Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DeWALT

Instruction Manual

Guide D’utilisation

Manual de instrucciones

DWE43066, DWE43066N, DWE43113, DWE43115,

DWE43115N, DWE43116

Heavy-Duty Small Angle Trigger Switch Grinder

Petite meuleuse angulaire industrielle à gâchette

Esmeriladora angular pequeña con interruptor de gatillo para

trabajos pesados

final page size: 8.5 x 5.5 in

Page 2

ENGLISH

English (original instructions) 1

Français (traduction de la notice d’instructions originale) 15

Español (traducido de las instrucciones originales) 30

Page 3

ENGLISH

DeWALT

DeWALT

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderateinjury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in propertydamage.

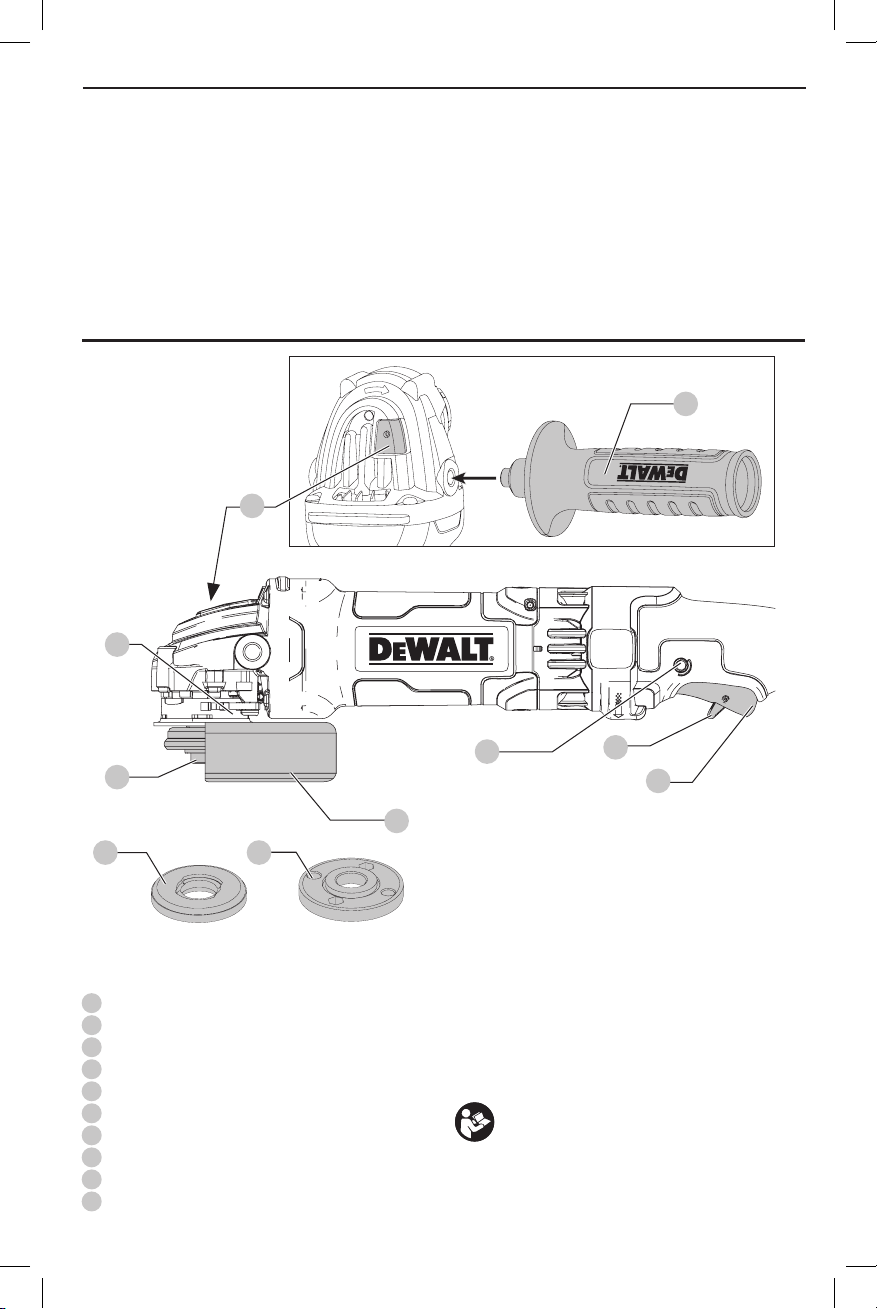

Fig. A

5

2

7

1

43

1

Spindle

2

Spindle lock button

3

Unthreaded backing flange

4

Threaded locking flange

5

Side handle

6

Guard

7

Guard release lever

8

Trigger switch

9

Trigger lock off

10

Lock-on button (DWE43066, DWE43113, DWE43115,

DWE43116)

10

6

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

WARNING: To reduce the risk of injury, read the

instructionmanual.

If you have any questions or comments about this or

any

1-800-4-

tool, call us toll free at:

9

8

(1-800-433-9258).

1

Page 4

ENGLISH

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

seriousinjury.

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

powertool.

1) Work Area Safety

a ) Keep work area clean and well lit. Cluttered or dark

areas inviteaccidents.

b ) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust orfumes.

c ) Keep children and bystanders away while

operating a power tool. Distractions can cause you

to losecontrol.

2) Electrical Safety

a ) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electricshock.

b ) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed orgrounded.

c ) Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electricshock.

d ) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electricshock.

e ) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electricshock.

f ) If operating a power tool in a damp location

is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electricshock.

3) Personal Safety

a ) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personalinjury.

b ) Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personalinjuries.

c ) Prevent unintentional starting. Ensure the

switch is in the off position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

finger on the switch or energizing power tools that

have the switch on invitesaccidents.

d ) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personalinjury.

e ) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpectedsituations.

f ) Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry or

long hair can be caught in movingparts.

g ) If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-relatedhazards.

4) Power Tool Use and Care

a ) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it wasdesigned.

b ) Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

berepaired.

c ) Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power

toolaccidentally.

d ) Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrainedusers.

e ) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are

caused by poorly maintained powertools.

f ) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier tocontrol.

g ) Use the power tool, accessories and tool bits, etc.

in accordance with these instructions, taking

2

Page 5

into account the working conditions and the

work to be performed. Use of the power tool for

operations different from those intended could result

in a hazardoussituation.

5) Service

a ) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool ismaintained.

SAFETY INSTRUCTIONS FOR ALL

OPERATIONS

Safety Warnings Common for Grinding,

Sanding, Wire Brushing, Polishing or

Abrasive, Cutting-Off Operations

a ) This power tool is intended to function as a

grinder, sander, wire brush, polisher or cut-off

tool. Read all safety warnings, instructions,

illustrations and specifications provided with

this power tool. Failure to follow all instructions

listed below may result in electric shock, fire and/or

seriousinjury.

b ) Do not use accessories which are not specifically

designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safeoperation.

c ) The rated speed of the accessory must be at least

equal to the maximum speed marked on the

power tool. Accessories running faster than their

rated speed can break and flyapart.

d ) The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories cannot

be adequately guarded orcontrolled.

e ) Threaded mounting of accessories must match

the grinder spindle thread. For accessories

mounted by flanges, the arbor hole of the

accessory must fit the locating diameter of the

flange. Accessories that do not match the mounting

hardware of the power tool will run out of balance,

vibrate excessively and may cause loss ofcontrol.

f ) Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged

accessories will normally break apart during this

testtime.

ENGLISH

g ) Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable

of stopping flying debris generated by various

operations. The dust mask or respirator must

be capable of filtrating particles generated by

your operation. Prolonged exposure to high intensity

noise may cause hearingloss.

h ) Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area ofoperation.

i ) Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact hidden

wiring or its own cord. Cutting accessory contacting

a “live” wire may make exposed metal parts of the

power tool “live” and could give the operator an

electricshock.

j ) Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the

spinningaccessory.

k ) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and pull the

power tool out of yourcontrol.

l ) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into yourbody.

m ) Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause

electricalhazards.

n ) Do not operate the power tool near flammable

materials. Sparks could ignite thesematerials.

o ) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution orshock.

p ) Do not use Type 11 (flaring cup) wheels on this

tool. Using inappropriate accessories can result

ininjury.

q ) Always use side handle. Tighten the handle

securely. The side handle should always be used to

maintain control of the tool at alltimes.

r ) When starting the tool with a new or

replacement wheel, or a new or replacement

wire brush installed, hold the tool in a well

protected area and let it run for one minute. If

the wheel has an undetected crack or flaw, it

should burst in less than one minute. If the wire

brush has loose wires, they will be detected.

3

Page 6

ENGLISH

Never start the tool with a person in line with the

wheel. This includes theoperator.

s ) Use of accessories not specified in this manual

is not recommended and may be hazardous.

Use of power boosters that would cause the tool

to be driven at speeds greater than its rated speed

constitutesmisuse.

t ) Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against your body leaves

it unstable and may lead to loss ofcontrol.

u ) Avoid bouncing the wheel or giving it rough

treatment. If this occurs, stop the tool and inspect the

wheel for cracks orflaws.

v ) Always handle and store wheels in a carefulmanner.

w ) Do not operate this tool for long periods of time.

Vibration caused by the operating action of this

tool may cause permanent injury to fingers,

hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily

time ofuse.

x ) Air vents often cover moving parts and should be

avoided. Loose clothes, jewelry or long hair can be

caught in movingparts.

Causes and Operator Prevention

of Kickback

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory.

Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool to

be forced in the direction opposite of the accessory’s rotation

at the point of thebinding.

For example, if an abrasive wheel is snagged or pinched by

the workpiece, the edge of the wheel that is entering into the

pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either jump

toward or away from the operator, depending on direction

of the wheel’s movement at the point of pinching. Abrasive

wheels may also break under theseconditions.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

a ) Maintain a firm grip on the power tool and

position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback or

torque reaction during start up. The operator can

control torque reaction or kickback forces, if proper

precautions aretaken.

b ) Never place your hand near the rotating

accessory. Accessory may kickback over yourhand.

c ) Do not position your body in the area where

power tool will move if kickback occurs. Kickback

will propel the tool in direction opposite to the wheel’s

movement at the point ofsnagging.

d ) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory and cause

loss of control orkickback.

e ) Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create frequent

kickback and loss ofcontrol.

Safety Warnings Specific for Grinding and

Abrasive Cutting-Off Operations

a ) Use only wheel types that are recommended for

your power tool and the specific guard designed

for the selected wheel. Wheels for which the power

tool was not designed cannot be adequately guarded

and areunsafe.

b ) The grinding surface of center depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel that

projects through the plane of the guard lip cannot be

adequatelyprotected.

c ) The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed towards

the operator. The guard helps to protect the operator

from broken wheel fragments, accidental contact with

wheel and sparks that could igniteclothing.

d ) Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied to

these wheels may cause them toshatter.

e ) Always use undamaged wheel flanges that

are of correct size and shape for your selected

wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheelflanges.

f ) Do not use worn down wheels from larger power

tools. Wheel intended for larger power tool is not

suitable for the higher speed of a smaller tool and

mayburst.

Additional Safety Warnings Specific for

Abrasive Cutting-Off Operations

a ) Do not “jam” the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases the

loading and susceptibility to twisting or binding of

the wheel in the cut and the possibility of kickback or

wheelbreakage.

b ) Do not position your body in line with and

behind the rotating wheel. When the wheel, at the

point of operation, is moving away from your body,

the possible kickback may propel the spinning wheel

and the power tool directly atyou.

4

Page 7

c ) When wheel is binding or when interrupting

a cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheelbinding.

d ) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted in

theworkpiece.

e ) Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under

their own weight. Supports must be placed under

the workpiece near the line of cut and near the edge of

the workpiece on both sides of thewheel.

f ) Use extra caution when making a “pocket

cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water pipes,

electrical wiring or objects that can causekickback.

Safety Warnings Specific for Sanding

Operations

a ) Do not use excessively oversized sanding disc

paper. Follow manufacturers recommendations,

when selecting sanding paper. Larger sanding

paper extending beyond the sanding pad presents a

laceration hazard and may cause snagging, tearing of

the disc orkickback.

Safety Warnings Specific for Polishing

Operations

a ) Do not allow any loose portion of the polishing

bonnet or its attachment strings to spin freely.

Tuck away or trim any loose attachment strings.

Loose and spinning attachment strings can entangle

your fingers or snag on theworkpiece.

Safety Warnings Specific for Wire

Brushing Operations

a ) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive load

to the brush. The wire bristles can easily penetrate

light clothing and/orskin.

b ) If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work and

centrifugalforces.

c ) Safety goggles or safety glasses with side shields

and a full face shield compliant with ANSI Z87.1

MUST be worn by the operator and others that

are within 50' (15.2 m) of the use of thisproduct.

ENGLISH

Additional Safety Information

WARNING: ALWAYS use safety glasses. Everyday

eyeglasses are NOT safety glasses. Also use face or

dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETYEQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratoryprotection.

WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to the State

of California to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicalsare:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemicallytreatedlumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specially designed to filter out microscopicparticles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmfulchemicals.

WARNING: Use of this tool can generate and/

or disperse dust, which may cause serious and

permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure. Direct particles

away from face andbody.

WARNING: Always wear proper personal hearing

protection that conforms to ANSI S12.6 (S3.19)

during use. Under some conditions and duration

of use, noise from this product may contribute to

hearingloss.

CAUTION: When not in use, place tool on its side

on a stable surface where it will not cause a

tripping or falling hazard. Some tools with large

battery packs will stand upright on the battery pack

but may be easily knockedover.

• Air vents often cover moving parts and should be

avoided. Loose clothes, jewelry or long hair can be

caught in movingparts.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The smaller

the gauge number of the wire, the greater the capacity

of the cable, that is, 16 gauge has more capacity than 18

gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using

more than one extension to make up the total length,

be sure each individual extension contains at least the

5

Page 8

ENGLISH

DeWALT

minimum wire size. The following table shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

lower the gauge number, the heavier thecord.

Minimum Gauge for Cord Sets

Volts

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Ampere Rating

More

Not

Than

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz ....................... hertz

min ..................... minutes

or DC ......direct current

...................... Class I Construction

…/min .............. per minute

BPM .................... beats per minute

IPM ..................... impacts per minute

RPM .................... revolutions per

sfpm ................... surface feet per

SPM .................... strokes per minute

A ......................... amperes

W ........................ watts

or AC ........... alternating current

Total Length of Cord in Feet

American Wire Gauge

(grounded)

minute

minute

no ....................... no load speed

n ......................... rated speed

(meters)

or AC/DC .... alternating or

direct current

...................... Class II

Construction

(double insulated)

...................... earthing terminal

..................... safety alert symbol

..................... visible radiation

..................... wear respiratory

protection

..................... wear eye

protection

..................... wear hearing

protection

..................... read all

documentation

Lanyard Connection (Fig. B)

DWE43066N, DWE43115N

Safety Warnings Specific for Use At Height

WARNING: If the tool is dropped for any reason the

lanyard connection must be inspected and properly

serviced prior to re-use. The lanyard connection is

designed to stretch to absorb the shock of a drop.

Any permanent stretch to the connection exposing

the red marked internal coils indicates it has been

compromised and must be serviced prior to reuse.

• Always keep the tool and accessories tethered when

working "at height". (Maximum lanyard length:

6.5 ft [2m])

• Use only with lanyards appropriate for this tool type and

rated for at least 6.0 lbs (2.72 Kg).

• Crush, cut or entanglement hazard. Do not use near

moving parts, mechanisms or runningmachinery.

• Do not anchor the tool lanyard to anything on your body.

Anchor to a rigid structure that can withstand the forces

of a droppedtool.

• Make sure the lanyard is properly secure at each end prior

touse.

• Inspect tool and lanyard before each use for damage and

proper function (including fabric and stitching). Do not

use if damaged or not functioningproperly.

• Do not alter the lanyard connection or use in a manner

other than as instructed in thismanual.

• Only attach tool to a lanyard with a locking carabiner. Do

not attach by looping or knotting the lanyard. Do not use

rope orcord.

• Electrical shock hazard. Be sure power is off when working

in high voltage areas. Some lanyards areconductive.

• Dropped tools will swing on the lanyard, which could

cause injury or loss ofbalance.

• Do not carry the tool by attachment device or thelanyard.

• Do not attach more than one tool to eachlanyard.

• Only use appropriate

NEVER modify tools to create attachmentpoints.

• Only transfer the tool between hands while properly

balanced in a stableorientation.

• Do not attach lanyards to tool in a way that keeps guards,

switches or lock-offs from operatingproperly.

• Avoid getting tangled in thelanyard.

• Keep lanyard away from the cutting area of thetool.

• Do not use lanyards or attachment devices to get

additional leverage from thetool.

• Do not use for personal fallprotection.

• Falling object hazard! Only change accesories and

attachments where a dropped object won't cause a

hazard below you. Consult your AHJ or site supervisor for

procedures for working atheight.

• Use multi-action and screw gate type carabineers. Do not

use single action spring clip carabineers.

The lanyard connection

competent personnel, who are trained and knowledgeable

regarding working with tools in and around machinery and

"at height".A lanyard connection may be added to certain

models by an authorized service center.

Fig. B

brand attachment point.

21

is intended for use by

21

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Motor

Be sure your power supply agrees with the nameplate

marking. Voltage decrease of more than 10% will cause loss

6

Page 9

of power and overheating.

DeWALT

if this tool does not operate, check power supply.

tools are factory tested;

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Refer to Figure A at the beginning of this manual for a

complete list ofcomponents.

Intended Use

Your heavy-duty small angle grinder has been designed

for professional grinding, sanding, wire brush, and cut-off

applications at various work sites (i.e., construction sites).

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

Your heavy-duty small angle grinders is a professional

power tool. DO NOT let children come into contact with the

tool. Supervision is required when inexperienced operators

use thistool.

Features

(DWE43113, DWE43116 excluded)

E-switch Protection™

The ON/OFF trigger switch has a no-volt release function.

In the event of a power outage or other unexpected shut

down, the trigger switch will need to be cycled (turned on

and off) to restarttool.

E-Clutch™

This unit is equipped with an E-Clutch™ (Electronic Clutch),

which in the event of a high-load or wheel pinch, the

unit will be shut off to reduce the reaction torque to the

user. The switch needs to be cycled (turned on and off) to

restarttool.

Power-OFF™ Overload Protection

The power supply to the motor will be reduced in case

of motor overload. With continued motor overload, the

tool will shut off. The switch needs to be cycled (turned

on and off) to restart tool. The tool will power off each

time the current load reaches the overload current value

(motor burn-up point). If continued overload shutdowns

occur, apply less force/weight on the tool until the tool will

function without the overloadengaging.

Electronic Soft Start

This feature limits the initial start up momentum, allowing

the speed to build up gradually over a 1 secondperiod.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

ENGLISH

Screw the side handle

either side of the gear case. The side handle should always

be used to maintain control of the tool at alltimes.

5

tightly into one of the holes on

Guards

CAUTION: Guards must be used with all grinding

wheels, cutting wheels, sanding flap discs,

wire brushes, and wire wheels. The tool may

be used without a guard only when sanding with

conventional sanding discs. Refer to Figure A to see

guards provided with the unit. Some applications may

require purchasing the correct guard from your local

dealer or authorized service center.

NOTE: Edge grinding and cutting can be performed with

Type 27 wheels designed and specified for this purpose;

6.35 mm thick wheels are designed for surface grinding

while thinner Type 27 wheels need to be examined for

the manufacturer's label to see if they can be used for

surface grinding or only edge grinding/cutting. A Type 1

guard must be used for any wheel where surface grinding

is forbidden. Cutting can also be performed by using a

Type41 wheel and a Type 1guard.

NOTE: See the Accessories Chart to select the proper guard

/ accessory combination.

Adjusting and Mounting

Guard (Fig. C, D)

CAUTION: Turn unit off and unplug the tool before

making any adjustments or removing or installing

attachments or accessories.

CAUTION: BEFORE operating the tool, identify which

guard adjustment option your tool is set to.

Adjustment Options

For guard adjustment, the guard release lever

one of the alignment holes

ratcheting feature. Your grinder offers two options for this

adjustment.

• One-touch

is slanted and will ride over to the next alignment

hole when guard is rotated in a clockwise direction

(spindle facing user) but self-locks in the counterclockwisedirection.

• Two-touch

straight and squared off. It will NOT ride over to the next

alignment hole unless guard release lever is pressed and

held while simultaneously rotating the guard in either

a clockwise or counter-clockwise direction (spindle

facinguser).

TM

TM

13

on the guard collar using a

: In this position the engaging face

: In this position the engaging face is

7

engages

Attaching Side Handle (Fig. A)

WARNING: Before using the tool, check that the

handle is tightenedsecurely.

7

Page 10

ENGLISH

Fig. C

11

7

12

desired working position. Press and hold the guard

release lever

clockwise direction.

Two-touch

lever

clockwise into the desired working position.

NOTE: The guard body should be positioned between

the spindle and the operator to provide maximum

operator protection.

The guard release lever should snap into one of the

alignment holes

that the guard is secure.

5. To remove the guard, follow steps 1–3 of these

instructions in reverse.

Fig. D

7

to rotate the guard in the counter-

TM

: Press and hold the guard release

7

. Rotate the guard clockwise or counter-

13

on the guard collar. This ensures

13

TM

One-Touch

Setting Guard Adjustment Options

To adjust the guard release lever

adjustmentoption:

1. Remove screw

2. Remove the guard release lever taking note of the

spring position. Choose the end of the lever for the

desired adjustment option. One-touch will use the

slanted end of the lever

holes

squaredend to engage the alignment holes

guard collar.

3. Replace the lever, positioning the chosen end under the

spring

thespring.

4. Replace screw and torque to 2.0-3.0N-m. Ensure proper

installation with spring return function by depressing

guard release lever

Mounting Guard (Fig. D)

CAUTION: Prior to mounting guard, ensure the screw,

lever, and spring are fitted correctly before mounting

theguard.

1. With the spindle facing the operator, press and hold the

guard release lever

2. Align the lugs

the gearcase cover.

3. Push the guard down until the guard lugs engage

and rotate them in the groove on the gear case cover.

Release the guard release lever.

4. To position the guard:

One-touch

8

11

using a T20 bit.

13

on the guard collar. Two-touch will use the

12

. Ensure the lever is in proper contact with

14

on the guard with the slots

TM

: Rotate the guard clockwise into the

7

7

to engage the alignment

7

.

7

.

Two-Touch

for desired

TM

13

on the

15

on

15

14

7

Flanges and Wheels

CAUTION: Turn unit off and unplug the tool before

making any adjustments or removing or installing

attachments or accessories.

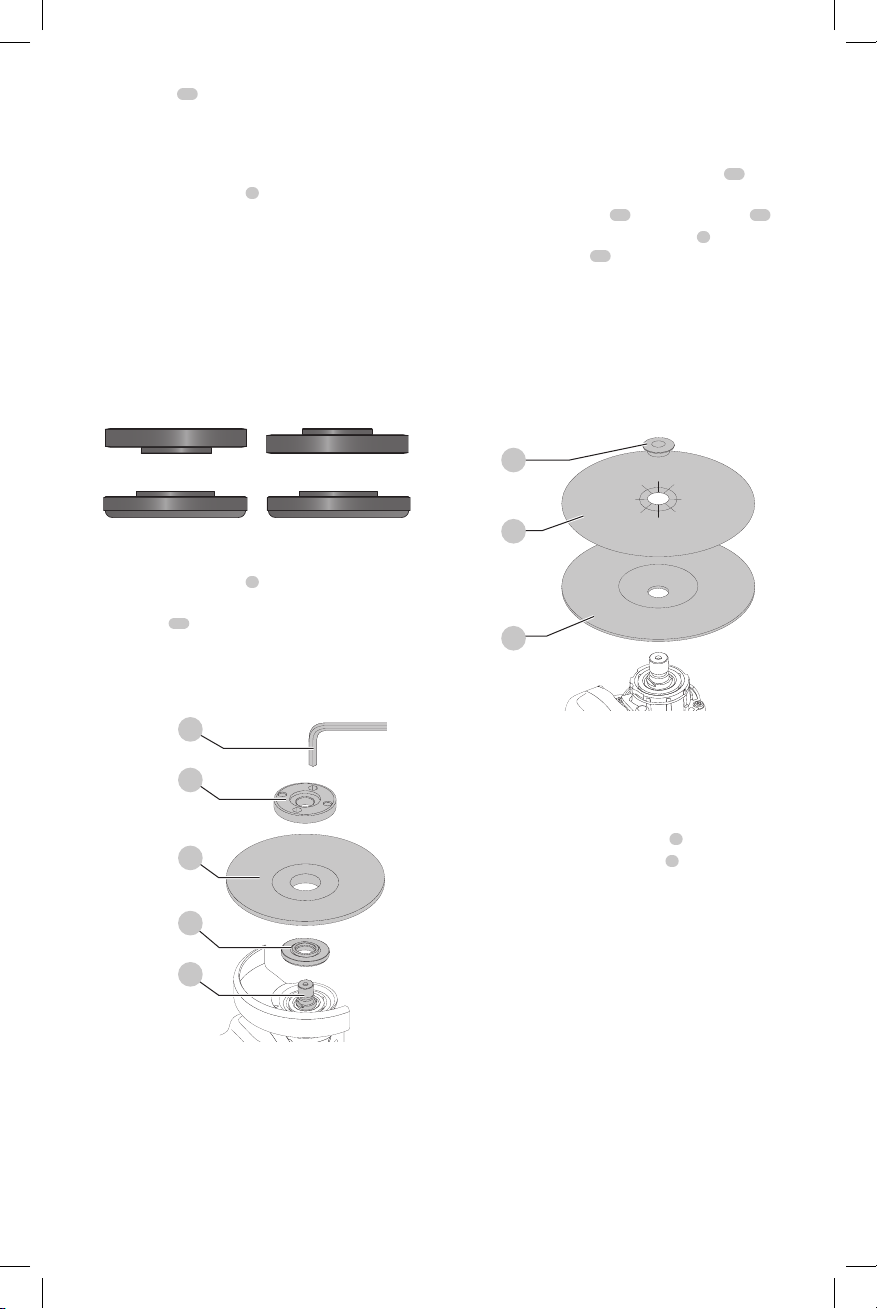

Mounting Non-Hubbed Wheels (Fig. E, F)

WARNING: Failure to properly seat the flanges and/or

wheel could result in serious injury (or damage to the

tool or wheel).

CAUTION: Included flanges must be used with

depressed center Type 27/42 grinding wheels and

Type1/41 cutting wheels. See the Accessories Chart

for more information.

WARNING: A closed, two-sided cutting wheel guard

is required when using abrasive cutting wheels or

diamond coated cutting wheels.

WARNING: Use of a damaged flange or guard or fail-

ure to use proper flange and guard can re sult in injury

due to wheel breakage and wheel contact. See the

Accessories Chart for more information.

1. Place the tool on a table, guard up.

2. Install the unthreaded backing flange

with the raised center (pilot) facing the wheel.

3

on spindle

1

Page 11

3. Place wheel

centering the wheel on the raised center (pilot) of the

backingflange.

4. While depressing the spindle lock button and with the

hex depressions facing away from the wheel, thread the

threaded locking flange

engage the two slots in the spindle.

NOTE: If the wheel you are installing is more than 1/8"

(3.17mm) thick, place the threaded locking flange on

the spindle so that the raised section (pilot) fits into the

center of the wheel. If the wheel you are installing is

1/8" (3.17mm) thick or less, place the threaded locking

flange on the spindle so that the raised section (pilot) is

not against thewheel.

Fig. E

17

against the backing flange,

Over 1/8" (3.17mm)

wheels

Locking flange

4

on spindle so that the lugs

1/8" Or less (3.17mm)

wheels

Locking flange

ENGLISH

WARNING: Proper guard must be reinstalled for

grinding wheel, cutting wheel, sanding flap disc,

wire brush or wire wheel applications after sanding

applications are complete.

1. Place or appropriately thread backing pad

thespindle.

2. Place the sanding disc

3. While depressing spindle lock button

sanding clamp nut

hub on the clamp nut into the center of san ding disc

and backingpad.

4. Tighten the clamp nut by hand. Then depress the

spindle lock button while turning the sanding disc until

the sanding disc and clamp nut are snug.

5. To remove the wheel, grasp and turn the backing pad

and sanding pad while depressing the spindle

lock button.

Fig. G

19

18

on the backing pad

19

on spindle, piloting the raised

20

2

, thread the

on

20

.

Backing Flange

5. While depressing the spindle lock button, tighten the

threaded locking flange

a. Tighten the threaded locking flange using a

b. Tighten a keyless locking flange by hand. (Only use a

6. To remove the wheel, depress the spindle lock button

and loosen the threaded locking flange.

Mounting Sanding Backing Pads (Fig. G)

NOTE: Use of a guard with sanding discs that use backing

pads, often called fiber resin discs, is not required. Since a

guard is not required for these accessories, the guard may or

may not fit correctly if used.

16

wrench

keyless locking flange if it is in perfect condition.)

Fig. F

WARNING: Failure to properly seat the clamp nut

and/or pad could result in serious injury (or damage

to the tool or wheel).

.

16

4

17

3

1

4

:

Backing Flange

18

20

Mounting and Removing Hubbed

Wheels (Fig. A)

Hubbed wheels install directly on the spindle. Thread of

accessory must match thread of spindle.

1. Remove backing flange by pulling away from tool.

2. Thread the wheel on the spindle

3. Depress the spindle lock button

tighten the hub of the wheel.

4. Reverse the above procedure to remove the wheel.

NOTICE: Failure to properly seat the wheel before

turning the tool on may result in damage to the tool

or the wheel.

Mounting Wire Cup Brushes and

Wire Wheels (Fig. A)

WARNING: Failure to properly seat the brush/wheel

could result in serious injury (or damage to the tool

or wheel).

CAUTION: To reduce the risk of personal injury,

wear work gloves when handling wire brushes

and wheels. They can become sharp.

CAUTION: To reduce the risk of damage to the

tool, wheel or brush must not touch guard when

mounted or while in use. Undetectable damage

1

by hand.

2

and use a wrench to

9

Page 12

ENGLISH

could occur to the accessory, causing wires to

fragment from accessory wheel or cup.

Wire cup brushes or wire wheels install directly on the

threaded spindle without the use of flanges. Use only wire

brushes or wheels provided with a threaded hub. These

accessories are available at extra cost from your local dealer

or authorised service center.

1. Place the tool on a table, guard up.

2. Thread the wheel on the spindle by hand.

3. Depress spindle lock button

hub of the wire wheel or brush to tighten the wheel.

4. To remove the wheel, reverse the above procedure.

NOTICE: To reduce the risk of damage to the tool,

properly seat the wheel hub before turning the tool on.

2

and use a wrench on the

Prior to Operation

• Install the guard and appropriate disc or wheel. Do not

use excessively worn discs orwheels.

• Be sure the backing and threaded locking flange are

mounted correctly. Follow the instructions given in the

Grinding and Cutting AccessoryChart.

• Make sure the disc or wheel rotates in the direction of

the arrows on the accessory and thetool.

• Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheels for chips

and cracks, backing pad for cracks, tear or excess wear,

wire brush for loose or cracked wires. If power tool or

accessory is dropped, inspect for damage or install an

undamaged accessory. After inspecting and installing

an accessory, position yourself and bystanders away

from the plane of the rotating accessory and run the

power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during

this testtime.

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Proper Hand Position (Fig. H)

WARNING: To reduce the risk of serious personal

injury, ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

sudden reaction.

Proper hand position requires one hand on the side

5

handle

, with the other hand on the body of the tool, as

shown in FigureH.

Fig. H

Trigger Switch and Lock-off Lever (Fig. I)

WARNING: Before using the tool, check that the side

handle is tightened securely.

CAUTION: Hold the side handle and body of the tool

firmly to maintain control of the tool at start up and

during use and until the wheel or accessory stops

rotating. Make sure the wheel has come to a complete

stop be fore laying the tooldown.

1. To turn the tool on, push the lock-off lever

the back of the tool, then depress the trigger switch

The tool will run while the switch is depressed.

2. Turn the tool off by releasing the releasing switch.

WARNING: Allow the tool to reach full speed before

touching tool to the work surface. Lift the tool from

the work surface before turning the tool off.

Fig. I

10

Lock-On Button

DWE43066, DWE43113, DWE43115, DWE43116

The lock-on button

extended use applications. To lock the tool on, depress

the lock-on button while the tool is running. The tool will

continue to run after the switch is released. To unlock and

turn off the tool, depress and release the switch.

NOTE: A grinder should never be locked ON by any

othermeans.

10

offers increased comfort in

9

toward

8

9

Spindle Lock (Fig. A)

The spindle lock

rotating when installing or removing wheels. Operate the

spindle lock only when the tool is turned off, unplugged

from the power supply, and has come to a completestop.

2

is provided to prevent the spindle from

NOTICE: To reduce the risk of damage to the tool, do

not engage the spindle lock while the tool is operating.

Damage to the tool will result and attached accessory

may spin off possibly resulting ininjury.

5

8

.

10

Page 13

To engage the lock, depress the spindle lock button

and rotate the spindle until you are unable to rotate the

spindlefurther.

Surface Grinding, Sanding and Wire

Brushing (Fig. J)

CAUTION: Always use the correct guard per the

instructions in this manual.

WARNING: Metal dust build-up. Extensive use

of flap discs in metal applications can result in the

increased potential for electric shock. To reduce

this risk, insert an RCD before use and clean the

ventilation slots daily by blowing dry compressed air

into the ventilation slots inaccordance with the below

maintenanceinstructions.

To perform work on the surface of a workpiece:

1. Allow the tool to reach full speed before touching the

tool to the work surface.

2. Apply minimum pressure to the work surface, allowing

the tool to operate at high speed. Material removal rate

is greatest when the tool operates at high speed.

Fig. J

Angle

3. Maintain an appropriate angle between the tool

and work surface. Refer to the chart according to

particularfunction.

Function Angle

Grinding 20˚-30˚

Sanding with Flap Disc 5˚-10˚

Sanding with Backing Pad 5˚-15˚

Wire Brushing 5˚-10˚

4. Maintain contact between the edge of the wheel and

the work surface.

- If grinding, sanding with flap discs or wire brushing

move the tool continuously in a forward and

back motion to avoid creating gouges in the

worksurface.

- If sanding with a backing pad, move the tool

constantly in a straight line to prevent burning and

swirling of worksurface.

NOTE: Allowing the tool to rest on the work surface without

moving will damage the work piece.

5. Remove the tool from work surface before turning tool

off. Allow the tool to stop rotating before laying it down.

CAUTION: Use extra care when working over an edge,

as a sudden sharp movement of grinder

may be experienced.

ENGLISH

Precautions To Take When Working on

a Painted Workpiece

1. Sanding or wire brushing of lead based paint is NOT

RECOMMENDED due to the difficulty of controlling

the contaminated dust. The greatest danger of lead

poisoning is to children and pregnant women.

2. Since it is difficult to identify whether or not a paint

contains lead without a chemical analysis, we

recommend the following precautions when sanding

any paint:

Personal Safety

1. No children or pregnant women should enter the work

area where the paint sanding or wire brushing is being

done until all clean up is completed.

2. A dust mask or respirator should be worn by all persons

entering the work area. The filter should be replaced

daily or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with

lead paint dust and fumes should be used. Ordinary

painting masks do not offer this protection. See your

local hardware dealer for the proper N.I.O.S.H.

approved mask.

3. NO EATING, DRINKING or SMOKING should be done in

the work area to prevent ingesting contaminated paint

particles. Workers should wash and clean up BEFORE

eating, drinking or smoking. Articles of food, drink, or

smoking should not be left in the work area where dust

would settle on them.

Environmental Safety

1. Paint should be removed in such a manner as to

minimize the amount of dust generated.

2. Areas where paint removal is occurring should be sealed

with plastic sheeting of 4 mils thickness.

3. Sanding should be done in a manner to reduce tracking

of paint dust outside the work area.

Cleaning and Disposal

1. All surfaces in the work area should be vacuumed

and thoroughly cleaned daily for the duration of

the sanding project. Vacuum filter bags should be

changedfrequently.

2. Plastic drop cloths should be gathered up and disposed

of along with any dust chips or other removal debris.

They should be placed in sealed refuse receptacles and

disposed of through regular trash pick-up procedures.

During clean up, children and pregnant women should

be kept away from the immediate work area.

3. All toys, washable furniture and utensils used by

children should be washed thoroughly before being

used again.

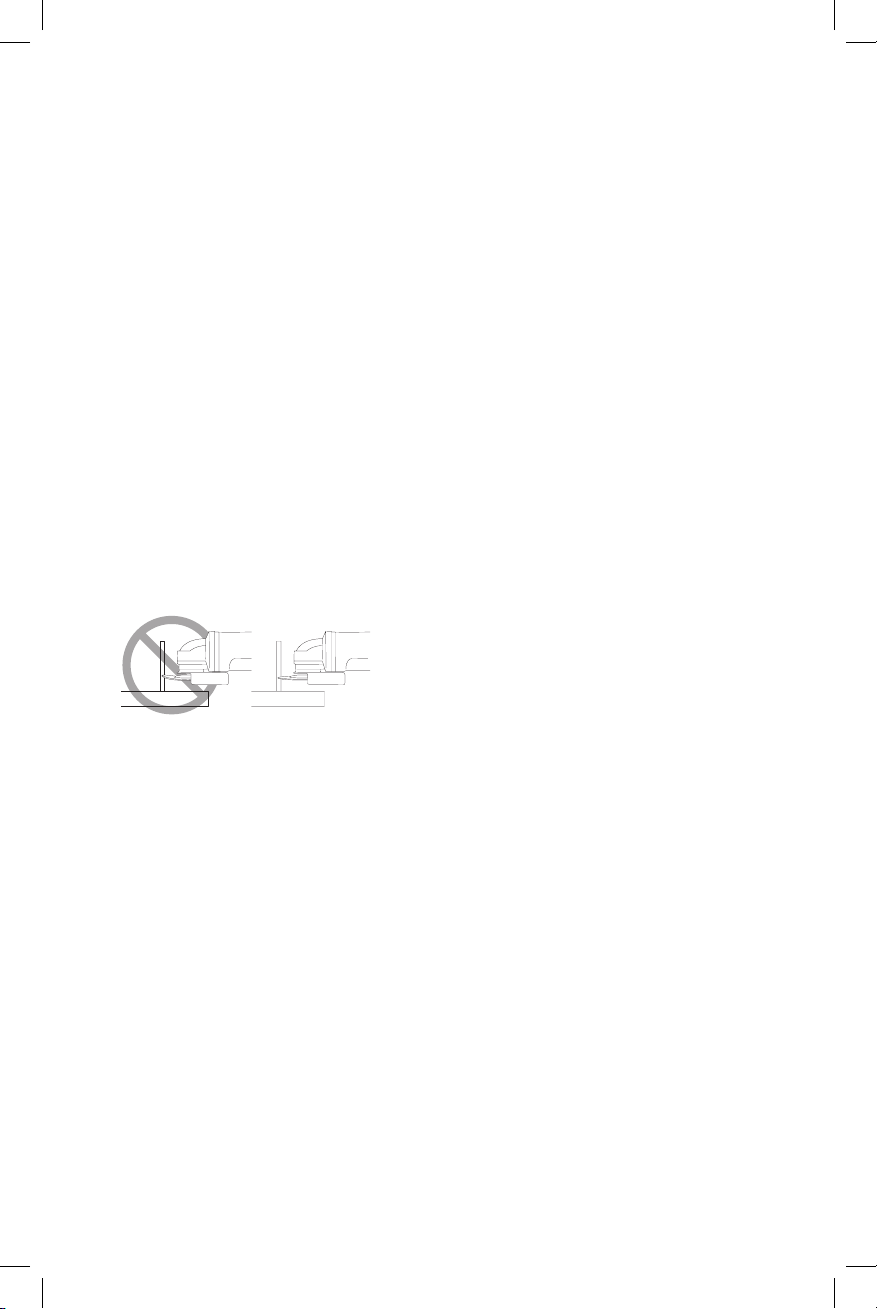

Edge Grinding and Cutting (Fig. K)

WARNING: Do not use edge grinding/cutting wheels

for surface grinding applications because these wheels

are not designed for side pressures encountered with

surface grinding. Wheel breakage and injury

may result.

11

Page 14

ENGLISH

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

DeWALT

CAUTION: Wheels used for edge grinding and cutting

may break or kick back if they bend or twist while

the tool is being used. In all edge grinding/cutting

operations, the open side of the guard must be

positioned away from theoperator.

NOTICE: Edge grinding/cutting with a Type27 wheel

must be limited to shallow cutting and notching—

less than 13mm in depth when the wheel is new.

Reduce the depth of cutting/notching equal to the

reduction of the wheel radius as it wears down. Refer

to the Accessories Chart for more information. Edge

grinding/cutting with a Type 41 wheel requires usage

of a Type 1 guard.

1. Allow the tool to reach full speed before touching the

tool to the work surface.

2. Apply minimum pressure to the work surface, allowing

the tool to operate at high speed. Grinding/cutting rate

is greatest when the tool operates at high speed.

3. Position yourself so that the open-underside of the

wheel is facing away from you.

4. Once a cut is begun and a notch is established in

the workpiece, do not change the angle of the cut.

Changing the angle will cause the wheel to bend and

may cause wheel breakage. Edge grinding wheels

are not designed to withstand side pressures caused

bybending.

Fig. K

5. Remove the tool from the work surface before turning

the tool off. Allow the tool to stop rotating before laying

itdown.

MAINTENANCE

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Cleaning

WARNING: Blow dirt and dust out of all air vents with

clean, dry air at least once a week. To minimize the risk

of eye injury, always wear ANSI Z87.1 approved eye

protection when performingthis.

WARNING: Never use solvents or other harsh

chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic

materials used in these parts. Use a cloth dampened

only with water and mild soap. Never let any liquid

get inside the tool; never immerse any part of the tool

into aliquid.

Accessories

WARNING: Since accessories, other than those

offered by

product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only

recommended accessories should be used with

thisproduct.

Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorized service center. If you need assistance in

locating any accessory, please contact

Tool Co., 701East Joppa Road, Towson, MD 21286, call

1-800-4www.dewalt.com.

, have not been tested with this

(1-800-433-9258) or visit our website:

Repairs

The charger and battery pack are notserviceable.

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should

be performed by a

or a

identical replacementparts.

authorized service center. Always use

factory service center

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRANTY SERVICE: Registering your product will

help you obtain more efficient warranty service in case

there is a problem with yourproduct.

• CONFIRMATION OF OWNERSHIP: In case of

an insurance loss, such as fire, flood or theft, your

registration of ownership will serve as your proof

ofpurchase.

• FOR YOUR SAFETY: Registering your product will

allow us to contact you in the unlikely event a safety

notification is required under the Federal Consumer

SafetyAct.

Register online at www.dewalt.com/register.

Three Year Limited Warranty

will repair, without charge, any defects due to

faulty materials or workmanship for three years from the

date of purchase. This warranty does not cover part failure

due to normal wear or tool abuse. For further detail of

warranty coverage and warranty repair information, visit

www.dewalt.com or call 1-800-4This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states

orprovinces.

In addition to the warranty,

byour:

will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

afterpurchase.

1 YEAR FREE SERVICE

(1-800-433-9258).

tools are covered

Industrial

12

Page 15

90 DAY MONEY BACK GUARANTEE

DeWALT

DeWALT

If you are not completely satisfied with the performance of

your

can return it within 90 days from the date of purchase with

a receipt for a full refund – no questionsasked.

LATIN AMERICA: This warranty does not apply to products

sold in Latin America. For products sold in Latin America,

see country specific warranty information contained in

the packaging, call the local company or see website for

warrantyinformation.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4(1-800-433-9258) for a freereplacement.

Power Tool, Laser, or Nailer for any reason, you

ENGLISH

13

Page 16

ENGLISH

ACCESSORIES CHART

4.5" (115 mm) and 6" (150mm) Grinding Wheels

Wire Wheels

Type 27 guard

unthreaded backing flange

Type 27

depressed center wheel

threaded locking flange

4.5" (115 mm)and 6" (150mm) Cutting Wheels

Type 27 guard

Type 27 hubbed wheel

4.5" (115 mm) and 6" (150mm) Sanding Flap Discs

Type 27 guard

unthreaded backing flange

non-hubbed sanding flap disc

threaded locking flange

Type 27 guard

3 - 5" * (76.2 - 127 mm)

wire cup brush

Type 27 guard

hubbed sanding flap disc

Type 27 guard

4"-6" (100-150 mm) wire

wheel

Sanding Discs

rubber backing pad

sanding disc

sanding clamp nut

Type 1/41 guard*

unthreaded backing flange

Type 27/42 depressed

center wheel, cutting only

threaded locking flange

Type 1/41 guards are intended for use with Type 1/41 cutting wheels and Type 27 wheels marked for cutting only.

Grinding with wheels other than Type 27 and Type 29 require different accessory guards. Always use the smallest proper

guard possible that does not contact the accessory.

* NOTE: A Type 1/41 guard is available at extra cost from your local dealer or authorized service center.

* NOTE: A Type 1/41 guard is included with the DWE43066 and DWE43066N.

14

Type 1/41 guard*

unthreaded backing flange

Type 1/41 abrasive cutting

wheel

threaded locking flange

Type 1/41 guard*

unthreaded backing flange

diamond cutting wheel

threaded locking flange

Page 17

Définitions : symboles et termes d'alarmes sécurité

DeWALT

DeWALT

Ces guides d'utilisation utilisent les symboles et termes d'alarmes sécurité suivants pour vous prévenir de situations

dangereuses et de risques de dommages corporels ou matériels.

DANGER: indique une situation dangereuse imminente qui, si elle n’est pas évitée, entraînera la mort ou des

blessuresgraves.

AVERTISSEMENT: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner la

mort ou des blessuresgraves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait entraîner des

blessures légères oumodérées.

(Si utilisé sans aucun terme) Indique un message propre à la sécurité.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien n’est fait

pour l’éviter, pourrait poser des risques de dommages matériels.

Fig. A

5

2

FRANÇAIS

7

1

43

1

Broche

2

Bouton de verrouillage de la broche

3

Bride de soutien non fileté

4

Bride de verrouillage taraudée

5

Poignée latérale

6

Carter

7

Levier de déverrouillage du carter

8

Gâchette

9

Verrouillage de gâchette

10

Bouton de verrouillage en position de marche

(DWE43066, DWE43113, DWE43115, DWE43116)

10

6

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non-respect

des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une

blessuregrave.

AVERTISSEMENT : afin de réduire le risque de

blessures, lire le mode d’emploi del’outil.

Pour toute question ou remarque au sujet de cet outil

ou de tout autre outil

sans frais : 1-800-4-

9

8

, composez le numéro

(1-800-433-9258).

15

Page 18

FRANÇAIS

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRAUX

POUR LES OUTILS ÉLECTRIQUES

AVERTISSEMENT! lire tous les avertissements de

sécurité et toutes les directives. Le non-respect

des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une

blessuregrave.

CONSERVER TOUS LES

AVERTISSEMENTS ET TOUTES

LES DIRECTIVES POUR UN USAGE

ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se

rapporte à votre outil électrique à alimentation sur secteur

(avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a ) Tenir l’aire de travail propre et bien éclairée.

Les lieux encombrés ou sombres sont propices

auxaccidents.

b ) Ne pas faire fonctionner d’outils électriques

dans un milieu déflagrant, tel qu’en présence de

liquides, de gaz ou de poussières inflammables.

Les outils électriques produisent des étincelles qui

pourraient enflammer la poussière ou lesvapeurs.

c ) Éloigner les enfants et les personnes à proximité

pendant l’utilisation d’un outil électrique. Une

distraction pourrait en faire perdre la maîtrise à

l’utilisateur.

2) Sécurité en matière d’électricité

a ) Les fiches des outils électriques doivent

correspondre à la prise. Ne jamais modifier la

fiche d’aucune façon. Ne jamais utiliser de fiche

d’adaptation avec un outil électrique mis à la

terre. Le risque de choc électrique sera réduit par

l’utilisation de fiches non modifiées correspondant à

laprise.

b ) Éviter tout contact physique avec des surfaces

mises à la terre comme des tuyaux, des

radiateurs, des cuisinières et des réfrigérateurs.

Le risque de choc électrique est plus élevé si votre corps

est mis à laterre.

c ) Ne pas exposer les outils électriques à la pluie ou

à l’humidité. La pénétration de l’eau dans un outil

électrique augmente le risque de chocélectrique.

d ) Ne pas utiliser le cordon de façon abusive.

Ne jamais utiliser le cordon pour transporter,

tirer ou débrancher un outil électrique. Tenir le

cordon éloigné de la chaleur, de l’huile, des bords

tranchants et des pièces mobiles. Les cordons

endommagés ou enchevêtrés augmentent les risques

de chocélectrique.

e ) Pour l’utilisation d’un outil électrique à

l’extérieur, se servir d’une rallonge convenant à

cette application. L’utilisation d’une rallonge conçue

pour l’extérieur réduira les risques de chocélectrique.

f ) S’il est impossible d’éviter l’utilisation d’un

outil électrique dans un endroit humide,

brancher l’outil dans une prise ou sur un circuit

d’alimentation dotés d’un disjoncteur de fuite à

la terre (GFCI). L’utilisation de ce type de disjoncteur

réduit les risques de chocélectrique.

3) Sécurité personnelle

a ) Être vigilant, surveiller le travail effectué et faire

preuve de jugement lorsqu’un outil électrique

est utilisé. Ne pas utiliser d’outil électrique en

cas de fatigue ou sous l’influence de drogues,

d’alcool ou de médicaments. Un simple moment

d’inattention en utilisant un outil électrique peut

entraîner des blessures corporellesgraves.

b ) Utiliser des équipements de protection

individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection

comme un masque antipoussière, des chaussures

antidérapantes, un casque de sécurité ou des

protecteurs auditifs lorsque la situation le requiert

réduira les risques de blessurescorporelles.

c ) Empêcher les démarrages intempestifs. S’assurer

que l’interrupteur se trouve à la position

d’arrêt avant de relier l’outil à une source

d’alimentation et/ou d’insérer un bloc-piles, de

ramasser ou de transporter l’outil. Transporter

un outil électrique alors que le doigt repose sur

l’interrupteur ou brancher un outil électrique dont

l’interrupteur est à la position de marche risque de

provoquer unaccident.

d ) Retirer toute clé de réglage ou clé avant de

démarrer l’outil. Une clé ou une clé de réglage

attachée à une partie pivotante de l’outil électrique

peut provoquer des blessurescorporelles.

e ) Ne pas trop tendre les bras. Conserver

son équilibre en tout temps. Cela permet

de mieux maîtriser l’outil électrique dans les

situationsimprévues.

f ) S’habiller de manière appropriée. Ne pas porter

de vêtements amples ni de bijoux. Garder les

cheveux, les vêtements et les gants à l’écart des

pièces mobiles. Les vêtements amples, les bijoux ou

les cheveux longs risquent de rester coincés dans les

piècesmobiles.

g ) Si des composants sont fournis pour le

raccordement de dispositifs de dépoussiérage

et de ramassage, s’assurer que ceux-ci sont bien

raccordés et utilisés. L’utilisation d’un dispositif de

dépoussiérage peut réduire les dangers engendrés par

lespoussières.

4) Utilisation et entretien d’un outil

électrique

a ) Ne pas forcer un outil électrique. Utiliser l’outil

électrique approprié à l’application. L’outil

électrique approprié effectuera un meilleur travail,

de façon plus sûre et à la vitesse pour laquelle il a

étéconçu.

16

Page 19

b ) Ne pas utiliser un outil électrique dont

l’interrupteur est défectueux. Tout outil électrique

dont l’interrupteur est défectueux est dangereux et

doit êtreréparé.

c ) Débrancher la fiche de la source d’alimentation

et/ou du bloc-piles de l’outil électrique avant de

faire tout réglage ou changement d’accessoire

ou avant de ranger l’outil. Ces mesures préventives

réduisent les risques de démarrage accidentel de

l’outilélectrique.

d ) Ranger les outils électriques hors de la portée

des enfants et ne permettre à aucune personne

n’étant pas familière avec un outil électrique ou

son mode d’emploi d’utiliser cet outil. Les outils

électriques deviennent dangereux entre les mains

d’utilisateursinexpérimentés.

e ) Entretien des outils électriques. Vérifier si les

pièces mobiles sont mal alignées ou coincées,

si des pièces sont brisées ou présentent toute

autre condition susceptible de nuire au bon

fonctionnement de l’outil électrique. En cas de

dommage, faire réparer l’outil électrique avant

toute nouvelle utilisation. Beaucoup d’accidents

sont causés par des outils électriques malentretenus.

f ) S’assurer que les outils de coupe sont aiguisés et

propres. Les outils de coupe bien entretenus et affûtés

sont moins susceptibles de se coincer et sont plus

faciles àmaîtriser.

g ) Utiliser l’outil électrique, les accessoires, les

forets, etc. conformément aux présentes

directives en tenant compte des conditions de

travail et du travail à effectuer. L’utilisation d’un

outil électrique pour toute opération autre que celle

pour laquelle il a été conçu estdangereuse.

5) Réparation

a ) Faire réparer l’outil électrique par un réparateur

professionnel en n’utilisant que des pièces de

rechange identiques. Cela permettra de maintenir

une utilisation sécuritaire de l’outilélectrique.

CONSIGNES DE SÉCURITÉ POUR TOUTES LES

OPÉRATIONS

Avertissements de sécurité communs

à toutes les opérations de meulage,

ponçage, brossage à l’aide d’une brosse

métallique, polissage ou de coupe

a ) Cet outil électrique est conçu pour fonctionner

comme une meule, une ponceuse, une brosse

métallique, une polisseuse ou un outil de coupe.

Lire tous les avertissements de sécurité, les

directives, les illustrations et les spécifications

fournies avec cet outil électrique. Négliger de

suivre l’ensemble des directives suivantes pourrait

entraîner des risques de choc électrique, d’incendie et/

ou de blessuresgraves.

FRANÇAIS

b ) Ne pas utiliser d’accessoire non conçu

spécifiquement pour cet outil ou qui n’aurait pas

reçu une approbation spécifique du fabricant

de l’outil. En effet, il est parfois possible de fixer

un accessoire à l’outil électrique; toutefois, cela ne

garantit pas une utilisationsécuritaire.

c ) Le régime nominal de l’accessoire doit être au

moins égal au régime maximal inscrit sur l’outil

électrique. Les accessoires soumis à un régime plus

élevé que celui pour lequel ils sont conçus peuvent se

briser et êtreprojetés.

d ) Le diamètre externe et l’épaisseur de l’accessoire

doivent être adéquats pour la capacité de l’outil

électrique. Il est impossible de protéger l’utilisateur

d’un bris d’accessoire de mauvais calibre ou de le

maîtrisercorrectement.

e ) Les raccords filetés d’accessoires doivent

correspondre au filetage de la broche de la

meuleuse. Pour les accessoires à installation

par brides, l’alésage central de l’accessoire

doit correspondre au diamètre de référence

de la bride. Les accessoires ne correspondant pas

au dispositif d’installation de l’outil électrique ne

tourneront pas correctement, vibreront de façon

excessive et pourront causer la perte de contrôle de

l’outil.

f ) Ne jamais utiliser un accessoire endommagé.

Avant toute utilisation, inspecter la meule

abrasive à la recherche d’éclats et de fissures; le

tampon pour tout signe de fissures, déchirures

ou d’usure excessive; et la brosse métallique,

pour déceler s’il y a des fils métalliques fissurés

ou détachés. En cas de chute de l’outil ou

de l’accessoire, les inspecter à la recherche

de dommages ou insérer un accessoire non

endommagé. Après l’inspection et l’insertion

d’un accessoire, se positionner (l’utilisateur

ou quiconque aux alentours) hors du plan de

rotation de l’accessoire et faire tourner, pendant

une minute, l’outil électrique à plein régime, à

vide. Normalement, tout accessoire endommagé se

brisera au cours de cette période d’essai.

g ) Porter un équipement de protection individuelle.

Utiliser un masque facial, des lunettes de

sécurité ou des lunettes protectrices en fonction

de l’application. Au besoin, porter un masque

antipoussières, des protecteurs auditifs, des

gants et un tablier d’atelier capable d’arrêter

de petits fragments d’abrasifs ou de pièces. La

protection oculaire doit être en mesure d’arrêter tout

débris produit par les diverses opérations et le masque

antipoussières ou le respirateur, de filtrer les particules

produites par l’opération en cours. Une exposition

prolongée à un bruit d’intensité élevée pourrait causer

une perteauditive.

h ) Éloigner tout observateur à une distance

sécuritaire de la zone de travail. Toute personne

qui pénètre dans la zone de travail devra

également porter un équipement de protection

17

Page 20

FRANÇAIS

individuelle. Il est possible qu’un fragment de pièce

ou un accessoire brisé soit projeté et provoque des

blessures au-delà de la zone immédiate detravail.

i ) Tenir l’outil électrique par les surfaces isolées

prévues à cet effet pendant toute utilisation où

l’organe de coupe pourrait entrer en contact

avec des fils électriques cachés ou son propre

cordon. Tout contact de l’organe de coupe avec un fil

sous tension mettra les parties métalliques exposées

de l’outil électrique sous tension et

électrocutera l’utilisateur.

j ) Positionner le cordon d’alimentation hors

d’atteinte de l’accessoire en mouvement. En

cas de perte de maîtrise, il est possible de couper

ou d’effilocher le cordon et la main ou le bras de

l’utilisateur risqueraient d’être happés par l’accessoire

enmouvement.

k ) Ne jamais déposer l’outil électrique avant

l’immobilisation complète de l’accessoire.

L’accessoire en mouvement risquerait de mordre dans

la surface et de projeter l’outilélectrique.

l ) Mettre l’outil hors tension pour tout

déplacement de celui-ci par l’utilisateur. Un

contact accidentel avec l’accessoire en mouvement

pourrait happer les vêtements de l’opérateur et

projeter l’accessoire contre soncorps.

m ) Nettoyer régulièrement les évents de l’outil

électrique. Le ventilateur du moteur aspirera la

poussière à l’intérieur du boîtier. Une accumulation

excessive de poudre métallique représente un danger

d’origineélectrique.

n ) Ne pas faire fonctionner l’outil électrique à

proximité de matières inflammables. Les étincelles

produites risquent de lesenflammer.

o ) Ne pas utiliser d’accessoires qui exigent

l’utilisation d’un liquide de refroidissement.

L’utilisation d’eau ou de tout autre liquide

de refroidissement pourrait se solder par une

électrocution ou une secousseélectrique.

p ) Ne jamais utiliser de meules de type11 (boisseau

conique) sur cet outil. L’utilisation d’accessoires

inadéquats peut se solder par desblessures.

q ) Toujours se servir de la poignée latérale. La fixer

solidement. La poignée latérale doit être utilisée pour

maîtriser l’outil en touttemps.

r ) Au démarrage de l’outil avec une meule ou

une brosse métallique neuve, ou après l’avoir

changée, maintenir l’outil dans un espace

sécuritaire et le laisser tourner une minute. Si le

disque était affecté d’une fêlure ou d’un défaut caché,

il éclaterait en moins d’une minute. Si des fils de la

brosse métallique étaient lâches, cela serait alors

détecté. Ne jamais démarrer l’outil lorsque quelqu’un

se tient directement devant le disque, y compris

l’utilisateur.

s ) L’utilisation d’accessoires non spécifiés dans

ce manuel n’est pas recommandée et peut être

dangereuse. L’utilisation de compresseurs pour faire

18

fonctionner l’outil à une vitesse supérieure à sa vitesse

nominale estprohibée.

t ) Utiliser des serre-joints, ou tout autre moyen,

pour fixer et soutenir le matériau sur une surface

stable. Tenir la pièce à la main ou contre son corps

offre une stabilité insuffisante qui pourrait vous en

faire perdre lecontrôle.

u ) Protéger le disque contre tout choc ou traitement

brutal. Si c’était le cas, arrêter l’outil et vérifier que la

meule ne comporte ni fissures nidéfauts.

v ) Manipuler et stocker les meules en prenant

systématiquement desprécautions.

w ) Ne pas utiliser cet outil de façon prolongée. Les

vibrations inhérentes à l’utilisation de cet outil

posent des risques de dommages corporels

permanents aux doigts, mains et bras. Utiliser

des gants pour en atténuer l’impact, faire des pauses

fréquentes, et en limiter l’usagejournalier.

x ) Prendre des précautions à proximité des évents,

car ils cachent des pièces mobiles. Les vêtements

amples, bijoux ou cheveux longs pourraient s’y

faireprendre.

Causes de l’effet de rebond et prévention

par l’opérateur

L’effet de rebond est une réaction soudaine d’une meule,

d’un tampon, d’une brosse ou d’un tout autre accessoire, en

mouvement, qui est pincé ou qui s’accroche. Un pincement

ou un accrochage provoque un arrêt rapide de l’accessoire en

mouvement qui, à son tour, projette l’outil électrique, hors de

maîtrise, dans la direction opposée à la rotation de l’outil au

point degrippage.

Par exemple, si une meule abrasive se pince ou s’accroche

dans la pièce, le bord de la meule introduite au point de

pincement peut mordre dans la surface de la pièce et

projeter la meule hors de la rainure. La meule peut être

projetée vers l’opérateur ou dans la direction opposée selon

le sens de rotation de la meule au point de pincement. Il est

également possible que les meules abrasives se brisent dans

cesconditions.

Un effet de rebond est le résultat d’une mauvaise utilisation de

l’outil et/ou de procédures ou conditions de fonctionnement

incorrectes. Il peut être évité en prenant les précautions

nécessaires telles que décrites ci-dessous:

a ) Saisir fermement l’outil électrique et positionner

le corps et les bras de sorte à résister à la

force de l’effet de rebond. Utiliser toujours la

poignée auxiliaire, s’il y en a une, pour contrôler

au maximum l’effet de rebond ou le couple

de réaction au démarrage. Avec de bonnes

précautions, l’opérateur est en mesure de contrôler le

couple de réaction ou l’effet derebond.

b ) Ne jamais placer les mains près de l’accessoire en

mouvement. Il pourrait en effet être projeté sur cellesci en cas derebond.

c ) Ne pas positionner le corps dans la trajectoire

probable de l’outil électrique, en cas de rebond.

Page 21

Au moment du grippage, l’outil sera projeté dans la

direction opposée au déplacement de lameule.