Page 1

ENGlISH

ANGlE

GRINDERS DWE4557, DWE4559, DWE4579,

DWE4579R, DWE4597, DWE4599

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product development and innovation make

DEWALT one of the most reliable partners for professional power tool users.

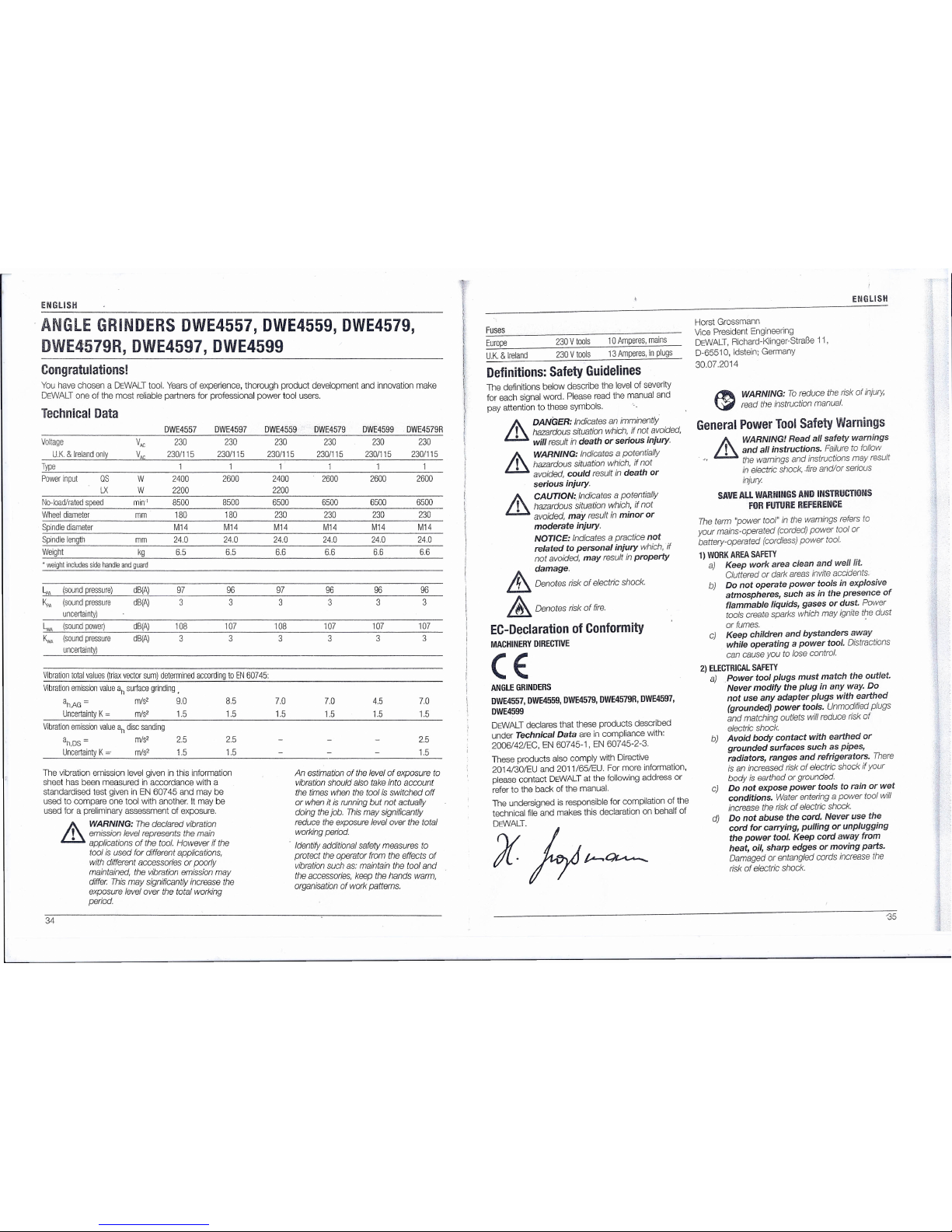

Technical Data

DWE4557 DWE4597 DWE4559 DWE4579 DWE4599 DWE4579R

Voltage

V'"

230 230 230 230 230 230

U.K.&Ireland only

V'"

230/115 230/115 230/115 230/115 230/115 230/115

Type 1 1 1 1 1 1

Power input QS W 2400

2600

2400

2600

2600 2600

LX

W

2200

2200

No-Ioad/rated speed rnrr

8500

8500

6500 6500

6500 6500

Wheel diameter

mm 180

180

230 230 230

230

Spindle diameter M14 M14 M14

M14

M14 M14

Spindle length

mm 24.0 24.0 24.0 24.0 24.0 24.0

Weight kg 6.5

6.5

6.6 6.6 6.6 6.6

• weightincludessidehandleandguard

4A

(sound pressure) dB(A)

97 96 97 96 96 96

K,A

(sound pressure

dB(A)

3 3 3 3 3

3

uncertainty)

LwA

(sound power)

dB(A) 108 107 108 107 107 107

!<..vA

(sound pressure dB(A)

3 3 3 3

3 3

uncertainty)

lJibrationtotal values (triaxvector sum) delermined according lo EN60745:

Vibralion emission value ah surface grinding •

ah,AG

=

mls

2

9.0 8.5 7.0

Uncertainty K

=

mls

2

1.5 1.5 1.5

7.0

1.5

4.5

1.5

7.0

1.5

Vibrationemissionvalue ah disc sanding

a

h.DS

=

mls

2

2.5 2.5

Uncertainty K='m/s21.5 1.5

2.5

1.5

The vibration emission level given in this information

sheet has been measured in accordance with a

slandardised test given in EN 60745 and may be

used to compare one tool with another. It may be

used for a preliminary assessment of exposure.

A

WARNING: The dee/ared vibration

ill

emission level represents the main

• applications of the tool. However if the

tool is used for different applications,

with different accessories or poorly

maintained, the vibration emission may

differ. This may significant/y increase the

exposure level over the total working

periodo

An estimation of the levelof exposure to

vibration should a/so take into account

the times when the tool is switched off

or when it is running but not actual/y

doing thelobo Thismay significant/y

reduce the exposure level over the total

working periodo

. Identify additional safety measures to

protect the operator from the effects of

vibration such

as:

maintain the tool and

the accessories, keep the hands warm,

organisation of work pattems.

34

Fuses

ENGLlSH

Europe

230 V tools

10 Amperes, mains

Horst Grossmann

Vice President Engineering

DEWALT, Richard-Klinger-StraBe 11,

D-6551O, Idstein; Germany

30.07.2014

U.K.&Ireland

230V tools

13 Amperes, in plugs

J!I\

WARNING: To reduce the risk of injU/y,

\:iiiI read the instruction manual.

Generai Power Tool Safety Warnings

A

WARNING! Read ali

safety

warnings

ill

and ali instructions. Failure to fol/ow

the wamings and instructions may result

in eleetric shock, .fireand/or serious

injury

SAVE ALL WARNINGS AND INSTRUCTlONS

FOR FUTURE REFERENCE

The term "power tool" in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless)power tool.

1) WORK AREA SAFm

a)

Keep work area clean and welllit.

Cluttered or dark areas invite accidents.

b) Do not operate power too/s in explosive

atmospheres, suchasin the presence

of

flammable /iquids,

gases

or dust. Power

too/s create sparks which may ignite the dust

or fumes. .

c) Keep chHdren and bystanders away

while operatingapower tool. Distractions

can cause you to lose control.

2)

ELEGTRIGALSAFm

a) Power

tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power toots. Unmodified plugs

and matching outlets wil/ reduce risk of

eleetric shock.

b) Avoid body contact with earthed or

grounded

surfaces

suchaspipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock ifyour

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of eleetric shock.

d) Do not abuse tne cord. Never

use

the

cord for cerrvtnq, pulling or unplugging

the power tool. Keep cord away from

heat, oit, sharp edgesormoving parts.

Damaged or entangled cords increase the

risk of electric shock.

Definitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and

pay attention to these symbols.

A

DANGER: Indicates an imminent/y

ill

hazardous situation which,ifnot avoided,

wi/l result in deathorserious injury.

A

WARNING: Indicates a potentially

ill

hazardous situalion which, if not

avoided, could resuft in death or

serious injury.

A

CAUTlON:. Indicalesapotential/y

ill

hazardous situation which, if noi

avoided, may result in minor

or

moderate injury.

NOTlCE: Indicates a practice not

relafedfopersonal injury which, if

not avoided, may result in property

damage.

&

Denotes risk of electric shock.

&

Denotes risk of fire.

EC-Declaration of Conformity

MAGHINERY DIREGTIVE

'35

CE

ANGLE GRINDERS

DWE4557, DWE4559, DWE4579, DWE4579R, DWE4597,

DWE4599

DEWALT deelares that these products described

under

Technical Data

are in compliance with:

2006/42/EC, EN 60745-1, EN 60745-2-3.

These products also comply with Directive

2014/30/EU and 2011/65/EU. For more information,

please contact DEWALTatthe following address or

refer to the back of the rnanual.

The undersigned is responsible for compilation of the

technical file and makes this declaration on behalf of

J/h~~

Page 2

ENGlISH

e)

When operatingapower tool outdoors,

use an extension

cord

suitable for

outdoor use.

Use ofacord suitable for

outdoor use reduces the risk of electric

shock.

&

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCO reduces the risk of electric

shock.

3) PERSONAL SAFETY

a)

Stay alert, watch what you are

doing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the influence of drugs, alcohol or

medication.

A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection.

Protective

equipment such as dust mask, non-skid

safety

shoes,

hard hat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

c)

Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to power

source

and/or

battery pack, Picking up or carrying the

tool.

Carrying power tools with your finger

on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before tuming the power tool ono

A

wrench orakey left attached toarotating

part of the power tool may result in personal

injury. .

e)

Do not overreach. Keep proper

footing and balance at ali times.

This

enables better control of the power tool in

unexpected situations.

&

Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts.

Loose clothes, jewellery or long hair

can be caught in moving parts.

g)

If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of dust

collection can reduce dust-related hazards.

4) POWER TOOL USE ANO CARE

a)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b) Do not use the power tool if the switch

does not

tum

it on and off.

Any power

tool that cannot be controlled with the switch

is dangerous and must be repaired.

c)

Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories, or

storing power tools.

Such preventive safety

measures reduce the risk of starting the

power tool accidentally

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power too/s are dangerous in the hands of

untrained users.

e)

Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tool's operation. If damaged, have the

power

tool repaired before use.

Many

accidents are caused by poor/y maintained

power tools.

&

Keep cutting tools sharp and c/ean.

Proper/y maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g)

Use the power tool, accessories and

tool bits

etc.,

in accordance with these

instructions taking into account the

working conditions and the work to

be performed.

Use of the power tool for

operations different from those intended

could result inahazardous situation.

5) SERVICE

a)

Have your power tool serviced by

a' qualified repair person using only

identical replacement parts.

This will

ensure that the safety of the power tool

is

maintained.

ADOITIONAL SPECIFIC SAFETY RULES

Safety Instructions for Ali Operations

a)

This power tool is intended to function as a

grinder, sander (DWE4557 and DWE4597),

wire brush, or cut-off tool. Read ali safety

warnings, instructions, illustrations and

specifications provided with this power

tool.

Fai/ure to follow ali instructions listed below

may result in electric shock, fire and/or serious

injury.

36

ENGlISH

b)

Operation such as polishing is not

recommended to be performed with this

powertool.

Operation such as sanding (DWE4559;

DWE4579; DWE4579R and DWE4599) is not

recommended to be performed with this

powertool.

Operations for which the power tool

was

not

designed may createahazard and cause

personal injury.

c)

Do not use accessories which are not

specifically designed_and recommended

by the tool manufacturer.

Just because the

accessory

can be attached to your power tool,

it does not assure safe operation.

d)

The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool.

Accessories

running faster than their rated speed can break

and fly apart.

e)

The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool.

Incorrectly sized

accessories cannot be adequately guarded or

controlled.

&

The arbour size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool.

Accessories

with arbour holes that do not match the

mounting hardware of the power tool will run

out of balance, vibrate excessively and may

cause loss of control.

g)

Do not useadamaged accessory. Before

each use

inspect

the accessory such

as abrasive wheel for chips and cracks,

backing pad for

crecks,

tear or excess

wear, wire brush for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. Atter inspecting

and instal/ing an accessory, position

yourself and bystanders away from the

piane of the rotating accessory and run

the power tool at maximum no-loed speed

for one minute.

Damaged accessories will

normally break apart during this test time.

h)

Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses.

As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping smallabrasive or

workpiece fragments.

The eye protection

must be capable of stopping flying debris

generated by various operations. The dust

mask or respirator must be capable of

filtrating particles generated by your operation.

Prolonged expoeote to high intensity noise may

cause hearing loss.

i)

Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal protective

equipment.

Fragments of workpiece or of

a

broken accessory may fly away and cause injury

beyond immediate area of operation.

j)

Hold power tool by insulated gripping

surfaces only, when performing an

.opereiion where the cutting accessory

may contact hidden wiring or its own corti.

Cutting

accessory

contactinga"live" wire may

make exposed metal parts of the power tool

"live" and could give the operator an electrical

shock.

k)

Position the cord clear of the spinning

accessory.

If you lose control, the cord may be

cut or snagged and your hand or arm may be

pulled into the spinning accessory.

I)

Never lay the power tool down unti! the

accessory has cometoa complete stop.

The spinning accessory may grab the surface

and pull the power tool out of your control.

m) Do not run the power tool while carrying

it at your side.

Accidental contact with the

spinning

accessory

could snag your clothing,

pulling the

accessory

into your body

n)

Regularly clean the power tool's air vents.

The motor's fan will draw the dust inside

the housing and excessive accumulation of

powdered metal may cause electrical hazards.

o)

Do not operate the power tool near

flammable materials.

Sparks could ignite

these materia/s.

p)

Do not use accessories that require liquid

coolants.

Using water or other liquid coolants

may result in electrocution or shock.

FURTHER SAFETY INSTRUCTIONS

FOR ALL OPERATIONS

Causes and Operator Prevention

of Kickback

Kickback isasudden reaction toapinched or

snagged rotating wheel, backing pad, brush or

any other

accessory.

Pinching or snagging

causes

rapid stalling of the rotating accessory which in turn

cause;' the uncontrolled power tool to be forced in

37

Page 3

ENGLlSH

the direclion opposite of the accessory's rotation at

the point of the bindlng.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig l17to the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward

or away from the operator, depending on direction

of the whee/'s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

glven below:

a)

Maintain a firm grip on the power tool

and position your body and arm to allo w

you to resist kickback forces. Always use

auxiliary handle, if provided, for maximum

control over kickback or torque reaction

during start up. The operator can control

torque reaction or kickback forces, If proper

precautions are taken.

b) Never piace your hand near the rotating

accessory. Accessory may klckback over your

hand.

c) Do not position your body in the area

where power tool will move if kickback

occurs. Kickback wlll propel the tool

in

direction

opposite to the wheel's movement at

tre

point

of snagging,

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory. Comers, sharp

edges or bounclng have a tendency to snag the

rotating accessory and cause loss of control or

klckback.

e) Do not attach a saw chain woodcarving

biade or toothed saw biade. Such blades

create frequent kickback and loss of control.

Safety Warnings Specific for

Grinding and Abrasive Cutting-Off

Operations

a)

Use only wheel types that are

recommended for your power tool and the

specific guard designed for the selected

wheel. Whee/s for which the power tool

was

not designed cannot be adequately guarded

and are unsafe.

b) The guard must be securely attached

to the power tool and positioned for

maximum safety, so the least amount of

wheel is exposed towards the operator. The

guard helps to protect the operator from broken

wheel fragments, accidental contact wlth wheel

and sparks that could ignite clothing.

c)

Whee/s must be used only for

recommended applications. For example:

do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for

peripheral grindlng, slde forces applied to these

whee/s may cause them to shatler.

d) Always use undamaged wheel flanges

that are of correct size and shape for

your

selected wheel. Proper wheel flanges support

the wheel thus reducing the possibility of wheel

breakage. Flanges for cut -off wheels may be

different from grinding wheel flanges.

e)

Do not use worn down wheels from larger

power too/s. Wheel intended for larger power

tool is not suitable far the hlgher speed of a

smaller tool and may burst.

Additional Safety Warnings Specific

for Abrasive Cutting-Off Operations

a) Do not ''jam'' the cut-off wheel or app/y

excessive pressure. Do not attempt

to make an excessive depth of cut.

Overstressing the wheel increases the loading

and susceptibility to twisting or binding of the

wheel in the cut and the possibility of kickback

or wheel breakage.

b) Do not position your body in line with and

behind the rotating wheel. When the wheel,

at the point of operations, is moving away from

your body, the possible kickback may propel the

spinning wheel and the power tool directiy

al

you.

c)

When wheel is binding or when

interrupting a

cut

for any reason, switch

off the power tool and hold the power tool

motionless unti! the wheel comes to a

complete stop. Never attempt to remove

the cut-off wnee! from the cut while tfÌe

wheel is in motion btherwise kickback may

occur. Invesligate and take corrective action to

eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully reenter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

38

ENGlISH

e)

Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed

under the workpiece near the line of cut and

near the edge of the workpiece on both sides ot

the wheel.

~ Use extra caution when making a "pocket

cui" into existing walls or other blind areas.

The protruding wheel may cut gas or water

pipes, electrical wiring or objects that can cause

kickback.

Safety Warnings Specific far Sanding

Operations

DWE4557, DWE4597 ONLY

a)

Do not use excessively oversized sanding

disc paper. Follow manufacturer's

recommendations, when selecting sanding

paper. Larger sanding paper extending beyond

the sanding pad presents a laceralion hazard

and may cause snagging, tearing of the disc

or kickback.

Safety Warnings Specific for Wire

Brushing Operations

a)

Be aware that wire bristles are thrown by

the brush even during ordinary operation.

Do not overstress the wires by applying

excessive loadrothe brush. The wire bristies

can easi/y penetrate lighl clothing and/or skin.

b) /f the use of a guard is recommended

for wire brushing, do not allow any

interference of the wire wheel or brush

with the guardo Wire wheel or brush may

expand in diameter due to work load and

centrifugai forces.

Additional Safety Rules far Grinders

• Threaded mounting of accessories must match

the grinder spindle thread. For accessories

mounted by flanges, the arbor hole of the

accessory must fit the locating diameter of

the flange. Accessories thal do not match the

mounling hardware of the power tool will run

out of balance, vibrate excesslvely and may

cause loss of control.

o The grinding surface of the centte depressed

whee/s must be mounled below the piane of

the guard lip. An improperly mounted wheel

that projects through the piane of the guard lip

cannot be adequately prolected.

• Do not use Type 11 (flaring cup) wheels on

this too/. Using inappropriate accessories can

result

lil

injU/y

• A/ways use side handle. Tighten the handle

securely. The side handle should always be

used to maintain contrai of the tool at ali times.

Residual Risks

In spite of the application of the relevant safety

regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are.

- Impairment of hearing.

Risk of personal injury due to f/ying particles.

- Risk of burns due to accessories becoming hot

during operation.

- Risk of personal injury due to prolonged use.

Markings on

Iool .

The following pictograms are shown on the tool:

~ Read instruction mar-ual before use.

O

Wear ear protection.

~ Wear eye protection.

DATE CODE POSITION

(FIG. 1)

The date code (u), Wllich also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX XX

Year of Manufacture

Package Contents

The package contains:

1

Angle grinder

1 Guard

1

Side

handle

1

Flange set

1

Keyless flange (DWE4579R only)

1 Spanner (DWE4579R only)

1 Two-pin spanner

1 Instruction manual

39

Page 4

ENGLlSH

• Check for damage to the tool, parts or

accessories which may have occurred during

transport.

• Take the time to thoroughly read and

understand this manual prior to operation.

Descrlptlon

(fig. 1)

A

WARNING:

Never modify the power

ill

tool or any part of

lt.

Oamage or

personal injury could result.

a. On/off switch

b. Unlocking switch

c. Spindle lock

d. Guard

e. Side handle

f.

LED indicator (DWE4579, DWE4579R,

DWE4597,DWE4599)

g. Lock-on button (DWE4579, DWE4579R,

DWE4597,DWE4599)

INTENDED USE

The DWE4557, DWE4597 heavy-duty angle grinders

have been designed for professional grinding,

cutting, sanding and wire brushing.

The DWE4559, DWE4579, DWE4599, DWE4579R

heavy-duty angle grinders have been designed for

professional grinding

'and

cutting applications.

DO NOT

use grinding wheels other than centre

depressed wheels and fìap-disk.

DO NOT

use under wet conditions or in presence

01

flammable liquids or gases.

These heavy-duty angle grinders are prolessional

power tools.

DO NOT

let children come into contact with the

tool.

Supervision is required when inexperienced

operators use this

tool,

• This product is not intended for use by persons

(including children) suffering Irom diminished

physical, sensory or mental abilities; lack

01

experience, knowledge or skills unless they are

supervised by a person responsible lor their

safety. Children should never be left alone with

this

product,

Oust Ejection System

The dust ejection system defiects debris that would

be harmful to the motor and allows cleaner air to

pass over the motor.

Overload Protection

DVVE4579,DVVE4579R,DVVE4597,DVVE4599

The power supply to the motor will be reduced in

case01motor overload. The power will retum to

normal once the tool has cooled down to suitable

operating temperature.

Electronic Clutch

DVVE4579, DVVE4579R, DVVE4597, DVVE4599

The electronic torque limiting clutch reduces the

maximum torque reaction transmitted to the

operator in case01jamming of a disco This leature

also prevents the gearing and electric motor trom

stalling. The level01the electronic clutch has been

factory set and cannot be adjusted.

LED Indicator (fig. 1)

DVVE4579, DVVE4579R, DVVE4597, DVVE4599

The LED indicator light

(D,

mounted at the top

01

the handle, acts as an alert to the activation01the

electronic leatures01the unit described above.

The light will activate and maintain a constant light

when one01the above clutch or overload leatures is

activated. Once the unit has been reset by releasing

the switch or allowing the unit to cool the light will

de-activate. Il the LED light is Ilashing constantly

please consult your local DEWALT service agent

No-volt Release Switch

DVVE4579,DVVE4579R,DVVE4597,DVVE4599

The on/off switch has a no-volt release lunction.

Il the tool should become disconnected frorn the

power source tor any reason, the switch has to be

deliberately reactivated.

Soft Start Feature

DVVE4579, DVVE4579R, DVVE4597, DVVE4599

The soft start feature allows a slow speed build-up

to avoid an initial jerk when starting. This leature is

particularly uselul when working in confined

spaces.

Auto-balance Feafure

DVVE4599 ONLY

The auto-balance leature continuously adjusts

balance to reduce the vibration of the tool when it

is running. This improves user comfort during the

operation and is particularly uselul when using the

tool for long periods01time.

40

ENGlISH

Electrical Safety

The electric motor has been designed lor one

voltage only. Always check that the power supply

corresponds to the voltage on the rating plate.

[Q]

Your DEWALT tool is double insulated in

D

accordancewith EN 60745; therelore no

earth wire i~ required. .

A

WARNING: 115

V units have to

ili

be operated viaafail-safe isolating

transformer with an earth screen

between the primary and secondary

winding.

Il the supply cord is damaged, it must be replaced

by a specially prepared cord available through the

DEWALT service organization.

Mains Plug Replacement

(U.K.&Ireland Only)

Ifanew mains plug needs to be fitted:

• 5afely dispose of the old plug.

• Connect the brown lead to the live terminai in

theplug.

• Connect the blue lead to the neutral terminai.

/;).. WARNING:

No connectionisto be

L.:J.::::.

made to the earth terminai.

Follow the fitting instructions supplied with gooa

qua/ity plugs. Recommended fuse:13A.

Using an Extension Cable

Il an extension cable is required, use an approved

3-core extension cable suitable lor the power input

01

this tool (see

Technical Data).The

minimum

conductor size is 1.5 mm'; the maximum length

is30 m.

When using a cable reel, always unwind the cable

completely.

ASSEMBLY ANO AOJUSTMENTS

A

WARNING:Toreduce the risk

ill

of serious personal injury, tum

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the tooli8off.

Attaching Side Handle (fig.

6)

A

WARNING:

Before using the tool,

ill

check that the handleistightened

seèurelr

Far grinding, screw the side handle (e)tightly into

one01the holes (q) on either side01the gear case

(lig.6).

For cutting,:screw the side handle (e)tightly into the

top hole (r) or into one of the holes (q) 011 either side

of the gear case.

Fitting and Removing a

8acking pad/Sanding

sheet

(fig. 1, 4)

1. Piace the tool on a table or flat surface, with the

guard facing

up.

2. Remove the backing flanqe (I).

3.

Piace the rubber backing pad correctly onta the

spindle (m).

4. Piace the sanding sheet on the rubber backing

pad,

5. Screw the threaded clamp nut (n) onto the

spindle. The ring on the threaded clamp nut

must

tace

towards the rubber backing pad.

6. Press the spindle lock bulton

(c)

and rotate the

spindle (m) until it locks in position.

7. Tighten the threaded clamp nut (n) with the two-

pin spanner.

8.

Release the spindle lock.

9. To remove the rubber backing pad, loosen

the threaded clamp nut (n) with the two-pin

spanner.

Fitting a Wire Cup

Brush

Screw the wire-cup brush directly onta the spindle

without the use01the spacer and threaded Ilange.

Mounting and Removing

the

Guard

(fig.

2)

A

WARNlNG: To reduce the risk

ill

of serious personal injury, tum

tool off and disconnect tool from

power source before making any

adjustments orremoving/installing

attachments or accessories.

Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the tool is off.

"" CAUTION:

Guards must be used with

/III

this grinder.

-41

Page 5

ENGLlSH

When using the DWE4557, DWE4559, DWE4579,

DWE4579R, DWE4597 or the DWE4599 grinder for

cutting metal or masonry a Type 1 guard MUST be

used. Type 1 guards are available at extra cost from

DEWALT distributors. .

NOTE:

Please refer to the

Grinding and Cutting

Accessory Chart

at the end of this section to

show other accessaries that can be used with these

9rinders.

1. Piace the angle grinder on a table, spindle up.

2

Release the clamping lock (h) and hold the

guard (d) over the tool as shown.

3.

Align the lugs (i) with the notches

U)

4. Press the guard down and rotate it to the

required posiiton.

5. If required, increase the clamping force by

tightening the screw (k).

6.

Tighten the clamping lock.

To remove the guard, release the clamping lock.

A

CAUTION: If the guard cannol be

ill

lighlened by Ihe adjusling screw, do

noi use the 1001.Toreduce Ihe risk of

personal injury, lake Ihe 1001and guard

lo

<il

service cenlre to repair or replace

Ihe guardo

fitting

and Bemovìnq

a Grinding or

Cutting

Dlsc

(fig. 1, 3-5)

'" WARNlNG: Do not useadamaged

as=

1. Piace the tool on a table, guard up.

2.

Fit the backing flange (I) carrectly onto the

spindle (m) (fig.

3).

3. Piace the disc (o) on the backing flange (I)

(fig. 4). When fitting a disc with a raised centre,

make sure that the raised centre (p) is facing the

backing flange (I).

4. Screw the threaded clamp nut (n) onto the

spindle (m) (fig. 5):

a. The ring on the threaded clamp nut (n) must

face towards the disc when fitting a grinding

disc (fig. 5A);

b. The ring on the threaded clamp nut (n) must

face away from the disc when fitting a cutting

disc (fig. 5B).

5. Press the spindle lock butto n (c) and rotate the

spindle (m) until it locks in position (fig. 4)

6. Tighten the threaded clamp nut (n) with the

two-pin spanner supplied.

NOTE:

Refer to

Fitting and RemovingaGrinding or Cutting

Disc with a Keyless Flange

when using the

DWE4579R.

7. Release the spindle lock.

8.

To remove the disc, loosen the threaded clamp

nut (n) with the two-pin spanner.

fitting and Removing a Grinding or

Cutting Disc with a Keyless flange

(fig.

7, 8)

DWE4579R ONlY

1. Perform steps 1-5 of

Fitting and Removing

a

Grinding or Cutting Disc.

2.

Tighten the threaded keyless flange (s) by

turning it by hand clockwise firmly. (Only use a

flawless keyless flange.)

a. Be sure that the printed side of the keyless

flange is facing you.

b. The arrow must point to the index mark

(fig. 7).

3.

Releas~ the spindle lock.

An undamaged keyless flange can be loosened

by hand when turning the flange ring in an anti-

clockwise direction.

NOTlCE: NEVER loosen a Ilghl keyless

flange with pliers. Always use Ihe Ihe

two-pin spanner

(I)

(fig. 8).

Prior to

Operation

• Install the guard and appropriate disc or wheel.

Do not use excessively worn discs or wheels.

o

Be sure the inner and outer flange are mounted

correctly. Follow the instructions given in the

Grinding and Cutting Accessory Chart.

• Make sure the disc or wheel rotates in the

direction of the arrows on the accessory and the

tool,

• Do not use a darnaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chipsand cracks, backing pad

for cracks, tearO(excess wear, wire brush

for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage

or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the piane of

the rotating accessory and run the power tool

at maximum no-Ioad speed far one minute.

Damaged accessories will normally break apart

during this test time.

42

ENGlISH

OPERATION

lnstructions

for Use

'" WARNING: Always observe Ihe safety

Lll

inslruclions and applicable regulations.

'" WARNING:Toreduce the risk

Lll

ot serious personal injury, turn

tool off and disconnect tool trom

power source before making any

adjustments or removing/installing

attachments or accessories. Before

reconnecting Ihe tool, depress and

release Ihe Irigger swilchloensure Ihat

Ihe 1001is off

'" WARNING:

Lll .

Ensure a/lmalerialslobe ground or

cui are secured in piace.

o

Secure and support the workpiece.

Use clamps oravicelohold and

support the workpiece

loastable

plafform. Il is importanl to clamp and

support I/le workpiece securely to

prevenl movemenl of Ihe workpiece

and loss of control. Movemenl of

the workpiece or loss of control may

create a rezera and cause personal

injury

• Support panels or any oversized

workpiece to minimize the risk

of

wheel pinching and kickback.

Large workpieces tend to sag under

Iheir own weighl. Supports must be

placed under Ihe workpiece near the

line of cut and near Ihe edge of the

workpiece on both sides of the wheel.

• Always wear regular working gloves

while operating this 1001.

• Apply only a gentle pressureloIhe

1001.Do noi exert side pressure on Ihe

disco

o Avoid overloading. Should the 1001

become hol, lei it runafew minules

under no load conditionlocool Ihe

accessory Do not touch accessories

before they have cooled. The discs

become very hol during use.

• Never work with Ihe grinding cup

withoulasuitable prolection guard in

piace.

o

Do not use Ihe power tool withacut-

off stand.

• Never use blotters logelher wilh

bonded abrasive producls.

• Be

aware, tne wheel continues

lo

•rotaie after Ihe toolsisswitched ott.

o

The 1001is noi designedlobe used

wilhagrinding cupo

o Do noi use separale reducing

bushings or adaptersloadapl large

hole abrasive wheels.

Proper

Hand

Positìon

(fig.

1)

A

WARNING: Toreduce Ihe risk of

ili

serious personal injury, ALWAYS use

proper hand posilion es shown.

A. WARNING: Toreduce Ihe risk of

ill

serious personal injury, ALWAYS hold

securely in anlicipation ofasudden

reaclion.

Proper hand position

rèquires

one hand on the side

handle (e), with the other hand Oll the body of the

tool, as shown ill figure 1.

Switchingonand

OH (fig. 1)

The on/off switch is equipped withanunlockinq

switch.

To run the tool, depress the unlocking switch (b) and

subsequently operate the on/off switch (a).

Release the uillockillg switch (b).To stop the tool,

release the switch.

tock-on Button

(fig.

1)

DWE4579, DWE4579R, DWE4597, DWE4599

For continuous operation depress the lock -Oll buttor

(g) and release the on/off trigger switch.

To stop the tool press the

on/of

switch aqain.

The lock-on button

can

be permanently removed

without cornprorrisirc compliance with regulatory

agencies shown on the tool's nameplate. Removal

of the lock pin must be done by a DEWALT Service

Centre.

Spindle

lock

(fig.

1)

The spindle lock (c) is provided to prevent the

spindle from rotating when ìnstallinq or removing

wheels. Operate the spindle lock only when the tool

is turned off, unplugged from the power supply, and

has come to a complete stop.

NOTICE: Toreduce the risk of damage

lo

the 1001,do not engage Ihe spindle

lock whi/e the 1001isoperaling. Damage

lo

Ihe 1001will resull and attached

43

Page 6

ENGlISH

accessory may spin off possib/y

resu/ting in injury.

To engage the lock, depress the spindle lock button

and rotate the spindle until you are unable to rotate

the spindle further.

Metal Applications

When using the tool in metal applications, make

sure that a residual current device (RCO) has been

inserted to avoid residual risks caused by metal

swarf.

If the power supply is shGf"OO'bithe1"ìCD;"18:R6the

tool to authorìsed OEWALT repair agent.

lA.

WARNING:

In extreme working

ili

conditions, conductive dust can

accumulate inside the machine housing

when working with metal. This can result

in the protective insulation inthe machine

becoming degraded withapotential risk

of an electrical shock.

To avoid build-up of metal swarf inside the machine,

we recommend to clear the ventilation slots on a

daily basis. Refer to

Maintenance.

Cutting Metal

For cutting with bonded abrasives, always use

a protection guarèl type 1.

When cutting, work with moderate feed, adapted to

the material being cut. Do not exert pressure onto

the cutting disc, tilt or oscillate the machine.

Do not reduce the speed of running down cutting

discs by applying sideward pressure.

The machine must always work in an upgrinding

motion. Otherwise, the danger exists of it being

pushed uncontrolled out of the cut.

When cutting profiles and square bar, it is best to

start at the smallest cross section.

Rough Grinding

Never use a cutting disc for roughing.

Always use the guard type 27.

The best roughing results are achieved when setting

the machine at an angle of 30° to 40°. Move the

machine back and forth with moderate pressure. In

this manner, the workpiece will not become too hot,

does not discolour and no grooves are formed.

Cutting Stone

The machine shall be used only for dry cutting.

For cutting stone,

itìsbest to use a diamond

cutting disco Operate the machine bnly with

additional dust protection mask.

Working Advice

Exercise caution when cutting slots in

structural walls.

Slots in structural walls are subject to the country-

specific regulations. These regulations are to be

observed under ali circumstances. Before beginning

work, consult the responsible structural engineer,

architect or the construction supervisor.

Using Flap Discs

----IA..-

WARNING: Metal d!!st build-up.

ill

Extensive use of flap discs in metal

applications can result in the increased

potential for electric shock. To reduce

this risk, insert an RCO before use

and c1ean the ventilation s/ots daily by

blowing dry compressed air into the

ventilation s/ots inaccordance with the

below maintenance instructlon»,

MAINTENANCE

Your OEWALT power tool has been designed to

operate over a long period of time with a minimum

of maintenance. Continuous satisfactory operation

depends upon proper tool care and regular cleaning.

~ WARNING: To reduce the risk

~ of serious personal injury, tum

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Before

reconnecting the tool, depress and

release the trigger switch to ensure that

the 1001is off.

Pop-off Brushes

The motor will be automatically shut off indicating

that the carbon brushes are nearly wom out and

that the tool needs servicing. The carbon brushes

are not user-serviceable. Take the tool to an

authorised OEWALT repair agent.

till

Lubrication

Your power tool requires no additional lubrication.

44

ENGlISH

---

.----

Max.

Imml

Min.

Periphical

Threaded

[mml

RotatiOfl

speed

hOlelength

D

b

d

[min."]

1m/si

Imml

180

12

M14

8,500

80

25.0

230

12

M14

8,500

80

25.0

~

Cleaning

A

WARNING:

Blow dirt end dust out of

ili

the main housing with dry air as often as

dirt is seen cottecting in and around the

air vents. Wear approveçJ eye protection

and approved dust mask when

performing this procedure.

A

WARNING:

Never use solvents or

ili

other harsh chemica/s for cteaning the

non-metallic parts of the tool. These

chemica/s may weaken the materia/s

used in these parts. Use a cloth

dampened only with water and mi/d

soap. Never let any liquid get inside the

tool; never immerse any part of the tool

intoaliquid.

Optional Accessories

A,

WARNING:

Since accessories, other

~ than those offered by

OEWALT,

have

not been tested with this product, use

of such accessories with this tool could

be hazardous. To reduce the risk of

injury, only

OEWALT,

recommended

accessories should be used with this

producI.

Consult your dealer for further information on the

appropriate accessories.

ACGESSORY GHART

Protecting the Environment

)t

Separate collection. This product must

not be disposed of with normal

. household waste.

Max.

[mml

Imml

Min.

Rotatlon

[min:'1

PeriphicalIThreaded

speed hole length

1m/si [mml

-

Should you find one day that your OEWALT product

needs replacement, or if it is of no further use to you,

do not dispose of it with household waste. Make this

product available for separate collection.

W

Separate collection of used products and

n

(9

packaging allows materials to be

\Q

recycled and used again. Re-use of

recycled materials helps prevent

environmental pollutibn and reduces

the demand for raw materials.

Local regulations may provide for separate collection

of electrical products trom the household, at

municipal waste sites or by the retailer when you

purchase a new product.

OEWALT provides a facility for the collection and

recycling of OEWALT products once they have

reached the end of their working life. To take

advantage of this service please retum your product

to any authorised repair agent who will collect them

on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your local

OEWALT office at the address indicated in this

manual. Altematively, a list of authorised OEWALT

repair agents and full details of our after-sales

service and contacts are available on the Intemet at:

www.2helpU.com.

D I b

22,231 8,500 I 80

80

45

8,500 I

80

'I

1 1 1

DWE4557 IDWE4597

jdl

b

!~:";

IsoI." I

8,;00

I

45

I

25.0

IDI

Page 7

ENGLlSH

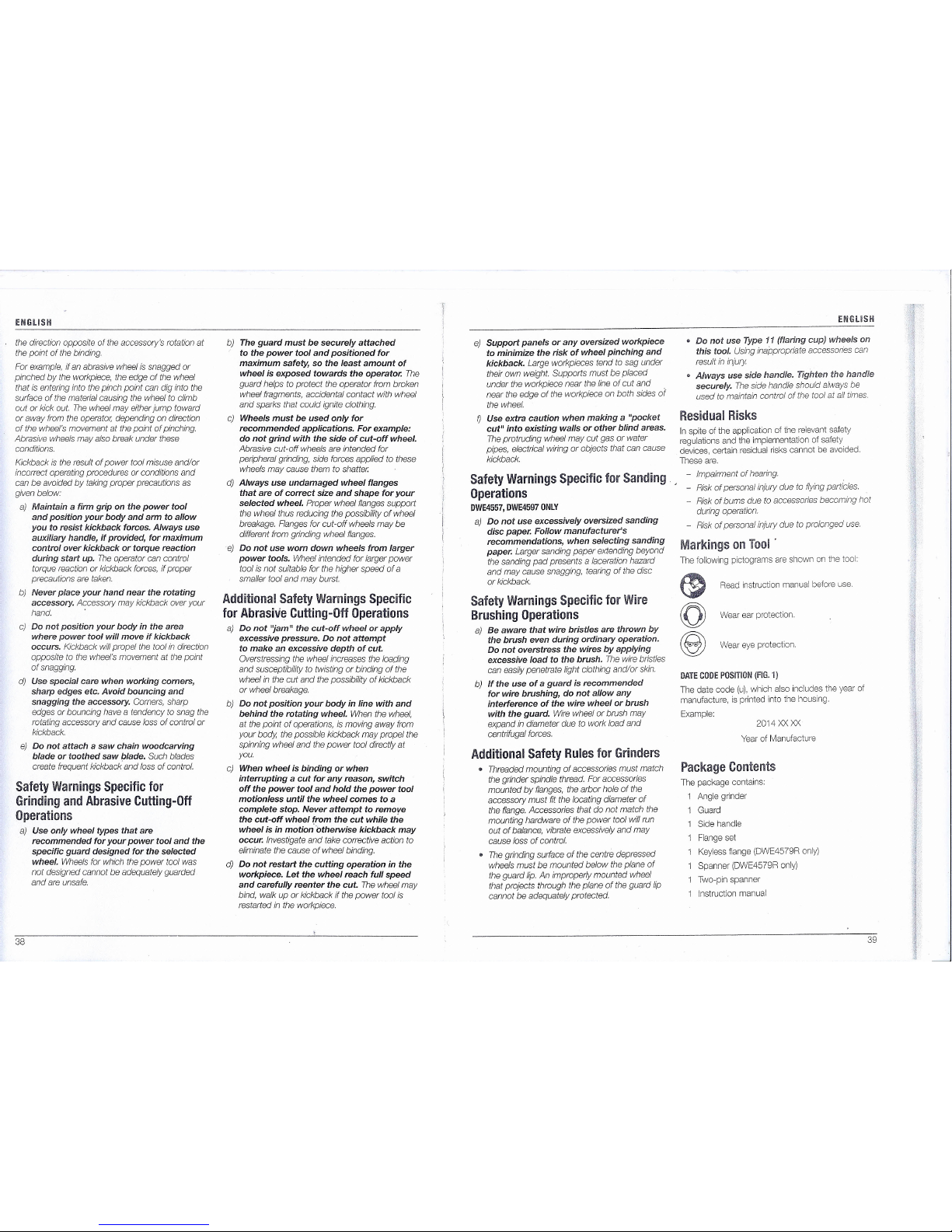

GRINDING ANO CUTTING ACCESSORV CHART

Guard Type

~

TYPE 27

GUARD

Accessory

@

Description

Depressed

centre grinding

disc

Flap wheel

Wirewheels

Wire wheels

with threaded

nut

How to Fit Grinder

~

Type 27 guard

~

Backing flange

C§:)

~=

Type 27 depressed

centre wheel

®

Threaded clamp nut

~

Type 27 guard

Wirewheel

u

Wire cup with

threaded nut

~

Type 27 guard

~

~

Wire brush

80

Backing pad!

sanding sheet

~

Type 27 guard

~

Rubber backing pad

~

Sanding disc

@

Threaded clamp nut

46

ENGLlSH

GRINDING ANO CUTTING ACCESSORV CHART

(cont.)

Gliard Type Accessory Description

How to Fit Grinder

~

9

Masonry

~

cutting disc,

-- - 'J

bonded

TYPE1

Type 1 guard

GUARD

@

Metal

cutting disc,

~

bonded

.

Backing flange .

~

(O

Diamond

cutting wheels

~

TYPE 1

Cutting wheel

GUARD

OR

®

~

Threaded clamp nut

TYPE 27

GUARD

47

~

il

Il

~

1

"

Loading...

Loading...