Page 1

Final Page size: A5 (148mm x 210mm)

DWE4347

DWE4357

DWE4369

Page 2

DeWALT

English (original instructions) 3

Copyright

B

Page 3

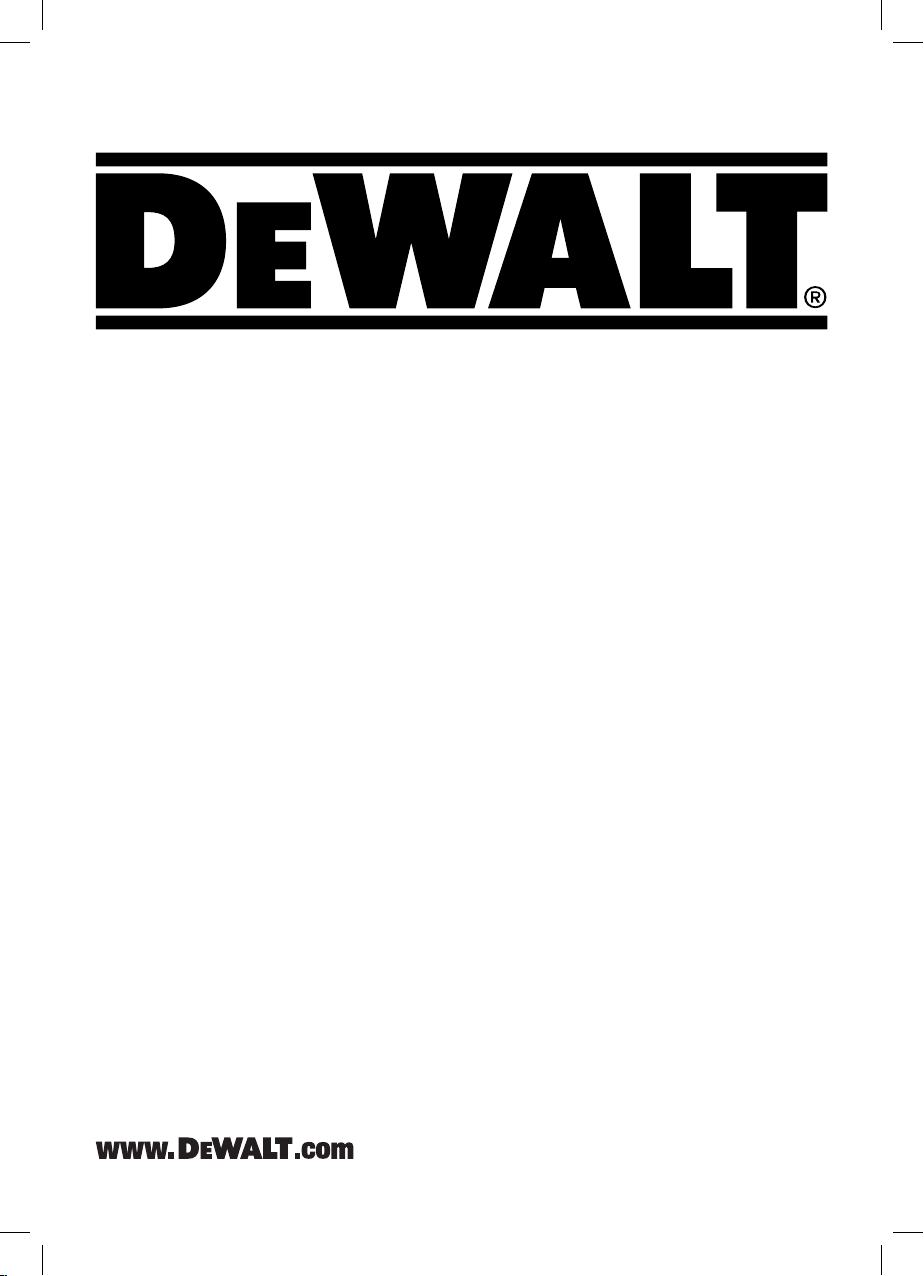

Fig. A

10

9

7

6

2

Fig. B Fig. C

4 5

8

DWE4357, DWE4369

12

3

1

20

9

1

Page 4

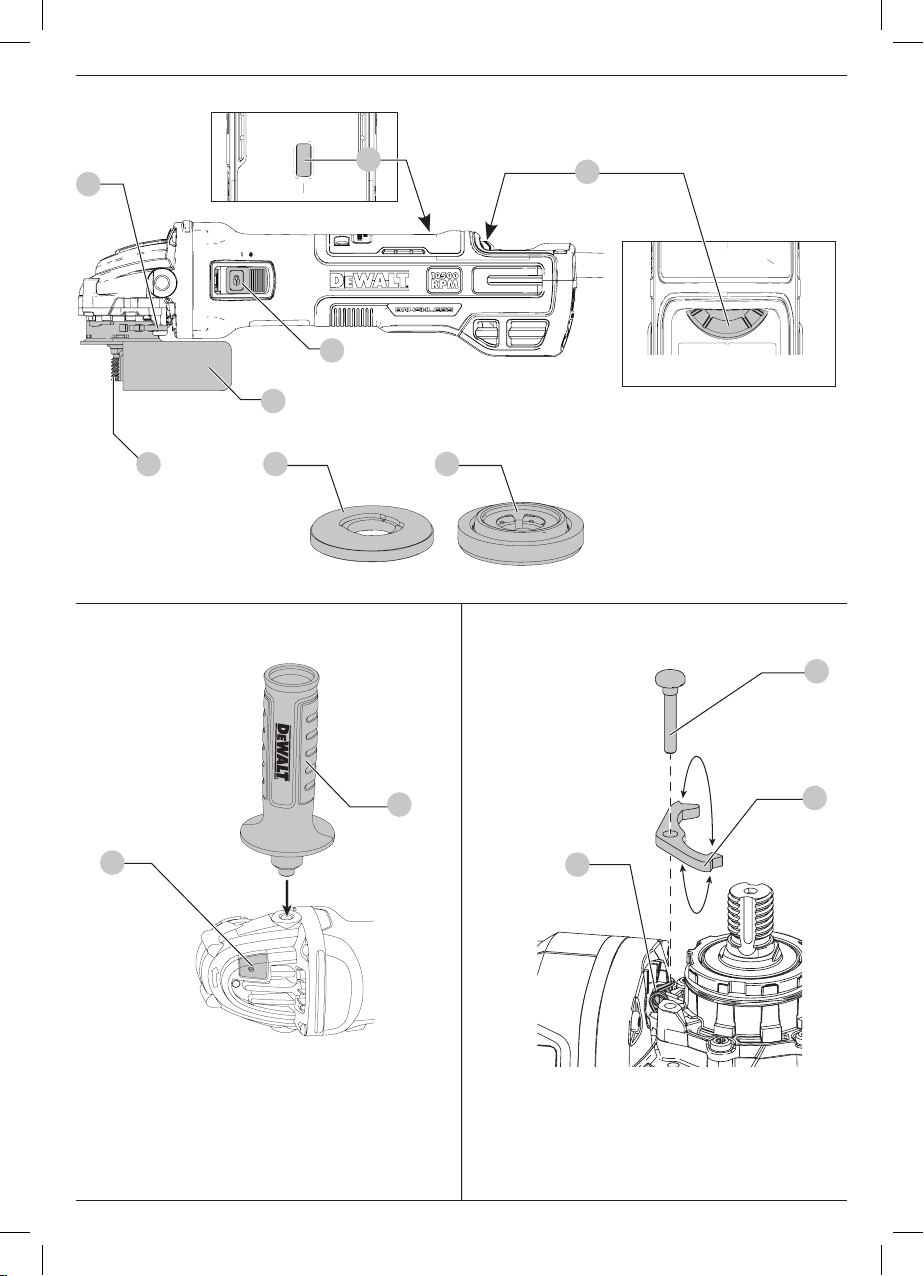

Fig. D

Fig. E

Fig. F

15

5

16

14

11

13

4

9

2

Fig. G

19

3

18

17

2

Page 5

DeWALT

SMALL ANGLE GRINDERS

DeWALT

DeWALT

DWE4347, DWE4357, DWE4369

Congratulations!

You have chosen a

most reliable partners for professional power toolusers.

Technical Data

Voltage V

UK & Ireland V

Type 1 1 1

Power input W

No-load speed min

Rated speed min

Wheel diameter mm

Wheel thickness (max) mm

Spindle diameter

Spindle length mm

Weight kg

* weight includes side handle and guard

Noise and vibration total values (triax vector sum) according to EN 60745-2-3:

LPA (emission sound pressure level) dB(A) 89 89 88

LWA (sound power level) dB(A) 100 100 99

K (uncertainty for the given sound level) dB(A) 3 3 3

tool. Years of experience, thorough product development and innovation make

DWE4347 DWE4357 DWE4369

AC

AC

-1

-1

230 230 230

115/230 115/230 115/230

1700 1700 1700

10500 2200–10500 1800–8000

10500 10500 8000

125 125 125

6.0 6.0 6.0

M14 M14 M14

18.5 18.5 18.5

2.39 2.41 2.53

one of the

ENGLISH

Surface grinding

Vibration emission value a

Uncertainty K = m/s² 1.5 1.5 1.5

Disc sanding

Vibration emission value a

Uncertainty K = m/s² 1.5 1.5 1.5

The vibration emission level given in this information sheet has

been measured in accordance with a standardised test given in

EN60745 and may be used to compare one tool with another. It

may be used for a preliminary assessment ofexposure.

WARNING: The declared vibration emission level

represents the main applications of the tool. However if

the tool is used for different applications, with different

accessories or poorly maintained, the vibration emission

may differ. This may significantly increase the exposure

level over the total workingperiod.

An estimation of the level of exposure to vibration should

also take into account the times when the tool is switched

off or when it is running but not actually doing the job.

This may significantly reduce the exposure level over the

total workingperiod.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool

h,AG

h,DS

=

=

m/s²

m/s²

5.8 5.8 4.1

2.5 2.5 3.3

and the accessories, keep the hands warm, organisation

of workpatterns.

CAUTION: Working with the wire brush or the abrasive

cutting can lead to different vibration levels!

EC-Declaration of Conformity

Machinery Directive

Small Angle Grinders

DWE4347, DWE4357, DWE4369

declares that these products described under

Technical Data are in compliance with:

2006/42/EC, EN60745-1:2009+A1:2010, EN60745-23:2011+A2:2013+A11:2014 +A12:2014+A13:2015.

3

Page 6

ENGLISH

DeWALT

DeWALT

DeWALT

These products also comply with Directive 2014/30/EU and

2011/65/EU. For more information, please contact

the following address or refer to the back of themanual.

The undersigned is responsible for compilation of the technical

file and makes this declaration on behalf of

Markus Rompel

Director Engineering

, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

02.07.2018

WARNING: To reduce the risk of injury, read the

instructionmanual.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each

signal word. Please read the manual and pay attention to

thesesymbols.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in death or

seriousinjury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or

seriousinjury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, may result in minor or

moderateinjury.

NOTICE: Indicates a practice not related to

personal injury which, if not avoided, may result in

propertydamage.

Denotes risk of electricshock.

Denotes risk offire.

General Power Tool Safety Warnings

WARNING: Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

powertool.

1) Work area safety

a ) Keep work area clean and well lit. Cluttered or dark

areas inviteaccidents.

b ) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust orfumes.

4

at

.

c ) Keep children and bystanders away while operating

a power tool. Distractions can cause you to losecontrol.

2) Electrical safety

a ) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of

electricshock.

b ) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if

your body is earthed orgrounded.

c ) Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electricshock.

d ) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electricshock.

e ) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electricshock.

f ) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electricshock.

3) Personal safety

a ) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result in

serious personalinjury.

b ) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personalinjuries.

c ) Prevent unintentional starting. Ensure the switch

is in the off position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch on

invitesaccidents.

d ) Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in

personalinjury.

e ) Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpectedsituations.

f ) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in movingparts.

Page 7

g ) If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-relatedhazards.

4) Power tool use and care

a ) Do not force the power tool. Use the correct power

tool for your application. The correct power tool

will do the job better and safer at the rate for which it

wasdesigned.

b ) Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must berepaired.

c ) Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the

risk of starting the power toolaccidentally.

d ) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrainedusers.

e ) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained powertools.

f ) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are less

likely to bind and are easier tocontrol.

g ) Use the power tool, accessories and tool bits etc.,

in accordance with these instructions taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardoussituation.

5) Service

a ) Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool ismaintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety Warnings Common for Grinding,

Sanding, Wire Brushing or Abrasive CuttingOff Operations

a ) This power tool is intended to function as a

grinder, sander, wire brush, cut-off tool. Read all

safety warnings, instructions, illustrations and

specifications provided with this power tool. Failure

to follow all instructions listed below may result in electric

shock, fire and/or seriousinjury.

b ) Operations such as polishing are not recommended

to be performed with this power tool. Operations for

which the power tool was not designed may create a

hazard and cause personalinjury.

ENGLISH

c ) Do not use accessories which are not specifically

designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safeoperation.

d ) The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated speed can

break and flyapart.

e ) The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories can not be

adequately guarded orcontrolled.

f ) Threaded mounting of accessories must match the

grinder spindle thread. For accessories mounted by

flanges, the arbour hole of the accessory must fit the

locating diameter of the flange. Accessories that do

not match the mounting hardware of the power tool will

run out of balance, vibrate excessively and may cause loss

ofcontrol.

g ) Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheel for

chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for

damage or install an undamaged accessory. After

inspecting and installing an accessory, position

yourself and bystanders away from the plane of

the rotating accessory and run the power tool at

maximum no-load speed for one minute. Damaged

accessories will normally break apart during this testtime.

h ) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety

glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of

stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping flying

debris generated by various operations. The dust mask or

respirator must be capable of filtrating particles generated

by your operation. Prolonged exposure to high intensity

noise may cause hearingloss.

i ) Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area ofoperation.

j ) Hold the power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and

could give the operator an electricalshock.

k ) Position the cord clear of the spinning accessory. If

you lose control, the cord may be cut or snagged and your

hand or arm may be pulled into the spinningaccessory.

5

Page 8

ENGLISH

l ) Never lay the power tool down until the accessory

has come to a complete stop. The spinning accessory

may grab the surface and pull the power tool out of

yourcontrol.

m ) Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into

yourbody.

n ) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause

electricalhazards.

o ) Do not operate the power tool near flammable

materials. Sparks could ignite thesematerials.

p ) Do not use accessories that require liquid coolants.

Using water or other liquid coolants may result in

electrocution orshock.

FURTHER SAFETY INSTRUCTIONS FOR ALL

OPERATIONS

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating

wheel, backing pad, brush or any other accessory. Pinching or

snagging causes rapid stalling of the rotating accessory which

in turn causes the uncontrolled power tool to be forced in the

direction opposite of the accessory’s rotation at the point of

thebinding.

For example, if an abrasive wheel is snagged or pinched by the

workpiece, the edge of the wheel that is entering into the pinch

point can dig into the surface of the material causing the wheel

to climb out or kick out. The wheel may either jump toward or

away from the operator, depending on direction of the wheel’s

movement at the point of pinching. Abrasive wheels may also

break under theseconditions.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a ) Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction

during start up. The operator can control torque reaction

or kickback forces, if proper precautions aretaken.

b ) Never place your hand near the rotating accessory.

Accessory may kickback over yourhand.

c ) Do not position your body in the area where power

tool will move if kickback occurs. Kickback will propel

the tool in direction opposite to the wheel’s movement at

the point ofsnagging.

d ) Use special care when working corners, sharp edges

etc. Avoid bouncing and snagging the accessory.

Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control

orkickback.

e ) Do not attach a saw chain woodcarving blade or

toothed saw blade. Such blades create frequent kickback

and loss ofcontrol.

Safety Warnings Specific for Grinding and

Cutting-Off Operations

a ) Use only wheel types that are recommended for your

power tool and the specific guard designed for the

selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and areunsafe.

b ) The grinding surface of centre depressed wheels

must be mounted below the plane of the guard lip.

An improperly mounted wheel that projects through the

plane of the guard lip cannot be adequatelyprotected.

c ) The guard must be securely attached to the power

tool and positioned for maximum safety, so the least

amount of wheel is exposed towards the operator.

The guard helps to protect the operator from broken wheel

fragments, accidental contact with wheel and sparks that

could igniteclothing.

d ) Wheels must be used only for recommended

applications. For example: do not grind with the side

of cut-off wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to these wheels

may cause them toshatter.

e ) Always use undamaged wheel flanges that are

of correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus reducing the

possibility of wheel breakage. Flanges for cut-off wheels

may be different from grinding wheelflanges.

f ) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not suitable

for the higher speed of a smaller tool and mayburst.

Additional Safety Warnings Specific for

Cutting-Off Operations

a ) Do not "jam" the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive depth

of cut. Overstressing the wheel increases the loading and

susceptibility to twisting or binding of the wheel in the cut

and the possibility of kickback or wheelbreakage.

b ) Do not position your body in line with and behind

the rotating wheel. When the wheel, at the point of

operations, is moving away from your body, the possible

kickback may propel the spinning wheel and the power

tool directly atyou.

c ) When wheel is binding or when interrupting a cut

for any reason, switch off the power tool and hold

the power tool motionless until the wheel comes to

a complete stop. Never attempt to remove the cutoff wheel from the cut while the wheel is in motion

otherwise kickback may occur. Investigate and take

corrective action to eliminate the cause of wheelbinding.

d ) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

6

Page 9

carefully re-enter the cut. The wheel may bind, walk up

DeWALT

DeWALT

or kickback if the power tool is restarted in theworkpiece.

e ) Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback.

Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near the line

of cut and near the edge of the workpiece on both sides

of thewheel.

f ) Use extra caution when making a “pocket cut” into

existing walls or other blind areas. The protruding

wheel may cut gas or water pipes, electrical wiring or

objects that can causekickback.

Additional Safety Instructions for Sanding

Operations

a ) Do not use excessively oversized sanding disc

paper. Follow manufacturer’s recommendations,

when selecting sanding paper. Larger sanding paper

extending beyond the sanding pad presents a laceration

hazard and may cause snagging, tearing of the disc

orkickback.

Additional Safety Instructions for Wire

Brushing Operations

a ) Be aware that wire bristles are thrown by the brush

even during ordinary operation. Do not overstress

the wires by applying excessive load to the brush.

The wire bristles can easily penetrate llight clothing and/

orskin.

b ) If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work and

centrifugalforces.

Additional Safety Rules for Grinders

a ) Do not use Type 11 (flaring cup) wheels on this tool.

Using inappropriate accessories can result ininjury.

b ) Always use side handle. Tighten the handle securely.

The side handle should always be used to maintain control

of the tool at alltimes.

Residual Risks

In spite of the application of the relevant safety regulations

and the implementation of safety devices, certain residual risks

cannot be avoided. These are:

• Impairment ofhearing.

• Risk of personal injury due to flyingparticles.

• Risk of burns due to accessories becoming hot

duringoperation.

• Risk of personal injury due to prolongeduse.

• Risk of dust from hazardoussubstances.

ENGLISH

Electrical Safety

The electric motor has been designed for one voltage only.

Always check that the power supply corresponds to the voltage

on the ratingplate.

Your

with EN60745; therefore no earth wire isrequired.

If the supply cord is damaged, it must be replaced by a

specially prepared cord available through the

serviceorganisation.

WARNING: We recommend the use of a residual current

device with a residual current rating of 30mA orless.

tool is double insulated in accordance

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the oldplug.

• Connect the brown lead to the live terminal in theplug.

• Connect the blue lead to the neutralterminal.

WARNING: No connection is to be made to the

earthterminal.

Follow the fitting instructions supplied with good quality plugs.

Recommended fuse: 13A.

Using an Extension Cable

If an extension cable is required, use an approved 3–core

extension cable suitable for the power input of this tool (see

Technical Data). The minimum conductor size is 1.5 mm2; the

maximum length is30m.

When using a cable reel, always unwind the cablecompletely.

Package Contents

The package contains:

1 Angle grinder

1 Guard

1 Side handle

1 Backing flange

1 Keyless clamp nut

1 Hex key

1 Instruction manual

• Check for damage to the tool, parts or accessories which may

have occurred duringtransport.

• Take the time to thoroughly read and understand this manual

prior tooperation.

Markings on Tool

The following pictograms are shown on the tool:

Read instruction manual beforeuse.

Wear earprotection.

7

Page 10

ENGLISH

Wear eyeprotection.

Electronic Brake

Date Code Position (Fig. D)

The date code

is printed into thehousing.

Example:

11

, which also includes the year of manufacture,

2018 XX XX

Year of Manufacture

Description (Fig. A, B)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury couldresult.

1

Spindle lock button

2

Spindle

3

Side handle

4

Backing flange

5

Clamp nut

6

Guard

7

Slider switch

8

Variable speed dial (DWE4357, DWE4369)

9

Guard release lever

10

LED Indicator

Intended Use

Your heavy-duty small angle grinder has been designed

for professional grinding, sanding, wire brushing and

cuttingapplications.

DO NOT use grinding wheels other than centre depressed

wheels and flapdiscs.

DO NOT use under wet conditions or in the presence of

flammable liquids orgases.

Your heavy-duty angle grinder is a professional powertool.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

• Young children and the infirm. This appliance is not

intended for use by young children or infirm persons

without supervision.

• This product is not intended for use by persons (including

children) suffering from diminished physical, sensory or

mental abilities; lack of experience, knowledge or skills

unless they are supervised by a person responsible for their

safety. Children should never be left alone with thisproduct.

Features

Anti-vibration Side Handle

DWE4369

The anti-vibration side handle offers added comfort by

absorbing the vibrations caused by thetool.

No-Volt

The No-volt function stops the grinder restarting without the

switch being cycled if there is a break in the powersupply.

E-Clutch

This unit is equipped with an E-Clutch (Electronic Clutch), which

in the event of a stall or wheel pinch, the unit will be shut off to

reduce the reaction torque to the user. The switch needs to be

cycled (turned on and off) to restarttool.

Brake

When the slider switch is released the motor immediately turns

off and electronically brakes stopping the accessoryquickly.

Kickback Brake™

When a severe pinch, stall, or bind-up event is sensed the

electronic brake engages with maximum force to quickly stop

the wheel, reduce the movement of the grinder, and shut the

grinder off. The switch needs to be cycled (turned off and then

on) to restarttool.

Constant Clutch™

When overloaded or stalled the motor torque is reduced. If load

is reduced the torque and RPM will increase. If the tool is stalled

for an extended amount of time it will shut-off and require the

switch to cycle torestart.

Electronic Soft Start

This feature limits the initial start up momentum, allowing the

speed to build up gradually over a 1 secondperiod.

LED Indicator (Fig. A)

The LED indicator

activity, or blink in a pattern of red light to alert you a tool

protection feature has been activated. Refer to the LED Guide at

the back of this manual for explanations of blinkpatterns.

10

will remain lit green during normal

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from power

source before making any adjustments or removing/

installing attachments or accessories. Be sure the

trigger switch is in the OFF position. An accidental start-up

can causeinjury.

Attaching Side Handle (Fig. B)

WARNING: Before using the tool, check that the handle is

tightenedsecurely.

Screw the side handle

side of the gear case. The side handle should always be used to

maintain control of the tool at alltimes.

3

tightly into one of the holes on either

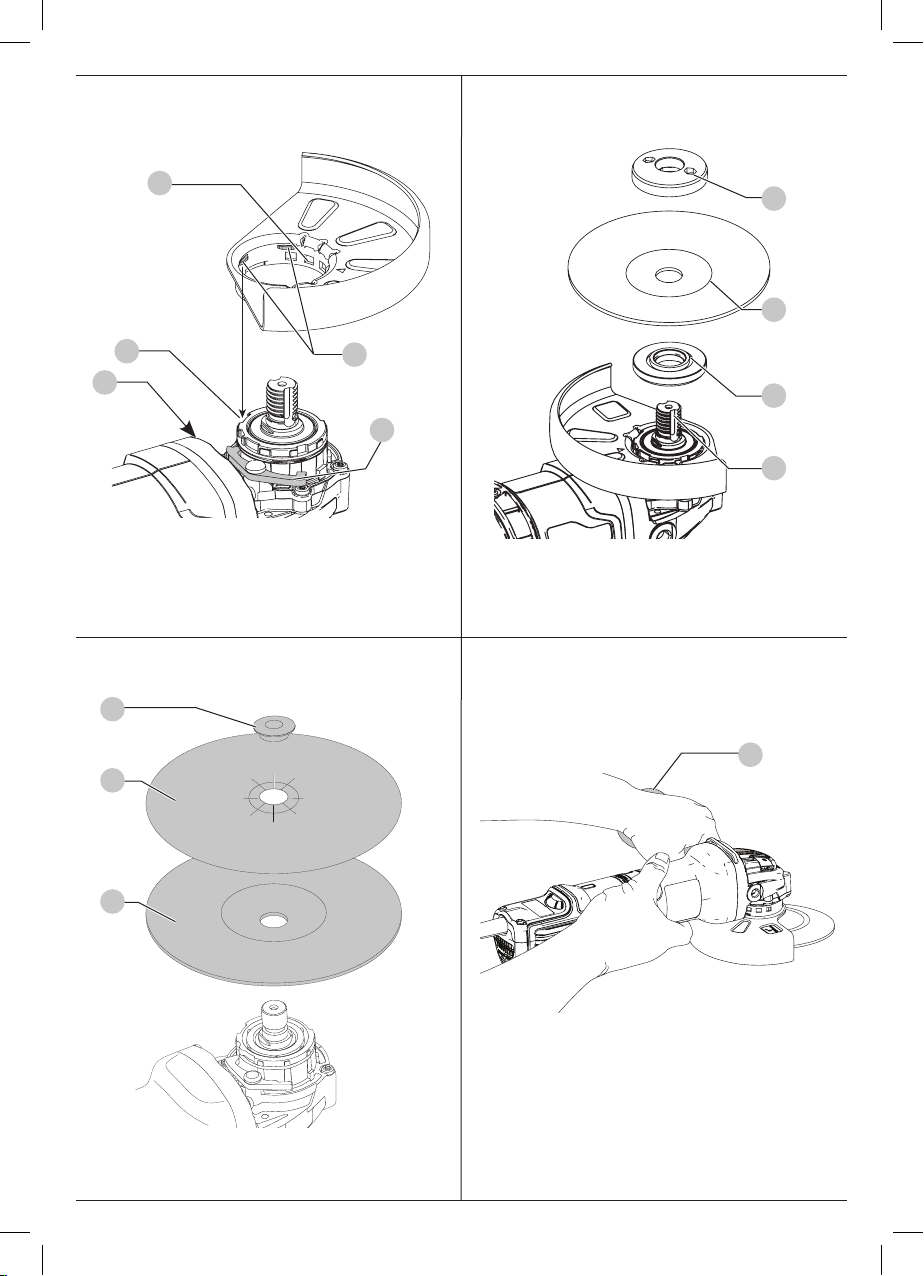

Guards

CAUTION: Guards must be used with all grinding

wheels, cutting wheels, sanding flap discs, wire

brushes, and wire wheels. Refer to Figure A to see

guards provided with the unit. Some applications may

require purchasing the correct guard from your local

dealer or authorized servicecentre.

8

Page 11

NOTE: Edge grinding and cutting can be performed with Type

27 wheels designed and specified for this purpose; 6 mm thick

wheels are designed for surface grinding while thinner Type 27

wheels need to be examined for the manufacturer's label to see

if they can be used for surface grinding or only edge grinding/

cutting. A Type 1 guard must be used for any wheel where

surface grinding is forbidden. Cutting can also be performed by

using a Type41 wheel and a Type 1guard.

NOTE: See the Grinding and Cutting AccessoryChart to select

the proper guard / accessorycombination.

Adjusting and Mounting Guard (Fig. C, D)

CAUTION: Turn unit off and unplug the tool before

making any adjustments or removing or installing

attachments oraccessories.

CAUTION: BEFORE operating the tool, identify which

guard adjustment option your tool is set to.

Adjustment Options

Two-Touch

9

engages one of

TM

15

on the guard

For guard adjustment, the guard release lever

the alignment holes

feature. Your grinder offers two options for thisadjustment.

• One-touchTM: In this position the engaging face is slanted

and will ride over to the next alignment hole when guard

is rotated in a clockwise direction (spindle facing user) but

self-locks in the anti-clockwisedirection.

• Two-touchTM: In this position the engaging face is straight

and squared off. It will NOT ride over to the next alignment

hole unless guard release lever is pressed and held while

simultaneously rotating the guard in either a clockwise or

anti-clockwise direction (spindle facing user).

Setting Guard Adjustment Options

To adjust the guard release lever

adjustmentoption:

1. Remove screw

2. Remove the guard release lever taking note of the spring

position. Choose the end of the lever for the desired

adjustment option. One-touch will use the slanted end of

the lever

collar. Two-touch will use the squaredend to engage the

alignmnet holes

3. Replace the lever, positioning the chosen end under the

spring

thespring.

4. Replace screw and torque to 2.0-3.0N-m. Ensure proper

installation with spring return function by depressing guard

release lever

15

on the guard collar using a ratcheting

TM

One-Touch

9

for desired

12

using a T20bit.

9

to engage the alignment holes

15

on the guardcollar.

20

. Ensure the lever is in proper contact with

9

.

ENGLISH

Mounting Guard (Fig. D)

CAUTION: Prior to mounting guard, ensure the screw,

lever, and spring are fitted correctly before mounting

theguard.

1. With the spindle facing the operator, press and hold the

guard release lever

2. Align the lugs

gearcase.

3. Push the guard down until the guard lugs engage and

rotate them in the groove on the gear case hub. Release the

guard releaselever.

4. To position the guard:

One-touchTM: Rotate the guard clockwise into the

desired working position. Press and hold the guard release

9

lever

release lever to rotate the guard in the anti-

clockwisedirection.

Two-touchTM: Press and hold the guard release lever

Rotate the guard clockwise or anti-clockwise into the

desired working position.

NOTE: The guard body should be positioned between

the spindle and the operator to provide maximum

operatorprotection.

The guard release lever should snap into one of the

alignment holes

the guard issecure.

5. To remove the guard, follow steps 1–3 of these instructions

inreverse.

9

.

13

on the guard with the slots

15

on the guard collar. This ensures that

14

on the

9

Flanges and Wheels

Mounting Non-Hubbed Wheels (Fig. E)

WARNING: Failure to properly seat the flange/ clamp nut/

wheel could result in serious injury (or damage to the tool

orwheel).

CAUTION: Included flanges must be used with Type 27

grinding wheels and Type41 and Type 42 cutting wheels.

See the Grinding and Cutting AccessoryChart for

moreinformation.

WARNING: A closed, two-sided cutting wheel guard is

re quired when using cutting wheels.

WARNING: Use of a damaged flange or guard or fail ure

to use proper flange and guard can re sult in injury due

to wheel breakage and wheel contact. See the Grinding

and Cutting AccessoryChart for moreinformation.

1. Place the tool on a table, guardup.

2. Install the unthreaded backing flange

the raised centre (pilot) facing the wheel.

3. Place wheel

wheel on the raised centre (pilot) of the backingflange.

4. While depressing the spindle lock button and with the

hex depressions facing away from the wheel, thread the

clampnut

slots in thespindle.

5. While depressing the spindle lock button, tighten the

clamp nut

16

against the backing flange, centreing the

5

on spindle so that the lugs engage the two

5

using a Hexwrench.

4

on spindle

2

with

.

9

Page 12

ENGLISH

6. To remove the wheel, depress the spindle lock button and

loosen the clampnut.

Mounting Sanding Backing Pads (Fig. B, F)

NOTE: Use of a guard with sanding discs that use backing pads,

often called fiber resin discs, is not required. Since a guard is

not required for these accessories, the guard may or may not fit

correctly ifused.

WARNING: Failure to properly seat the flange/ clamp nut/

wheel could result in serious injury (or damage to the tool

orwheel).

WARNING: Proper guard must be reinstalled for grinding

wheel, cutting wheel, sanding flap disc, wire brush or

wire wheel applications after sanding applications

arecomplete.

1. Place or appropriately thread backing pad

thespindle.

2. Place the sanding disc

3. While depressing spindle lock

spindle, piloting the raised hub on the clamp nut into the

centre of san ding disc and backingpad.

4. Tighten the clamp nut by hand. Then depress the spindle

lock button while turning the sanding disc until the sanding

disc and clamp nut aresnug.

5. To remove the wheel, grasp and turn the backing pad and

sanding pad while depressing the spindle lockbutton.

Mounting Wire Cup Brushes and

Wire Wheels (Fig. A, B)

WARNING: Failure to properly seat the flange/ clamp nut/

wheel could result in serious injury (or damage to the tool

orwheel).

CAUTION: To reduce the risk of personal injury,

wear work gloves when handling wire brushes and

wheels. They can becomesharp.

CAUTION: To reduce the risk of damage to the tool,

wheel or brush must not touch guard when mounted

or while in use. Undetectable damage could occur to

the accessory, causing wires to fragment from accessory

wheel orcup.

Wire cup brushes or wire wheels install directly on the threaded

spindle without the use of flanges. Use only wire brushes or

wheels provided with a M14 threaded hub. These accessories

are available at extra cost from your local dealer or authorised

servicecentre.

1. Place the tool on a table, guardup.

2. Thread the wheel on the spindle byhand.

3. Depress spindle lock button

hub of the wire wheel or brush to tighten thewheel.

4. To remove the wheel, reverse the aboveprocedure.

NOTICE: To reduce the risk of damage to the tool, properly

seat the wheel hub before turning the toolon.

18

on the backing pad

1

1

and use a wrench on the

17

on

17

, thread clamp nut

.

19

on

Prior to Operation

• Install the guard and appropriate disc or wheel. Do not use

excessively worn discs orwheels.

10

• Be sure the inner and outer flange are mounted correctly.

Follow the instructions given in the Grinding and Cutting

AccessoryChart.

• Make sure the disc or wheel rotates in the direction of the

arrows on the accessory and thetool.

• Do not use a damaged accessory. Before each use inspect

the accessory such as abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped,

inspect for damage or install an undamaged accessory. After

inspecting and installing an accessory, position yourself and

bystanders away from the plane of the rotating accessory

and run the power tool at maximum no-load speed for one

minute. Damaged accessories will normally break apart

during this testtime.

OPERATION

Instructions for Use

WARNING: Always observe the safety instructions and

applicableregulations.

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from power

source before making any adjustments or removing/

installing attachments or accessories. Be sure the

trigger switch is in the OFF position. An accidental start-up

can causeinjury.

WARNING:

• Ensure all materials to be ground or cut are secured

inplace.

• Secure and support the workpiece. Use clamps or a

vice to hold and support the workpiece to a stable

platform. It is important to clamp and support the

workpiece securely to prevent movement of the

workpiece and loss of control. Movement of the

workpiece or loss of control may create a hazard and

cause personalinjury.

• Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge of the

workpiece on both sides of thewheel.

• Always wear regular working gloves while operating

thistool.

• The gear becomes very hot duringuse.

• Apply only a gentle pressure to the tool. Do not exert

side pressure on thedisc.

• Always install the guard and appropriate disc or

wheel. Do not use excessively worn disc orwheel.

• Be sure the inner and outer flange are

mountedcorrectly.

• Make sure the disc or wheel rotates in the direction of

the arrows on the accessory and thetool.

• Avoid overloading. Should the tool become hot, let it

run a few minutes under no load condition to cool the

Page 13

accessory. Do not touch accessories before they have

cooled. The discs become very hot duringuse.

• Never work with the grinding cup without a suitable

protection guard inplace.

• Do not use the power tool with a cut-offstand.

• Never use blotters together with bonded

abrasiveproducts.

• Be aware, the wheel continues to rotate after the tools

is switchedoff.

Proper Hand Position (Fig. G)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position asshown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the side handle

with the other hand on the body of the tool, as shown in

FigureG.

3

Variable Speed Dial (Fig. A)

DWE4357, DWE4369

WARNING: Regardless of the speed setting, the rated

speed of the accessory must be at least equal to the

maximum speed marked on the powertool.

The variable speed dial offers added tool control and enables

the tool to be used at optimum conditions to suit the accessory

andmaterial.

• Turn the dial

higher speed and downwards for lowerspeed.

8

to the desired level. Turn the dial upward for

Slider Switch (Fig. A)

CAUTION: Hold the side handle and body of the tool

firmly to maintain control of the tool at start up and

during use and until the wheel or accessory stops rotating.

Make sure the wheel has come to a complete stop be fore

laying the tooldown.

NOTE: To reduce unexpected tool movement, do not switch

the tool on or off while under load conditions. Allow the grinder

to run up to full speed before touching the work surface. Lift the

tool from the surface before turning the tool off. Allow the tool

to stop rotating before putting itdown.

WARNING: Before connecting the tool to a power supply,

be sure the slider switch is in the off position by pressing

the rear part of the switch and releasing. Ensure the slider

switch is in the off position as described above after any

interruption in power supply to the tool, such as the

activation of a ground fault interrupter, throwing of a

circuit breaker, accidental unplugging, or power failure. If

the slider switch is locked on when the power is connected,

the tool will startunexpectedly.

To start the tool, slide the ON/OFF slider switch

the front of the tool. To stop the tool, release the ON/OFF

sliderswitch.

7

toward

For continuous operation, slide the switch toward the front of

the tool and press the forward part of the switch inward. To stop

the tool while operating in continuous mode, press the rear part

of the slider switch andrelease.

Spindle Lock (Fig. B)

The spindle lock

rotating when installing or removing wheels. Operate the

spindle lock only when the tool is turned off, unplugged from

the power supply, and has come to a completestop.

To engage the lock, depress the spindle lock button and rotate

the spindle until you are unable to rotate the spindlefurther.

,

Surface Grinding, Sanding and Wire

1

is provided to prevent the spindle from

NOTICE: To reduce the risk of damage to the tool, do

not engage the spindle lock while the tool is operating.

Damage to the tool will result and attached accessory

may spin off possibly resulting ininjury.

Brushing

CAUTION: Always use the correct guard per the

instructions in thismanual.

WARNING: Metal dust build-up. Extensive use of flap

discs in metal applications can result in the increased

potential for electric shock. To reduce this risk, insert an

RCD before use and clean the ventilation slots daily by

blowing dry compressed air into the ventilation slots

inaccordance with the below maintenanceinstructions.

To perform work on a the surface of a workpiece:

1. Allow the tool to reach full speed before touching the tool

to the worksurface.

2. Apply minimum pressure to the work surface, allowing

the tool to operate at high speed. Material removal rate is

greatest when the tool operates at highspeed.

Angle

3. Maintain an appropriate angle between the tool and work

surface. Refer to the chart according to particularfunction.

Function Angle

Grinding 20˚-30˚

Sanding with Flap Disc 5˚-10˚

Sanding with Backing Pad 5˚-15˚

Wire Brushing 5˚-10˚

4. Maintain contact between the edge of the wheel and the

worksurface.

- If grinding, sanding with flap discs or wire brushing

move the tool continuously in a forward and back

motion to avoid creating gouges in the worksurface.

- If sanding with a backing pad, move the tool constantly

in a straight line to prevent burning and swirling of

worksurface.

ENGLISH

11

Page 14

ENGLISH

NOTE: Allowing the tool to rest on the work surface without

moving will damage the workpiece.

5. Remove the tool from work surface before turning tool off.

Allow the tool to stop rotating before laying itdown.

CAUTION: Use extra care when working over an edge, as

a sudden sharp movement of grinder may beexperienced.

Precautions To Take When Working on a

Painted Workpiece

1. Sanding or wire brushing of lead based paint is NOT

RECOMMENDED due to the difficulty of controlling the

contaminated dust. The greatest danger of lead poisoning is

to children and pregnantwomen.

2. Since it is difficult to identify whether or not a paint contains

lead without a chemical analysis, we recommend the

following precautions when sanding any paint:

Personal Safety

1. No children or pregnant women should enter the work area

where the paint sanding or wire brushing is being done

until all clean up iscompleted.

2. A dust mask or respirator should be worn by all persons

entering the work area. The filter should be replaced daily or

whenever the wearer has difficultybreathing.

NOTE: Only those dust masks suitable for working with lead

paint dust and fumes should be used. Ordinary painting

masks do not offer this protection. See your local hardware

dealer for the proper N.I.O.S.H. approvedmask.

3. NO EATING, DRINKING or SMOKING should be done in the

work area to prevent ingesting contaminated paint particles.

Workers should wash and clean up BEFORE eating, drinking

or smoking. Articles of food, drink, or smoking should not be

left in the work area where dust would settle onthem.

Environmental Safety

1. Paint should be removed in such a manner as to minimize

the amount of dustgenerated.

2. Areas where paint removal is occurring should be sealed

with plastic sheeting of 4 milsthickness.

3. Sanding should be done in a manner to reduce tracking of

paint dust outside the workarea.

Cleaning and Disposal

1. All surfaces in the work area should be vacuumed and

thoroughly cleaned daily for the duration of the sanding

project. Vacuum filter bags should be changedfrequently.

2. Plastic drop cloths should be gathered up and disposed

of along with any dust chips or other removal debris. They

should be placed in sealed refuse receptacles and disposed

of through regular trash pick-upprocedures.

During clean up, children and pregnant women should be

kept away from the immediate workarea.

3. All toys, washable furniture and utensils used by children

should be washed thoroughly before being usedagain.

Edge Grinding and Cutting

WARNING: Do not use edge grinding/cutting wheels for

surface grinding applications because these wheels are

12

not designed for side pressures encountered with surface

grinding. Wheel breakage and injury mayresult.

CAUTION: Wheels used for edge grinding and cutting

may break or kick back if they bend or twist while the tool

is being used. In all edge grinding/cutting operations, the

open side of the guard must be positioned away from

theoperator.

NOTICE: Edge grinding/cutting with a Type27 wheel

must be limited to shallow cutting and notching—less

than 13mm in depth when the wheel is new. Reduce the

depth of cutting/notching equal to the reduction of the

wheel radius as it wears down. Refer to the Grinding and

Cutting AccessoryChart for more information. Edge

grinding/cutting with a Type 41 wheel requires usage of a

Type 1guard.

1. Allow the tool to reach full speed before touching the tool

to the worksurface.

2. Apply minimum pressure to the work surface, allowing

the tool to operate at high speed. Grinding/cutting rate is

greatest when the tool operates at highspeed.

3. Position yourself so that the open-underside of the wheel is

facing away fromyou.

4. Once a cut is begun and a notch is established in the

workpiece, do not change the angle of the cut. Changing

the angle will cause the wheel to bend and may cause

wheel breakage. Edge grinding wheels are not designed to

withstand side pressures caused bybending.

5. Remove the tool from the work surface before turning

the tool off. Allow the tool to stop rotating before laying

itdown.

Metal Applications

When using the tool in metal applications, make sure that a

residual current device (RCD) has been inserted to avoid residual

risks caused by metalswarf.

If the power supply is shut off by the RCD, take the tool to an

authorised DeWALT repairagent.

WARNING: In extreme working conditions, conductive

dust can accumulate inside the machine housing when

working with metal. This can result in the protective

insulation in the machine becoming degraded with a

potential risk of an electricalshock.

To avoid build-up of metal swarf inside the machine, we

recommend to clear the ventilation slots on a daily basis. Refer

toMaintenance.

Cutting Metal

For cutting with bonded abrasives, always use the

guardtype1.

When cutting, work with moderate feed, adapted to the

material being cut. Do not exert pressure onto the cutting disc,

tilt or oscillate themachine.

Do not reduce the speed of running down cutting discs by

applying sidewardpressure.

Page 15

The machine must always work in an upgrinding motion.

DeWALT

DeWALT

DeWALT

D

b

D

D

d

D

Otherwise, the danger exists of it being pushed uncontrolled

out of thecut.

When cutting profiles and square bar, it is best to start at the

smallest crosssection.

Rough Grinding

Never use a cutting disc forroughing.

Always use the guard type27.

The best roughing results are achieved when setting the

machine at an angle of 30° to 40°. Move the machine back and

forth with moderate pressure. In this manner, the workpiece

will not become too hot, does not discolour and no grooves

areformed.

Cutting Stone

The machine shall be used only for drycutting.

For cutting stone, it is best to use a diamond cutting disc.

Operate the machine only with additional dust protectionmask.

Working Advice

Exercise caution when cutting slots in structuralwalls.

Slots in structural walls are subject to the country-specific

regulations. These regulations are to be observed under all

circumstances.Before beginning work, consult the responsible

structural engineer, architect or the constructionsupervisor.

Optional Accessories

WARNING: Since accessories, other than those offered

by

of such accessories with this tool could be hazardous.

To reduce the risk of injury, only

accessories should be used with thisproduct.

Consult your dealer for further information on the

appropriateaccessories.

d

b

, have not been tested with this product, use

Min.

recommended

Periphical

speed

[m/s]

Max.

[mm]

[mm]

D b d

125 6 22,23 10500 80 –

125 – – 10500 80 –

75 30 M14 10500 45 20.0

Rotation

[min.–1]

ENGLISH

Threaded

hole length

[mm]

MAINTENANCE

Your

over a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper tool

care and regularcleaning.

power tool has been designed to operate

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from power

source before making any adjustments or removing/

installing attachments or accessories. Be sure the

trigger switch is in the OFF position. An accidental start-up

can causeinjury.

Protecting the Environment

recovered or recycled reducing the demand for raw materials.

Please recycle electrical products and batteries according to

local provisions. Further information is available at

www.2helpU.com.

125 12 M14 10500 80 20.0

Separate collection. Products and batteries marked

with this symbol must not be disposed of with normal

householdwaste.

Products and batteries contain materials that can be

Lubrication

Your power tool requires no additionallubrication.

Cleaning

WARNING: Blow dirt and dust out of the main housing

with dry air as often as dirt is seen collecting in and around

the air vents. Wear approved eye protection and approved

dust mask when performing thisprocedure.

WARNING: Never use solvents or other harsh chemicals

for cleaning the non-metallic parts of the tool. These

chemicals may weaken the materials used in these parts.

Use a cloth dampened only with water and mild soap.

Never let any liquid get inside the tool; never immerse any

part of the tool into aliquid.

13

Page 16

ENGLISH

LED Guide

The section provides a list of possible LED blink patterns, their

causes and corrective solutions. The user or maintenance

personnel can perform some corrective actions, and others

may require the assistance of qualified DeWALT technician or

yourdealer.

No-Volt Protection

Problem Solution

The switch is in the on position

and power has been applied. The

unit stayed off.

Problem Solution

A pinch has been sensed by

the tool and the kickback brake

has activated.

Problem Solution

The unit has shut down to prevent

permanent damage due to

overheating.

Problem Solution

The unit has been in a stalled

condition for an extended period

and it has shut down.

Problem Solution

The unit is running on a poor

quality power source like a low

quality generator. This power may

damage the tool.

Cycle the switch to restart.

Kick Back Brake

Inspect accessory for damage from

pinch and replace if necessary. Adjust

work piece and tool position as

necessary and cycle switch to restart.

Thermal Protection

Ensure intake and exhaust vents are

not blocked by users hands, clothing

or debris during use. Reduce frequency

of feathering the tool on/off and cycle

switch to restart and/or unplug the unit

and then plug it back in.

Stall/Overload Protection

Remove load from tool and cycle the

switch to restart.

Problem Power Line

Try another power source, reduce

extension cord length or reduce

equipment used on the power source

at one time.

14

Page 17

Grinding and Cutting Accessory Chart

Guard Type Accessory Description How to Fit Grinder

Depressed centre

grinding disc

ENGLISH

Type 27

Guard

Type 27 guard

Flap wheel

Backing flange

Wire wheels

Type 27 depressed

centre wheel

Threaded clamp nut

Wire wheels with

threaded nut

Type 27 guard

Wire wheel

Wire cup with

threaded nut

Type 27 guard

Backing pad/

sanding sheet

Wire brush

Type 27 guard

Rubber backing pad

Sanding disc

Threaded clamp nut

15

Page 18

ENGLISH

Grinding and Cutting Accessory Chart (cont.)

Guard Type Accessory Description How to Fit Grinder

Masonry cutting

disc, bonded

Type 1

Guard

Type 1

Guard

OR

Type 27

Guard

Type 1 guard

Metal

cutting disc,

bonded

Backing flange

Diamond cutting

wheels

Cutting wheel

Threaded clamp nut

16

Page 19

Page 20

Belgique et

Luxembourg België

en Luxemburg

DeWALT - Belgium BVBA

Egide Walschaertsstraat 16

2800 Mechelen

Tel: NL 32 15 47 37 63

Tel: FR 32 15 47 37 64

Fax: 32 15 47 37 99

www.dewalt.be

enduser.BE@SBDinc.com

Danmark DeWALT

Roskildevej 22

2620 Albertslund

Tel: 70 20 15 10

Fax: 70 22 49 10

www.dewalt.dk

kundeservice.dk@sbdinc.com

Deutschland DeWALT

Richard Klinger Str. 11

65510 Idstein

Tel: 06126-21-1

Fax: 06126-21-2770

www.dewalt.de

infodwge@sbdinc.com

Ελλάς DeWALT (Ελλάς) Α.Ε.

EΔΡΑ-ΓΡΑΦΕΙΑ : Στράβωνος 7

& Λ. Βουλιαγμένης, Γλυφάδα 166 74, Αθήνα

SERVICE : Ημερος Τόπος 2 (Χάνι Αδάμ) – 193 00 Ασπρόπυργος

Τηλ: 00302108981616

Φαξ: 00302108983570

www.dewalt.gr

Greece.Service@sbdinc.com

España DeWALT Ibérica, S.C.A.

Parc de Negocios “Mas Blau”

Edificio Muntadas, c/Bergadá, 1, Of. A6

08820 El Prat de Llobregat (Barcelona)

Tel: 934 797 400

Fax: 934 797 419

www.dewalt.es

respuesta.postventa@sbdinc.com

France DeWALT

5, allée des Hêtres

BP 30084, 69579 Limonest Cedex

Tel: 04 72 20 39 20

Fax: 04 72 20 39 00

www.dewalt.fr

scufr@sbdinc.com

Schweiz

Suisse

Svizzera

DeWALT

In der Luberzen 42

8902 Urdorf

Tel: 044 - 755 60 70

Fax: 044 - 730 70 67

www.dewalt.ch

service@rofoag.ch

Ireland DeWALT

Calpe House Rock Hill

Black Rock, Co. Dublin

Tel: 00353-2781800

Fax: 00353-2781811

www.dewalt.ie

Italia DeWALT

via Energypark

20871 Vimercate (MB), IT

Tel: 800-014353

39 039 9590200

Fax: 39 039 9590313

www.dewalt.it

Nederlands DeWALT Netherlands BV

Holtum Noordweg 35

6121 RE BORN, Postbus 83, 6120 AB BORN

Tel: 31 164 283 063

Fax: 31 164 283 200

www.dewalt.nl

Norge DeWALT

Postboks 4613, Nydalen

0405 Oslo

Tel: 45 25 13 00

Fax: 45 25 08 00

www.dewalt.no

kundeservice.no@sbdinc.com

Österreich DeWALT

Werkzeug Vertriebsges m.b.H

Oberlaaerstrasse 248, A-1230 Wien

Tel: 01 - 66116 - 0

Fax: 01 - 66116 - 614

www.dewalt.at

service.austria@sbdinc.com

Portugal DeWALT Limited, SARL

Centro de Escritórios de Sintra Avenida

Almirante Gago Coutinho, 132/134, Edifício 14

2710-418 Sintra

Tel: 214 66 75 00

Fax: 214 66 75 80

www.dewalt.pt

resposta.posvenda@sbdinc.com

Suomi DeWALT

PL 47

00521 Helsinki

Puh: 010 400 4333

Faksi: 0800 411 340

www.dewalt.fi

asiakaspalvelu.fi@sbdinc.com

Sverige DeWALT

Box 94

431 22 Mölndal

Tel: 031 68 61 60

Fax: 031 68 60 08

www.dewalt.se

kundservice.se@sbdinc.com

Türkiye Sanayi ve Ticareet Bakanlığı tebliğince kullanim ömrü 7 yıldır.

Stanley Black & Decker Turkey Alet Üretim San. Tic. Ltd.Şti.

Kozyataği Mh Değirmen Sk.

Nida Kule No: 18 Kat: 6, 34742

Kadıköy, İstanbul, Türkiye

Tel: 0212 533 52 55

Faks: 0212 533 10 05

www.dewalt.com.tr

United

Kingdom

DeWALT, 210 Bath Road;

Slough, Berks SL1 3YD

Tel: 01753-567055

Fax: 01753-572112

www.dewalt.co.uk

emeaservice@sbdinc.com

Australia DeWALT

810 Whitehorse Road Box Hill

VIC 3103 Australia

Tel: Aust 1800 338 002

Tel: NZ 0800 339 258

www.dewalt.com.au

www.dewalt.co.nz

Middle East Africa DeWALT

P.O. Box - 17164,

Jebel Ali Free Zone (South), Dubai, UAE

Tel: 971 4 812 7400

Fax: 971 4 2822765

www.dewalt.ae

Service.MEA@sbdinc.com

N629371

18

07/18

Loading...

Loading...