﻮﻳﺰﻟا وأ ةراﺮﺤﻟا ﻦﻋ ﻚﻠﺴﻟا ﺪﻌﺑأ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

وأ ﺔﻔﻟﺎﺘﻟا كﻼﺳﻷا ﺪﻳﺰﺗ ذإ .ﺔﻛﺮﺤﺘﻤﻟا ءاﺰﺟﻷا وأ ةدﺎﺤﻟا

.ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻦﻣ ﺔﻜﺑﺎﺸﺘﻤﻟا

ﻚﻠﺳ مﺪﺨﺘﺳا ،لﺰﻨﻤﻟا جرﺎﺧ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﺪﻨﻋ (ـﻫ

نإ ﺚﻴﺣ .ﺔﻴﺟرﺎﺨﻟا ﻦﻛﺎﻣﻷا ﻲﻓ ماﺪﺨﺘﺳﻼﻟ ﻢﺋﻼﻣ ﺔﻟﺎﻄﺘﺳا

ﺮﻄﺧ ﻦﻣ ﻞﻠﻘﻳ ﻲﺟرﺎﺨﻟا ماﺪﺨﺘﺳﻼﻟ ﻢﺋﻼﻤﻟا ﻚﻠﺴﻟا ماﺪﺨﺘﺳا

ﺪﺣأ ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﻦﻣ ﺮﻔﻣ كﺎﻨﻫ ﻦﻜﻳ ﻢﻟ اذإ (و

ﻊﻃﺎﻗ زﺎﻬﺠﺑ ﻲﻤﺤﻣ داﺪﻣإ رﺪﺼﻣ مﺪﺨﺘﺳﺎﻓ ،ﺔﺒﻃﺮﻟا ﻦﻛﺎﻣﻷا

ثوﺪﺣ ﻦﻣ ﻞﻠﻘﻳ ﻲﻘﺒﺘﻤﻟا رﺎﻴﺘﻟا زﺎﻬﺟ ماﺪﺨﺘﺳا .(RCD) ةروﺪﻟا

ﺔﻣﺎﻌﻟا ساﻮﺤﻟﺎﺑ ﻦﻌﺘﺳاو ﻪﻠﻌﻔﺑ مﻮﻘﺗ ﺎﻣ ﺐﻗارو

ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا مﺪﺨﺘﺴﺗ ﻻ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﻞﻴﻐﺸﺗ ﺪﻨﻋ

وأ لﻮﺤﻜﻟا وأ تارﺪﺨﻤﻟا ﺮﻴﺛﺄﺗ ﺖﺤﺗ وأ ﺎ

تاودﻷا ﻞﻴﻐﺸﺗ ءﺎﻨﺛأ ﻮﻬﺴﻟا ﻦﻣ ﺔﻈﺤﻟ يأ يدﺆﺗ ﺪﻗ .ﺔﻳودﻷا

.ﺔﻤﻴﺴﺟ ﺔﻳﺪﺴﺟ ﺔﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﻲﻗاو ءاﺪﺗرﺎﺑ ﺎًﻣود ﻢﻗ .ﺔﻴﺼﺨﺸﻟا ﺔﻳﺎﻗﻮﻟا تاﺪﻌﻣ مﺪﺨﺘﺳا (ب

،ﺔﺑﺮﺗﻷا تﺎﻣﺎﻤﻛ ﻞﺜﻣ ﺔﻳﺎﻗﻮﻟا تاﺪﻌﻣ ماﺪﺨﺘﺳا نأ ذإ .ﻦﻴﻨﻴﻌﻟا

نذﻷا ﻲﻗاو وأ ،ﺔﺒﻠﺼﻟا ةذﻮﺨﻟاو ،قﻻﺰﻧﻼﻟ ﺔﻌﻧﺎﻤﻟا نﺎﻣﻷا ﺔﻳﺬﺣأو

.ﺔﻴﺼﺨﺸﻟا تﺎﺑﺎﺻﻹا ﻦﻣ ﻞﻠﻘﻴﺳ ﺔﻠﺼﻟا تاذ تﻻﺎﺤﻠﻟ

20

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻘﻌﺼﻟا ثوﺪﺣ

ﻞﻤﻌﻟﺍ ﺔﻘﻄﻨﻣ ﻥﺎﻣﺃ (1

.ثداﻮﺤﻟا

.ﺔﻨﺧدﻷا وأ ﺔﺑﺮﺗﻷا

.ﻚﺗﺮﻄﻴﺳ

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺔﻣﻼﺴﻟﺍ (2

ً

ﻘﻠﻄﻣ ﻢﻘﺗ ﻻ .ﻲﺋﺎﺑﺮﻬﻜﻟا

.ﺔﻴﺋﺎﺑﺮﻬﻛ

.ضرﻷا ﻰﻠﻋ ﺎ

.ﺔﻴﺋﺎﺑﺮﻬﻛ

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻘﻌﺼﻟا

ﺔﻴﺼﺨﺸﻟﺍ ﺔﻣﻼﺴﻟﺍ (3

ً

ﺎﻈﻘﻴﺘﻣ ﻖﺑا (أ

ﺒﻌﺘﻣ نﻮﻜﺗ ﺎﻣﺪﻨﻋ

ً

!ﺎﻨﻴﻧﺎﻬﺗ

ﺕﺎﻴﻠﻤﻋ ﺎﻬﻟﻼﺧ ﺪﺘﻤﺗ ﻲﺘﻟﺍ ﺓﺮﺒﺨﻟﺍ ﺕﺍﻮﻨﺳ .DEWALT ﺓﺍﺩﺃ ﺕﺮﺘﺧﺍ ﺪﻘﻟ

ﻦﻳﺬﻟﺍ ءﺎﻛﺮﺸﻟﺍ ﺮﺜﻛﺃ ﻦﻣ DEWALT ﻞﻌﺠﺗ ﺎﻫﺭﺎﻜﺘﺑﺍﻭ ﺕﺎﺠﺘﻨﻤﻟﺍ ﺮﻳﻮﻄﺗ

.ﻦﻴﻓﺮﺘﺤﻤﻟﺍ ﺔﻴﻟﻵﺍ ﺕﺍﻭﺩﻷﺍ ﻲﻣﺪﺨﺘﺴﻤﻟ ﺔﺒﺴﻨﻟﺎﺑ ﻢﻬﻴﻠﻋ ﺩﺎﻤﺘﻋﻻﺍ ﻦﻜﻤﻳ

ﺔﻴﻨﻔﻟﺍ ﺕﺎﻧﺎﻴﺒﻟﺍ

DWE4887N

240–220 ددﺮﺘﻣ رﺎﻴﺗ ﺖﻟﻮﻓ ﻲﺋﺎﺑﺮﻬﻜﻟا ﺪﻬﺠﻟا

127

(ج

1 عﻮﻨﻟا

450 تاو ﺔﻗﺎﻄﻟا ﻞﺧد

25000

38 ﻢﻣ ﺔﻧاﻮﻄﺳﻷا ﺮﻄﻘﻟ ﻰﺼﻗﻷا ﺪﺤﻟا

M15 ناروﺪﻟا دﻮﻤﻋ

6 ﻢﻣ ﻲﻧﺪﻌﻤﻟا قﻮﻄﻟا ﺔﻌﺳ

1.6 ﻢﺠﻛ نزﻮﻟا

1-

ﺔﻘﻴﻗد ﻞﻤﺣ نوﺪﺑ ﺔﻋﺮﺴﻟا

ﻥﺎﻣﻷﺍ ﺕﺎﻤﻴﻠﻌﺗ :ﺕﺎﻔﻳﺮﻌﺘﻟﺍ

ﺓءﺍﺮﻗ ﻰﺟﺮﻳ .ﺔﻳﺮﻳﺬﺤﺗ ﺔﻤﻠﻛ ﻞﻛ ﺔﻴﻤﻫﺃ ﻯﻮﺘﺴﻣ ﺔﻴﻟﺎﺘﻟﺍ ﺕﺎﻔﻳﺮﻌﺘﻟﺍ ﻒﺼﺗ

ﺘﺑﺎﺛ

ً

اذإو ،ﺔﻳﺎﻐﻠﻟ عﻮﻗﻮﻟا ﺔﻜﻴﺷو ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﻳ :ﺮﻄﺧ

تﺎﺑﺎﺻﻹا وأ ةﺎﻓﻮﻟا ثوﺪﺣ ﻰﻟإ يدﺆﺘﺴﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ ﻢﻟ

ﻢﻟ اذإو ،عﻮﻗﻮﻟا ﺔﻠﻤﺘﺤﻣ ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﻳ :ﺮﻳﺬﺤﺗ

ﺔﺑﺎﺻﻹا وأ ةﺎﻓﻮﻟا ثوﺪﺣ ﻰﻟإ يدﺆﺗ ﺪﻘﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ

ﻢﻟ اذإو ،عﻮﻗﻮﻟا ﺔﻠﻤﺘﺤﻣ ةﺮﻄﺧ ﺔﻟﺎﺣ ﻰﻟإ ﺮﻴﺸﻳ :ﻪﻴﺒﻨﺗ

وأ ﺔﻔﻴﻔﺧ تﺎﺑﺎﺻإ ثوﺪﺣ ﻰﻟإ يدﺆﺗ ﺪﻘﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ

ﺔﺑﺎﺻﺈﺑ ﺔﻘﻠﻌﺘﻣ ﺮﻴﻏ ﺔﺳرﺎﻤﻣ ﻰﻟإ ﺮﻴﺸﺗ :ﺔﻈﺣﻼﻣ

رﺮﺿ ﻰﻟإ يدﺆﺗ ﺪﻘﻓ ،ﺎﻬﻳدﺎﻔﺗ ﻢﺘﻳ ﻢﻟ اذإ ،ﺔﻴﺼﺨﺷ

.ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﺮﻄﺧ ﻰﻟإ ﺮﻴﺸﺗ

.ﻖﻳﺮﺣ بﻮﺸﻧ ﺮﻄﺧ ﻰﻟإ ﺮﻴﺸﺗ

ﻞﻴﻟد ةءاﺮﻗ ﻰﺟﺮﻳ ،تﺎﺑﺎﺻﻹا ثوﺪﺣ ﺮﻄﺧ ﻞﻴﻠﻘﺘﻟ :ﺮﻳﺬﺤﺗ

.ﺯﻮﻣﺮﻟﺍ ﻚﻠﺘﻟ ﻩﺎﺒﺘﻧﻻﺍﻭ ﻞﻴﻟﺪﻟﺍ

.ﺔﻤﻴﺴﺠﻟا

.ﺔﻤﻴﺴﺠﻟا

.ﺔﻄﺳﻮﺘﻣ

.تﺎﻜﻠﺘﻤﻤﻟا

.تﺎﻤﻴﻠﻌﺘﻟا

ﺔﻴﺋﺎﺑﺮﻬﻜﻟﺍ ﺕﺍﻭﺩﻸﻟ ﺔﻣﺎﻌﻟﺍ ﻥﺎﻣﻷﺍ ﺕﺍﺮﻳﺬﺤﺗ

ﺔﻓﺎﻛو نﺎﻣﻷا تاﺮﻳﺬﺤﺗ ﻊﻴﻤﺟ ةءاﺮﻗ ﻰﺟﺮﻳ !ﺮﻳﺬﺤﺗ

تاﺮﻳﺬﺤﺘﻟا هﺬﻫ عﺎﺒﺗﺎﺑ ماﺰﺘﻟﻻا مﺪﻋ .تادﺎﺷرﻹا

وأ/و ،ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﻰﻟإ يدﺆﻳ ﺪﻗ تﺎﻤﻴﻠﻌﺘﻟاو

ﻞﺒﻘﺘﺴﻤﻟﺍ ﻲﻓ ﺎﻬﻴﻟﺇ ﻉﻮﺟﺮﻟﺍ ﻞﺟﺃ ﻦﻣ ﺕﺎﻤﻴﻠﻌﺘﻟﺍﻭ ﺕﺍﺮﻳﺬﺤﺘﻟﺍ ﻊﻴﻤﺠﺑ ﻆﻔﺘﺣﺍ

.ﺔﻤﻴﺴﺟ ﺔﺑﺎﺻإ وأ/و ،ﻖﻳﺮﺣ بﻮﺸﻧ

Page 23

ﺔﻴﺑﺮﻌﻟﺍ

حﻼﺻإ ﻲﻨﻓ ﺪﻳ ﻰﻠﻋ ﻚﺑ ﺔﺻﺎﺨﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺔﻧﺎﻴﺼﺑ ﻢﻗ (أ

.ﻂﻘﻓ ﺔﻘﺑﺎﻄﺘﻣ ﺔﻠﻳﺪﺑ ءاﺰﺟأ ماﺪﺨﺘﺳا لﻼﺧ ﻦﻣ ﻚﻟذو ﻞﻫﺆﻣ

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا نﺎﻣأ ﻰﻠﻋ ظﺎﻔﺤﻟا ﻚﻟذ ﻦﻤﻀﻴﺳ ﺚﻴﺣ

ﺔﻣﺪﺨﻟﺍ (5

ﺔﻴﻓﺎﺿﻹﺍ ﺓﺩﺪﺤﻤﻟﺍ ﻥﺎﻣﻷﺍ ﺪﻋﺍﻮﻗ

ﺕﺎﻴﻠﻤﻋ ﻊﻴﻤﺠﺑ ﺔﺻﺎﺨﻟﺍ ﻥﺎﻣﻷﺍ ﺕﺎﻤﻴﻠﻌﺗ

ﻞﻴﻐﺸﺘﻟﺍ

أﺮﻗا .ﺔﺧﻼﺠﻛ ﻞﻤﻌﻠﻟ ﺔﺼﺼﺨﻣ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا هﺬﻫ نإ (أ

تﺎﻔﺻاﻮﻤﻟاو تﺎﺣﺎﻀﻳﻹاو تﺎﻤﻴﻠﻌﺘﻟاو نﺎﻣﻷا تاﺮﻳﺬﺤﺗ ﻊﻴﻤﺟ

ﻊﻴﻤﺟ عﺎﺒﺗا مﺪ ﻋ يدﺆﻳ ﺪﻗ ذإ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا هﺬﻫ ﻊﻣ ةدراﻮﻟا

وأ/و ﻖﻳﺮﺣ بﻮﺸﻧ وأ/و ﺔﻴﺋﺎﺑﺮﻬﻛ ﺔﻘﻌﺻ ثوﺪﺣ ﻰﻟإ تادﺎﺷرﻹا

ةﺎﺷﺮﻔﻟﺎﺑ ﺶﻳﺮﻔﺘﻟاو ﻢﻴﻌﻨﺘﻟا ﻞﺜﻣ تﺎﻴﻠﻤﻋ ءاﺮﺟإ مﺪﻌﺑ ﻰﺻﻮﻳ (ب

.ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻟﻵا هﺬﻫ ماﺪﺨﺘﺳﺎﺑ ﻊﻄﻘﻟاو ﻊﻴﻤﻠﺘﻟاو ﺔﻴﻜﻠﺴﻟا

ﺔﻴﺑﺮﻬﻜﻟا ةادﻷا هﺬﻫ ﻢﻤﺼﺗ ﻢﻟ ﻲﺘﻟا تﺎﻴﻠﻤﻌﻟا ﺐﺒﺴﺘﺗ ﺪﻘﻓ

.ﺔﻴﺼﺨﺷ تﺎﺑﺎﺻإ ثاﺪﺣإو ﺮﻃﺎﺨﻣ عﻮﻗو ﻲﻓ ﺎﻬﺑ مﺎﻴﻘﻠﻟ

ﺎﻬﺑ ﻰﺻﻮﻣ ﺮﻴﻏو ﺔﺼﺼﺨﻣ ﺮﻴﻏ تﺎﻘﺤﻠﻣ ﺔﻳأ مﺪﺨﺘﺴﺗ ﻻ (ج

ﺔﻴﻧﺎﻜﻣإ ﻲﻨﻌﺗ ﻼﻓ .ةادﻸﻟ ﺔﻌﻨﺼﻤﻟا ﺔﻛﺮﺸﻟا ﻞﺒﻗ ﻦﻣ ا

.ﻦﻣﻵا ﻞﻴﻐﺸﺘﻟا ﻦﻤﻀﺗ ﺎﻬﻧأ ﺔﻴﺑﺮﻬﻜﻟا ةادﻷﺎﺑ تﺎﻘﺤﻠﻤﻟا ﻞﻴﺻﻮﺗ

ﻞﻗﻷا ﻰﻠﻋ ﺔﻳوﺎﺴﻣ ﻖﺤﻠﻤﻠﻟ ةرﺪﻘﻤﻟا ﺔﻋﺮﺴﻟا نﻮﻜﺗ نأ ﺐﺠﻳ (د

ﺪﻗ ذإ .ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷﺎﺑ ةدﺪﺤﻤﻟا ﺔﻋﺮﺴﻠﻟ ﻰﺼﻗﻷا ﺪﺤﻠﻟ

ﻦﻣ ﺮﺒﻛأ ﺔﻋﺮﺴﺑ ﻞﻤﻌﺗ ﻲﺘﻟا تﺎﻘﺤﻠﻤﻟا ءاﺰﺟأ ﺮﻳﺎﻄﺘﺗ وأ ﻢﻄﺤﺘﺗ

ﻦﻤﺿ ﻖﺤﻠﻤﻟا ﻚﻤﺳو ﻲﺟرﺎﺨﻟا ﺮﻄﻘﻟا نﻮﻜﻳ نأ ﺐﺠﻳ (ه

ﻦﻜﻤﻳ ﻻ .ﻚﺑ ﺔﺻﺎﺨﻟا ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻸﻟ ﺔﻌﺴﻟا ﻒﻴﻨﺼﺗ

ﻢﻜﺤﺘﻟا وأ ﺔﺤﻴﺤﺼﻟا ﺮﻴﻏ مﺎﺠﺣﻷا تاذ تﺎﻘﺤﻠﻤﻟا ﻦﻣ رﺬﺤﻟا

وأ هﺎﻔﺸﻟا وأ تﺎﻧاﻮﻄﺳﻷا ءﺎﻄﻏ ﻢﺠﺣ ﺐﺳﺎﻨﺘﻳ نأ ﺐﺠﻳ (و

ةادﻷا نارود دﻮﻤﻋ ﻊﻣ ىﺮﺧأ تﺎﻘﺤﻠﻣ ﺔﻳأ وأ ﻢﻋﺪﻟا ﺪﺋﺎﺳو

ﻲﻓ تﺎﺤﺘﻔﺑ ةدوﺰﻤﻟا تﺎﻘﺤﻠﻤﻟا نإ ﺚﻴﺣ .ﺔﻗﺪﺑ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا

ﺪﻘﻔﺘﺳ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺐﻴﻛﺮﺗ ةﺰﻬﺟأ ﻊﻣ ﻖﺑﺎﻄﺘﺗ ﻻ ءﺎﻄﻐﻟا

.ةﺮﻄﻴﺴﻟا ناﺪﻘﻓ ﻰﻟإ يدﺆﺗ ﺪﻗو ةﺪﺸﺑ ﺰﺘﻬﺗو ﺎﻬﻧزاﻮﺗ

ﻢﻴﻌﻨﺘﻟا تﺎﻧاﻮﻄﺳأو تﺎﻧاﻮﻄﺳﻷا ﺖﻴﺒﺜﺗ قﺎﻴﺷ ﺐﻴﻛﺮﺗ ﺐﺠﻳ (ز

اذإ .فﺮﻈﻟا وأ ﻲﻧﺪﻌﻤﻟا قﻮﻄﻟا ﻲﻓ ﻞﻣﺎﻛ ﻞﻜﺸﺑ ﻊﻄﻘﻟا تاودأو

ﻦﻣ زرﺎﺒﻟا ءﺰﺠ ﻟا نﺎﻛ وأ/و

ﺔﺘﺒﺜﻤﻟا ﺔﻧاﻮﻄﺳﻷا ﺢﺒﺼﺗ ﺪﻘﻓ ،ﺔﻳﺎﻐﻠﻟ ﻞﻳﻮﻃ ﺔﻧاﻮﻄﺳﻷا

ﺺﺤﻓا ،ماﺪﺨﺘﺳا ﻞﻛ ﻞﺒﻗ .ﺔﻔﻟﺎﺘﻟا تﺎﻘﺤﻠﻤﻟا مﺪﺨﺘﺴﺗ ﻻ (ح

وأ قﺰﻤﺘﻟا وأ تﺎﻋﺪﺼﺘﻟا ﻦﻋ ﺎًﺜﺤﺑ ﻢﻋﺪﻟا ﺪﺋﺎﺳوو ،تﺎﻋﺪﺼﺘﻟاو

ﺔﺒﺋﺎﺴﻟا كﻼﺳﻷا ﻦﻋ ﺎًﺜﺤﺑ ﺔﻴﻜﻠﺴﻟا ةﺎﺷﺮﻔﻟاو ،ﺪﺋاﺰﻟا ﻒﻠﺘﻟا

،تﺎﻘﺤﻠﻤﻟا ﺪﺣأ وأ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا ﺖﻄﻘﺳ اذإ .ةﺮﺴﻜﺘﻤﻟا وأ

ﻖﺤﻠﻣ ﺐﻴﻛﺮﺘﺑ ﻢﻗ وأ ﻪﺑ ﺖﻘﺤﻟ ﻲﺘﻟا راﺮﺿﻷا ﻦﻋ ﺎ

ﺖﻧأ ﺪﻌﺘﺑا ،ﻖﺤﻠﻤﻟا ﺐﻴﻛﺮﺗو ﺺﺤﻔﺑ مﺎﻴﻘﻟا ﺪﻌﺑ .ﻢﻴﻠﺳ

ﻞﻴﻐﺸﺘﺑ ﻢﻗو ﻖﺤﻠﻤﻟا نارود ىﻮﺘﺴﻣ ﻦﻋ كراﻮﺠﺑ ﻦﻴﻔﻗاﻮﻟاو

ﺔﻘﻴﻗد ةﺪﻤﻟ ﺔﻳدﺎﻌﻟا ﺔﻋﺮﺴﻠﻟ ﺪﺣ ﻰﺼﻗﻷ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ةادﻷا

اﺬﻫ ﺖﻗو ءﺎﻨﺛأ ﺔﻔﻟﺎﺘﻟا تﺎﻘﺤﻠﻤﻟا ﻢﻄﺤﺗ ﻲﻌﻴﺒﻄﻟا ﻦﻣو .ةﺪﺣاو

ﻪﺟﻮﻟا ﻲﻣﺎﺣ ءاﺪﺗرا نإ ﺚﻴﺣ .

ﻰﻠﻋ ﻒﻗﻮﺘﻳ ﺔﻴﻗاﻮﻟا ﺔﻴﺟﺎﺟﺰﻟا تارﺎﻈﻨﻟا وأ ﺔﻴﻗاﻮﻟا تارﺎﻈﻨﻟا وأ

ءاﺪﺗرﺎﺑ ﻢﻗ ،ﺔﺟﺎﺤﻟا ﻪﻴﻀﺘﻘﺗ ﺎﻣ ﻖﻓوو .زﺎﻬﺠﻟا ماﺪﺨﺘﺳا

يﺬﻟا ﻞﻤﻌﻟا ﻒﻄﻌﻣو تازﺎﻔﻘﻟاو نذﻷا تﺎﻴﻗاوو ﺔﺑﺮﺗﻷا تﺎﻣﺎﻤﻛ

ﺪﺿ ﺔﻳﺎﻗﻮﻟا ﻰﻠﻋ ا

نأ ﺐﺠﻳ .ﺔﻔﻠﺘﺨﻤﻟا تﺎﻴﻠﻤﻌﻟا ﻦﻋ ﺔﻤﺟﺎﻨﻟا ةﺮﻳﺎﻄﺘﻤﻟا ﺎﻳﺎﻈﺸﻟا

ً

خوﺮﺸﻟا ﻦﻋ ﺎ

ﺜﺤﺑ ﺔﻄﺷﺎﻜﻟا ﺔﻧاﻮﻄﺳﻻا ﻞﺜﻣ تﺎﻘﺤﻠﻤﻟا

ﺎﻳﺎﻈﺷ وأ ةﺮﻴﻐﺼﻟا ﺦﻴﻠﺠﺘﻟا ﺎﻳﺎﻈﺷ ﻦﻣ ﻚﺘﻳﺎﻤﺣ ﻪﻨﻜﻤﻳ

ردﺎﻗ ﻦﻴﻌﻟا ﻲﻗاو نﻮﻜﻳ نأ ﺐﺠﻳ .ﻞﻤﻌﻟا ﻊﻄﻗ

ً

.ﺔﻤﻴﺴﺟ ﺔﺑﺎﺻإ عﻮﻗو

ﺪﻳﺪﺤﺗ

ً

.ةرﺪﻘﻤﻟا ﺎﻬﺘﻋﺮﺳ

ٍ