Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DWE46100

Tuckpoint Shroud

Carter de tronçonnage du béton

Cubierta protectora para rejuntar

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE

USAR EL PRODUCTO.

Page 2

Page 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay attention

to these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury

which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

EWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

(1-800-433-9258).

WARNING: To reduce the risk of injury, read the instruction

manual.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

General Safety Warnings

WARNING: For your own safety, read the instruction manual for

both the grinder tool and the dust extractor vacuum before using

any accessory. Failure to heed these warnings may result in personal

injury and serious damage to the tool and the accessory. When

servicing this tool, use only identical replacement parts.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

b) Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

c) Ensure the workplace is well ventilated. Exposure to dust

at a poorly ventilated workplace may result in damage to the

health.

2) ELECTRICAL SAFETY

a) Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is earthed or

grounded.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a

power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

unexpected situations.

d) Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair can be caught in

moving parts.

English

1

Page 4

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool

for your application. The correct power tool will do the job

better and safer at the rate for which it was designed.

WARNING: The use of any accessory or attachment or

performance of any operation with this tool, other than those

recommended in this instruction manual may present a risk of

English

personal injury.

b) Store idle power tools out of the reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

c) Use the power tool, accessories and tool bits etc., in

accordance with these instructions taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

Tuckpointing Safety Rules

• Do not use accessories which are not specifically designed

and recommended by the tool manufacturer. Just because

the accessory can be attached to your power tool, it does not

assure safe operation.

• The rated speed of the accessory must be at least equal to

the maximum speed marked on the power tool. Accessories

running faster than their rated speed can break and fly apart.

• The outside diameter and the thickness of your accessory

must be within the capacity rating of your power tool.

Incorrectly sized accessories cannot be adequately guarded or

controlled.

• The arbor size of wheels, flanges, backing pads or any other

accessory must properly fit the spindle of the power tool.

Accessories with arbor holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

• The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

of wheel is exposed towards the operator. The guard helps

to protect operator from broken wheel fragments and accidental

contact with wheel.

• Hold power tool by insulated gripping surfaces only, when

performing an operation where the cutting accessory may

contact hidden wiring or its own cord. Cutting accessory

contacting a "live" wire may make exposed metal parts of the

power tool "live" and shock the operator.

• Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the tool

at all times.

• Do not use a damaged accessory. Before each use inspect

the accessory such as diamond wheel for chips and cracks,

backing pad for cracks, tear or excess wear, wire brush

for loose or cracked wires. If power tool or accessory is

dropped, inspect for damage or install an undamaged

accessory. After inspecting and installing an accessory,

position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum

no-load speed for one minute. Damaged accessories will

normally break apart during this test time.

2

Page 5

• DO NOT grind or cut metal with a diamond wheel.

• Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing protectors, gloves

and workshop apron capable of stopping small abrasive or

workpiece fragments. The eye protection must be capable of

stopping flying debris generated by various operations. The dust

mask or respirator must be capable of filtrating particles generated

by your operation. Prolonged exposure to high intensity noise may

cause hearing loss.

• Do not "jam" the cut-off wheel or apply excessive pressure.

Do not attempt to make an excessive depth of cut.

Overstressing the wheel increases the loading and susceptibility

to twisting or binding of the wheel in the cut and the possibility of

kickback or wheel breakage.

• Position the cord clear of the spinning accessory. If you lose

control, the cord may be cut or snagged and your hand or arm may

be pulled into the spinning accessory.

• Never lay the power tool down until the accessory has come

to a complete stop. The spinning accessory may grab the surface

and pull the power tool out of your control.

• Do not run the power tool while carrying it at your side.

Accidental contact with the spinning accessory could snag your

clothing, pulling the accessory into your body.

• Regularly clean the power tool’s air vents. The motor’s fan will

draw the dust inside the housing and excessive accumulation of

powdered metal may cause electrical hazards.

• Do not operate the power tool near flammable materials.

Sparks could ignite these materials.

• Do not use accessories that require liquid coolants. Using

water or other liquid coolants may result in electrocution or shock.

• DO NOT use abrasive wheels.

• ALWAYS use with a dust collector.

WARNING: When not in use, place grinder on a stable surface

where it will not move inadvertantly, roll or cause a tripping or

falling hazard. Serious personal injury may result.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are

NOT safety glasses. Also use face or dust mask if cutting operation is

dusty. ALWAYS wear certified safety equipment:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3).

• ANSI S12.6 (S3.19) hearing protection.

• NIOSH/OSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do

this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment,

such as those dust masks that are specially designed to filter out

microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

English

3

Page 6

WARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate

for the dust exposure. Direct particles away from face and body.

WARNING: Before beginning the work, check to determine

the hazard classification of the dust produced. Use an industrial

dust extractor vacuum of the appropriate officially approved

safety class that is in compliance with your local dust hazard

English

control regulations.

WARNING: Always wear proper personal hearing protection.

Under some conditions and duration of use, noise from this product

may contribute to hearing loss.

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or snagged rotating

wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be forced in the

direction opposite of the accessory’s rotation at the point of the

binding.

For example, if an diamond wheel is snagged or pinched by the

workpiece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump toward or away

from the operator, depending on direction of the wheel’s movement

at the point of pinching. diamond wheels may also break under

these conditions.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a) Maintain a firm grip on the power tool and position your

body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start up.

The operator can control torque reaction or kickback forces, if

proper precautions are taken.

b) Never place your hand near the rotating accessory.

Accessory may kickback over your hand.

c) Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool

in direction opposite to the wheel’s movement at the point of

snagging.

d) Use special care when working corners, sharp edges etc.

Avoid bouncing and snagging the accessory. Corners,

sharp edges or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of

control.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

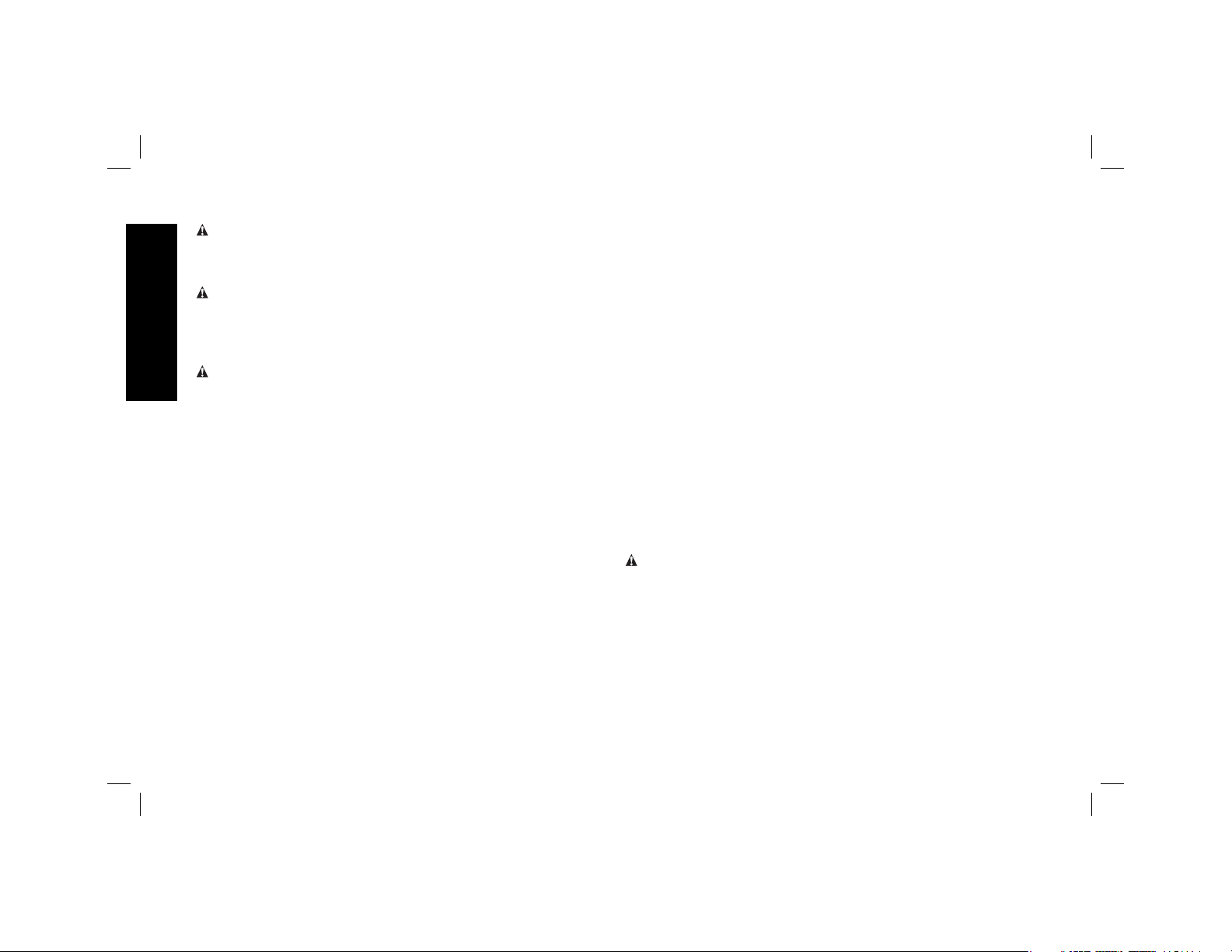

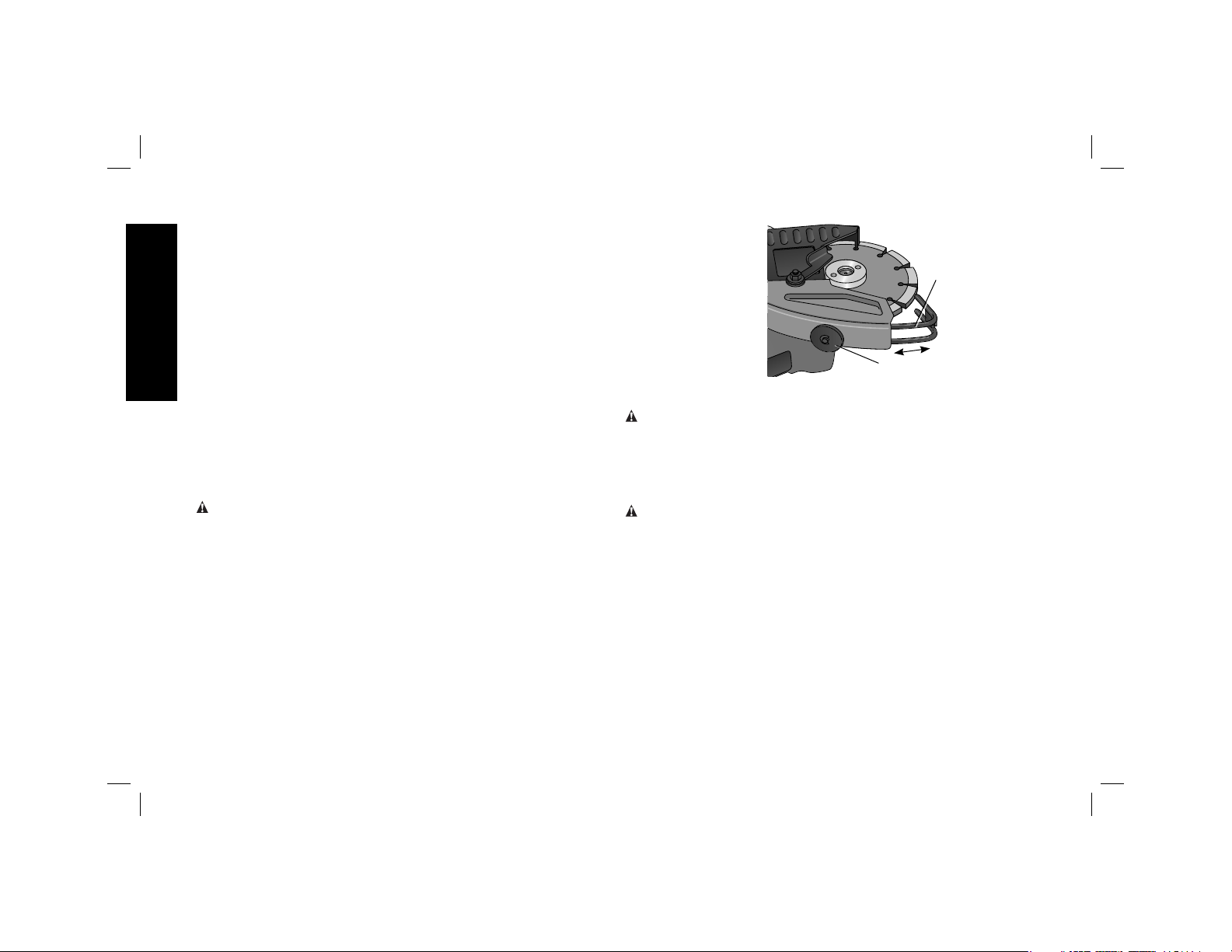

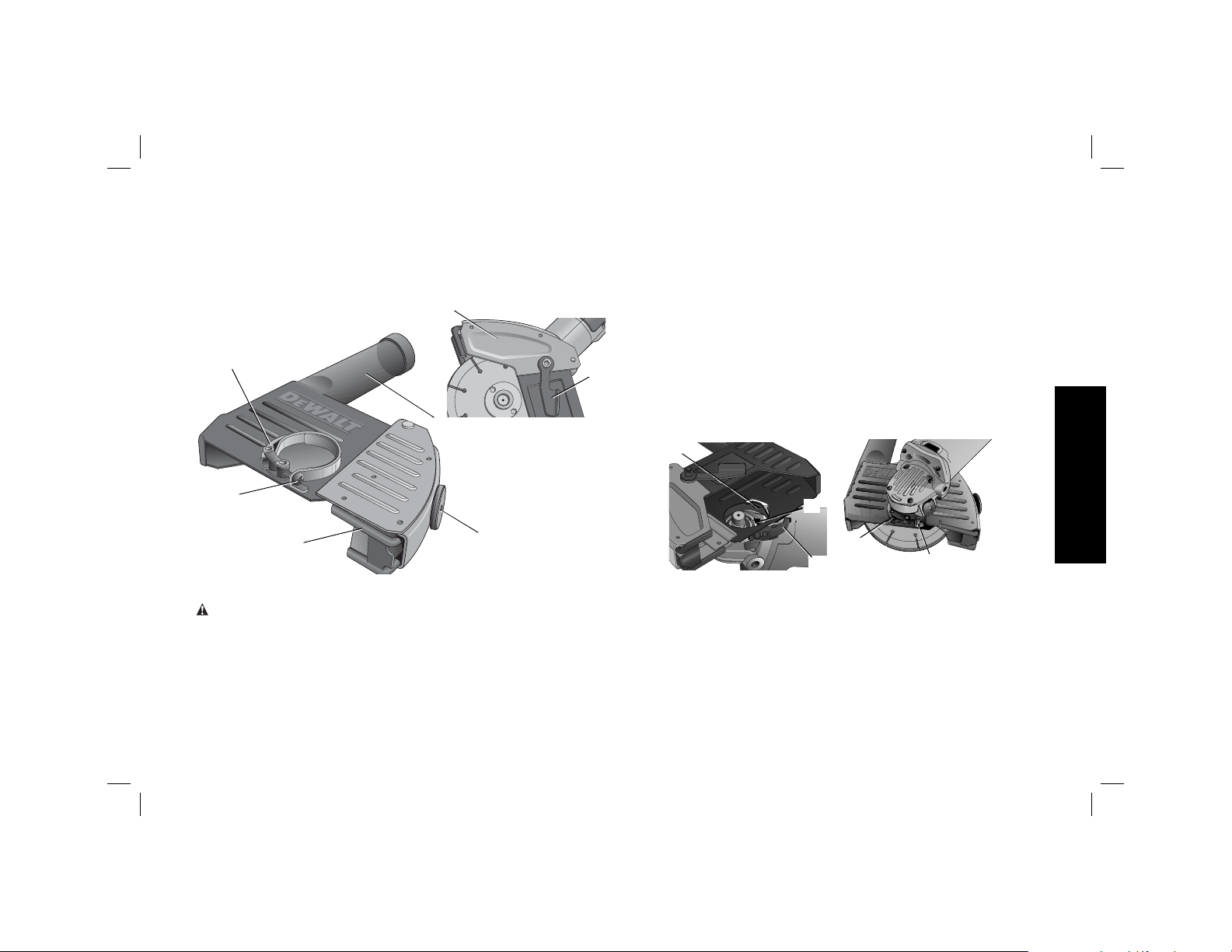

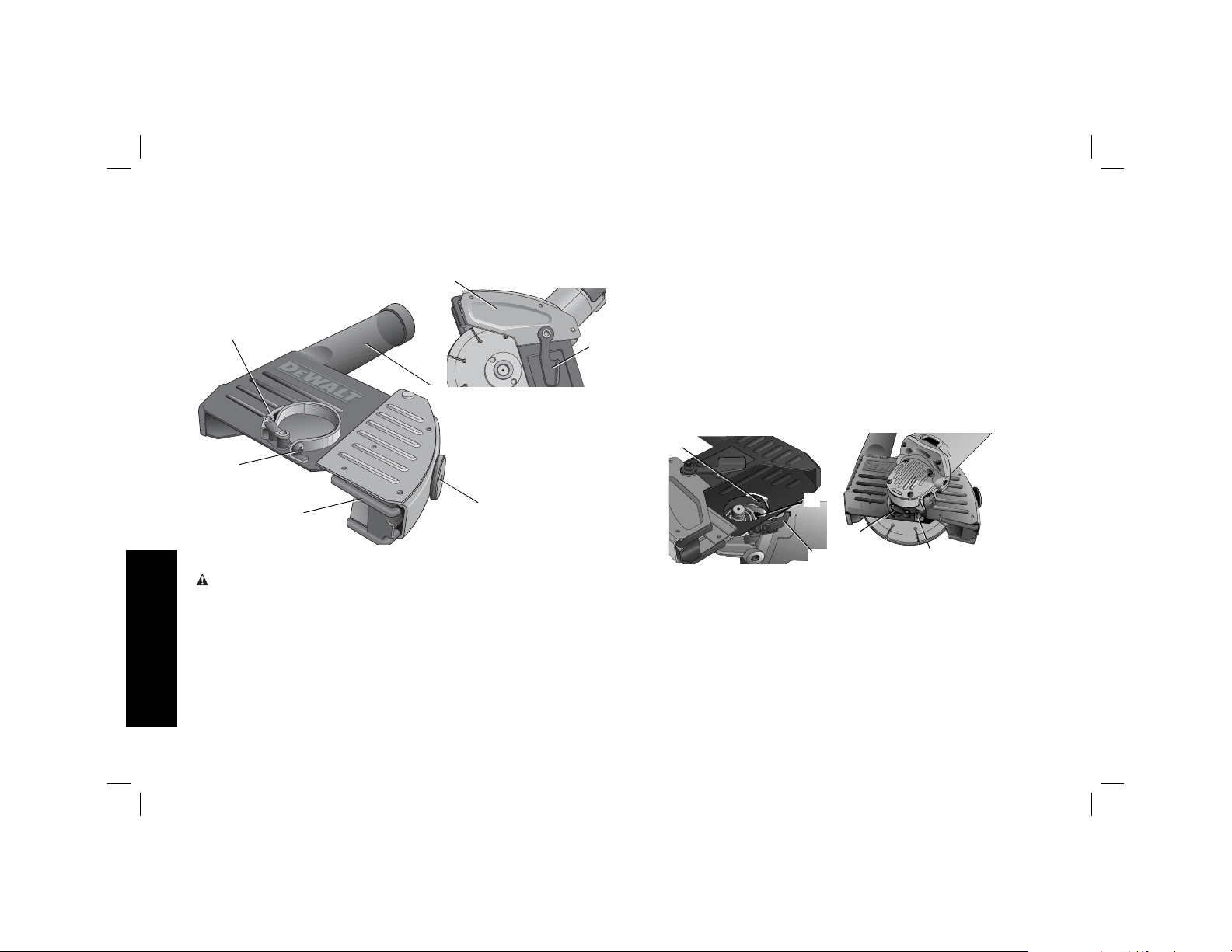

COMPONENTS (FIG. 1)

WARNING: Never modify the power tool or any part of it. Damage

or personal injury could result.

A. Dust port E. Cornering door locking lever

B. Clamp adjusting screw (locks and unlocks cornering door)

C. Depth of cut shoe F. Cornering door (opens and

D. Depth of cut shoe allows cutting of an inside corner)

locking knob G. Clamp lever

INTENDED USE

Your tuckpoint shroud has been designed for professional tuckpoint

masonry applications. It is not intended for use with metal or wood.

4

Page 7

Using the appropriate grinder, wheel and dust extractor vacuum it can

be used to remove the vast majority of static and airborne dust which

without the use of the tuckpoint shroud could otherwise contaminate

the working environment or pose an increased health risk to the

operator and those in close proximity.

DO NOT use under wet conditions or in presence of flammable liquids

or gases.

The tuckpoint shroud is a professional tool. DO NOT let children come

into contact with the tool. Supervision is required when inexperienced

operators use this tool.

Recommended power tools to be used with this attachment are

available at extra cost from your local dealer or authorized service

center. If you need assistance in locating any power tool, please

contact D

MD 21286, call 1-800-4-D

EWALT Industrial Tool Co., 701 East Joppa Road, Baltimore,

EWALT (1-800-433-9258) or visit our

website www.dewalt.com.

FIG. 1

G

F

E

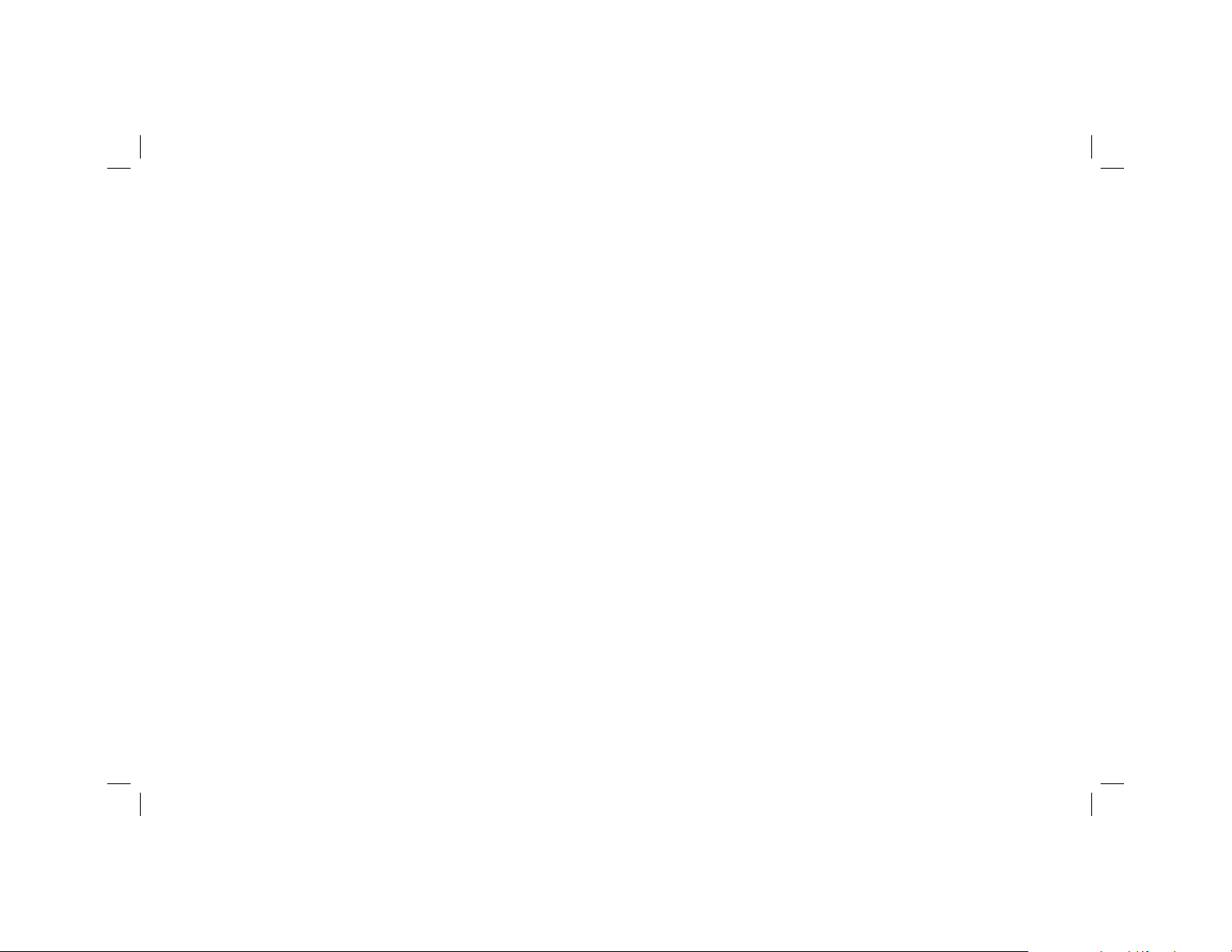

ASSEMBLY AND ADJUSTMENT (FIG. 1, 2)

WARNING: To reduce the risk of injury, ALWAYS turn off the

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

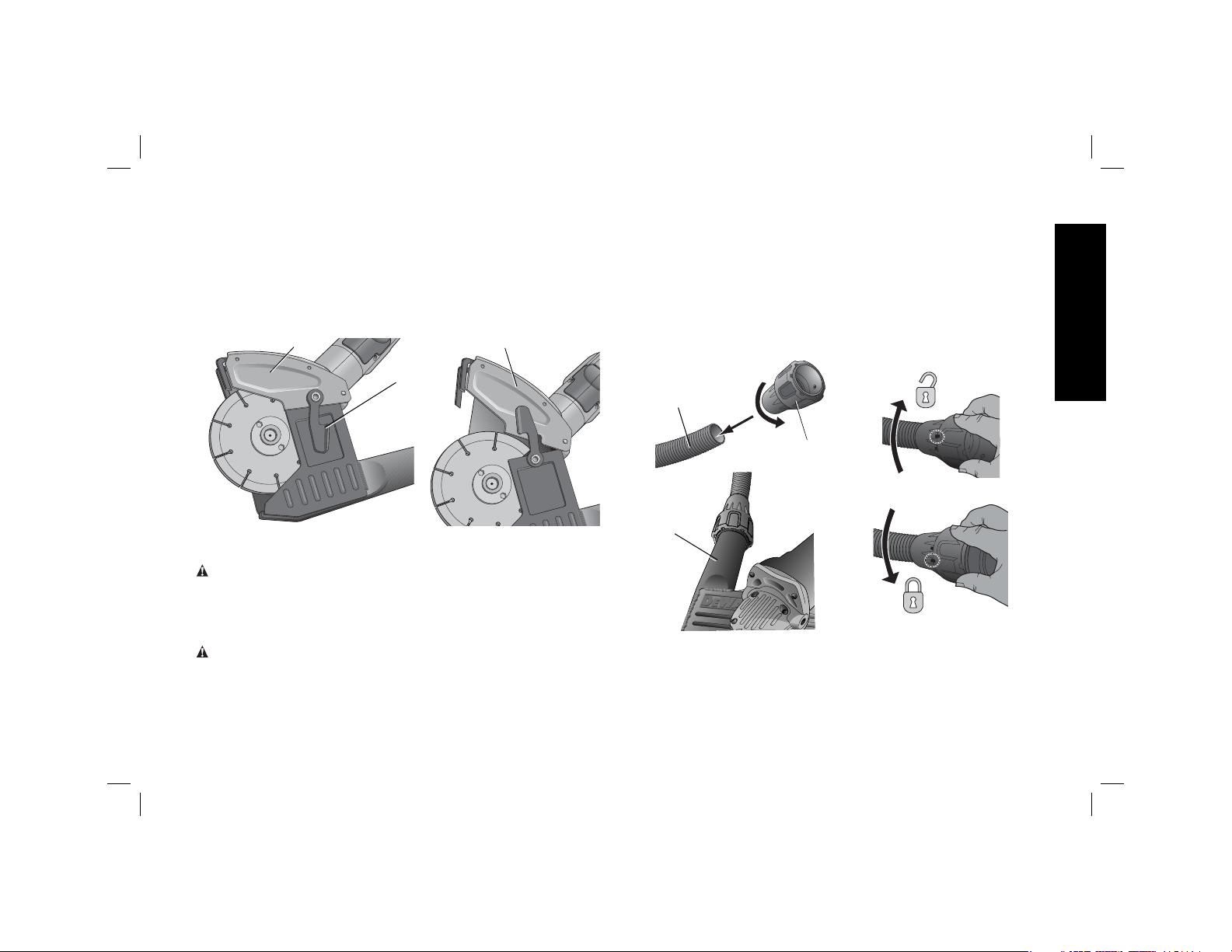

Mounting and Removing Tuckpoint

Shroud

NOTE: The tuckpoint shroud is only recommended for use with the

DWE46102 heavy-duty small angle grinder.

1. Follow the mounting and removing guard instructions in the tool

manual to remove the guard from grinder (DWE46102).

2. Open the clamp lever (G) on the tuckpoint shroud and align the

tabs (I) on the tuckpoint shroud with the slots (J) on the grinder

gear case.

FIG. 2

I

English

A

B

3. With the clamp lever open, rotate the shroud into the desired

J

G

G

B

working position. The shroud should be positioned between the

C

D

spindle and the operator to provide optimum efficiency.

5

Page 8

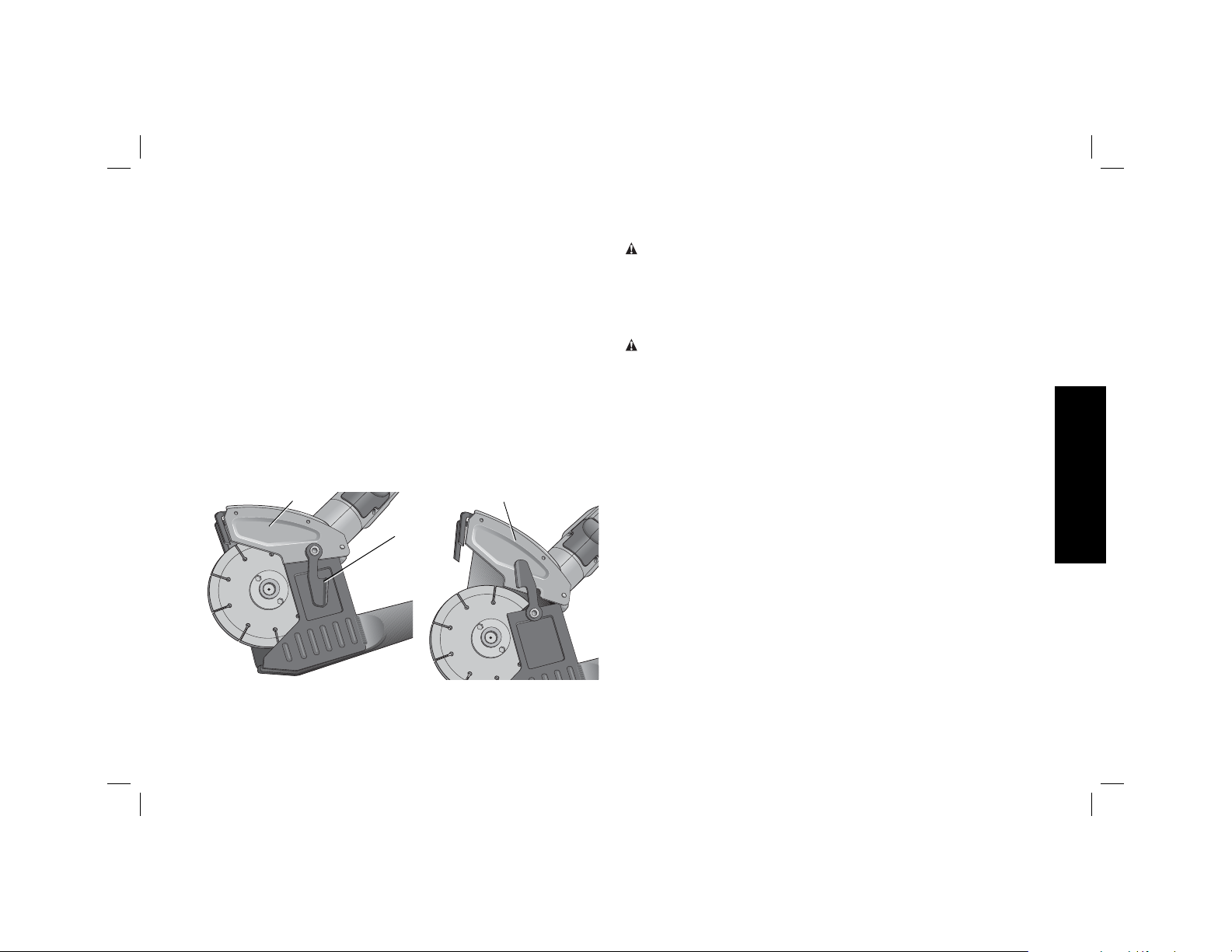

4. Close the clamp lever (G) to secure the tuckpoint shroud on the

gear case. Do not operate the grinder with a loose tuckpoint

shroud or the clamp lever in open position.

5. To remove the tuckpoint shroud, open the clamp lever, rotate the

tuckpoint shroud to align the slots and tabs and pull up on the

tuckpoint shroud.

NOTE: The tuckpoint shroud is pre-adjusted to the diameter of the

gear case hub at the factory. If, after a period of time, the tuckpoint

English

shroud becomes loose, tighten the clamp adjusting screw (B) with

clamp lever in the closed position.

NOTICE: Do not tighten the clamp adjusting screw with the clamp

lever in open position. Undetectable damage to the tuckpoint shroud

or the mounting hub may result.

NOTICE: If tuckpoint shroud cannot be tightened by the clamp

adjusting clamp, do not use tool. Take the tool and tuckpoint shroud

to a service center to repair or replace the tuckpoint shroud.

Mounting Cutting (Type 1) Wheels (Fig. 1)

WARNING: Only Type 1 Diamond Wheels shall be used with

Tuck-Point Shroud. Do not cut metal. Do not use with bonded

abrasive wheels.

Follow the mounting and using cutting (Type 1) wheels instructions in

the tool manual and mount the grinding wheel.

It may be necessary to open the cornering door to install 6" (152.4mm)

tuckpointing wheels, see Cornering Door Application.

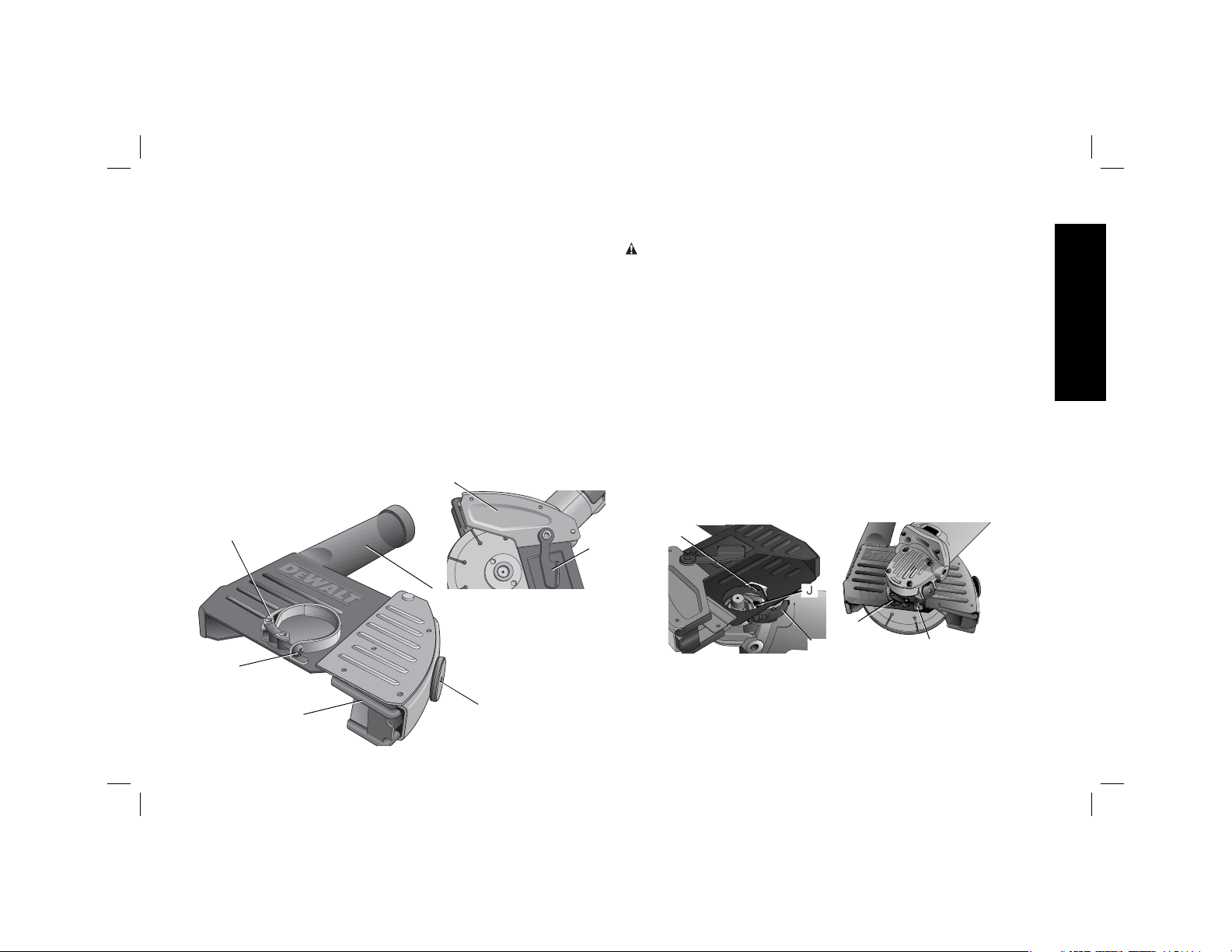

Depth of Cut Adjustment (Fig. 3)

1. Loosen the depth of cut shoe locking knob (D).

2. Slide the depth of cut shoe (C) to the desired position.

3. Tighten depth of cut shoe locking knob.

FIG. 3

C

D

Corner Door Application (Fig. 4)

WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

WARNING: Risk of personal injury. The corner door should only

be opened for cutting inside corners. Keep hands and body away

from cutting area at all times. Ensure corner door is closed in all other

applications.

This feature allows the cutting of an inside corner.

1. Ensure the tool is off and wheel has come to a complete stop.

2. Turn cornering door locking lever (E) counterclockwise one full

rotation. Grasp the corner door (F) and rotate open as shown in

Figure 4.

3. Place hands away from the wheel area and position yourself so

the open underside of the shroud is facing away from you.

4. Turn the tool on and allow the tool to reach full speed before

touching the tool to the work surface.

6

Page 9

5. Place the wheel onto the work surface and move the grinder from

right to left to cut around the inside corner for best dust collection.

6. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

7. Close the corner door and lock in place using the cornering door

locking lever (E).

FIG. 4

F

E

F

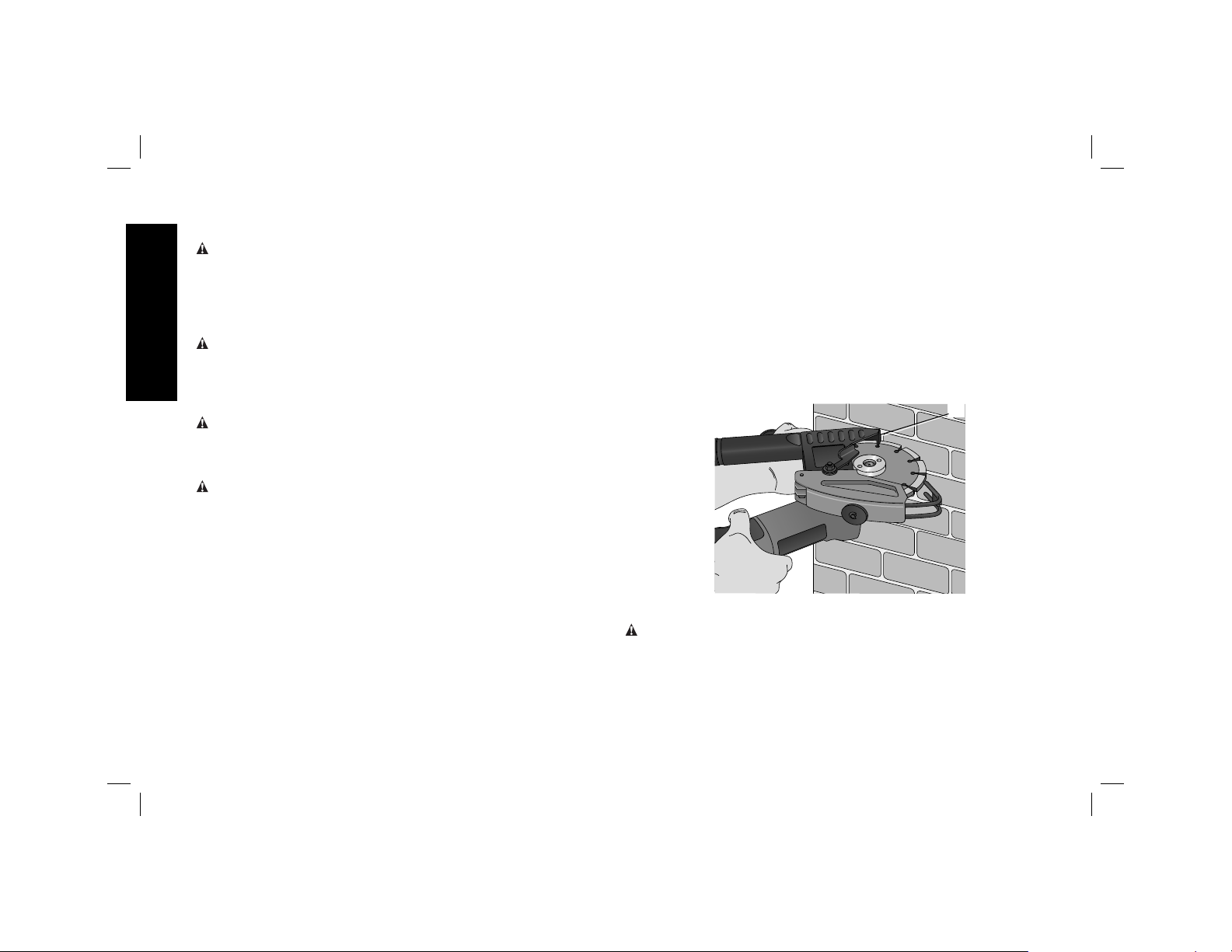

Dust Extraction (Fig. 1, 5)

WARNING: Use only power tools recommended by DEWALT with

this attachment.

For more information about D

attachment, please contact your local dealer, call 1-800-4-D

(1-800-433-9258) or visit our website www.dewalt.com.

WARNING: This attachment MUST BE used with a dust extractor

system. ALWAYS wear certified safety face or dust mask.

NOTE: Ensure hose connection is secure.

EWALT power tools compatible with this

EWALT

NOTE: The amount of dust retained by the dust extractor vacuum

is dependent on its filter system. Refer to the dust extractor vacuum

instruction manual for more information.

All D

EWALT dust collection shrouds are designed to work with the

D

EWALT universal DWV9000 connector.

1. Attach the DWV9000 connector (H) to your dust collector hose (K).

2. Unlock the DWV9000 connector (H) and slide onto dust port (A).

3. Lock the DWV9000 connector (H) to secure.

FIG. 5

K

H

A

TRADITIONAL DUST EXTRACTOR VACUUM HOSES

Attach recommended dust extractor vacuum hose to dust port (A).

English

7

Page 10

OPERATION

WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

English

WARNING: For your own safety, read the instruction manual for

both the grinding tool and the dust extractor vacuum before using any

accessory. Failure to heed these warnings may result in personal injury

and serious damage to the tool and the accessory. When servicing this

tool, use only identical replacement parts.

WARNING: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come to

a complete stop be fore laying the tool down.

WARNING: Ensure corner door is closed.

1. Ensure all assembly and adjustment instructions have been

completed.

2. Turn the dust extractor vacuum on as instructed in the dust

extractor vacuum instruction manual.

3. Start grinder as instructed in tool instruction manual.

NOTE: Allow the tool to reach full speed before applying to the

work surface.

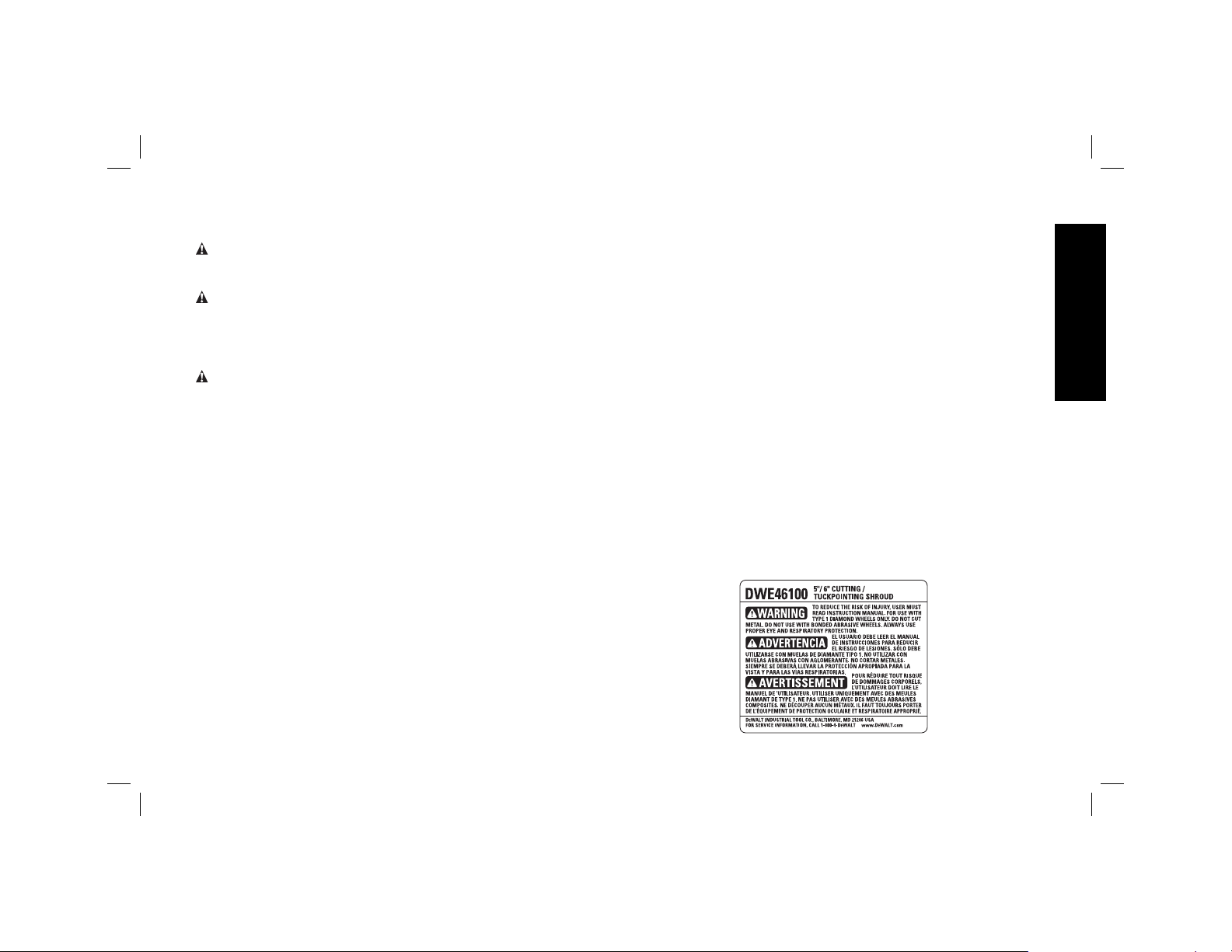

Tuckpointing and Cutting Application

(Fig. 6)

1. Set the desired depth of cut, see Depth of Cut Adjustment

under Assembly and Adjustments.

2. Allow the tool to reach full speed before touching it to the work

surface.

3. Position yourself so the open underside of the shroud and the

wheel are facing away from you.

4. Place the edge (L) of shroud onto the work surface and begin cut

by plunging into the work surface. NOTE: Keep the edge (L) of the

shroud against the work surface to ensure proper dust collection.

5. With the shroud oriented as shown in Figure 6, move the grinder

right to left along the work surface. For the best results the

grinder should be positioned at a 45° angle to the dust port when

tuckpointing/cutting.

6. Remove the tool from work surface before turning off the tool.

Allow the tool to stop rotating before laying it down.

FIG. 6

L

MAINTENANCE

WARNING: To reduce the risk of injury, ALWAYS turn off

tool and disconnect the tool from the power source before

making any adjustments or removing or installing attachments

or accessories. This applies to both the grinder and the dust

extractor vacuum. Such preventative safety measures reduce the

risk of starting the tool accidentally.

8

Page 11

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning

the non-metallic parts of the tool. These chemicals may weaken the

plastic materials used in these parts. Use a cloth dampened only with

water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid. Accessories

WARNING: Since accessories, other than those offered by DEWALT,

have not been tested with this product, use of such accessories with

this tool could be hazardous. To reduce the risk of injury, only D

EWALT

recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-D

EWALT (1-800-433-9258) or visit our website: www.dewalt.

com.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (including brush inspection and replacement) should be

performed by a D

EWALT factory service center, a DEWALT authorized

service center or other qualified service personnel. Always use

identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials

or workmanship for three years from the date of purchase. This

warranty does not cover part failure due to normal wear or tool abuse.

For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258).

This warranty does not apply to accessories or damage caused where

repairs have been made or attempted by others. This warranty gives

you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

EWALT Power Tool, Laser, or Nailer for any reason, you can return it

D

within 90 days from the date of purchase with a receipt for a full refund

– no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local

company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT (1-800-433-

9258) for a free replacement.

English

9

Page 12

Défi nitions: lignes directrices en

matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour

chaque mot-indicateur employé. Lire le mode d’emploi et porter

une attention particulière à ces symboles.

DANGER: indique une situation dangereuse imminente qui,

si elle n’est pas évitée, entraînera la mort ou des blessures

graves.

AVERTISSEMENT : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessures graves.

ATTENTION : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères ou modérées.

AVIS : indique une pratique ne posant aucun risque de

dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages

Français

matériels.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL

OU DE TOUT AUTRE OUTIL D

SANS FRAIS : 1-800-4-D

AVERTISSEMENT : afin de réduire le risque de blessures, lire

le mode d’emploi de l’outil.

EWALT, COMPOSEZ LE NUMÉRO

EWALT (1-800-433-9258).

CONSERVER TOUS LES AVERTISSEMENTS

ET TOUTES LES DIRECTIVES POUR UN

USAGE ULTÉRIEUR

Consignes générales de sécurité

AVERTISSEMENT : pour votre sécurité, lire le manuel de

l’utilisateur de la meuleuse, mais aussi de l’aspirateur avant

l’utilisation de tout accessoire. Tout manquement à ces avertissements

augmente les risques de blessures, et les risques d’endommager

sérieusement l’appareil et ses accessoires. Lors de la maintenance de

cet outil, n’utiliser que des pièces de rechange identiques.

1) SÉCURITÉ DU LIEU DE TRAVAIL

a) Tenir l’aire de travail propre et bien éclairée. Les lieux

encombrés ou sombres sont propices aux accidents.

b) Éloigner les enfants et les personnes à proximité pendant

l’utilisation d’un outil électrique. Une distraction pourrait en

faire perdre la maîtrise à l’utilisateur.

c) S’assurer que les lieux de travail sont bien aérés. Toute

exposition à la poussière sur des lieux de travail mal aérés pose

des risques à la santé.

2) SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a) Éviter tout contact physique avec des surfaces mises à la

terre comme des tuyaux, des radiateurs, des cuisinières

et des réfrigérateurs. Le risque de choc électrique est plus

élevé si votre corps est mis à la terre.

3) SÉCURITÉ PERSONNELLE

a) Être vigilant, surveiller le travail effectué et faire preuve

de jugement lorsqu’un outil électrique est utilisé. Ne

pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un

simple moment d’inattention en utilisant un outil électrique peut

entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle.

Toujours porter une protection oculaire. L’utilisation

d’équipements de protection comme un masque antipoussière,

des chaussures antidérapantes, un casque de sécurité ou des

10

Page 13

protecteurs auditifs lorsque la situation le requiert réduira les

risques de blessures corporelles.

c) Ne pas trop tendre les bras. Conserver son équilibre en

tout temps. Cela permet de mieux maîtriser l’outil électrique

dans les situations imprévues.

d) S’habiller de manière appropriée. Ne pas porter de

vêtements amples ni de bijoux. Garder les cheveux, les

vêtements et les gants à l’écart des pièces mobiles. Les

vêtements amples, les bijoux ou les cheveux longs risquent de

rester coincés dans les pièces mobiles.

4) UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique

approprié à l’application. L’outil électrique approprié

effectuera un meilleur travail, de façon plus sûre et à la vitesse

pour laquelle il a été conçu.

AVERTISSEMENT: l’utilisation de tout accessoire ou pièce,

ou l’exécution de toute opération avec cet outil, autre que celle

recommandée dans ce manuel de l’utilisateur pose des risques

de dommages corporels.

b) Ranger les outils électriques hors de la portée des

enfants et ne permettre à aucune personne n’étant pas

familière avec un outil électrique ou son mode d’emploi

d’utiliser cet outil. Les outils électriques deviennent dangereux

entre les mains d’utilisateurs inexpérimentés.

c) Utiliser l’outil électrique, les accessoires, les forets,

etc. conformément aux présentes directives en tenant

compte des conditions de travail et du travail à effectuer.

L’utilisation d’un outil électrique pour toute opération autre que

celle pour laquelle il a été conçu est dangereuse.

RÉPARATION

a) Faire réparer l’outil électrique par un réparateur

professionnel en n’utilisant que des pièces de rechange

identiques. Cela permettra de maintenir une utilisation

sécuritaire de l’outil électrique.

Règles de sécurité propres au

tronçonnage du béton

• Ne pas utiliser des accessoires qui n’ont pas été spécialement

conçus pour cet outil ou recommandés par son fabricant.

Le fait qu’un accessoire peut être connecté à l’outil ne veut pas

automatiquement dire que son utilisation ne posera aucun risque.

• La vitesse nominale des accessoires utilisés doit être

équivalente ou supérieure à la vitesse maximale apposée

sur l’outil. Les accessoires utilisés à une vitesse plus rapide que

leur vitesse nominale peuvent éclater ou se détacher de l’outil.

• Le diamètre externe et l’épaisseur de l’accessoire utilisé

doivent se conformer aux spécifications de la plaque

signalétique de l’outil électrique. Les accessoires aux

spécifications incorrectes ne peuvent être ni maintenus ni contrôlés

de façon adéquate.

• L’alésage des meules, brides, tampons de soutien, ou de

tout autre accessoire, doit correspondre parfaitement à la

taille de la broche de l’outil. Les accessoires dont l’alésage

ne correspond pas au dispositif d’installation de l’outil électrique

ne tourneront pas correctement, vibreront de façon excessive et

pourront causer la perte de contrôle de l’outil.

• Le dispositif de protection doit être solidement fixé à

l’outil électrique et installé pour optimiser la sécurité pour

que l’utilisateur soit le moins possible exposé à la meule.

Le carter aide à protéger l’utilisateur contre toute projection de

fragments et contre tout contact avec la meule.

• Tenir l’outil électrique par les surfaces isolées prévues à cet

effet pendant toute utilisation où l’organe de coupe pourrait

entrer en contact avec des fils électriques cachés ou son

Français

11

Page 14

propre cordon. Tout contact de l’organe de coupe avec un fil sous

tension met les parties métalliques exposées de l’outil électrique

sous tension et électrocute l’utilisateur.

• Utiliser systématiquement la poignée latérale. Fixer la

poignée solidement. La poignée latérale doit être

systématiquement utilisée pour maîtriser l’outil en permanence.

• Ne pas utiliser d’accessoire endommagé. Avant toute

utilisation, vérifier que les accessoires, comme les meules

diamant et les tampons de soutien, ne comportent aucune

fissure ou cassure, ou ne sont affectés d’aucune usure

excessive, et que les fils des brosses métalliques ne sont

ni lâches ni endommagés. En cas de chute, vérifier que

l’outil électrique ou l’accessoire n’a pas été endommagé,

et remplacer toute pièce abîmée. Après avoir inspecté et

installé un accessoire, se positionner, soi-même et tout

individu présent, hors du plan de rotation de l’accessoire

et laisser tourner l’outil une minute à sa vitesse à vide

maximale. En général, les accessoires endommagés se brisent

Français

pendant le temps d’essai.

• NE PAS meuler ou découper le métal avec une meule

diamant.

• Porter un équipement individuel de protection. Utiliser

une protection faciale et des lunettes ou un masque de

protection. Si approprié, porter un masque anti-poussières,

une protection auditive, des gants et un tablier d’atelier

capables de vous protéger contre toute projection abrasive

ou tout fragment. La protection oculaire doit pouvoir arrêter

toute projection de débris engendrés par des opérations diverses.

Le masque anti-poussières, ou l’appareil de protection des voies

respiratoires, doit pouvoir filtrer les particules engendrées par

l’opération en cours. Toute exposition prolongée à un haut niveau

de décibels peut occasionner une perte de l’acuité auditive.

• Ne pas « bloquer « la meule à tronçonner ou lui appliquer une

pression excessive. Ne pas effectuer des profondeurs de

coupe excessives. Surcharger la meule augmente la contrainte

sur l’outil et les risques de torsion ou grippage de la meule dans la

coupe et, en conséquence, les risques de rebonds ou de cassure

de la meule.

• Positionner le cordon hors du chemin de l’accessoire en

rotation. En cas de perte de contrôle de l’outil, le cordon pourrait

être coupé ou arraché, et les mains ou bras pourraient entrer en

contact avec l’accessoire en rotation.

• Attendre systématiquement l’arrêt complet de l’accessoire

avant de poser l’outil électrique. L’accessoire en rotation

pourrait s’accrocher à une surface et vous faire perdre le contrôle

de l’outil électrique.

• Ne pas laisser l’outil électrique tourner alors que vous le

transportez à votre côté. Tout contact accidentel de l’accessoire

en rotation pourrait faire que ce dernier s’accroche aux vêtements

et entre en contact avec le corps.

• Nettoyer régulièrement les orifices d’aération de l’outil. Le

ventilateur du moteur attirera de la poussière à l’intérieur du boîtier

et l’accumulation excessive de poussières métalliques pose des

risques d’électrocution.

• Ne pas utiliser cet outil électrique à proximité de matériaux

inflammables, car des étincelles pourraient les enflammer.

• Ne pas utiliser d’accessoires nécessitant l’utilisation de

réfrigérants fluides. L’utilisation d’eau ou de réfrigérants fluides

pose des risques d’électrocution ou de chocs électriques.

• NE PAS utiliser de meules abrasives.

AVERTISSEMENT : lorsqu’elle est inutilisée, déposer la

meuleuse sur une surface stable où elle sera immobile et ne

risquera pas de rouler ou de faire trébucher ou chuter

quiconque. Cela pose des risques de dommages corporels graves.

12

Page 15

• Utiliser SYSTÉMATIQUEMENT un système de dépoussiérage.

AVERTISSEMENT: porter SYSTÉMATIQUEMENT des lunettes

de protection. Les lunettes courantes NE sont PAS des lunettes de

protection. Utiliser aussi un masque antipoussières si la découpe doit

en produire beaucoup. Porter SYSTÉMATIQUEMENT un équipement

de sécurité homologué:

• Protection oculaire ANSI Z87.1 (CAN/CSA Z94.3);

• Protection auditive ANSI S12.6 (S3.19;

• Protection des voies respiratoires NIOSH/OSHA/MSHA.

AVERTISSEMENT : les scies, meules, ponceuses, perceuses

ou autres outils de construction peuvent produire des poussières

contenant des produits chimiques reconnus par l’État californien pour

causer cancers, malformations congénitales ou être nocifs au système

reproducteur. Parmi ces produits chimiques, on retrouve:

• Le plomb dans les peintures à base de plomb;

• La silice cristallisée dans les briques et le ciment, ou autres

produits de maçonnerie; et

• L’arsenic et le chrome dans le bois ayant subi un traitement

chimique.

Le risque associé à de telles expositions varie selon la fréquence à

laquelle on effectue ces travaux. Pour réduire toute exposition à ces

produits: travailler dans un endroit bien aéré, en utilisant du matériel

de sécurité homologué tel un masque antipoussières spécialement

conçu pour filtrer les particules microscopiques.

• Limiter toute exposition prolongée avec les poussières

provenant du ponçage, sciage, meulage, perçage ou toute

autre activité de construction. Porter des vêtements de

protection et nettoyer à l’eau savonneuse les parties du

corps exposées. Le fait de laisser la poussière pénétrer dans la

bouche, les yeux ou la peau peut favoriser l’absorption de produits

chimiques dangereux.

AVERTISSEMENT : cet outil peut produire et/ou répandre

de la poussière susceptible de causer des dommages sérieux et

permanents au système respiratoire. Utiliser systématiquement un

appareil respiratoire antipoussières homologué par le NIOSH ou

l’OSHA. Diriger les particules dans le sens opposé au visage et au

corps.

AVERTISSEMENT: avant de se mettre au travail, s’assurer

de déterminer la classification des dangers posés par les

poussières produites. Utiliser un aspirateur industriel de

la classe officielle de sécurité, appropriée et homologuée,

conformément aux consignes locales de lutte contre les

risques posés par les poussières.

AVERTISSEMENT: porter systématiquement une protection

auditive individuelle appropriée. Sous certaines conditions et

suivant la durée d’utilisation, le bruit émanant de ce produit pourrait

contribuer à une perte de l’acuité auditive.

Causes de l’effet de rebond et prévention

par l’opérateur

L’effet de rebond est une réaction soudaine d’une meule, d’un

tampon, d’une brosse ou d’un tout autre accessoire, en mouvement,

qui est pincé ou qui s’accroche. Un pincement ou un accrochage

provoque un arrêt rapide de l’accessoire en mouvement qui, à son

tour, projette l’outil électrique, hors de maîtrise, dans la direction

opposée à la rotation de l’outil au point de grippage.

Par exemple, si une meule diamant reste accrochée ou pincée

dans une pièce à travailler, le bord de la meule engagée au point

de grippage peut s’enfoncer dans la surface du matériau et faire

sauter ou rebondir la meule. La meule peut alors rebondir en

direction ou à l’opposé de l’utilisateur, selon le sens du mouvement

de la meule au point de grippage. Dans ces conditions, il peut aussi

arriver que les meules diamant se brisent.

Français

13

Page 16

Un effet de rebond est le résultat d’une mauvaise utilisation de l’outil

et/ou de procédures ou conditions de fonctionnement incorrectes.

Il peut être évité en prenant les précautions nécessaires telles que

décrites ci-dessous:

a) Saisir fermement l’outil électrique et positionner le corps

et les bras de sorte à résister à la force de l’effet de

rebond. Utiliser toujours la poignée auxiliaire, s’il y en

a une, pour contrôler au maximum l’effet de rebond

ou le couple de réaction au démarrage. Avec de bonnes

précautions, l’opérateur est en mesure de contrôler le couple

de réaction ou l’effet de rebond.

b) Ne jamais placer les mains près de l’accessoire en

mouvement. Il pourrait en effet être projeté sur celles-ci en cas

de rebond.

c) Ne pas positionner le corps dans la trajectoire probable

de l’outil électrique, en cas de rebond. Au moment du

grippage, l’outil sera projeté dans la direction opposée au

Français

déplacement de la meule.

d) Être particulièrement attentif lors de travaux dans un coin,

sur des bords tranchants, etc. Éviter de faire rebondir

l’accessoire. Éviter tout type de grippage de l’accessoire.

Un travail dans un coin ou sur des bords tranchants ou un

travail en faisant rebondir l’accessoire provoquent souvent

un grippage et une perte de maîtrise de l’outil ou un effet de

rebond.

e) Ne pas fixer de lame de tronçonneuse pour sculpter

le bois ou de lame de scie dentée. Ces types de lames

provoquent des effets de rebond et des pertes de maîtrise

fréquents.

CONSERVER CES CONSIGNES POUR

UTILISATION ULTÉRIEURE

DESCRIPTION (FIG. 1)

AVERTISSEMENT: ne jamais modifier l’outil électrique ni aucun

de ses composants, car il y a risques de dommages corporels ou

matériels.

A. Buse de dépoussiérage

B. Vis de réglage du collier de serrage

C. Butée de profondeur de coupe

D. Bouton de verrouillage de butée de profondeur de coupe

E. Levier de verrouillage du capot de coin (verrouille et déverrouille

le capot de coin)

F. Capot de coin (amovible pour permettre de couper à l’intérieur

d’un coin)

G. Levier de serrage

USAGE PRÉVU

Votre carter de tronçonnage du béton a été conçu pour effectuer

des applications professionnelles de maçonnerie de tronçonnage du

béton. Il n’a pas été conçu pour être utilisé sur le métal ou le bois. Avec

l’utilisation d’une meuleuse à disque, une meule et d’un aspirateur

appropriés, le carter de tronçonnage du béton peut être utilisé pour

retirer une vaste majorité des poussières statiques atmosphériques

qui en son absence pourraient contaminer l’environnement de travail

ou poser des risques accrus pour la santé de l’utilisateur et de ceux

à proximité.

NE PAS les utiliser en milieu ambiant humide ou en présence de

liquides ou de gaz inflammables.

Ce carter de tronçonnage du béton est un outil de professionnel. NE

PAS le laisser à la portée des enfants. Une supervision est nécessaire

auprès de tout utilisateur non expérimenté.

Les outils électriques recommandés pour être utilisés avec cet

accessoire sont vendus séparément auprès de votre distributeur

14

Page 17

local ou dans les centres de réparation agréés. Si vous avez besoin

d’aide pour localiser ces outils électriques, veuillez contacter D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, ou

appeler 1-800-4-D

EWALT (1-800-433-9258) ou vous rendre sur notre

site www.dewalt.com.

FIG. 1

G

F

E

A

Installation et retrait du carter de

tronçonnage du béton

REMARQUE : il est recommandé d’utiliser uniquement ce carter

de tronçonnage du béton avec les petites meuleuses angulaires

industrielles DWE46102.

1. Suivez les instructions de la section Installation et retrait du

dispositif de protection dans le manuel de l’outil pour retirer ce

dispositif de la meuleuse (DWE46102).

2. Ouvrez le levier de serrage (G) sur le carter de tronçonnage du

béton puis alignez les languettes (I) du carter de tronçonnage du

béton sur les encoches (J) du carter d’engrenage de la meuleuse.

FIG. 2

I

Français

B

C

D

ASSEMBLAGE ET RÉGLAGE (FIG.1, 2)

AVERTISSEMENT : pour réduire le risque de blessures,

arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout

accessoire. Cela s’applique aussi bien à la meuleuse à disque

qu’à l’aspirateur. Ces mesures préventives de sécurité réduisent les

risques de démarrage accidentel de l’outil.

J

G

G

B

3. Avec le levier de serrage toujours ouvert, faites pivoter le carter

sur la position de travail désirée. Le carter de tronçonnage du

béton devrait se trouver entre la broche et l’utilisateur pour

maximiser son efficacité.

4. Refermez le levier de serrage (G) pour fixer le carter de tronçonnage

du béton sur le carter d’engrenage. N’utilisez pas la meuleuse si

le carter de tronçonnage du béton est lâche ou si son levier de

serrage est ouvert.

15

Page 18

5. Pour retirer le carter de tronçonnage du béton, ouvrez le levier

de serrage, faites pivoter le carter de tronçonnage du béton pour

aligner les encoches sur les languettes puis retirez le carter de

tronçonnage du béton.

REMARQUE: le carter de tronçonnage du béton est préréglé d’usine

au diamètre du moyeu du carter d’engrenage. S’il s’avérait après un

certain temps que le carter de tronçonnage du béton se desserre,

resserrez la vis de réglage du collier de serrage (B) avec le levier de

serrage en position fermée.

AVIS : ne pas resserrer la vis de réglage du collier de serrage si le

levier de serrage est en position ouverte. Le carter de tronçonnage

du béton ou le moyeu d’assemblage pourrait subir des dommages

indécelables.

AVIS : s’il est impossible de resserrer le carter de tronçonnage du

béton avec la vis de réglage du collier de serrage, ne pas utiliser l’outil.

Apportez l’outil et le carter de tronçonnage du béton chez un centre

de réparation pour faire réparer ou remplacer ce dernier.

Installation de meules à tronçonner

Français

(Type1, Fig.1)

AVERTISSEMENT : utiliser exclusivement des meules

diamant de type 1 avec le carter de tronçonnage du béton.

Ne découper aucun métal. Ne pas utiliser avec des meules abrasives

composites.

Suivez les instructions de la section Installation et utilisation des meules

à tronçonner (Type1) dans le manuel de l’outil pour installer la meule.

Il pourra s’avérer nécessaire d’ouvrir le capot de coin pour installer les

meules à tronçonner le béton de 152,4mm (6po), reportez-vous à la

section Applications: capot de coin.

Réglage de la profondeur de coupe

(Fig.3)

1. Desserrez le bouton de verrouillage de butée de profondeur de

coupe (D).

2. Poussez la butée de profondeur de coupe (C) sur la position

désirée.

3. Resserrez le bouton de verrouillage de butée de profondeur de

coupe.

FIG. 3

C

D

Applications: capot de coin (Fig.4)

AVERTISSEMENT : pour réduire le risque de blessures,

arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout

accessoire. Cela s’applique aussi bien à la meuleuse à disque

qu’à l’aspirateur. Ces mesures préventives de sécurité réduisent les

risques de démarrage accidentel de l’outil.

AVERTISSEMENT: risques de dommages corporels. Le capot de

coin ne doit être ouvert que pour couper l’intérieur des coins. Garder

systématiquement les mains et le corps éloignés des zones de coupe.

S’assurer que le capot de coin est fermé pour toute autre application.

Cette fonctionnalité permet de couper à l’intérieur d’un coin.

16

Page 19

1. Assurez-vous de l’arrêt complet de l’outil et de la meule.

2. Tournez le levier de verrouillage du capot de coin (E) vers la gauche

d’un tour complet. Saisissez le capot de coin (F) et faites-le pivoter

pour l’ouvrir, comme illustré en Figure4.

3. Protégez vos mains de la meule et positionnez-vous de façon à ce

que le dessous ouvert du carter soit à votre opposé.

4. Mettez l’outil en marche et laissez-le tourner à plein régime avant

de le mettre en contact avec la surface à travailler.

5. Placez la meule sur la surface à travailler et déplacez la meuleuse

de la droite vers la gauche pour couper à l’intérieur du coin tout en

maximisant la collecte des poussières.

6. Retirez l’outil de la pièce à travailler avant de l’arrêter. Laissez l’outil

s’arrêter complètement de tourner avant de le poser.

7. Fermez le capot de coin et verrouillez-le à l’aide du levier de

verrouillage de capot de coin (E).

FIG. 4

F

E

F

Dépoussiérage (Fig.1, 5)

AVERTISSEMENT : utiliser exclusivement les outils électriques

recommandés par D

Pour plus d’informations concernant les outils électriques D

compatibles avec cet accessoire, contacter votre détaillant local,

appeler le 1-800-4-D

site www.dewalt.com.

AVERTISSEMENT : cet accessoire DOIT ÊTRE utilisé avec un

extracteur de poussière. Porter SYSTÉMATIQUEMENT un écran facial

ou un masque anti-poussières de sécurité homologué.

REMARQUE: vérifier que la connexion tuyau est fiable.

REMARQUE : la quantité de poussière éliminée par l’aspirateur

dépend de son système de filtrage. Se reporter au manuel de

l’utilisateur de l’aspirateur pour des informations complémentaires.

Tous les carters d’aspiration D

avec les connecteurs universels DWV9000 DeWALT.

1. Rattachez le connecteur DWV9000 (H) au tuyau de votre système

de dépoussiérage (K).

2. Déverrouillez le connecteur DWV9000 (H) et l’insérez sur la buse

de dépoussiérage (A).

3. Verrouillez le connecteur DWV9000 (H) pour l’arrimer.

EWALT avec cet accessoire.

EWALT

EWALT (1-800-433-9258) ou se rendre sur notre

EWALT ont été conçus pour fonctionner

Français

17

Page 20

FIG. 5

K

H

A

Français

TUYAUX D’ASPIRATEUR TRADITIONNELS

Rattachez le tuyau d’aspirateur recommandé à la buse de

dépoussiérage (A).

UTILISATION

AVERTISSEMENT : pour réduire le risque de blessures,

arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout

accessoire. Cela s’applique aussi bien à la meuleuse à disque

qu’à l’aspirateur. Ces mesures préventives de sécurité réduisent les

risques de démarrage accidentel de l’outil.

AVERTISSEMENT : pour votre sécurité, lire le manuel de

l’utilisateur de la meuleuse, mais aussi de l’aspirateur avant l’utilisation

de tout accessoire. Tout manquement à ces avertissements augmente

les risques de blessures, et les risques d’endommager sérieusement

l’appareil et ses accessoires. Lors de la maintenance de cet outil,

n’utiliser que des pièces de rechange identiques.

AVERTISSEMENT: saisir fermement la poignée latérale et le corps

de l’outil pour le maîtriser à l’amorçage, en cours de fonctionnement et

jusqu’à l’arrêt complet de la meule ou de l’accessoire. S’assurer que

la meule soit vraiment immobile avant de déposer l’outil.

AVERTISSEMENT: s’assurer que le capot de coin est fermé.

1. Assurez-vous que toutes les instructions d’assemblage et de

réglage ont bien été suivies.

2. Allumez l’aspirateur comme indiqué dans le manuel de l’utilisateur

de l’aspirateur.

3. Mettez la meuleuse à disque en marche comme

indiqué dans le manuel de l’utilisateur de l’outil.

REMARQUE : laisser l’outil tourner à plein régime avant de le

mettre en contact avec la surface à travailler.

Applications de tronçonnage et de coupe

du béton (Fig.6)

1. Réglez la profondeur de coupe désirée, reportez-vous à la section

Réglage de la Profondeur de coupe sous Assemblage et

réglages.

2. Laissez l’outil tourner à plein régime avant de le mettre en contact

avec la surface à travailler.

3. Positionnez-vous de façon à ce que le dessous ouvert du carter

et la meule soient orientés à l’opposée de vous.

4. Placez le bord (L) du carter sur la surface à travailler et commencez

à couper en plongeant dans la surface à travailler. REMARQUE:

maintenir le bord (L) du carter contre la surface à travailler pour

assurer la collecte correcte de la poussière.

18

Page 21

5. Avec le carter orienté comme illustré en Figure 6, déplacez la

meuleuse de la droite vers la gauche le long de la surface à

travailler. Pour des résultats optimums, la meuleuse doit être

positionnée à un angle de 45° de la buse de dépoussiérage lors

du tronçonnage du béton.

6. Retirez l’outil de la pièce à travailler avant de l’arrêter. Laissez l’outil

s’arrêter complètement de tourner avant de le poser.

FIG. 6

L

MAINTENANCE

AVERTISSEMENT : pour réduire le risque de blessures,

arrêter et débrancher SYSTÉMATIQUEMENT l’outil avant tout

réglage ou avant de retirer ou installer toute pièce ou tout

accessoire. Cela s’applique aussi bien à la meuleuse à disque

qu’à l’aspirateur. Ces mesures préventives de sécurité réduisent les

risques de démarrage accidentel de l’outil.

Nettoyage

AVERTISSEMENT : enlever les saletés et la poussière hors des

évents au moyen d’air comprimé propre et sec, au moins une fois

par semaine. Pour minimiser le risque de blessure aux yeux, toujours

porter une protection oculaire conforme à la norme ANSI Z87.1 lors

du nettoyage.

AVERTISSEMENT : ne jamais utiliser de solvants ni d’autres

produits chimiques puissants pour nettoyer les pièces non métalliques

de l’outil. Ces produits chimiques peuvent affaiblir les matériaux

de plastique utilisés dans ces pièces. Utiliser un chiffon humecté

uniquement d’eau et de savon doux. Ne jamais laisser de liquide

pénétrer dans l’outil et n’immerger aucune partie de l’outil dans un

liquide.

AVERTISSEMENT : puisque les accessoires autres que ceux

offerts par D

pourrait s’avérer dangereuse. Pour réduire le risque de blessures,

utiliser exclusivement les accessoires D

présent produit.

Les accessoires recommandés pour cet outil sont vendus séparément

au centre de service de votre région. Pour obtenir de l’aide concernant

l’achat d’un accessoire, communiquer avec D

Co., 701 East Joppa Road, Baltimore, MD 21286 aux États-Unis;

composer le 1 800 433-9258 (1 800 4-D

Web : www.dewalt.com.

EWALT n’ont pas été testés avec ce produit, leur utilisation

EWALT recommandés avec le

EWALT Industrial Tool

EWALT) ou visiter notre site

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les réparations,

l’entretien et les réglages doivent être réalisés (cela comprend

l’inspection et le remplacement du balai) par un centre de réparation

en usine D

d’autres techniciens qualifiés. Toujours utiliser des pièces de rechange

identiques.

EWALT, un centre de réparation agréé DEWALT ou par

Garantie limitée de trois ans

DEWALT réparera, sans frais, tout produit défectueux causé par un

défaut de matériel ou de fabrication pour une période de trois ans à

compter de la date d’achat. La présente garantie ne couvre pas les

Français

19

Page 22

pièces dont la défectuosité a été causée par une usure normale ou

l’usage abusif de l’outil. Pour obtenir de plus amples renseignements

sur les pièces ou les réparations couvertes par la présente garantie,

visiter le site www.dewalt.com ou composer le 1 800 433-9258 (1 800

4-D

EWALT). Cette garantie ne s’applique pas aux accessoires et ne

vise pas les dommages causés par des réparations effectuées par un

tiers. Cette garantie confère des droits légaux particuliers à l’acheteur,

mais celui-ci pourrait aussi bénéficier d’autres droits variant d’un état

ou d’une province à l’autre.

En plus de la présente garantie, les outils D

EWALT sont couverts par

notre :

CONTRAT D’ENTRETIEN GRATUIT D’UN AN

EWALT entretiendra l’outil et remplacera les pièces usées au cours

D

d’une utilisation normale et ce, gratuitement, pendant une période

d’un an à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si l’acheteur n’est pas entièrement satisfait, pour quelque raison que

Français

ce soit, du rendement de l’outil électrique, du laser ou de la cloueuse

D

EWALT, celui-ci peut le retourner, accompagné d’un reçu, dans les

90 jours à compter de la date d’achat pour obtenir un remboursement

intégral, sans aucun problème.

AMÉRIQUE LATINE : cette garantie ne s’applique aux produits vendus

en Amérique latine. Pour ceux-ci, veuillez consulter les informations

relatives à la garantie spécifique présente dans l’emballage, appeler

l’entreprise locale ou consulter le site Web pour les informations

relatives à cette garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D’AVERTISSEMENT : si les étiquettes d’avertissement deviennent

illisibles ou sont manquantes, composer le 1 800 433-9258 (1 800

4-D

EWALT) pour en obtenir le remplacement gratuit.

20

Page 23

Defi niciones: Normas de seguridad

Las siguientes definiciones describen el nivel de gravedad de

cada palabra de señal. Lea el manual y preste atención a estos

símbolos.

PELIGRO: indica una situación de peligro inminente que, si

no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial

que, si no se evita, podría provocar la muerte o lesiones

graves.

ATENCIÓN: indica una situación de peligro potencial que,

si no se evita, posiblemente provocaría lesiones leves o

moderadas.

AVISO: se refiere a una práctica no relacionada a lesiones

corporales que de no evitarse puede resultar en daños a la

propiedad.

SI TIENE ALGUNA DUDA O ALGÚN COMENTARIO SOBRE ÉSTA

U OTRA HERRAMIENTA D

GRATUITO: 1-800-4-D

ADVERTENCIA: Para reducir el riesgo de lesiones, lea el

manual de instrucciones.

EWALT, LLÁMENOS AL NÚMERO

EWALT (1-800-433-9258).

CONSERVE TODAS LAS ADVERTENCIAS

E INSTRUCCIONES PARA FUTURAS

CONSULTAS

Advertencias generales sobre seguridad

ADVERTENCIA: Por su propia seguridad, lea el manual de

instrucciones para la esmeriladora y la aspiradora extractora de

polvo antes de usar los accesorios. De no seguir estas advertencias

podrían producirse lesiones corporales y graves daños a la herramienta

y al accesorio. Cuando realice el mantenimiento de esta herramienta,

utilice únicamente repuestos originales.

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las

áreas abarrotadas y oscuras propician accidentes.

b) Mantenga alejados a los niños y a los espectadores de la

herramienta eléctrica en funcionamiento. Las distracciones

pueden provocar la pérdida de control.

c) Asegúrese de que el lugar de trabajo esté bien ventilado.

La exposición al polvo en un lugar de trabajo con poca

ventilación puede dar como resultado el deterioro de la salud.

2) SEGURIDAD ELÉCTRICA

a) Evite el contacto corporal con superficies con descargas

a tierra como, por ejemplo, tuberías, radiadores, cocinas

eléctricas y refrigeradores. Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y

utilice el sentido común cuando emplee una herramienta

eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o

medicamentos. Un momento de descuido mientras se opera

una herramienta eléctrica puede provocar lesiones personales

graves.

b) Utilice equipos de protección personal. Siempre utilice

protección para los ojos. En las condiciones adecuadas, el

uso de equipos de protección, como máscaras para polvo,

calzado de seguridad antideslizante, cascos o protección

auditiva, reducirá las lesiones personales.

Español

21

Page 24

c) No se estire. Conserve el equilibrio y párese

adecuadamente en todo momento. Esto permite un mejor

control de la herramienta eléctrica en situaciones inesperadas.

d) Use la vestimenta adecuada. No use ropas holgadas ni

joyas. Mantenga el cabello, la ropa y los guantes alejados

de las piezas en movimiento. Las ropas holgadas, las joyas

o el cabello largo pueden quedar atrapados en las piezas en

movimiento.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA

ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica correcta para el trabajo que realizará. Si se la

utiliza a la velocidad para la que fue diseñada, la herramienta

eléctrica correcta permite trabajar mejor y de manera más

segura.

ADVERTENCIA: El uso de accesorios o adaptadores, o el

desempeño de cualquier operación con esta herramienta,

distintos a los recomendados en este manual de instrucciones

puede representar un riesgo de lesiones personales.

b) Guarde la herramienta eléctrica que no esté en uso fuera

del alcance de los niños y no permita que otras personas

no familiarizadas con ella o con estas instrucciones

operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios no capacitados.

c) Utilice la herramienta eléctrica, los accesorios y las

brocas de la herramienta, etc. de acuerdo con estas

instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de la

Español

herramienta eléctrica para operaciones diferentes de aquéllas

para las que fue diseñada podría originar una situación peligrosa.

5) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que

realice el mantenimiento de su herramienta eléctrica

y que sólo utilice piezas de repuesto idénticas. Esto

garantizará la seguridad de la herramienta eléctrica.

Normas de seguridad para rejuntar

• No utilice accesorios que no estén diseñados y recomendados

específicamente por el fabricante de la herramienta. El hecho

de que el accesorio pueda acoplarse a la herramienta eléctrica no

garantiza un funcionamiento sin riesgos.

• La velocidad prevista del accesorio debe ser como mínimo

igual a la velocidad máxima marcada en la herramienta

eléctrica. Los accesorios operados a velocidades superiores a su

velocidad nominal pueden romperse y salir despedidos.

• El diámetro externo y el grosor del accesorio deben estar

dentro de la capacidad de su herramienta eléctrica. Los

accesorios de tamaños incorrectos no pueden ser protegidos o

controlados adecuadamente.

• El tamaño del eje de los discos, las bridas, almohadillas

de respaldo o cualquier otro accesorio debe acoplarse

bien al eje de la herramienta eléctrica. Los accesorios que

tienen orificios para montaje en eje que no se corresponden con

los accesorios de montaje de la herramienta eléctrica harán que

la herramienta pierda el equilibrio, vibre excesivamente y que el

operador pierda el control de la herramienta.

• El protector debe ir firmemente ajustado a la herramienta

eléctrica y en posición para el máximo de seguridad, de

modo que se exponga la menor parte posible del disco

al operador. El protector ayuda a proteger al operador de los

fragmentos despedidos por discos rotos y el contacto accidental

con el disco.

22

Page 25

• Sostenga la herramienta eléctrica solamente en superficies

de agarre aisladas cuando realice una operación en la cual

el accesorio para cortar pudiera entrar en contacto con

instalaciones eléctricas ocultas o su propio cable. El contacto

de los accesorios de corte con un cable cargado, puede cargar las

partes metálicas expuestas de la herramienta eléctrica y producir

una descarga eléctrica al operador.

• Siempre use el mango lateral. Apriete con firmeza el mango.

Se debe utilizar siempre el mango lateral para mantener el control

de la herramienta en todo momento.

• No utilice un accesorio dañado. Antes de cada uso

inspeccione el accesorio, como por ejemplo el disco de

diamante, para verificar si tiene muescas o grietas, la

almohadilla de respaldo para verificar si tiene grietas o

roturas o si está muy desgastada, la escobilla de alambre

para comprobar si tiene alambres sueltos o agrietados. Si la

herramienta o el accesorio se cae accidentalmente, revise

que no esté dañado o, si es necesario, cambie el accesorio

por uno que no esté dañado. Después de inspeccionar e

instalar un accesorio, colóquense usted y las personas

presentes alejados del plano del accesorio en movimiento

y ponga la herramienta eléctrica en funcionamiento a

la velocidad sin carga máxima durante un minuto. Si el

accesorio está dañado, normalmente se terminará de romper

durante este período de prueba.

• NO esmerile ni corte metal con un disco de diamante.

• Póngase un equipo de protección personal. Dependiendo de

la aplicación, use un protector facial y gafas protectoras. Si

corresponde, póngase una mascarilla antipolvo, protectores

para el oído, guantes y un delantal de trabajo que pueda

detener pequeños fragmentos abrasivos o de la pieza de

trabajo. La protección ocular utilizada debe ser capaz de detener

desechos despedidos por las diversas operaciones realizadas

con la herramienta. La máscara antipolvo o el respirador debe

poder filtrar partículas generadas por la operación realizada. La

exposición prolongada a ruidos de alta intensidad puede causar

pérdida auditiva.

• No "atasque" el disco de corte ni aplique excesiva presión.

No intente hacer un corte de profundidad excesiva. El

ejercer demasiada presión sobre el disco aumenta la carga y

la susceptibilidad de giro o bloqueo del disco en el corte y la

posibilidad de rebote o rotura del disco.

• Coloque el cable lejos del accesorio rotativo. Si pierde el

control, el cable puede cortarse o engancharse y puede arrastrar a

la mano o el brazo hacia el accesorio rotativo.

• Nunca suelte la herramienta hasta que el accesorio haya

dejado de girar totalmente. El accesorio rotativo puede aferrarse

a la superficie y tirar de la herramienta, haciéndole perder el control

de la misma.

• No ponga en funcionamiento la herramienta eléctrica

mientras la transporte a su lado. El contacto accidental con el

accesorio rotativo podría enganchar su ropa y tirar del accesorio

hacia su cuerpo.

• Limpie periódicamente los orificios de ventilación de la

herramienta eléctrica. El ventilador del motor atraerá el polvo

dentro de la caja protectora y la acumulación excesiva del metal en

polvo puede ocasionar riesgos eléctricos.

• No utilice la herramienta eléctrica cerca de materiales

inflamables. Las chispas podrían prender fuego a estos materiales.

• No utilice accesorios que requieran líquidos refrigerantes.

El utilizar agua u otros refrigerantes líquidos puede ocasionar

electrocución o descarga.

• NO use discos abrasivos.

• SIEMPRE use un colector de polvo.

Español

23

Page 26

ADVERTENCIA: Cuando no la utilice, coloque la esmeriladora

en una superficie estable donde no pueda moverse de manera

accidental, deslizarse ni provocar tropezones o caídas. Puede

resultar en lesiones corporales serias.

ADVERTENCIA: Use SIEMPRE lentes de seguridad. Los

anteojos de diario NO SON lentes de seguridad. Utilice además una

cubrebocas o mascarilla antipolvo si la operación de corte genera

demasiado polvo. SIEMPRE lleve equipo de seguridad certificado:

• Protección ocular ANSI Z87.1 (CAN/CSA Z94.3).

• Protección auditiva ANSI S12.6 (S3.19)

• Protección respiratoria NIOSH/OSHA.

ADVERTENCIA: Algunas partículas de polvo generadas al lijar,

serrar, esmerilar y taladrar con herramientas eléctricas, así como al

realizar otras actividades de construcción, contienen químicos que

el Estado de California sabe que pueden producir cáncer, defectos

congénitos u otras afecciones reproductivas. Ejemplos de estos

químicos son:

• plomo de algunas pinturas en base a plomo,

• polvo de sílice proveniente de ladrillos y cemento y otros

productos de albañilería, y

• arsénico y cromo provenientes de madera tratada químicamente.

Su riesgo de exposición a estos químicos varía, dependiendo de

la frecuencia con la cual realiza usted este tipo de trabajo. Para

reducir la exposición a esas sustancias químicas: trabaje en una zona

bien ventilada y llevando equipos de seguridad aprobados, como

mascarillas antipolvo especialmente diseñadas para filtrar partículas

microscópicas.

• Evite el contacto prolongado con polvo generado por el

Español

lijado, aserrado, pulido, taladrado y otras actividades de

construcción. Vista ropas protectoras y lave las áreas de

la piel expuestas con agua y jabón. Si permite que el polvo se

introduzca en la boca u ojos o quede sobre la piel, puede favorecer

la absorción de productos químicos peligrosos.

ADVERTENCIA: La utilización de esta herramienta puede generar

polvo o dispersarlo, lo que podría causar daños graves y permanentes

al sistema respiratorio, así como otras lesiones. Siempre use protección

respiratoria aprobada por NIOSH (Instituto Nacional de Seguridad y

Salud en el Trabajo) u OSHA (Administración de Seguridad y Salud en

el Trabajo) apropiada para la exposición al polvo. Dirija las partículas

en dirección contraria a la cara y el cuerpo.

ADVERTENCIA: Antes de comenzar el trabajo, verifique para

determinar la clasificación de riesgo del polvo producido. Utilice

una aspiradora extractora de polvo industrial apropiada, de la

clase de seguridad aprobada oficialmente, y en cumplimiento

con sus normativas locales de control de riesgo del polvo.

ADVERTENCIA: Utilice siempre protección auditiva personal

apropiada. Bajo algunas condiciones y duraciones de uso, el ruido

producido por este producto puede contribuir a la pérdida auditiva.

Causas del retroceso y su prevención por

parte del operador

El retroceso es una reacción repentina al pellizco o atascamiento

de un disco giratorio, una almohadilla de respaldo, un cepillo o

cualquier otro accesorio. El pellizco o el atascamiento hacen que el

accesorio giratorio se trabe rápidamente, lo que a su vez provoca

que la herramienta eléctrica fuera de control vaya en sentido

opuesto al giro del accesorio en el punto del atascamiento.

Por ejemplo, si un disco de diamante se atasca o se engancha en

la pieza de trabajo, el borde del disco que está entrando al punto

de atasque puede penetrar la superficie del material y hacer que

el disco rebote o patee. El disco puede entonces saltar hacia el

operador o en dirección contraria al mismo, dependiendo de la

dirección en la que se movía el disco al momento de engancharse.

24

Page 27

En estas condiciones los discos de diamante pueden además

romperse.

El retroceso es el resultado de un mal uso de la herramienta o de

condiciones o procedimientos operativos incorrectos y se puede

evitar tomando las precauciones apropiadas que se indican a

continuación:

a) Sostenga la herramienta eléctrica con firmeza y ubique

el cuerpo y el brazo para poder resistir las fuerzas de

retroceso. Siempre utilice el mango lateral, en caso de

tenerlo, para lograr el máximo control sobre el retroceso

o la reacción de torsión durante el encendido. El operador

puede controlar la reacción de torsión o las fuerzas de retroceso

si toma las precauciones adecuadas.

b) Nunca coloque la mano cerca del accesorio giratorio, ya

que éste puede hacer un retroceso sobre la mano.

c) No ubique el cuerpo en el área hacia donde la herramienta

eléctrica se desplazará si se produce un retroceso. El

retroceso impulsará la herramienta en la dirección opuesta al

movimiento del disco en el punto de atascamiento.

d) Tenga especial cuidado al trabajar en esquinas, bordes

filosos, etc. Evite hacer rebotar o enganchar el accesorio.

Las esquinas, los bordes filosos y el rebote tienden a enganchar

el accesorio giratorio y producir la pérdida de control o el

retroceso de la unidad.

e) No conecte una hoja para carpintería para sierra de

cadena ni una hoja de sierra dentada. Estas hojas puede

producir el retroceso y la pérdida de control frecuentes.

GUARDE ESTAS INSTRUCCIONES

PARA FUTURAS CONSULTAS

COMPONENTES (FIG. 1)

ADVERTENCIA: Nunca modifique la herramienta eléctrica, ni

tampoco ninguna de sus piezas. Podría producir lesiones corporales

o daños.

A. Puerto de polvo

B. Tornillo de fijación de la abrazadera

C. Base de profundidad de corte

D. Base de profundidad de corte botón de bloqueo

E. Palanca de bloqueo de la puerta curva

(bloquea y desbloquea la puerta curva)

F. Puerta curva (abre y permite cortar una curva interna)

G. Palanca de abrazadera

USO DEBIDO

Su cubierta protectora para rejuntar ha sido diseñada para aplicaciones

profesionales de rejuntado de albañilería. No está prevista para

ser usada en metal o madera. Al usar la esmeriladora, el disco y

la aspiradora extractora de polvo adecuadas, se puede usar para

eliminar la mayor cantidad de polvo estático y transportado por el

aire, que sin el uso de la cubierta protectora para rejuntar podría

contaminar el entorno de trabajo o suponer un riesgo elevado para la

salud del operador y de las personas a su alrededor.

NO utilice la herramienta en condiciones de humedad o en presencia

de líquidos o gases inflamables.

La cubierta protectora para rejuntar es una herramienta profesional.

NO permita que los niños toquen la herramienta. Si el operador no

tiene experiencia operando esta herramienta, su uso deberá ser

supervisado.

Las herramientas eléctricas a ser utilizadas con este aditamento están

disponibles con un cargo adicional en su distribuidor local o en el

centro de servicio autorizado. Si necesita ayuda para ubicar alguna

herramienta eléctrica, por favor póngase en contacto con D

EWALT

Español

25

Page 28

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, llame

al 1-800-4-D

EWALT (1-800-433-9258) o visite nuestro sitio web www.

dewalt.com.

FIG. 1

G

B

F

E

A

Cómo montar y sacar la cubierta

protectora para rejuntar

NOTA: Se recomienda que la cubierta protectora para rejuntar

únicamente se use con la esmeriladora de ángulo pequeño para

trabajo pesado DWE46102.

1. Siga las instrucciones de Montaje y desmontaje del protector

en el manual de la herramienta para quitar el protector de la

esmeriladora (DWE46102).

2. Abra la palanca de abrazadera (G) de la cubierta protectora para

rejuntar y alinee las lengüetas (I) en la cubierta protectora con las