Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contactenos.

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DWE46100

Tuckpoint Shroud

Carter de tron_onnage du b_ton

Cubierta protectora para rejuntar

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA DE

GARANT[A. ADVERTENOIA: LEASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

®

Page 2

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay attention

to these symbols.

,_,DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

i_ WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

_, CAUTION." Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

X. which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258}.

_ ARNING: To reduce the risk of injury, read the instruction

manual.

J

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

General Safety Warnings

_ WARNING: For your own safety, read the instruction manual for

both the grinder tool and the dust extractor vacuum before using

any accessory, Failure to heed these warnings may result in personal

injury and serious damage to the tool and the accessory, When

servicing this tool, use only identical replacement parts.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control

c) Ensure the workplace is well ventilated. Exposure to dust

at a poorly ventilated workplace may result in damage to the

health.

2) ELECTRICAL SAFETY

a) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury,

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

d) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

Page 3

4) POWER TOOL USE AND CARE •

a) Do not force the power tooL Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

A WARNIN6: The use of any accessory or attachment or •

performance of any operation with this tool, other than those

recommended in this instruction manual may present a risk of

personal injury.

b) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these •

instructions to operate the power tool. Power too/s are

dangerous in the hands of untrained users.

c) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed. •

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Tuckpointing Safety Rules

• Do not use accessories which are not specifically designed

and recommended by the tool manufacturer. Just because

the accessory can be attached to your power tool, it does not

assure safe operation.

• The rated speed of the accessory must be at least equal to

the maximum speed marked on the power tool Accessories

running faster than their rated speed can break and fly apart.

The outside diameter and the thickness of your accessory

must be within the capacity rating of your power tool

Incorrectly sized accessories cannot be adequately guarded or

controlled.

The arbor size of wheels, flanges, backing pads or any other

accessory must properly fit the spindle of the power tool.

Accessories with arbor holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. The guard helps

to protect operator from broken wheel fragments and accidental

contact with wheel.

Hold power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the

power tool "live" and shock the operator.

Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the tool

at all times.

Do not use a damaged accessory. Before each use inspect

the accessory such as diamond wheel for chips and cracks,

backing pad for cracks, tear or excess wear, wire brush

for loose or cracked wires. If power tool or accessory is

dropped, inspect for damage or install an undamaged

accessory. After inspecting and installing an accessory,

position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum

no-load speed for one minute. Damaged accessories will

normally break apart during this test time.

Page 4

• DO NOT grind or cut metal with a diamond wheel

• Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping small abrasive or

workpiece fragments. The eye protection must be capable of

stopping flying debris generated by various operations. The dust

mask or respirator must be capable of filtrating particles generated

by your operation. Prolonged exposure to high intensity noise may

cause hearing loss.

• Do not '_am" the cut-off wheel or apply excessive pressure.

Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut and the possibility of

kickback or wheel breakage.

• Position the cord clear of the spinning accessory. If you lose

control, the cord may be cut orsnagged and your hand or arm may

be pulled into the spinning accessory.

• Never lay the power tool down until the accessory has come

to a complete stop. The spinning accessory may grab the surface

and pull the power tool out of your control

• Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag your

clothing, pulling the accessory into your body.

• Regularly clean the power tool's air vents. The motor's fan will

draw the dust inside the housing and excessive accumulation of

powdered metal may cause electrical hazards.

• Do not operate the power tool near flammable materials.

Sparks could ignite these materials.

• Do not use accessories that require liquid coolants. Using

water or other liquid coolants may result in electrocution or shock.

• DO NOT use abrasive wheels.

• ALWAYS use with a dust collector.

_ WARNING: When not in use, place grinder on a stable surface

where it will not move inadvertantly, roll or cause a tripping or

falling hazard. Serious personal injury may result.

_ WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3).

• ANSI $12.6 ($3. 19) hearing protection.

• NIOSH/OSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Yourrisk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

Page 5

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure. Direct particles away from face and body.

A WARNING: Before beginning the work, check to determine

the hazard classification of the dust produced. Use an industrial

dust extractor vacuum of the appropriate officially approved

safety class that is in compliance with your local dust hazard

control regulations.

A WARNING: Always wear proper personal hearing protection.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or snagged rotating

wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be forced in the

direction opposite of the accessory's rotation at the point of the

binding.

For example, if an diamond wheel is snagged or pinched by the

workpiece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel's movement

at the point of pinching, diamond wheels may also break under

these conditions.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a) Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up.

The operator can control torque reaction or kickback forces, if

proper precautions are taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool

in direction opposite to the wheel's movement at the point of

snagging.

d) Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of

control

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

COMPONENTS (FIG. 1)

_, WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Dust port

B. Clamp adjusting screw

C. Depth of cut shoe

D. Depth of cut shoe

locking knob

INTENDED USE

Your tuckpoint shroud has been designed for professional tuckpoint

masonry applications. It is not intended for use with metal or wood.

E. Cornering door locking lever

(locks and unlocks cornering door)

F.Cornering door (opens and

allows cutting of an inside corner)

G. Clamp lever

Page 6

Usingtheappropriategrinder,wheelanddustextractorvacuumitcan

beusedtoremovethevastmajorityofstaticandairbornedustwhich

withouttheuseofthetuckpointshroudcouldotherwisecontaminate

theworkingenvironmentorposeanincreasedhealthrisktothe

operatorandthoseincloseproximity.

DO NOT use under wet conditions or in presence of flammable liquids

or gases.

The tuckpoint shroud is a professional tool. DO NOT let children come

into contact with the tool. Supervision is required when inexperienced

operators use this tool.

Recommended power tools to be used with this attachment are

available at extra cost from your local dealer or authorized service

center. If you need assistance in locating any power tool, please

contact DEWALTIndustrial Tool Co., 701 East Joppa Road, Baltimore,

MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our

website www.dewalt.com.

FIG.1 F

G

ASSEMBLY AND ADJUSTMENT (FIG. 1, 2)

A WARNING: To reduce the risk of injury, ALWAYS turn off the

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

Mounting and Removing Tuckpoint

Shroud

NOTE: The tuckpoint shroud is only recommended for use with the

DWE46102 heavy-duty small angle grinder.

1. Follow the mounting and removing guard instructions in the tool

manual to remove the guard from grinder (DWE46102).

2. Open the clamp lever (G) on the tuckpoint shroud and align the

tabs (I)on the tuckpoint shroud with the slots (J) on the grinder

gear case.

FIG. 2

B

3. With the clamp lever open, rotate the shroud into the desired

working position. The shroud should be positioned between the

spindle and the operator to provide optimum efficiency.

Page 7

4.Closetheclamplever(G)tosecurethetuckpointshroudonthe

gearcase.Donotoperatethegrinderwitha loosetuckpoint

shroudortheclampleverinopenposition.

5.Toremovethetuckpointshroud,opentheclamplever,rotatethe

tuckpointshroudtoaligntheslotsandtabsandpulluponthe

tuckpointshroud.

NOTE"Thetuckpointshroudispre-adjustedtothediameterofthe

gearcasehubatthefactory.If,afteraperiodoftime,thetuckpoint

shroudbecomesloose,tightentheclampadjustingscrew(B)with

clampleverintheclosedposition.

NOTICE: Do not tighten the clamp adjusting screw with the clamp

lever in open position. Undetectable damage to the tuckpoint shroud

or the mounting hub may result.

NOTICE: If tuckpoint shroud cannot be tightened by the clamp

adjusting clamp, do not use tool Take the tool and tuckpoint shroud

to a service center to repair or replace the tuckpoint shroud.

Mounting Cutting (Type 1) Wheels (Fig. 1)

WARNING: Only Type 1 Diamond Wheels shall be used with

Tuck-Point Shroud. Do not cut metal. Do not use with bonded

abrasive wheels.

Follow the mounting and using cutting (Type 1)wheels instructions in

the tool manual and mount the grinding wheel.

Itmay be necessary to open the cornering door to install 6" (152.4 mm)

tuckpointing wheels, see Cornering Door Application.

Depth of Cut Adjustment (Fig. 3)

1. Loosen the depth of cut shoe locking knob (D).

2. Slide the depth of cut shoe (C) to the desired position.

3. Tighten depth of cut shoe locking knob.

FIG. 3

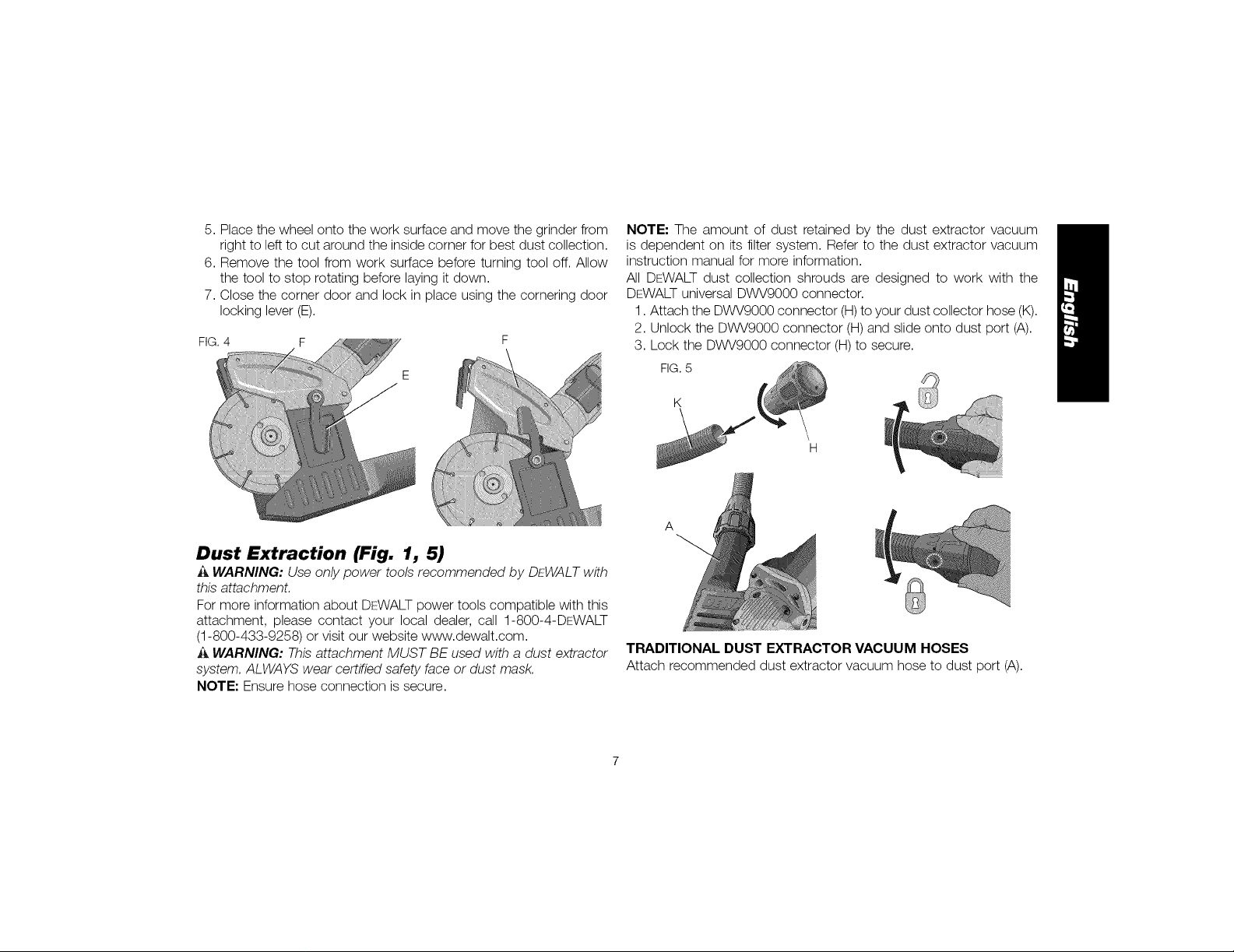

Corner Door Appfication (Fig. 4)

_ WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

WARNING: Risk of personal injury. The comer door should only

be opened for cutting inside comers. Keep hands and body away

from cutting area at all times. Ensure comer door is closed in all other

applications.

This feature allows the cutting of an inside corner.

1. Ensure the tool is off and wheel has come to a complete stop.

2. Turn cornering door locking lever (E) counterclockwise one full

rotation. Grasp the corner door (F) and rotate open as shown in

Figure 4.

3. Place hands away from the wheel area and position yourself so

the open underside of the shroud is facing away from you.

4. Turn the tool on and allow the tool to reach full speed before

touching the tool to the work surface.

Page 8

5.Placethewheelontotheworksurfaceandmovethegrinderfrom

righttolefttocutaroundtheinsidecornerforbestdustcollection.

6.Removethetoolfromworksurfacebeforeturningtooloff.Allow

thetooltostoprotatingbeforelayingitdown.

7.Closethecornerdoorandlockinplaceusingthecorneringdoor

lockinglever(E).

FIG. 4

Dust Extraction (Fig. 1, 5)

A WARNING: Use only power tools recommended by DEWALT with

this attachment.

For more information about DEWALT power tools compatible with this

attachment, please contact your local dealer, call 1-800-4-DEWALT

(1-800-433-9258) or visit our website www.dewalt.com.

_, WARNING: This attachment MUST BE used with a dust extractor

system. ALWAYS wear certified safety face or dust mask.

NOTE: Ensure hose connection is secure.

NOTE: The amount of dust retained by the dust extractor vacuum

is dependent on its filter system. Refer to the dust extractor vacuum

instruction manual for more information.

All DEWALT dust collection shrouds are designed to work with the

DEWALTuniversal DWV9000 connector.

1. Attach the DWV9000 connector (H)to your dust collector hose (K).

2. Unlock the DWV9000 connector (H) and slide onto dust port (A).

3. Lock the DWV9000 connector (H) to secure.

TRADITIONAL DUST EXTRACTOR VACUUM HOSES

Attach recommended dust extractor vacuum hose to dust port (A).

Page 9

OPERATION

WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

,_ WARNING: For your own safety, read the instruction manual for

both the grinding tool and the dust extractor vacuum before using any

accessory. Failure to heed these warnings may result in personal injury

and serious damage to the tool and the accessory. When servicing this

tool, use only identical replacement parts.

WARNING: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come to

a complete stop before laying the tool down.

,_ WARNING: Ensure comer door is closed.

1. Ensure all assembly and adjustment instructions have been

completed.

2. Turn the dust extractor vacuum on as instructed in the dust

extractor vacuum instruction manual.

3. Start grinder as instructed in tool instruction manual.

NOTE: Allow the tool to reach full speed before applying to the

work surface.

Tuckpointing and Cutting Appfication

(Fig. 6)

1. Set the desired depth of cut, see Depth of Cut Adjustment

under Assembly and Adjustments.

2. Allow the tool to reach full speed before touching it to the work

surface.

3. Position yourself so the open underside of the shroud and the

wheel are facing away from you.

4. Place the edge (L)of shroud onto the work surface and begin cut

by plunging into the work surface. NOTE: Keep the edge (L)of the

shroud against the work surface to ensure proper dust collection.

5. With the shroud oriented as shown in Figure 6, move the grinder

right to left along the work surface. For the best results the

grinder should be positioned at a 45° angle to the dust port when

tuckpointing/cutting.

6. Remove the tool from work surface before turning off the tool.

Allow the tool to stop rotating before laying it down.

FIG.6 I

MAINTENANCE

i_ WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

Page 10

Cleaning

i_,WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. Tominimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

_ WARNING: Never use solvents or other harsh chemicals for cleaning

the non-metallic parts of the tool These chemicals may weaken the

plastic materials used in these parts. Use a cloth dampened only with

water and mild soap. Never let any liquid get inside the tool,"never

immerse any part of the tool into a liquid. Accessories

i_ WARNING: Since accessories, other than those offered by DEWALT,

have not been tested with this product, use of such accessories with

this tool could be hazardous. To reduce the risk of injury,only DEWALT

recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-DEWALT (1-800-433-9258) or visit our website: www.dewalt.

com.

Repairs

Toassure product SAFETY and RELIABILITY,repairs, maintenance and

adjustment (including brush inspection and replacement) should be

performed by a DEWALTfactory service center, a DEWALT authorized

service center or other qualified service personnel. Always use

identical replacement parts.

Three Year Limited Warranty

DEWALTwill repair,without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, DEWALTtools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

DEWALTPower Tool, Laser, or Nailer for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund

- no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-DEWALT (1-800-433-

9258) for a free replacement.

f

DWE46100 _/_CU_,NG/

_ T0 REDUCE THERISK 0F INJURY, USER MtlS¥READ INSTI_UCTION MANUAL. FOR USE WiTH

METAL DONOT USE WiTH BON])E0 AB_tASHVEWHEELS. ALWAYS USE

PROPER EYEAND RESPIRATORYPROTECTION.

_ DE INSTRUCCIONE$ PARA _EDUCIR

UTILJZARSECON MUELAO DE DiAMANTE TIPO 1. NOUTiLiZAR CON

MUELAS ABRASiVA_ CON AGLOMERANTE. _O CORTAX ME[ALES.

SiEMPRE SE DEBE_A LLEVAR LAPROTECCHON AP_OPiADA PAPA LA

VISTA Y PARA ]_ASVJAS RESPIRATOJ_IAS. POUft R_DUiRE TOUT RISQUE

_J_mm_r h"_T.'_q'iT_ o EO0 M MAGES C0 RPOSELS,

MANUEL DE "U1iLIOATEU]_.tlTdLISEn UNgQUEMENT AVECDES MEULES

DBAMANT DE TYPE _.NE PAS tlTit JSEf_AVEC DES MEULE$ ABRASIVES

COMPOSITES, NE DECOOPSRAOCON METAUX, JLFAOTTOUJOURS PO_TER

DE L'EQUiPEMENTDE PSOTECTIONOCULAIRE ETRESPiRATOIREAPP_OPRiE,

D_WALTI_0_JSTRIALTOO_CO.,BALTIMOre,cadZZ2_USA

FO R 5ERVICE INFO_t MATiO N, CALL I_O9_-DP,_ALT www,gEWALT,con_

TUCKPOiNTJNG SHROUD

TYPE I DIAMOND WHEELS ONLY.DO NOT CUT

ELUSUA_IO DEBELEE_ EL MANUAL

ELRiESGO DE LESIONES. SOLOOEBE

L'UTlUSATEURO01TLIRELE

Page 11

D_finitions : lignes directrices en

mati_re de s_curit_

Les definitions ci-dessous decrivent le niveau de danger pour

chaque mot-indicateur employe. Lire lemode d'emploi et porter

une attention particuliere a.ces symboles.

i_ DANGER : indique une situation dangereuse imminente qui,

si elle n'est pas evitee, entraTnera la mort ou des blessures

graves.

AAVERTISSEMENT : indique une situation potentie//ement

dangereuse qui, si e//e n'est pas evitee, pourrait entra_ner /a

mort ou des blessures graves.

.t_ATTENTION : indique une situation potentie//ement

dangereuse qui, si el/e n'est pas evitee, pourrait entra_nerdes

blessures I_g_res ou modifies.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n'est far

pour /'eviter, pourra_t poser des risques de dommages

materiels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DECET OUTIL

OU DE TOUT AUTRE OUTIL DEWALT, COMPOSE LE NUMC:RO

SANS FRAIS : 1-800-4-DEWALT (1-800-433-9258).

_ VERTISSEMENT : afin de reduire le risque de blessures, life

le mode d'emploi de I'outil.

CONSERVER TOUSLES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTERIEUR

Consignes g_n_rales de s_curit_

_ AVERTISSEMENT : pour votre securite, life le manuel de

I'utilisateur de la meuleuse, mais aussi de I'aspirateur avant

I'utilisation de tout accessoire. Toutmanquement aces avertissements

augmente les risques de blessures, et les risques d'endommager

serieusement I'appareil et ses accessoires. Lots de la maintenance de

cet outil, n'utiliser que des pieces de rechange identiques.

1) S#CURIT# DU LIEU DE TRAVAIL

a) Tenir I'aire de travail propre et bien _clair_e. Les Iieux

encombres ou sombres sont propices aux accidents.

b) E-Ioigner les enfants et les personnes aproximit_ pendant

I'utilisation d'un outil _lectrique. Une distraction pourrait en

faire perdre la ma_trisea I'utilisateur.

c) S'assurer que les lieux de travail sent bien a_r_s. Toute

exposition a la poussiere sur des Iieux de travail mal aeres pose

des risques a la sante.

2) S#CURIT# EN MATIERE D'#LECTRICIT#

a) Eviter tout contact physique avec des surfaces mises a la

terre comme des tuyaux, des radiateurs, des cuisini_res

et des r_frig_rateurs. Le risque de choc dectrique est plus

deve si votre corps est mis a la terre.

3) SI_CURITI_ PERSONNELLE

a) Etre vigilant, surveiller le travail effectu_ et faire preuve

de jugement Iorsqu'un outil _lectrique est utilis_. Ne

pas utiliser d'outil _lectrique en cas de fatigue ou sous

I'influence de drogues, d'alcool ou de m_dicaments. Un

simple moment d'inattention en utilisant un outil dectrique peut

entra_nerdes blessures corporelles graves.

b) Utiliser des _quipements de protection individuelle.

Toujours porter une protection oculaire. L'uti/isation

d'equipements de protection comme un masque antipoussiere,

des chaussures antiderapantes, un casque de securite ou des

lO

Page 12

protecteurs auditifs Iorsque la situation le requiert reduira les

risques de blessures corporelles.

c) Ne pas trop tendre les bras. Conserver son _quilibre en

tout temps. Ce/a permet de mieux ma_triser /'outi/ dectrique

dans les situations imprevues.

d) S'habiller de mani_re appropri_e. Ne pas porter de

v_tements amples ni de bijoux. Garder les cheveux, les

v_tements et les gants a I'_cart des pi_ces mobiles. Les

v_tements amp/es, /es bijoux ou /es cheveux longs risquent de

rester coinces dans les pbces mobiles.

4} UTILISATION ET ENTRETIEN D'UN OUTIL #LECTRIQUE

a) Ne pas forcer un outil _lectrique. Utiliser I'outil _lectrique

appropri_ a I'application. L'outil dectrique approprie

effectuera un meilleur travail, de faqon plus sore eta la vitesse

pour laquelle il a ete conqu.

AAVERTISSEMENT : I'utilisation de tout accessoire ou pbce,

ou I'execution de toute operation avec cet outil, autre que celle

recommandee clans ce manuel de I'utilisateur pose des risques

de dommages corporels.

b) Ranger les outils _lectriques hers de la pottle des

enfants et ne permettre a aucune personne n'_tant pas

famili_re avec un outil _lectrique ou son mode d'emploi

d'utiliser cet outil. Les outi/s dectriques deviennent dangereux

entre les mains d'utilisateurs inexperimentes.

c) Utiliser I'outil _lectrique, les accessoires, les forets,

etc. conform_ment aux pr_sentes directives en tenant

compte des conditions de travail et du travail a effectuer.

L'utilisation d'un outil dectrique pour toute operation autre que

celle pour laquelle il a ete conquest dangereuse.

R#PARATION

a) Faire r_parer I'outil _lectrique par un r_parateur

professionnel en n'utilisant que des pi_ces de rechange

identiques. Cela permettra de maintenir une utilisation

securitaire de I'outil dectrique.

R_gles de s_curit_ propres au

tron_;onnage du bdton

• Nepasutiliserdesaccessoiresquin'ontpas_t_sp_cialement

conqus pour cet outil ou recommand_s par son fabricant.

Le fait qu'un accessoire peut _tre connecte a I'outil ne veut pas

automatiquement dire que son utilisation ne posera aucun risque.

• La vitesse nominale des accessoires utilis_s dolt _tre

_quivalente ou sup_rieure a la vitesse maximale appos_e

sur I'outil. Les accessoires utilises a une vitesse plus rapide que

leur vitesse nominale peuvent eclater ou se detacher de I'outil.

• Le diam_tre externe et I'_paisseur de I'accessoire utilis_

doivent se conformer aux specifications de la plaque

signal_tique de I'outil _lectrique. Les accessoires aux

specifications incorrectes ne peuvent _tre ni maintenus ni contr¢les

de faqon adequate.

• L'al_sage des meules, brides, tampons de soutien, ou de

tout autre accessoire, doR correspondre parfaitement a la

taille de la broche de I'outil. Les accessoires dont /'a/esage

ne correspond pas au dispositif d'instal/ation de I'outil dectrique

ne toumeront pas correctement, vibreront de faqon excessive et

pourront causer laperte de contr¢le de I'outil.

• Le dispositif de protection dolt _tre solidement fix_

I'outil _lectrique et install_ pour optimiser la s_curit_ pour

que I'utilisateur soit le moins possible expos_ a la meule.

Le carter aide a proteger I'utilisateur contre toute projection de

fragments et contre tout contact avec la meule.

• Tenir I'outil _lectrique par les surfaces isol_es pr_vues a cet

effet pendant toute utilisation oQI'organe de coupe pourrait

entrer en contact avec des ills _lectriques caches ou son

11

Page 13

propre cordon. Toutcontact de I'organe de coupe avec un fil sous

tension met les parties metalliques exposees de I'outil dectrique

sous tension et dectrocute I'utilisateur.

• Utiliser syst_matiquement la poign_e lat_rale. Fixer la

poign_e solidement. La poignee laterale doit _tre

systematiquement utilisee pour ma_triserI'outil en permanence.

• Ne pas utiliser d'accessoire endommag_. Avant toute

utilisation, v_rifier que les accessoires, comme les meules

diamant et les tampons de soutien, ne comportent aucune

fissure ou cassure, ou ne sent affect_s d'aucune usure

excessive, et que les ills des brosses m_talliques ne sent

ni I&ches ni endommag_s. En cas de chute, v_rifier que

I'outil _lectrique ou I'accessoire n'a pas _t_ endommag_,

et remplacer toute piece abFm_e. Apr_s avoir inspect_ et

install_ un accessoire, se positionner, soi-m_me et tout

individu present, hers du plan de rotation de I'accessoire

et laisser tourner I'outil une minute a sa vitesse a vide

maximale. En general, les accessoires endommages se brisent

pendant le temps d'essaL

• NE PAS meuler ou d_couper le m_tal avec une meule

diamanL

• Porter un _quipement individuel de protection. Utiliser

une protection faciale et des lunettes ou un masque de

protection. Si appropri_, porter un masque anti-poussi_res,

une protection auditive, des gants et un tablier d'atelier

capables de vous prot_ger contre toute projection abrasive

ou tout fragment. La protection oculaire doit pouvoir arr_ter

toute projection de debris engendres par des operations diverses.

Le masque anti-poussieres, ou I'appareil de protection des voles

respiratoires, dolt pouvoir flitter les particules engendrees par

I'operation en cours. Toute exposition prolongee a un haut niveau

de decibels peut occasionner une perte de I'acuite auditive.

• Ne pas. bloquer, la meule _ tron_onner ou lui appliquer une

pression excessive. Ne pas effectuer des profondeurs de

coupe excessives. Surcharger la meule augmente la contrainte

sur I'outil et les risques de torsion ou grippage de la meule dans la

coupe et, en consequence, les risques de rebonds ou de cassure

de la meule.

• Positionner le cordon hers du chemin de I'accessoire en

rotation. En cas de perte de contr61e de I'outil, le cordon pourrait

_tre coupe ou arrache, et les mains ou bras pourraient entrer en

contact avec I'accessoire en rotation.

• Attendre syst_matiquement I'arr_t complet de I'accessoire

avant de poser I'outil _lectrique. £'accessoire en rotation

pourrait s'accrocher a une surface et vous faire perdre le contr61e

de I'outil dectrique.

• Ne pas laisser I'outil _lectrique tourner alors que vous le

transportez a votre c_t_. Tout contact accidentel de I'accessoire

en rotation pourrait faire que ce demier s'accroche aux v_tements

et entre en contact avec le corps.

• Nettoyer r_guli_rement les orifices d'a_ration de I'outil. Le

ventilateur du moteur attirera de la poussiere a I'interieur du bo_tier

et I'accumulation excessive de poussieres metalliques pose des

risques d'dectrocution.

• Ne pas utiliser cet outil _lectrique a proximit_ de mat_riaux

inflammables, car des etincelles pourraient les enflammer.

• Ne pas utiliser d'accessoires n_cessitant I'utilisation de

r_frig_rants fluides. L'utilisation d'eau ou de refrigerants fluides

pose des risques d'dectrocution ou de chocs dectriques.

• NE PAS utiliser de meules abrasives.

_AVERTISSEMENT : Iorsqu'elle est inutilis_e, d_poser la

meuleuse sur une surface stable ob elle sera immobile et ne

risquera pas de fouler ou de faire tr_bucher ou chuter

quiconque. Cela pose des risques de dommages corporels graves.

12

Page 14

• UtiliserSYSTEMATIQUEMENTun syst_me ded_poussi_rage.

_AVERTISSEMENT : porter SYSTEMATIQUEMENT des/unettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussieres si la decoupe doit

en produire beaucoup. Porter SYSTEMATIQUEMENT un equipement

de securite homologue :

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S 12.6 ($3.19 ;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AAVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussieres

contenant des produits chimiques reconnus par I'Etat califomien pour

causer cancers, malformations congenitales ou _tre nocifs au systeme

reproducteur. Parmi ces produits chimiques, on retrouve :

• Le plomb clans les peintures a base de plomb;

• La silice cristallisee dans les briques et le ciment, ou autres

produits de maqonnerie; et

• L'arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associe a de telles expositions varie selon la frequence

laquelle on effectue ces travaux. Pour reduire toute exposition aces

produits : travailler dans un endroit bien aere, en utilisant du materiel

de securite homologue tel un masque antipoussieres specialement

conqu pour filtrer les particules microscopiques.

• Limiter toute exposition prolong_e avec les poussi_res

provenant du ponqage, sciage, meulage, perqage ou toute

autre activit_ de construction. Porter des v_tements de

protection et nettoyer a I'eau savonneuse les parties du

corps expos_es. Le fait de laisser la poussiere penetrer clans la

bouche, les yeux ou la peau peut favoriser I'absorption de produits

chimiques dangereux.

_AVERTISSEMENT : cet outil peut produire et/ou repandre

de la poussiere susceptible de causer des dommages serieux et

permanents au systeme respiratoire. Utiliser systematiquement un

appareil respiratoire antipoussieres homologue par le NIOSH ou

I'OSHA. Diriger les particules dans le sens oppose au visage et au

corps.

AAVERTISSEMENT : avant de se mettre au travail, s'assurer

de d_terminer la classification des dangers pos_s par les

poussi_res produites. Utiliser un aspirateur industriel de

la classe officielle de s_curit_, appropri_e et homologu_e,

conform_ment aux consignes locales de lutte centre /es

risques pos_s par/es poussi_res.

A AVERTISSEMENT: porter syst_matiquement une protection

auditive individuelle appropri_e. Sous certaines conditions et

suivant la duree d'utilisation, le bruit emanant de ce produit pourrait

contribuer a une perte de I'acuite auditive.

Causes de reffet de rebond et prevention

par I'op_rateur

L'effet de rebond est une reaction soudaine d'une meule, d'un

tampon, d'une brosse ou d'un tout autre accessoire, en mouvement,

qui est pince ou qui s'accroche. Un pincement ou un accrochage

provoque un arr_t rapide de I'accessoire en mouvement qui, a son

tour, projette I'outil dectrique, hors de ma_trise, dans la direction

opposee a la rotation de I'outil au point de grippage.

Par exemple, si une meule diamant reste accrochee ou pincee

dans une piece a travailler, le bord de la meule engagee au point

de grippage peut s'enfoncer dans la surface du materiau et faire

sauter ou rebondir la meule. La meule peut alors rebondir en

direction ou a I'oppose de I'utilisateur, selon le sens du mouvement

de la meule au point de grippage. Dans ces conditions, ilpeut aussi

arriver que les meules diamant se brisent.

13

Page 15

Un effet de rebond est le resultat d'une mauvaise utilisation de I'outil

et/ou de procedures ou conditions de fonctionnement incorrectes.

IIpeut _tre evite en prenant les precautions necessaires telles que

decrites ci-dessous :

a) Saisir fermement I'outil _lectrique et positionner le corps

et les bras de sorte a r_sister a la force de I'effet de

rebond. Utiliser toujours la poign_e auxiliaire, s'il y en

a une, pour contr61er au maximum I'effet de rebond

ou le couple de r_action au d_marrage. Avec de bonnes

precautions, I'operateur est en mesure de contr61er le couple

de reaction ou I'effet de rebond.

b) Ne jamais placer les mains pros de I'accessoire en

mouvement. // pourrait en effet _tre projete sur ce//es-ci en cas

de rebond.

c) Ne pas positionner le corps clans la trajectoire probable

de I'outil _lectrique, en cas de rebond. Au moment du

grippage, I'outil sera projete dans la direction opposee au

deplacement de la meule.

d) Etre particuli_rement attentif lors de travaux clans un coin,

sur des bords tranchants, etc. Eviter de faire rebondir

I'accessoire. Eviter tout type de grippage de I'accessoire.

Un travail dans un coin ou sur des bords tranchants ou un

travail en faisant rebondir I'accessoire provoquent souvent

un grippage et une perte de maRrise de I'outil ou un effet de

rebond.

e) Ne pas fixer de lame de trongonneuse pour sculpter

le bois ou de lame de scie dent_e. Ces types de lames

provoquent des effets de rebond et des pertes de ma_trise

frequents.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTERIEURE

DESCRIPTION (FIG. 1)

_AVERTISSEMENT : ne jamais modifier I'outil dectrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

materiels.

A. Buse de depoussierage

B. Vis de reglage du collier de serrage

C. Butee de profondeur de coupe

D. Bouton de verrouillage de butee de profondeur de coupe

E. Levier de verrouillage du capot de coin (verrouille et deverrouille

le capot de coin)

F.Capot de coin (amovible pour permettre de couper a, I'interieur

d'un coin)

G. Levier de serrage

USAGE PR#VU

Votre carter de trongonnage du beton a et6 congu pour effectuer

des applications professionnelles de ma_onnerie de tron_onnage du

beton. IIn'a pas et6 con_u pour _tre utilise sur lemetal ou lebois. Avec

I'utilisation d'une meuleuse a, disque, une meule et d'un aspirateur

appropries, le carter de tron_onnage du beton peut _tre utilise pour

retirer une vaste majorite des poussieres statiques atmospheriques

qui en son absence pourraient contaminer I'environnement de travail

ou poser des risques accrus pour la sante de I'utilisateur et de ceux

a,proximite.

NE PAS les utiliser en milieu ambiant humide ou en presence de

liquides ou de gaz inflammables.

Ce carter de tron_onnage du beton est un outil de professionnel. NE

PAS le laisser a,la portee des enfants. Une supervision est necessaire

aupres de tout utilisateur non experimente.

Les outils electriques recommandes pour _tre utilises avec cet

accessoire sont vendus separement aupres de votre distributeur

14

Page 16

local ou dans les centres de reparation agrees. Si vous avez besoin

d'aide pour Iocaliser ces outils electriques, veuillez contacter DEWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, ou

appeler 1-800-4-DEWALT (1-800-433-9258) ou vous rendre sur notre

site www.dewalt.com.

FIG.1 F

G

B

Installation et retrait du carter de

tronfonnage du b_ton

REMARQUE : il est recommande d'utiliser uniquement ce carter

de trongonnage du beton avec les petites meuleuses angulaires

industrielles DWE46102.

1. Suivez les instructions de la section Installation et retrait du

dispositif de protection dans le manuel de I'outil pour retirer ce

dispositif de la meuleuse (DWE46102).

2. Ouvrez le levier de serrage (G) sur le carter de trongonnage du

beton puis alignez les languettes (I) du carter de trongonnage du

beton sur les encoches (J)du carter d'engrenage de la meuleuse.

FIG.2

G

ASSEMBLAGE ET REGLAGE (FIG. 1, 2)

AAVERTISSEMENT : pour r_duire le risque de blessures,

arr_ter et d_brancher SYSTEMATIQUEMENT routil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Cela s'applique aussi bien a la meuleuse a disque

qu'_ raspirateur. Ces mesures preventives de securite reduisent les

risques de demarrage accidentel de I'outil.

3. Avec le levier de serrage toujours ouvert, faites pivoter le carter

sur la position de travail desiree. Le carter de trongonnage du

beton devrait se trouver entre la broche et I'utilisateur pour

maximiser son efficacite.

4. Refermez le levier de serrage (G)pour fixer le carter de trongonnage

du beton sur le carter d'engrenage. N'utilisez pas la meuleuse si

le carter de trongonnage du beton est I_,che ou si son levier de

serrage est ouvert.

15

Page 17

5. Pour retirer le carter de tron_onnage du beton, ouvrez le levier

de serrage, faites pivoter le carter de tron_onnage du beton pour

aligner les encoches sur les languettes puis retirez le carter de

tron_onnage du beton.

REMARQUE • le carter de tron_onnage du beton est preregle d'usine

au diametre du moyeu du carter d'engrenage. S'il s'averait apres un

certain temps que le carter de tron_onnage du beton se desserre,

resserrez la vis de reglage du collier de serrage (B) avec le levier de

serrage en position fermee.

AVIS : ne pas resserrer la vis de reglage du collier de serrage si le

levier de serrage est en position ouverte. Le carter de trongonnage

du beton ou le moyeu d'assemblage pourrait subir des dommages

indecelables.

AVIS : s'il est impossible de resserrer le carter de tronqonnage du

beton avec la vis de reglage du collier de serrage, ne pas utiliser I'outil.

Apportez I'outil et le carter de tronqonnage du beton chez un centre

de reparation pour faire reparer ou remplacer ce demier.

Installation de meules _ trongonner

(Type 1, Fig. 1)

_AVERTISSEMENT : utiliser exclusivement des meules

diamant de type 1 avec le carter de tronqonnage du b_ton.

Ne decouper aucun metal. Ne pas utiliser avec des meules abrasives

composites.

Suivez lesinstructions de lasection Installation et utilisation des meules

a.tron_onner (Type 1)dans le manuel de I'outil pour installer la meule.

IIpourra s'averer necessaire d'ouvrir le capot de coin pour installer les

meules a.tron_onner le beton de 152,4 mm (6 po), reportez-vous a.la

section Applications : capet de coin.

Rdglage de la profondeur de coupe

(Fig. 3)

1. Desserrez Ie bouton de verrouillage de butee de profondeur de

coupe (D).

2. Poussez la butee de profondeur de coupe (C) sur la position

desiree.

3. Resserrez ie bouton de verrouillage de butee de profondeur de

coupe.

FIG.3

D

Appfications : capot de coin (Fig. 4)

_AVERTISSEMENT : pour r_duire le risque de blessures,

arr_ter et d_brancher SYSTEMATIQUEMENT I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Cela s'applique aussi bien a la meuleuse a disque

qu'a I'aspirateur, Ces mesures preventives de securite reduisent les

risques de demarrage accidentel de I'outil.

AVERTISSEMENT : risques de dommages corporels. Le capot de

coin ne doit _tre ouvert que pour couper I'interieur des coins. Garder

systematiquement les mains et le corps eloignes des zones de coupe.

S'assurer que le capot de coin est ferme pour toute autre application.

Cette fonctionnalite permet de couper a.i'interieur d'un coin.

16

Page 18

1. Assurez-vous de I'arr_t complet de I'outil et de la meule.

2. Tournez lelevier de verrouillage du capot de coin (E)vers lagauche

d'un tour complet. Saisissez le capot de coin (F)et faites-le pivoter

pour I'ouvrir, comme illustre en Figure 4.

3. Protegez vos mains de la meule et positionnez-vous de fagon a,ce

que le dessous ouvert du carter soit a,votre oppose.

4. Mettez I'outil en marche et laissez-le tourner a,plein regime avant

de le mettre en contact avec la surface a,travailler.

5. Placez la meule sur la surface a,travailler et deplacez la meuleuse

de la droite vers la gauche pour couper a,I'interieur du coin tout en

maximisant la collecte des poussieres.

6. Retirez I'outil de la piece a,travailler avant de I'arr_ter. Laissez I'outil

s'arr_ter completement de tourner avant de le poser.

7. Fermez le capot de coin et verrouillez-le a, I'aide du levier de

verrouillage de capot de coin (E).

FIG.4

F F

E

D_poussi_rage (Fig. 1, 5)

J_,AVERTISSEMENT : utiliser exclusivement les outils dectriques

recommandes par DEWALT avec cet accessoire,

Pour plus d'informations concernant les outils electriques DEWALT

compatibles avec cet accessoire, contacter votre detaillant local,

appeler le 1-800-4-DEWALT (1-800-433-9258) ou se rendre sur notre

site www.dewalt.com.

_.AVERTISSEMENT : cet accessoire DOlT _I-RE utilise avec un

extracteur de poussiere, Porter SYSTEMATIQUEMENT un ecran facial

ou un masque anti-poussieres de securite homologue,

REMARQUE :verifier que la connexion tuyau est fiable.

REMARQUE : la quantite de poussiere elimin6e par I'aspirateur

depend de son systeme de filtrage. Se reporter au manuel de

I'utilisateur de I'aspirateur pour des informations complementaires.

Tousles carters d'aspiration DF-WALTont et6 congus pour fonctionner

avec les connecteurs universels DWV9000 DeWALT.

1. Rattachez leconnecteur DWV9000 (H) au tuyau de votre systeme

de depoussierage (K).

2. Deverrouillez le connecteur DWV9000 (H) et I'inserez sur la buse

de depoussierage (A).

3. Verrouillez le connecteur DWV9000 (H)pour I'arrimer.

17

Page 19

TUYAUX D'ASPIRATEUR TRADITIONNELS

Rattachez le tuyau d'aspirateur recommande a, la buse de

depoussierage (A).

UTILISATION

_AVERTISSEMENT : pour r_duire le risque de blessures,

arr_ter et d_brancher SYSTEMATIQUEMENT I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Cela s'applique aussi bien a la meuleuse a disque

qu'_ I'aspirateur. Ces mesures preventives de securite reduisent les

risques de demarrage accidentel de I'outil,

AAVERTISSEMENT : pour votre securite, life le manuel de

I'utilisateur de lameuleuse, mais aussi de I'aspirateur avant I'utilisation

de tout accessoire, Tout manquement aces avertissements augmente

les risques de blessures, et les risques d'endommager serieusement

I'appareil et ses accessoires, Lots de la maintenance de cet outil,

n'utiliser que des pieces de rechange identiques,

_ A VERTISSEMENT: saisir fermement lapoignee laterale et le corps

de I'outil pour le maRriser a I'amorqage, en cours de fonctionnement et

jusqu'a I'arr_t complet de la meule ou de I'accessoire, S'assurer que

la meule soit vraiment immobile avant de deposer I'outil,

/_ AVERTISSEMENT : s'assurer que le capot de coin est ferme,

1. Assurez-vous que toutes les instructions d'assemblage et de

reglage ont bien et6 suivies.

2. Allumez I'aspirateur comme indique dans lemanuel de I'utilisateur

de I'aspirateur.

3. Mettez la meuleuse a, disque en marche comme

indique dans le manuel de I'utilisateur de I'outil.

REMARQUE : laisser I'outil tourner a, plein regime avant de le

mettre en contact avec la surface a,travailler.

Applications de tron_;onnage et de coupe

du bdton (Fig. 6)

1. Reglez la profondeur de coupe desiree, reportez-vous a,la section

Reglage de la Profondeur de coupe sous Assemblage et

r_glages.

2. Laissez I'outil tourner a,plein regime avant de le mettre en contact

avec la surface a,travailler.

3. Positionnez-vous de fagon a,ce que le dessous ouvert du carter

et la meule soient orientes a,I'opposee de vous.

4. Placez le bord (L)du carter sur lasurface a,travailler et commencez

a,couper en plongeant dans la surface a,travailler. REMARQUE :

maintenir le bord (L) du carter contre la surface a,travailler pour

assurer la collecte correcte de la poussiere.

18

Page 20

5. Avec le carter oriente comme illustre en Figure 6, deplacez la

meuleuse de la droite vers la gauche le long de la surface a.

travailler. Pour des resultats optimums, la meuleuse doit _tre

positionnee a.un angle de 45° de la buse de depoussierage Iors

du trongonnage du beton.

6. Retirez I'outil de la piece a.travailler avant de rarr_ter. Laissez routil

s'arr_ter completement de tourner avant de le poser.

FIG.6 L

MAINTENANCE

,_AVERTISSEMENT : pour r_duire le risque de blessures,

arr_ter et d_brancher SYSTEMATIQUEMENT I'outil avant tout

r_glage ou avant de retirer ou installer toute piece ou tout

accessoire. Cela s'applique aussi bien a la meuleuse a disque

qu'_ I'aspirateur. Ces mesures preventives de securite reduisent les

risques de demarrage accidentel de I'outil.

Nettoyage

i_.AVERTISSEMENT : en/ever /es sa/etes et /a poussiere hors des

events au moyen d'air comprime propre et sec, au moins une lois

par semaine. Pour minimiser le risque de blessure aux yeux, toujours

porter une protection oculaire conforme a la norme ANSI Z87.1 lots

du nettoyage.

i_,AVERTISSEMENT : ne jamais utiliser de solvants ni d'autres

produits chimiques puissants pour nettoyer les pieces non metalliques

de I'outil. Ces produits chimiques peuvent affaiblir les materiaux

de plastique utilises dans ces pieces. Utiliser un chiffon humecte

uniquement d'eau et de savon doux. Ne jamais laisser de liquide

penetrer dans I'outil et n'immerger aucune partie de I'outil dans un

liquide.

i_,AVERTISSEMENT : puisque les accessoires autres que ceux

offerts par DEWALTn' ont pas ete testes avec ceproduit, leur utilisation

pourrait s'averer dangereuse. Pour reduire le risque de blessures,

utiliser exclusivement les accessoires DEWALT recommandes avec le

present produit.

Les accessoires recommandes pour cet outil sont vendus separement

au centre de service de votre region. Pour obtenir de I'aide concernant

I'achat d'un accessoire, communiquer avec DEWALT Industrial Tool

Co., 701 East Joppa Road, Baltimore, MD 21286 aux Etats-Unis;

composer le 1 800 433-9258 (1 800 4-DEWALT) ou visiter notre site

Web : www.dewalt.com.

Rdparations

Pour assurer la SFtCURIT¢:et laFIABILIT¢: du produit, les reparations,

I'entretien et les reglages doivent _tre realises (cela comprend

I'inspection et le remplacement du balai) par un centre de reparation

en usine D[_-_WALT,un centre de reparation agree DEWALT ou par

d'autres techniciens qualifies. Toujours utiliser des pieces de rechange

identiques.

Garantie limit_e de trois ans

DEWALT reparera, sans frais, tout produit defectueux cause par un

defaut de materiel ou de fabrication pour une periode de trois ans a.

compter de la date d'achat. La presente garantie ne couvre pas les

19

Page 21

pieces dont la defectuosite a et6 causee par une usure normale ou

I'usage abusif de routil. Pour obtenir de plus amples renseignements

sur les pieces ou les reparations couvertes par la presente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-DEWALT). Cette garantie ne s'applique pas aux accessoires et ne

vise pas les dommages causes par des reparations effectuees par un

tiers. Cette garantie confere des droits legaux particuliers a,I'acheteur,

mais celui-ci pourrait aussi beneficier d'autres droits variant d'un etat

ou d'une province a,I'autre.

En plus de la presente garantie, les outils DEWALT sont couverts par

notre :

CONTRAT D'ENTRETIEN GRATUIT D'UN AN

DEWALT entretiendra I'outil et remplacera les pieces usees au cours

d'une utilisation normale et ce, gratuitement, pendant une periode

d'un an a,compter de la date d'achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si I'acheteur n'est pas entierement satisfait, pour quelque raison que

ce soit, du rendement de routil electrique, du laser ou de la cloueuse

DE!WALT,celui-ci peut le retourner, accompagne d'un re,u, dans les

90 jours a,compter de la date d'achat pour obtenir un remboursement

integral, sans aucun probleme.

AMI_RIQUE LATINE •cette garantie ne s'applique aux produits vendus

en Amerique latine. Pour ceux-ci, veuillez consulter les informations

relatives a,la garantie specifique presente dans I'emballage, appeler

I'entreprise locale ou consulter le site Web pour les informations

relatives a,cette garantie.

REMPLACEMENT GRATUIT DES eTIQUETTES

D'AVERTISSEMENT : si les etiquettes d'avertissement deviennent

illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-DEWALT) pour en obtenir leremplacement gratuit.

r

DWE46100 _"/6"c._l.G/

_ TO REDUCETHE NISK OFiNJURY, USERMtlSTREAD iNSTRUCTiON MANUAl. FOR USEWITH

-- TYpE I DiAMOnD WHEELS ONLY. 90 NOT CiJ T

METAL DONOT USE WiTH BOP_DEDABRASIVE WHEELS• ALWAYS USE

PROPER EYEAND RESPIRATORYPROTECTION.

_ oE INSTRUCCION ES PAPA ]}EI_UCIR

UTILJZARSECON M]JELAS DE DiAMANTE TIPO 1. NO]JTJLISARCON

MUELAS ABRASIVAS CQP_AGLOMERANTE. NOCORTAR METAL£S.

SiEMPRE SE DEBER,_ LLEVAR LAPRQTECCi0N APROP_DA PARA LA

VISTA Y PA}tA LAS ViA$ _ESPI$_ATO_IAS. POU_ REDUBRETOUT RISQUE

MANUELOE'U_IUSATEOR.U_LISE_UN_OUEMENTAWCOESM_UL_S

OiAMANT DE TYPE_. NE PAS UTILiSE_,AVEC DES MEULESABRASIVES

COMDOSITES.I_E DECOtJPER AtJCUN METAUX.ZL FAUTTDUJOURS PO_E_

DE L'EQUJPEME_T OE pfiOTECT_ON OCULAJ_E E_ RESPS_ATOJRE APP_OP_JE,

O_WALT IN DO STRiAL TOOL C0., BALTiM 0_E, MO 21285 USA

FO R SERVICE 1_3FO_MA110 N, CALL I_0D-4-D_WALT www.O_WALT.com

TUCKP0JNTJNG SHROUD

ELDSUARiO D£1_£LEEREL MANUAL

ELRIESOODgLESIONES.SOLODEBE

£0TILiSATEUR DOlT LIRE LE

2O

Page 22

f

Definiciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada palabra de sepal. Lea el manual y preste atenciOn a estos

dmbolos.

,_ PELIGRO: indica una situacidn de peligro inminente que, si

no se evita, provocara la muerte o lesiones graves.

J_,ADVERTENCIA: indica una situacidn de peligro potencial

que, si no se evita, podr(a provocar la muerte o lesiones

graves.

_,ATENClON: indica una situacidn de peligro potencial que,

si no se evita, posiblemente provocarfa lesiones leves o

moderadas.

AVlSO: se refiere a una practica no relacionada a lesiones

corporales que de no evitarse puede resu/tar en da_os a la

propiedad.

SI TIENE ALGUNA DUDA O ALGON COMENTARIO SOBRE FI:STA

U OTRA HERRAMIENTA DEWALT, LL_,MENOS AL NOMERO

GRATUITO: 1-800-4-DEWALT (1-800-433-9258}.

_ DVERTENCIA: Para reducir el riesgo de lesiones, lea el

manual de instrucciones.

CONSERVE TODAS LAS ADVERTENCIAS

E INSTRUCCIONES PARA FUTURAS

CONSULTAS

Advertencias generales sobre seguridad

_ DVEFtTENClA: Pot su propia seguridad, lea el manual de

instrucciones para la esmeriladora y la aspiradora extractora de

polvo antes de usar los accesorios. De no seguir estas advertencias

podrfan producirse lesiones corporales y graves dahos a laherramienta

y al accesorio. Cuando realice el mantenimiento de esta herramienta,

utilice dnicamente repuestos originales.

1) SEGURIDAD EN EL AREA DE TRABAJO

a) Mantenga el area de trabajo limpia y bien iluminada. Las

areas abarrotadas y oscuras propician accidentes.

b) Mantenga alejados a los ni_os y a los espectadores de la

herramienta el_ctrica en funcionamiento. Las distracciones

pueden provocar la perdida de control

c) Aseg(/rese de que el lugar de trabajo est_ bien ventilado.

La exposicidn al polvo en un lugar de trabajo con poca

ventilacidn puede dar como resultado el deterioro de la salud.

2} SEGURIDAD EL#CTRICA

a) Evite el contacto corporal con superficies con descargas

a tierra como, per ejemplo, tuber(as, radiadores, cocinas

el_ctricas y refrigeradores. Existe mayor riesgo de descarga

electrica si su cuerpo esta puesto a tierra.

3} SEGURIDAD PERSONAL

a) Permanezca alerta, controle Io que esta haciendo y

utilice el sentido com_n cuando emplee una herramienta

el_ctrica. No utilice una herramienta el_ctrica si

esta cansado o bajo el efecto de drogas, alcohol o

medicamentos. Un momento de descuido mientras se opera

una herramienta electrica puede provocar lesiones personales

graves.

b) Utilice equipos de proteccion personal. Siempre utilice

proteccion para los ojos. En /as condiciones adecuadas, el

uso de equipos de proteccidn, como mascaras para polvo,

calzado de seguridad antideslizante, cascos o proteccidn

auditiva, reducira las lesiones personales.

21

Page 23

c) No se estire. Conserve el equilibrio y parese

adecuadamente en todo momento. Esto permite un mejor

control de laherramienta electrica en situaciones inesperadas.

d) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas ho/gadas, /asjoyas

o el cabello largo pueden quedar atrapados en las piezas en

movimiento.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

EL#CTRICA

a) No fuerce la herramienta el_ctrica. Utilice la herramienta

el_ctrica correcta para el trabajo que realizara. Si se /a

utiliza a la velocidad para la que rue disehada, la herramienta

electrica correcta permite trabajar mejor y de manera mas

segura.

AADVERTENCIA: El uso de accesorios o adaptadores, o el

desempeho de cualquier operacidn con esta herramienta,

distintos a los recomendados en este manual de instrucciones

puede representar un riesgo de lesiones personales.

b) Guarde la herramienta el_ctrica que no est_ en use fuera

del alcance de los nibos y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas electricas son

peligrosas si son operadas pot usuarios no capacitados.

c) Utilice la herramienta el_ctrica, los accesorios y las

brocas de la herramienta, etc. de acuerdo con estas

instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de /a

herramienta electrica para operaciones diferentes de aqud/as

para las que ruedisehada podrfa originar una situacidn peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que

realice el mantenimiento de su herramienta el_ctrica

y que solo utilice piezas de repuesto id_nticas. Esto

garantizara la seguridad de la herramienta electrica.

Normas de seguridad para rejuntar

• Noutiliceaccesoriosquenoest_ndise_adosyrecomendados

especificamente per el fabricante de la herramienta. El hecho

de que el accesorio pueda acoplarse a la herramienta electrica no

garantiza un funcionamiento sin riesgos.

• La velocidad prevista del accesorio debe ser come minimo

igual a la velocidad maxima marcada en la herramienta

el_ctrica. Los accesorios operados a velocidades superiores a su

velocidad nominal pueden romperse y salir despedidos.

• E1 diametro externo y el grosor del accesorio deben estar

dentro de la capacidad de su herramienta el_ctrica. Los

accesorios de tamahos incorrectos no pueden set protegidos o

controlados adecuadamente.

• E1 tamale del eje de los discos, las bridas, almohadillas

de respaldo o cualquier otto accesorio debe acoplarse

bien al eje de la herramienta el_ctrica. Los accesorios que

tienen orificios para montaje en eje que no se corresponden con

los accesorios de montaje de la herramienta electrica haran que

la herramienta pierda el equilibrio, vibre excesivamente y que el

operador pierda el control de la herramienta.

• E1protector debe ir firmemente ajustado a la herramienta

el_ctrica yen posicidn para el maximo de seguridad, de

modo que se exponga la menor parte posible del disco

al operador. El protector ayuda a proteger al operador de los

fragmentos despedidos pot discos rotos y el contacto accidental

con el disco.

22

Page 24

• Sostenga la herramienta el_ctrica solamente en superficies

de agarre aisladas cuando realice una operaci6n en la cual

el accesorio para cortar pudiera entrar en contacto con

instalaciones el_ctricas ocultas o su propio cable. Elcontacto

de los accesorios de corte con un cable cargado, puede cargar las

partes metalicas expuestas de la herramienta electrica y producir

una descarga electrica al operador.

• Siempre use el mango lateral. Apriete con firmeza el mango.

Se debe utilizar siempre el mango lateral para mantener el control

de la herramienta en todo momento.

• No utilice un accesorio da_ado. Antes de cada uso

inspeccione el accesorio, como por ejemplo el disco de

diamante, para verificar si tiene muescas o grietas, la

almohadilla de respaldo para verificar si tiene grietas o

roturas o siesta muy desgastada, la escobilla de alambre

para comprobar si tiene alambres sueltos o agrietados. Si la

herramienta o el accesorio se cae accidentalmente, revise

que no est_ da_ado o, si es necesario, cambie el accesorio

por uno que no est_ da_ado. Despu_s de inspeccionar e

instalar un accesorio, col6quense usted y las personas

presentes alejados del piano del accesorio en movimiento

y ponga la herramienta el_ctrica en funcionamiento a

la velocidad sin carga maxima durante un minuto. Si el

accesorio esta dahado, normalmente se terminara de romper

durante este perfodo de prueba.

• NO esmerile ni corte metal con un disco de diamante.

• P6ngase un equipo de protecci6n personal Dependiendo de

la aplicaci6n, use un protector facial y galas protectoras. Si

corresponde, p6ngase una mascarilla antipolvo, protectores

para el oido, guantes y un delantal de trabajo que pueda

detener peque_os fragmentos abrasivos o de la pieza de

trabajo. La proteccidn ocular utilizada debe set capaz de detener

desechos despedidos por las diversas operaciones realizadas

con la herramienta. La mascara antipolvo o el respirador debe

poder filtrar partfculas generadas pot la operacidn realizada. La

exposicidn prolongada a ruidos de alta intensidad puede causar

perdida auditiva.

• No "atasque" el disco de corte ni aplique excesiva presi6n.

No intente hacer un corte de profundidad excesiva. El

ejercer demasiada presidn sobre el disco aumenta la carga y

la susceptibilidad de giro o bloqueo del disco en el corte y la

posibilidad de rebote o rotura del disco.

• Coloque el cable lejos del accesorio rotativo. Si pierde el

control, el cable puede cortarse o engancharse y puede arrastrar a

la mano o el brazo hacia el accesorio rotativo.

• Nunca suelte la herramienta hasta que el accesorio haya

dejado de girar totalmente. Elaccesorio rotativo puede aferrarse

ala superficie y tirar de la herramienta, haciendole perder el control

de la misma.

• No ponga en funcionamiento la herramienta el_ctrica

mientras la transporte a su lado. El contacto accidental con el

accesorio rotativo podrfa enganchar su ropa y tirar del accesorio

hacia su cuerpo.

• Limpie periodicamente los orificios de ventilacion de la

herramienta el_ctrica. El ventilador del motor atraera el polvo

dentro de la caja protectora y la acumulacidn excesiva del metal en

polvo puede ocasionar riesgos electricos.

• No utilice la herramienta el_ctrica cerca de materiales

inflamables. Las chispas podrfan prender fuego a estosmateriales.

• No utilice accesorios que requieran liquidos refrigerantes.

El utilizar agua u otros refrigerantes Ifquidos puede ocasionar

electrocucidn o descarga.

• NO use discos abrasivos.

• SIEMPRE use un colector de polvo.

23

Page 25

J_ADVERTENCIA: Cuando no la utilice, coloque la esmeriladora

en una superficie estable donde no pueda moverse de manera

accidental, deslizarse ni provocar tropezones o ca(das. Puede

resultar en lesiones corporales serias.

_ADVERTENCIA:Use SIEMPRE lentes de seguridad. Los

anteojos de diario NO SON lentes de seguridad. Utilice ademas una

cubrebocas o mascarilla antipolvo si la operacidn de corte genera

demasiado polvo. SIEMPRE Ileve equipo de seguridad certificado:

• Proteccidn ocularANSI Z87.1 (CAN/CSA Z94.3).

• Proteccidn auditiva ANSI $12.6 ($3.19)

• Proteccidn respiratoria NIOSH/OSHA.

_ADVERTENOIA: Algunas partfculas de polvo generadas al lijar,

serrar, esmerilar y taladrar con herramientas electricas, asf como al

realizar otras actividades de construccidn, contienen qufmicos que

el Estado de California sabe que pueden producir cancer, defectos

congenitos u otras afecciones reproductivas. Ejemplos de estos

qufmicos son:

• plomo de algunas pinturas en base a plomo,

• polvo de sflice proveniente de ladrillos y cemento y otros

productos de albahilerfa, y

• arsenicoycromo provenientes de madera tratada qufmicamente.

Su riesgo de exposicidn a estos qufmicos varfa, dependiendo de

la frecuencia con la cual realiza usted este tipo de trabajo. Para

reducir la exposicidn a esas sustancias qufmicas: trabaje en una zona

bien ventilada y Ilevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente disehadas para filtrar partfculas

microscdpicas.

• Evite el contacto prolongado con polvo generado per el

lijado, aserrado, pulido, taladrado y otras actividades de

construccion. Vista ropas protectoras y lave las areas de

la piel expuestas con agua y jabdn. Si permite que el polvo se

introduzca en la boca u ojos o quede sobre lapiel, puede favorecer

la absomidn de productos qufmicos peligrosos.

/_ ADVERTENCIA: La utilizacidn de esta herramienta puede generar

polvo o dispersarlo, Io que podrfa causar dahos graves y permanentes

alsistema respiratorio, asf como otras lesiones. Siempre use proteccidn

respiratoria aprobada por NIOSH (Instituto Nacional de Seguridad y

Salud en el Trabajo)u OSHA (Administracidn de Seguridad y Salud en

el Trabajo) apropiada para la exposicidn al polvo. Dirija las partfculas

en direccidn contraria a la cara y el cuerpo.

_ ADVERTENCIA: Antes de comenzar el trabajo, verifique para

determinar la clasificacidn de riesgo del polvo producido. Utilice

una aspiradora extractora de polvo industrial apropiada, de la

clase de seguridad aprobada oficialmente, y en cumplimiento

con sus normativas locales de control de riesgo del polvo.

ADVERTENCIA: Utilice siempre proteccion auditiva personal

apropiada. Bajo algunas condiciones y duraciones de uso, el ruido

producido pot este producto puede contribuir a la perdida auditiva.

Causas del retroceso y su prevenci6n por

parte del operador

El retroceso es una reaccidn repentina al pel/izco o atascamiento

de un disco giratorio, una almohadilla de respaldo, un cepillo o

cualquier otro accesorio. Elpellizco o el atascamiento hacen que el

accesorio giratorio se trabe rapidamente, Io que a su vez provoca

que la herramienta electrica fuera de control vaya en sentido

opuesto al giro del accesorio en el punto del atascamiento.

Pot ejemplo, si un disco de diamante se atasca o se engancha en

la pieza de trabajo, el borde del disco que esta entrando al punto

de atasque puede penetrar la superficie del material y hacer que

el disco rebote o patee. El disco puede entonces saltar hacia el

operador o en direccidn contraria al mismo, dependiendo de la

direccidn en la que se movfa el disco almomento de engancharse.

24

Page 26

En estas condiciones los discos de diamante pueden ademas

romperse.

El retroceso es el resultado de un mal uso de la herramienta o de

condiciones o procedimientos operativos incorrectos y se puede

evitar tomando las precauciones apropiadas que se indican a

continuacidn:

a) Sostenga la herramienta el_ctrica con firmeza y ubique

el cuerpo y el brazo para pealer resistir las fuerzas de

retroceso. Siempre utilice el mango lateral, en case de

tenerlo, para Iograr el maximo control sobre el retroceso

o la reaccion de torsion durante el encendido. El operador

puede controlar la reaccidn de torsidn o las fuerzas de retroceso

si toma las precauciones adecuadas.

b) Nunca coloque la mane cerca del accesorio giratorio, ya

que este puede hacer un retroceso sobre lamano.

c) No ubique el cuerpo en el area hacia donde la herramienta

electrica se desplazara si se produce un retroceso. El

retroceso impulsara la herramienta en la direccidn opuesta al

movimiento del disco en el punto de atascamiento.

d) Tenga especial cuidado al trabajar en esquinas, bordes

filosos, etc. Evite hacer rebotar o enganchar el accesorio.

Las esquinas, los bordes filosos y elrebote tienden a enganchar

el accesorio giratorio y producir la perdida de control o el

retroceso de la unidad.

e) No conecte una hoja para carpinteria para sierra de

cadena ni una hoja de sierra dentada. Estas hojas puede

producir elretroceso y laperdida de control frecuentes.

GUARDE ESTAS INSTRUCCIONES

PARA FUTURAS CONSULTAS

COMPONENTES (FIG. 1)

i_ADVERTENClA: Nunca modifique la herramienta electrica, ni

tampoco ninguna de sus piezas. Podrfa producir lesiones corporales

o dahos.

A. Puerto de polvo

B. Tornillo de fijaciOn de la abrazadera

C. Base de profundidad de corte

D. Base de profundidad de corte botOn de bloqueo

E. Palanca de bloqueo de la puerta curva

(bloquea y desbloquea la puerta curva)

F. Puerta curva (abre y permite cortar una curva interna)

G. Palanca de abrazadera

USO DEBIDO

Su cubierta protectora para rejuntar hasido diseflada para aplicaciones

profesionales de rejuntado de albafliler[a. No est6. prevista para

ser usada en metal o madera. AI usar la esmeriladora, el disco y

la aspiradora extractora de polvo adecuadas, se puede usar para

eliminar la mayor cantidad de polvo est6.tico y transportado por el

aire, que sin el uso de la cubierta protectora para rejuntar podr[a

contaminar el entorno de trabajo o suponer un riesgo elevado para la

salud del operador y de las personas a su alrededor.

NO utilice la herramienta en condiciones de humedad o en presencia

de liquidos o gases inflamables.

La cubierta protectora para rejuntar es una herramienta profesional.

NO permita que los niflos toquen la herramienta. Si el operador no

tiene experiencia operando esta herramienta, su uso deber6, ser

supervisado.

Las herramientas electricas a ser utilizadas con este aditamento est6.n